Page 1

4. LUBRICATION SYSTEM

4-0

Mongoose/KXR 250

4

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

LUBRICATION SYSTEM

__________________________________________________________________________________

SERVICE INFORMATION -------------------------------------------- 4- 2

TROUBLESHOOTING ------------------------------------------------- 4- 2

ENGINE OIL/OIL FILTER -------------------------------------------- 4- 3

OIL PUMP --------------------------------------------------------------- 4- 3

4

Page 2

4. LUBRICATION SYSTEM

4-1

Mongoose/KXR 250

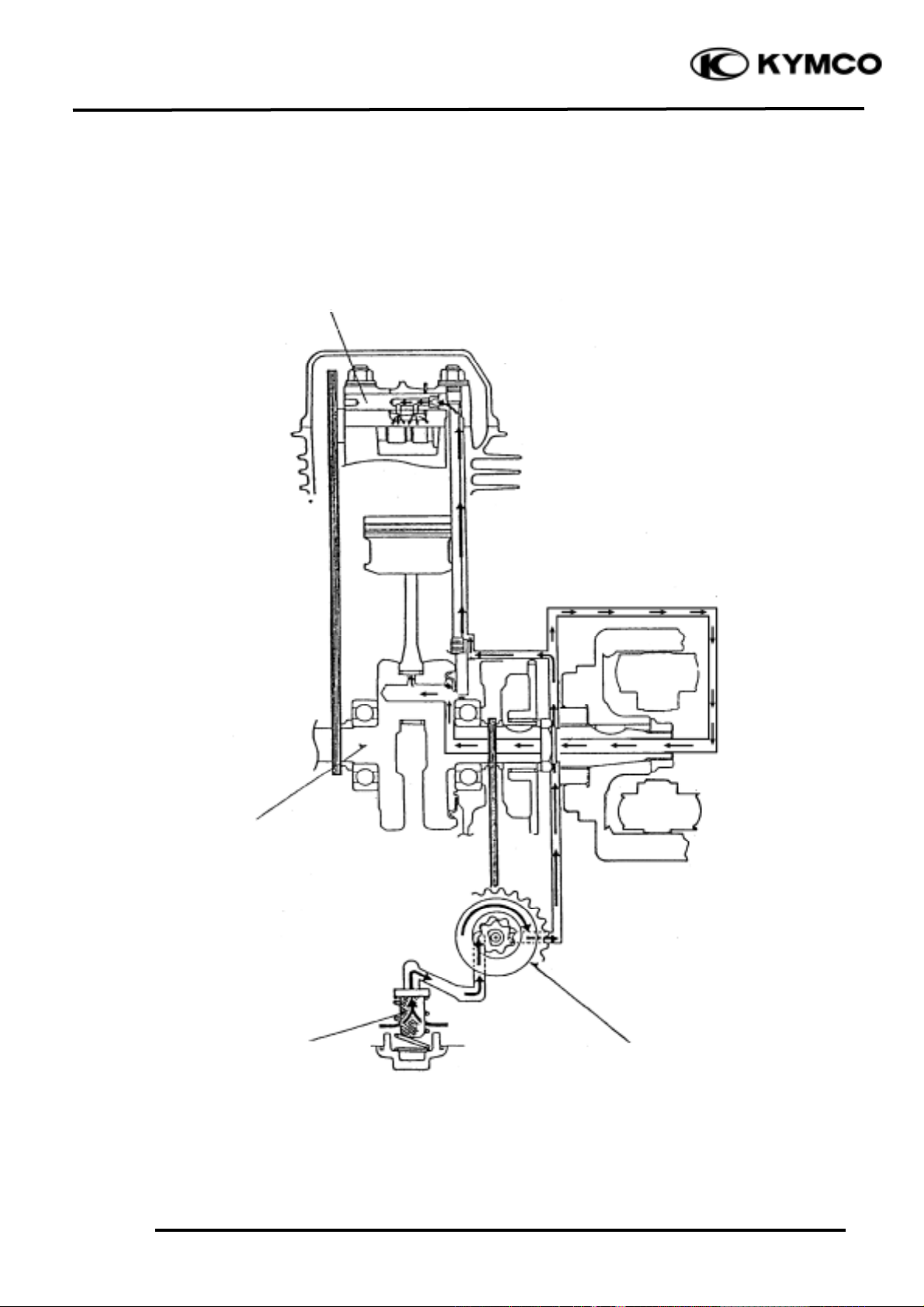

LUBRICATION SYSTEM

Oil Pump

Oil Filter Screen

Crankshaft

Rocker Arm Shaft

Page 3

4. LUBRICATION SYSTEM

4-2

Mongoose/KXR 250

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• The maintenance of lubrication system can be performed with the engine installed in the frame.

• Use care when removing and installing the oil pump not to allow dust and foreign matters to enter

the engine and oil line.

• Do not attempt to disassemble the oil pump. The oil pump must be replaced as a set when it

reaches its service limit.

• After the oil pump is installed, check each part for oil leaks.

