Page 1

8. DRIVE AND DRIVEN PULLEYS/

KICK STARTER

8-0

GRAND DINK 125/15 0

8

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

DRIVE AND DRIVEN PULLEYS/

KICK STARTER

__________________________________________________________________________________

SCHEMATIC DRAWING ---------------------------------------------- 8- 1

SERVICE INFORMATION -------------------------------------------- 8- 2

TROUBLESHOOTING ------------------------------------------------- 8- 2

LEFT CRANKCASE COVER------------------------------------------ 8- 3

DRIVE PULLEY -------------------------------------------------------- 8- 4

CLUTCH/DRIVEN PULLEY ------------------------------------------ 8- 8

KICK STARTER -------------------------------------------------------- 8-15

8

Page 2

8. DRIVE AND DRIVEN PULLEYS/

KICK STARTER

8-1

GRAND DINK 125/15 0

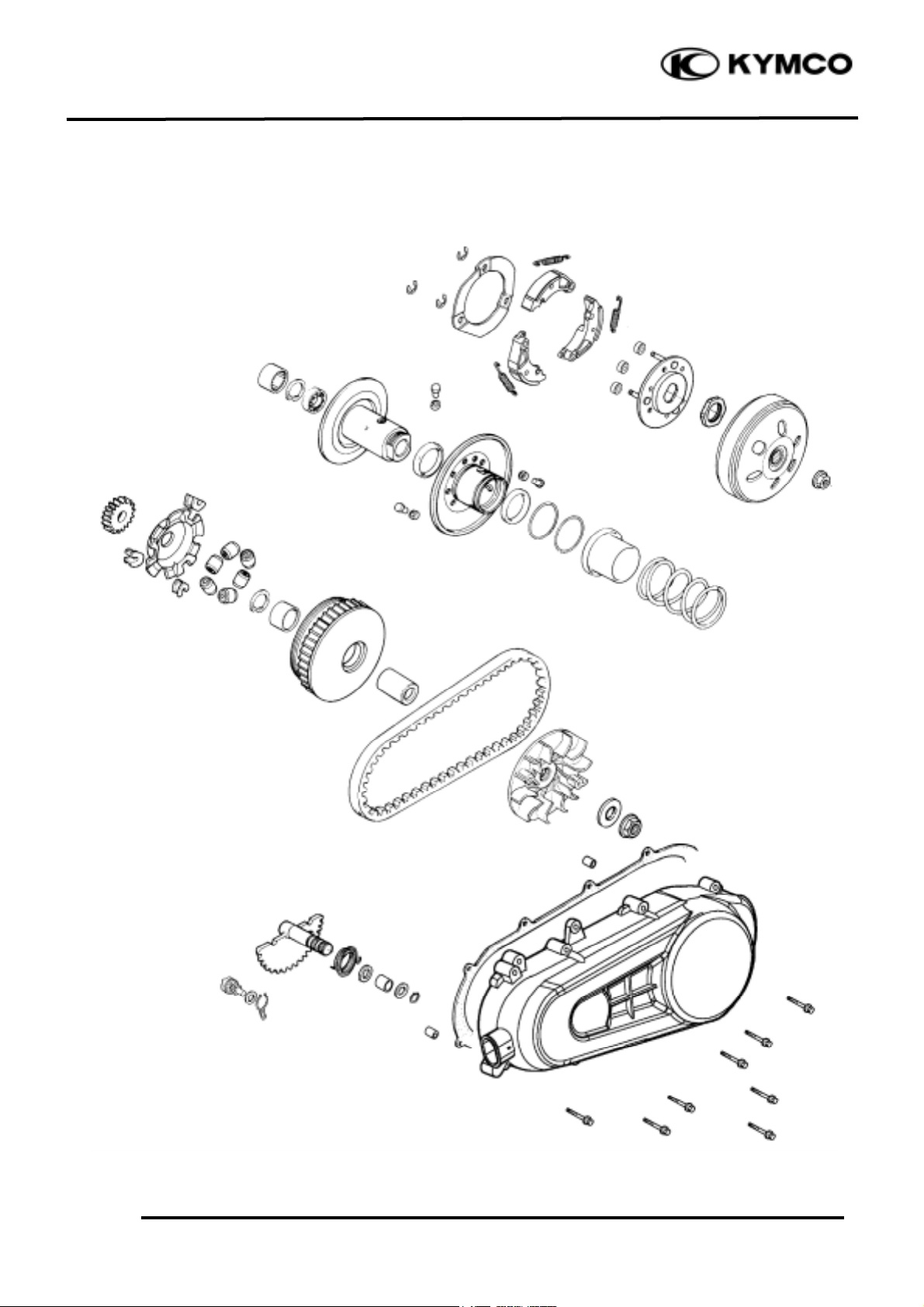

SCHEMATIC DRAWING

Page 3

8. DRIVE AND DRIVEN PULLEYS/

KICK STARTER

8-2

GRAND DINK 125/15 0

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• The drive pulley, clutch and driven pulley can be serviced with the engine installed.

• Avoid getting grease and oil on the drive belt and pulley faces. Remove any oil or grease from

them to minimize the slipping of drive belt and drive pulley.

SPECIFICATIONS

Item

Standard (mm)

Service Limit (mm)

Movable drive face bushing I.D.

33.000_ 33.025

33.06

Drive face collar O.D.

32.006_ 32.009

31.90

Drive belt width

19.0

17.5

Clutch lining thickness

3.963_ 4.037

2.0

Clutch outer I.D.

130.0_ 130.2

130.5

Driven face spring free length

88.3

83.2

Driven face O.D.

33.965_ 33.985

33.94

Movable driven face I.D.

34.00_ 34.025

34.06

Weight roller O.D.

