Page 1

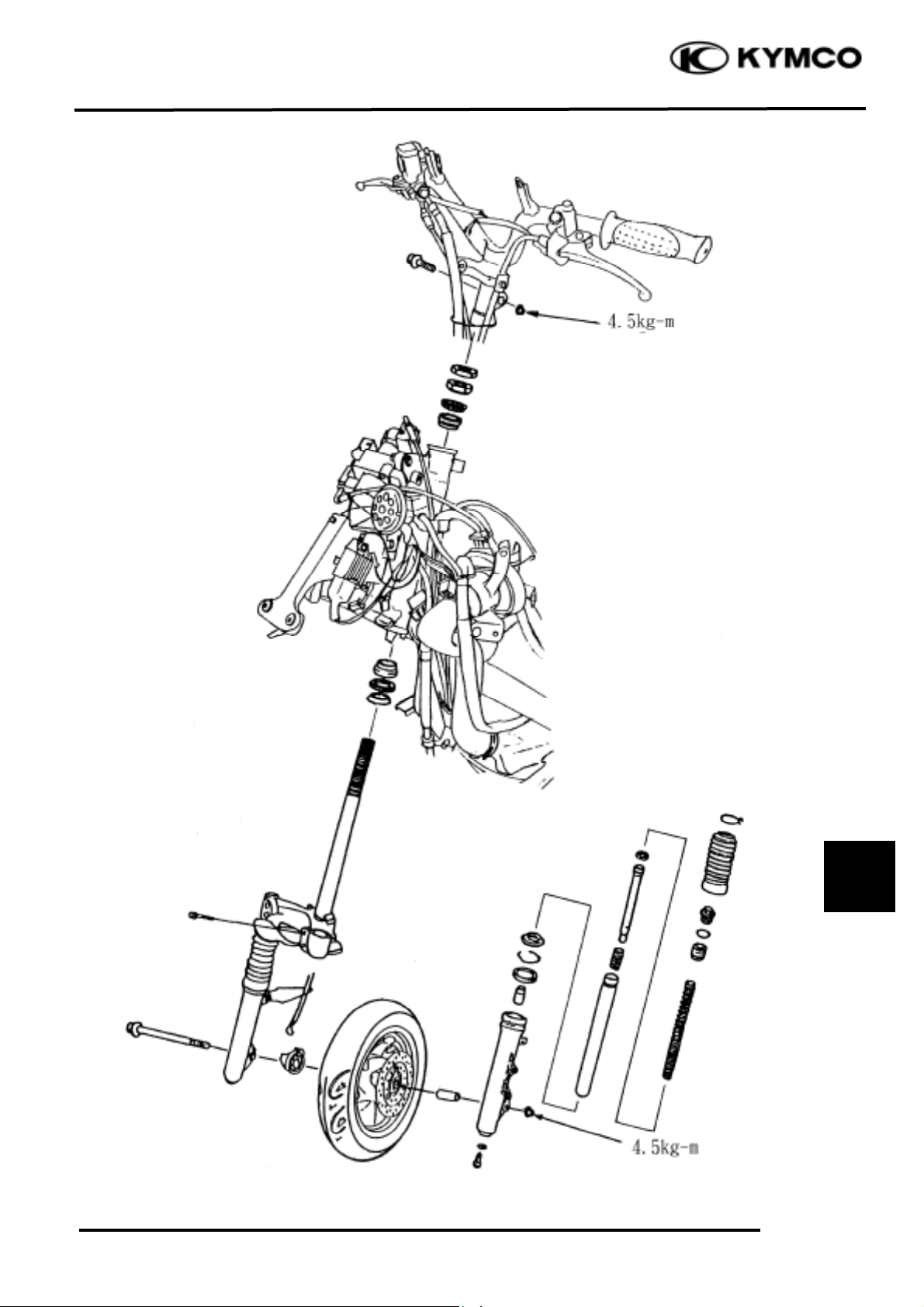

12. FRONT WHEEL/FRONT BRAKE/

FRONT SUSPENSION

12-0

FILLY LX 50

12

12

Page 2

12. FRONT WHEEL/FRONT BRAKE/

FRONT SUSPENSION

12-1

FILLY LX 50

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• Remove the motorcycle frame covers before removing the front wheel. Jack the motorcycle front

wheel off the ground and be careful to prevent the motorcycle from falling down.

• During servicing, keep oil or grease off the brake drum and brake linings.

SPECIFICATIONS

Item

Standard (mm)

Service Limit (mm)

Axle shaft runout

æ

0.2

Radialæ2.0

Front wheel rim runout

Axialæ2.0

Front brake drum I.D

110(SG20AB)

111(SG20AB)

Front brake lining thickness

4.0(SG20AB)

2.0(SG20AB)

Front shock absorber spring free length

210.9

206.4

TORQUE VALUES

Handlebar bolt 4.5~5.5kgf-m

Steering stem lock nut 6.0~8.0kgf-m

Steering top cone race 0.5~1.3kgf-m

Front shock absorber bolt 3.0kgf-m

Front axle nut 5.0~7.0kgf-m

Brake arm bolt 0.8~1.2kgf-m

SPECIAL TOOLS

Long socket wrench,32mm 8angle

SERVICE INFORMATION

....................

12-1 FRONT BRAKE

.....................................

12- 7

TROUBLESHOOTING

..........................

12-2 FRONT SHOCK ABSORBER

...............

