Page 1

18. EVAPORATIVE/EXHAUST EMISSION

CONTROL SYSTEM

18-0

FILLY LX 50

18

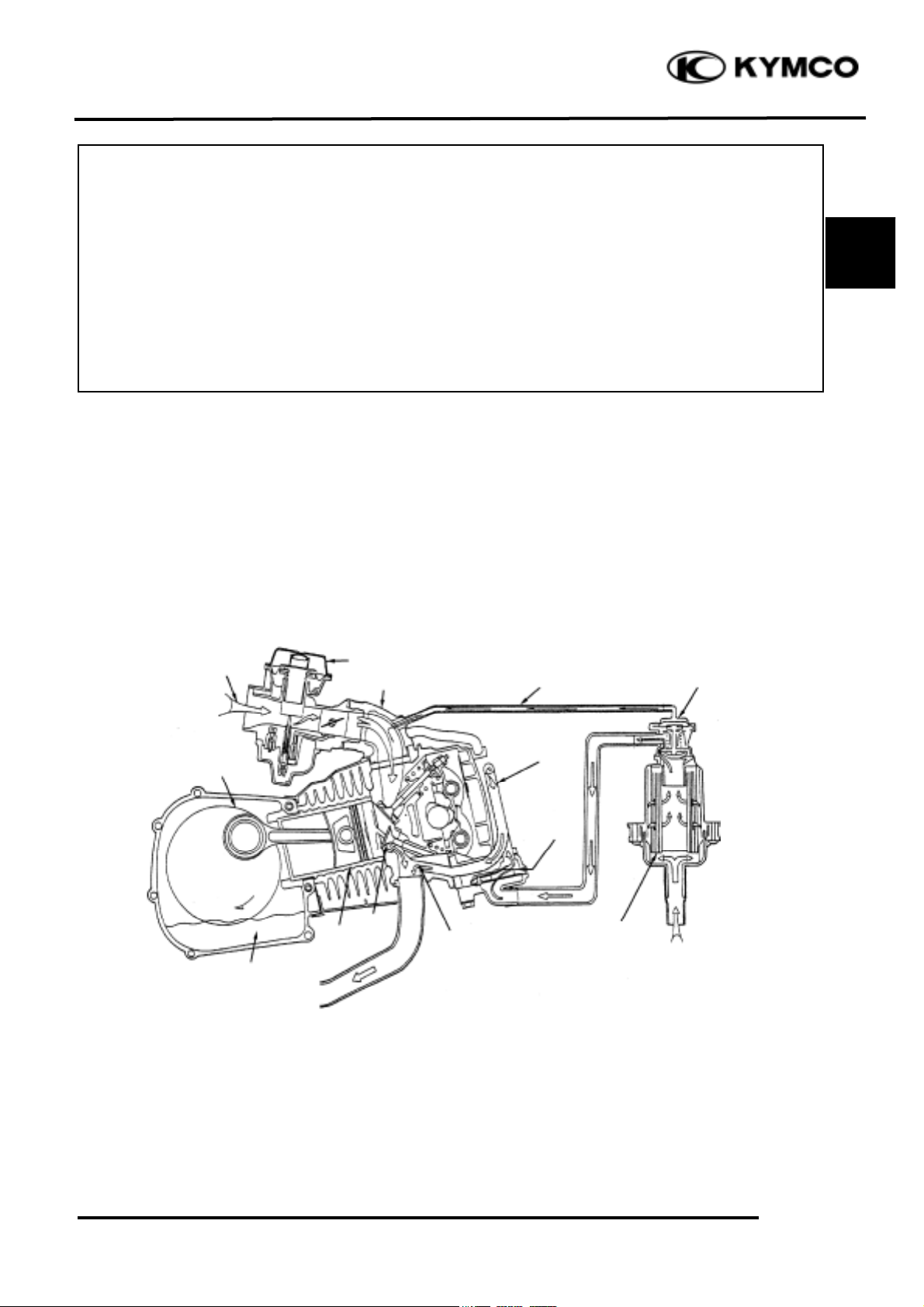

EXHAUST EMISSION CONTROL SYSTEM DIAGRAM

18

EXHAUST EMISSION CONTROL SYSTEM DIAGRAM

.................................................

18-0

EXHAUST EMISSION CONTROL SYSTEM

......................................................................

18-1

SERVICE INFORMATION

....................................................................................................

18-1

TROUBLESHOOTING

...........................................................................................................

18-1

MAINTENANCE SCHEDULE

..............................................................................................

