Page 1

OWNER`S MANUAL

MANUALE D`USO

MANUEL D`UTILISATION

MANUAL DE INSTRUCCIONES

ART.NR: 3.210.85

640 LC4 ENDURO

640 LC4 SUPERMOTO

BEDIENUNGSANLEITUNG2004

Page 2

ENGLISH

1

IMPORTANT

WE STRONGLY SUGGEST THAT YOU READ THIS MANUAL

CAREFULLY AND COMPLETELY BEFORE GOING ON YOUR FIRST

RIDE. IT CONTAINS A GREAT DEAL OF INFORMATION AND

ADVICE WHICH WILL HELP YOU USE AND HANDLE YOUR BIKE

PROPERLY. IN YOUR OWN INTEREST, PLEASE PAY PARTICULAR

ATTENTION TO NOTICES THAT ARE MARKED AS FOLLOWS:

WARNING

IGNORING THESE INSTRUCTIONS, CAN ENDANGER YOUR

BODY AND YOUR LIFE.

!

CAUTION

!

IGNORING THESE INSTRUCTIONS COULD CAUSE DAMAGE TO

PARTS OF YOUR MOTORCYCLE OR THAT THE MOTOR-CYCLE

IS NOT ROAD-SAFE ANYMORE.

Please insert the serial numbers of your motorcycle in the boxes below

Frame number

Engine number

Key number

Stamp of dealer

Tampering with noise control system prohibited

Owners are warned that the law may prohibit:

(a) The removal or rendering inoperative by any person other than for purposes of maintenance,

repair or replacement, of any device or element of design incorporated into any new vehicle for

the purpose of noise control prior to its sale or delivery to the ultimate purchaser or while it is

in use; and

(b) the use of the vehicle after such device or element of design has been removed or rendered

inoperative by any person.

COMSUMER INFORMATION FOR AUSTRALIA ONLY

KTM S

PORTMOTORCYCLE

AG

RESERVES THE RIGHT TO MODIFY ANY EQUIPMENT, TECHNICAL SPECIFICATIONS, COLORS

,

MATERIALS, SERVICES OFFERED AND RENDERED, AND THE LIKE SO AS TO ADAPT THEM TO LOCAL CONDITIONS WITHOUT

PREVIOUS ANNOUNCEMENT AND WITHOUT GIVING REASONS

,

OR TO CANCEL ANY OF THE ABOVE ITEMS WITHOUT SUBSTI

-

TUTING THEM WITH OTHERS

. I

T SHALL BE ACCEPTABLE TO STOP MANUFACTURING A CERTAIN MODEL WITHOUT PREVIOUS

ANNOUNCEMENT

. I

N THE EVENT OF SUCH MODIFICATIONS, PLEASE ASK YOUR LOCAL

KTM

DEALER FOR INFORMATION

.

Page 3

ENGLISH

2

Introduction

We would like to congratulate you on your purchase of a KTM motorcycle.

You are now the owner of a state-of-the-art sport motorcycle that guarantees to bring

you lots of fun and enjoyment, provided that you clean and maintain it appropriately.

Before you go for your first ride, be sure to read this manual carefully and thoroughly in

order to familiarize yourself with how to operate your new motorcycle and with its

characteristics, even if this means that you will have to dedicate some of your valuable

time to this task. Only by doing so will you learn how to tune your motorcycle to your

specific needs and how to protect yourself against injury. Besides, this manual contains

important information on motorcycle maintenance. At the time this manual was typeset,

it was up-to-date with the latest state of this production series. It cannot be completely

ruled out, however, that minor discrepancies may exist resulting from further design

upgrades of these motorcycles.This manual is an important part of your motorcycle and

should be passed on to any subsequent owner in case you decide to sell it.

We expressly point out that work marked with an asterisk in the chapter "Maintenance

work on the chassis and engine" must be performed. If maintenance work should

become necessary during a competition it should be performed by a trained mechanic.

KTM strongly recommends that all service work to your KTM should be performed by a

qualified KTM dealer.

For your own safety, use KTM-approved parts and accessories only. KTM is not liable

for damage that arises in connection with the use of other products.

Take special care to follow the recommended run in, inspection, and maintenance

intervals. Heeding these guidelines will significantly increase the life of your motorcycle.

To ensure that all work to your KTM is performed properly and to avoid warranty

conflicts, KTM recommends that you always have your KTM serviced by a recognized

and qualified KTM dealer.

Off-road motorcycle driving is a wonderful sport and we hope that you will be able to

enjoy it to the full. It may, however, involve potential problems for the environment or

lead to conflicts with others. These problems or conflicts can be avoided if the motorcycle

is used responsibly. To safeguard the future of motorcycle sports, make sure that you use

the motorcycle in accordance with the law, show that you are environmentally conscious

and respect the rights of others.

We wish you a lot of fun when driving !

KTM SPORTMOTORCYCLE AG

5230 MATTIGHOFEN, AUSTRIA

ALL RIGHTS RESERVED TO MAKE ALTERATIONS TO DESIGN AND MODEL.

©

by KTM SPORTMOTORCYCLE AG, AUSTRIA All rights reserved

Page 4

ENGLISH

3

In accordance with the international quality management

ISO 9001 standard, KTM uses quality assurance processes

that lead to the highest possible product quality.

IMPORTANT LIMITED WARRANTY AND

LIMITED GUARANTEE INFORMATION

The 640 LC4 Enduro model was designed to resist the usual wear and tear of

normal use on the road and easy terrain (unpaved roads).

The 640 LC4 Supermoto model is designed for regular on-road service but

not for use off of paved roads.

The service, care and operating instructions for the engine and chassis

specified in the owner's manual must be observed to ensure that the bike

runs smoothly and to avoid premature wear.

The service work specified in the "Lubrication and Maintenance Schedule"

must be performed and service records must be kept for warranty

documentation. Lack of proper service and maintenance records or

documentation could void warranty.

The fuels and lubricants specified in the owner's manual or those of an equal

quality must be used in accordance with the maintenance schedule.

The warranty or guarantee shall become void for damage and consequential

damage caused by manipulations or conversions to the motorcycle.

The use of the motorcycle under extreme conditions, e.g. on extremely

muddy and wet terrain, can lead to higher than average wear on

components such as the drive train or the brakes. In this case it may become

necessary to service or replace wear parts before the service limit specified in

the maintenance schedule has been reached.

No warranty will be assumed if the bike is used in races or competitions.

Page 5

ENGLISH

4

Page

SERIAL NUMBER LOCATIONS .............................................5

Chassis number ................................................................5

Engine number, engine type.............................................5

OPERATION INSTRUMENTS ...............................................5

Clutch lever ......................................................................5

Hand decompression lever................................................5

Hand brake lever..............................................................5

Multi-functional digital speedometer ................................6

Seeting options in the display ...........................................7

Indicator lamps.................................................................8

Choke lever......................................................................8

Ignition lock .....................................................................8

Combination switch..........................................................9

Starter tip switch, emergency OFF switch, light switch .....9

Filler cap...........................................................................9

Fuel tap..........................................................................10

Shift lever .......................................................................10

Kickstarter ......................................................................10

Foot brake pedal ............................................................10

Compression damping of fork ........................................11

Rebound damping of fork ..............................................11

Compression damping of shock absorber .......................11

Rebound damping of shock absorber .............................11

Holding bars...................................................................11

GENERAL TIPS AND WARNINGS FOR STARTING THE

MOTORCYCLE...................................................................12

Instructions for initial operation ......................................12

Running in the LC4 models ............................................12

Accessories and payload.................................................12

DRIVING INSTRUCTIONS ..................................................13

Check the following before each start ............................13

Starting when the engine is cold.....................................14

Starting when the engine is warm or hot ........................14

What to do when the engine is „flooded“......................14

Kickstart instructions.......................................................15

Starting off .....................................................................15

Shifting, Riding...............................................................15

Braking...........................................................................15

Stopping and parkling ....................................................16

Fuel................................................................................16

PERIODIC MAINTENANCE-SCHEDULE ..............................18

MAINTENANCE WORK ON CHASSIS AND ENGINE ..........20

Tool set ..........................................................................20

Removing the seat..........................................................20

Checking and adjusting steering head bearing................21

Breather plug front fork..................................................21

Cleaning the dust sleeves of the telescopic fork ..............21

Changing the spring preload of the shock absorber........22

Lubricate shock absorber linkage ....................................22

Checking rubber ring on the rear shock absorber............22

Checking chain tension...................................................23

Correct chain tension......................................................23

Chain maintenance.........................................................24

Chain wear.....................................................................24

Page

General information on KTM disc brakes ........................25

Adjisting of free travel at the hand brake lever ...............26

Changing the basic position of the handbrake lever........26

Checking of brake fluid level - front brake......................26

Refilling the front brake fluid reservoir............................26

Checking the front brake pads........................................27

Changing the basic position of the foot brake pedal .......27

Check the rear brake fluid level ......................................28

Refilling the rear brake fluid reservoir .............................28

Checking the rear brake pads .........................................28

Dismounting and mounting the front wheel (LC4) .........29

Dismounting and mounting the front wheel

(LC4 Supermoto)............................................................29

Dismounting and mounting the rear wheel.....................30

Checking the shock absorbtion rubbers in the rear hub ..30

Tires, air pressure............................................................31

Checking spoke tension..................................................31

Changing the wheel size.................................................31

Battery ...........................................................................32

Charging the battery ......................................................32

Fuses..............................................................................33

Exchanging the headlight lamp.......................................33

Replacing the parking light bulb .....................................33

Exchanging the brake light and tail light bulb .................34

Cooling system...............................................................34

Checking the cooling liquid level ....................................35

Cleaning the air filter ......................................................35

Changing the orginal position of the clutch lever............36

Checking the oil level of the hydraulic clutch ..................36

Adjusting the throttle cable ............................................36

Checking and adjusting the chocke cable play ................37

Checking the adjustment of the hand decompression cable..37

Activating the ignition curve for low-octane fuel ............37

Adjust idling speed .........................................................37

Draining the carburetor float chamber............................38

Engine oil .......................................................................38

Checking the engine oil level..........................................38

Oil circuit........................................................................39

