Page 1

12. COOLING SYSTEM

12-0

Mongo ose/KXR 250

12

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

COOLING SYSTEM

__________________________________________________________________________________

SERVICE INFORMATION -------------------------------------------- 12- 1

TROUBLESHOOTING ------------------------------------------------- 12- 1

COOLING SYSTEM TESTING --------------------------------------- 12- 3

RADIATOR -------------------------------------------------------------- 12- 4

WATER PUMP ---------------------------------------------------------- 12- 6

THERMOSENSOR ------------------------------------------------------ 12-10

THERMOSTAT---------------------------------------------------------- 12-11

12

Page 2

12. COOLING SYSTEM

12-1

Mongo ose/KXR 250

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• The water pump must be serviced after removing the engine.

Other cooling system service can be done with the engine installed in the frame.

• The engine must be cool before servicing the cooling system.

When the coolant temperature is over 100¢J, never remove the radiator cap to release the

pressure because the boiling coolant may cause danger.

• Avoid spilling coolant on painted surfaces because the coolant will corrode the painted surfaces.

Wash off any spilled coolant with fresh water as soon as possible.

• After servicing the system, check for leaks with a cooling system tester.

SPECIAL TOOL

Mechanical seal driver

TORQUE VALUES

Water pump impeller 1.0_ 1.4kgf-m

Water pump cover bolt 0.8_ 1.2kgf-m

TROUBLESHOOTING

Engine temperature too high Coolant leaks

• Faulty temperature gauge or thermosensor • Faulty pump mechanical (water) seal

• Faulty radiator cap • Deteriorated O-rings

• Faulty thermostat • Damaged or deteriorated water hoses

• Insufficient coolant

• Passages blocked in hoses or water jacket

• Clogged radiator fins

• Passages blocked in radiator

• Faulty water pump