16.99_ 17.00

16.00

TORQUE VALUES

Drive face nut 49.0_ 58.8N-m

Clutch outer nut 49.0_ 58.8N-m

Clutch drive plate nut 49.0_ 58.8N-m

SPECIAL TOOLS

Universal holder Clutch spring compressor

Bearing driver Lock nut wrench, 39mm

Kick starter spring remover

TROUBLESHOOTING

Engine starts but motorcycle won‘t move Lack of power

• Worn drive belt • Worn drive belt

• Broken ramp plate • Weak driven face spring

• Worn or damaged clutch lining • Worn weight roller

• Broken driven face spring • Faulty driven face

Engine stalls or motorcycle creeps

• Broken clutch weight spring

Page 4

8. DRIVE AND DRIVEN PULLEYS/

KICK STARTER

8-3

GRAND DINK 125/15 0

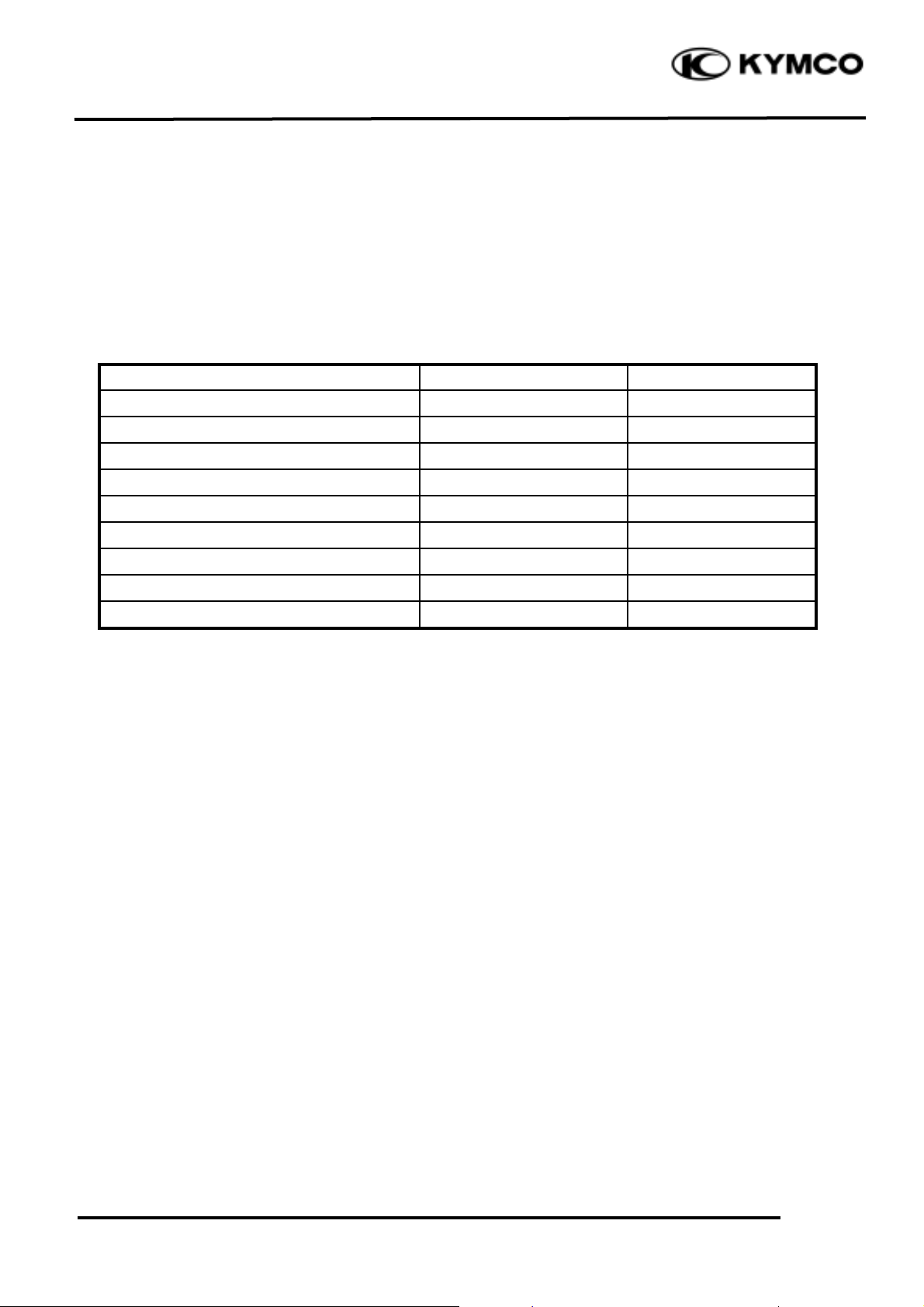

LEFT CRANKCASE COVER

REMOVAL

Loosen the drive belt air tube band screw.

Remove the left crankcase cover bolts and left

crankcase cover.

Remove the seal rubber and dowel pins.

INSTALLATION

Install the dowel pins and the gasket.

Install the left crankcase cover.

Install the cable clamp to the specified

location. Install and tighten the left crankcase

cover bolts.

Kick Lever

Left Crankcase Cover

Air Tube Band

Bolts

• Do not pull out the kick starter spindle.

Press in the kick starter spindle when

installing the left crankcase cover.

