Page 1

20. HIGH-SPEED TIRE

20-0

20

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

HIGH-SPEED TIRE (TUBELESS TIRE)

__________________________________________________________________________________

HIGH-SPEED TIRE CONSTRUCTION & FEATURES ------------ 20- 2

HIGH-SPEED TIRE MAINTENANCE PRECAUTIONS ----------- 20- 4

HIGH-SPEED TIRE REMOVAL/INSTALLATION ---------------- 20- 5

HIGH-SPEED TIRE REPAIR------------------------------------------ 20-16

20

Page 2

20. HIGH-SPEED TIRE

20-1

HIGH-SPEED TIRE CONSTRUCTION & FEATURES

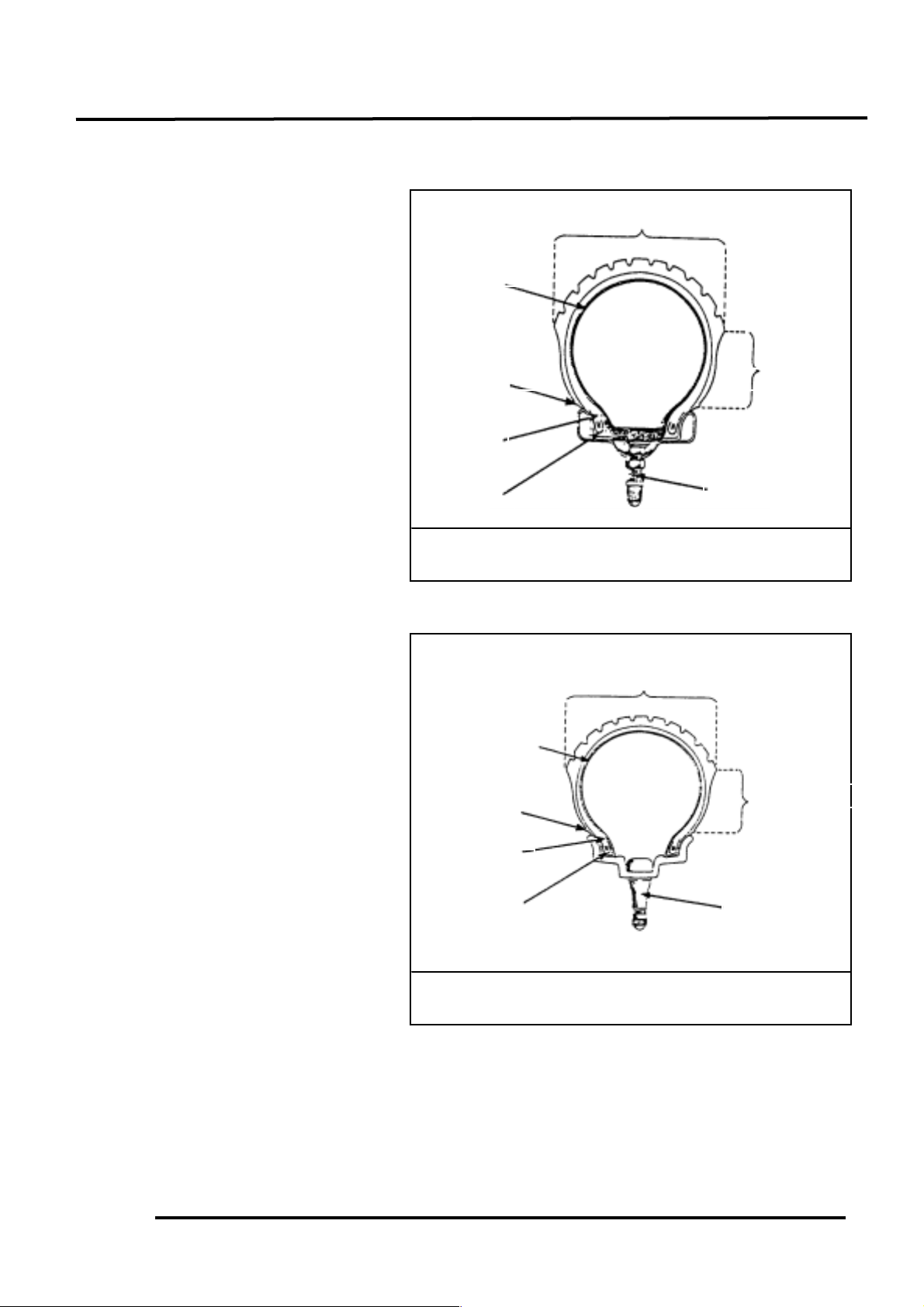

CONSTRUCTION

INNER LINER

A layer of rubber (inner liner) which

replaces the inner tube is stuck to the

inside wall of the high-speed tire. The

inner liner is made of thick rubber, a

material that high-pressure air can not

pass through. The liner can not be

lengthened like other inner tubes, so

when nails are inserted into the tire,

breaks will not be enlarged because

the nails are suppressed to avoid air

leaks. When tire break occurs, the

inserted nails will spring out to make

the tire run under low pressure. It is

very dangerous because the tire

temperature will raise highly to make

tire wobble during riding. Therefore,

riders must be very careful to check

tire pressure and inserted nails before

riding at high-speed.

•Tire pressure

•Tire deformation and damage

•Tire groove depth and abnormal

wear

Tire Depth: Front : 0.8mm

Rear : 0.8mm

•Imbedded metals, stones, or other

foreign matters

The bead base where tire and rim

contact is wrapped by rubber fabrics

called tire bead in order to reinforce

its function. The fabrics is specially

adopted for the high-speed tire to

keep its air density because air can

not pass through this material. Also,

the fabrics can keep the tire from

damage when the tire falls off, and

protect tire from damage due to

friction of wheel rim while riding.