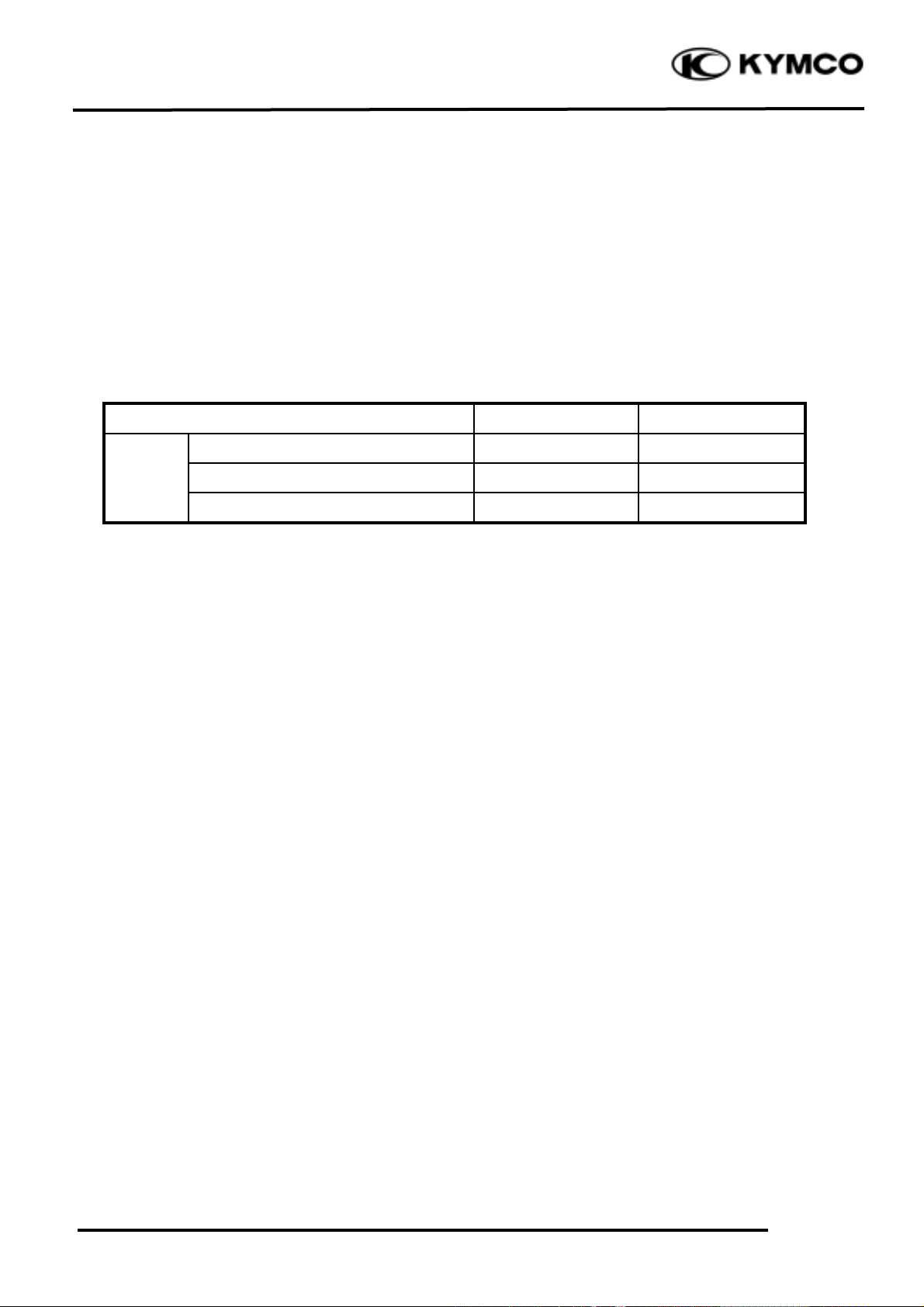

SPECIFICATIONS

Item

Standard (mm)

Service Limit (mm)

Inner rotor-to-outer rotor clearance

0.15

0.20

Oil pump

Outer rotor-to-pump body clearance

0.15_ 0.20

0.25

Rotor end-to-pump body clearance

0.04_ 0.09

0.12

TROUBLESHOOTING

Oil level too low Poor lubrication pressure

• Natural oil consumption • Oil level too low

• Oil leaks • Clogged oil filter or oil passages

• Worn or poorly installed piston rings • Not use the specified oil

• Worn valve guide or seal

Page 4

4. LUBRICATION SYSTEM

4-3

Mongoose/KXR 250

Bolts

ENGINE OIL/OIL FILTER

OIL LEVEL AND OIL CHANGE

Refer to the “ENGINE OIL” section in the

chapter 3 to check the oil level and

replacement and oil filter cleaning.

OIL PUMP

REMOVAL

Remove the right crankcase cover and the

A.C. generator flywheel. (Refer to the “A.C.

GENERATOR/FLYWHEEL” section in the

chapter 16)

Remove the starter clutch gear. (Refer to the

“STARTER CLUTCH” section in the

chapter 18)

Remove the two bolts and oil separator

cover.

Pry the circlip off and remove the oil pump

driven gear, then remove the oil pump drive

chain and oil driven sprocket.

Oil Separator Cover

Circlip

Page 5

4. LUBRICATION SYSTEM

4-4

Mongoose/KXR 250

Screw

Pump Body

Remove the two oil pump bolts for remove

