Page 1

5. ENGINE REMOVAL/INSTALLATION

5-0

DINK 20 0

5

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

__________________________________________________________________________________

ENGINE REMOVAL/INSTALLATION

__________________________________________________________________________________

SCHEMATIC DRAWING ---------------------------------------------- 5-1

SERVICE INFORMATION -------------------------------------------- 5-2

ENGINE REMOVAL --------------------------------------------------- 5-3

ENGINE INSTALLATION -------------------------------------------- 5-5

5

Page 2

5. ENGINE REMOVAL/INSTALLATION

5-1

DINK 20 0

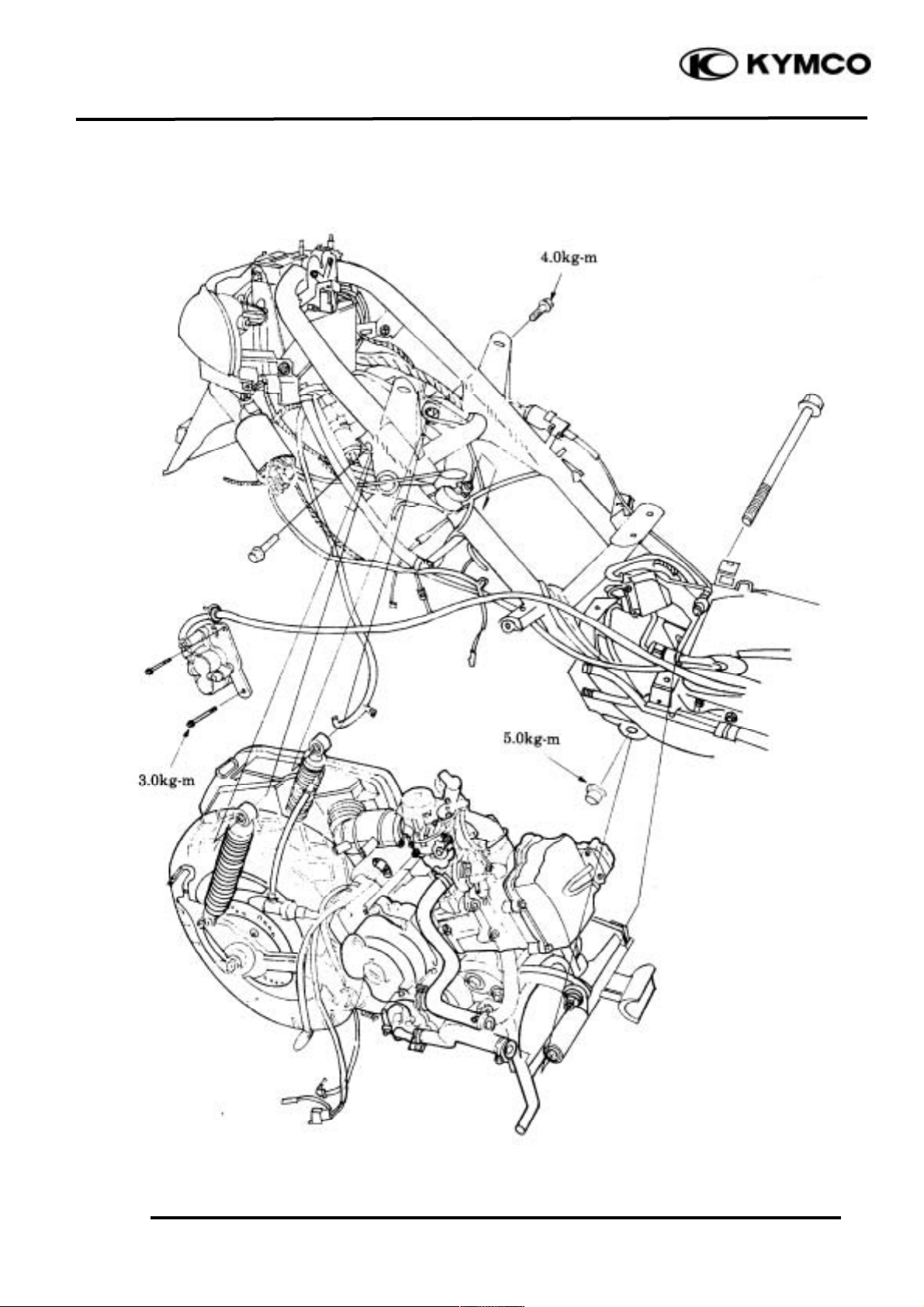

SCHEMATIC DRAWING

3.0kg-m

5.0kg-m

4.0kg-m

Page 3

5. ENGINE REMOVAL/INSTALLATION

5-2

DINK 20 0

SERVICE INFORMATION

GENERAL INSTRUCTIONS

• A floor jack or other adjustable support is required to support and maneuver the engine. Be

careful not to damage the motorcycle body, cables and wires during engine removal.

• Use shop towels to protect the motorcycle body during engine removal.

• Drain the coolant before removing the engine.

• After the engine is installed, fill the cooling system with coolant and be sure to bleed air from the

water jacket. Start the engine to check for coolant leaks.

• Before removing the engine, the rear brake caliper must be removed first. Be careful not to bend

or twist the brake fluid tube.

SPECIFICATIONS

Engine dry weight: 30kg

Engine oil capacity: at disassembly: 1.1 liter

Coolant capacity:

Total capacity : 1165cc

Radiator capacity : 825cc

Reserve tank capacity : 340cc

TORQUE VALUES

Engine mounting bolt 5.0kg-m

Rear shock absorber upper mount bolt 4.0kg-m

Page 4

5. ENGINE REMOVAL/INSTALLATION

5-3

DINK 20 0

ENGINE REMOVAL

Disconnect the battery negative cable.

Remove the frame body cover. (2-3)