18-2

SECONDARY AIR CLEANER

...............................................................................................

18-3

AIR INJECTION CUT-OFF VALVE (A.I.C.V.)

....................................................................

18-4

REED VALVE

..........................................................................................................................

18-5

EXHAUST MUFFLER

...........................................................................................................

18-6

EXHAUST EMISSION RELATED SYSTEM INSPECTION

...............................................

18-7

Secondary

Air Cleaner

Carburetor

Fresh Air

Fresh Air

Exhaust

Intake Manifold

Piston

Crankshaft

Engine Oil

Valve

Reed Valve

Secondary

Air Inlet

Secondary Air

Vacuum Tube

Air Injection

Cut-off Valve

Page 2

18. EVAPORATIVE/EXHAUST EMISSION

CONTROL SYSTEM

18-1

FILLY LX 50

EXHAUST EMISSION CONTROL SYSTEM

The exhaust emission control system adopted in this model utilizes the reed valve to draw

secondary air into the exhaust system for re-combustion by means of exhaust pulsation so as to

minimize the exhaust emission.

FUNCTION

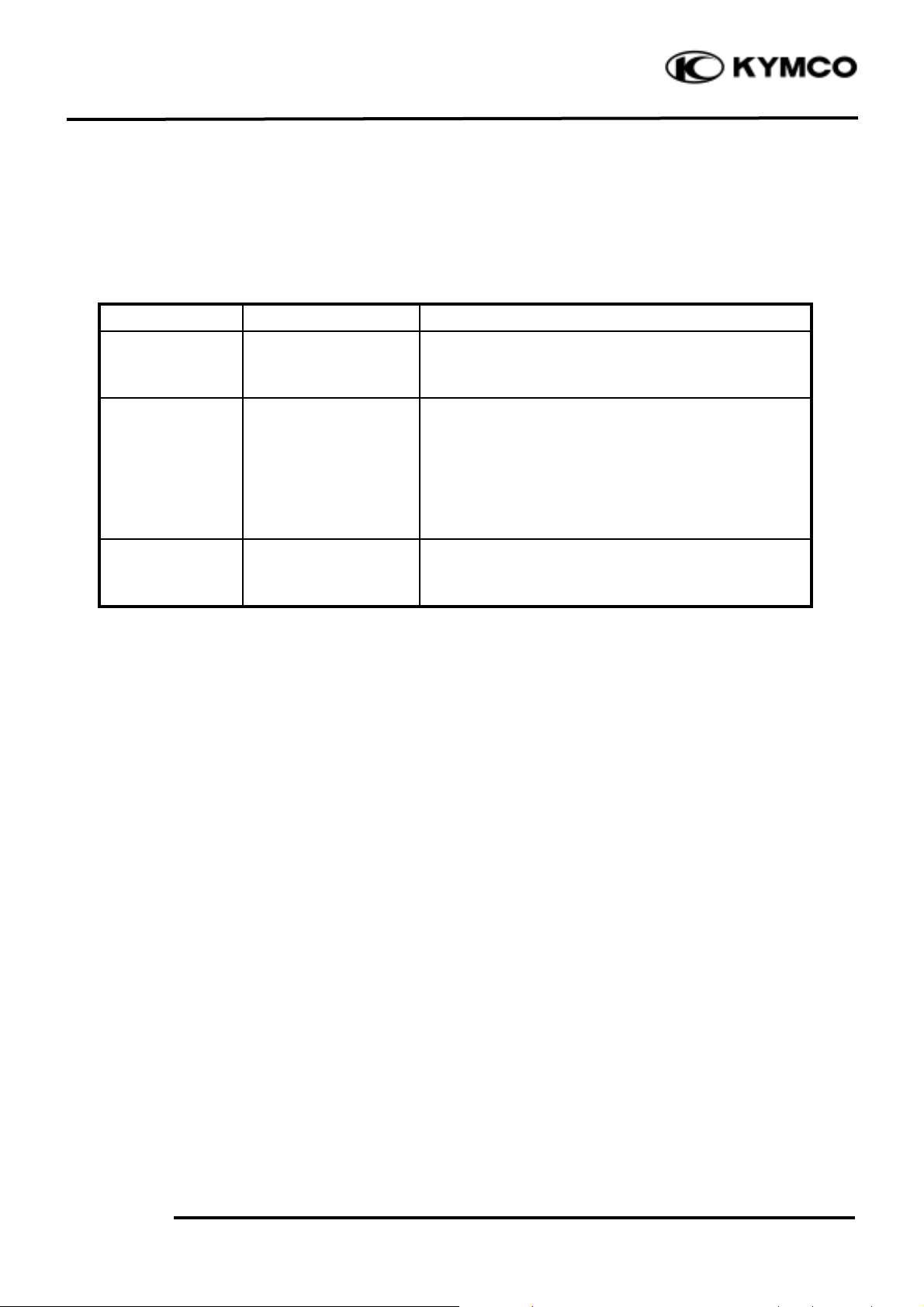

Item

Purpose

Function

Secondary Air

Cleaner

Filter secondary air.