Oil and fine screen filter change, bleeding of the oil system..39

Changing oil filter ..........................................................40

TROUBLE SHOOTING........................................................41

CLEANING..........................................................................44

CONSERVATION FOR WINTER OPERATION ....................44

STORAGE ...........................................................................44

Re-initation after time of storage....................................44

TECHNICAL SPECIFICATIONS - CHASSIS...........................45

TECHNICAL SPECIFICATIONS - ENGINE ...........................47

HEAD WORD INDEX..........................................................48

WIRING DIAGRAM................................................APPENDIX

INDEX

Page 6

ENGLISH

5

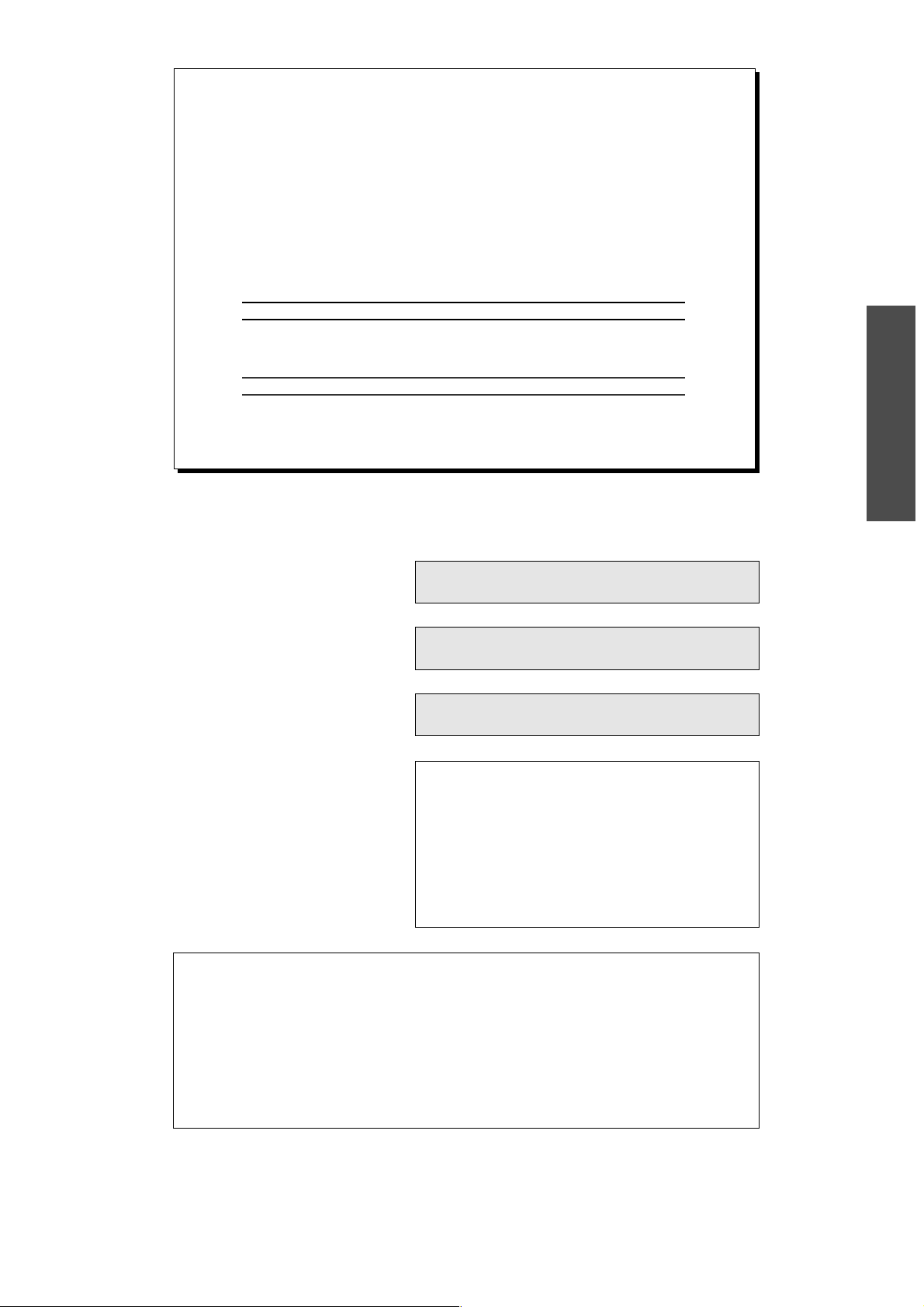

Chassis number

The chassis number is stamped on the right side of the steering head tube.

Write this number into the relevant area on page 1.

Engine number, engine type

The engine number and engine type are stamped on the right hand side of

the engine below the chain sprocket. Write this number into the relevant

area on page 1.

Clutch lever

The clutch lever 1 is located on the left side of the handlebar. The adjusting

screw

A is used to change the original position of the clutch lever (see

maintenance work on chassis and engine).

Hand decompression lever

The hand decompression lever 2 is only used in two special cases:

a)When the engine stalled.

It is possible that the starter motor is not able to crank the engine on the

next attempt. This is due to the fact that the automatic decompressor

doesn’t work properly. If this happens, pull the manual decompression

lever and start again. Afterwards normal starting will be possible.

b) When you want to push the motorcycle.

While pushing, pull the hand decompression lever to make it easier to get

the engine going.

Hand brake lever

The hand brake lever 3 is mounted on the handlebars on the right and

actuates the front wheel brake. The adjusting screw

B can be used to

change the basic position of the hand brake lever (see "Maintenance").

SERIAL NUMBER LOCATIONS

OPERATION INSTRUMENTS

2

1

A

3

B

Page 7

ENGLISH

6

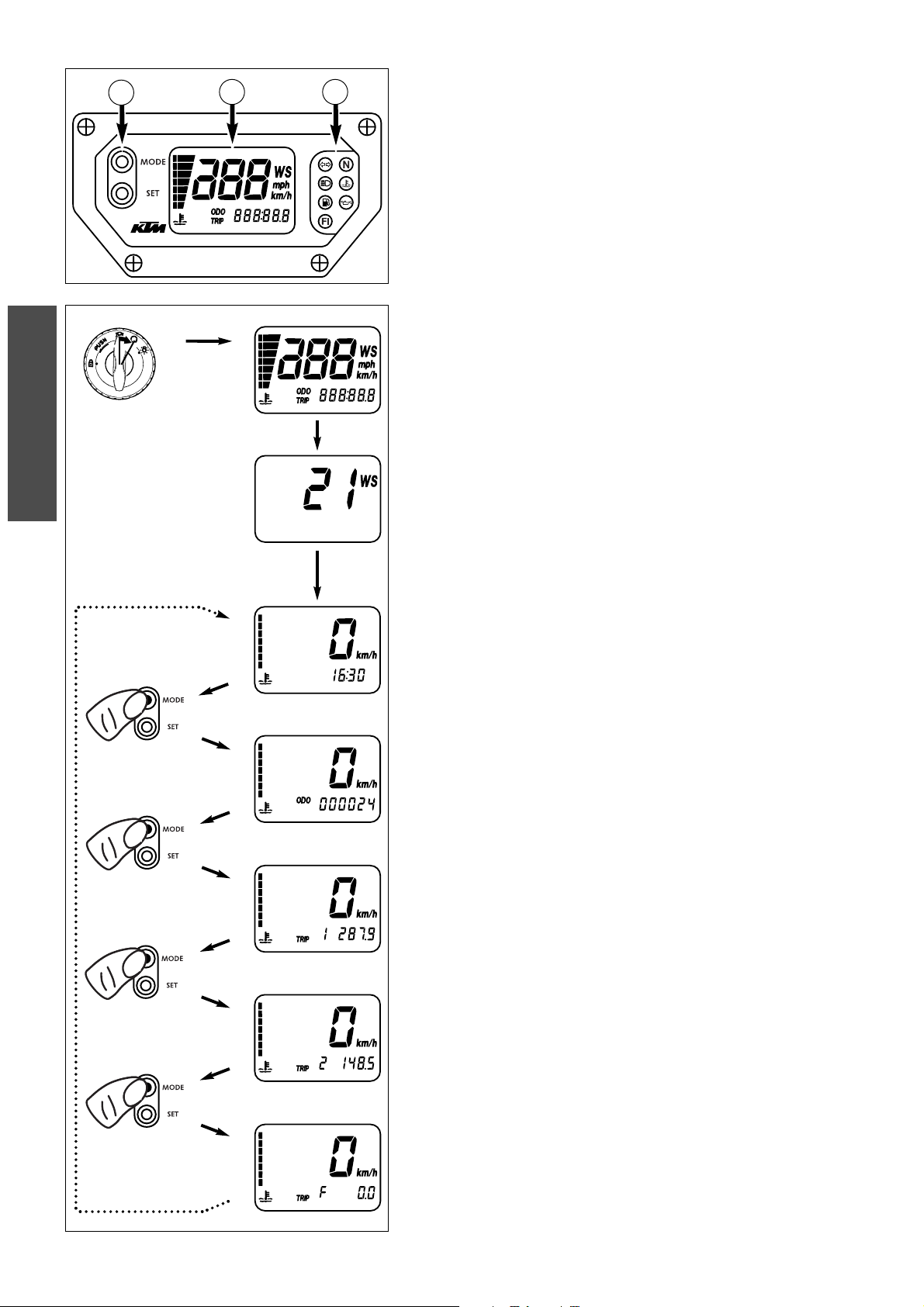

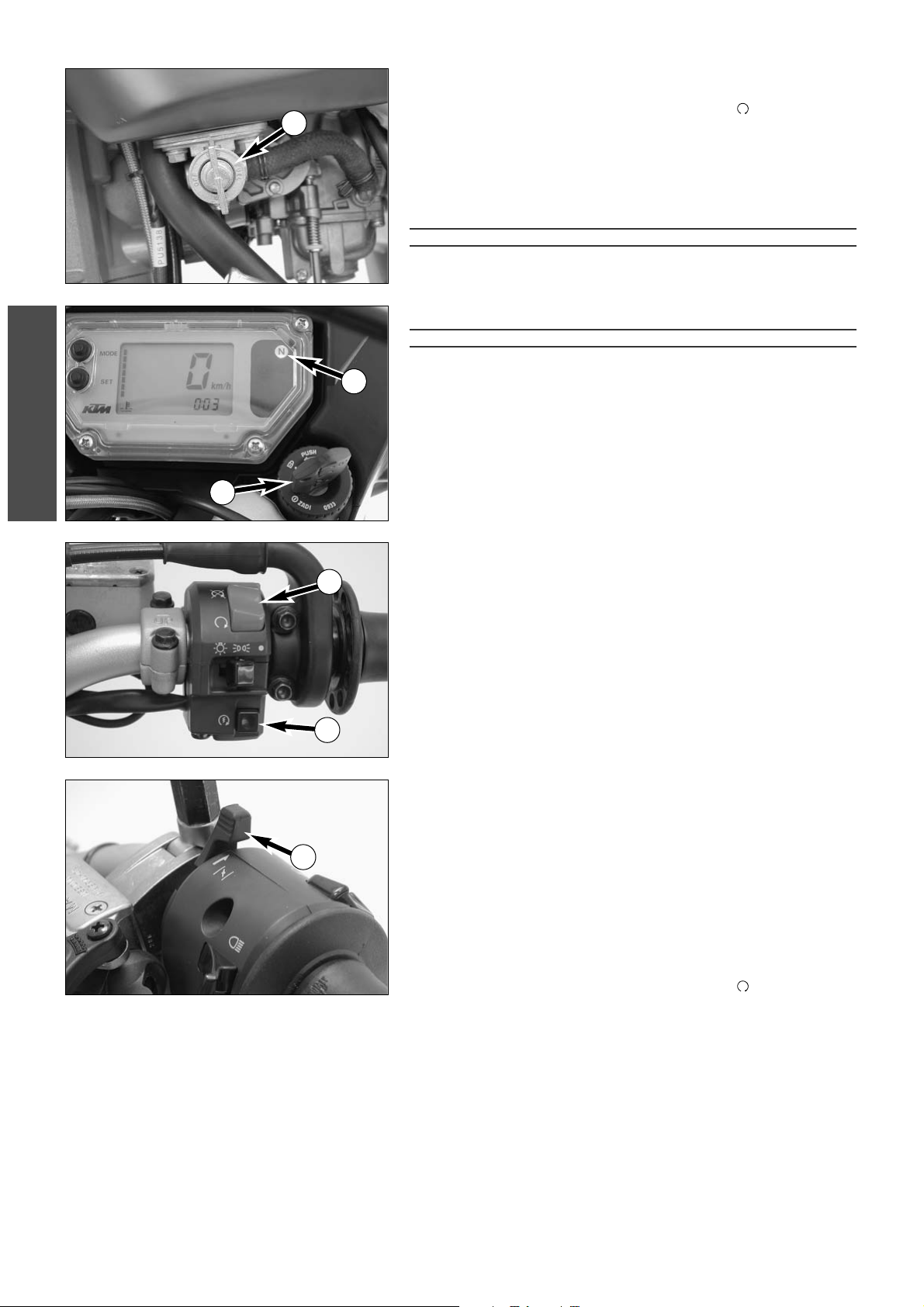

Multi-functional digital speedometer

The universal instrument is divided into 3 parts.

Use the MODE and SET

1 button to change the display and the basic set-

tings in the display.

Display

2 shows all of the information that may be of interest to you. 5

display modes can be selected with the MODE button.

The indicator lamps

3 provide additional information on the motorcycle's

running condition.

Display

TEST

When you switch on the ignition, all of the display elements will light up for

1 second for the function test.

WS (wheel size)

The display will change and show the diameter of the front wheel in inches

for 1 second (WS = wheel size).

Then the CLOCK mode will be displayed, or the mode that was active

when the ignition was switched off.