*

Dowel Pins

Gasket

Left Crankcase Cover

Page 5

8. DRIVE AND DRIVEN PULLEYS/

KICK STARTER

8-4

GRAND DINK 125/15 0

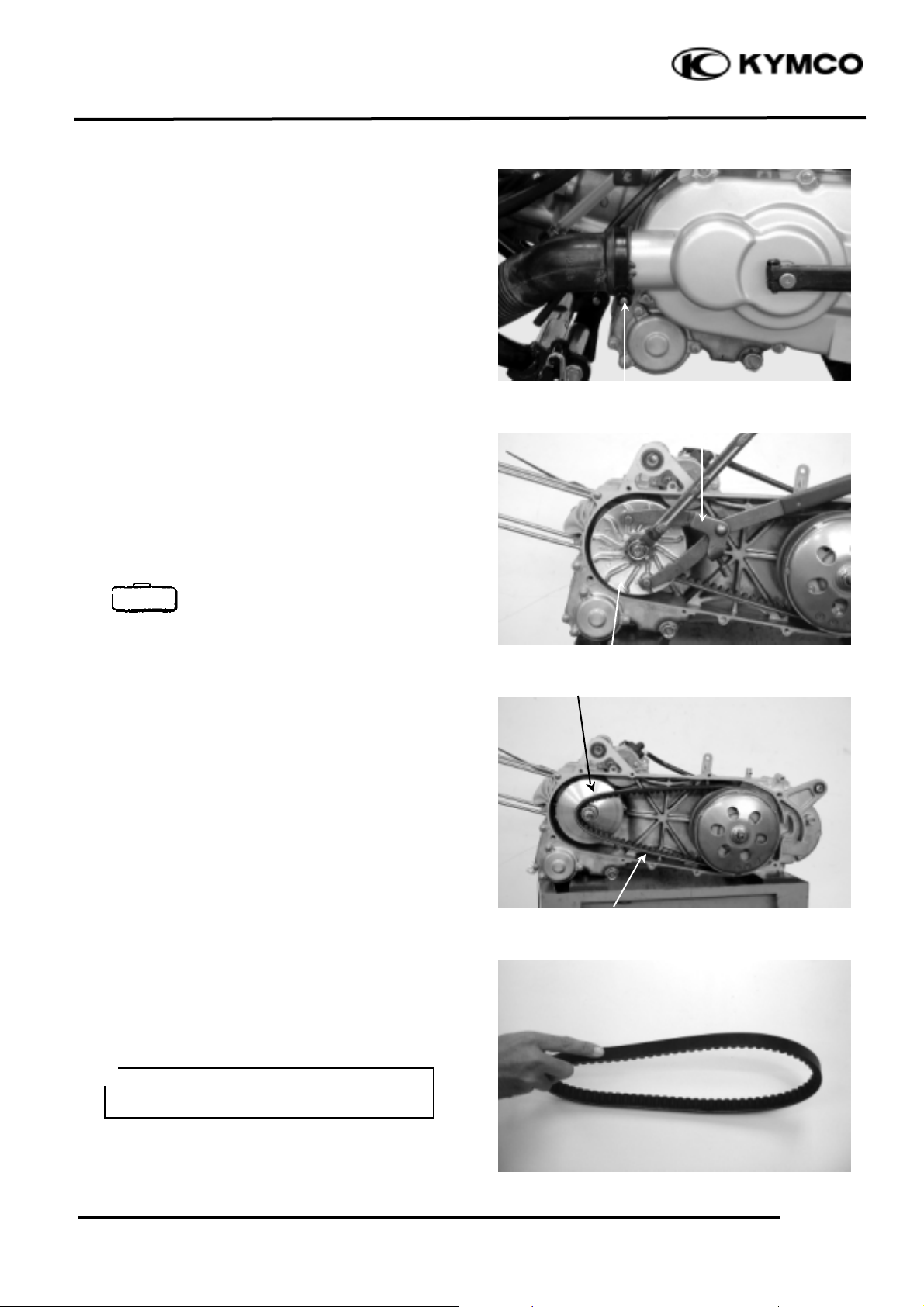

Install the drive belt air tube and tighten the

tube band screw.