Inner Tube

Tire Bead

Tube Valve

Tube Tire

Tread

Tire Flange

Circle Boundary

Tire Shoulder

Circle Boundary

Tire Flange

Tubeless Tire

Inner Liner

Tire Bead

Tread

Tire Valve

Tire Shoulder

Page 3

20. HIGH-SPEED TIRE

20-2

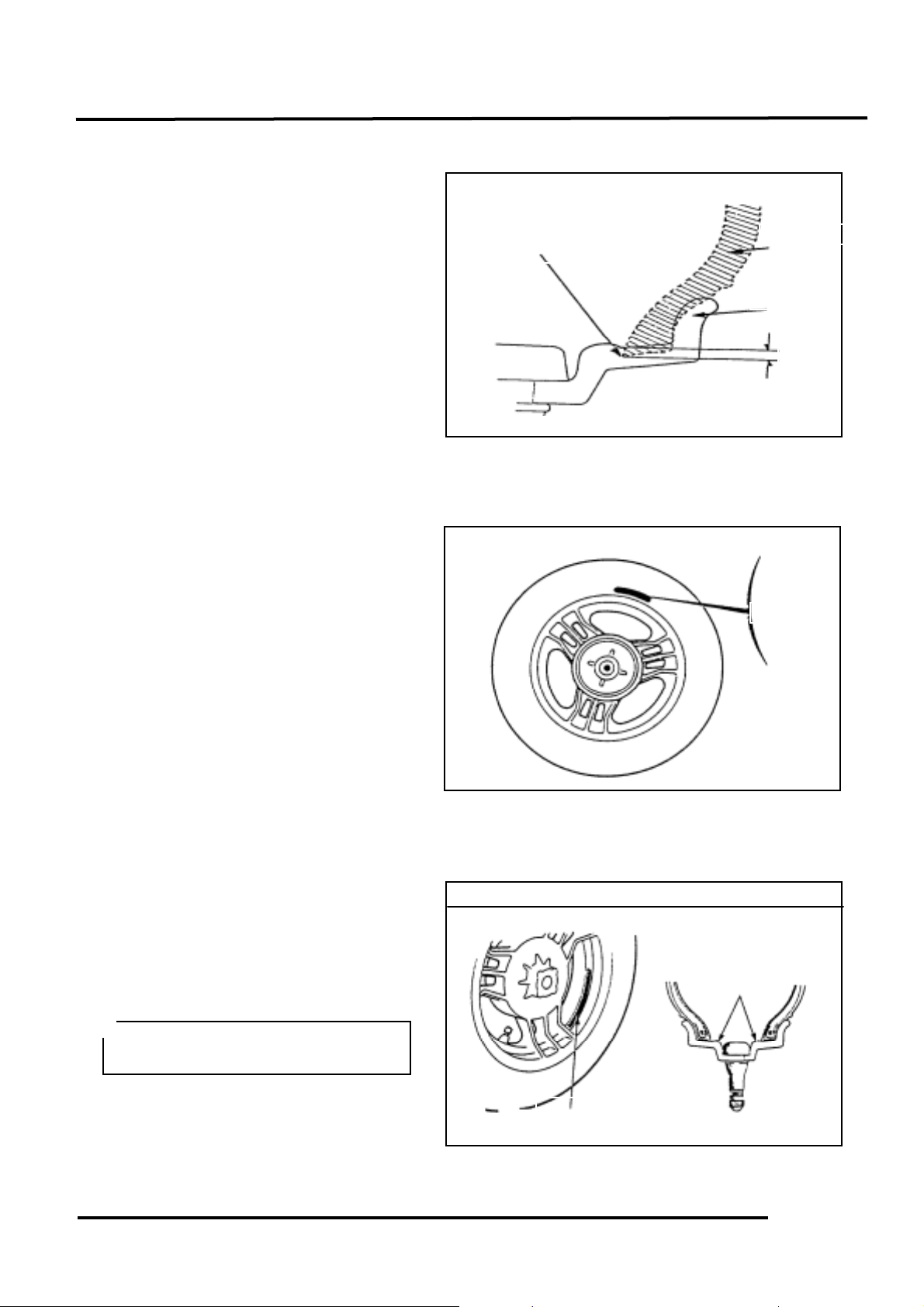

TIRE FLANGE BEVEL ANGEL

If the tire flange radius is smaller than the

wheel rim radius, the tire and wheel can be

locked tightly. Take the advantage of tire

bead bevel angle to enlarge tire bead so

that the tire and rim can combine with

each other precisely. Consequently, it

can prevent air leaks and tire will not fall

off the rim when tire break or low

pressure occurs.

METHOD TO IDENTIFY A HIGHSPEED TIRE

For distinguishing a high-speed tire from a

tube-tire, the word “TUBELESS” is

stamped on the side wall of the highspeed tire. A tire without this word

cannot be used as a high-speed tire.

RIM USED FOR HIGH-SPEED TIRE

For the purpose of preventing tire from

falling off the wheel rim while driving,

there are special requirements on the size,

shape and pressure density of rim used

for high-speed tire. It is necessary to use

special rims.

Refer to the Figure shown for distinction.

Air leaks occur easily when the wheel rim

is deformed. Avoid driving on rugged road

and crashing against stones.

When replacing the high-speed tire, also

replace the valve as a set.

• When replacing the high-speed tire,

use a tire of the same specification.

