Page 1

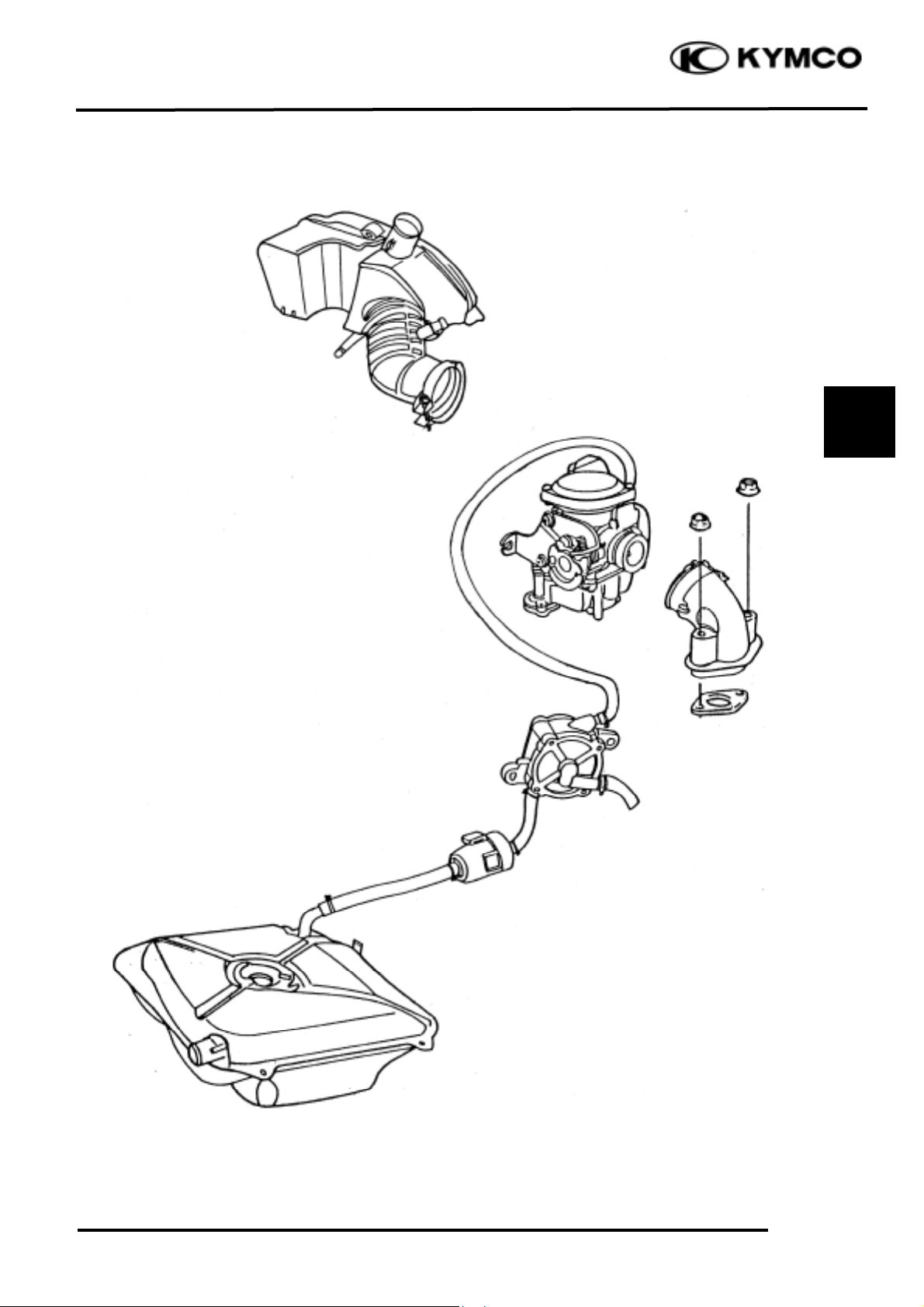

5. FUEL SYSTEM

5-0

FILLY LX 50

5

5

Page 2

5. FUEL SYSTEM

5-1

FILLY LX 50

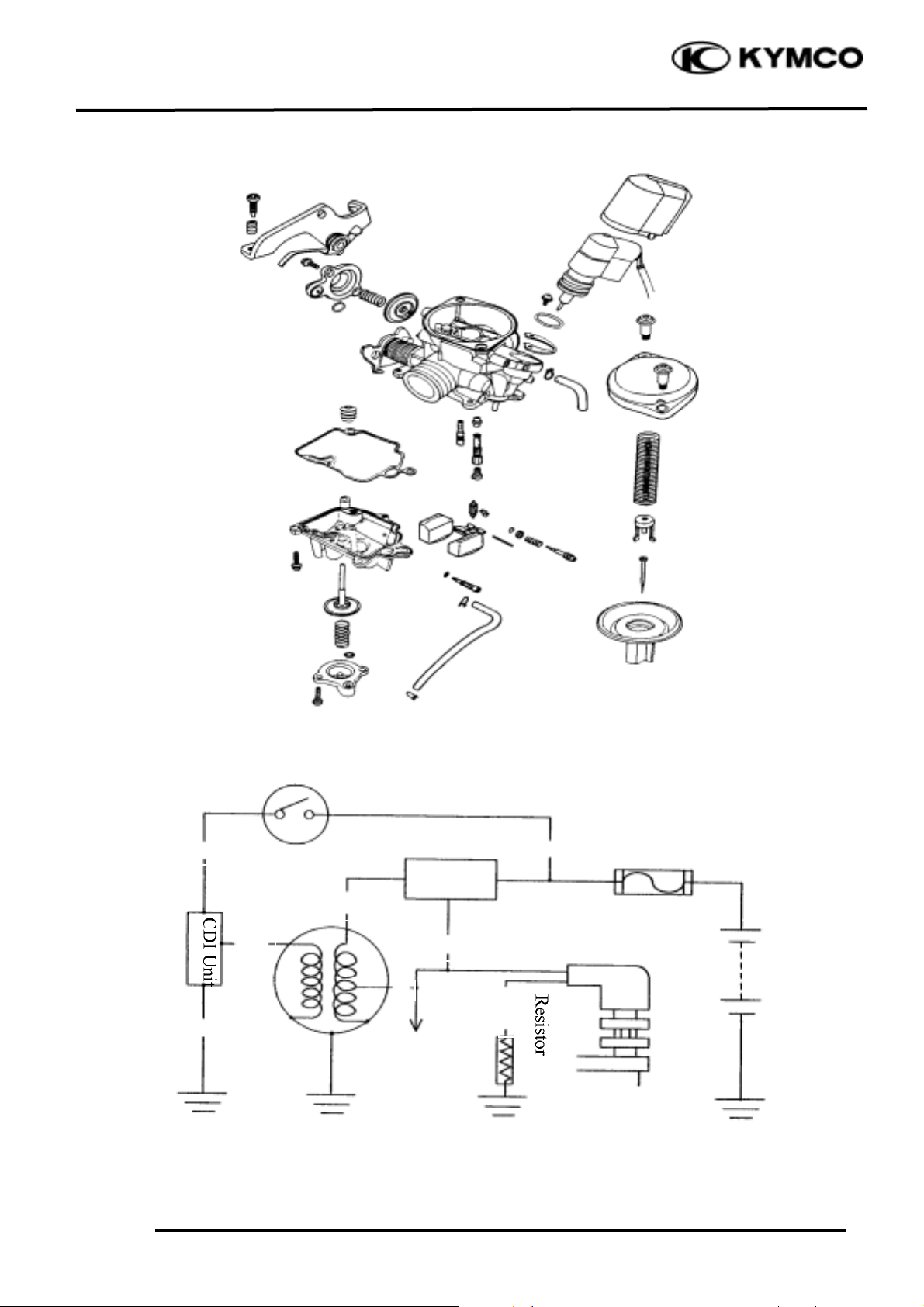

Fuse

12V Battery

Regulator

/Rectifier

L/Y

W

Auto Bystarter