12-18

STEERING HANDLEBAR

.....................

12-3 FRONT FORK

........................................

12-21

FRONT WHEEL

......................................

12-4

Page 3

12. FRONT WHEEL/FRONT BRAKE/

FRONT SUSPENSION

12-2

FILLY LX 50

TROUBLESHOOTING

Hard steering (heavy) Front wheel wobbling

• Excessively tightened steering stem top • Bent rim

cone race

• Excessive wheel bearing play

• Broken steering balls • Bent spoke plate

• Insufficient tire pressure • Faulty tire

Steers to one side or does not track straight • Improperly tightened axle nut

• Uneven front shock absorbers Soft front shock absorber

• Bent front fork • Weak shock springs

• Bent front axle or uneven tire • Insufficient damper oil

Poor brake performance Front shock absorber noise

• Incorrectly adjusted brake • Slider bending

• Worn brake linings • Loose fork fasteners

• Contaminated brake lining surface • Lack of lubrication

• Worn brake shoes at cam contacting area

• Worn brake drum

• Poorly connected brake arm

Page 4

12. FRONT WHEEL/FRONT BRAKE/

FRONT SUSPENSION

12-3

FILLY LX 50

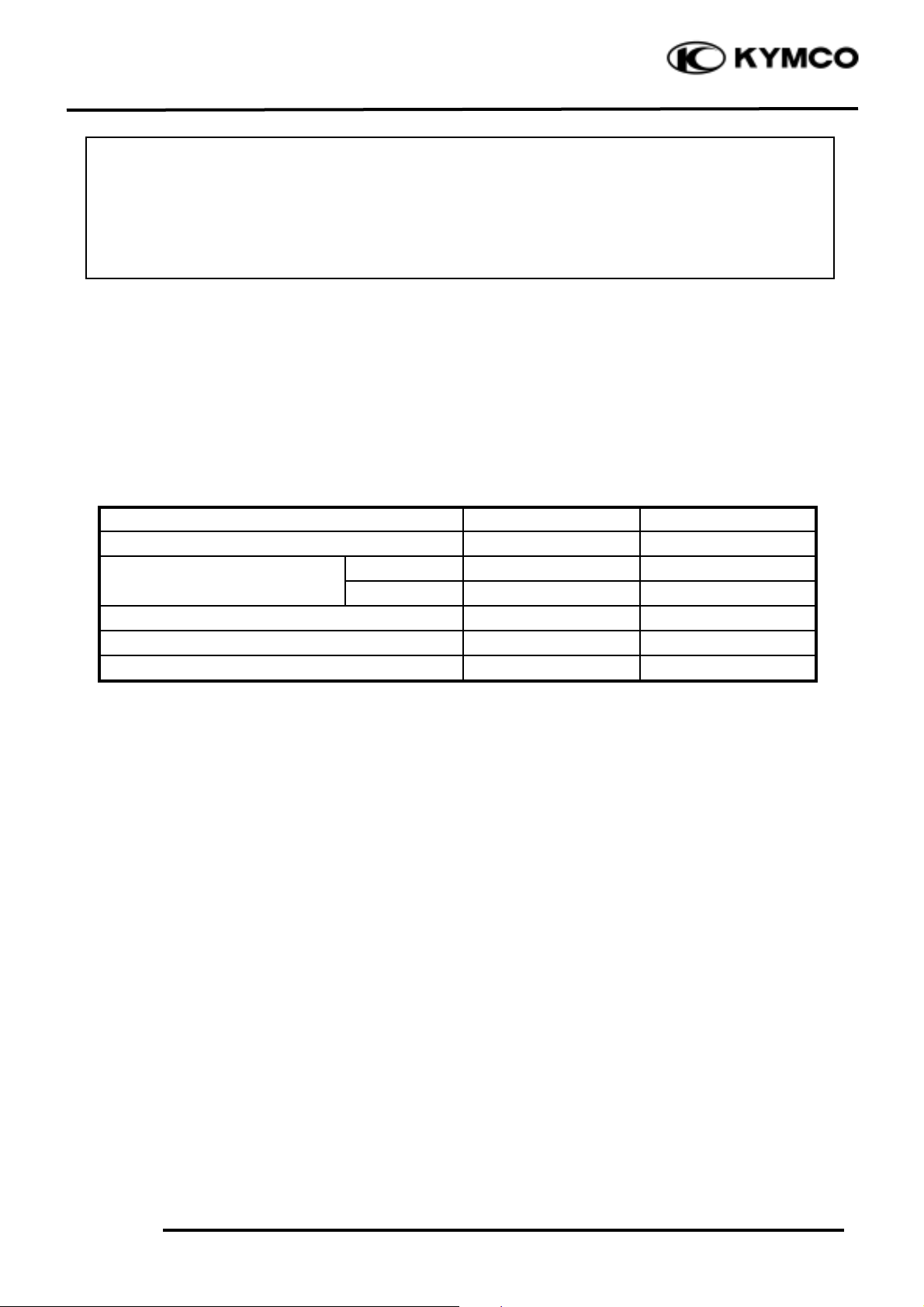

STEERING HANDLEBAR

REMOVAL

Remove the handlebar front and rear covers.

(!2-2)

Remove the two bolts attaching each of the

front and rear brake levers.

Remove the front and rear brake levers.

Remove the two throttle holder screws and

throttle holder.

Disconnect the throttle cable from the throttle

pipe and then remove the throttle pipe from

the handlebar.