the oil pump.

OIL PUMP DISASSEMBLY

Remove the screw and disassemble the oil

pump.

INSPECTION

Measure the rotor end-to-pump body

clearance.

Service Limit: 0.12mm

Oil Pump Driven Sprocket

Oil Pump Drive Chain

Oil Pump Bolts

Page 6

4. LUBRICATION SYSTEM

4-5

Mongoose/KXR 250

Outer Rotor

Outer Rotor

Inner Rotor

Pump Body

Inner Rotor

Dowel Pin

Pump Cover

Measure the inner rotor-to-outer rotor

clearance.

Service Limit: 0.2mm

Measure the pump body-to-outer rotor

clearance.

Service Limit: 0.25mm

ASSEMBLY

Install the outer rotor, inner rotor and pump

shaft into the pump body.

Install the dowel pin.

Install the pump cover by aligning the hole

in the cover with the dowel pin.

Tighten the screw to secure the pump cover.

INSTALLATION

Reverse the “OIL PUMP REMOVAL”

procedures.

Outer Rotor

Oil Pump Bolts

Insert the pump shaft by aligning the flat

on the shaft with the flat in the inner

rotor.

°Ø

Install the oil pump with the arrow on

the pump body facing up and fill the oil

pump with engine oil before installation.

°Ø

Page 7

4. LUBRICATION SYSTEM

4-6

Mongoose/KXR 250

Pump Shaft

Make sure that the pump shaft rotates

freely without binding.

Install oil pump driven sprocket and drive

chain, circlip and oil separator cover.

Loading...

Loading...