*

Rim Used for High-speed Tire

Tire flange bevel angle is

larger than rim bevel angle

Tire Shape

TUBELESS

Rim Shape

Locked

Mark of

TUBELESS

Rim Valve

Page 4

20. HIGH-SPEED TIRE

20-3

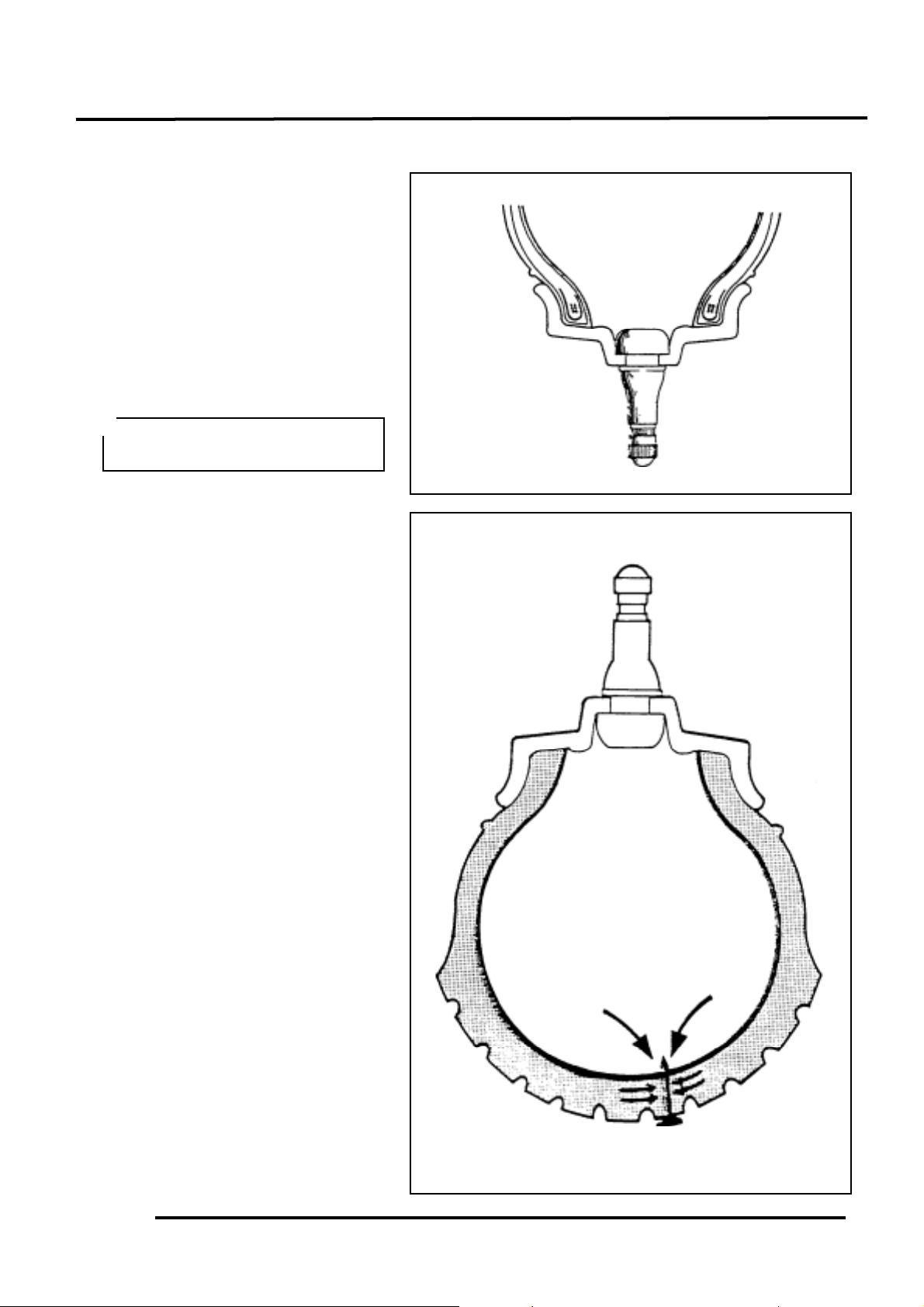

RIM VALVE USED FOR HIGHSPEED TIRE

Air-tight valve is specially designed

for rim valve of a high-speed tire.

AIR-TIGHT VALVE

A rubber of special shape is used to

cover around the valve hole. The

spring of rubber can prevent air leaks.

Install the valve from the inner side of

the rim and then pull it out through

the rim valve hole with a special tool.

HIGH-SPEED TIRE FEATURES

•Air will not release quickly when a

nail is inserted into the tire. It is the

same as the tube-tire that tire break

may occur to a high-speed tire when

nails or other objects are inserted

into it. However, when a nail is

inserted into a high-speed tire,

external rubber and internal anti-leak

rubber will grip the nail tightly to

prevent air leaks. If the nail is deeply

inserted, air will not release quickly

to avoid sudden slipping of steering

handlebar.

•EXCELLENT COOLING

PERFORMANCE

Because the high-speed tire is

tubeless, the air within the tire will

contact the rim directly. Heat

produced during driving can be

dissipated through the rim. Heat

affects the rubber greatly and if the

tire temperature is not high, the tire

service life can be prolonged .

• Use only the KYMCO

recommended air-tight valve.

*

There is no air leak when a nail is

inserted into the tire.

