Page 1

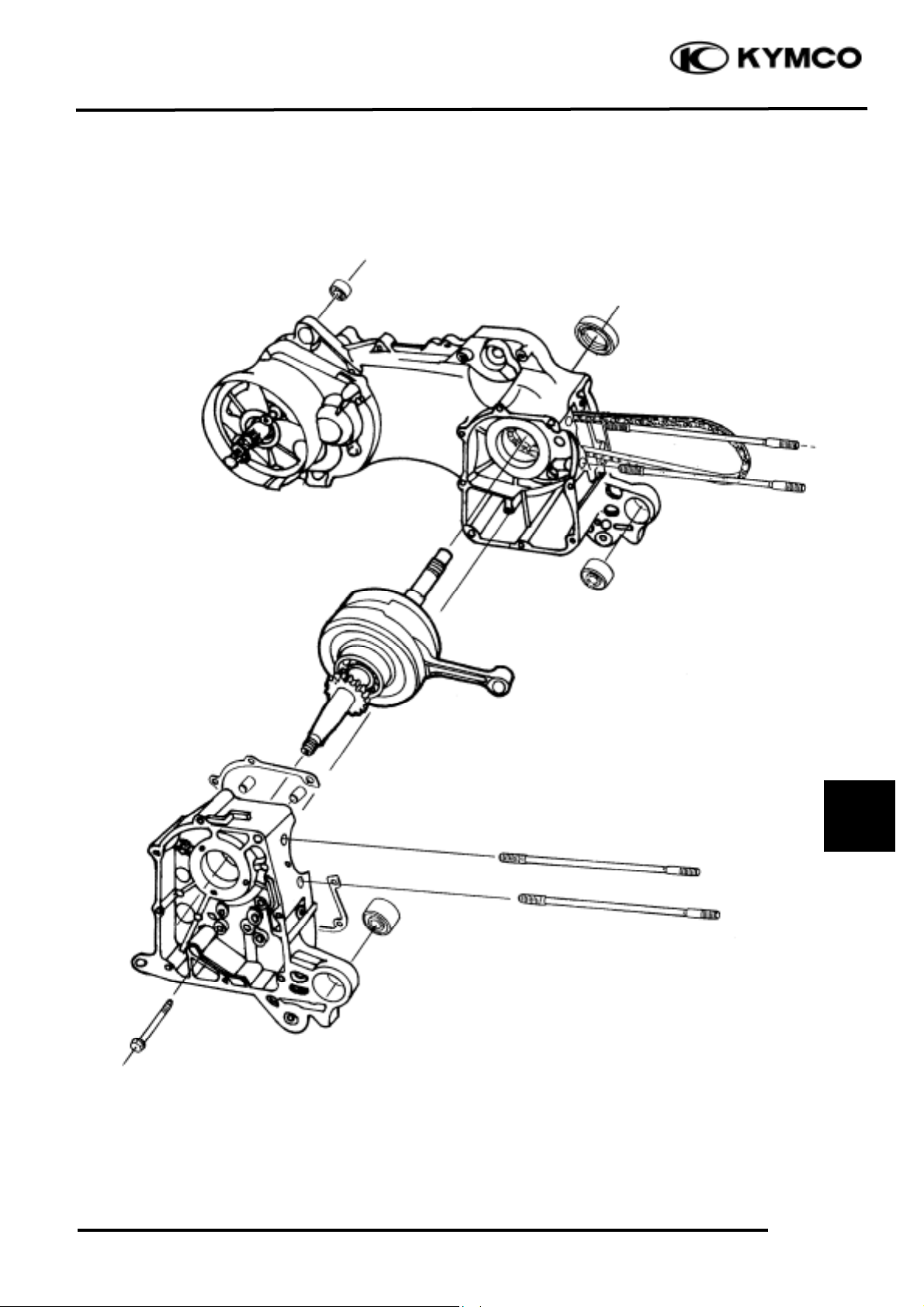

11. CRANKCASE/CRANKSHAFT

11-0

FILLY LX 50

11

11

Page 2

11. CRANKCASE/CRANKSHAFT

11-1

FILLY LX 50

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• This section covers crankcase separation to service the crankshaft. The engine must be removed

for this operation.