Temperature gauge pointer does not register

the correct coolant temperature

• Faulty temperature gauge or thermosensor

• Faulty thermostat

Page 3

12. COOLING SYSTEM

12-2

Mongo ose/KXR 250

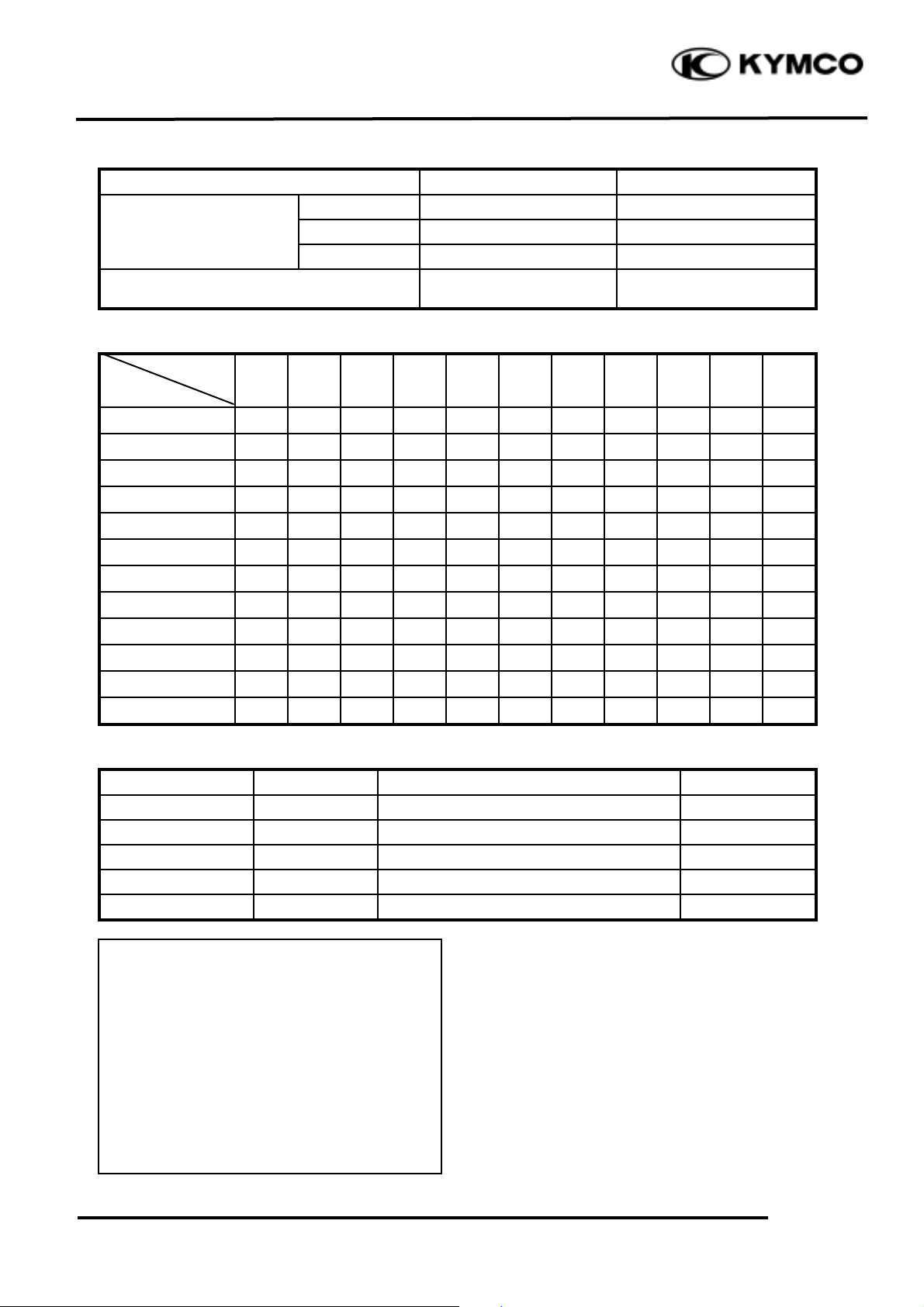

SPECIFICATIONS

Radiator cap relief pressure

075~1.05kg/cm_

Begins to open

80±2¢J

Thermostat temperature

Full-open

90¢J

Valve lift

3.5_ 4.5mm

Coolant capacity

Total system 1400±20cc

Radiator: 1100±20cc

Reserve tank: 300±20cc

COOLANT GRAVITY

Temp. ¢J

Coolant

concentration

05101520253035404550

5%

1.009

1.009

1.008

1.008

1.007

1.006

1.005

1.003

1.001

0.009

0.997

10%

1.018

1.107

1.017

1.016

1.015

1.014

0.013

1.011

1.009

1.007

1.005

15%

1.028

1.027

1.026

1.025

1.024

1.022

1.020

1.018

1.016

1.014

1.012

20%

1.036

1.035

1.034

1.033

1.031

1.029

1.027

1.025

1.023

1.021

1.019

25%

1.045

1.044

1.043

1.042

1.040

1.038

1.036

1.034

1.031

1.028

1.025

30%

1.053

1.051

1.051

1.049

1.047

1.045

1.043

1.041

1.038

1.035

1.032

35%

1.063

1.062

1.060

1.058

1.056

1.054

1.052

1.049

1.046

1.043

1.040

40%

1.072

1.070

1.068

1.066

1.064

1.062

1.059

1.056

1.053

1.050

1.047

45%

1.080

1.078

1.076

1.074

1.072

1.069

1.056

1.063

1.062

1.057

1.054

50%

1.086

1.084

1.082

1.080

1.077

1.074

1.071

1.068

1.065

1.062

1.059

55%

1.095

1.093

1.091

1.088

1.085

1.082

1.079

1.076

1.073

1.070

1.067

60%

1.100

1.098

1.095

1.092

1.089

1.086

1.083

1.080

1.077

1.074

1.071

COOLANT MIXTURE (WITH ANTI-RUST AND ANTI-FREEZING EFFECTS)

Freezing Point

Mixing Rate

KYMCO SIGMA Coolant Concentrate

Distilled Water

-9¢J

20%

-15¢J

30%

425cc

975cc

-25¢J

40%

-37¢J

50%

-44.5¢J

55%

Cautions for Using Coolant:

• Use coolant of specified mixing rate. (The

mixing rate of 425cc KYMCO SIGMA

coolant concentrate + 975cc distilled

water is 30%.)

• Do not mix coolant concentrate of

different brands.

