Page 1

13. FUEL SYSTEM/CARBURETOR/FUEL PUMP

13-0

DINK 20 0

13

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

FUEL SYSTEM/CARBURETOR/FUEL PUMP

__________________________________________________________________________________

SCHEMATIC DRAWING ---------------------------------------------- 13- 1

SERVICE INFORMATION -------------------------------------------- 13- 4

TROUBLESHOOTING ------------------------------------------------- 13- 4

CARBURETOR REMOVAL ------------------------------------------- 13- 6

VACUUM CHAMBER DISASSEMBLY------------------------------ 13- 6

FLOAT CHAMBER DISASSEMBLY--------------------------------- 13- 8

AUTO BYSTARTER INSPECTION/REMOVAL-------------------- 13-10

AIR CUT-OFF VALVE (A.C.V.)-------------------------------------- 13-11

AUTO BYSTARTER INSTALLATION ------------------------------ 13-13

FLOAT CHAMBER ASSEMBLY ------------------------------------- 13-14

FLOAT LEVEL INSPECTION ---------------------------------------- 13-15

VACUUM CHAMBER ASSEMBLY ---------------------------------- 13-15

CARBURETOR INSTALLATION ------------------------------------ 13-16

FUEL PUMP REMOVAL/DISASSEMBLY -------------------------- 13-17

FUEL PUMP INSPECTION-------------------------------------------- 13-18