It filters the fresh air drawn for re-burning to

prevent dirt or dust from affecting the operation of

the air injection cut-off valve.

Air Injection Cutoff Valve

Prevent exhaust

muffler noise and

backfiring at sudden

deceleration.

The air injection cut-off valve usually opens to lead

air into the exhaust muffler in which air is reburned to reduce CO. When the throttle valve

closes suddenly, the air injection cut-off valve is

actuated by vacuum to close and cut off secondary

air in order to prevent exhaust muffler backfiring

due to air in the exhaust system.

Reed Valve

Control the secondary

air inlet to reduce CO.

When the motorcycle speed is less than 50km per

hour, the reed valve operates to draw secondary air

into the exhaust system for re-combustion.

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• During operation, be careful to avoid scalding caused by the exhaust muffler.

• Note the locations of tubes for proper installation.

• Replace any damaged tube with a new one.

• Make sure to tighten the connector of each tube securely

TOOLS SPECIFICATIONS

• Vacuum pump- Air injection cut-off valve actuating pressure-

250mm/Hg- 30 liter/min.

Reed valve stopper clearance- 6.6mm

TROUBLESHOOTING

High CO at idle speed Exhaust muffler noise

• Damaged or clogged reed valve • Faulty air injection cut-off valve

• Damaged or clogged air injection cut-off valve • Broken vacuum tube

• Clogged air cleaner • Faulty reed valve

Backfiring at sudden deceleration

• Damaged reed valve (malfunction)

• Faulty air injection cut-off valve (unable to close)