Page 5

20. HIGH-SPEED TIRE

20-4

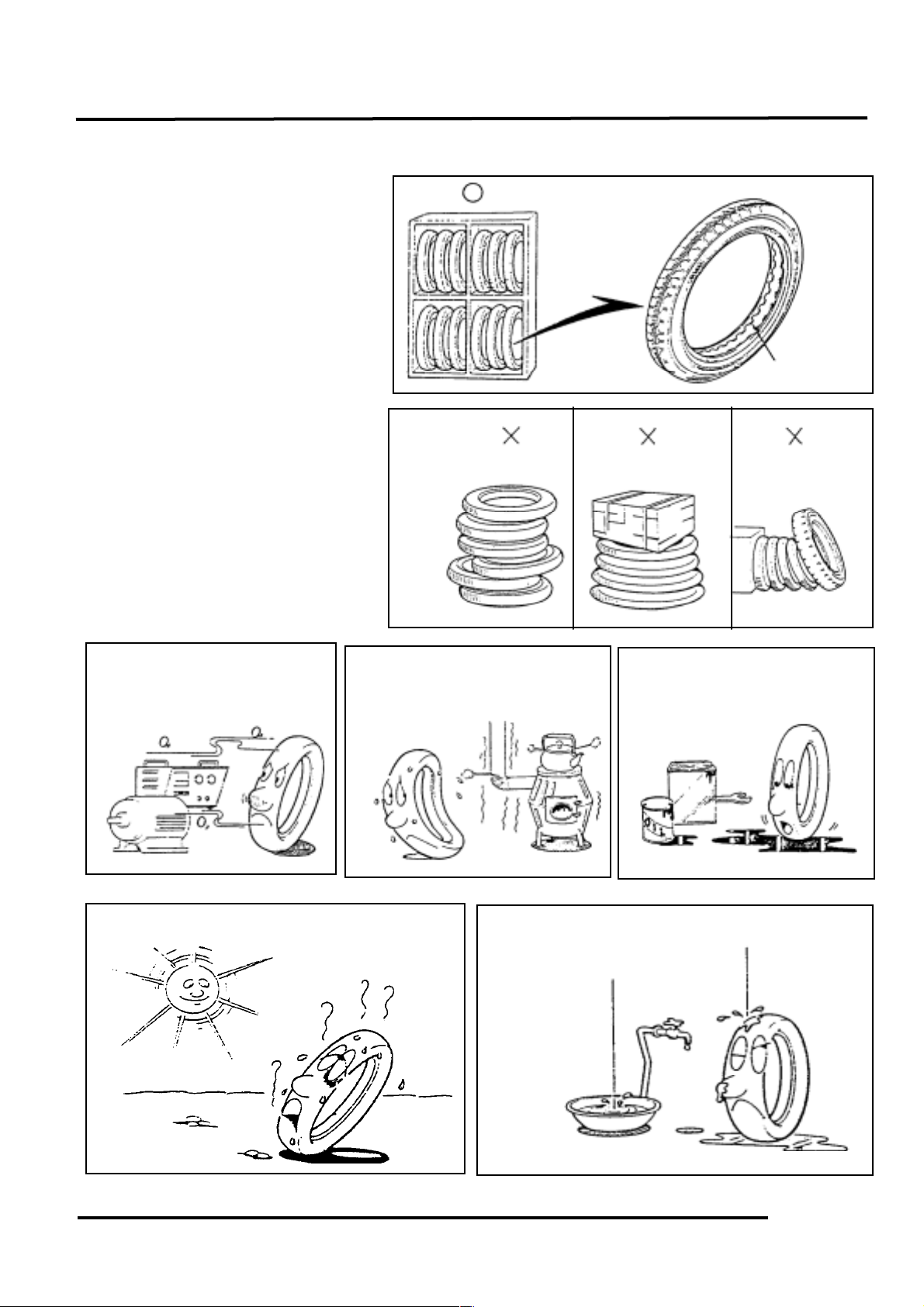

PRECAUTIONS FOR HIGH SPEED

TIRE STORAGE

STORAGE METHODS

If the space within the tire bead of a

high-speed tire is narrower than the

width of its rim, it is hard to install

the tire to the rim and pump air into

the tire. Therefore, it is better to put

cardboard within the tire bead and

put tires in order.

Tires deform easily if they are piled

horizontally. Avoid doing so.

As to the reused tires, the structure

of the rim remains the same. Install

the valve cap when the tire pressure

is lowered to 1/2 of the specified

pressure.