FUEL PUMP ASSEMBLY --------------------------------------------- 13-18

FUEL PUMP INSTALLATION --------------------------------------- 13-19

13

Page 2

13. FUEL SYSTEM/CARBURETOR/FUEL PUMP

13-1

DINK 20 0

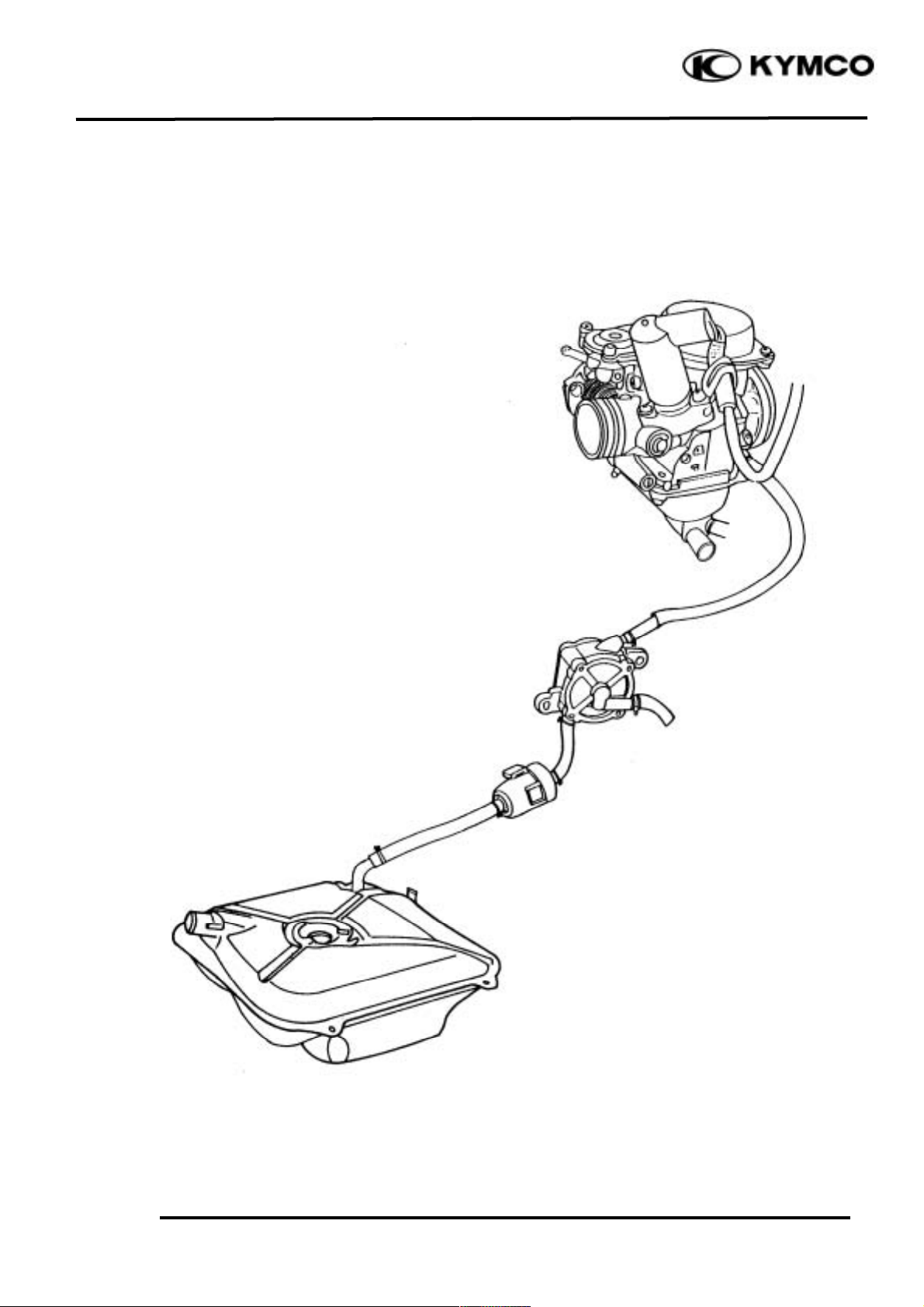

FUEL SYSTEM

Page 3

13. FUEL SYSTEM/CARBURETOR/FUEL PUMP

13-2

DINK 20 0

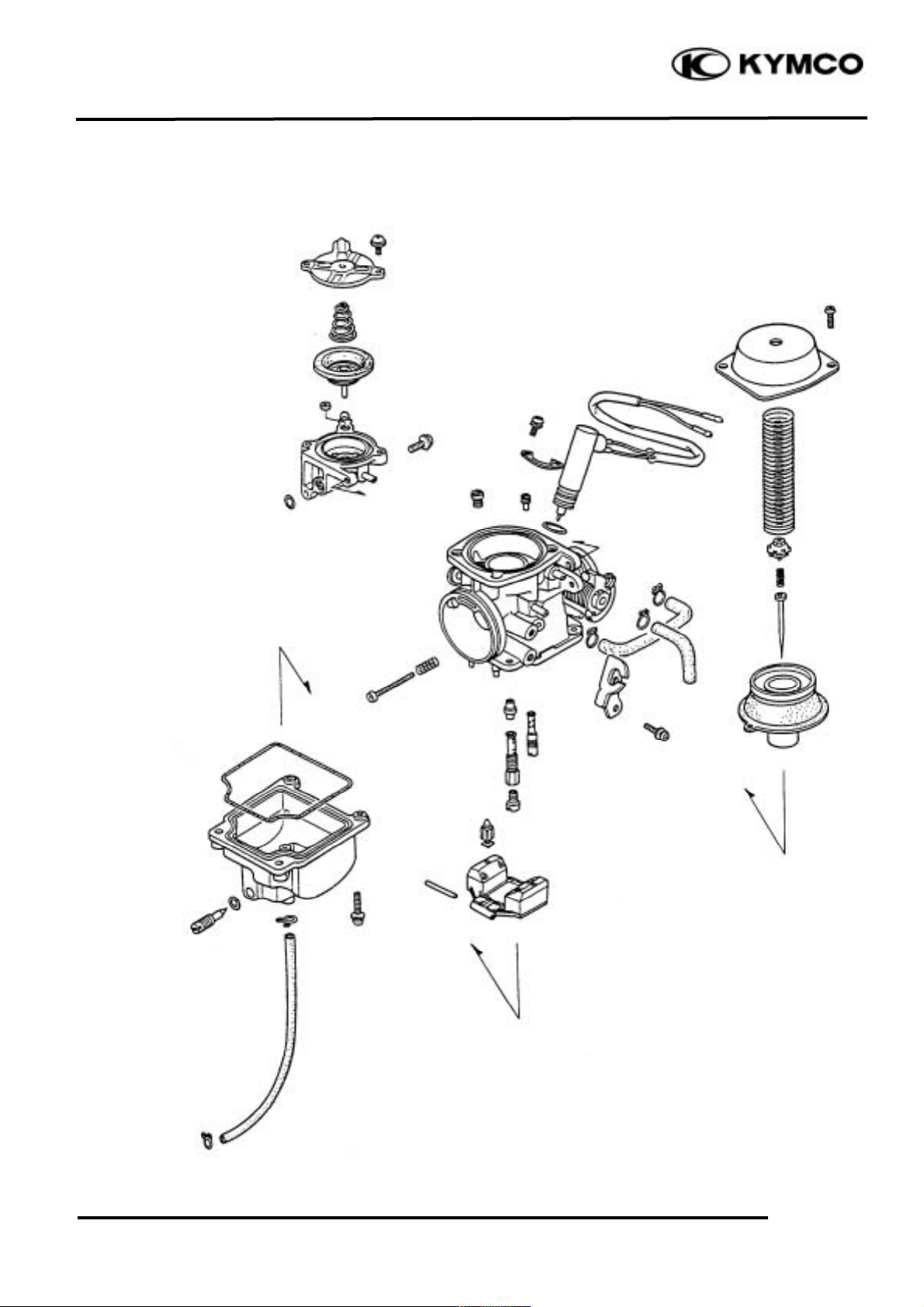

SCHEMATIC DRAWING

Page 4

13. FUEL SYSTEM/CARBURETOR/FUEL PUMP

13-3

DINK 20 0

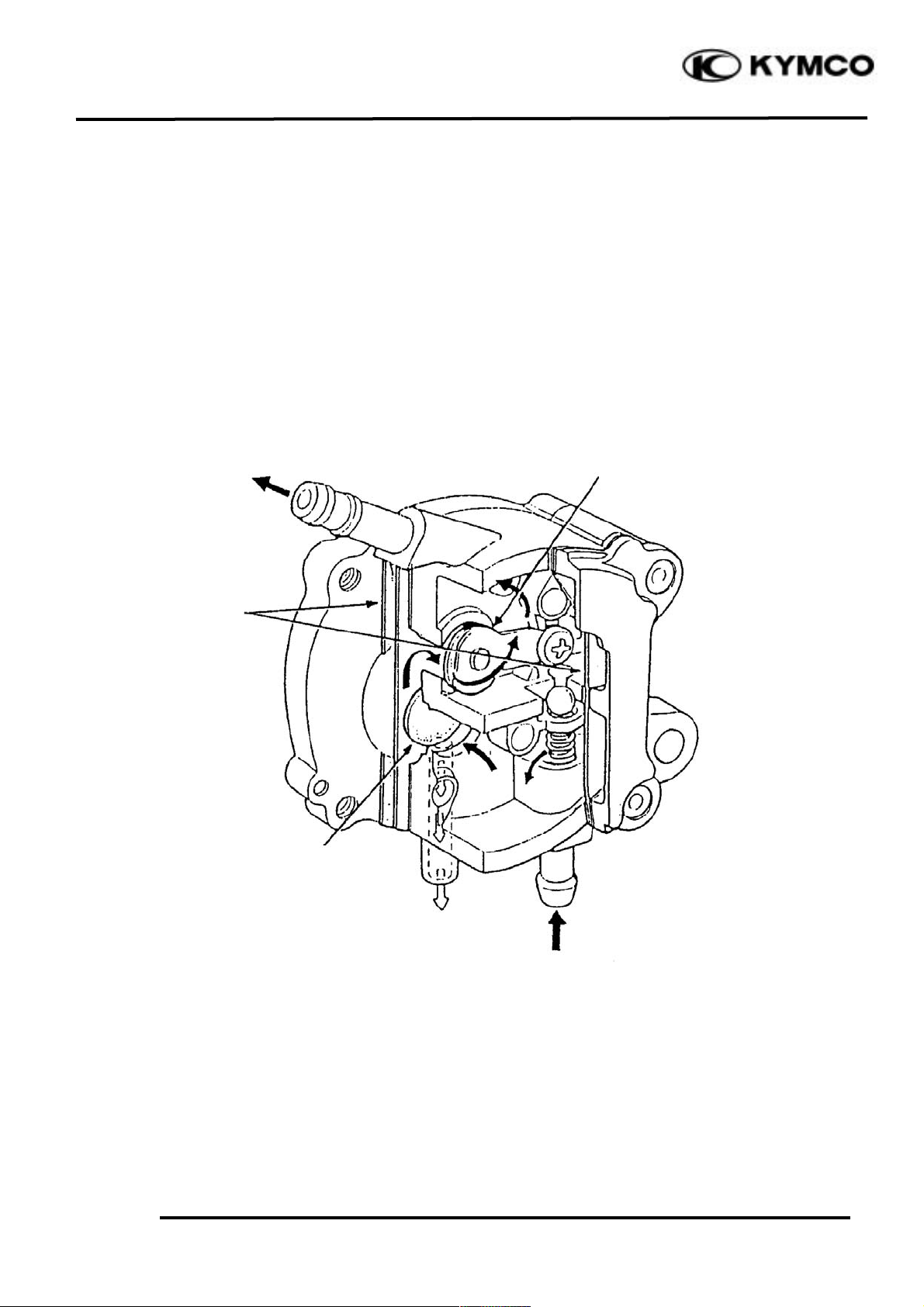

FUEL PUMP

CONSTRUCTION:

The fuel pump adopted for this model is a vacuum-type fuel pump which utilizes the positive and

negative pulsating pressures produced by the engine crankcase to control the oil pump diaphragms

and deliver fuel from the fuel tank to the carburetor through the suction valve and outlet valve.

FUEL PUMP CONSTRUCTION

Diaphragms

Inlet

Outlet

Suction Valve

Outlet Valve

Pulsating Pressure

from Crankcase

Page 5

13. FUEL SYSTEM/CARBURETOR/FUEL PUMP

13-4

DINK 20 0

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• When working with gasoline, keep away from sparks and flames.

• Note the locations of O-rings when disassembling and replace them with new ones during

assembly.