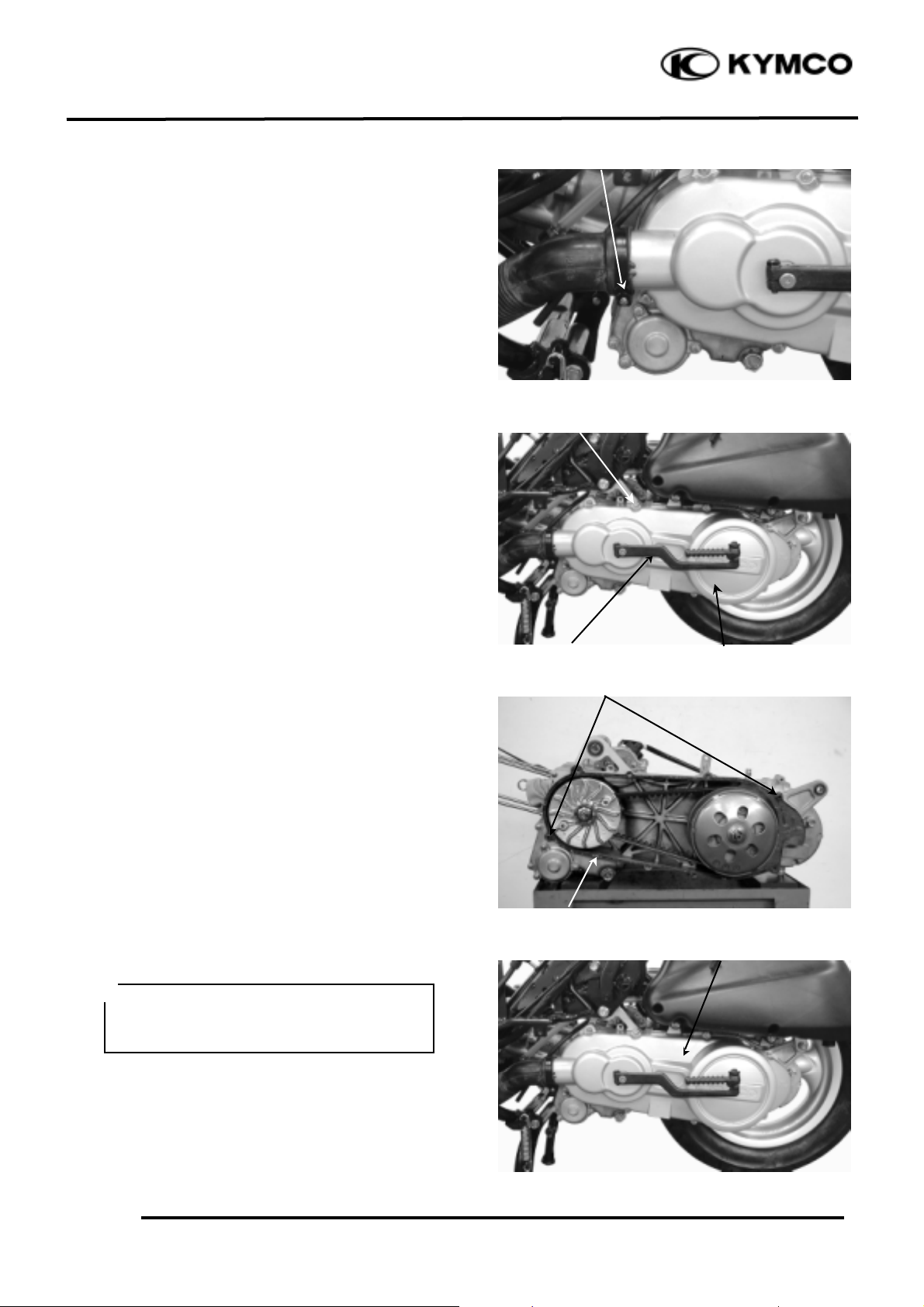

DRIVE PULLEY

REMOVAL

Remove the left crankcase cover.

Hold the drive pulley using an universal

holder and remove the drive face nut and

washer.

Remove the drive pulley face.

Universal Holder

Remove the drive belt from the movable drive

face.

INSPECTION

Check the drive belt for cracks, separation or

abnormal or excessive wear.

Measure the drive belt width.

Service Limit: 17.5mm replace if below

Drive Pulley Face

Universal Holder

• Use specified genuine parts for

replace-ment.

*

Movable Drive Face

Drive Belt

Tube Band Screw

Special

Page 6

8. DRIVE AND DRIVEN PULLEYS/

KICK STARTER

8-5

GRAND DINK 125/15 0

Remove the movable drive face assembly.

Remove the drive pulley collar.

DISASSEMBLY

Remove the ramp plate.

Remove the weight rollers.

INSPECTION

Check each weight roller for wear or damage.

Measure each weight roller O.D.

Service Limit: 16.00mm replace if below

Drive Pulley Collar

Ramp Plate

Weight Roller

Movable Drive Face Assembly

Page 7

8. DRIVE AND DRIVEN PULLEYS/

KICK STARTER

8-6

GRAND DINK 125/15 0

Measure the movable drive face bushing

assemblyy I.D.

Service Limit: 27.20mm replace if over

Check the drive pulley collar for wear or

damage.

Measure the O.D. of the drive pulley collar

sliding surface.

Service Limit: 26.90mm replace if below

ASSEMBLY

Install the weight rollers into the movable

drive face.