CLOCK

You will recognize the OK display by the blinking dots between the hours

and minutes. It displays the speed, temperature of the cooling liquid and

the clock.

To switch to the next display mode, press the MODE button.

ODO

The speed, temperature of the cooling liquid and the total kilometers or

miles traveled are shown in the ODO mode.

To switch to the next display mode, press the MODE button.

TRIP 1

The TRIP 1 mode shows the speed, the temperature of the cooling liquid

and the trip odometer 1.

To switch to the next display mode, press the MODE button.

TRIP 2

The TRIP 2 mode shows the speed, the temperature of the cooling liquid

and the trip odometer 2.

To switch to the next display mode, press the MODE button.

TRIP F

The TRIP F (fuel) mode shows the speed, the temperature of the cooling

liquid and the distance traveled since reaching the low-fuel mark (the lowfuel indicator lamp will blink).

To return to the UHR mode, press the MODE button.

1

2

3

TEST

WS

ODO

CLOCK

TRIP 1

TRIP 2

TRIP F

Page 8

ENGLISH

7

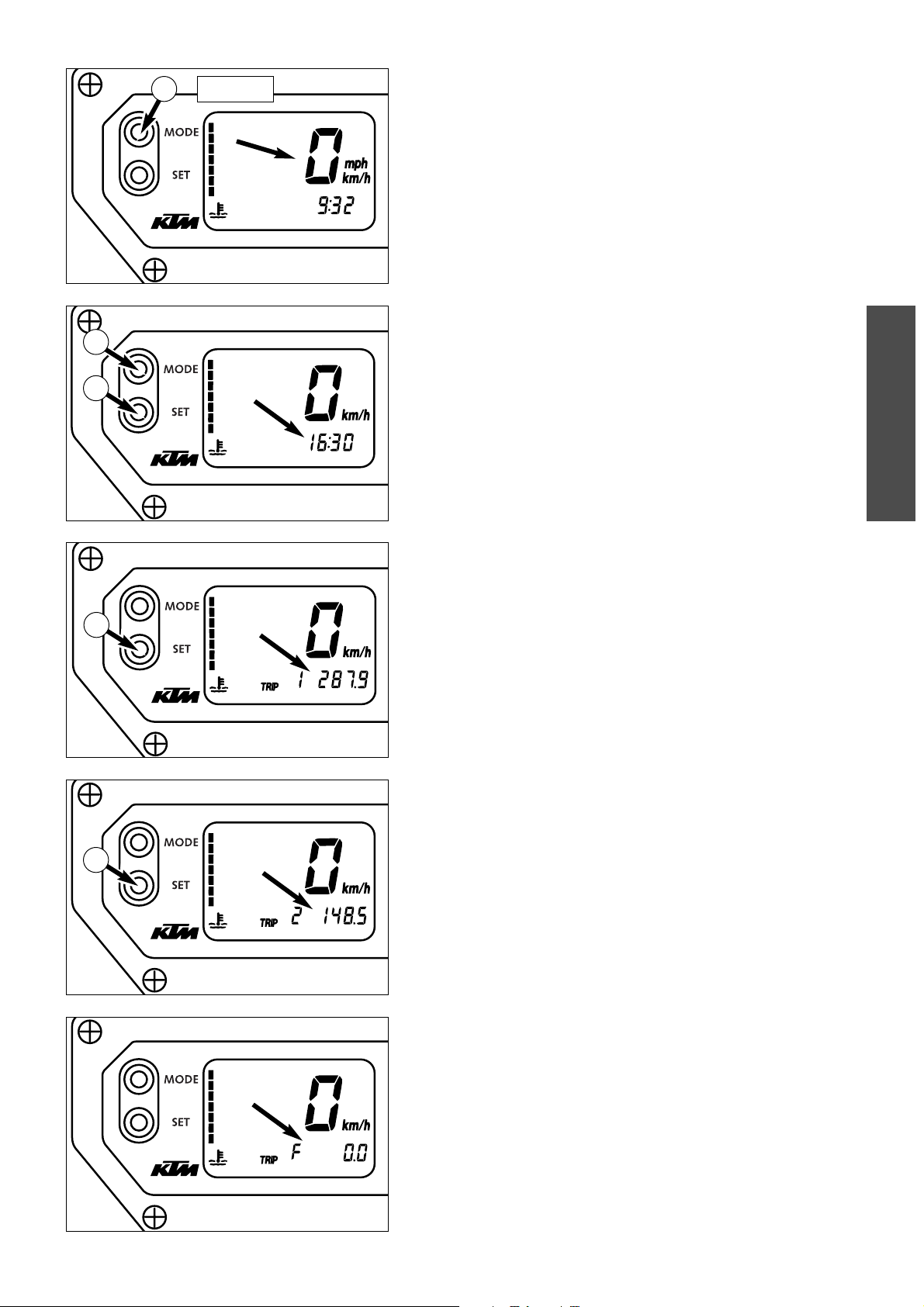

Setting options in the display

KILOMETERS OR MILES.

You can have the speed and distance shown in kilometers or miles in the

display. The display can be adapted to the respective country on longdistance trips.

To switch from kilometers to miles, switch on the ignition and press the

MODE

1 button for approx. 10 seconds. The km/h display will switch to

mph. The speed and the stored distances will be converted and displayed in

miles.

To return to kilometers, proceed as described above.

CLOCK

Switch on the ignition and change to the CLOCK mode.

Simultaneously press MODE

1 and SET 2. The numbers on the clock will

start to blink. Use the MODE button to set the hours and the SET button to

set the minutes.

The press the MODE and SET buttons simultaneously.

NOTE: 0:00 will be displayed if the clock is not supplied with electricity. This

can be caused by a defective fuse or a fault in the board electric system (see

Troubleshooting).

TRIP 1

The trip meter 1 runs continuously and counts up to 999.9. It can be used

to measure the length of a certain route on a trip or the distance between

two refueling stops.

To return the trip meter 1 to zero, switch on the ignition, change to the

TRIP 1 mode and press the SET button.

RESETTING TRIP 2

The trip meter 2 runs continuously and counts up to 999.9. It can be used

similarly to TRIP 1 or together with a switch available as an accessory (see

below) for trips according to a roadbook.

To return the trip meter 2 to zero, switch on the ignition, change to the

TRIP 2 mode and press the SET button.

NOTE: A Tripmaster switch (Part no. 582.14.069.044) is available as an

accessory and enhances the trip meter 2 functions. You can correct the

displayed route by increasing or decreasing in increments of 0.1. For

example, if you have taken the wrong road when driving according to a

roadbook, you can easily correct the display to correspond to the roadbook

again. It can also be used to change the display modes. The switch is mounted on the handlebars so that you can keep your hands on the handlebars.

TRIP F

When the fuel level reaches the reserve mark, the display will automatically

switch to TRIP F and begin to count (no matter which display mode was

active before). At the same time, the fuel warning lamp will start to blink.

You will still have enough reserve fuel for at least 35 kilometers.

After refueling, it will take approx. 3 minutes for TRIP F to automatically

reset to 0 and return to the previous display mode.

NOTE: To use up the reserve fuel in the tank, move the fuel cock to the RES

position by hand.

10 sec

1

1

2

2

2

Page 9

ENGLISH

8

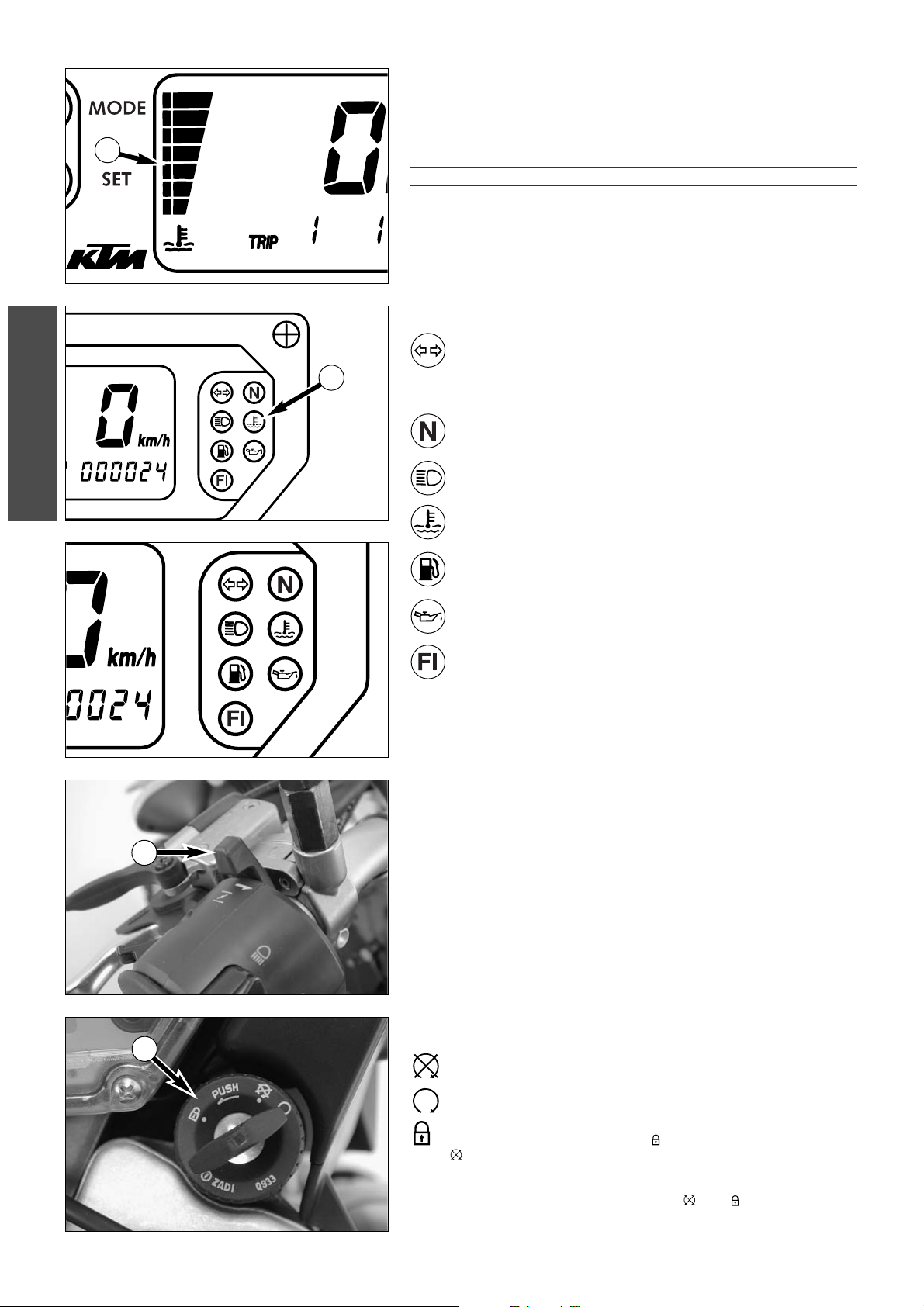

Cooling liquid temperature display

The temperature display 1 is shown in 7 bars. The more bars that light up,

the hotter the cooling liquid. When the lowest bar lights up, the cooling

liquid has reached a temperature of approx. 40°C (104°F). When the upper

bar lights up 120°C (248°F), all of the bars will start to blink and the red

warning lamp

2 will light up.

WARNING

P

OSSIBLE CAUSES FOR AN INCREASE IN TEMPERATURE, CAUSING THE RED WARNING LIGHT

FOR THE COOLING LIQUID TEMPERATURE TO LIGHT UP

:

– D

RIVING TOO SLOWLY AND DRIVING WITH A HEAVY LOAD AT HIGH AIR TEMPERATURES

– N

OT ENOUGH COOLING LIQUID IN THE SYSTEM

– T

HE VENTILATOR ON THE RADIATOR IS NOT RUNNING

– IMPROPER USE OF THE CLUTCH WHEN DRIVING SLOWLY

Indicator lamps

The green indicator lamp will blink in the blinker rhythm when the

blinker is switched on.