Remove the handlebar lock nut and bolt to

remove the handlebar.

INSTALLATION

Install the handlebar onto the steering stem

by aligning the tab on the handlebar with the

groove on the steering stem.

Install and tighten the handlebar bolt and lock

nut.

Torque: 4.5_ 5.5kgf-m

Screws

Bolts

Throttle Pipe

Throttle

Bolts

Nut

Tab/Groove

Bolt

Page 5

12. FRONT WHEEL/FRONT BRAKE/

FRONT SUSPENSION

12-4

FILLY LX 50

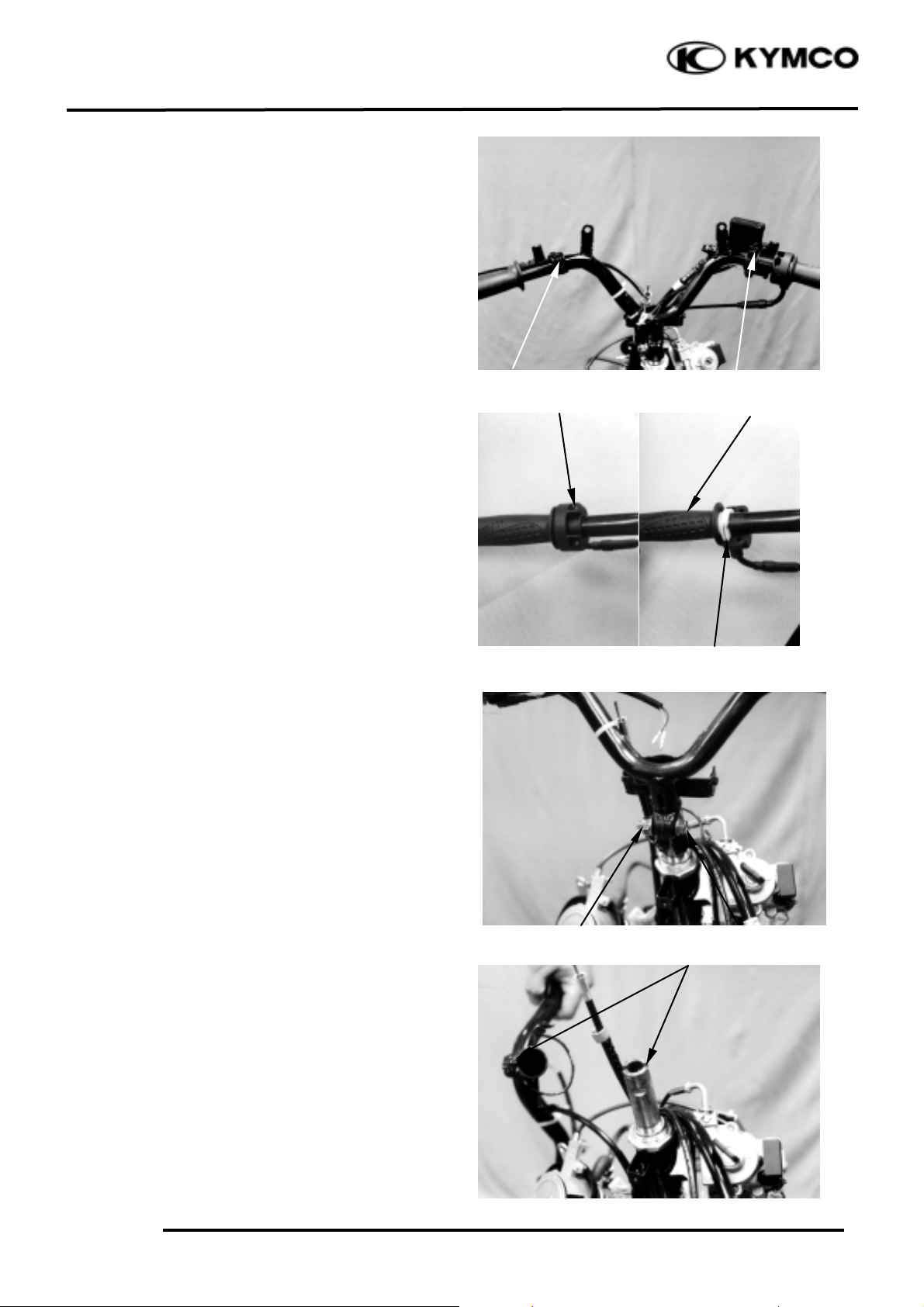

Apply grease to the tip of the throttle pipe.

Install the throttle pipe and connect the

throttle cable.

Install the front and rear brake levers in the

reverse order of removal.

FRONT WHEEL

REMOVAL

Jack the motorcycle front wheel off the

ground.

Remove the speedometer cable set screw and

disconnect the speedometer cable.

Remove the front brake cable.

Remove the front axle nut and pull out the

axle.

Remove the front wheel.

Remove the front brake panel and side collar.

INSPECTION

AXLE RUNOUT

Set the axle in V blocks and measure the

runout using a dial gauge.

The actual runout is

1

/2

of the total indicator

reading.