PLACE FOR STORAGE

The place used for storage should

avoid the following conditions:

A place where produces

ozone (a place near motors

or chargers)

A place with oils or

lubricants (especially in

service working area)

A place where produces

heat (a place near stoves

or steam pipes)

Cardboard

A place with high moisture

A place with direct sunshine

Page 6

20. HIGH-SPEED TIRE

20-5

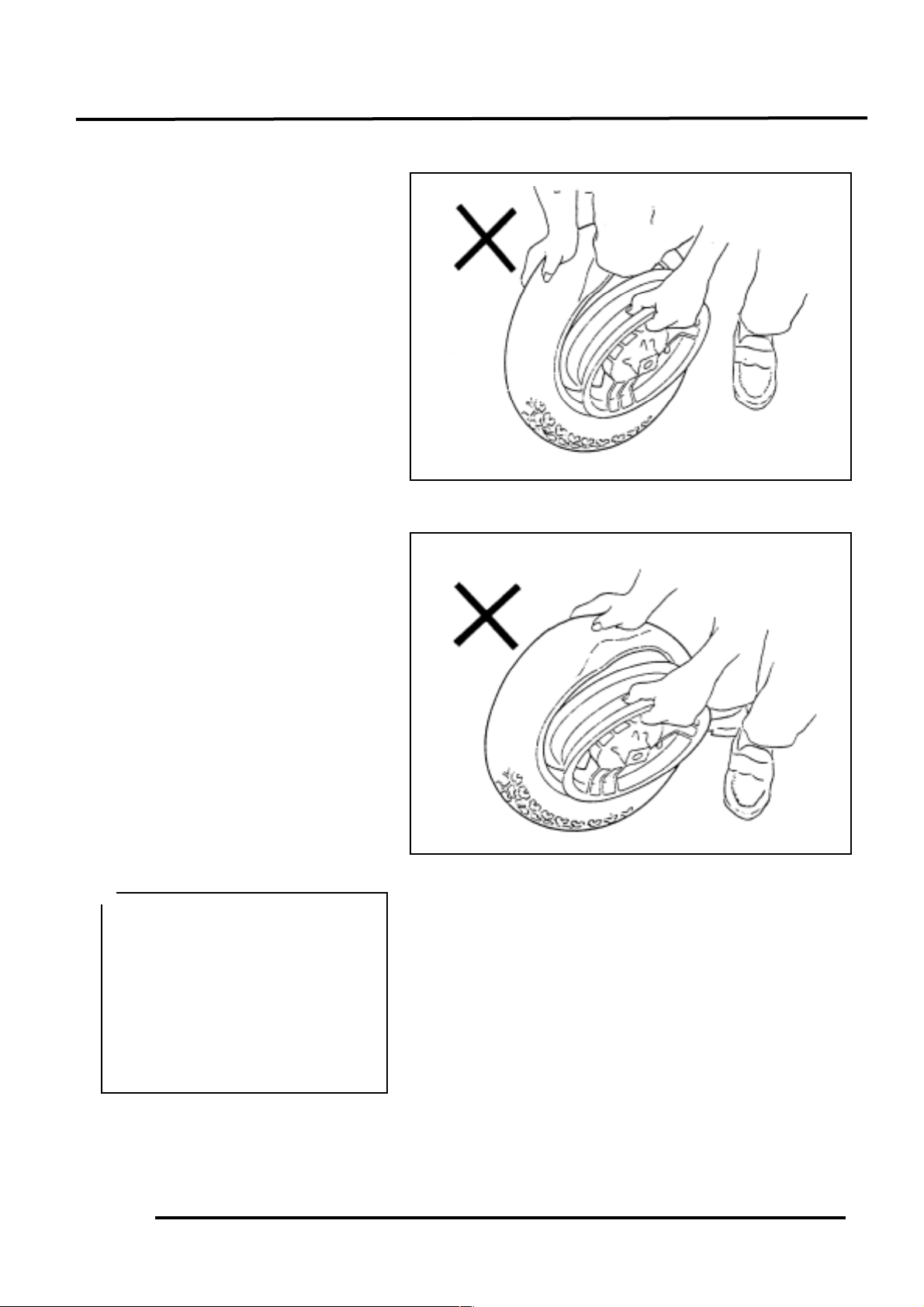

HIGH-SPEED TIRE

REMOVAL/INSTALLATION

In comparison with the tube-tire, the

following points must be noticed

when removing and installing a highspeed tire.

•When removing the high-speed tire,

avoid damaging the tire bead (special

plastic seat), tire liner (internal antileak material) and rim flange (bead

base).