Ignition Switch

BGY

Y

Lighting

System

5W

5W

G/B

M

Page 3

5. FUEL SYSTEM

5-2

FILLY LX 50

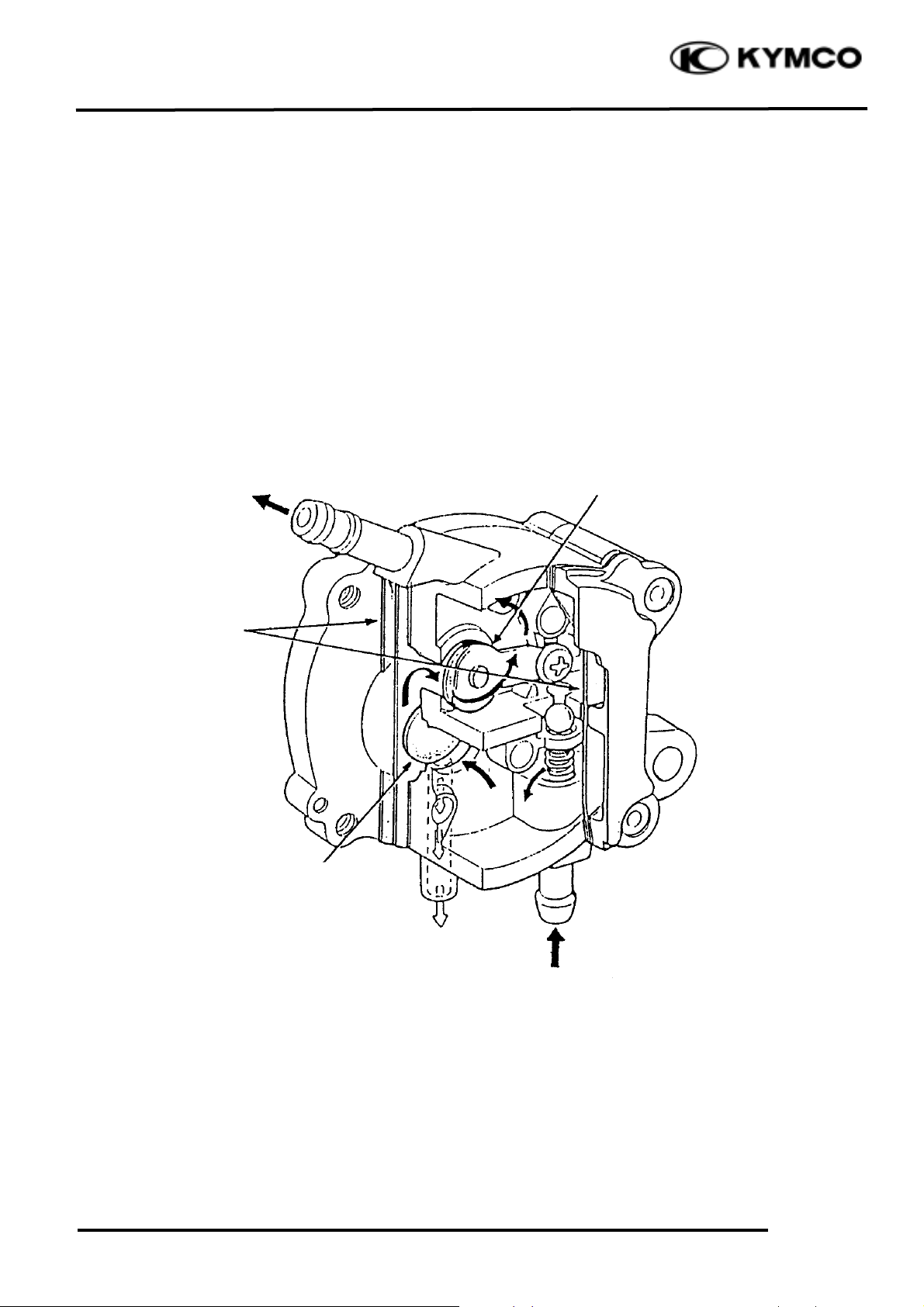

FUEL PUMP

CONSTRUCTION:

The fuel pump adopted for this model is a vacuum-type fuel pump which utilizes the positive and

negative pulsating pressures produced by the engine crankcase to control the oil pump diaphragms

and deliver fuel from the fuel tank to the carburetor through the suction valve and outlet valve.