• Before float chamber disassembly, drain the residual gasoline from the float chamber.

• Do not try to disassemble the auto bystarter.

• When assembling the vacuum chamber and air cut-off valve, be careful not to damage the

diaphragms.

• All cables, fuel lines and wires must be routed and secured at correct locations.

SPECIFICATIONS

Venturi dia. (mm)

VE26

Identification number

VE090

Float level (mm)

18.5

Pilot screw opening

2±_

Main jet

102#

Slow jet

35#

Idle speed

1600±100rpm

Fuel pump output

40cc/1600rpm/10 seconds

SPECIAL TOOLS

Float level gauge

Fuel unit remover

TROUBLESHOOTING

Engine does not start Engine idles roughly, stalls or runs poorly

• No fuel in tank • Incorrect idle speed

• Restricted fuel line • Rich mixture

• Too much fuel getting to cylinder • Lean mixture

• Clogged air cleaner • Clogged air cleaner

• Contaminated fuel • Intake air leak

• Faulty fuel pump • Contaminated fuel

• Faulty air-cut off valve

• Damaged vacuum tube and connectors

• Damaged carburetor insulator

B

Page 6

13. FUEL SYSTEM/CARBURETOR/FUEL PUMP

13-5

DINK 20 0

Throttle does not open fully, so engine stalls Rich mixture

• Damaged vacuum piston diaphragm • Auto bystarter valve opens excessively