• Do not drink the coolant which is

poisonous.

• The freezing point of coolant mixture shall

be 5¢Jlower than the freezing point of the

riding area.

Page 4

12. COOLING SYSTEM

12-3

Mongo ose/KXR 250

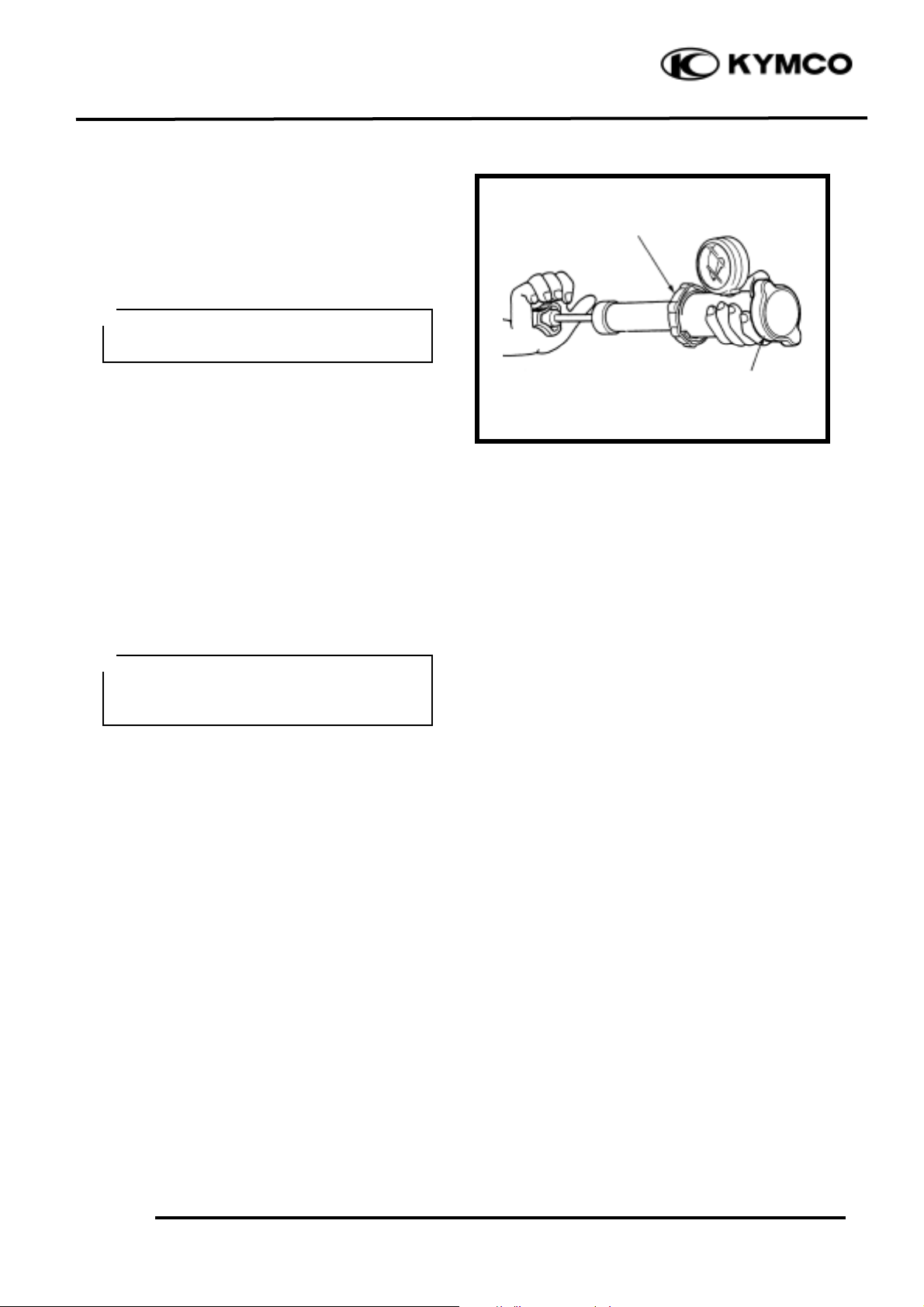

COOLING SYSTEM TESTING

RADIATOR CAP INSPECTION

Install the radiator cap onto the radiator

tester and apply specified pressure to it. It

must hold specified pressure for at least six

seconds.