FUEL PUMP CONSTRUCTION

Diaphragms

Inlet

Outlet

Suction Valve

Outlet Valve

Pulsating Pressure

from Crankcase

Page 4

5. FUEL SYSTEM

5-3

FILLY LX 50

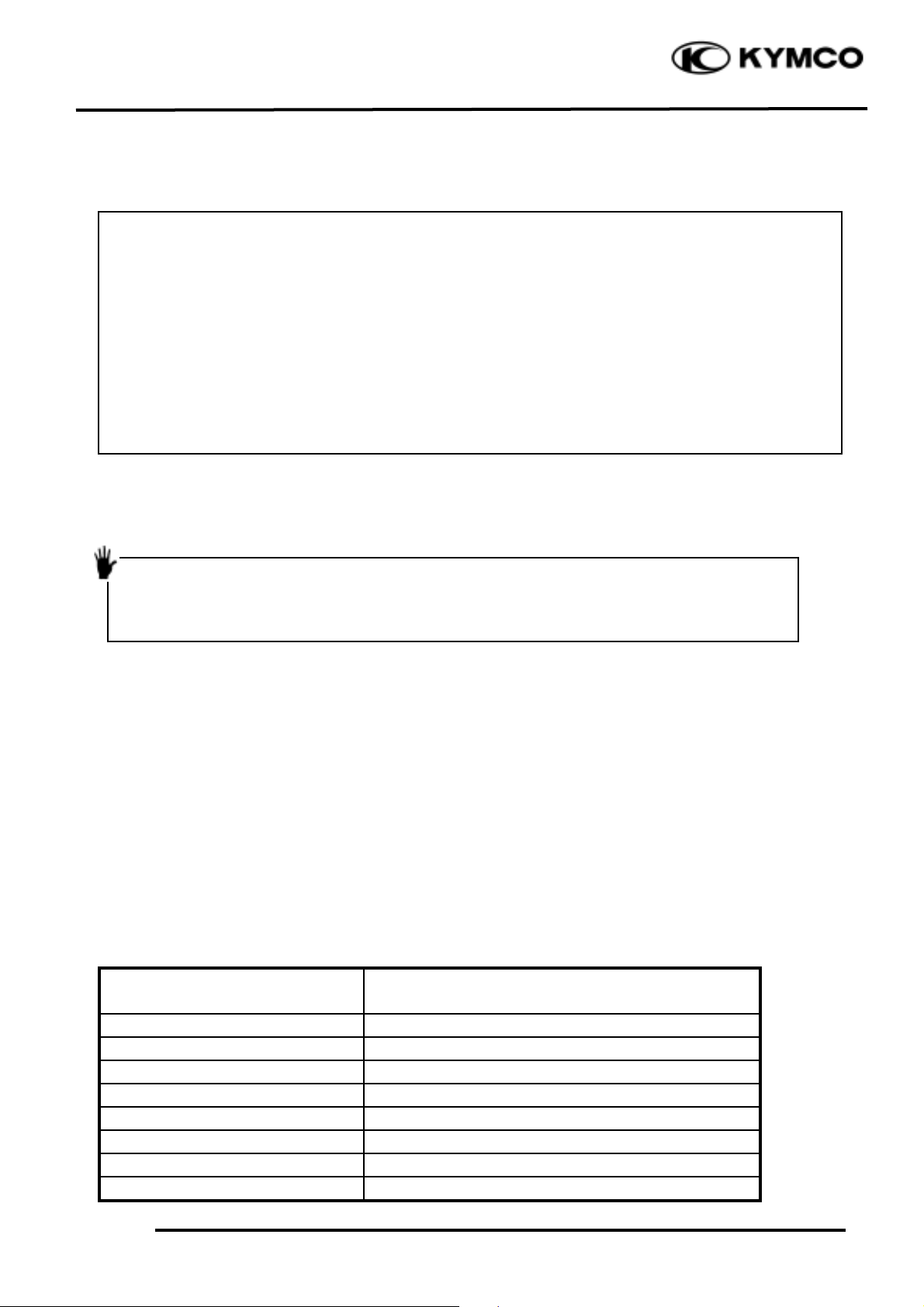

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• When disassembling the carburetor, be sure to service the vacuum piston and float chamber.