• Clogged diaphragm hole • Faulty float valve

• Float level too high

Lean mixture • Clogged air jets

• Clogged fuel jets • Auto bystarter valve set plate installed in

• Clogged fuel tank cap breather hole

the wrong groove

• Clogged fuel filter •Clogged air cleaner

• Bent, kinked or restricted fuel line

• Faulty float valve

• Float level too low

• Faulty fuel pump or insufficient output

Page 7

13. FUEL SYSTEM/CARBURETOR/FUEL PUMP

13-6

DINK 20 0

CARBURETOR REMOVAL

Remove the seat, met-in box and center

cover.

Disconnect the fuel tube and vacuum tube at

the carburetor.

Disconnect the auto bystarter wire.

Loosen the throttle cable adjusting nut and

lock nut, and disconnect the throttle cable

from the carburetor.

Loosen the air cleaner connecting tube band

and carburetor intake manifold band and then

remove the carburetor.

VACUUM CHAMBER

DISASSEMBLY

Loosen the drain screw and drain the fuel

from the float chamber.

Auto Bystarter Wire

Auto Bystarter

Fuel Tube

Intake Manifold Band

Air Cleaner Connecting Tube Band

Drain Screw

Page 8

13. FUEL SYSTEM/CARBURETOR/FUEL PUMP

13-7

DINK 20 0

Remove the two vacuum chamber cover

screws and the cover.

Remove the compression spring and vacuum

piston.