•Apply vegetable soapy water to the

contact area between the tire bead

and rim, and use a tire iron for

installation.

•It will cause tire deformation when

removing the tire forcedly as the

figure shown. Be sure to remove the

tire following the instructions given

in the manual.

•The tight joint of tire and rim can

prevent air leaks. As long as the rim

is deformed, air leaks will occur

easily. Therefore, do not remove or

install the tire forcedly. Use special

tools and rim protector for servicing.

Frequently check if there is any

deformed part and do not use tools

of poor quality.

•Rust and rubber materials on bead

base are the main cause of air leaks.

Remove them thoroughly.

•Be sure to remove and install the tire

following the procedures provided in

the manual.

• When removing or installing a

high-speed tire, do not damage

the axle bearing. Draw or pull the

rubber on the rim lower part.

• It is difficult to remove a tire

when the rim valve is pressed by

tire flange. In this situation, do

not remove it forcedly because

the rim valve hole will be

damaged.

*

Page 7

20. HIGH-SPEED TIRE

20-6

TOOLS & PARTS REQUIRED

FOR SERVICING

Tire iron

Wheel rim protector

Knife

Water pan and probe

Vegetable soapy water

Pressure gauge

Valve core assembly tool

Valve assembly tool

Rim valve used for high-

speed tire

Valve core

11 High-speed tire

High-speed tire

Model: KYMCO DINK50

Tire size: 110/70-12 (Front)

130/70-12 (Rear)

Make sure to use KYMCOrecommend high-speed tire and

rim valve.

Page 8

20. HIGH-SPEED TIRE

20-7

REMOVAL METHODS

Use the valve core assembly

tool to take the valve core out and

bleed air from the tire.

If there is no special tool to

pry off the tire bead, use your feet

to do this as the figure shown.

After the tire bead is separated

from the rim and before removing

the tire, press the tire bead at the

back of the valve into the rim

groove completely, Then push the

tire to the same side.

When removing the valve core, be

careful that the high tire pressure

may force out the valve core.

*

It is easier to remove the tire when

it is pushed to the same side of

rim.

*

•Don‘t step on the wheel rim and

spoke wire.

•Before installing the tire, make

sure that the rim and axle bearing

are not damaged. Be careful during

installation.

*

Rim Center

Page 9

20. HIGH-SPEED TIRE

20-8

Apply vegetable soapy water to

the area between the rim and tire

and install the rim protector at the

rim side. Then insert the tire iron to

pry off the tire bead from the rim.

At this time, the tire bead at the

back side of the valve is in the rim

groove completely. After making

sure the above mentioned is done,

remove the tire by following the

sequence of 1234.

Insert the second tire iron

30_ 50mm from the first one.

Then separate the tire bead from

the rim.

It is the same as . Use the

first tire iron to pry off tire bead

from the rim, then use the second

one to pry off another part of the

tire rim from the rim (distance:

30_ 50mm) slowly.

Do not use a tool other than the

tire iron for motorcycle tire

removal. Use the wheel rim

protector for removal.

*

If you want to separate the tire

bead from the rim only by one tire

iron, the tire bead will be deformed

due to using too much force. The

rim will also be damaged seriously.

Avoid this way of removal.

*

Page 10

20. HIGH-SPEED TIRE

20-9

The procedure is the same as

and . If 1/3 of the tire bead is

separated from the rim, the whole

tire is easily taken off.

When 1/2 of the tire bead is pried

off the rim, the tire will be easily

removed by using only one tire

iron.

The bead at the back side can be

pried off in the same procedures

described in _ .

Page 11

20. HIGH-SPEED TIRE

20-10

Take out the rim from the tire.

Check the rim valve for damage.

Replace any faulty parts.

RIM VALVE REMOVAL

Cut the rim valve from it bottom.

RIM VALVE INSTALLATION

Apply vegetable soapy water to

facilitate the installation of rim valve.

Apply after other foreign objects are

removed.

• Apply around the valve when

installation.

• Apply to the tire bead while

assembling the tire and rim.

Apply vegetable soapy water to the

inner side of rim valve and then use a

special tool to pull the valve out.

When the tire is replaced, replace

the valve as a set.

*

Be careful not to damage the rim

valve hole.