NOTE:

The indicator lamp will blink slower when a blinker is broken.

The green indicator lamp will light up when the gearbox is in an

idling position.

The blue indicator lamp will light up when the high beams are

switched on.

The red warning lamp will start to blink when the cooling liquid

reaches 120°C (248°F).

This warning light has no function.

This warning light has no function.

This indicator lamp has no function.

Choke lever

If the choke lever 3 is pulled backwards, a bore will be opened in the

carburetor through which the engine may draw in additional fuel. This

produces a „rich“ fuel/air mixture necessary for cold start. If the choke lever

is pushed forward up to the stop, the bore will be closed again. In this

position the choke cable must have a play of approx. 4 mm.

Ignition lock with 3 switch positions

Switch positions of ignition lock 4:

= Ignition off, (engine can't be started)

= Ignition on, (engine can be started)

= Ignition off, handlebar blocked

To switch the ignition to position turn the ignition key to position

and firmly press it into the lock. Turn the handlebar all the way to

the left, then turn the ignition key to the left.

The ignition key can be withdrawn in position and .

120°C (248°F)

110°C (230°F)

100°C (212°F)

70°C (158°F)

60°C (140°F)

50°C (122°F)

40°C (104°F)

1

2

3

4

Page 10

ENGLISH

9

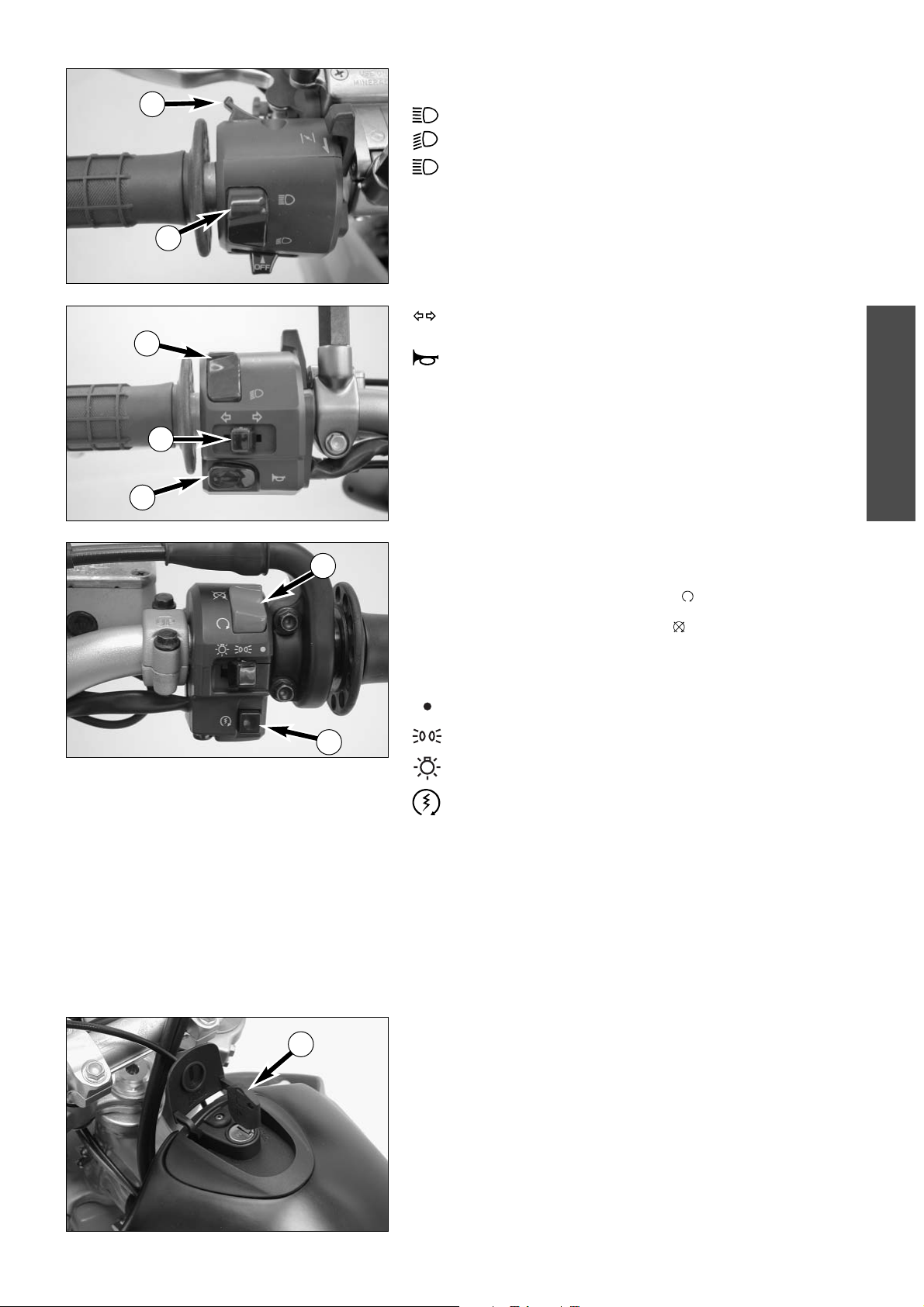

Combination switch

The rocker switch LIGHTS 1 actuates the high beam or low beam.

= High-beam light

= Low-beam light

The light signal (high beam) is actuated with button

2.

The indicator switch

3 returns to central position after actuation.

Press flasher switch towards switch housing to switch off the flasher.

The horn is sounded with button

4.

Starter tip switch, emergency OFF tip switch, light switch

The emergency off switch 5 is provided for emergency situations and

should not be used to switch off the engine.

The engine is ready for operation in position (ignition circuit and starter

circuit are switched on).

The engine cannot be started in position (ignition circuit and starter

circuit are interrupted).

The light switch has 3 positions:

= Light off

= Parking light on

= Headlight on

Use the starter tip switch

6 to operate the electric starter.

Filler cap

The filler cap 7 can be locked and is provided with a fuel evaporation

control system.

To open the cap insert the ignition key, turn it 90° counterclockwise, then

lift off the filler cap.

To close the tank insert the filler cap, turn the ignition key 90° clockwise

and take out the key.

1

5

7

6

2

1

3

4

Page 11

ENGLISH

10

Fuel tap

OFF In this position the fuel tap is closed. No fuel may flow to the

carburetor.

ON When using the motorcycle, the twist grip must be set to the ON

position. Now fuel may flow to carburetor. In this position the tank

empties down to the fuel reserve of approx. 2.5 liters.

RES The reserve, approximately 2.5 liters, cannot be tapped until the twist

grip is turned to the RES position. Fill the tank as soon as possible and

remember to turn the twist grip back to the ON position so that you

will have backup fuel next time, too.

Shift lever

The shift lever is mounted on the left side of the engine. The position of

the gears is shown in the illustration. Neutral, or the idle speed, is located

between first and second gear.

Kickstarter

The kickstarter is mounted on the left side of the engine. Its upper part can

be swivelled.

Foot brake pedal

The foot brake pedal is located in front of the right footrest. Its basic

position can be adjusted to your seat position (see maintenance work).

2,3,4,5

1

N

OFF ON RES

S

E

R

F

U

E

F

L

F

O

N

O

S

E

R

F

U

E

F

L

F

O

N

O

S

E

R

F

U

E

F

L

F

O

N

O

Page 12

ENGLISH

11

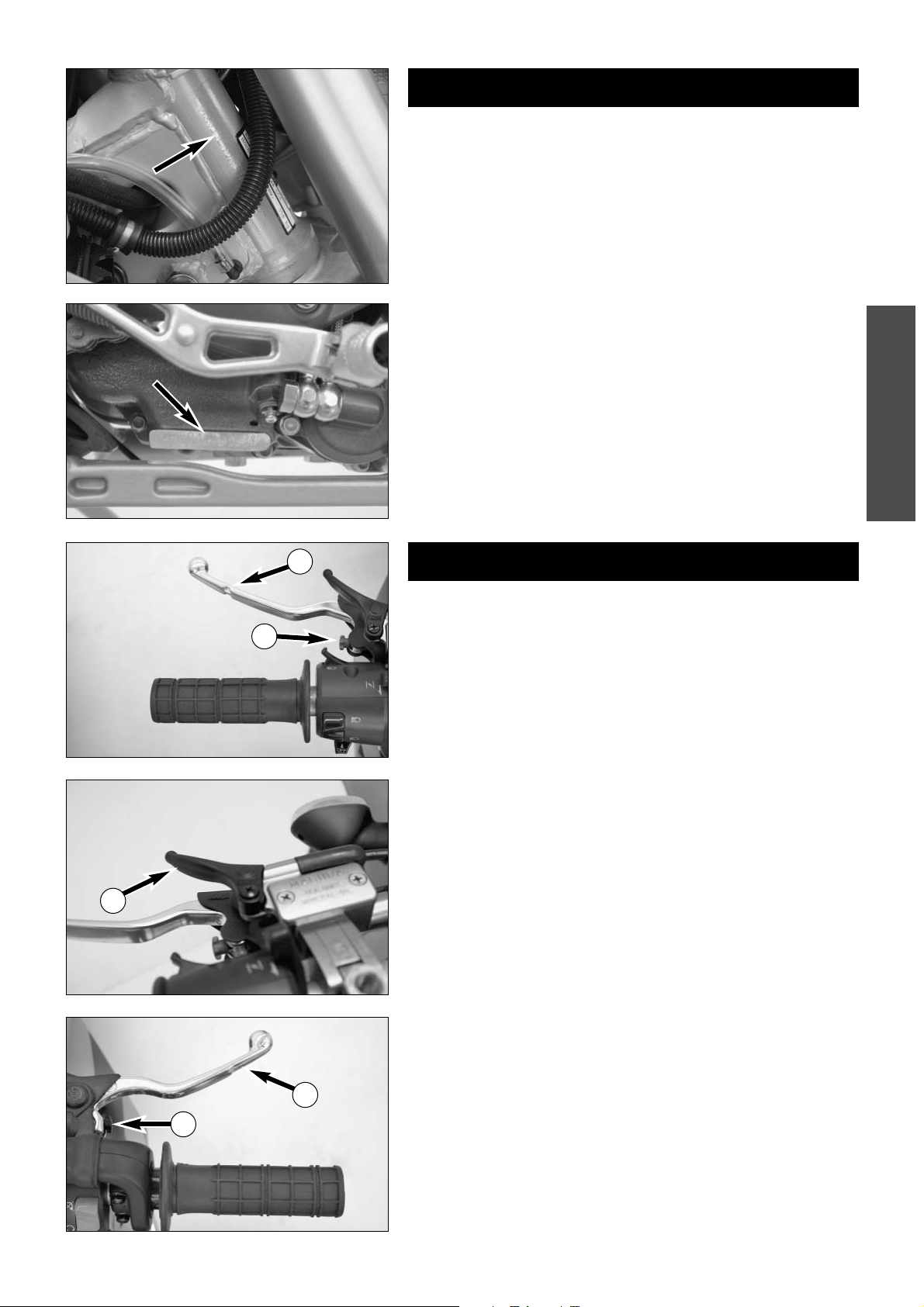

Compression damping of fork

The compression damping is to be set at the lower end of the fork tubes. It

only regulates the degree of damping during compression. Remove closing

cap

A. By using the knob 1 (COM), the degree of damping of the

compression can be adjusted. Turn the knob clockwise to increase damping,

turn it counterclockwise to reduce damping during compression.

BASIC SETTING:

– turn rotary knob clockwise as far as it will go

– turn it back counter-clockwise by as many clicks as are specified for the

relevant type of fork

WP 0518Y737 .............20 Klicks (640 LC4)

WP 1418Y750 .............20 Klicks (640 LC4 Supermoto)

Rebound damping of fork

The rebound damping is to be set at the upper end of the fork tubes. It only

regulates the degree of damping during rebounding.