• Carburetor incorrectly adjusted

• Faulty air cut-off valve

• Leaking vacuum tube

Page 3

18. EVAPORATIVE/EXHAUST EMISSION

CONTROL SYSTEM

18-2

FILLY LX 50

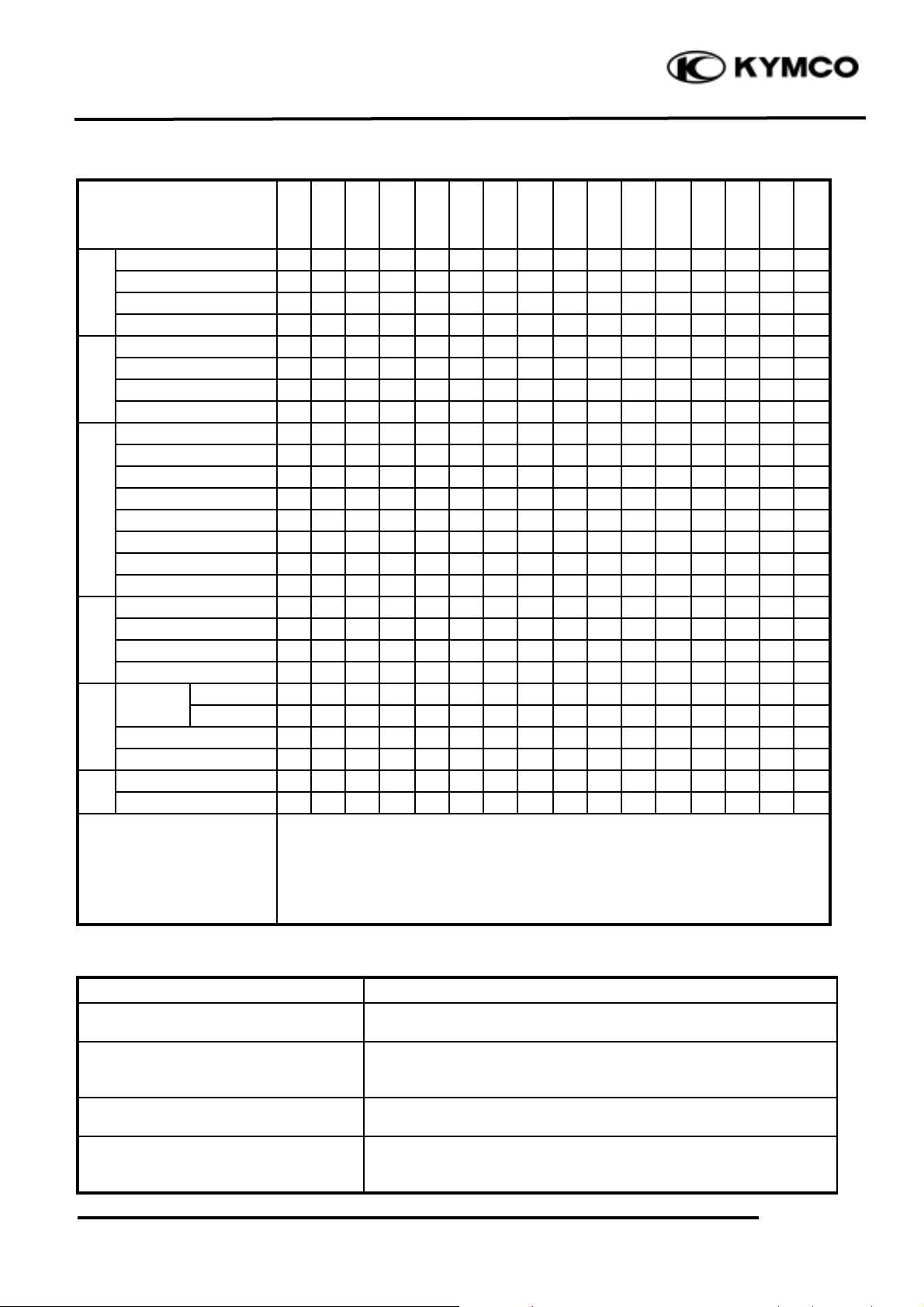

MAINTENANCE SCHEDULE:

(1) PERIODIC MAINTENANCE

Service Mileage

Item

300

1000

2000

3000

4000

5000

6000

7000

8000

9000

100001100012000130001400015000

Engine oil

RRRRRRR

R

Oil filter screen

CCCCC

Gear oil

RRR

R

Lubrication

System

Motor oil filter

III

Fuel filter

III

I

Fuel filter screen

CCC

C

Carburetor

AAA

A

Fuel System

Fuel line

III

Air cleaner

CRR

R

Charcoal canister

III

I

Secondary air cleaner

IRR

R

Secondary air inlet line

I

Intake manifold screw

I

Purge control valve

III

I

Air lines

III

Air Supply System

Catalytic converter

III

I

Cam chain

III

I

Drive chain

III

I

Drive belt

III

I

Drive

System

Valve clearance

III

I

Spark

4-stroke

I

R

Plug

2-stroke

IRR

R

C.D.I.

III

Ignition

System

Ignition system wires

III

Bolts and nuts

TTTTTTTTTTTTTTT

Other

Brake system

AAAAAAAAAAAAAAA

Remarks

I: Inspect, A: Adjust, C: Clean, R: Replace, T: Tighten

•During riding or inspection, if any part is found to be cleaned, adjusted

or replaced, do it directly and take a record if the exhaust emission

control system is not seriously affected. It must be reported and

approved if the exhaust emission control system is seriously affected.

(2) IRREGULAR MAINTENANCE:

Item

Contents

Ignition system

Inspect and repair when obvious symptoms of ignition

failure, engine overheating and stalling are found frequently.

Carbon deposit removal

Remove carbon deposits from the exhaust system, cylinder

head and piston head when the engine horsepower decreases

greatly during the service mileage of 10000_ 15000 km.

Transmission system

Perform CVT system maintenance and inspection when the

engine performance decreases obviously.

Piston

Severe use in the first 1000 km may cause worn or seized

cylinder, piston and piston rings. Clean or replace with new

ones if necessary.

Page 4

18. EVAPORATIVE/EXHAUST EMISSION

CONTROL SYSTEM

18-3

FILLY LX 50

SECONDARY AIR CLEANER

REMOVAL

Remove the frame body covers.

Remove the two nuts attaching the rear light

shell.

Remove the rear turn signal light bulb and

replace with a new one.

Disconnect the secondary air cleaner

connecting tube.

Remove the air cleaner attaching bolts and the

air cleaner.

DISASSEMBLY

Remove the two screws attaching the air

cleaner cover to remove the cover.

Remove the air cleaner element.

Inspect the air cleaner.

INSTALLATION

The installation sequence is the reverse of

removal.