Remove the needle holder, spring and jet

needle from the piston.

VACUUM PISTON INSPECTION

Inspect the vacuum piston and jet needle for

wear or damage.

Inspect the diaphragm for deterioration and

tears.

Vacuum Chamber Cover

Diaphragm

Screws

Spring

Spring

• Be careful not to damage the vacuum

piston diaphragm.

*

Vacuum Piston

Vacuum Piston

Needle Holder

Jet Needle

Page 9

13. FUEL SYSTEM/CARBURETOR/FUEL PUMP

13-8

DINK 20 0

FLOAT CHAMBER DISASSEMBLY

Remove the four float chamber screws and

the float chamber.

Remove the float pin, float and float valve.

FLOAT VALVE INSPECTION

Inspect the float valve seat contact area for

wear.

Float Chamber

Float Valve

Float

Float Pin

Float Valve Seat

Screws

Float Valve

Page 10

13. FUEL SYSTEM/CARBURETOR/FUEL PUMP

13-9

DINK 20 0

JETS/SCREWS REMOVAL

Remove the main jet, needle jet holder and

needle jet.

Remove the slow jet.

Clean the removed the main jet, needle jet

holder, needle jet and slow jet with detergent

oil.

Pilot Screw (P.S.)

Pilot Screw

Slow Jet

• Be sure to use clean detergent oil.

*

Main Jet

Needle Jet Holder

• Before removing the pilot screw, turn

the pilot screw clockwise until it seats

lightly and record the rotating turns.

Do not force the pilot screw against its

seat to avoid seat damage.

*

Needle Jet Holder

Slow Jet

Main Jet

Page 11

13. FUEL SYSTEM/CARBURETOR/FUEL PUMP

13-10

DINK 20 0

AUTO BYSTARTER INSPECTION

/REMOVAL

AUTO BYSTARTER INSPECTION

Measure the resistance between the auto

bystarter wire terminals.

Resistance: 10Ω (10 minutes minimum

after stopping the engine)

If the reading is not within the limit, replace

the auto bystarter with a new one.

Connect a hose to the fuel enriching circuit

of the carburetor. Connect the auto

bystarter yellow wire to the positive (+)

terminal of a battery and green wire to the

negative (-) terminal. Wait 5 minutes and

blow the hose with mouth. If the passage is

blocked, the auto bystarter is normal.

Disconnect the auto bystarter from the

battery. Wait 30 minutes and blow the hose

with mouth.. If air can be blown into the

hose, the auto bystarter is normal.

AUTO BYSTARTER REMOVAL

Remove the two set plate screws and set

plate and then remove the auto bystarter

from the carburetor body.

Auto Bystarter

Screws

Set Plate

Hose

Yellow

Green

Page 12

13. FUEL SYSTEM/CARBURETOR/FUEL PUMP

13-11

DINK 20 0

AUTO BYSTARTER INSPECTION

Check the auto bystarter valve and needle

for nicks, wear or damage.

If any faulty part is found, replace the auto

bystarter with a new one.

AIR CUT-OFF VALVE (A.C.V.)

A.C.V. REMOVAL

Remove the two screws and the air cut-off

valve cover.

Remove the spring, diaphragm and O-rings.

Inspect the diaphragm and spring for wear or

damage.

Bystarter Needle

Air Cut-off Valve Cover

Bystarter Valve

Spring

Screws

Cover

Diaphragm

Page 13

13. FUEL SYSTEM/CARBURETOR/FUEL PUMP

13-12

DINK 20 0

Disconnect the hose at the valve seat.

Remove the two screws and the air cut-off

valve body.

CARBURETOR BODY CLEANING

Blow compressed air through all passages of

the carburetor body.

A.C.V. ASSEMBLY

Install the O-ring onto the air-cut-off valve

body and then install the valve body to the

carburetor with the two screws.

Hose

O-ring

Air Cut-off Valve Body

• Make sure that no fuel jet is clogged.

*

• Install the O-ring with the flat face

toward the valve body side.

*

Air Cut-off Valve Body

Screws

Page 14

13. FUEL SYSTEM/CARBURETOR/FUEL PUMP

13-13

DINK 20 0

Install the O-ring onto the air-cut-off valve

body securely.

Install the diaphragm, spring, and cover.

Install and tighten the two screws attaching

the air cut-off valve cover.

