Page 1

8. FINAL REDUCTION

8-0

8

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

FINAL REDUCTION

__________________________________________________________________________________

SERVICE INFORMATION........................................................ 8-2

TROUBLESHOOTING.............................................................. 8-2

FINAL REDUCTION DISASSEMBLY....................................... 8-3

FINAL REDUCTION INSPECTION........................................... 8-3

FINAL REDUCTION ASSEMBLY............................................. 8-6

8

Page 2

8. FINAL REDUCTION

8-1

Page 3

8. FINAL REDUCTION

8-2

SERVICE INFORMATION

Specified Oil: SAE90#

At disassembly: 0.12 liter

At change: 0.1 liter

SPECIAL TOOLS

Bearing remover set, 12mm

Bearing remover set, 15mm

Crankcase assembly collar

Crankcase assembly shaft

Bearing outer driver, 37x40mm

Bearing outer driver, 32x35mm

Bearing driver pilot, 17mm

Bearing driver pilot, 15mm

Bearing driver pilot, 12mm

Bearing outer driver handle A

TROUBLESHOOTING

Engine starts but motorcycle won‘t move

• Damaged transmission

• Seized or burnt transmission

Abnormal noise

• Worn, seized or chipped gears

• Worn bearing

Oil leaks

• Oil level too high

• Worn or damaged oil seal

Page 4

8. FINAL REDUCTION

8-3

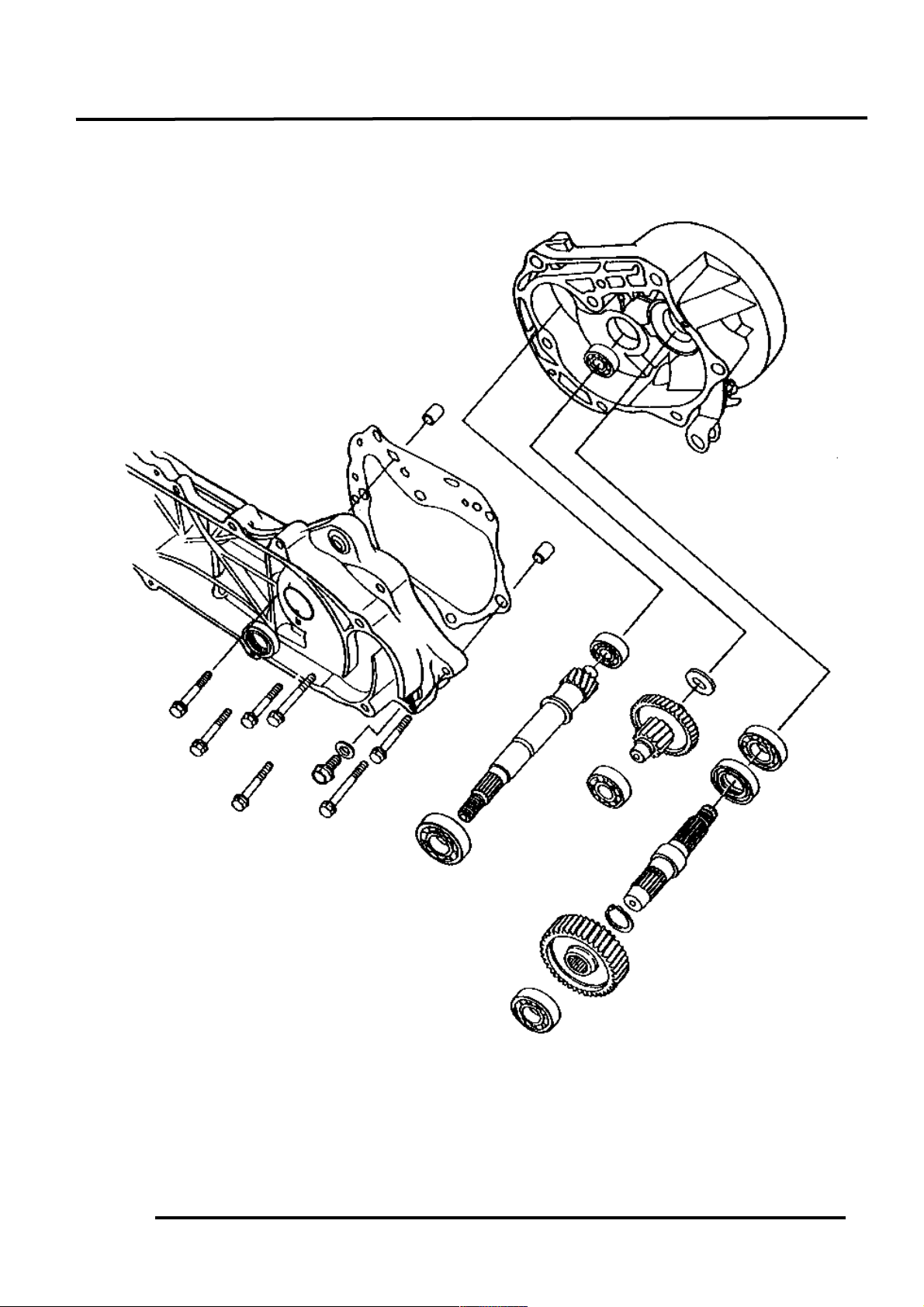

FINAL REDUCTION DISASSEMBLY

Remove the rear wheel. (14-3)

Remove the left crankcase cover. (7-3)

Remove the clutch/driven pulley. (7-12)

Drain the transmission gear oil into a clean

container.

Remove the transmission case cover

attaching bolts.

Remove the transmission case cover.

Remove the gasket and dowel pins.

Remove the final gear and countershaft.

FINAL REDUCTION INSPECTION

Inspect the countershaft and gear for wear

or damage.

Dowel Pin

Final Gear

Countershaft

Dowel Pin

Countershaft

Driver shift

Driver shift

Bolts

Page 5

8. FINAL REDUCTION

8-4

Inspect the final gear and final shaft for

wear, damage or seizure.

Check the left crankcase bearings for

excessive play and inspect the oil seal for

wear or damage.

Inspect the drive shaft and gear for wear or

damage.

Check the transmission case cover bearings

for excessive play and inspect the final