Nuts

Rear Light Shell

Air Outlet Tube

Air Cleaner Element

Screws

Air Inlet Tube

Vacuum Tube

Air Injection Cut-off Valve

Tube to Reed Valve

Secondary Air

Cleaner

Bolt

Air Injection

Cut-off Valve

• The secondary air cleaner must be

assembled and installed properly to

avoid dust entering the air cleaner.

*

Page 5

18. EVAPORATIVE/EXHAUST EMISSION

CONTROL SYSTEM

18-4

FILLY LX 50

AIR INJECTION CUT-OFF VALVE

INSPECTION

Inspect the air injection cut-off valve flow

using a vacuum pump. If the flow is not

within the specified values, replace with a

new one.

The flow should be at least 30 liter/min when

a vacuum of 250mm/Hg is applied. The flow

should be at least 1.6 liter/min when a vacuum

of 320mm/Hg is applied. Check each

connecting tube for cracks or damage and

replace if necessary.

INSTALLATION

The installation sequence is the reverse of

removal.

Vacuum Pump

Air Injection Cut-off Valve

• When installing, be careful not to bend

or twist the tubes and check for

proper installation.

• The tube length is very important to

its performance, use the tube of same

specification for replacement.

*

Page 6

18. EVAPORATIVE/EXHAUST EMISSION

CONTROL SYSTEM

18-5

FILLY LX 50

REED VALVE

REMOVAL

Remove the met-in box and frame center

cover.

Disconnect the secondary air inlet tube

connector.

Remove the four cylinder head cover bolts

and two secondary air outlet tube bolts.

INSPECTION

Remove the three screws attaching the reed

valve cover and the reed valve.

Check the reed valve for damaged or weak

reeds.

Check the reed valve seat for cracks, damage

or clearance between the seat and reed.

Check the gasket and O-ring for damage or

deterioration and replace if necessary.

Reed valve stopper clearance: 6.6mm

INSTALLATION

Install the reed valve in the reverse order of

removal.

• When installing, be careful not to bend

or twist the tubes and check for

proper installation.

*

Cylinder Head Cover

Bolts

Secondary Air Inlet

Tube Bolt

Reed Stopper

Reed Valve Cover Bolts

Screws

Page 7

18. EVAPORATIVE/EXHAUST EMISSION

CONTROL SYSTEM

18-6

FILLY LX 50

EXHAUST MUFFLER

REMOVAL

Remove the two exhaust muffler joint lock

nuts and two exhaust muffler lock bolts.

Remove the exhaust muffler.

INSPECTION

1. Inspect the exhaust muffler and joint for

damage or crack. Replace if necessary.

2. Inspect the exhaust muffler joint packing

collar for deformation or damage. Replace if

necessary.

INSTALLATION

1. Install the exhaust muffler in the reverse

order of removal.

• The temperature of exhaust muffler is

very high. Be careful to avoid burns

during working.

*

Exhaust Muffler

Lock Bolts

Exhaust Muffler Joint Lock Nut

• A large amount of unburned mixture

flowing into the high-heat catalytic

converter will burn again and cause damage

to the converter due to overheat. Pay

attention to the following.

• Use 92# or 95# nonleaded gasoline only.

(Leaded gasoline will cause catalytic

converter failure.)

• During riding, do not turn the ignition

switch OFF to avoid a large amount of

unburned mixture flowing into the exhaust

muffler.

• Faulty ignition system or fuel system will

cause overheat and damage to the catalytic

converter.

*

Page 8

18. EVAPORATIVE/EXHAUST EMISSION

CONTROL SYSTEM

18-7

FILLY LX 50

EXHAUST EMISSION RELATED

SYSTEM INSPECTION

Clean or replace the air cleaner. (!3-4)

Clean and adjust the carburetor. (!3-5)

Inspect the auto bystarter system. (!5-4)

Clean and inspect the spark plug. (!3-4)

Inspect the ignition system. (!3-6)

EXHAUST EMISSION TEST AND

ADJUSTMENT

1. Start the engine and warm up for several

minutes. (Engine surface temperature

50℃_ 60℃ )

2. Adjust the idle speed to 1900rpm.

3. Connect the emission tester sampling pipe

to the exhaust muffler.

Standard:

CO: 2.5±0.5%

HC: 700PPM max.

4. If CO or HC exceeds the specified values,

adjust the carburetor pilot screw (P.S.)

until CO and HC are within the specified

standard values.

P.S. Opening: 2±_ turns

5. If the adjustment of carburetor makes no

difference, inspect exhaust emission related

system. (!18-9)

Loading...

Loading...