By using the knob

2 (REB), the degree of damping of the rebound can be

adjusted. Turn the knob clockwise to increase damping, turn it counterclockwise to reduce damping during rebounding.

BASIC SETTING:

– turn rotary knob clockwise as far as it will go

– turn it back counter-clockwise by as many clicks as are specified for the

relevant type of fork

WP 0518Y737 .............12 Klicks (640 LC4)

WP 1418Y750 .............15 Klicks (640 LC4 Supermoto)

Compression damping of shock absorber

With the knob 3 the degree of damping of the compression can be

adjusted to 7 positions. Turn the knob counterclockwise to increase

damping, turn it clockwise to reduce damping during compression.

BASIC SETTING:

WP 0118Y734 .............Position 3 (640 LC4)

WP 0118Y733 .............Position 4 (640 LC4 Supermoto)

Rebound damping of shock absorber

With the setting wheel 4 the degree of damping of the rebound can be

adjusted to 11 positions. Turn the knob to the left side to increase damping,

turn it to the right side to reduce damping during rebounding.

BASIC SETTING:

WP 0118Y734 .............Position 7 (640 LC4)

WP 0118Y733 .............Position 8 (640 LC4 Supermoto)

WARNING

T

HE DAMPING UNIT OF THE SHOCK ABSORBER IS FILLED WITH HIGHLY COMPRESSED

NITROGEN

. NEVER TRY TO TAKE THE SHOCK ABSORBER APART OR TO DO ANY

MAINTENANCE WORK YOURSELF

. SEVERE INJURIES COULD BE THE RESULT.

Holding bars

The passenger can hold on to the holding bars on the rear end of the

vehicle.

2

2

1

A

3

4

Page 13

ENGLISH

12

GENERAL TIPS AND WARNINGS FOR STARTING THE MOTORCYCLE

Instructions for initial operation

– Verify that your KTM dealer performed the PREPARATION

OF VEHICLE jobs (see Customer Service Manual).

– Read these operating instructions carefully before your first

ride.

– Enter the chassis, engine and key numbers on page 1.

– Familiarize yourself with the operating elements.

– Adjust the hand brake lever and foot brake lever to your

most comfortable position.

– Get used to handling the motorcycle on an empty parking

lot or open space, before starting on a longer drive. Also try

to drive as slowly as possible and in standing position, to

improve your feeling for the vehicle.

– Do not drive along off-road tracks which go beyond your

abitily and experience.

– Hold the handlebars with both hands and leave your feet on

the foot rests while driving.

–

Remove your foot from the foot brake lever when you

are not braking. If the foot brake lever is not released the

brake pads rub continuously and the braking system is

overheated.

– Do not make any alterations to the motorcycle and always

use ORIGINAL KTM SPARE PARTS. Spare parts from other

manufacturers can impair the safety of the motorcycle.

– Motorcycles are sensitive to alterations in the distribution of

weight. If you are taking luggage with you, this should be

secured as close as possible to the middle of the vehicle;

distribute the weight evenly between the front and rear

wheel. Never exceed the maximum permissible laden

weight and the axle weights. The maximum permissible

laden weight is made up of the following components:

– Motorcycle ready for operation and tank full

– Luggage

–

Driver with protective clothing and helmet.

– Pay attention to running-in procedure.

Running in the LC4 models

Even very precisely machined sections of engine components

have rougher surfaces than components which have been

sliding against one another for quite some time. Therefore,

every engine needs to be broken in. For this reason, during its

first 1000 kilometers (620 miles) the engine must not be

revved up to its performance limits. The engine speed of 4800

r.p.m. must not be exceeded during the first 1000 kilometers

(620 miles). During this break-in time, you should ride your

motorcycle in different conditions (roads, easy off-road

terrain). The following table shows you the maximum velocity

values in the different gears at 4800 r.p.m. as based on the

rear wheel transmission ratio of your motorcycle.

NOTE: D

URING THE STAGE OF RUNNING THE ENGINE IN, THAT IS THE

FIRST

1000 KM (620 MILES), THE ENGINE OIL USED SHOULD BE OF A

MINERAL OIL FORMULA

. THIS ALSO APPLIES IF THE ENGINE HAS BEEN

REPAIRED

.

WARNING

–W

EAR SUITABLE CLOTHING WHEN DRIVING A MOTORCYCLE

. C

LEVER

KTM DRIVERS ALWAYS WEAR A HELMET, BOOTS, GLOVES AND A

JACKET

, REGARDLESS OF WHETHER DRIVING ALL DAY OR JUST FOR A

SHORT TRIP

. THE PROTECTIVE CLOTHING SHOULD BE BRIGHTLY

COLORED SO THAT OTHER VEHICLE CAN SEE YOU AS EARLY AS

POSSIBLE

. YOUR PASSENGER WILL ALSO NEED SUITABLE PROTECTIVE

CLOTHING

.

–D

O NOT DRIVE AFTER HAVING CONSUMED ALCOHOL.

–A

LWAYS TURN ON THE LIGHT TO MAKE SURE THAT OTHER DRIVERS

BECOME AWARE OF YOU AS EARLY AS POSSIBLE

.

–O

NLY USE ACCESSORIES THAT HAVE BEEN RELEASED BY

KTM. FOR

EXAMPLE

, FRONT PANELLING CAN IMPAIR THE DRIVING PROPERTIES OF

THE MOTORCYCLE

. CASES,

EXTRA TANKS ETC. CAN ALTER THE

WEIGHT DISTRIBUTION AND THUS ALSO IMPAIR THE VEHICLES DRIVING

PROPERTIES

.

–T

HE FRONT AND REAR WHEEL ARE ALLOWED TO BE FITTED ONLY

WITH TIRES THAT HAVE THE SAME PROFILE TYPE

.

–N

EW WHEELS HAVE A SMOOTH SURFACE, WHICH MEANS THAT THEY

MUST BE RUN IN TO ACHIEVE FULL GRIP

. FOR THIS PURPOSE, RIDE THE

MOTORCYCLE CAREFULLY AT MODERATE SPEED DURING THE FIRST

200 KILOMETERS WITH NEW TIRES, TILTING THE VEHICLE AT

DIFFERENT ANGLES SO THAT ALL SECTIONS ARE PROPERLY

ROUGHENED

. TIRES WILL NOT DISPLAY THEIR FULL GRIP

CHARACTERISTICS UNTIL THEY ARE PROPERLY RUN IN

.

–D

RIVE AT A MODERATE SPEED FOR THE FIRST FEW KILOMETERS OF

EACH TRIP TO ALLOW THE TIRES TO REACH THE NECESSARY

OPERATING TEMPERATURE

. M

AXIMUM ROAD GRIP IS ASSURED WHEN

THE TIRES ARE WARM

.

–O

BSERVE THE TRAFFIC REGULATIONS

, DRIVE DEFENSIVELY AND TRYING

TO LOOK AHEAD AS FAR AS POSSIBLE SO THAT ANY HAZARDS CAN BE

RECOGNIZED AS EARLY AS POSSIBLE

.

–C

HOOSE YOUR DRIVING SPEED ACCORDING TO THE CONDITIONS AND

YOUR DRIVING SKILLS

.

–D

RIVE CAREFULLY ON UNKNOWN ROADS OR ON UNFAMILIAR TRIALS.

–

RENEW THE VIZOR ON YOUR HELMET OR THE GLASS OF YOUR

GOGGLES ON TIME SO AS TO ENSURE OPTIMUM VISION IN ANY

SITUATION

. WHEN LIGHT SHINES DIRECTLY ON SCRATCHED VISOR OR

GOGGLES

, THE OPERATOR WILL BE BLINDED.

–N

EVER LEAVE YOUR MOTORCYCLE WITHOUT SUPERVISION IF THE

ENGINE IS RUNNING

.

Accessories and payload

Accessory parts and baggage can significantly decrease a

motorcycle's driving stability. Please observe the following

warnings.

WARNING

–N

EVER DRIVE FASTER THAN

130

KPH (80

MPH) IF YOU HAVE MOUN-

TED ACCESSORY PARTS ON YOUR MOTORCYCLE. ACCESSORY PARTS

CAN SIGNIFICANTLY IMPAIR THE MOTORCYCLE

'S HANDLING, ESPECI-

ALLY IN THE MAXIMUM SPEED RANGE.

– N

EVER DRIVE FASTER THAN 130 KPH (80 MPH) IF YOUR MOTORCY-

CLE IS LOADED WITH CASES OR OTHER BAGGAGE

. THEY WILL IMPAIR

THE MOTORCYCLE

'S HANDLING AT HIGHER SPEEDS AND CAN EASILY

CAUSE IT TO GO OUT OF CONTROL

–I

F YOU HAVE CASES MOUNTED, DO NOT EXCEED THE MANUFACTU-

RER'S RECOMMENDED MAXIMUM PAYLOAD.

–F

ASTEN THE BAGGAGE CLOSE TO THE CENTER OF THE MOTORCYCLE

AND DISTRIBUTE THE WEIGHT EVENLY ON THE FRONT AND REAR

WHEELS AND ON THE LEFT AND RIGHT

.

–BAGGAGE MUST BE SECURELY AND ADEQUATELY FASTENEND; LOOSE

BAGGAGE WILL SIGNIFICANTLY IMPAIR DRIVING SAFETY

.

–A

HIGH PAYLOAD WILL CHANGE THE MOTORCYCLE'S HANDLING AND

CONSIDERABLY INCREASE THE BRAKING DISTANCE

; ADAPT YOUR

DRIVING SPEED ACCORDINGLY

.

625 LC4

LC4 SUPERMOTO

16:42 Z 17:42 Z

1. G 35 kmh 35 km/h

2. G 50 kmh 55 km/h

3. G 70 kmh 75 km/h

4. G 90 kmh 90 km/h

5. G 100 kmh 100 km/h

gear

ratio

Page 14

ENGLISH

13

Check the following before each start

When you start, the motorcycle must be in perfect mechanical condition.

For safety reasons, you should make a habit of performing an overall check

of your motorcycle before each start.

The following checks should be performed:

1 CHECK OIL LEVEL

Insufficient oil results in premature wear and consequently to engine

damage.

2 FUEL

Check that there is sufficient fuel in the tank; when closing the filler cap,

check that the tank venting hose is free of kinks.

3 CHAIN

A loose chain can fall from the chain wheels; an extremely worn chain

can tear, and insufficient lubrication can result in unnecessary wear of

chain and chain wheels.

4 TIRES

Check for damaged tires. Tires showing cuts or dents must be replaced.

The tread depth must comply with the legal regulations. Also check the

air pressure. Insufficient tread and incorrect air pressure deteriorate the

driving performance.

5 BRAKES

Check correct functioning of the braking system. Check for sufficient

brake fluid in the reservoir. The reservoirs have been designed in such a

way that brake fluid does not need to be refilled even when the brake

pads are worn. If the level of brake fluid falls below the minimum value,

this indicates a leak in the braking system or completely worn out brake

pads. Arrange for the braking system to be checked by a KTM specialist,

as complete failure of the braking system can be avoided.

Also check the state of the brake hose and the thickness of the brake

linings.

Check free travel at hand brake lever and foot brake lever.

6 CABLES

Check correct setting and smooth operation of all control cables.

7 COOLING FLUID

Check the level of cooling fluid when the engine is cold.

8 ELECTRICAL SYSTEM

Check correct operation of headlamps, tail-lights, brake lights, indicators,

control lamps and horn while the engine is running.

9 LUGGAGE

If you are taking luggage with you, check that this is securely fastened.

10 REAR MIRROR

Sit on the motorcycle and check the adjustment of the rear mirror.

DRIVING INSTRUCTIONS

Page 15

ENGLISH

14

Starting when the engine is cold

1 Open the fuel tap 1

2 Switch on ignition (turn ignition key 2 into position ).

3 Switch on emergency OFF switch 3.

4 Switch transmission to idle (green indicator lamp N

4 lights up).

5 Operate cold starting device (choke)

5.

6 Do not accelerate; operate starter button

6.

