Page 1

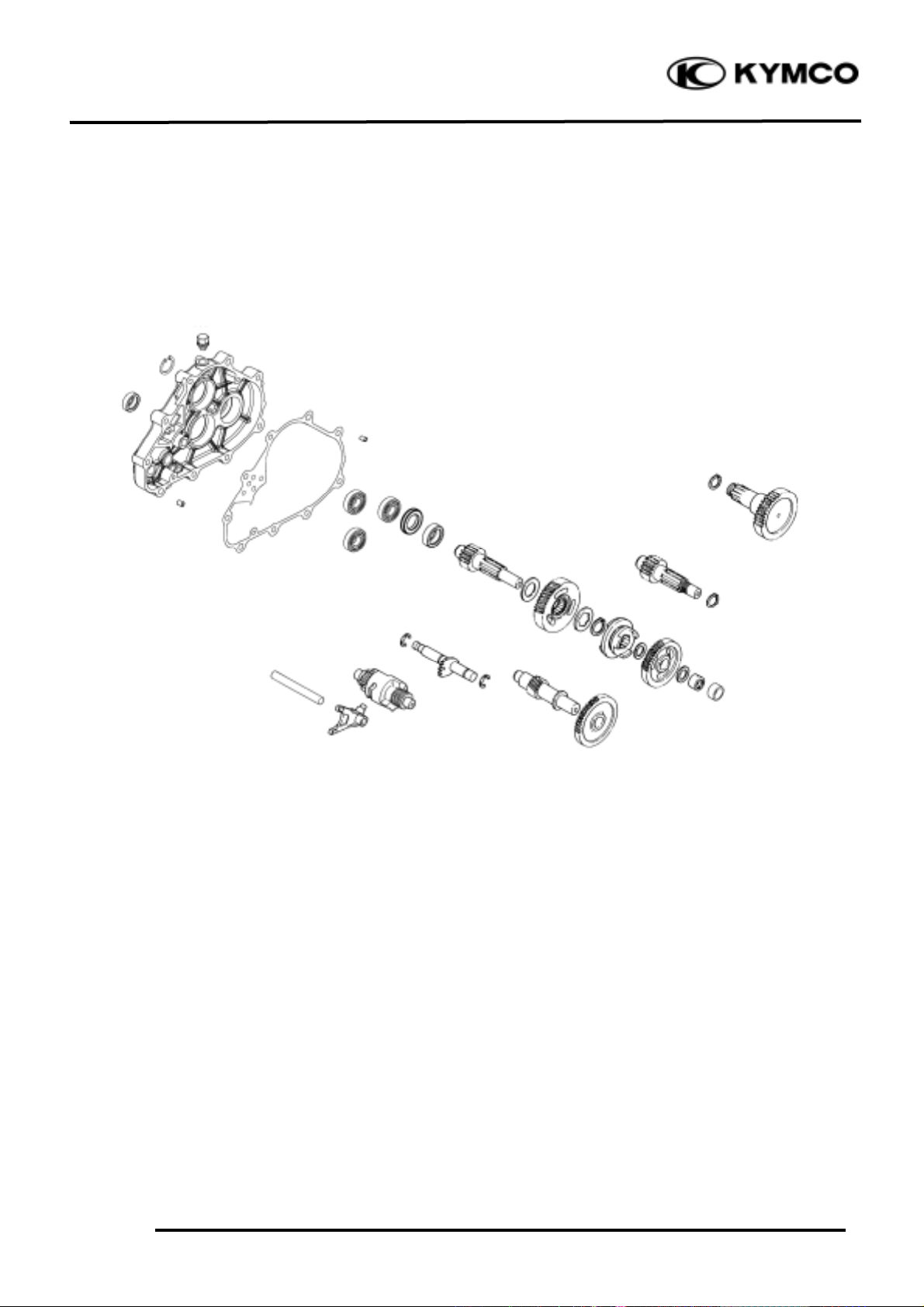

10.FINAL REDUCTION/

TRANSMISSION SYSTEM

10-0

Mongoose/KXR 250

10

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

FINAL REDUCTION/TRANSMISSION SYSTEM

__________________________________________________________________________________

SERVICE INFORMATION -------------------------------------------- 10- 2

TROUBLESHOOTING ------------------------------------------------- 10- 2

TRANSMISSION CASE COVER------------------------------------------ 10- 3

TRANSMISSION-------------------------------------------------------- 10- 5

10

Page 2

10.FINAL REDUCTION/

TRANSMISSION SYSTEM

10-1

Mongoose/KXR 250

Page 3

10.FINAL REDUCTION/

TRANSMISSION SYSTEM

10-2

Mongoose/KXR 250

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• The transmission system can be serviced with the engine installed in the frame.

• When replacing the drive shaft, use a special tool to hold the bearing inner race for this operation.

SPECIFICATIONS

Specified Oil: GEAR OIL SAE 90#

Oil Capacity: At change : 0.3 liter

At disassembly : 0.4 liter

TORQUE VALUES

Transmission case cover bolt 2.4_ 3.0kgf-m

TROUBLESHOOTING

Engine starts but motorcycle won‘t move

• Damaged transmission

• Seized or burnt transmission

Oil leaks

• Oil too rich

• Worn or damaged oil seal

Page 4

10.FINAL REDUCTION/

TRANSMISSION SYSTEM

10-3

Mongoose/KXR 250

TRANSMISSION CASE COVER

REMOVAL

Drain transmission gear oil into a clean

container. (Refer to the “TRANSMISSION

OIL REPLACEMENT” section in the

chapter 3)

Remove the three and then remove the drive

sprocket cover.

Remove the two bolts and then remove the

washer and drive sprocket.

Remove the bolt and then disconnect the

drive shift arm from the shift shaft.

Remove the transmission case cover attaching

bolts.

Bolts

Drive Sprocket

Bolts

Drive Sprocket Cover

Select Arm

Bolt

Bolts

Page 5

10.FINAL REDUCTION/

TRANSMISSION SYSTEM

