Page 1

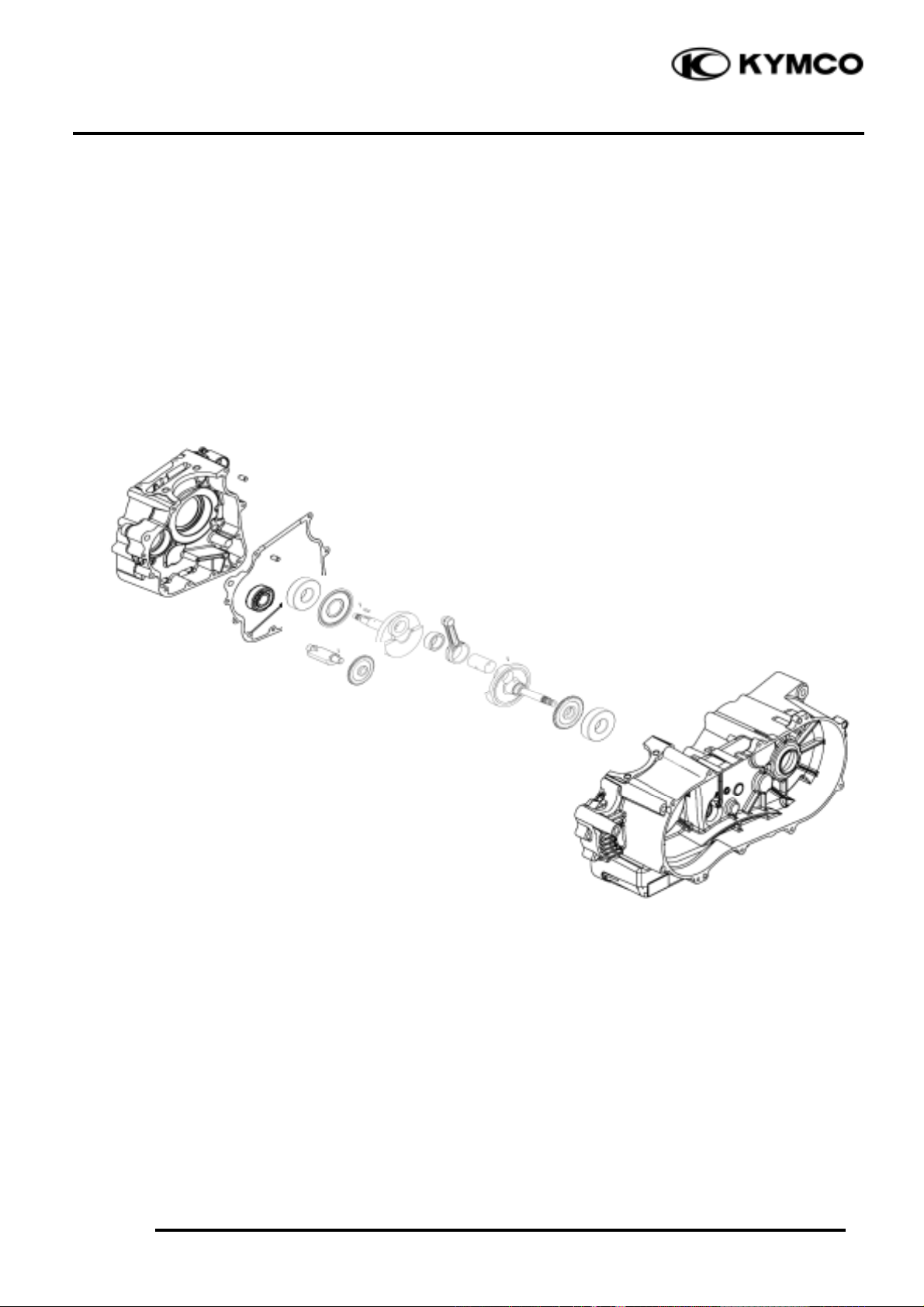

11.CRANKSCASE/CRANKSHAFT/

BALANCE SHAFT

11-0

Mongoose/KXR 250

11

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

CRANKCASE/CRANKSHAFT/BALANCE SHAFT

__________________________________________________________________________________

SERVICE INFORMATION -------------------------------------------- 11- 2

TROUBLESHOOTING ------------------------------------------------- 11- 2

CRANKCASE/CRANKSHAFT/BALANCE SHAFT----------------- 11- 3

11

Page 2

11.CRANKCASE/CRANKSHAFT/

BALANCE SHAFT

11-1

Mongoose/KXR 250

Page 3

11.CRANKSCASE/CRANKSHAFT/

BALANCE SHAFT

11-2

Mongoose/KXR 250

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• This section covers crankcase separation to service the crankshaft. The engine must be removed

for this operation.

• The following parts must be removed before separating the crankcase.

-Cylinder head (!Chapter 7)

-Cylinder/piston (!Chapter 8)

-Drive and driven pulleys (!Chapter 9)

-A.C. generator (!Chapter 16)

-Starter clutch (!Chapter 18)

-Oil pump (!Chapter 4)

SPECIFICATIONS

Item

Standard (mm)

Service Limit (mm)

Connecting rod big end side clearance

0.05_ 0.4

0.6

Crankshaft

Connecting rod big end radial clearance

0_ 0.008

0.05

Run outæ0.10

TORQUE VALUES

Crankcase bolt 0.8_ 1.2kgf-m

Cam chain tensioner slipper bolt 0.8_ 1.2kgf-m

Cam chain cover bolt 0.8_ 1.2kgf-m

TROUBLESHOOTING

Excessive engine noise

Excessive bearing play

Page 4

11.CRANKCASE/CRANKSHAFT/

BALANCE SHAFT

11-3

Mongoose/KXR 250

CRANKCASE/CRANKSHAFT/BA

LANCE SHAFT

REMOVAL

Remove the timing chain from right

crankcase.

Remove the left and right crankcase

attaching bolts.

Separate the left and right crankcase halves.

Remove the gasket and dowel pins.