Radiator Cap Relief Pressure:

0.75~1.05kg/cm_

Install the radiator tester onto the radiator

and apply specified pressure to it. It must

hold specified pressure for at least six

seconds.

Check the water hoses and connectors for

leaks.

The test pressure should not exceed 1.05

kg/cm_. Excessive pressure can damage

the radiator and its hose connectors.

°Ø

Apply water to the cap sealing surface

before testing.

°Ø

Radiator Cap

Radiator Tester

Page 5

12. COOLING SYSTEM

12-4

Mongo ose/KXR 250

RADIATOR

RADIATOR INSPECTION

Remove the front fender. (!2-5)

Inspect the radiator soldered joints and

seams for leaks.

Blow dirt out from between core fins with

compressed air. If insects, etc., are clogging

the radiator, wash them off.

Carefully straighten any bent fins.

RADIATOR REMOVAL

Drain the coolant. (!3-20)

Remove the front fender. (!2-5)

Disconnect the air vent tube from the

radiator filler.

Remove the overflow tube clamp and

disconnect the overflow tube.

Disconnect the fan motor wire coupler.

Remove the two bolts on the radiator filler

hold plate.

Remove the two bolts on the radiator.

Disconnect the thermostatic switch wire

leads.

Loosen the hose bands and disconnect the

upper hose and lower hose from the

radiator.

Pull the radiator upward to remove the

radiator.

Radiator

Air Vent Tube

Overflow Tube

Fan Motor Coupler

Bolts

Bolts

Thermostatic Switch Lead

Upper Hose

Lower Hose

Page 6

12. COOLING SYSTEM

12-5

Mongo ose/KXR 250

RADIATOR DISASSEMBLY

Remove the three bolts and then remove the

fan/shroud from the radiator.

Check fan motor by battery.

CHECK THERMOSTATIC SWITCH

When coolant temperature lower then

85~90¢J the thermostatic switch OFF.

When coolant temperature over 85~90¢J

the thermostatic switch ON.

RADIATOR ASSEMBLY

Install the fan shroud on the radiator with

the three bolts.

RADIATOR INSTALLATION

Reverse the “RADIATOR REMOVAL”

procedures.

Fill the radiator with coolant. (!3-20)

Connect the vent tube to the radiator filler.

After installation, check for coolant leaks.

Bolts

If you want to refill the coolant , the

following procedure must be checked.

1. Please make the radiator filler and the

air vent tube to be separated.

2. Then start the engine , filled in the

coolant till the coolant flowed out

from the air vent tube.

3. Put the air vent tube on.

°Ø

Thermostatic Switch

Page 7

12. COOLING SYSTEM

12-6

Mongo ose/KXR 250

WATER PUMP

MECHANICAL SEAL (WATER SEAL)

INSPECTION

Inspect the

telltale hole for signs of

mechanical seal coolant leakage.

If the mechanical seal is leaking, remove the

right crankcase cover and replace the

mechanical seal.

WATER PUMP/IMPELLER REMOVAL

Drain the coolant. (!3-20)

Loosen the screw and disconnect the

coolant inlet hose.

Remove the four bolts and the water pump

cover.

Remove the gasket and 2 dowel pins

Remove the water pump impeller, washer

and seal washer (porcelain).

Telltale Hole

Water Pump

Inlet Hose

Bolts

Water Pump Cover

Water Pump Impeller

Gasket

Dowel Pins

The impeller has left hand threads.

°Ø

Page 8

12. COOLING SYSTEM

12-7

Mongo ose/KXR 250

Inspect the mechanical (water) seal and seal

washer for wear or damage.

WATER PUMP SHAFT REMOVAL

Remove the water pump impeller. (

!12-6

)

Disconnect the water hose from the right

crankcase cover.

Remove the twelve bolts attaching the right

crankcase cover.

Remove the water pump bearing snap ring

from the water pump assembly.

Remove the water pump shaft and inner

bearing.

Mechanical Seal

Seal Washer (Porcelain)

Impeller

The mechanical seal and seal washer

must be replace as a set.