• Do not bend or twist control cables. Damaged control cables will not operate smoothly.

• When disassembling fuel system parts, note the locations of O-rings. Replace them with new

ones during assembly.

• Before float chamber disassembly, loosen the drain screw to drain the residual gasoline into a

clean container.

• After the carburetor is removed, plug the intake manifold side with a clean shop towel to prevent

foreign matters from entering.

• Remove the vacuum diaphragm before cleaning the carburetor air and fuel passages with

compressed air to avoid damaging the vacuum diaphragm.

• When the motorcycle is not used for over one month, drain the residual gasoline from the float

chamber to avoid erratic idling and clogged slow jet due to deteriorated fuel.

SPECIFICATIONS

Item

Standard

Venturi dia. (mm)

20

Type

CVK

Float level (mm)

17

Main jet

#85

Slow jet

#35

Idle speed

1900rpm

Throttle grip free play

2_ 6mm

Pilot screw opening

2±

1

/2

Gasoline is very dangerous. When working with gasoline, keep sparks and flames away

from the working area.

Gasoline is extremely flammable and is explosive under certain conditions. Be sure to

work in a well-ventilated area.

SERVICE INFORMATION

......................

5-3 ACCELERATING PUMP

......................

5-11

TROUBLESHOOTING

.............................

5-4 CARBURETOR INSTALLATION

........

5-12

CARBURETOR REMOVAL

....................

5-5 PILOT SCREW ADJUSTMENT

............

5-13

AUTO BYSTARTER

.................................

5-5 FUEL TANK

...........................................

5-14

AIR CUT-OFF VALVE

.............................

5-7 AUTO FUEL VALVE

.............................

5-15

VACUUM CHAMBER

.............................

5-7 FUEL UNIT

.............................................

5-18

FLOAT CHAMBER

..................................

5-9 AIR CLEANER

........................................

5-18

Page 5

5. FUEL SYSTEM

5-4

FILLY LX 50

TROUBLESHOOTING

Engine is hard to start Misfiring during acceleration

• No spark at plug (!Section 15) • Faulty ignition system

• Compression too low • Lean mixture

• No fuel to carburetor • Faulty accelerating pump

-Clogged fuel filter Engine idles roughly, stalls or runs poorly

-Restricted fuel line • Clogged fuel system

-Faulty float valve • Ignition malfunction

-Incorrectly adjusted float level • Rich or lean mixture

• Engine flooded with fuel • Contaminated fuel

-Clogged air cleaner • Intake air leak

-Fuel overflowing • Incorrect idle speed

• Intake air leak • Incorrectly adjusted pilot screw

• Contaminated fuel • Clogged idle system or auto bystarter passages

• Faulty auto bystarter • Incorrectly adjusted float level

• Clogged idle system or auto bystarter passages Lean mixture

Rich mixture • Clogged fuel jets

• Faulty auto bystarter • Faulty float valve

• Faulty float valve • Float level too low

• Float level too high • Clogged fuel system

• Clogged air jets • Intake air leak

• Dirty air cleaner • Improper vacuum piston operation

• Flooded carburetor • Improper throttle operation

Backfiring at deceleration

• Lean mixture in idle system

• Improper air cut-off valve operation

Page 6

5. FUEL SYSTEM

5-5

FILLY LX 50

CARBURETOR REMOVAL

Remove the frame right side cover. (!2-4)

Disconnect the auto bystarter wire

connector.

Remove the met-in box. (!2-3)

Loosen the drain screw and drain the fuel

from the float chamber.

Disconnect the fuel tube and vacuum tube at

the carburetor.

Loosen the throttle cable adjusting nut and

lock nut, and disconnect the throttle cable

from the carburetor.

Loosen the carburetor intake manifold band

and air cleaner connecting tube band screws

and then remove the carburetor.

AUTO BYSTARTER

OPERATION INSPECTION

Measure the resistance between the auto

bystarter wire terminals.