Remove the crankshaft from the left

crankcase.

Timing Chain

Do not damage the crankcase gasket

surface.

°Ø

Bolts

Crankshaft

Page 5

11.CRANKSCASE/CRANKSHAFT/

BALANCE SHAFT

11-4

Mongoose/KXR 250

Remove balance shaft from the left

crankcase.

Clean off all gasket material from the

crankcase mating surfaces.

Inspect the balance shaft gear teeth.

Burrs/chips/roughness/wear _ Replace.

CRANKSHAFT INSPECTION

Inspect the crankshaft gear teeth.

Burrs/chips/roughness/wear _ Replace.

Measure the connecting rod small end I.D.

Service Limit: 17.06 mm replace if over

Balance Shaft

Avoid damaging the crankcase mating

surfaces.

°Ø

Page 6

11.CRANKCASE/CRANKSHAFT/

BALANCE SHAFT

11-5

Mongoose/KXR 250

Measure the connecting rod small end free

play (A).

Out of specification (0.8 ~ 1.0 mm) _

Replace the crankshaft.

Measure the crankshaft run out (B).

Service Limit: 0.10mm replace if over

Measure the connecting rod big end side

clearance (C).

Service Limit: 0.05mm replace if over

Measure the crank width (D).

Out of specification (55.15 ~ 55.2 mm) _

Replace the crankshaft.

Turn the crankshaft bearings and check for

excessive play.

Measure the crankshaft bearing play.

Service Limit:

Axial : 0.20mm replace if over

Radial : 0.05mm replace if over

Play

Play

Radial

Axial

ABBCD

Page 7

11.CRANKSCASE/CRANKSHAFT/

BALANCE SHAFT

11-6

Mongoose/KXR 250

CRANKCASE/BALANCER

INSTALLATION

Install the balance shaft and crankshaft into

the left crankcase.

Install the dowel pins and new gasket.

Install the right crankcase and tighten the

crankcase attach bolts.

Install the timing chain.

Align the mark on the balance shaft with

the mark on the crankshaft.

°Ø

Mark (Balancer)

Mark (Crankshaft)

Loading...

Loading...