Page 1

16. BATTERY/CHARGING SYSTEM

16-0

16

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

BATTERY/CHARGING SYSTEM

__________________________________________________________________________________

CHARGING SYSTEM LAYOUT-------------------------------------- 16-1

SERVICE INFORMATION -------------------------------------------- 16-2

TROUBLESHOOTING ------------------------------------------------- 16-3

BATTERY---------------------------------------------------------------- 16-4

CHARGING SYSTEM -------------------------------------------------- 16-5

A.C. GENERATOR INSPECTION ------------------------------------ 16-5

REGULATOR/RECTIFIER INSPECTION --------------------------- 16-6

16

Page 2

16. BATTERY/CHARGING SYSTEM

16-1

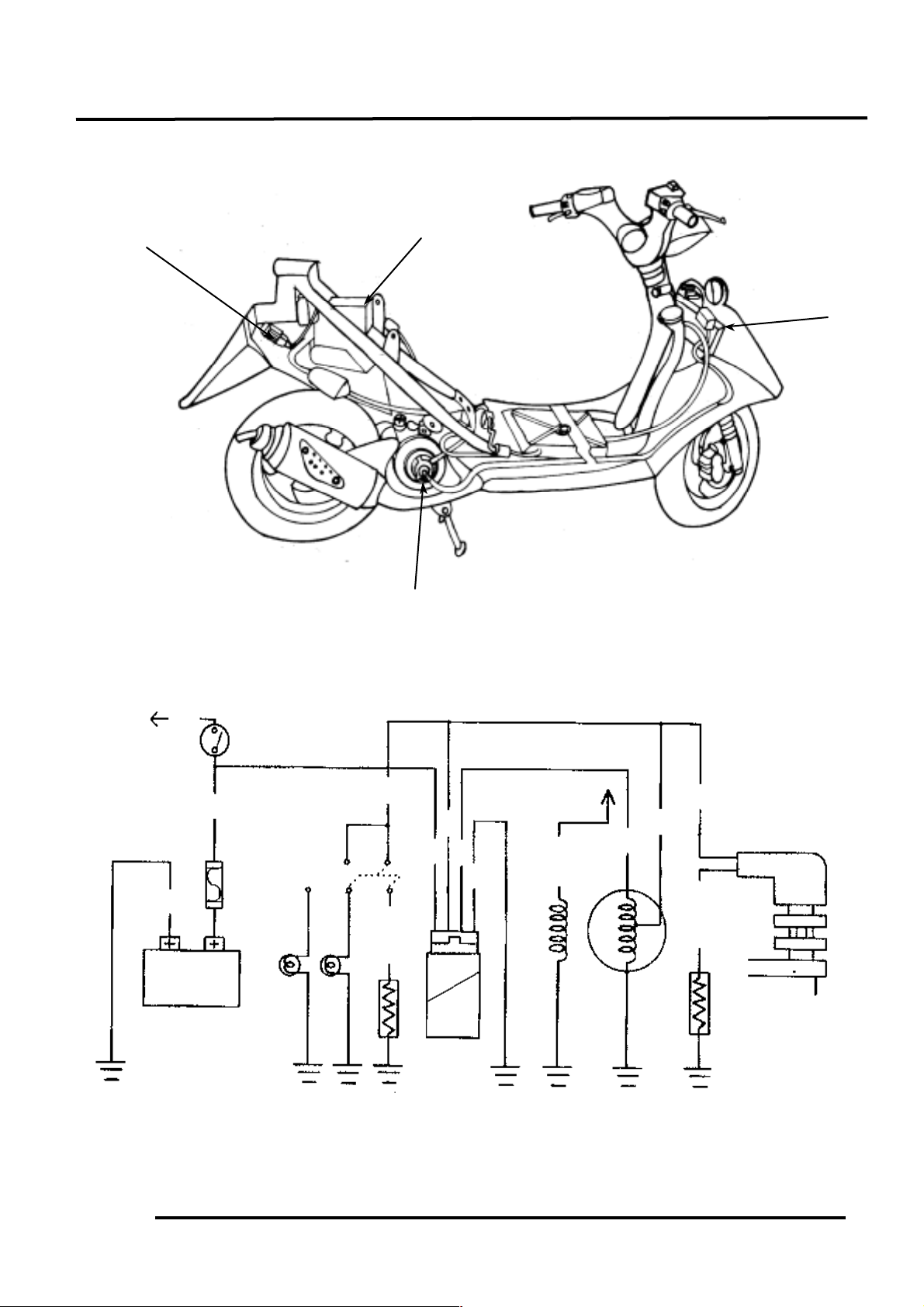

CHARGING SYSTEM LAYOUT

CHARGING CIRCUIT

Fuse

Regulator/Rectifier

A.C. Generator

Battery

Battery

Y

W

5. 9Ω

30W

Wire Harness R

GRWGR

YYY

Auto

Bystarter

Fuse

Regulator/

Rectifier

Ignition Switch

P

Resistor

Resistor

A.C. Generator

Pulser Coil

10.2Ω

5W

L/Y

G/B

Page 3

16. BATTERY/CHARGING SYSTEM

16-2

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• The battery can be charged and discharged repeatedly. If a discharged battery is not used for a

long time, its service life will be shortened. Generally, the capacity of a battery will decrease after

it is used for 2_ 3 years. A capacity-decreased battery will resume its voltage after it is

recharged but its voltage decreases suddenly and then increases when a load is added.

• When a battery is overcharged, some symptoms can be found. If there is a short circuit inside the

battery, no voltage is produced on the battery terminals. If the rectifier won‘t operate, the

voltage will become too high and shorten the battery service life.

• If a battery is not used for a long time, it will discharge by itself and should be recharged every 3

months.

• A new battery filled with electrolyte will generate voltage within a certain time and it should be

recharged when the capacity is insufficient. Recharging a new battery will prolong its service life.

• Inspect the charging system according to the sequence specified in the Troubleshooting.

• Do not disconnect and soon reconnect the power of any electrical equipment because the electronic

parts in the regulator/rectifier will be damaged. Turn off the ignition switch before operation.

• It is not necessary to check the MF battery electrolyte or fill with distilled water.

• Check the load of the whole charging system.

• Do not quick charge the battery. Quick charging should only be done in an emergency.

• Remove the battery from the motorcycle for charging.

• When replacing the battery, do not use a traditional battery.

• When charging, check the voltage with an electric tester.