Resistance: 10W max. (10 minutes

minimum after stopping the engine)

If the reading is not within the limit, replace

the auto bystarter with a new one.

Adjusting Nut

Fuel Tube

Intake Manifold

Band

Air Cleaner Connect ing

T ube Band

Throttle Cable

Lock Nut

Auto Bystarter Wire

Page 7

5. FUEL SYSTEM

5-6

FILLY LX 50

Connect a hose to the fuel enriching circuit

of the carburetor. Connect the auto

bystarter yellow wire to the positive (+)

terminal of a battery and green wire to the

negative (-) terminal. Wait 5 minutes and

blow the hose with mouth or vacuum pump.

If the passage is blocked, the auto bystarter

is normal.

Disconnect the auto bystarter from the

battery. Wait 30 minutes and blow the hose

with mouth or vacuum pump. If air can be

blown into the hose, the auto bystarter is

normal.

REMOVAL

Remove the set plate screws and set plate.

Remove the auto bystarter from the

carburetor.

AUTO BYSTARTER INSPECTION

Check the auto bystarter valve and needle

for nicks, wear or damage.

If any faulty part is found, replace the auto

bystarter as a set.

INSTALLATION

Insert the auto bystarter into the carburetor

body until it bottoms.

Position the set plate into the groove in the

auto bystarter and tighten the screws.

Auto Bystarter

Screws

Bystarter Needle

Bystarter Valve

Auto Bystarter

Screws

Set Plate

Vacuum Pump

Adopter

Set Plate

• Be sure to install the auto bystarter and

set plate properly.

• Install the set plate with its bottom

face facing down.

*

Page 8

5. FUEL SYSTEM

5-7

FILLY LX 50

AIR CUT-OFF VALVE

DISASSEMBLY

Remove the two screws attaching the

throttle cable set plate and the set plate.

Remove the two screws attaching the air

cut-off valve.

Remove the spring and vacuum diaphragm.

Check the vacuum diaphragm for cracks or

damage and check each passage for clogging.

ASSEMBLY

Install the vacuum diaphragm onto the

carburetor.

Install the spring and air cut-off valve cover.

Install the throttle cable set plate and tighten

the two screws.

VACUUM CHAMBER

DISASSEMBLY

Remove the two vacuum chamber cover

screws and the cover.

Remove the spring and vacuum diaphragm/

piston.

Spring

Spring

Throttle Cable Set

Vacuum Diaphragm/Piston

Air Cut-off Valve Cover

Cover

Screws

O-ring

Screws

Screws

• Be sure to set the vacuum diaphragm

lip into the groove on the carburetor.

• When installing the air cut-off valve

cover, make sure that the vacuum

diaphragm is properly installed.

*

Diaphragm

Vacuum Chamber Cover

Spring

Page 9

5. FUEL SYSTEM

5-8

FILLY LX 50

Remove the needle holder and jet needle.

INSPECTION

Inspect the needle for stepped wear.

Inspect the vacuum piston for wear or

damage.

Inspect the diaphragm for deterioration and

tears.

ASS EMBLY

Install the vacuum piston/diaphragm in the

carburetor body.

Install the spring and then install the

vacuum chamber cover.

Tighten the two screws.

Vacuum Chamber Cover

Vacuum Diaphragm

Jet Needle

Vacuum Diaphragm

Be careful not to damage the vacuum

diaphragm.

*

• Be careful not to damage the diaphragm.

• Hold the vacuum piston while

tightening the vacuum chamber cover.

*

Page 10

5. FUEL SYSTEM

5-9

FILLY LX 50

FLOAT CHAMBER

DIS AS SEMBLY

Remove the three float chamber screws and

the float chamber.

Loosen the float pin screw.

Remove the float pin, float and float valve.

Remove the main jet, needle jet holder,

needle jet, slow jet and pilot screw.

Clean the removed fuel jets with detergent

oil and blow them open with compressed

air.

Blow compressed air through all passages of

the carburetor body.

Pilot Screw

Float Valve

Float

Float Pin

Float Chamber

Slow Jet

Main Jet

Needle Jet Holder

Needle Jet

Screws

• Be careful not to damage the fuel jets

and pilot screw.