7 If the engine starts, push the choke lever back a little bit, as soon as the

engine runs unevenly.

8 Take the motorcycle off of the main stand or side stand.

WARNING

–T

O AVOID INJURIES,

IT IS RECOMMENDED TO WEAR BOOTS WHEN USING THE

KICKSTARTER

.

–D

O NOT START THE ENGINE AND ALLOW IT TO IDLE IN A CLOSED ROOM

. E

XHAUST

FUMES ARE POISONOUS AND CAN CAUSE LOSS OF CONSCIOUSNESS AND DEATH

.

A

LWAYS PROVIDE ADEQUATE VENTILATION WHILE THE ENGINE IS RUNNING

.

!

CAUTION

!

–M

AXIMUM PERIOD FOR CONTINUOUS STARTING: 5 SECONDS

. WAIT AT LEAST

5 SECONDS BEFORE TRYING AGAIN

.

–D

ON’T RIDE YOUR MOTORCYCLE WITH FULL LOAD AND DON’T REV ENGINE WHEN

COLD

. BECAUSE THE PISTON IS WARMING UP FASTER THAN THE WATER COOLED

CYLINDER

, IT CAN CAUSE ENGINE DAMAGE

. ALWAYS LET THE ENGINE WARM UP

BEFORE AND REFRAIN FROM DRIVING WITH FULL LOAD UNTIL THE ENGINE IS WARM

.

IF THE ENGINE IS DOES NOT CRANK WHEN YOU ACTUATE THE

STARTER TIP SWITCH:

– the transmission is switched to idle

– Check if the emergency OFF switch is on

– Check if the ignition is on

– the headlight is on.

– If this is not the case, the battery is discharged

– If the lights are on, proceed as described in the „Trouble-shooting“

section or contact a KTM dealer.

IF THE ENGINE CRANKS BUT DOES NOT START, WHEN YOU ACTUATE

THE STARTER TIP SWITCH:

– Check if the fuel tap is open

– Check if the choke lever has been operated

– Check if sufficient fuel is in the tank

– If this is not the case, refill the tank

– if sufficient fuel is in the tank, proceed as described in the „Trouble-

shooting“ section or contact a KTM dealer.

NOTE LC4 / LC4 SUPERMOTO:

This motorcycle is equipped with a safety starter system. The engine can

only be started when the transmission is switched to idle or the clutch lever

is pulled, respectively.

Motorcycles with side stands are also equipped with a safety starting

system.

If you put in a gear with the side stand in its swung-out position, and if you

let go of the clutch lever, the engine will stop.

Starting when the engine is warm or hot

1 Open the fuel tap 1

2 Switch on ignition (turn ignition key 2 into position ).

3 Switch on emergency OFF switch

3.

4 Switch transmission to idle (green indicator lamp N

4 lights up).

5 Do not accelerate; operate starter button

6.

6 Take the motorcycle off of the main stand or side stand.

What to do when the engine is „flooded”

The throttle must be fully opened when starting. If necessary change sparkplug.

6

5

1

4

2

3

Page 16

ENGLISH

15

Kickstart instructions

Be sure to kick up the side stand before you start the engine to

avoid any damage.

Start as described above, then push the kickstarter hard ALL

THE WAY.

WARNING

–W

HEN STARTING THE ENGINE, MAKE SURE THAT YOU ALWAYS WEAR

STURDY MOTORCYCLING BOOTS IN ORDER TO AVOID INJURY

. YOU

MIGHT SLIDE OFF THE KICKSTARTER

, OR THE ENGINE MAY CAUSE THE

KICKSTARTER TO RECOIL

, THEREBY CAUSING INJURIES TO FOOT AND

LEG

.

–

ALWAYS KICK THE KICKSTARTER BRISKLY ALL THE WAY AND

, WHILE

DOING SO

, NEVER OPEN THE THROTTLE

. KICKSTARTING WITH

INSUFFICIENT MOMENTUM AND AN OPENED THROTTLE LEVER

INCREASES THE DANGER OF A POSSIBLE RECOIL

.

!

CAUTION

!

BEFORE YOU ACTUATE THE KICKSTARTER

, BE SURE TO KICK UP THE SIDE

STAND

.

Starting off

Pull the clutch lever. Put the engine into first gear, slowly

release the clutch lever and open throttle at the same time.

WARNING

B

EFORE YOU START OFF, CHECK THAT THE MAIN STAND HAS BEEN SWUNG

UP FULLY

. IF THE STAND DRAGS ON THE GROUND, THE MOTORCYCLE CAN

GO OUT OF CONTROL

.

Shifting/Riding

You are now in first gear, refered to as the drive or uphill gear.

Depending on the conditions (traffic, road gradient, etc.), you

can shift to a higher gear. Close throttle, at the same time pull

clutch lever and shift to the next higher gear. Let clutch lever

go again and open throttle. If you turned on the choke, make

sure you turn it off again as soon as engine is warm.

When you reach full speed through turning the throttle grip all

the way, turn throttle back to 3/4; the speed hardly decreases

although the engine will use less gas. Never open the throttle

wider than the engine can handle. Excessive turning of the

throttle grip will increase full consumption.

By shifting down, use the brakes if necessary and close throttle

at the same time. Pull clutch lever and shift down to the next

gear. Let clutch lever go slowely and open throttle or shift

down again.

If, for example, the engine stalls at an intersection, simply pull

the clutch lever and start. You do not need to shift into the

neutral position.

WARNING

–A

VOID ABRUPT LOAD CHANGES WHILE RIDING AROUND BENDS AND

ON WET OR SLIPPERY GROUND

. OTHERWISE YOU MIGHT EASILY LOSE

CONTROL OVER YOUR MOTORCYCLE

.

–

WHILE RIDING YOUR MOTORCYCLE, NEVER SWITCH THE IGNITION

LOCK TO POSITIONS

AND .

–D

O NOT TRY TO CHANGE THE SETTINGS WHILE DRIVING. YOUR

ATTENTION WILL BE DISTRACTED FROM THE TRAFFIC AND MAY CAUSE

YOU TO LOSE CONTROL OF YOUR MOTORCYCLE

.

–A

FTER FALLING WITH THE MOTORCYCLE, CHECK ALL FUNCTIONS

THOROUGHLY BEFORE STARTING UP OPERATIONS AGAIN

.

!

CAUTION

!

–HIGH RPM RATES WHEN THE ENGINE IS COLD HAVE AN ADVERSE

EFFECT ON THE LIFE OF YOUR ENGINE

. WE RECOMMEND YOU RUN

THE ENGINE IN A MODERATE RPM RANGE FOR A FEW MILES GIVING IT

A CHANCE TO WARM UP

. AFTER THAT NO FURTHER PRECAUTIONS IN

THIS RESPECT NEED BE TAKEN

. THE ENGINE HAS REACHED ITS

OPERATING TEMPERATURE AS SOON AS THE RADIATORS BECOME

WARM

.

–N

EVER HAVE THE THROTTLE WIDE OPEN WHEN CHANGING DOWN TO

A LOWER GEAR

. THE ENGINE WILL OVERSPEED, DAMAGING THE

VALVES

. IN ADDITION

, THE REAR WHEEL BLOCKS SO THAT THE

MOTORCYCLE CAN EASILY GET OUT OF CONTROL

.

–L

ONG WHEELIES LEAD TO A DROP IN THE OIL PRESSURE WHICH CAN

LEAD TO ENGINE DAMAGE

.

–N

EVER USE YOUR MOTORCYCLE WITHOUT AN AIR FILTER. OTHERWISE

DUST AND DIRT MAY ENTER THE ENGINE AND CAUSE INCREASED WEAR

.

–

THE RED COOLANT WARNING LAMP LIGHTS UP WHEN THE COOLANT

TEMPERATURE HAS REACHED

120°C.

POSSIBLE CAUSES FOR THE INCREASE IN TEMPERATURE

:

-

LOW DRIVING VELOCITY AND HIGH LOAD SITUATION IN HIGH AIR

TEMPERATURES

-LEVEL OF COOLANT IN THE SYSTEM IS INSUFFICIENT

-FAN AT LEFT RADIATOR IS NOT RUNNING

-IMPROPER USE OF THE CLUTCH WHILE DRIVING AT LOW VELOCITIES

PLACE A CLOTH ON THE RADIATOR CAP

. OPEN THE CAP SLOWLY, SO

THE EXCESS PRESSURE IN THE COOLING SYSTEM CAN ESCAPE

.

- CAUTION SCALDING HAZARD! -

AND CHECK THE COOLING

LIQUID LEVEL

.

DO NOT DRIVE ON

, UNTIL THERE IS SUFFICIENT LIQUID IN THE COLING

SYSTEM

. HOWEVER, CALL ON ONE OF KTM’S DEALERS AS SOON AS

POSSIBLE IN ORDER TO HAVE THE DEFECT REMEDIED

.

–IF ANY ABNORMAL VIBRATIONS OCCUR WHILE DRIVING

, CHECK THAT

THE ENGINE FASTENING BOLTS ARE TIGHT

.

–I

N THE EVENT THAT, WHILE RIDING ON YOUR MOTORCYCLE, YOU

NOTICE ANY UNUSUAL OPERATION

-

RELATED NOISE,

STOP IMMEDIA-

TELY

, TURN THE ENGINE OFF

, AND CONTACT AN AUTHORIZED

KTM

DEALER.

Braking

Close throttle and apply the hand and foot brakes at the same

time. When driving on sandy, wet or slippery ground use

mainly the rear wheel brake. Always brake with feeling,

blocking wheels can cause you to skid or fall. Also change

down to lower gears depending on your speed.

When driving downhill, use the braking effect of the engine.

Change down one or two gears but do not overspeed the

engine. In this way, you will not need to brake so much and

the brakes will not overheat.

WARNING

–I

N THE RAIN, OR AFTER THE MOTORCYCLE HAS BEEN WASHED,

BRAKING ACTION MAY BE DELAYED DUE TO WET BRAKE DISCS. FIRST,

THE BRAKES MUST BE BRAKED DRY

.

–O

N SALT-SPRAYED OR DIRTY ROADS BRAKE ACTION MAY BE DELAYED

AS WELL

. FIRST, THE BRAKES MUST BE BRAKED CLEAN.

–WHEN YOU BRAKE

, THE BRAKE DISCS, BRAKE PADS, BRAKE CALIPER

AND BRAKE FLUID HEAT UP

. THE HOTTER THESE PARTS GET, THE

WEAKER THE BRAKING EFFECT

. IN EXTREME CASES, THE ENTIRE BRAKING

SYSTEM CAN FAIL

.

–D

IRTY BRAKE DISCS CAUSE INCREASED TEAR OF BRAKE PADS AND

BRAKE DISCS

.

Page 17

ENGLISH

16

Stopping and parking

Apply the brakes fully and put the engine into neutral. To stop the engine,

switch off the ignition. Turn the fuel tap to the OFF position, park on an

area where the ground is firm, and lock the motorcycle.

WARNING

–

ALWAYS PARK YOUR MOTORBIKE ON A SOLID AND HORIZONTAL SURFACE.

–N

EVER LEAVE YOUR MOTORCYCLE WITHOUT SUPERVISION AS LONG AS THE ENGINE IS

RUNNING

.

–M

OTORCYCLE ENGINES PRODUCE A GREAT AMOUNT OF HEAT WHILE RUNNING. THE

ENGINE RADIATORS

, EXHAUST, EXHAUST SYSTEM, BRAKE DISCS, AND SHOCK

ABSORBERS CAN BECOME VERY HOT

. DO NOT TOUCH ANY OF THESE PARTS AFTER

OPERATING THE MOTORCYCLE

, AND TAKE CARE TO PARK IT WHERE PEDESTRIANS ARE

NOT LIKELY TO TOUCH IT AND GET BURNED

–NEVER PARK YOUR MOTORCYCLE IN PLACES WHERE THERE EXIST FIRE HAZARDS DUE

TO DRY GRASS OR OTHER EASILY FLAMMABLE MATERIALS

.

