Page 1

19. SWITCHES/HORN/FUEL UNIT/THERMOSTATIC SWITCH

/TEMPERATURE GAUGE/INSTRUMENTS/LIGHTS

19-0

19

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

SWITCHES/HORN/FUEL UNIT/THERMOSTATIC

SWITCH/TEMPERATURE GAUGE/ INSTRUMENTS/LIGHTS

__________________________________________________________________________________

ELECTRICAL EQUIPMENT LAYOUT------------------------------ 19-1

SERVICE INFORMATION -------------------------------------------- 19-2

TROUBLESHOOTING ------------------------------------------------- 19-2

SWITCHES -------------------------------------------------------------- 19-3

HORN INSPECTION --------------------------------------------------- 19-5

FUEL UNIT-------------------------------------------------------------- 19-5

THERMOSTATIC SWITCH ------------------------------------------- 19-6

TEMPERATURE GAUGE --------------------------------------------- 19-6

INSTRUMENTS--------------------------------------------------------- 19-7

LIGHTS ------------------------------------------------------------------ 19-8

19

Page 2

19. SWITCHES/HORN/FUEL UNIT/THERMOSTATIC SWITCH

/TEMPERATURE GAUGE/INSTRUMENTS/LIGHTS

19-1

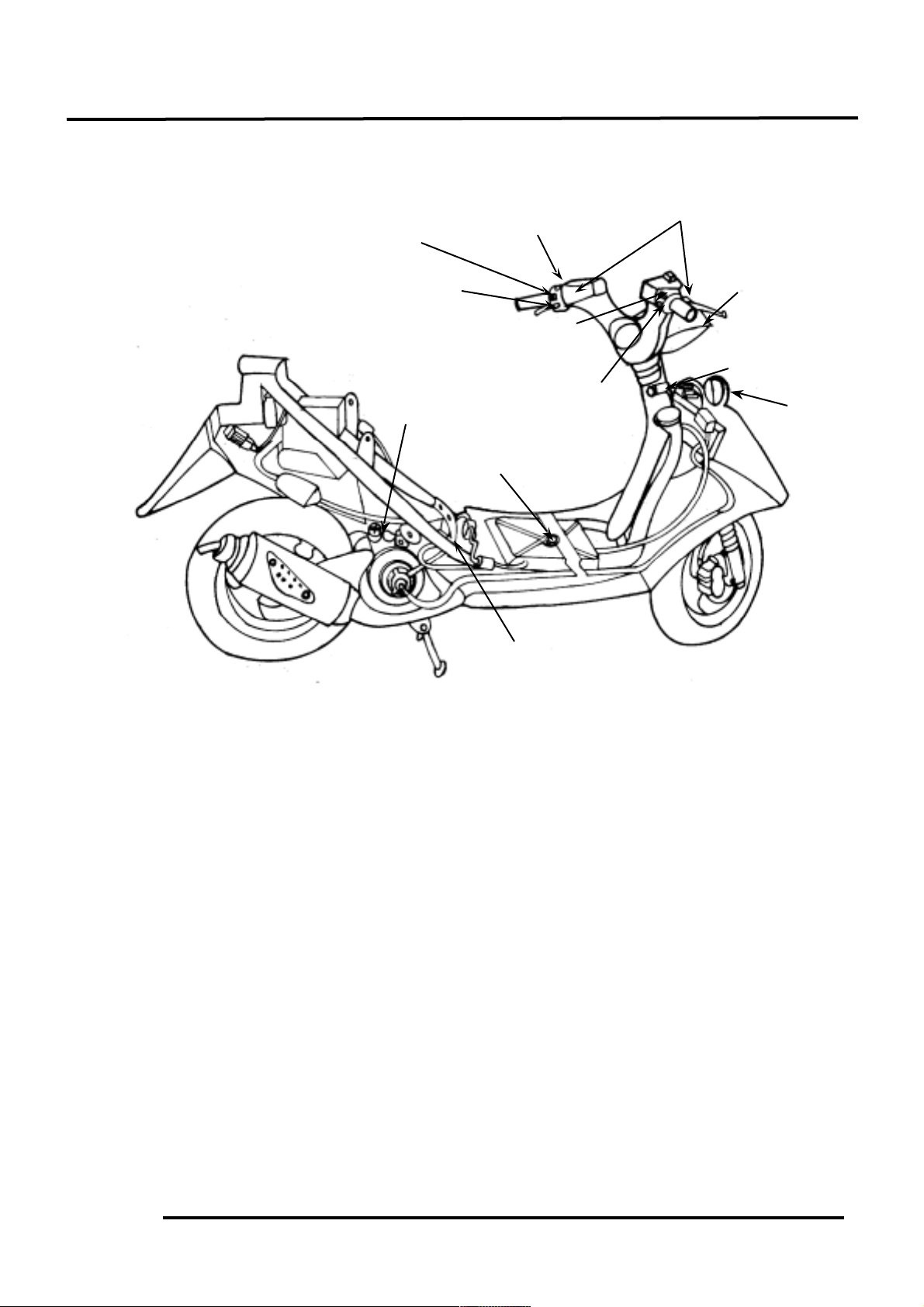

ELECTRICAL EQUIPMENT LAYOUT

Fuel Unit

Starter Button

Horn

Ignition Switch

Auto Bystarter

Thermosensor

Turn Signal Switch

Stop Switches

Horn Button

Headlight

Dimmer Switch

Instruments

Headlight

Switch

Page 3

19. SWITCHES/HORN/FUEL UNIT/THERMOSTATIC SWITCH

/TEMPERATURE GAUGE/INSTRUMENTS/LIGHTS

19-2

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• After installation of each switch, a continuity check must be performed. A continuity check can

usually be made without removing the part from the motorcycle.

TESTING INSTRUMENT

Electric tester

SPECIAL TOOL

Fuel unit wrench

TROUBLESHOOTING

Lights do not come on when ignition Temperature gauge does not register

switch is “ON” correctly

• Burned bulb • Faulty temperature gauge

• Faulty switch • Faulty thermosensor

• Poorly connected, broken or shorted wire • Broken or shorted wire between

temperature gauge and thermosensor

Fuel gauge pointer does not move or

register correctly

• Faulty fuel gauge

• Faulty fuel unit

• Poorly connected wire between fuel

gauge and fuel unit

• Fuse burned out

SPECIFICATIONS

Fuse 20A

Headlight bulb 12V 35W/35W

Turn signal light bulb 12V 10W

Stoplight/taillight 12V 5W

License plate light 12V 3.4W

Instrument light 12V 1.7W

Position light 12V 3W/5W

Turn signal indicator light 12V 10W

Page 4

19. SWITCHES/HORN/FUEL UNIT/THERMOSTATIC SWITCH