Weight Roller

Page 8

8. DRIVE AND DRIVEN PULLEYS/

KICK STARTER

8-7

GRAND DINK 125/15 0

Install the ramp plate.

Insert the drive pulley collar into the movable

drive face.

INSTALLATION

Install the movable drive face onto the

crankshaft.

Lay the drive belt on the driven pulley.

Set the drive belt on the drive pulley collar.

Drive Pulley Collar

Ramp Plate

Driven Pulley

Movable Drive Face Assembly

Drive Pulley Collar

Drive Belt

Page 9

8. DRIVE AND DRIVEN PULLEYS/

KICK STARTER

8-8

GRAND DINK 125/15 0

Install the drive pulley face, washer and drive

face nut.

Hold the drive pulley with the universal

holder and tighten the drive face nut.

Torque: 49.0_ 58.5N-m

Universal Holder

CLUTCH/DRIVEN PULLEY

Remove the left crankcase cover. (!8-3)

Remove the drive pulley and drive belt. (!8-

4)

Hold the clutch outer with the universal

holder and remove the clutch outer nut.

Universal Holder

Remove the clutch outer.

INSPECTION

Inspect the clutch outer for wear or damage.

Measure the clutch outer I.D.

Service Limit: 130.5mm replace if over

Drive Pulley Face

Washer

Special

Special

• Do not get oil or grease on the

drive belt or drive pulley faces.