–N

EVER LEAVE YOUR MOTORCYCLE WITHOUT SUPERVISION AS LONG AS THE ENGINE IS

RUNNING

.

!

CAUTION

!

–CLOSE THE FUEL TAP WHEN LEAVING YOUR VEHICLE

.OTHERWISE THE CARBURETOR

CAN OVERFLOW AND FUEL WILL ENTER THE ENGINE

.

–A

LWAYS TAKE OUT THE IGNITION KEY WHEN PARKING YOUR MOTORCYCLE SO THAT

IT CANNOT BE USED BY UNAUTHORIZED PERSONS

.

INFORMATION ABOUT THE SIDE STAND:

Use your foot to push the side stand forward as far as possible, and lean

your motorcycle to the side. Make sure that your motorcycle is standing

safely on solid ground. Just in case, you can also put in a gear.

!

CAUTION

!

THE SIDE STAND IS DIMENSIONED FOR THE WEIGHT OF THE MOTORCYCLE ONLY. IF YOU

ARE SITTING ON THE MOTORBIKE AND THUS APPLY AN ADDITIONAL LOAD ONTO THE SIDE

STAND

, YOU MAY CAUSE DAMAGE TO THE SIDE STAND OR THE FRAME

, AND YOUR

MOTORBIKE MAY FALL OVER

.

NOTE REGARDING THE CENTER STAND: (is available as an accessory)

We advise the following procedure to place the motorcycle on the center

stand as effortlessly as possible:

a) press main stand to ground using foot

b) swing out kickstarter and pull motorcycle backwards at an angle as

illustrated (see illustration).

Make sure that the ground is solid and that your motorcycle is standing

securely.

!

CAUTION

!

T

HE CENTER STAND IS DESIGNED TO HOLD THE WEIGHT OF THE MOTORCYCLE ONLY

. BY

SITTING ON THE MOTORCYCLE

, YOU WILL PUT ADDITIONAL WEIGHT ON THE CENTER

STAND

, POSSIBLY CAUSING THE CENTER STAND OR FRAME TO BE DAMAGED OR THE

MOTORCYCLE TO FALL DOWN

.

Fuel

In the condition at delivery, the LC4 engine requires unleaded premiumgrade fuel with at least 95 octane (ROZ).

If using lower octane fuel, it is easy to change over to the pre-programmed

ignition curve for 80 - 94 octane (ROZ) (see activating the ignition curve for

low-octane fuel).

!

CAUTION

!

USE UNLEADED PREMIUM-GRADE 95 OCTANE (ROZ) FUEL. IF USING LOWER OCTANE

FUEL

, THE IGNITION CURVE MUST BE CHANGED, OTHERWISE ENGINE DAMAGE WILL

OCCUR

.

WARNING

G

ASOLINE IS HIGHLY FLAMMABLE AND POISONOUS

. EXTREME CAUTION SHOULD BE USED

WHEN HANDLING GASOLINE

. DO NOT REFUEL THE MOTORCYCLE NEAR OPEN FLAMES OR

BURNING CIGARETTES

. ALWAYS SWITCH OFF THE ENGINE BEFORE REFUELLING. BE

CAREFUL NOT TO SPILL GASOLINE ON THE ENGINE OR EXHAUST PIPE WHILE THE ENGINE IS

HOT

. WIPE UP SPILLS PROMPTLY. IFGASOLINE IS SWALLOWED OR SPLASHED IN THE EYES,

SEEK A DOCTOR

’S ADVICE IMMEDIATELY.

Fuel expands when its temperature rises. Therefore do not fill the tank to

the top (see fig.).

35 mm

Page 18

ENGLISH

17

Page 19

ENGLISH

18

PERIODIC MAINTENANCE SCHEDULE

1. Service

after

1000 km

2. Service after

5000 km, then

every 5000 km or

once a year

IF MOTORCYCLE IS USED FOR COMPETITION 5000 KM SERVICE SHOULD BE CARRIED OUT AFTER EVERY RACE!

S

ERVICE INTERVALLS SHOULD NEVER BE EXCEED BY MOOR THAN

500

KM

.

M

AINTENANCE WORK DONE BY

KTM

AUTHORISED WORKSHOPS IS NOT A SUBSTITUTE OF CARE AND CHECKS DONE BY THE RIDER

!

A washed motorcycle can be checked more quickly which saves money!

Change engine oil, oil filter, and fine filter ●●

Clean oil screens and magnet of drain plug ●●

Check oil lines for damage and kink-less arrangement ●●

Check and adjust spark plug, replace it every 10,000 km ●

Check and adjust valve clearance ●●

Check engine fastening screws for tight fit ●●

Make sure all engine screws accessible from the outside are screwed tight ●●

Check carburetor connection boots for cracks and leaks ●

Check idle setting ●●

Check bleeder hoses for damage and kink-free arrangement ●●

Check cooling system for leaks, antifreeze protection ●●

Check radiator fan for proper operation ●

Check exhaust system for leaks and suspension ●●

Check actuating cables for damage, smooth operation, and kink-less arrangement,adjust and lubricate them ●●

Check the oil level in the master cylinder of the hydraulic clutch ●●

Clean air filter and air filter box ●

Check cables for damage and kink-less arrangement ●

Check headlamp adjustment ●

Check electrical system for function (low/high beams, stop light, turn indicators,headlamp flasher, ●●

tell-tale lamps, speedometer illumination, horn, side-stand switch, clutch switch, emergency-off switch)

Make sure all screws and nuts are tight. ●●

Check brake fluid level, lining thickness, and brake discs ●●

Check brake lines for damage and leaks ●●

Check/adjust smooth operation, free travel of handbrake/footbrake levers ●●

Check screws of brake system for tight fit

●●

Check suspension strut and fork for leaks and proper operation ●●

Check O-ring of suspension strut for wear ●

Clean fork dust sleeves ●

Bleed fork legs ●●

Check swinging-fork pivot ●●

Check/adjust steering-head bearing ●●

Lubricate reversing lever ●

Check all chassis screws for tight fit (fork plates, fork leg, axle nuts/screws, ●●

swinging-fork pivot, reversing lever, suspension strut)

Check spoke tension and rim joint ●●

Check tire condition and inflation pressure ●●

Check chain and chain guides for wear, force fit and tension. ●●

Check screws on pinion and chain sprocket for locking devices and a tight fit. ●●

Lubricate chain ●●

Check wheel bearings and jerk damper for play

●

IMPORTANT RECOMMENDED MAINTENANCE PROCEDURES TO BE PERFORMED BASED ON A SEPARATE SUPPLEMENTARY ORDER

Perform complete fork maintenance ●

Perform complete suspension strut maintenance ●

Perform complete reversing lever maintenance ●

Clean and lubricate steering-head bearing and sealing elements ●

Clean and adjust the carburetor ●

Treat the electrical contacts and switches with contact spray ●

Treat battery connections with contact grease ●

Change the brake fluid

●

WHEELS CHASSIS BRAKES ADD-ON-PARTS

CARBURETOR

ENGINE

640 LC4

640 LC4 SUPERMOTO

every 2 years

or 20000 km

at least

once a year

Page 20

ENGLISH

19

VITAL CHECKS AND CARE PROCEDURES TO BE CONDUCTED BY THE OWNER OR THE MECHANIC

Check oil level ●

Check brake fluid level ●

Check brake pads for wear ●

Check lighting system for proper operation ●

Check horn for proper operation ●

Lubricate and adjust actuating cables and nipples ●

Bleed fork legs in regular intervals ●

Remove and clean fork dust sleeves in regular intervals ●

Clean and lubricate chain as necessary ●●

Check chain tension ●●●

Clean air filter and filter box (depending on the dirt accumulation) ●

Check tire pressure and wear ●

Check coolant level ●

Check fuel lines for leaks ●

Drain float chamber ●

Check all control elements for smooth running. ●

Check brake performance ●●

Treat exposed metal components (except for the braking and exhaust ●

systems) with wax-based anti-corrosion agents

Treat ignition/steering lock and light switch with contact spray ●

Check all screws, nuts, and hose clamps for their tight fit ●

once a yearfor cross

country use

after every

cleaning

before each

start

PERIODIC MAINTENANCE SCHEDULE

640 LC4

640 LC4 SUPERMOTO

Page 21

ENGLISH

20

WARNING

ALL SERVICING AND ADJUSTMENT PROCEDURES DESIGNATED BY AN ASTERISK * REQUIRE THE KNOWLEDGE

AND SKILLS OF A PROFESSIONAL. FOR YOUR OWN SAFETY, ALWAYS HAVE SUCH WORK PERFORMED BY A

SPECIALIZED KTM DEALER WHERE YOUR MOTORCYCLE WILL BE OPTIMALLY SERVICED BY APPROPRIATELY

QUALIFIED,SKILLED STAFF.

!

CAUTION

!

–W

HEN CLEANING THE MOTORCYCLE

, DO NOT USE A HIGH PRESSURE CLEANING UNIT IF POSSIBLE

, OTHERWISE WATER WILL PENETRATE THE BEARINGS,

CARBURETOR, ELECTRIC CONNECTORS ETC.

–W

HEN TRANSPORTING YOUR KTM, ENSURE THAT IT IS HELD UPRIGHT WITH RESTRAINING STRAPS OR OTHER MECHANICAL FASTENING DEVICES

. IF THE

MOTORCYCLE SHOULD FALL OVER

, FUEL CAN LEAK FROM THE CARBURETOR OR FUEL TANK

–D

O NOT USE TOOTHED WASHERS OR SPRING WASHERS WITH THE ENGINE FASTENING SCREWS

, AS THESE WORK INTO THE FRAME PARTS AND KEEP

WORKING LOOSE

. INSTEAD, USE SELF

-LOCKING NUTS.

–L

ET YOUR MOTORCYCLE COOL DOWN BEFORE BEGINNING ANY MAINTENANCE WORK IN ORDER TO AVOID GETTING BURNED

.

–D

ISPOSE OF OIL, GREASE, FILTERS, FUELS, CLEANING AGENTS ETC. ACCORDING TO YOUR LOCAL REGULATIONS.

–U

NDER NO CIRCUMSTANCES MAY USED OIL BE DISPOSED OF IN THE SEWAGE SYSTEM OR IN THE OPEN COUNTRYSIDE. 1 LITER USED OIL CONTAMINATES

1,000.000 LITERS WATER.

–

IF YOU UNFASTEN SELF-LOCKING NUTS, YOU HAVE TO REPLACE THEM BY NEW ONES.

–AFTER REMOVING ANY SCREWS AND NUTS SECURED WITH LOCTITE THEY MUST BE MOUNTED AND SECURED IN THE SAME MANNER (SEE TECHNICAL

DATA – TIGHTENING

TORQUES

).

Tool set

The tool set 1 is located in the tool box under the right side cover.

Removing the seat

Remove the collar screws 2 from the underside of the fender. Lift the rear

of the seat, pull backwards, and unhook it from the oval-head screw

3.

To mount the seat hook it into the oval head screw, lower the rear part of

the seat and push the whole seat forwards. If necessary push the middle of

the seat slightly down to let the retaining bracket

4 engage with the seat.

Finally fasten the seat with the corresponding screw.