/TEMPERATURE GAUGE/INSTRUMENTS/LIGHTS

19-3

SWITCHES

IGNITION SWITCH INSPECTION

Remove the frame front covers. (2-5)

Disconnect the ignition switch wire couplers.

Check for continuity between the wire

terminals.

Color

Position

R

B/WGB

LOCK

○

○

OFF

○

○

ON○○

HEADLIGHT SWITCH INSPECTION

Remove the frame front covers. (2-5)

Disconnect the headlight switch wire

couplers. Check for continuity between the

wire terminals.

Color

Position

Y

BR/W

BR

L/W

P

○

○

P

○○○

H

○○○

STARTER SWITCH INSPECTION

Remove the frame front covers. (2-5)

Disconnect the starter switch wire couplers.

Depress the starter button and check for

continuity between the wire terminals.

Color

Position

Y/R

G

FREE

PUSH

○

○

PASSING SWITCH

Remove the front upper cover. (2-5)

Disconnect the headlight switch wire

couplers. Check for continuity between the

passing switch wire terminals.

Color

Position

L

L/W

FREE

PUSH

○

○

Passing Switch

Ignition Switch

Headlight Switch

G

B

B/W

G

R

BR

Y

L/W

P

G

Y/R

L

L/W

Starter Switch

Passing

Page 5

19. SWITCHES/HORN/FUEL UNIT/THERMOSTATIC SWITCH

/TEMPERATURE GAUGE/INSTRUMENTS/LIGHTS

19-4

HORN BUTTON INSPECTION

Remove the frame front covers. (2-5)

Disconnect the horn wire couplers.

Depress the horn button and check for

continuity between the wire terminals.

Color

Position

LG

BR/L

FREE

PUSH

○

○

TURN SIGNAL SWITCH INSPECTION

Remove the frame front covers. (2-5)

Disconnect the turn signal switch wire

couplers and turn on the turn signal switch.

Check for continuity between the wire

terminals.

Color

Position

SBOGR

L

○

○

N

R

○

○

DIMMER SWITCH INSPECTION

Remove the frame front covers. (2-5)

Disconnect the headlight dimmer switch wire

couplers.

Turn on the dimmer switch and check for

continuity between the wire terminals.

Color

Position

L/W

L

W

LO

○

○

N○○

○

HI

○

○

STOP SWITCH INSPECTION

Remove the frame front covers. (2-5)

Disconnect the front/rear stop switch wire

couplers.

Check for continuity between the wire

terminals when the front brake lever is

applied.

Color

Position

BR/L

G/Y

FREE

APPLY

○

○

Horn Button

Turn Signal Switch

Dimmer Switch

Stop Switch

BR/L

G/Y

W

L/W

L

SBOGR

LG

BR/L

Page 6

19. SWITCHES/HORN/FUEL UNIT/THERMOSTATIC SWITCH

/TEMPERATURE GAUGE/INSTRUMENTS/LIGHTS

19-5

HORN INSPECTION

Remove the front upper cover. (2-5)

Disconnect the horn wire couplers.

The horn is normal if it sounds when a 12V

battery is connected across the horn wire

terminals.