• Before removing, turn the pilot screw

in and carefully count the number of

turns until it seats lightly and then

make a note of this.

• Do not force the pilot screw against its

seat to avoid seat damage.

*

Page 11

5. FUEL SYSTEM

5-10

FILLY LX 50

INSPECTION

Inspect the float valve and valve seat for

damage or clogging.

Inspect the float valve and valve seat

contact area for stepped wear or

contamination.

ASSEMBLY

Install the slow jet, needle jet, needle jet

holder, main jet and pilot screw.

Standard Opening: 2±

1

/2

turns

Install the float valve, float and float pin.

Secure the float pin with the screw.

FLOAT LEVEL INSPECTION

Measure the float level.

Float Level: 17.0mm

This installation sequence is the reverse of

removal.

Float Level Gauge

Float Valve

• Check the operation of the float valve

and float before this inspection.

• Measure the float level by placing the

float level gauge on the float chamber

face parallel with the main jet.

*

Float Pin

Pilot Screw

Slow Jet

Main Jet

Needle Jet Holder

Needle Jet

Valve Seat

Float

Screw

Worn or contaminated float valve and

valve seat must be replaced because it

will result in float level too high due to

incomplete airtightness.

*

Return the pilot screw to the original

position as noted during removal.

*

Page 12

5. FUEL SYSTEM

5-11

FILLY LX 50

ACCELERATING PUMP

DISASSEMBLY

Remove the two accelerating pump cover

screws and accelerating pump cover.

Remove the spring and accelerating pump

diaphragm.

INSPECTION

Inspect the accelerating pump diaphragm for

cracks, damage or deterioration. Replace if

necessary.

Check each accelerating pump fuel passage

for clogging

Clean and blow them open with compressed

air.

Install the accelerating pump in the reverse

order of removal.

Compressed Air

Screws

Diaphragm

Diaphragm

Compressed Air

Be careful not to damage the diaphragm

during installation.

*

Page 13

5. FUEL SYSTEM

5-12

FILLY LX 50

CARBURETOR INSTALLATION

Tighten the drain screw.

Install the carburetor onto the intake

manifold, aligning the tab on the carburetor

with the cutout in the intake manifold.

Tighten the intake manifold band screw.

Install the air cleaner connecting tube and

tighten the band screw.

Connect the throttle cable to the throttle

wheel on the carburetor.

Tighten the lock nut.

Connect the fuel tube and vacuum tube to

the carburetor.

Connect the auto bystarter wire connector.

Perform the following inspections and

adjustments:

-Throttle grip free play (!3-3)

-Carburetor idle speed (!3-5)

Auto Bystarter Wire

Fuel Tube

Connecting Tube Band

Throttle Cable

Throttle Cable

Lock Nut

Adjusting Nut

Page 14

5. FUEL SYSTEM

5-13

FILLY LX 50

PILOT SCREW ADJUSTMENT

*

ADJUSTMENT

A tachometer must be used when adjusting

the engine speed.

Turn the pilot screw clockwise until it seats

lightly and back it out to the specification

given.

Standard Opening: 2±

1

/2

turns

Warm up the engine and adjust the throttle

stop screw to obtain the specified idle

speed.

Idle Speed: 1900± 100rpm

Turn the pilot screw in or out slowly to

obtain the highest engine speed.

Slightly accelerate several times to make

sure that the idle speed is within the

specified range.

If the engine misses or runs erratic, repeat

the above steps.

Pilot Screw

Throttle Stop Screw

• The pilot screw is factory pre-set and

no adjustment is necessary. During

carburetor disassembly, note the

number of turns of the pilot screw and

use as a reference when reinstalling it.

• Place the motorcycle on its main stand

on level ground for this operation.

*

• The carburetor must be adjusted when

the engine is warm and the auto

bystarter is closed.

• Do not force the pilot screw against its

seat to prevent damage.

*

Page 15

5. FUEL SYSTEM

5-14

FILLY LX 50

FUEL TANK REMOVE

Remove the net-in box. (!2-3)

Remove the frame center cover.

