Page 1

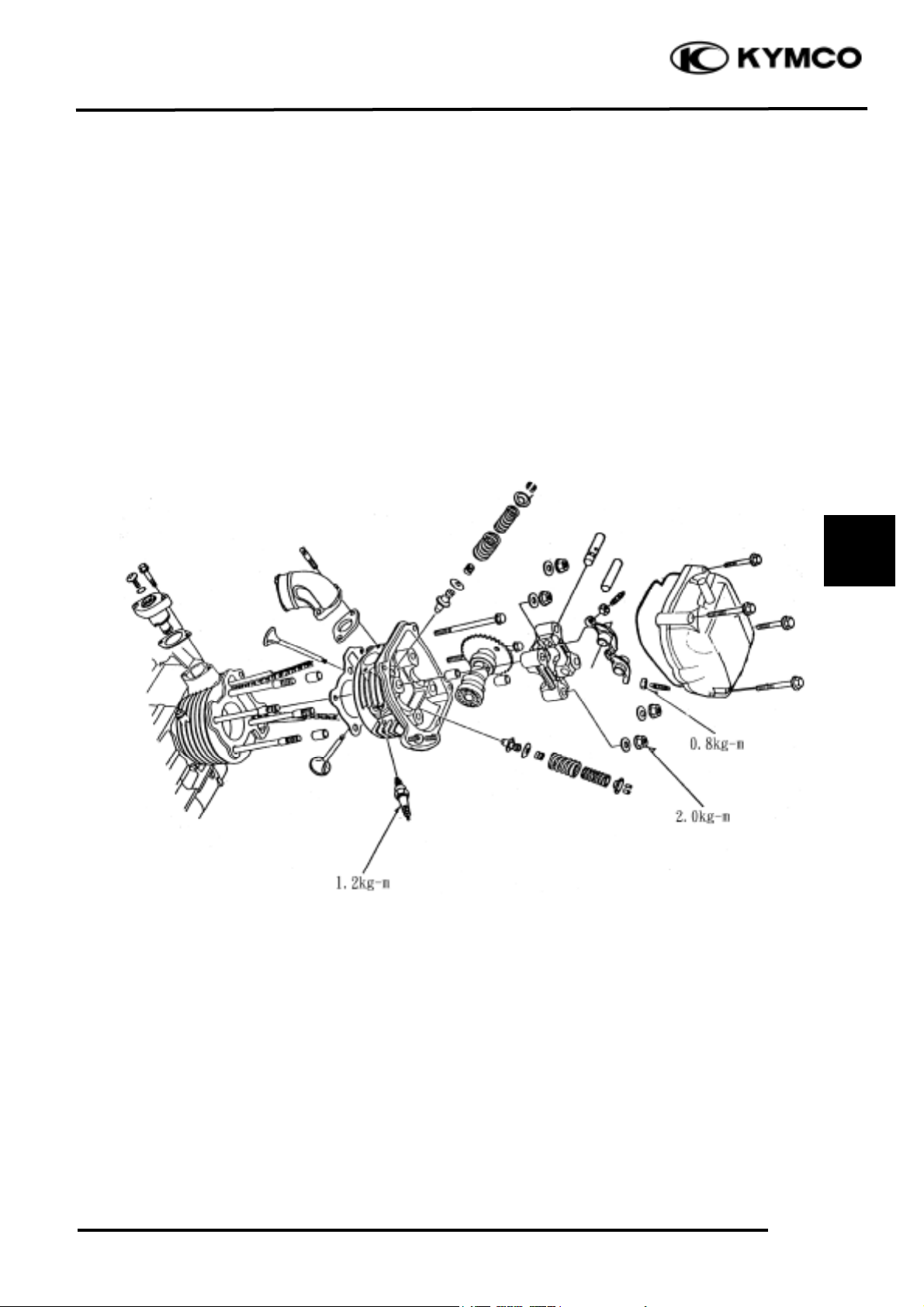

7. CYLINDER HEAD/VALVES

7-0

FILLY LX 50

7

7

0.7-1.1kg-m

1.0-1.4kg-m

1.2-1.6kg-m

Page 2

7. CYLINDER HEAD/VALVES

7-1

FILLY LX 50

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• The cylinder head can be serviced with the engine installed in the frame.

• When assembling, apply molybdenum disulfide grease or engine oil to the valve guide movable

parts, valve arm and camshaft sliding surfaces for initial lubrication.

• The camshaft is lubricated by engine oil through the cylinder head engine oil passages. Clean and

unclog the oil passages before assembling the cylinder head.

• After disassembly, clean the removed parts and dry them with compressed air before inspection.