*

Clutch Outer

Drive Face Nut

Drive Pulley

Universal Holder

Universal Holder

Page 10

8. DRIVE AND DRIVEN PULLEYS/

KICK STARTER

8-9

GRAND DINK 125/15 0

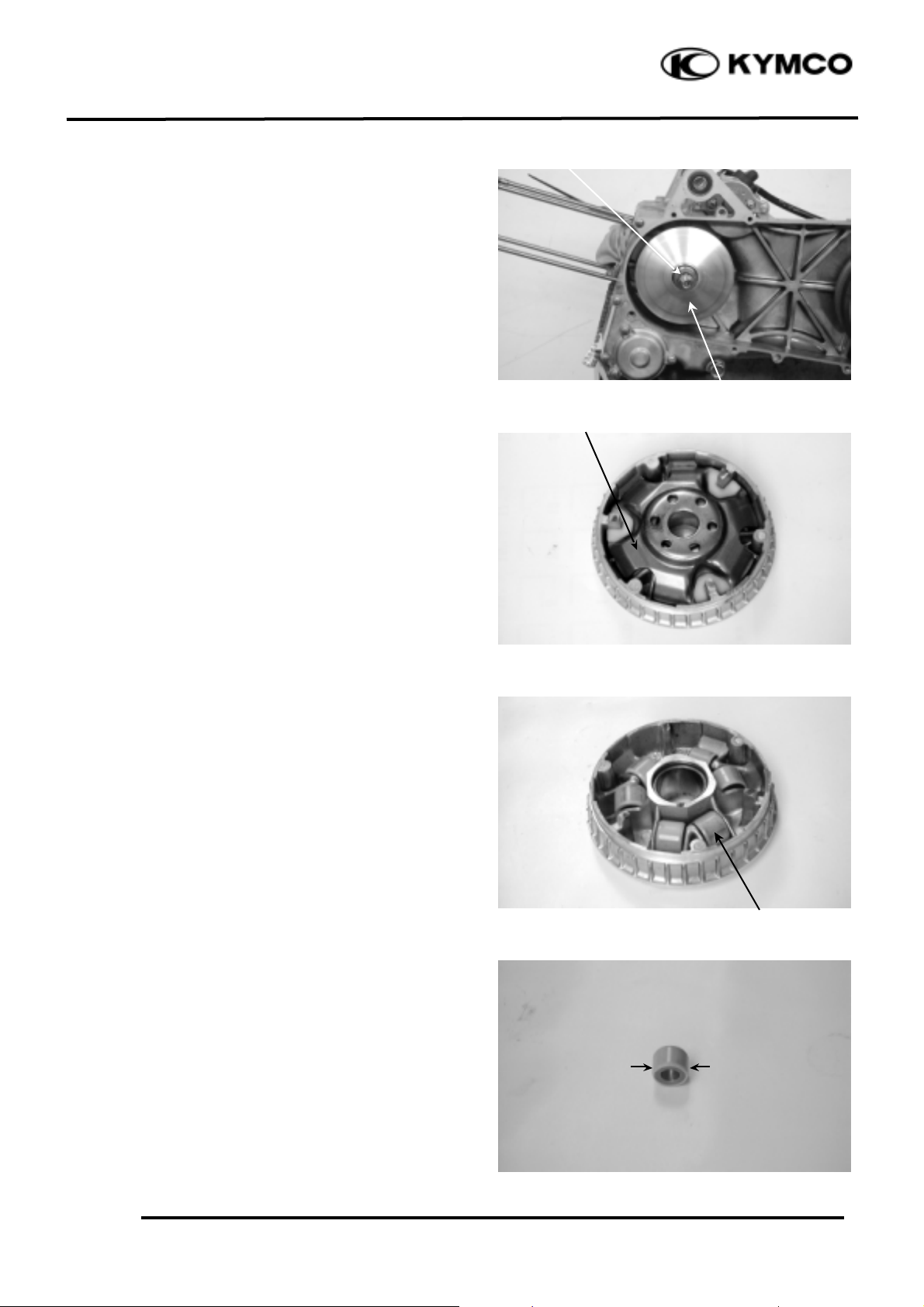

Check the clutch shoes for wear or damage.

Measure the clutch lining thickness.

Service Limit: 2.0mm replace if below

CLUTCH/DRIVEN PULLEY

DISASSEMBLY

Hold the clutch/driven pulley assembly with

the clutch spring compressor.

Clutch Spring Compressor

Set the tool in a vise and remove the clutch

drive plate nut.

Lock Nut Wrench, 39mm

Loosen the clutch spring compressor and

disassemble the clutch/driven pulley

assembly.

Remove the seal collar.

Clutch/Driven Pulley

Special

Special

Clutch Spring Compressor

• Be sure to use a clutch spring

compressor to avoid spring damage.

*

Lock Nut Wrench

Page 11

8. DRIVE AND DRIVEN PULLEYS/

KICK STARTER

8-10

GRAND DINK 125/15 0

Pull out the guide roller pins and guide rollers.

Remove the movable driven face from the

driven face.

Remove the oil seal from the movable driven

face.

INSPECTION

Measure the driven face spring free length.

Service Limit: 83.2mm replace if below

Check the driven face assembly for wear or

damage.

Measure the driven face O.D.

Service Limit: 33.94mm replace if below

Movable Driven Face

Guide Roller Pin

O-ring

Guide Roller

Oil Seal

Page 12