Remove the frame body cover. (!2-3)

Remove the floor board. (!2-4)

Remove the leg shield . (!2-5)

Remove the four bolts on the fuel tank, take

the upper bridge plate off.

Remove the fuel tube between the fuel tank

and the fuel filler.

Disconnect the fuel vapor tube.

Remove the inlet tube on the fuel pump.

Disconnect the fuel unit wire connector.

Remove the fuel tank.

The installation sequence is the reverse of

removal.

FUEL STRAINER REMOVAL

Remove the fuel strainer from the fuel tank.

INSPECTION

Inspect if the fuel strainer is clogged and

clean it with compressed air.

INSTALLATION

Install the fuel strainer with its arrow mark

toward the fuel pump.

Fuel Unit Wire

Connector

Bolts

Fuel

Pump

• When removing the fuel strainer, do not

allow flames or sparks near the

working area and drain the residual

gasoline into a container.

*

Bridge

Plate

Fuel Vapor

Tube

Arrow Mark

Fuel Strainer

Inlet

Tube

Fuel

Tank

Page 16

5. FUEL SYSTEM

5-15

FILLY LX 50

FUEL PUMP REMOVAL

Remove the met-box. (!2-3)

Remove the frame center cover. (!2-3)

Remove the floor board. (!2-4)

Disconnect the fuel pump inlet, outlet and

vacuum tubes.

Remove the fuel pump attaching bolts and

the fuel pump.

Remove the fuel pump.

FUEL PUMP DISASSEMBLY

Remove the four fuel pump body screws.

Disassemble the fuel pump.

Retainer

Fuel Pump

Inlet

Screws

Vacuum Tube

Outlet

Nut

Page 17

5. FUEL SYSTEM

5-16

FILLY LX 50

FUEL PUMP INSPECTION

Inspect the fuel pump diaphragms A and B

for damage.

Inspect each gasket for damage.

Inspect the suction valve, outlet valve and

relief valve in the fuel pump body for

damage, cracks or foreign matters.

FUEL PUMP ASSEMBLY

Assemble the fuel pump in the reverse order

of disassembly.

Diaphragm A

Gaskets

Inlet

Spring

Suction Valve

Outlet Valve

Relief Valve

Outlet

Diaphragm B

Dowel Pins

Dowel Pin Holes

Fuel Pump Body

• During assembly, be sure to install the

gaskets and diaphragms properly to

avoid damage.

• Do not allow any foreign matter to

enter the fuel pump during assembly.

*

Page 18

5. FUEL SYSTEM

5-17

FILLY LX 50

FUEL PUMP INSTALLATION

Install the fuel pump and secure it with the

bolts.

Connect the fuel pump inlet, outlet and

vacuum tubes.

Install the floor board, met-in box and frame

center cover.

MEASURE THE FUEL PUMP

OUTPUT

Start the engine and disconnect the fuel

outlet tube and place a clean container under

the tube to check the fuel output.

Output: 9cc/1700rpm/10 seconds .

22cc/4000rpm/10 seconds .

Fuel Pump

Outlet Tube

Container

Fuel Pump

Page 19

5. FUEL SYSTEM

5-18

FILLY LX 50

FUEL UNIT

REMOVAL

Remove the related parts.

Disconnect the fuel unit wire connector.

Turn the fixed plate on the fuel unit left,take

the fuel unit off.

INSTALLATION

Inspet if the fuel unit is damaged,or harden.

Assemble the fuel unit in the reverse order

of disassembly.

AIR CLEANER

Loosen the air cleaner connecting tube band

screw.

Disconnect the clinhead cover breather tube

from the air cleaner.

Remove the two bolts and air cleaner case.

Fuel Unit Wire

Align Mark

Fuel Unit

Fuel Tank

Do not bend the float arm on the fuel

unit,otherwise the figure on the fuel

meter will not correct.

*

• Align the groove on the fuel unit with

the angle on the fuel tank.

• Inspect if the fuel tank leaked after

installing and filling the gasoling.

*

bolts

air cleaner

Page 20

5. FUEL SYSTEM

5-19

FILLY LX 50

The installation sequence is the reverse of removal.

Loading...

Loading...