Service Limit: 0.2mm replace if over

Brake Levers

Speedometer Cable

Brake Cable

Axle Nut

Adjusting Nut

Throttle

Bolts

Bolts

Page 6

12. FRONT WHEEL/FRONT BRAKE/

FRONT SUSPENSION

12-5

FILLY LX 50

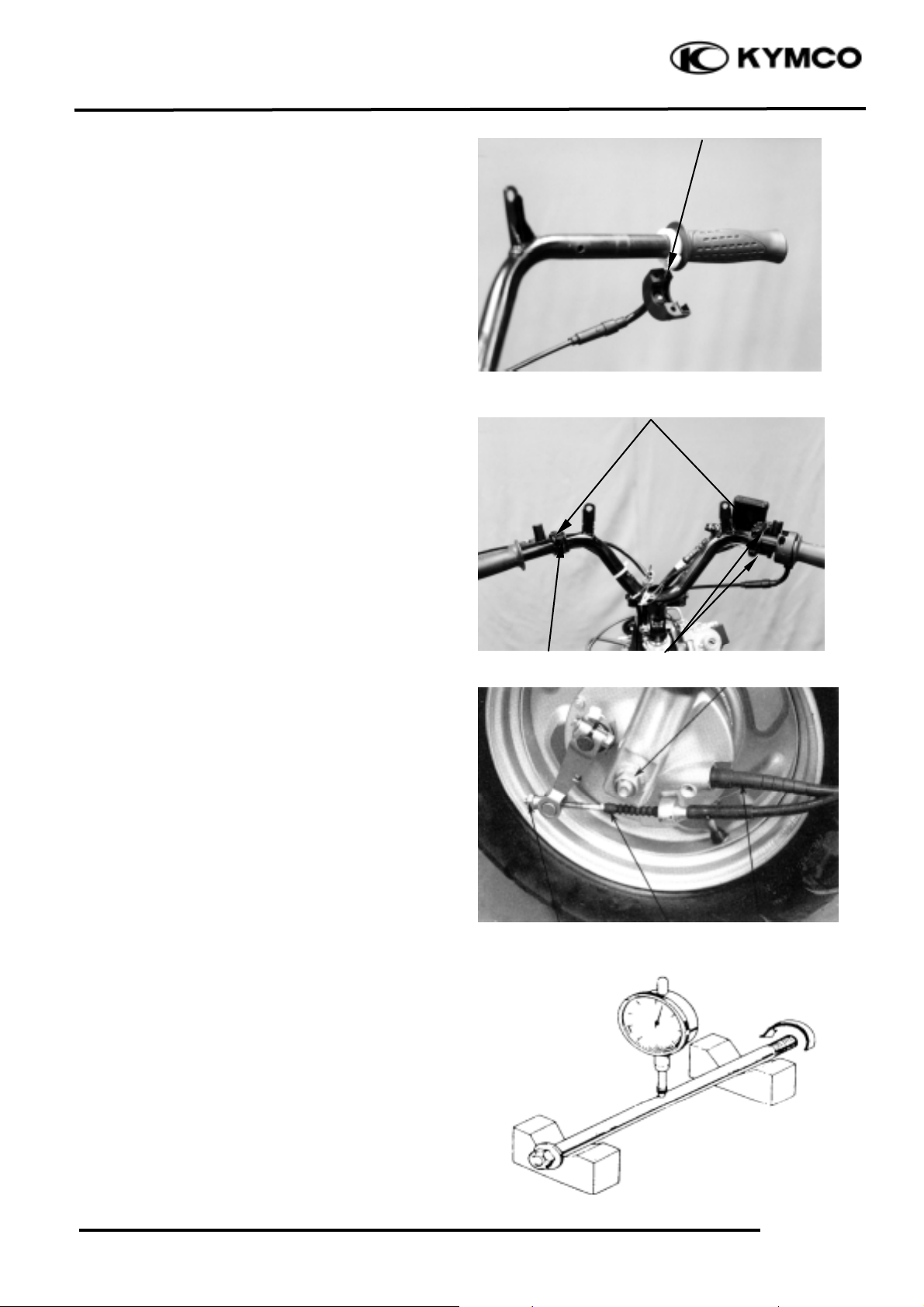

