Page 1

20. EXHAUST EMISSION CONTROL

SYSTEM

20-0

DINK 20 0

20

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

EXHAUST EMISSION CONTROL SYSTEM

__________________________________________________________________________________

SCHEMATIC DRAWING ............................................................ 20-1

EXHAUST EMISSION CONTROL SYSTEM FUNCTION............. 20-1

TROUBLESHOOTING ................................................................ 20-2

SERVICE INFORMATION .......................................................... 20-2

SECONDARY AIR CLEANER..................................................... 20-3

AIR INJECTION CUT-OFF VALVE (A.I.C.V.)............................. 20-3

REED VALVE ............................................................................ 20-4

20

Page 2

20. EXHAUST EMISSION CONTROL

SYSTEM

20-1

DINK 20 0

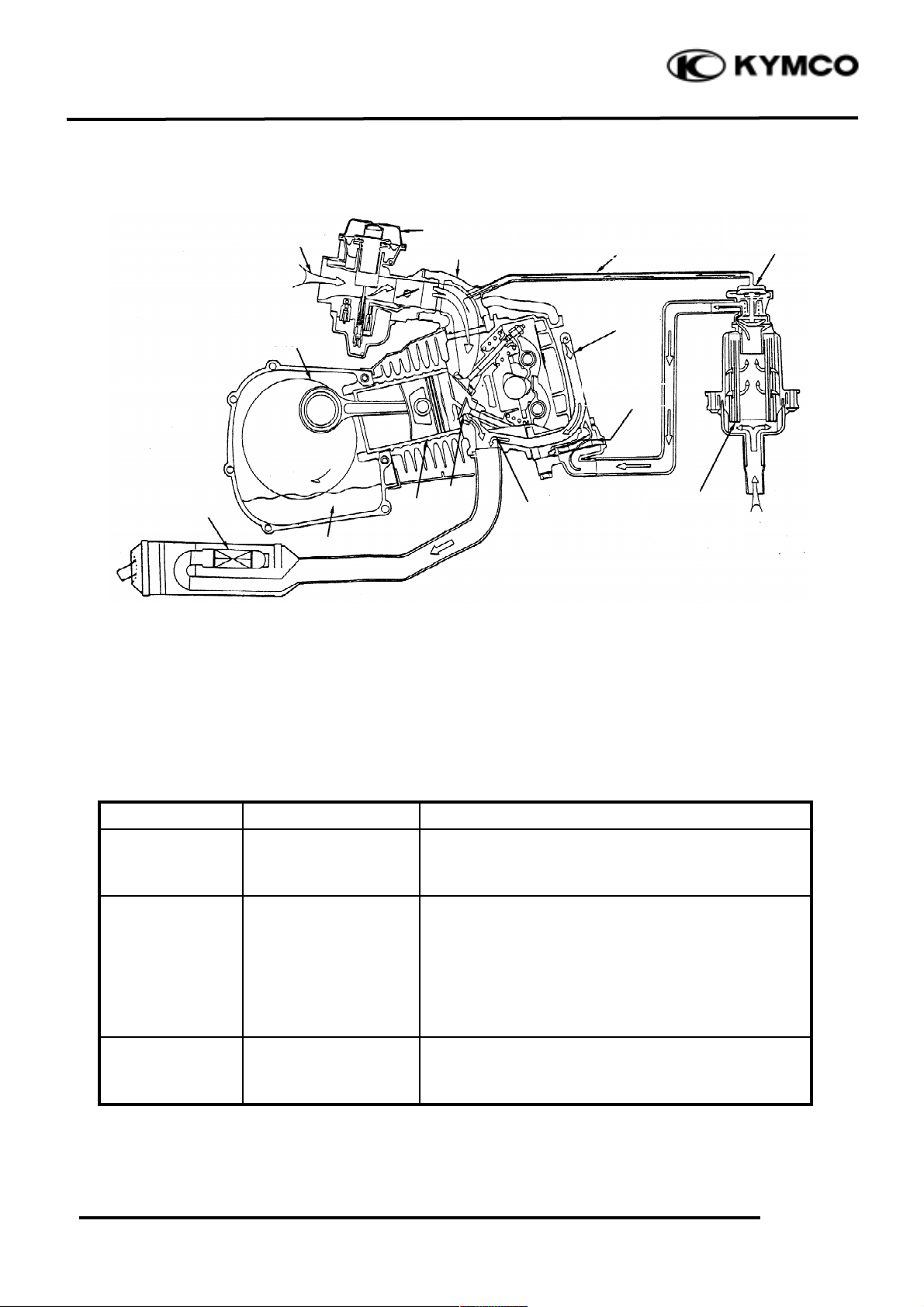

SCHEMATIC DRAWING

EXHAUST EMISSION CONTROL SYSTEM

The exhaust emission control system adopted in this model utilizes the reed valve to draw

secondary air into the exhaust system for re-combustion by means of exhaust pulsation so as to

minimize the exhaust emission.