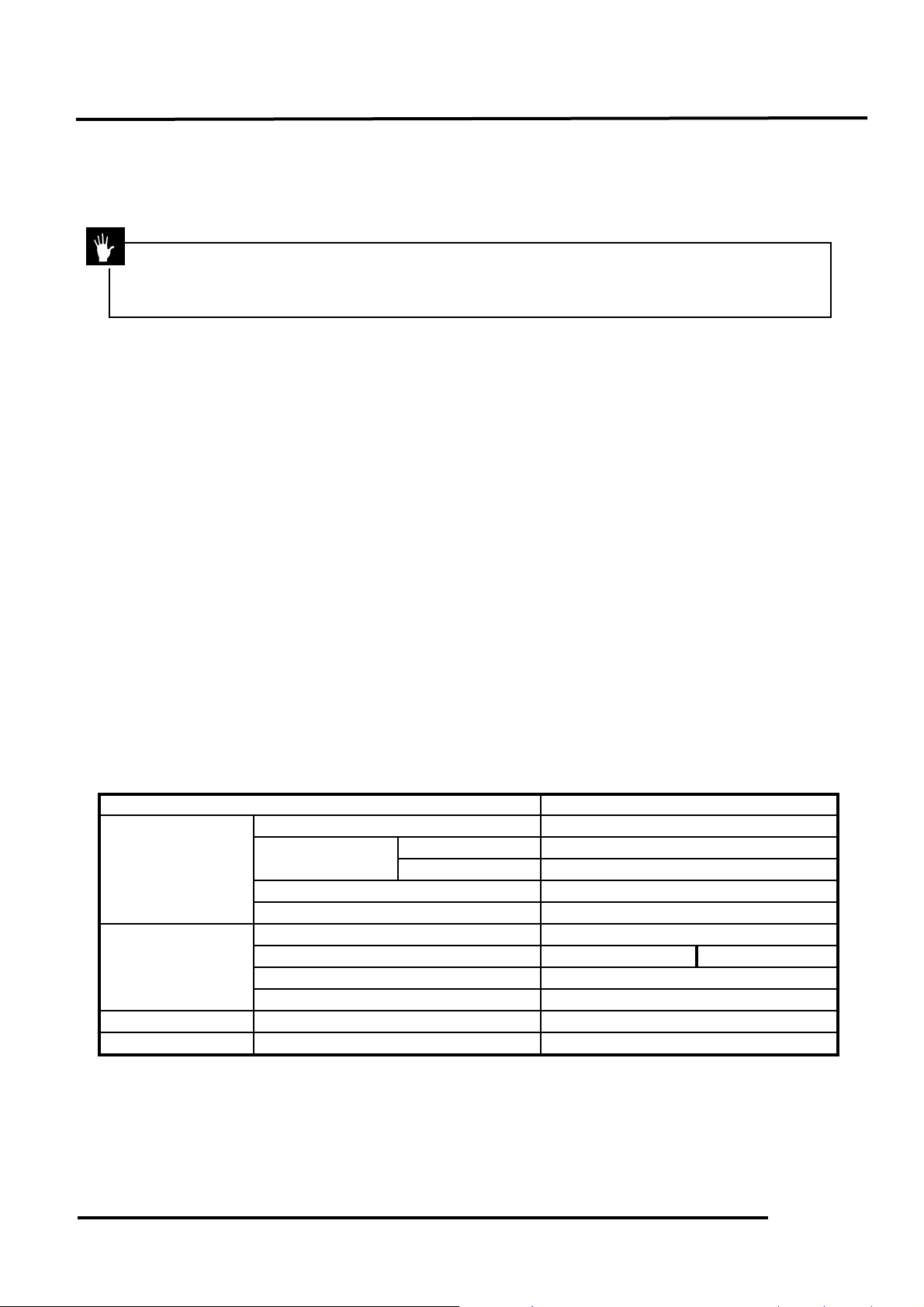

SPECIFICATIONS

Item

Standard

Capacity

12V4AH

Voltage

Fully charged

13.2V

Battery

(20℃ )

Undercharged

12.3V

Charging current

STD: 0.5A Quick: 5.0A

Charging time

STD: 5-10hr Quick: 30min

Capacity

160W/500rpm

A.C. Generator

Charging coil resistance (20℃ )

Yellow_ Yellow

0.6_ 1.6Ω

Charging rpm

1300rpm max (14V)

Charging performance

1.3A min/2500rpm 2.0A min/6000rpm

Regulator/Rectifier

Limit voltage

14.5±0.5V

TESTING INSTRUMENTS TORQUE VALUES

Ammeter Pulser coil bolt 0.5kg-m

Electric tester Coil lock bolt 0.9kg-m

Tachometer Flywheel nut 3.5_ 4.5kg-m

The battery electrolyte (sulfuric acid) is poisonous and may seriously damage the skin and

eyes. Avoid contact with skin, eyes, or clothing. In case of contact, flush with water and get

prompt medical attention

Page 4

16. BATTERY/CHARGING SYSTEM

16-3

SPECIAL TOOLS

Universal holder

Flywheel puller

TROUBLESHOOTING

No power Intermittent power

• Dead battery • Loose battery cable connection

• Disconnected battery cable • Loose charging system connection

• Fuse burned out • Loose connection or short circuit in

• Faulty ignition switch

ignition system

Low power Charging system failure

• Weak battery • Loose, broken or shorted wire or connector

• Loose battery connection • Faulty regulator/rectifier

• Charging system failure • Faulty A.C. generator

• Faulty regulator/rectifier

Page 5

16. BATTERY/CHARGING SYSTEM

16-4

BATTERY

Remove the seat and met-in box. (2-3)

Remove the battery.

First disconnect the battery negative (-) cable

and then the positive (+) cable.

The installation sequence is the reverse of

removal.

BATTERY VOLTAGE INSPECTION (OPEN

CIRCUIT VOLTAGE)

Disconnect the battery cables.