• After removal, mark and arrange the removed parts in order. When assembling, install them in the

reverse order of removal.

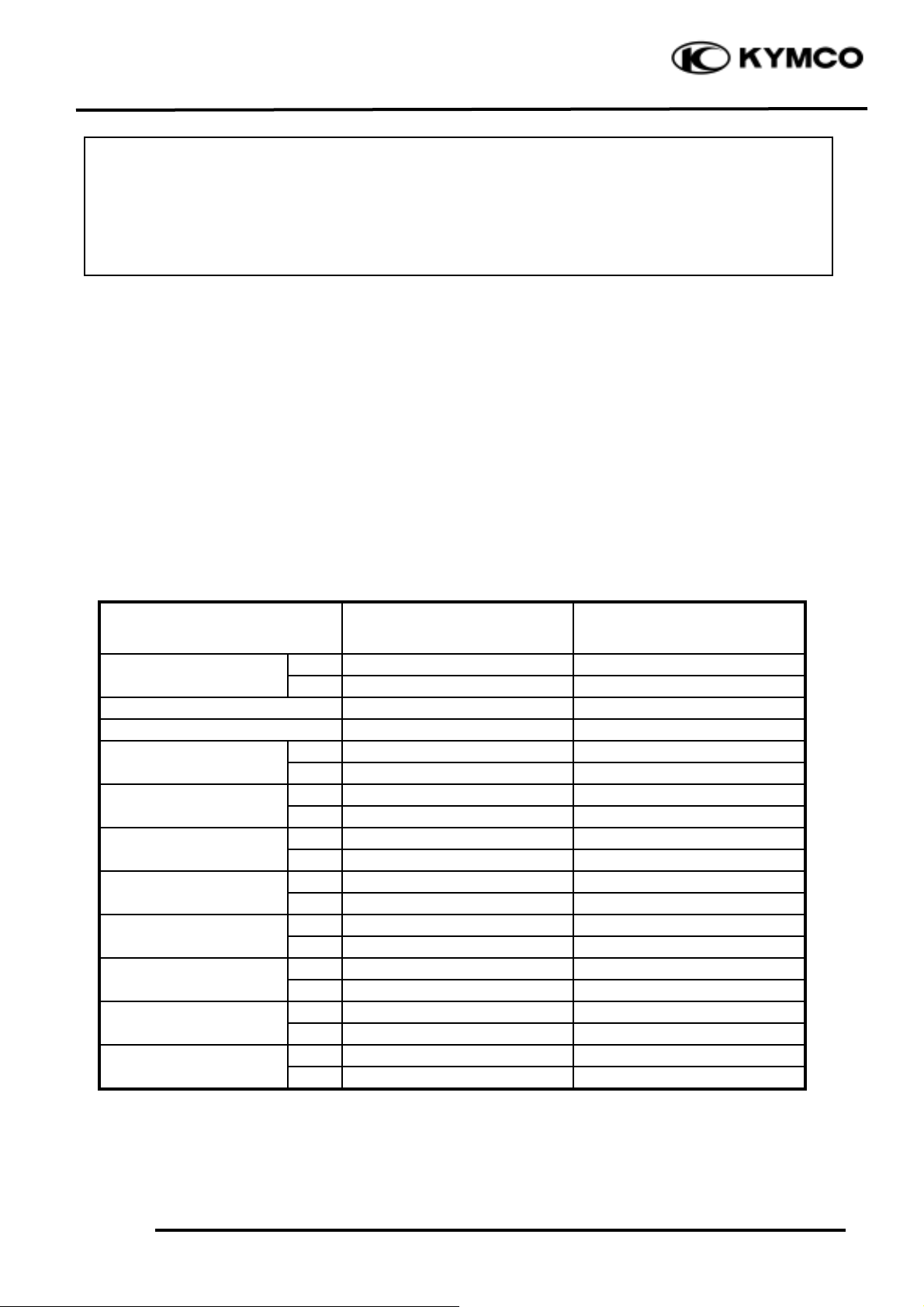

SPECIFICATIONS

Item

Standard (mm)

Service Limit (mm)

IN

0.04

æ

EX

0.04

æ

Cylinder head compression

14kg/cm

2

æ

Cylinder head warpage

æ

0.05

IN

26.438

26.038

EX

25.807

25.407

IN

10.000-10.015

10.10

EX

10.000-10.015

10.10

Valve rocker arm shaft

IN

9.972-9.987

9.91

O.D.

EX

9.972-9.987

9.91

IN

1.0

1.8

EX

1.0

1.8

IN

4.975-4.990

4.9

EX

4.955-4.970

4.9

IN

5.000-5.012

5.03

EX

5.000-5.012

5.03

Valve stem-to-guide

IN

0.010-0.037

0.08

clearance

EX

0.030-0.057

0.1

Inner

31.1

30.1

Outer

34.35

33.3

SERVICE INFORMATION

.....................