FUNCTION

Item

Purpose

Function

Secondary Air

Cleaner

Filter secondary air.

It filters the fresh air drawn for re-burning to

prevent dirt or dust from affecting the operation of

the air injection cut-off valve.

Air Injection Cutoff Valve

Prevent exhaust

muffler noise and

backfiring at sudden

deceleration.

The air injection cut-off valve usually opens to lead

air into the exhaust muffler in which air is reburned to reduce CO. When the throttle valve

closes suddenly, the air injection cut-off valve is

actuated by vacuum to close and cut off secondary

air in order to prevent exhaust muffler backfiring

due to air in the exhaust system.

Reed Valve

Control the secondary

air inlet to reduce CO.

When the motorcycle speed is less than 50km per

hour, the reed valve operates to draw secondary air

into the exhaust system for re-combustion.

Secondary

Air Cleaner

Carburetor

Reed Valve

Air Injection

Cut-off Valve

Vacuum

Secondary Air

Cleaner Into

Hole

Page 3

20. EXHAUST EMISSION CONTROL

SYSTEM

20-2

DINK 20 0

TROUBLESHOOTING

High CO at idle speed

1. Damaged or clogged reed valve

2. Damaged or clogged air injection cut-off valve

3. Clogged air cleaner

Backfiring at sudden deceleration

1. Damaged reed valve (malfunction)

2. Faulty air injection cut-off valve (unable to close)

3. Carburetor incorrectly adjusted

4. Faulty air cut-off valve

5. Leaking vacuum tube

Exhaust muffler noise

1. Faulty air injection cut-off valve

2. Broken vacuum tube

3. Faulty reed valve

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• During operation, be careful to avoid scalding caused by the exhaust muffler.

• Note the locations of tubes for proper installation.

• Replace any damaged tube with a new one.

• Make sure to tighten the connector of each tube securely

TOOLS

• Vacuum pump

SPECIFICATIONS

Air injection cut-off valve actuating pressure-

250mm/Hg- 30 liter/min.

Reed valve stopper clearance- 4.6mm

Page 4

20. EXHAUST EMISSION CONTROL

SYSTEM

20-3

DINK 20 0

SECONDARY AIR CLEANER /

AIR INJECTION CUT-OFF

VALVE (A.I.C.V.)

REMOVAL

Remove the seat. (2-4)

Remove the body cover.

Disconnect the secondary air cleaner

/(A.I.C.V) connecting tube.

INSPECTION

Inspect the air injection cut-off valve flow

using a vacuum pump. If the flow is not

within the specified values, replace with a

new one.

The flow should be at least 30 liter/min

when a vacuum of 250mm/Hg is applied.

The flow should be at least 1.6 liter/min

when a vacuum of 320mm/Hg is applied.

Check each connecting tube for cracks or

damage and replace if necessary.

INSTALLATION

The installation sequence is the reverse of

removal.

• The secondary air cleaner must be

assembled and installed properly to

avoid dust entering the air cleaner.

• When installing, be careful not to

bend or twist the tubes and check

for proper installation.

• The tube length is very important to

its performance, use the tube of

same specification for replacement.

*

Air Inlet Tube

Bolt

Secondary Air Cleaner / A.I.C.V.

Air Outlet Tube

Air Inlet Tube

Air Outlet Tube

Bolt

Vacuum Tube

Bolt

Vacuum Tube

Bolt

Page 5

20. EXHAUST EMISSION CONTROL

SYSTEM

20-4

DINK 20 0

REED VALVE

REMOVAL

Remove the frame center cover.

Remove the floor board cover.

Disconnect the secondary air inlet tube

connector.

Remove the reed valve cover three bolts and

two secondary air outlet tube bolts.

Remove the three bolts attaching the reed

valve cover and the reed valve.

INSPECTION

Check the reed valve for cracks, damage, big

clearance or weak reeds. Replace if

necessary.

Check the gasket and O-ring for damage or

deterioration and replace if necessary.

Reed valve stopper clearance: 4.6mm

INSTALLATION

Install the reed valve in the reverse order of

removal.

Cylinder Head Cover

Bolt

Secondary Air Inlet Tube Bolt

Reed Valve

Reed Stopper

Reed Valve Cover

Bolt

• When installing, be careful not to bend

or twist the tubes and check for

proper installation.

*

Loading...

Loading...