Disconnect the engine negative cable.

Disconnect all of the A.C. generator, auto

bystarter, spark plug, thermosensor wire

couplers and connectors.

Disconnect the engine fuel tube.

Drain the coolant. (3-9)

Disconnect the water hose.

Disconnect the starter motor wire that goes to

the starter relay.

Disconnect the fuel tube and vacuum tube

that go to the carburetor from the fuel pump.

Disconnect the vacuum tube from the air

injection cut-off valve (AICV).

Disconnect the throttle cable from the

carburetor.

Remove the brake fluid tube bolt of the rear

brake caliper.

Remove the rear brake caliper bolt and the

rear brake caliper.

Starter Relay

Wire Connectors

Fuel Tube

Throttle Cable

Fuel Pump Vacuum Tube

Brake Fluid Tube

Rear Brake Caliper

Page 5

5. ENGINE REMOVAL/INSTALLATION

5-4

DINK 20 0

Remove the right/left rear shock absorber

upper mount bolts.

Remove the two engine mounting bolts and

pull out the engine with the engine hanger

backward.

ENGINE HANGER REMOVAL

Remove the engine hanger bolts to remove the

engine hanger.

Inspect the engine hanger bushings and

stopper rubber for wear or damage.

Engine Mounting

Bushings

Rear Shock Absorber Upper Mount Bolts

Stopper Rubber

Bolt

Engine Hanger

Page 6

5. ENGINE REMOVAL/INSTALLATION

5-5

DINK 20 0

ENGINE INSTALLATION

Install the engine in the reverse order of

removal.

Tighten the engine mounting bolts.

Torque: 5.0kg-m

Tighten the rear shock absorber upper mount

bolts.

Torque: 4.0kg-m

After installation, inspect and adjust the

following:

• Throttle grip free play (3-3)

• Fill the rear brake reservoir with brake fluid

and bleed air from the rear brake.

• Fill the cooling system with coolant and

start the engine to bleed air from the

system.

Engine Mounting Nuts

Engine Hanger Bolt

Rear Shock Absorber Upper Mount Bolts

Loading...

Loading...