7-1 CYLINDER HEAD DISASSEMBLY

.......

7-7

TROUBLESHOOTING

............................

7-2 CYLINDER HEAD ASSEMBLY

..............

7-8

CAMSHAFT REMOVAL

........................

7-3 CYLINDER HEAD INSTALLATION

.....

7-8

CYLINDER HEAD REMOVAL

..............

7-5 CAMSHAFT INSTALLATION

...............

7-9

Valve clearance (cold)

Camshaft cam height

Valve rocker arm I.D.

Valve seat width

Valve stem O.D.

Valve guide I.D.

Valve spring free length

Page 3

7. CYLINDER HEAD/VALVES

7-2

FILLY LX 50

TORQUE VALUES

Cylinder head nut 1.8~2.2kgf-m Apply engine oil to threads

Valve clearance adjusting nut 0.7~1.1kgf-m Apply engine oil to threads

SPECIAL TOOLS

Valve spring compressor

TROUBLESHOOTING

• The poor cylinder head operation can be diagnosed by a compression test or by tracing engine

top-end noises.

Poor performance at idle speed White smoke from exhaust muffler

• Compression too low • Worn valve stem or valve guide

• Damaged valve stem seal

Compression too low

• Incorrect valve clearance adjustment Abnormal noise

• Burned or bend valves • Incorrect valve clearance adjustment

• Incorrect valve timing • Sticking valve or broken valve spring

• Broken valve spring • Damaged or worn camshaft

• Poor valve and seat contact • Worn cam chain guide

• Leaking cylinder head gasket • Worn camshaft and rocker arm

• Warped or cracked cylinder head

• Poorly installed spark plug

Compression too high

• Excessive carbon build-up in combustion

chamber

Page 4

7. CYLINDER HEAD/VALVES

7-3

FILLY LX 50

CAMSHAFT REMOVAL

Remove the center cover. (!2-3)

Remove the frame center.

Remove the four cylinder head cover bolts to

remove the cylinder head cover.

Remove the cam chain tensioner sealing bolt

and spring.

Remove the two bolts attaching the cam chain

tensioner and the tensioner.

Turn the flywheel counterclockwise so that

the “T” mark on the flywheel aligns with the

index mark on the crankcase to bring the

round hole on the camshaft gear facing up to

the top dead center on the compression

stroke.

Remove the two cylinder head bolts.

Remove the four cylinder head nuts and

washers.

Remove the camshaft holder.

Cylinder Head Cover

Sealing Bolt

Round Hole

Camshaft Gear

Bolts

Diagonally loosen the cylinder head nuts

in 2 or 3 times.

*

Punch Marks

Washer

Nut

Page 5

7. CYLINDER HEAD/VALVES

7-4

FILLY LX 50

Remove the camshaft holder and dowel pins.

Remove the camshaft gear from the cam chain

and remove the camshaft.

CAMSHAFT INSPECTION

Check each cam lobe for wear or damage.

Measure the cam lobe height.

Service Limits:

IN : 26.038mm replace if below

EX: 25.407mm replace if below

Check each camshaft bearing for play or

damage. Replace the camshaft assembly with

a new one if the bearings are noisy or have

excessive play.

Cam Chain

Camshaft Gear

Camshaft Bearings

Camshaft Holder

Dowel Pins

Camshaft

Page 6

7. CYLINDER HEAD/VALVES

7-5

FILLY LX 50

CAMSHAFT HOLDER DISASSEMBLY

Take out the valve rocker arm shafts using a

5mm bolt.

Remove the valve rocker arms.

CAMSHAFT HOLDER INSPECTION

Inspect the camshaft holder, valve rocker

arms and rocker arm shafts for wear or

damage.

Measure the I.D. of each valve rocker arm.

Service Limits: IN:10.10mm replace if over

EX:10.10mm replace if over

Measure each rocker arm shaft O.D.

Service Limits: IN: 9.91mm replace if over

EX: 9.91mm replace if over

CYLINDER HEAD REMOVAL

Remove the camshaft. (!7-3)

Remove the carburetor. (!5-5)

Remove the exhaust muffler. (!2-5)

Remove the carburetor intake manifold.

Intake Manifold

Camshaft Holder

If the valve rocker arm contact surface is

worn, check each cam lobe for wear or

damage.

*

Rocker Arm Shafts

5mm Bolt

Rocker Arm

Rocker Arm Shaft

Page 7

7. CYLINDER HEAD/VALVES

7-6

FILLY LX 50

Remove the cooling fan cover. (!14-6)

Remove the engine cover bolts and screws.