10-4

Mongoose/KXR 250

Remove the transmission case cover, dowel

pins and gasket.

Inspect the bearings for allow play in the

transmission case cover or the bearings turn

roughly.

If any defects are found, replace the bearing

with a new one.

TRANSMISSION CASE COVER

DISASSEMBLY

Remove the drive axle circlip.

Remove the drive axle from the transmission

case cover.

Remove the bearing circlip for remove the

bearing.

Inspect the bearing for allow play in the

transmission case cover or the bearing turns

roughly .

If any defects are found, replace the bearing

with a new one.

Inspect the drive axle gear teeth for wear or

damage.

Remove the bearing to expose the oil seal.

Inspect the oil seal for wear or damage.

If any defects are found, replace the oil seal

with a new one.

Transmission Case Cover

Bearing Circlip

Drive Axle Circlip

Drive Axle

Bearing

Oil Seal

Bearings

Page 6

10.FINAL REDUCTION/

TRANSMISSION SYSTEM

10-5

Mongoose/KXR 250

Inspect the needle bearing for allow play in

the transmission case cover or the bearing

turns roughly.

If any defects are found, replace the bearing

with a new one.

ASSEMBLY

Install the needle bearing.

Install the oil seal and bearing.

Install the bearing circlip.

Install the drive axle and drive axle cirelip.

TRANSMISSION

REMOVAL

Remove the transmission cover. (Refer to the

“TRANSMISSION CASE COVER REMOVAL” in

the chapter 10)

Check the transmission operation.

Unsmooth operation _ Repair.

Remove the shift shaft.

Needle Bearing

Needle Bearing

Bearing

Shift Shaft

Page 7

10.FINAL REDUCTION/

TRANSMISSION SYSTEM

10-6

Mongoose/KXR 250

Remove the stopper plug.

Remove spring, washer and shift cam

stopper.

Remove the transmission guide bar.

Remove shift cam.

Shift Cam Stopper

Washer

Spring

Plug

Plug

Guide Bar

Shift Cam

Page 8

10.FINAL REDUCTION/

TRANSMISSION SYSTEM

10-7

Mongoose/KXR 250

Remove the shift fork.