Measure the voltage between the battery

terminals.

Fully charged : 13.2V

Undercharged : 12.3V max.

CHARGING

Connect the charger positive (+) cable to the

battery positive (+) terminal.

Connect the charger negative (-) cable to the

battery negative (-) terminal.

Charging current : Standard : 0.5A

Quick : 5A

Charging time : Standard : 5_ 10 hours

Quick : 30 minutes

After charging: Open circuit voltage: 12.8V min.

• Quick charging should only be done in

an emergency.

• Measure the voltage 30 minutes after

the battery is charged.

*

Battery charging inspection must be

performed with a voltmeter.

*

When disconnecting the battery positive

(+) cable, do not touch the frame with

tool; otherwise it will cause short circuit

and sparks to fire the fuel.

First connect the positive (+) cable and then

negative (-) cable to avoid short circuit.

• Keep flames and sparks away

from a charging battery.

• Turn power ON/OFF at the

charger, not at the battery terminals to

prevent sparks near the battery.

• Charge the battery according to

the current specified on the battery.

• During quick charging, the

battery temperature should not exceed

Page 6

16. BATTERY/CHARGING SYSTEM

16-5

CHARGING SYSTEM

CURRENT TEST

Warm up the engine before taking readings.

Connect an electric tester across the battery

terminals.

Disconnect the red wire from the fuse

terminal and connect an ammeter between the

red wire lead and the fuse terminal.

Attach a tachometer to the engine.

Start the engine and gradually increase the

engine speed to measure the limit voltage and

current.

Limit Voltage/Current: 14_ 15V/0.5A

max. (5000rpm

max.)

If the limit voltage is not within the specified

range, check the regulator/rectifier.

PERFORMANCE TEST

Engine Speed

2500rpm

6000rpm

Charging Current

1.3A min.

2.0A min.

If the readings do not meet the specified

values, check the regulator/rectifier.

A.C. GENERATOR INSPECTION

Remove the met-in box. (2-4)

Disconnect the A.C. generator connector.

Measure the resistances between the charging

coil terminals (white–blue/yellow) and

lighting coil terminals (yellow–green).

Resistances:

Charging coil

white–green

0.2_ 1.2Ω

Lighting coil

yellow–green

0.3_ 1.0Ω

Use a fully charged battery (12.8V min.)

to check the charging system.

*

When measuring the charging current,

disconnect the wire from the

regulator/rectifier wire coupler.

*

A.C. Generator Connector

Inspect with the engine installed.

*

Red Wire

Page 7

16. BATTERY/CHARGING SYSTEM

16-6

RESISTOR INSPECTION

Remove the frame front cover. (2-3)

Measure the resistance between the resistor B

pink wire and ground.

Measure the resistance between the resistor

A green/black wire and ground.

Resistances:

Resistor A: 9.9_ 10.5Ω

Resistor B: 5.6_ 6.2Ω

REGULATOR/RECTIFIER

INSPECTION

Remove the frame body cover. (2-3)

Disconnect the regulator/rectifier wire coupler

and remove the bolt to remove the

regulator/rectifier.

Measure the resistances between the

terminals.

Replace the regulator/rectifier if the readings

are not within the specifications in the table

below.

Model

Brand

Range

SP-10D

Sanwa

KΩ

TH-5H

Kowa

100Ω

Probe⊕

Probe(-)

A (R)

B (W)

C (Y)

D (G)

A (R)

∞∞∞

B (W)

3-10KΩ

∞

∞

C (Y)

∞

∞

33-35KΩ

D (G)

∞

∞

33-35KΩ

• Due to the semiconductor in circuit, it

is necessary to use a specified tester

for accurate testing. Use of an

improper tester in an improper range

may give false readings.

• Use a Sanwa Electric Tester (07208-

0020000) or Kowa Electric Tester

(TH-5H). The proper range for

testing is listed below.

*

Coupler

Faulty resistor is the cause of faulty

operation of the auto bystarter.

*

A (Red)

C (Yellow)

D (Green)

B (White)

Resister A

Resister B

Regulator/Rectifier

Bolt

Loading...

Loading...