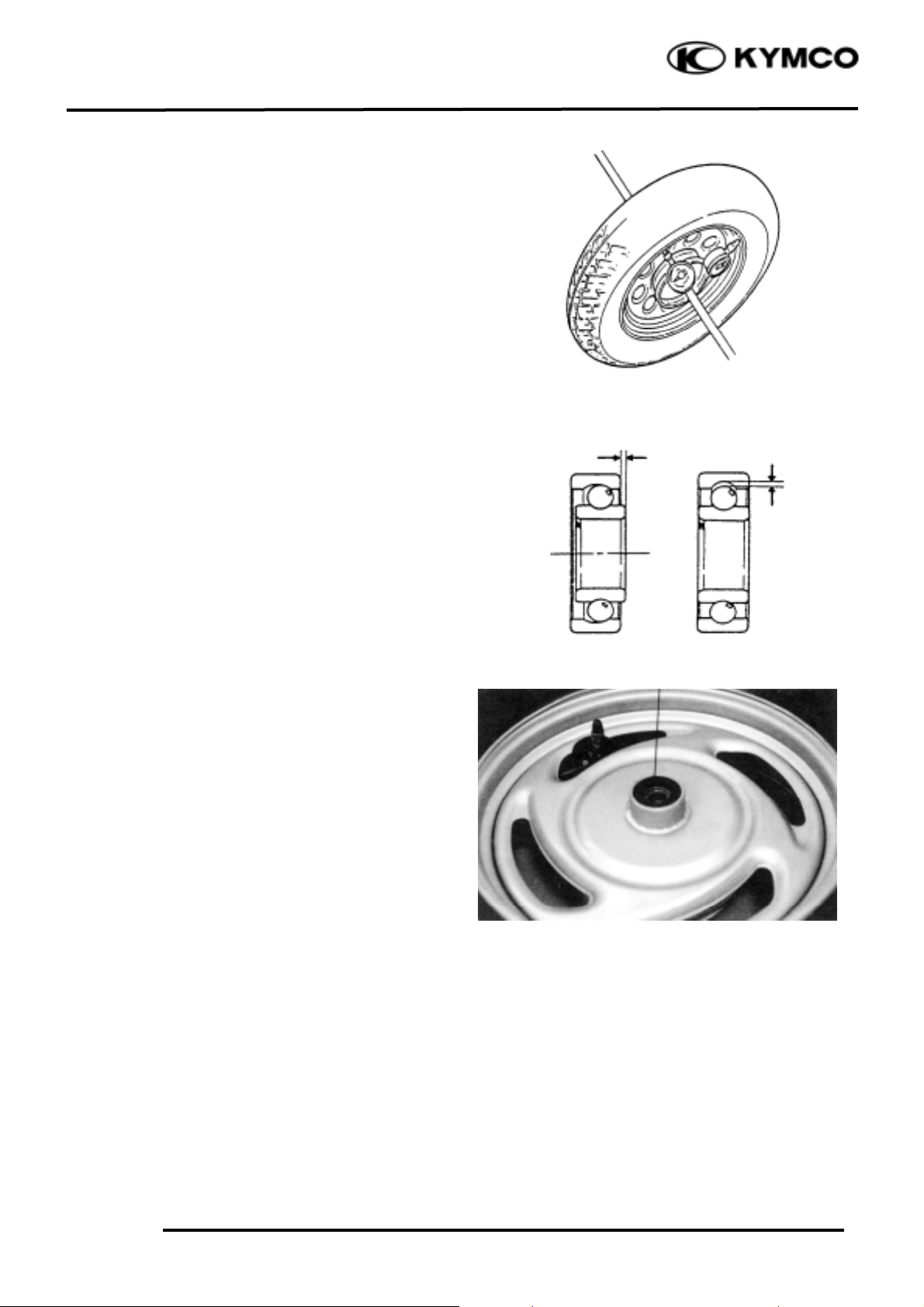

WHEEL RIM

Check the wheel rim runout.

Service Limits:

Radial: 2.0mm replace if over

Axial: 2.0mm replace if over

Turn the wheel bearings and replace the

bearings if they are noisy or have excessive

play.

DISASSEMBLY

Remove the dust seal.