Connect the hose.

AUTO BYSTARTER INSTALLATION

Install the auto bystarter and set plate.

Install and tighten the two screws.

Auto Bystarter

Screws

• Install the O-ring with the flat face

toward the valve body side.

*

Spring

Cover

Diaphragm

O-ring

Screws

Set Plate

• Insert the auto bystarter into the

carburetor body until it bottoms and

position the set plate into the upper

groove in the bystarter.

• Install the set plate with its round face

facing down.

*

Page 15

13. FUEL SYSTEM/CARBURETOR/FUEL PUMP

13-14

DINK 20 0

FLOAT CHAMBER ASSEMBLY

Install the needle jet and needle jet holder.

Install the main jet.

Install the slow jet.

Install the pilot screw.

Install the float valve, float and float pin.

Float Valve

Float

Float Pin

Pilot Screw

Needle Jet Holder

Slow Jet Holder

Main Jet Holder

• Be sure to record the rotating turns

when it is removed.

*

Page 16

13. FUEL SYSTEM/CARBURETOR/FUEL PUMP

13-15

DINK 20 0

FLOAT LEVEL INSPECTION

Measure the float level at the location of the

main jet (just contacting the float valve).

Float Level: 18.5±1.0mm

Replace the float if the level is incorrect.

Check the operation of the float and then

reinstall the float chamber.

VACUUM CHAMBER ASSEMBLY

First install the jet needle and spring into the

vacuum chamber and then install the needle

holder.

Install the vacuum piston into the carburetor

body.

Install the spring.

Diaphragm

Float

Spring

Vacuum Piston

• Align the hole in the diaphragm with

the vacuum passage in the carburetor

body.

*

Diaphragm

Spring

Vacuum Piston

Needle Holder

Jet Needle

Page 17

13. FUEL SYSTEM/CARBURETOR/FUEL PUMP

13-16

DINK 20 0

Install the vacuum chamber cover and tighten

it with the two screws.

CARBURETOR INSTALLATION

Tighten the drain screw.

Install the carburetor onto the intake

manifold and tighten the band.

Install the air cleaner connecting tube and

tighten the band.

Connect the throttle cable to the carburetor.

Connect the auto bystarter wire.

Connect the fuel tube and vacuum tube to

the carburetor.

Perform the following inspections and

adjustments:

•Throttle grip free play (3-3)

•Idle speed (3-6)

Install the seat, met-in box and frame center

cover.

Auto Bystarter Wire

• Be careful not to let the diaphragm slip.

• If the diaphragm cannot be positioned

correctly because of expansion, dry the

diaphragm before installation.

*

Vacuum Chamber Cover

Fuel Tube

Intake Manifold Band

Air Cleaner Connecting

Tube Band

Screws

• After connecting the throttle cable,

adjust the throttle grip free play to

2_ 6mm.

*

Throttle Cable

Page 18

13. FUEL SYSTEM/CARBURETOR/FUEL PUMP

13-17

DINK 20 0

FUEL PUMP REMOVAL

Remove the frame center cover.

Disconnect the fuel pump inlet, outlet and

vacuum tubes.

Remove the fuel pump attaching two bolts

and the fuel pump.

FUEL PUMP INSTALLATION

Install the fuel pump and secure it with the

two bolts.

Connect the fuel pump inlet, outlet and

vacuum tubes.

Install the seat, met-in box and frame center

cover.

Measure the fuel pump output.

Start the engine and disconnect the fuel

outlet tube and place a clean container under

the tube to check the fuel output.

Output: 40cc/1500rpm/10 seconds .

Container

Fuel Pump

Fuel Pump

Outlet Tube

Fuel Strainer

Outlet Tube

Vacuum Tube

Inlet Tube

Outlet Tube

Page 19

13. FUEL SYSTEM/CARBURETOR/FUEL PUMP

13-18

DINK 20 0

FUEL STRAINER REMOVAL

Remove the fuel strainer from the inlet tube.

INSPECTION

Inspect if the fuel strainer is clogged and

clean it with compressed air.

INSTALLATION

Install the fuel strainer with its arrow mark

toward the fuel pump.

• When removing the fuel strainer, do not

allow flames or sparks near the

working area and drain the residual

gasoline into a container.

*

Fuel Strainer

Arrow Mark

Loading...

Loading...