°Ø

Snap Ring

Inner Bearing

Water Pump Shaft

Page 9

12. COOLING SYSTEM

12-8

Mongo ose/KXR 250

Water Pump Assembly

Remove the water pump shaft outer

bearing.

MECHANICAL SEAL REPLACEMENT

Drive the mechanical seal out of the water

pump assembly from the inside.

Drive in a new mechanical seal using a

mechanical seal driver.

Inner Bearing

Apply sealant to the right crankcase

cover fitting surface of a new mechanical

seal and then drive in the mechanical seal.

°Ø

Mechanical Seal (Water

Snap Ring

Outer Bearing

Water Pump Shaft

Washer

Impeller

Seal Washer

Page 10

12. COOLING SYSTEM

12-9

Mongo ose/KXR 250

WATER PUMP S HAFT INSTALLATION

Drive a new water pump shaft

outer bearing

into the water pump assembly from the

inside.

Install the water pump shaft and shaft inner

bearing into the waster pump assembly.

Install the snap ring to secure the inner

bearing properly.

Install the dowel pins and a new gasket and

then install the water pump assembly to the

right crankcase cover.

Tighten the twelve bolts to secure the right

crankcase cover.

WATER PUMP/IMPELLER

INSTALLATION

When the mechanical seal is replaced, a new

seal washer must be installed to the

impeller.

Install the impeller onto the water pump

shaft.

Torque: 1.0_ 1.4kgf-m

Install the two dowel pins and a new

gasket.

Install the water pump cover and tighten

the four bolts.

Torque: 0.8_ 1.2 kgf-m

When installing the water pump

assembly, aligning the groove on the

water pump shaft with the tab on the oil

pump shaft.

°Ø

The impeller has left hand threads.

°Ø

Water Pump Assembly

Outer Bearing

Page 11

12. COOLING SYSTEM

12-10

Mongo ose/KXR 250

THERMOSENSOR

THERMOSENSOR REMOVAL

Drain the coolant. (

!3-20

)

Disconnect the thermosensor wire.

Remove the thermosensor from the

thermostat.

THERMOSENSOR INSPECTION

Suspend the thermosensor in a pan of water

over a burner and measure the resistance

through the sensor as the water heats up.

Temperature(¢J)

5080100

120

Resistance(W)

1545227

16

THERMOSENSOR INSTALLATION

Apply 3-BOND No. 1212 sealant or

equivalent to the thermosensor threads and

install it into the thermostat housing.

Connect the thermosensor wire.

Fill the radiator with coolant. (!3-20)

Thermosensor Wire

Thermosensor

Be sure to bleed air from the cooling

system.

°Ø

Page 12

12. COOLING SYSTEM

12-11

Mongo ose/KXR 250

THERMOSTAT

THERMOSTAT REMOVAL

Drain the coolant. (!3-20)

Disconnect the thermosensor wire from the

thermosensor.

Disconnect the water hose from the

thermostat housing.

Disconnect the air vent tube from the

thermostat housing.

Remove the mounting bolt and the

thermostat housing from the cylinder head.

Remove the two screws and separate the

thermostat housing halves.

Remove the thermostat from the thermostat

housing.

Thermostat

Bolts

Thermostat

Bolts

Air Vent Tube

Water Hose

Thermostat

Page 13

12. COOLING SYSTEM

12-12

Mongo ose/KXR 250

THERMOSTAT INSPECTION

Suspend the thermostat in a pan of water

over a burner and gradually raise the water

temperature to check its operation.

Technical Data

Begins to open

80±2¢J

Full-open

90¢J

Valve lift

3.5_ 4.5mm

THERMOSTAT INSTALLATION

The installation sequence is the reverse of

removal.

Fill the cooling system with the specified

coolant. (!3-20)

O-ring

Thermosensor

Thermostat

Thermometer

• Do not let the thermostat touch the pan

as it will give a false reading.

• Replace the thermostat if the valve

stays open at room temperature.

•Test the thermostat after it is opened

for about 5 minutes and holds the

temperature at 70¢J .

°Ø

Replace the O-ring with a new one and

apply grease to it.

°Ø

Loading...

Loading...