Radial

Dust Seal

Play

Play

Axial

Page 7

12. FRONT WHEEL/FRONT BRAKE/

FRONT SUSPENSION

12-6

FILLY LX 50

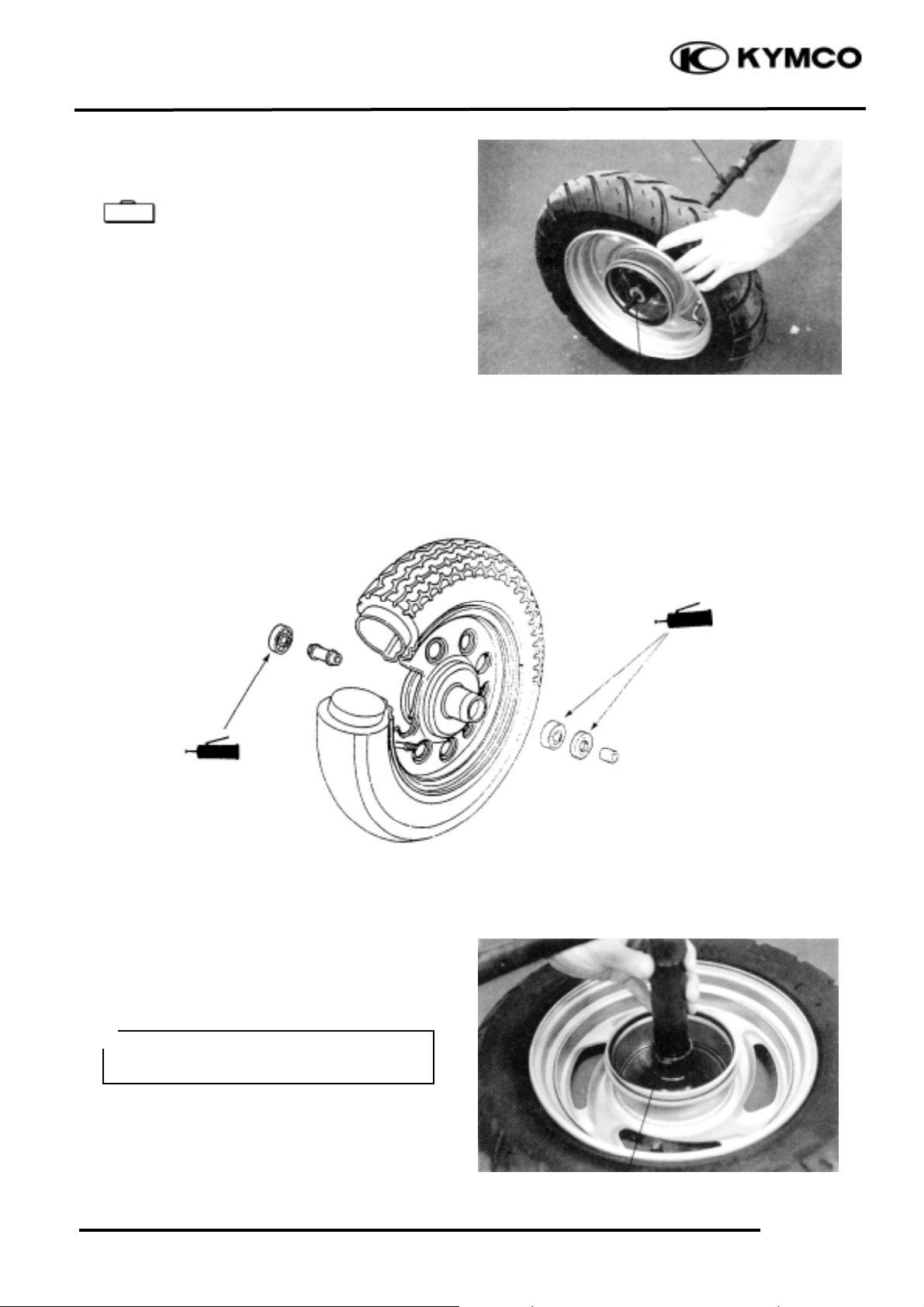

Remove the front wheel bearings and distance

collar.

Bearing Puller

ASSEMBLY

Pack all bearing cavities with grease.

Drive in the left bearing.

Install the distance collar.

Drive in the right bearing.

Bearing Puller

Pilot

Grease

Grease

Outer Driver

Pilot

Drive in the bearing squarely with the

sealed end facing out.

*

Special

Page 8

12. FRONT WHEEL/FRONT BRAKE/

FRONT SUSPENSION

12-7

FILLY LX 50

Apply grease to a new dust seal lip and

install the dust seal.

Install the side collar.

INSTALLATION

Install the front wheel by aligning the brake

panel groove with the front fork tab.

Insert the axle shaft and tighten the axle nut.

Torque: 4.5kg-m

Connect the speedometer cable and secure it

with the screw.

Install the front brake cable and adjust the

front brake lever free play.

FRONT BRAKE

Remove the front wheel. (!12-4)

Remove the front brake panel.

INSPECTION

Measure the brake drum I.D.

Service Limit: 111mm replace if over

Measure each brake lining thickness.

Service Limit: 2.00mmmm replace if below

Groove

Keep oil or grease off the brake linings.

*

Tab

Dust Seal

Side Collar

Brake Linings

Brake Shoe Springs

Brake Cam

Page 9

12. FRONT WHEEL/FRONT BRAKE/

FRONT SUSPENSION

12-8

FILLY LX 50

DISASSEMBLY

Do not swing the brake arm to expand the

brake shoes.

Remove the brake shoes by removing the

brake shoe springs using a screw driver.

Remove the brake arm and return spring.

Remove the wear indicator plate and felt seal.

Remove the brake cam.

Remove the dust seal and speedometer drive

gear.

ASSEMBLY

Apply grease to the speedometer drive gear

and then install it into the brake panel.

Apply grease to the dust seal lip and install it

into the brake panel.

Apply grease to the anchor pin and brake

cam.

Install the brake cam.

Brake Shoe

Speedometer Drive Gear

Dust Seal

Brake Arm

Brake Cam

Anchor Pin

Felt Seal

Return Spring

Brake Cam

1.0kg-m

Wear Indicator Plate

Speedometer Drive Gear

Dust Seal

Grease

Grease

Page 10

12. FRONT WHEEL/FRONT BRAKE/

FRONT SUSPENSION

12-9

FILLY LX 50

Install the return spring by aligning the spring

hook end with the hole in the brake panel.

Apply a small amount of engine oil to the felt

seal and install it to the brake panel.

Install the wear indicator plate on the brake

cam by aligning the tooth on the plate with

the groove on the brake cam.

Install the brake arm on the brake cam by

aligning the punch mark on the brake arm and

the scribed line on the brake cam.

Install and tighten the brake arm bolt.

Torque:0.8~1.2kgf-m

Install the brake shoe springs to the brake

shoes and then install the brake shoes into the

brake panel.

INSTALLATION

Install the brake panel onto the front wheel.

Install the front wheel. (!12-7)

Adjust the front brake lever free play.

Brake Arm

Wear Indicator Plate

Return Spring

Brake Shoe Springs

Brake Cam

Bolt

Brake Shoes

Page 11

12. FRONT WHEEL/FRONT BRAKE/

FRONT SUSPENSION

12-10

FILLY LX 50

HYDRAULIC BRAKE (FRONT BRAKE)

Brake Fluid Replacement/Air Bleeding

Check the brake fluid level on level ground.

Brake Fluid Bleeding

In order to avoid spill of brake fluid, connect

a transparent hose to the bleed valve.

Fully apply the brake lever and then loosen

the brake caliper bleed valve to drain the

brake fluid until there is no air bubbles in the

brake fluid. Then, tighten the bleed valve.

Repeat these steps until the brake system is

free of air.

Brake Fluid Refilling

Add DOT-4 brake fluid to the brake

reservoir.

Make sure to bleed air from the brake system.

• When operating the brake lever, the

brake reservoir cap must be tightened

securely to avoid spill of brake fluid.