• The following parts must be removed before separating the crankcase.

-Cylinder head (!Section 7)

-Cylinder/piston (!Section 8)

-Drive and driven pulleys (!Section 9)

-A.C. generator (!Section 14)

-Carburetor/air cleaner (!Section 5)

-Rear wheel/rear shock absorber (!Section 13)

-Starter motor (!Section 16)

-Oil pump (!Section 4)

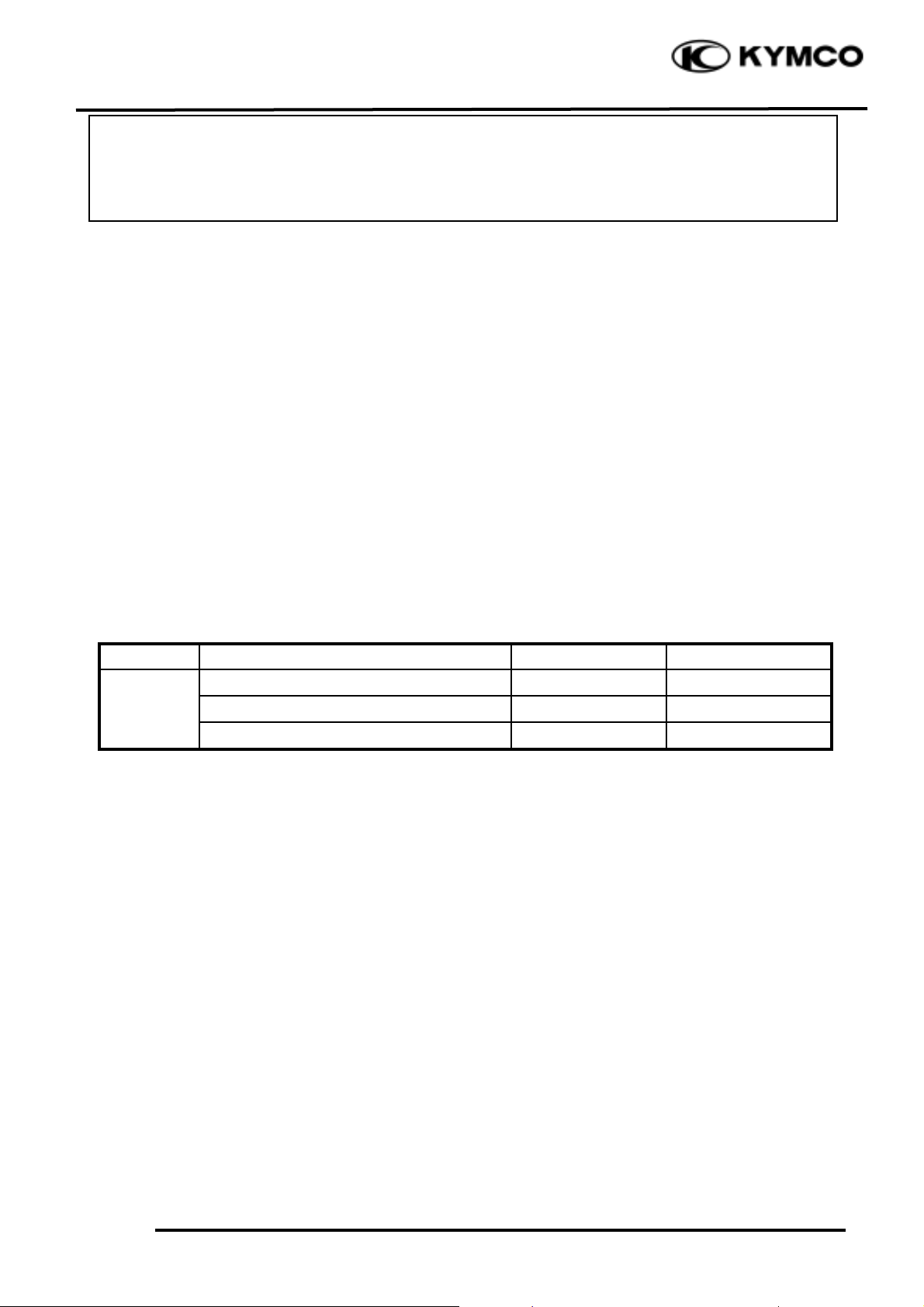

SPECIFICATIONS

Item

Standard (mm)