FUEL UNIT

FUEL UNIT INSPECTION

Remove the fuel unit.

Disconnect the fuel unit wire connectors.

Measure the resistance between the fuel unit

wire terminals with the float at upper and

lower positions.

Wire Terminals

Upper

Lower

Y/W_ G

33_ 45Ω

500_ 850Ω

L/W_ G

400_ 700Ω

100_ 200Ω

Y/W_ L/W

450_ 750Ω

450_ 750Ω

FUEL GAUGE INSPECTION

Connect the fuel unit wire connectors and

turn the ignition switch “ON”.

Check the fuel gauge needle for correct

indication by moving the fuel unit float up

and down.

Float Position

Needle Position

Upper

“F” (Full)

Lower

“E” (Empty)

Wire Terminals

Needle Position

Y/W_ G

From E to F

L/W_ G

From F to E

The fuel gauge is normal if it operates as

above indicated. If not, check for loosely

tightened nuts, poorly connected terminals or

shorted wires.

Fuel Unit

Before performing the following test,

operate the turn signals to determine that

the battery circuit is normal.

*

Horn

12V Battery

Lower

Upper

Lower

Upper

Upper

Fuel Gauge

Lower

Needle moves

from F to E.

Page 7

19. SWITCHES/HORN/FUEL UNIT/THERMOSTATIC SWITCH

/TEMPERATURE GAUGE/INSTRUMENTS/LIGHTS

19-6

OIL METER

INSPECTION

Remove the met-in box. (2-4)

Remove the frame body cover. (2-4)

Disconnect the oil meter wire connectors

and remove the oil meter. Keep the oil

meter float at the lower position.

Measure the resistances between the wire

terminals as and shown in the left

figure.

Wire Terminals

Resistance

Green/Red(+)_ Black(-)

5_ 16Ω

Green(-)_ Black(+)

∞

Oil Meter Operation Inspection

Connect the oil meter wire connectors and

turn the ignition switch ON.

Measure the resistance between the wire

terminals with the float at upper position.

Green/Red(+)_ Black(-)

About 340Ω

TEMPERATURE GAUGE

Disconnect the wire from the thermosensor

and ground it to the engine.

Turn the ignition switch ON.

The temperature gauge needle should move

all the way to “H”.

Do not leave the thermosensor wire

grounded for longer than 5 seconds or

the temperature gauge will be damaged.

*

Before performing the following test,

operate the turn signals to determine

that the battery circuit is normal.

*

Before removing the oil meter, be sure to

drain the motor oil and do not allow

sparks or flames near the working area.

*

Light OFF

Light ON

Oil Meter

Float

G/RBB

G

G

Page 8

19. SWITCHES/HORN/FUEL UNIT/THERMOSTATIC SWITCH

/TEMPERATURE GAUGE/INSTRUMENTS/LIGHTS

19-7

INSTRUMENTS

REMOVAL

Remove the front upper cover. (2-5)

Disconnect the instrument wire couplers and

connectors.

Disconnect the speedometer cable.

Remove the four instrument cover and leg

shield screws.

Remove the two instrument holder bolts.

Remove the instruments.

DISASSEMBLY/ASSEMBLY

Remove the three instrument holder nuts.

Remove the holder.

Remove the four screws to disassemble the

instruments and instrument cover .

Assemble the instruments in the reverse order

of disassembly.

INSTALLATION

The installation sequence is the reverse of

removal.

Wire Couplers

Speedometer Cable

Screws

Holder Bolts

Screws

Screws

Page 9

19. SWITCHES/HORN/FUEL UNIT/THERMOSTATIC SWITCH

/TEMPERATURE GAUGE/INSTRUMENTS/LIGHTS

19-8

LIGHTS

HEADLIGHT BULB REPLACEMENT

Remove the front upper cover. (2-5)

Disconnect the headlight and turn signal light

wire couplers.

Remove the rubber boot from the bulb socket.

Remove the bulb socket and replace the bulb.

Install the bulb socket, aligning the bulb

socket tab with the groove.

Install the rubber boot.

Install the front cover in the reverse order of

removal.

FRONT POSITION LIGHT BULB

REPLACEMENT

Remove the front upper cover. (2-5)

Disconnect the headlight and turn signal light

wire couplers.

Remove the bulb sockets by turning them

counterclockwise.

Remove the bulbs and replace them with new

ones.

FRONT TURN SIGNAL LIGHT BULB

REPLACEMENT

Remove the two screws attaching the turn

signal light shell and remove the light shell.

Remove the bulb and replace with a new one.

TAILLIGHT/REAR TURN SIGNAL LIGHT

BULB REPLACEMENT

Remove the rear protective cover. (2-3)

Remove the two screws attaching the rear

light shell and remove the light shell.

Remove the bulbs and replace with new ones.

The installation sequence is the reverse of

removal.

Screws

Front Position Light Bulb Sockets

Wire

Bulb Socket

Screws

Wire

Loading...

Loading...