Measure the guide bar runout.

Out of specification _ Replace.

Service Limit: Less than 0.03 mm

Inspect the shift fork cam follower and shift

fork pawl.

Scoring/beads/wear _ Replace.

Check the shift cam groove and shift cam

gear.

Wear or damage _ Replace.

Shift Fork

Do not attempt to straighten a bent guide

bar.

°Ø

Shift Fork Cam Follower

Shift Fork Cam Pawl

Page 9

10.FINAL REDUCTION/

TRANSMISSION SYSTEM

10-8

Mongoose/KXR 250

Inspect shift shaft gear.

Damage _ Replace.

Inspect shift shaft.

Damage/bends/wear _ Replace.

Remove the main axle.

MAIN AXLE DISASSEMBLY

Remove the washers, collar, primary driven

gear, bush and clutch dog.

Shift Shaft Gear

Shift Shaft

Main Axle

Collar

Washer

Primary Driven Gear

Clutch Dog

Washers

Primary Driven Gear

Clutch Dog

Collar

Main Axle

Bush

Page 10

10.FINAL REDUCTION/

TRANSMISSION SYSTEM

10-9

Mongoose/KXR 250

Remove the circlip and then remove the

washers, reverse wheel gear and needle

bearing.

Inspect the gear teeth.

Blue discoloration/pitting/wear _ Replace.

Inspect the mated dogs.

Rounded edges/cracks/missing portions

_ Replace.

Circlip

Washer

Reverse Wheel Gear

Washers

Circlip

Needle Bearing

Reverse Wheel Gear

Main Axle

Page 11

10.FINAL REDUCTION/

TRANSMISSION SYSTEM

10-10

Mongoose/KXR 250

MAIN AXLE ASSEMBLY

Reverse the “MAIN AXLE

DISASSEMBLY” procedures.

Washer

Circlip

Needle Bearing

Reverse Wheel Gear

Main Axle

Washer

Primary Driven Gear

Clutch Dog

Collar

Bush

Washer

Washer

Washer

Page 12

10.FINAL REDUCTION/

TRANSMISSION SYSTEM

10-11

Mongoose/KXR 250

Remove the counter axle.

Inspect the gear teeth.

Blue discoloration/pitting/wear _ Replace.

PRIMARY DRIVE AXLE REMOVAL

Remove the clutch/driven pulley. (Refer to

the chapter 9)

Remove the oil seal, circlip, screw and plate.

Remove the primary drive axle.

Inspect the bearings for allow play in the

transmission case cover or the bearing turns

roughly.

If any defects are found, replace the bearing

with a new one.

Counter Axle

Bearings

Bolt

Primary Drive Axle

Plate

Circlip

Oil Seal

Page 13

10.FINAL REDUCTION/

TRANSMISSION SYSTEM

10-12

Mongoose/KXR 250

INSTALLATION

Reverse the “TRANSMISSION REVOVAL”

section procedures.

Install the primary drive axle. (Reverse the

“PRIMARY DRIVE AXLE” procedures.)

Install the counter axle.

Install the main axle.

Install the shift cam.

Install the shift fork.

Install the guide bar.

Install the shift shaft.

Install the shift cam stopper and tighten the

plug.

Torque: 4.5_ 5.0kgf-m

Install the dowel pins and a new gasket onto

the right crankcase.

Install the transmission case cover and tighten

the transmission case cover bolt.

Torque: 2.4_ 3.0kgf-m

Fill the engine with oil and install the oil filler

bolt. (Refer to the “TRANSMISSION OIL

REPLACEMENT” section in the chapter 3)

Specified Gear Oil:

KYMCO SIGMA GEAR OIL 90#

Oil Capacity:

At disassembly : 0.4 liter

At change : 0.3liter

Gear Change Switch

Dowel Pins

Gasket

Make sure that the lever on the gear

change switch correctly engages with the

locating slot on the shift shaft.

Align the mark on the shift shaft gear

with the mark on the shift cam gear.

°Ø

Loading...

Loading...