• When servicing the brake system, use

shop towels to cover plastic parts and

coated surfaces to avoid damage

caused by spill of brake fluid.

*

Brake fluid spilled on brake pads or

brake disk will reduce the braking effect.

Clean the brake pads and brake disk

with a high quality brake degreaser.

Warning

• When bleeding, be careful not to allow

air in the brake reservoir flowing into

the brake system.

• When using a brake bleeder, follow the

manufacturer‘s instructions.

• Never use dirty or unspecified brake

fluid or mix different brake fluids because it will damage the brake system.

*

Upper Limit

Lower Limit

Bleed Valve

Front Brake Caliper

Page 12

12. FRONT WHEEL/FRONT BRAKE/

FRONT SUSPENSION

12-11

FILLY LX 50

Brake Pad/Disk Replacement

Remove the two bolts attaching the brake

caliper.

Remove the brake caliper.

Remove the brake pad pins to remove the

brake pads.

Install the brake pads in the reverse order of

removal.

Tighten the brake pad pin bolts.

Torque: 1.5_ 2.0kgf-m

Brake Disk

Measure the brake disk thickness.

Service Limit: 3.0mm

Measure the brake disk runout.

Service Limit: 0.3mm

The brake pads must be replaced as a

set to ensure the balance of the brake

disk.

*

_Keep grease or oil off the brake pads

to avoid brake failure.

_Do not reuse the brake pad pin bolts

that have been removed.

*

Pad Pin

Front Brake Caliper

Brake Pads

Front Brake Caliper

Page 13

12. FRONT WHEEL/FRONT BRAKE/

FRONT SUSPENSION

12-12

FILLY LX 50

BRAKE MASTER CYLINDER

Removal

First drain the brake fluid from the hydraulic

brake system.

Disassembly

Remove the piston rubber cover and snap ring

from the brake master cylinder.

Remove the washer, main piston and spring

from the brake master cylinder.

Clean the inside of the master cylinder and

brake reservoir with brake fluid.

• When servicing the brake system, use

shop towels to cover rubber and

plastic parts and coated surfaces to

avoid being contaminated by brake

fluid.

• When removing the brake fluid pipe

bolt, be sure to plug the pipe to avoid

*

Bolts

Brake Master Cylinder

Snap Ring

Main Piston

Spring

Master Cylinder

Snap Ring

Washer

Page 14

12. FRONT WHEEL/FRONT BRAKE/

FRONT SUSPENSION

12-13

FILLY LX 50

Inspection

Measure the brake master cylinder I.D.

Service Limit: 12.75mm

Inspect the master cylinder for scratch or

crack.

Measure the brake master cylinder piston

O.D.

Service Limit: 12.6mm

Before assembly, inspect the lst and 2nd

rubber cups for wear.

Assembly

Before assembly, apply brake fluid to all

removed parts.

Install the spring together with the 1st rubber

cup.

Install the main piston, spring and snap ring.

Install the rubber cover.

Install the brake lever.

• During assembly, the main piston and

spring must be installed as a unit

without exchange.

• When assembling the piston, soak the

cups in brake fluid for a while.

• Install the cups with the cup lips

facing the correct direction.

*

Page 15

12. FRONT WHEEL/FRONT BRAKE/

FRONT SUSPENSION

12-14

FILLY LX 50

Disassembly

Remove the brake caliper seat from the brake

caliper.

Remove the piston from the brake caliper.

If necessary, use compressed air to squeeze

out the piston through the brake fluid inlet

opening and place a shop towel under the

caliper to avoid contamination caused by the

removed piston.

Check the piston cylinder for scratch or wear

and replace if necessary.

Push the piston oil seal outward to remove it.

Clean the oil seal groove with brake fluid.

Be careful not to damage the piston

surface.

*

Brake Caliper Seat

Compressed Air

Piston Oil Seal

Page 16

12. FRONT WHEEL/FRONT BRAKE/

FRONT SUSPENSION

12-15

FILLY LX 50

Place the brake master cylinder on the

handlebar and install the holder with “up”

mark facing up. Be sure to align the punch

mark with the holder joint.

First tighten the upper bolt and then tighten

the lower bolt.

Torque: 3.0_ 4.0kgf-m

Install the brake fluid pipe with the attaching

bolt and two sealing washers.

Install the handlebar covers. (!12-3)

Fill the brake reservoir with recommended

brake fluid to the upper limit and bleed air

according to the method stated in 12-10.

BRAKE CALIPER (FRONT)

Removal

Remove the brake caliper.

Place a clean container under the brake caliper

and disconnect the brake fluid pipe from the

caliper.

Do not spill brake fluid on any coated

surfaces.

*

Punch Mark

Bolts

“Up” Mark

Bolt

Bleed Valve

Bleed Valve

Brake Caliper

Page 17

12. FRONT WHEEL/FRONT BRAKE/

FRONT SUSPENSION

12-16

FILLY LX 50

Check the piston for scratch or wear.

Measure the piston O.D. with a micrometer.

Service Limit: 26.3mm

Check the caliper cylinder for scratch or wear

and measure the cylinder bore.

Service Limit: 26.45mm

Assembly

Clean all removed parts.

Apply silicon grease to the piston and oil

seal. Lubricate the brake caliper cylinder

inside wall with brake fluid.

Install the brake caliper piston with grooved

side facing out.

Wipe off excessive brake fluid with a clean

shop towel. Apply silicon grease to the

brake caliper seat pin and caliper inside.