8. DRIVE AND DRIVEN PULLEYS/

KICK STARTER

8-11

GRAND DINK 125/15 0

Check the movable driven face for wear or

damage.

Measure the movable driven face I.D.

Service Limit: 34.06mm replace if over

DRIVEN PULLEY FACE BEARING

REPLACEMENT

Check the bearings for play and replace them

if they have excessive play.

Drive the inner needle bearing out of the

driven pulley face.

Remove the snap ring and drive the outer

bearing out of the driven face.

Apply grease to the outer bearing.

Drive a new outer bearing into the driven face

with the sealed end facing up.

Bearing Driver

Seat the snap ring in its groove.

Apply grease to the driven face bore areas.

Snap Ring

Inner Bearing

Outer Bearing

• Discard the removed bearing and

replace with a new one.

*

Pack all bearing cavities with 9_ 9.5g

grease.

*

• Discard the removed bearing and

replace with a new one.

*

Special

Page 13

8. DRIVE AND DRIVEN PULLEYS/

KICK STARTER

8-12

GRAND DINK 125/15 0

Press a new needle bearing into the driven

face.

Bearing Driver

CLUTCH DISASSEMBLY

Remove the circlips and retainer plate to

disassemble the clutch.

Circlips

Retainer Plate

Special

• Keep grease off the clutch

linings.

*

Clutch Lining

Page 14

8. DRIVE AND DRIVEN PULLEYS/

KICK STARTER

8-13

GRAND DINK 125/15 0

CLUTCH ASSEMBLY

Install the damper rubbers on the drive plate

pins.