*

Do not use oil or gasoline. Use

vegetable soapy water only.

*

Page 12

20. HIGH-SPEED TIRE

20-11

RIM AND TIRE INSPECTION

RIM INSPECTION

Check the rim and remove rust and

rubber materials from the rim.

Air leak will be caused by rim

deformation or cracks.

When the tire or rim has cracks, do

not repair them and immediately

replace with a new one.

THE DEPTH AND WIDTH OF

TIRE SCAR IS OVER 0.5MM AND

1.0MM

TIRE INSPECTION

The tire cannot be repaired and must

be replaced with a new one under the

following conditions.

•Tire crack or break is caused by a

foreign object of 6mm outer radius.

•The layer of tire-contact part falls

off.

•Worn tire tread.

•Worn tire bead.

•Broken tire bead stiffener or other

bead damage.

•Broken fabrics.

•Deflection caused by dragging force.

•Rubber cutting damage.

•Abnormal internal anti-leak rubber.

•Side wall breaks or damage.

•Tire tread depth is under 0.8mm

INSTALLATION

Before installation, check the tire

inside for damage.

Apply vegetable soapy water to the

right and left sides of tire bead. Keep

the tire upright and start to install the

tire from the back of the rim valve

according to the order of 1234.

Then, push the tire into the rim by

hand to the part where hands can

reach in.

When the tire is deformed, repair

and correct the deformed part by

hand.

*

Page 13

20. HIGH-SPEED TIRE

20-12

Put the wheel horizontally and put

the rim protector on the rim. Use 2

tire irons to install the tire bead into

the rim slowly (30_ 50mm).

Use 2 tire irons to install the tire bead

for the last 50_ 60mm part. By

this way, one side of the tire bead is

installed.

The installation of the other side of

tire bead should be started from the

opposite side of the tire valve

according to the order of 1234.

Page 14

20. HIGH-SPEED TIRE

20-13

Install the rim protector and insert 2

tire irons at an interval of 30mm to

install the tire bead into the rim.

Press to hold the installed part of tire

bead by knees.

After 1/2 of tire bead is installed,

insert 2 tire irons at an interval of

30_ 40mm to finish the installation

in order.

The pulled-out tire iron should be

inserted beside the other tire iron

which hasn‘t been pulled out.

After 2/3 of the tire bead is installed

into the rim, make sure if the installed

tire bead is completely inserted into

the rim groove.

• Both tire irons should be pulled

out at the same time.

• The already installed part should

be pressed.

*

If the tire bead is not completely

inserted into the rim groove, it will

be more difficult to install the rest

part of the tire bead. Moreover,

the rim bead is easily damaged.

*

Page 15

20. HIGH-SPEED TIRE

20-14

If 50_ 60mm of the tire bead is not

installed, use 2 tire irons to install the

rest part of tire bead.

Use the valve core installer to install

the valve core.

Apply vegetable soapy water to both

sides of the tire bead.

Page 16

20. HIGH-SPEED TIRE

20-15

In order to ensure that the tire and the

rim are well combined, raise the wheel

and rotate it. Press around the tire by

hand for several times to see if the tire

is perfectly combined with the rim.

Pump the tire up to the specified tire

pressure. If there is air leak between

tire bead and rim after pumping, turn

the valve down and press the upper

side of the tire with hand to rotate the

tire and pump the air in.

After pumping with specified air

pressure, make sure if the tire bead is

well installed into the rim.

Page 17

20. HIGH-SPEED TIRE

20-16

HIGH-SPEED TIRE REPAIR

Repair the tire using the repair methods and

repair agents recommended by the

manufacturers.

REPAIR PROCEDURES

First remove the tire from the wheel.

Find the crack and mark it.

Take out foreign objects and check if the

tire can be repaired.

Tire repair

Repair methods are divided into external

and internal repairs.

Perform the external repair first and then

the internal repair.

When repair agent is used, follow the

instructions provided by the manufacturer.

Remove dust and dirt from the tire bead.

Clean out the tire inside. Recheck the

repaired portion and make sure there is no

other damage.

Install the tire and wheel rim.

• Check the rim valve when removing

the tire and wheel rim.

• The gum on the repaired portion

may not completely stick to the

tire within 24 hours after repair, be

careful to control the driving speed

for safety.

*

Loading...

Loading...