Install the brake caliper seat.

Install the piston with its outer end

3_ 5mm protruding beyond the brake

caliper.

*

Page 18

12. FRONT WHEEL/FRONT BRAKE/

FRONT SUSPENSION

12-17

FILLY LX 50

Installation

Install the brake caliper and tighten the two

bolts.

Torque: 2.9_ 3.5kg-m

Connect the brake fluid pipe to the brake

caliper and tighten the fluid pipe bolt.

Torque: 2.5_ 3.5kg-m

Fill the brake reservoir with recommended

brake fluid and bleed air from the brake syst

em. (!12-10)

Bolts

Bolt

Page 19

12. FRONT WHEEL/FRONT BRAKE/

FRONT SUSPENSION

12-18

FILLY LX 50

FRONT SHOCK ABSORBER

REMOVAL

Remove the front wheel. (!12-4)

Remove the front lower cover. (!2-2)

Remove the front inner fender.

Remove the front shock absorber upper

mount bolts.

Loosen the lower mount bolts to remove the

front shock absorbers.

DISASSEMBLY

Remove the dust boot.

Remove the circlip.

Set the front shock absorber in a vise.

Remove the damper rod, hex bolt and copper

washer.

Pull out the front shock absorber tube.

Set the front shock absorber tube in a vise.

Remove the top nut, shock spring, damper,

and damper spring from the front shock

absorber tube.

Shock Absorber Tube

Washer/Bolt

Circlip

Shock Absorber

Dust Boot

• When holding the shock absorber tube,

place a shop towel to protect it and do

apply too much force .

*

Upper Mount Bolts

Front Shock Absorber

Lower Mount Bolts

Page 20

12. FRONT WHEEL/FRONT BRAKE/

FRONT SUSPENSION

12-19

FILLY LX 50

Measure the front shock absorber spring free

length.

Service Limits: Right : 206.4mm

Left : 206.4mm

ASSEMBLY

Front Shock

Absorber

Shock

Absorber

Tube

Top Nut

Damper

Shock Absorber

Spring

Damper

Spring

Dust Seal

Circlip

Oil Seal

Page 21

12. FRONT WHEEL/FRONT BRAKE/

FRONT SUSPENSION

12-20

FILLY LX 50

Install the damper spring onto the damper rod

and then install them into the front shock

absorber tube.

Install the shock absorber spring onto the

front shock absorber tube and tighten the top

nut.

Set the front shock absorber in a vise.

Insert the shock absorber tube into the shock

absorber and tighten the hex bolt.

(Apply locking agent to the washer and

install it together with the hex bolt.)

Torque: 3.0kgf-m

Add engine oil into the front shock absorber.

Specified Oil: SS#8

Oil Capacity: 38±1cc

Install the circlip.

Install the dust boot.

INSTALLATION

Install the front shock absorbers onto the

steering stem.

Install and tighten the front shock absorber

upper mount bolts.

Tighten the lower mount bolts.

Install the front wheel. (!12-7)

Circlip

Dust Boot

Install the front shock absorber spring

with the closely wound coils facing down.

*

Align the upper mount bolt hole with

the groove on the front fork.

*

Front Shock Absorber

Shock Absorber Tube

Upper Mount Bolts

Lower Mount Bolts

Page 22

12. FRONT WHEEL/FRONT BRAKE/

FRONT SUSPENSION

12-21

FILLY LX 50

FRONT FORK

REMOVAL

Remove the steering handlebar. (!12-3)

Remove the front wheel. (!12-4)

Disconnect the speedometer cable.

Remove the steering stem lock nut using long

socket wrench.

Long Socket Wrench,32mm 8Angle

Remove the top cone race and remove the

steering stem.

Inspect the ball races and cone races for wear

or damage and replace if necessary.

.

BOTTOM CONE RACE REPLACEMENT

Remove the bottom cone race using a chisel.

Drive a new bottom cone race into place with

a proper driver.

BALL RACE REPLACEMENT

Drive out the top and bottom ball races.

Top Cone Race

Long Socket Wrench

• Be careful not to lose the steel balls (26

on top race and 29 on bottom race).

*

Be careful not to damage the steering

stem and front fork.

*

Bottom Cone Race

Ball Race Remover

Lock Nut Wrench

Specia

Page 23

12. FRONT WHEEL/FRONT BRAKE/

FRONT SUSPENSION

12-22

FILLY LX 50

Drive new top and bottom ball races into the

steering head using the outer driver.

INSTALLATION

Apply grease to the top and bottom ball races

and install 26 steel balls on the top ball race

and 29 steel balls on the bottom ball race.

Apply grease to the ball races and install the

front fork.

Apply grease to the top cone race and install

it.

Tighten the top cone race and then turn the

steering stem right and left several times to

make steel balls contact each other closely.

Install the steering stem lock nut and tighten

it while holding the top cone race.

Torque: 6.0_ 8.0kgf-m

Install the front wheel. (!12-7)

Install the steering handlebar. (!12-3)

Install the speedometer cable. (!12-7)

Long Socket Wrench,32mm 8Angle

Top Cone Race

Outer Driver, 37x40mm

Check that the steering stem rotates

freely without vertical play.

*

Lock Nut Wrench

Driver Handle A

Be sure to completely drive in the ball

races.

*

Steel Balls

Long Socket Wrench

Specia

Loading...

Loading...