Service Limit (mm)

Connecting rod big end side clearance

0.10_ 0.35

0.55

Crankshaft

Connecting rod big end radial clearance

0-0.008

0.05

Runoutæ0.10

TORQUE VALUES

Crankcase bolt 0.8~1.2kgf-m

Cam chain tensioner slipper bolt 0.8~1.2kgf-m

TROUBLESHOOTING

Excessive engine noise

• Excessive bearing play

• Excessive crankpin bearing play

SERVICE INFORMATION

......................

11-1 CRANKSHAFT

......................................

11-3

TROUBLESHOOTING

.............................

11-1 CRANKCASE ASSEMBLY

...................

11-4

CRANKCASE SEPARATION

..................

11-2

Page 3

11. CRANKCASE/CRANKSHAFT

11-2

FILLY LX 50

CRANKCASE SEPARATION

Remove the cam chain tensioner slipper bolt

and cam chain tensioner slipper.

Remove the crankcase attaching bolt.

Separate the left and right crankcase halves.

Remove the gasket and dowel pins.

Remove the crankshaft from the left

crankcase.

Remove the cam chain.

Cam Chain T ensioner Slipper Bolt

Cam Chain

• Do not damage the crankcase

gasket surface.

• Never use a driver to pry the

crankcase mating surfaces apart.

*

Dowel Pins

Crankcase Bolt

Page 4

11. CRANKCASE/CRANKSHAFT

11-3

FILLY LX 50

Clean off all gasket material from the

crankcase mating surfaces.

Remove the oil seal from the left crankcase.

Remove the oil seal from the right crankcase.

CRANKSHAFT

Measure the connecting rod big end side

clearance.

Service Limit: 0.55mm replace if over

Avoid damaging the crankcase mating

surfaces.

*

Oil Seal

Connecting Rod Big End

Oil Seal

Page 5

11. CRANKCASE/CRANKSHAFT

11-4

FILLY LX 50

Measure the connecting rod big end radial

clearance at two points at right angels to the

shaft.

Service Limit: 0.05mm replace if over

Measure the crankshaft runout.

Service Limit: 0.10mm replace if over

Turn the crankshaft bearings and check for

excessive play.

If they do not turn smoothly, quietly or if

they fit loosely in the crankshaft, replace the

crankshaft as a set.

CRANKCASE ASSEMBLY

Install new oil seals into the right and left

crankcase .

Measuring Location

Crankshaft Bearings

Driver Handle A

Outer Driver

Page 6

11. CRANKCASE/CRANKSHAFT

11-5

FILLY LX 50

Install the cam chain into the left crankcase.

Install the crankshaft into the left crankcase.

Install the dowel pins and a new gasket onto

the left crankcase.

Tighten the crankcase attaching bolt.

Torque: 0.8~1.2kgf-m

Cam Chain

Gasket

Crankcase Bolt

Dowel Pins

When installing the cam chain, be careful

not to damage the oil seal.

*

Place the right crankcase over the

crankshaft and onto the left crankcase.

*

Driver Handle A

Outer Driver

Page 7

11. CRANKCASE/CRANKSHAFT

11-6

FILLY LX 50

Install the cam chain tensioner slipper.

Install a new O-ring onto the cam chain

tensioner slipper bolt.

Apply engine oil to the O-ring and tighten the

bolt.

Torque: 0.8~1.2kgf-m

Cam Chain Tensioner Slipper Bolt

O-ring

Be sure to install the O-ring into the

groove.

*

Loading...

Loading...