Install the clutch weights/shoes and clutch

springs onto the drive plate.

Install the retainer plate and secure with the

circlips.

CLUTCH/DRIVEN PULLEY ASSEMBLY

Clean the pulley faces and remove any grease

from them.

Apply grease to the O-rings and install them

onto the moveable driven face.

Circlips

Drive Plate

Movable Driven Face

Page 15

8. DRIVE AND DRIVEN PULLEYS/

KICK STARTER

8-14

GRAND DINK 125/15 0

Install the movable driven face onto the

driven face.

Apply grease to the guide rollers and guide

roller pins and then install them into the holes

of the driven face.

Install the seal collar.

Remove any excessive grease.

Set the driven pulley assembly, driven face

spring and clutch assembly onto the clutch

spring compressor.

Compress the tool and install the drive plate

nut.

Set the tool in a vise and tighten the drive

plate nut to the specified torque.

Torque: 49.0_ 58.8N-m

Clutch Spring Compressor

Outer Driver, 32x35mm

INSTALLATION

Install the clutch/driven pulley onto the drive

shaft.

• Be sure to clean the driven face

off any grease.

*

• Align the flat surface of the driven

face with the flat on the clutch drive

plate.

*

• Keep grease off the drive shaft.

*

Movable Driven Face

Guide Roller Pin

Seal Collar

Guide Roller

Clutch/Driven Pulley

Driven Face

Clutch Spring Compressor

Lock Nut Wrench

• Be sure to use a clutch spring

compressor to avoid spring damage.

*

Special

Page 16

8. DRIVE AND DRIVEN PULLEYS/

KICK STARTER

8-15

GRAND DINK 125/15 0

Install the clutch outer.

Hold the clutch outer with the universal

holder.

Install and tighten the clutch outer nut.

Torque: 49.0_ 58.8kg-m

Universal Holder

Install the drive belt. (!8-7)

Install the left crankcase cover. (!8-3)

KICK STARTER

REMOVAL

Remove the left crankcase cover. (!8-3)

Remove the seal rubber and dowel pins.

Remove the kick lever.

Remove the circlip and washer from the kick

starter spindle.

Gently turn the kick starter spindle to remove

the starter driven gear together with the

friction spring.

Remove the kick starter spindle and return

spring from the left crankcase cover.

Remove the kick starter spindle bushing.

Special

Return Spring

Kick Starter Spindle

Friction Spring

Kick Starter Spindle

Starter Driven Gear

Kick Lever

Clutch Outer

Page 17

8. DRIVE AND DRIVEN PULLEYS/

KICK STARTER

8-16

GRAND DINK 125/15 0

INSPECTION

Inspect the kick starter spindle and gear for

wear or damage.

Inspect the return spring for weakness or

damage.

Inspect the kick starter spindle bushings for

wear or damage.

Inspect the starter driven gear for wear or

damage.

Inspect the friction spring for wear or

damage.

Inspect the kick starter spindle and starter

driven gear forcing parts for wear or damage.

INSTALLATION

Install the kick starter spindle bushings and

return spring onto the left crankcase cover.

Install the starter driven gear and friction

spring as the figure shown.

Starter Driven Gear Shaft Forcing Part

Friction Spring

Starter Driven Gear

Spindle

Return Spring

Plastic Bushing

Spindle Bushing

Starting Ratchet

Kick Starter Spindle Forcing

Friction Spring

Kick Starter Spindle

When installing the return spring, use a

screw driver to press the inward and

outward return spring hooks into their

original positions respectively.

*

Page 18

8. DRIVE AND DRIVEN PULLEYS/

KICK STARTER

8-17

GRAND DINK 125/15 0

Install the kick lever.

Install the left crankcase cover and tighten the

cover bolts diagonally.

Connect the drive belt air tube and tighten the

band screw.

LEFT CRANKCASE COVER BEARING

INSPECTION

Inspect the bearing into the left crankcase

cove for loose, wear or damage.

If any abnormal problem is found, replace the

bearing with a new one.

Left Crankcase Cover

Loading...

Loading...