shaft bearing oil seal for wear or damage.

Do not remove the transmission case

cover except for necessary part replacement. When replacing the drive shaft,

also replace the bearing and oil seal.

*

Final Shaft Bearing

Final Shaft

Drive Shaft Bearing

Countershaft Bearing

Oil Seal

Countershaft

Drive Shaft Bearing

Page 6

8. FINAL REDUCTION

8-5

BEARING REPLACEMENT

(Transmission Case Cover)

Remove the transmission case cover

bearings using the bearing remover.

Remove the final shaft oil seal.

Drive new bearings into the transmission

case cover.

BEARING REPLACEMENT (Left

Crankcase Cover)

Remove the drive shaft.

Remove the drive shaft oil seal.

Remove the left crankcase bearings using

the bearing remover.

Drive Shaft Bearing

Bearing Outer Driver, 32x35mm

Bearing Remover Set

Bearing Remover Set, 12mm

Bearing Outer Driver Handle A

Page 7

8. FINAL REDUCTION

8-6

Drive new bearings into the left crankcase.

Install a new drive shaft oil seal.

FINAL REDUCTION ASSEMBLY

Install the drive shaft into the left

crankcase.

Install the final gear and final shaft into the

left crankcase.

Drive Shaft

Bearing Outer Driver

Page 8

8. FINAL REDUCTION

8-7

Install the countershaft and gear into the left

crankcase.

Install the resin washer onto the countershaft.

Install the dowel pins and a new gasket.

Install the transmission case cover.

Install and tighten the transmission case

cover bolts.

Install the clutch/driven pulley. (7-16)

Install other removed parts in the reverse

order of removal.

Resin Washer

Countershaft

Transmission Case Cover

Bolts

Dowel Pins

Page 9

8. FINAL REDUCTION

8-8

After installation, fill the transmission case

with the specified oil.

Specified Gear Oil: SAE90#

Oil Capacity: at disassembly: 0.12 liter

at change: 0.1 liter

Install and tighten the oil check bolt.

Torque: 1.0_ 1.5kg-m

Start the engine and check for oil leaks.

Check the oil level from the oil check bolt

hole and add the specified oil to the proper

level if the oil level is low.

• Place the motorcycle on its main stand

on level ground.

• Check the sealing washer for wear or

damage.

*

Drain Bolt

Oil Check Bolt Hole/Filler

Loading...

Loading...