Separate the engine cover joint claws.

Remove the cylinder head.

Remove the dowel pins and cylinder head

gasket.

Remove the cam chain guide.

Cylinder Head

Dowel Pins

Cam Chain Guide

Cylinder Head Gasket

Bolts

Page 8

7. CYLINDER HEAD/VALVES

7-7

FILLY LX 50

CYLINDER HEAD DISASSEMBLY

Remove the valve spring cotters, retainers,

springs, spring seats and valve stem seals

using a valve spring compressor.

Valve Spring Compressor

Valve Spring Compressor Attachment

Remove carbon deposits from the combustion

chamber.

Clean off any gasket material from the

cylinder head mating surface.

INSPECTION

CYLINDER HEAD

Check the spark plug hole and valve areas for

cracks.

Check the cylinder head for warpage with a

straight edge and feeler gauge.

Service Limit: 0.05mm repair or replace if

over

VALVE SPRING FREE LENGTH

Measure the free length of the inner and outer

valve springs.

Service Limits:

Inner : 30.1mm replace if below

Outer : 33.3mm replace if below

Valve Spring Compressor

• Be sure to compress the valve

springs with a valve spring compressor.

• Mark all disassembled parts to

ensure correct reassembly.

*

Special

Valve Spring Compressor Attachment

Be careful not to damage the cylinder

head mating surface.

*

Page 9

7. CYLINDER HEAD/VALVES

7-8

FILLY LX 50

VALVE/ VALVE GUIDE

Inspect each valve for bending, burning,

scratches or abnormal stem wear.

Check valve movement in the guide.

Measure each valve stem O.D.

Service Limits: IN : 4.9mm replace if below

EX: 4.9mm replace if below

CYLINDER HEAD ASSEMBLY

Valve Spring Compressor

Val ve Spring Compressor Attachment

Tap the valve stems gently with a plastic

hammer for 2_ 3 times to firmly seat the

cotters.

CYLINDER HEAD INSTALLATION

Install the dowel pins and a new cylinder

head gasket.

Install the cam chain guide.

Gasket

Cam Chain Guide

Valve Spring Compressor

Dowel Pins

Valve Spring Compressor

Attachment

• When assembling, a valve spring

compressor must be used.

• Install the cotters with the

pointed ends facing down from the

upper side of the cylinder head.

*

Special

Be careful not to damage the valves.

*

Page 10

7. CYLINDER HEAD/VALVES

7-9

FILLY LX 50

Install the cylinder head.

CAMSHAFT HOLDER ASSEMBLY

First assemble the camshaft holder.

Install the intake and exhaust valve rocker

arms and rocker arm shafts.

CAMSHAFT INSTALLATION

Turn the flywheel so that the “T” mark on

the flywheel aligns with the index mark on the

crankcase.

Keep the round hole on the camshaft gear

facing up and align the punch marks on the

camshaft gear with the cylinder head surface

(Position the intake and exhaust cam lobes

down.) and install the camshaft onto the

cylinder head.

Install the cam chain over the camshaft gear.

Install the dowel pins.

Dowel Pins

Valve Rocker Arm

Punch Marks

Cylinder Head

Camshaft Holder

Cam Chain

Round Hole

Camshaft Gear

• When installing the rocker arm

shaft, align the shaft front end with the

bolt hole of the camshaft holder.

*

Page 11

7. CYLINDER HEAD/VALVES

7-10

FILLY LX 50

Install the camshaft holder, washers and nuts

on the cylinder head.

Tighten the four cylinder head nuts and two

bolts.

Torque: Cylinder head nut: 1.8~2.2kgf-m

CAM CHAIN TENSIONER

INSTALLATION

First install a new cam chain tensioner gasket.

Install the tensioner using the two bolts.

Install the tensioner spring.

Install the O-ring and sealing bolt.

Torque:: 0.45~0.6kgf-m

Adjust the valve clearance. (!3-5)

Install a new cylinder head cover O-ring and

install the cylinder head cover.

Install and tighten the cylinder head cover

bolts.

Torque:: 0.8~1.2kgf-m

Nut

Washer

Cylinder Head Cover

O-ring

Cam Chain Tensioner

Sealing Bolt

Push Rod

Lock Pawl

Camshaft Holder

Spring

• Apply engine oil to the threads

of the cylinder head nuts.

• Diagonally tighten the cylinder

head nuts in 2_ 3 times.

*

When installing the tensioner, release the

lock pawl and push the push rod all the

way in.

*

Be sure to install the O-ring into the

groove properly.

*

Loading...

Loading...