MAINTENANCE WORK ON CHASSIS AND ENGINE

2

4

3

2

1

Page 22

ENGLISH

21

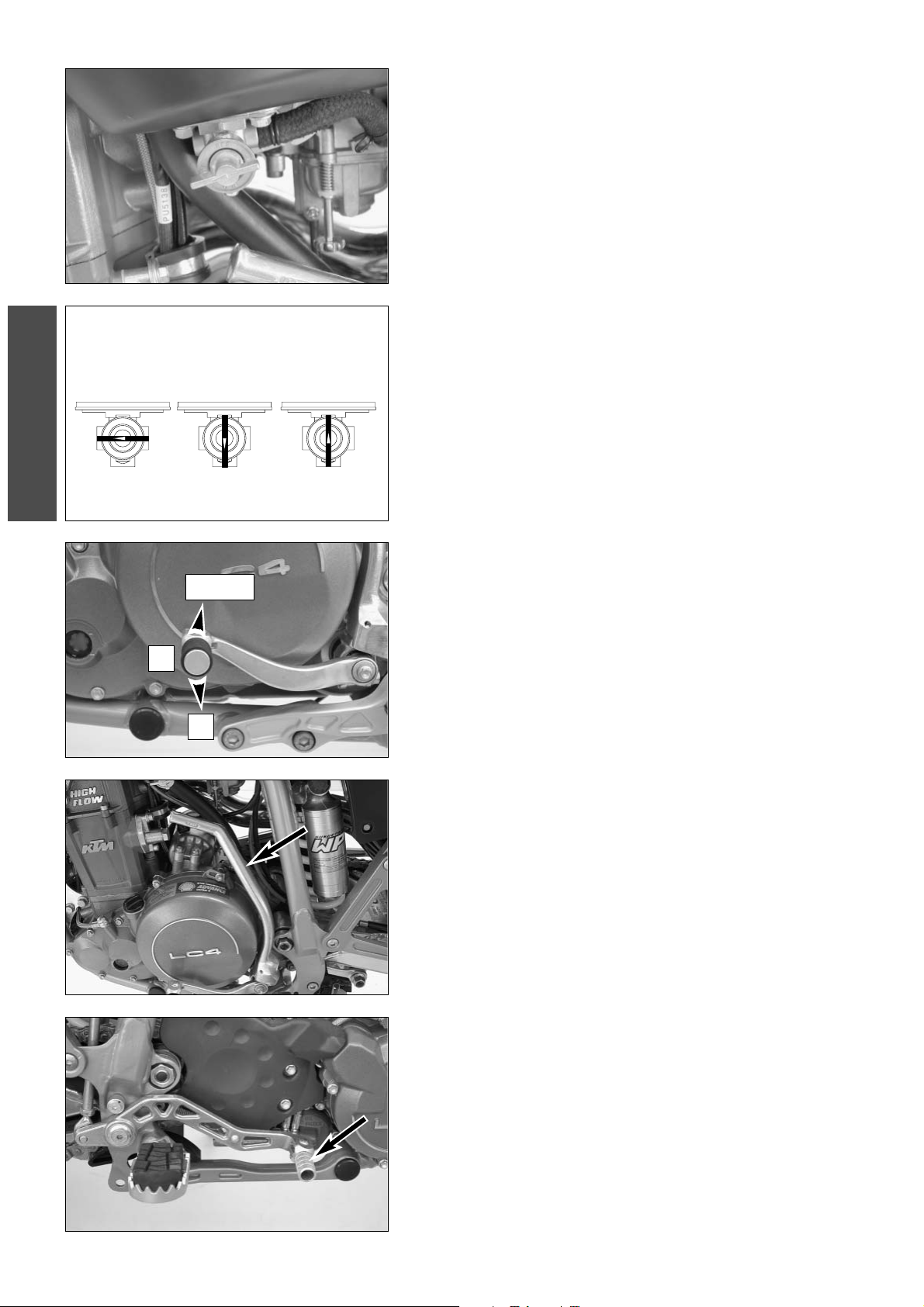

Checking and adjusting steering head bearing *

Check steering head bearing for play periodicaly. To check this put

motorcycle on a stand so that the front wheel is off the ground. Now try to

move the fork forward and backward. To adjust, loosen the five clamp

screws

1 of the top triple clamp and turn steering stem bolt clockwise 2

until there is no more play. Don’t tighten the steering stem bolt all the way,

otherwise the bearings will be damaged. With a plastic hammer, lightly rap

on the triple clamp to avoid tension. Re-tighten the five clamp screws with

20 Nm.

WARNING

I

F THE STEERING HEAD BEARING IS NOT ADJUSTED TO BE FREE OF PLAY, THE MOTOR-

CYCLE WILL SHOW AN UNSTEADY DRIVING PERFORMANCE AND CAN GET OUT OF

CONTROL

.

!

CAUTION

!

IF YOU DRIVE WITH PLAY IN THE STEERING HEAD BEARING FOR LONGER PERIODS

, FIRST

THE BEARINGS AND THEN THE BEARING SEATS IN THE FRAME WILL BE DESTROYED

.

At least once a year, the steering head bearings should be greased.

Bleeder screws for telescopic fork

After every 5 hours of use for competitive racing, slacken the breather

plugs

3 a few turns in order to relieve excess pressure from the inside of

the fork. To do this, place the motorcycle on a stand with the front wheel

lifted off the ground. When riding the motorcycle mainly on street, it will be

enough to have this job performed in the course of the periodical

maintenance service.

!

CAUTION

!

EXCESSIVE PRESSURE IN THE INTERIOR OF THE FORK CAN CAUSE LEAKS IN THE FORK

. I

F

YOUR FORK IS LEAKING

, IT IS RECOMMENDED TO OPEN THE BREATHER PLUGS BEFORE

HAVING THE SEALS REPLACED

.

Cleaning the dust sleeves of the telescopic fork

The dust-protection bellows 4 are to remove dust and coarse dirt particles

from the fork tube. However, after some time, dirt may also get in behind

the dust-protection bellows. If this dirt is not removed, the oil sealing rings

located behind it may start to leak.

Use a screwdriver to lever the dust-protection bellows out of the outer

tubes and slide them downward.

Clean dust-protection bellows, outer tubes, and fork tubes thoroughly, and

oil them thoroughly with silicone spray. Then, push dust-protection bellows

into the outer tubes by hand.

WARNING

N

OSILICONE OIL MAY REACH THE FRONT TIRE OR THE BRAKE DISKS SINCE THIS WOULD

CONSIDERABLY REDUCE THE TIRE

'S ROAD GRIP AND THE BRAKING EFFECT OF THE FRONT

BRAKE

.

2

1

3

4

Page 23

ENGLISH

22

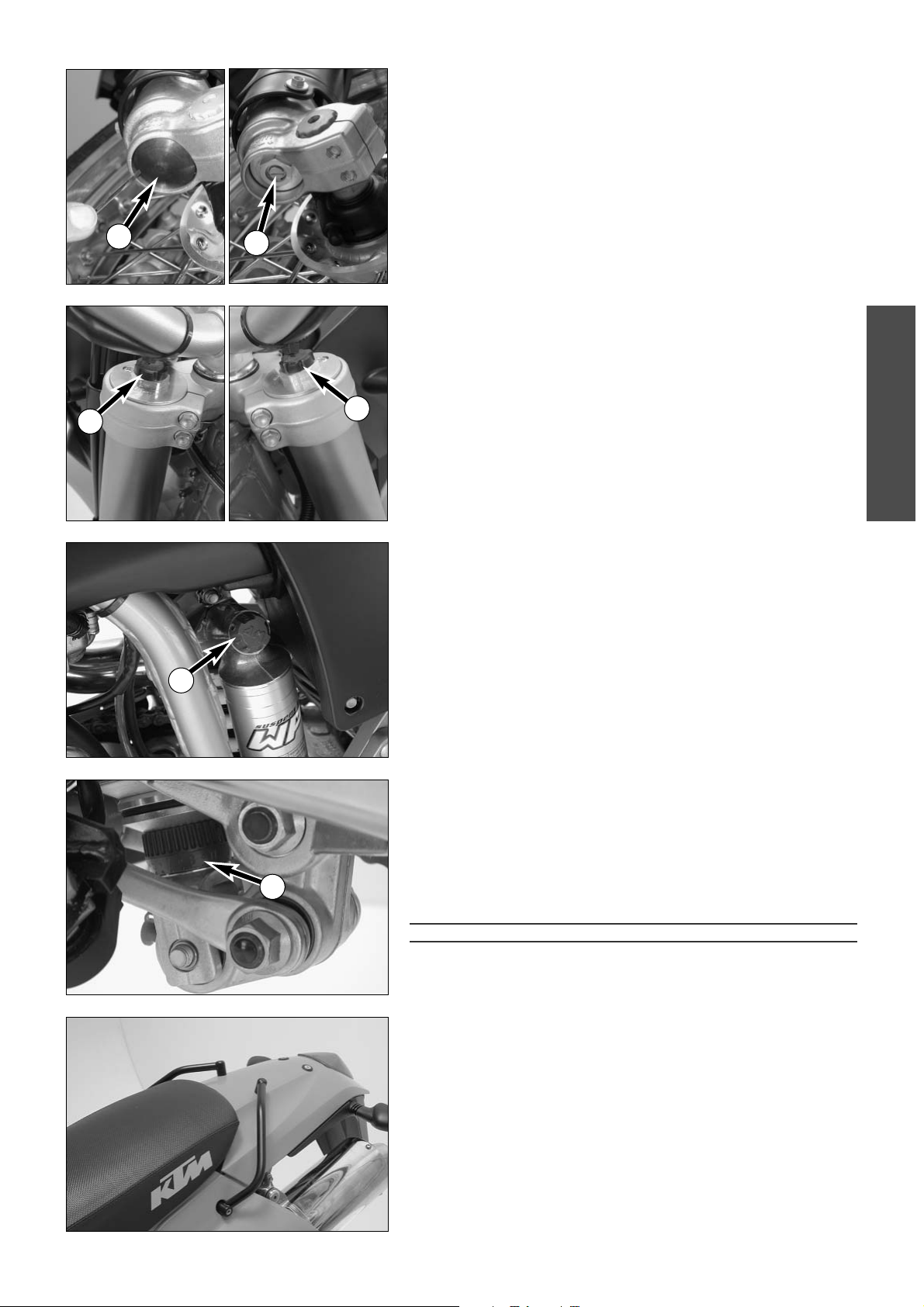

Changing the spring preload of the shock absorber

KTM sets the shock absorber for a driver only, weighing approximately 75

kg (165 lb). If you want to take a passenger with you, of if you weigh

considerably more or less than 75 kg (165 lb), you should change the spring

preload accordingly

A. This is easily done.

NOTE:

– Before changing the spring preload note down the basic setting, e.g.

how many threads are visible above the adjusting ring.

– One rotation of the adjusting ring

2 changes the spring preload by

approximately 1.75 mm (0.07 in).

Loosen the locking ring

1 with the hook wrench from the tool set. Change

the spring preload with the adjusting ring

2 and retighten the locking ring.

BASIC SETTING – SPRING PRELOAD:

WP 0118Y734 .............A = 23,5mm (640 LC4)

WP 0118Y733 .............A = 22mm (640 LC4 Supermoto)

Lubricating the shock absorber linkage

The bearings in the rocker arm must be greased (Motorex Long Therm

2000) in regular intervals. For this purpose, a grease nipple

3 is mounted

on the rocker arm.

!

CAUTION

!

AFTER EACH TIME THE MOTORCYCLE IS WASHED

,

IT IS ESPECIALLY IMPORTANT TO

GREASE THE GREASE NIPPLE TO PUSH ANY WATER OUT OF THE BEARINGS

.

Checking rubber ring on the WP rear shock absorber

A rubber ring mounted on the rear shock absorber serves as a vibration

damper. This ring gets pressed together with time and loses its shock

absorbing quality.

Measure the distance between the two discs at various points around their

circumferences. The space should be at least 2.5 mm (0.1 in) wide. Have

the rubber ring replaced by an KTM dealer when compaction due to wear

has exceeded this lower limit.

!

CAUTION

!

N

OT REPLACING THE RUBBER RING IN TIME CAN RESULT IN DAMAGE TO THE REAR SHOCK

ABSORBER

.

WARNING

T

HE DAMPING UNIT OF THE SHOCK ABSORBER IS FILLED WITH HIGH COMPRESSED

NITROGEN

. NEVER TRY TO TAKE THE SHOCK ABSORBER APART OR TO DO ANY

MAINTENANCE WORK YOURSELF

. S

EVERE INJURIES COULD BE THE RESULT.

A

min. 2,5 mm

2

1

3

Page 24

ENGLISH

23

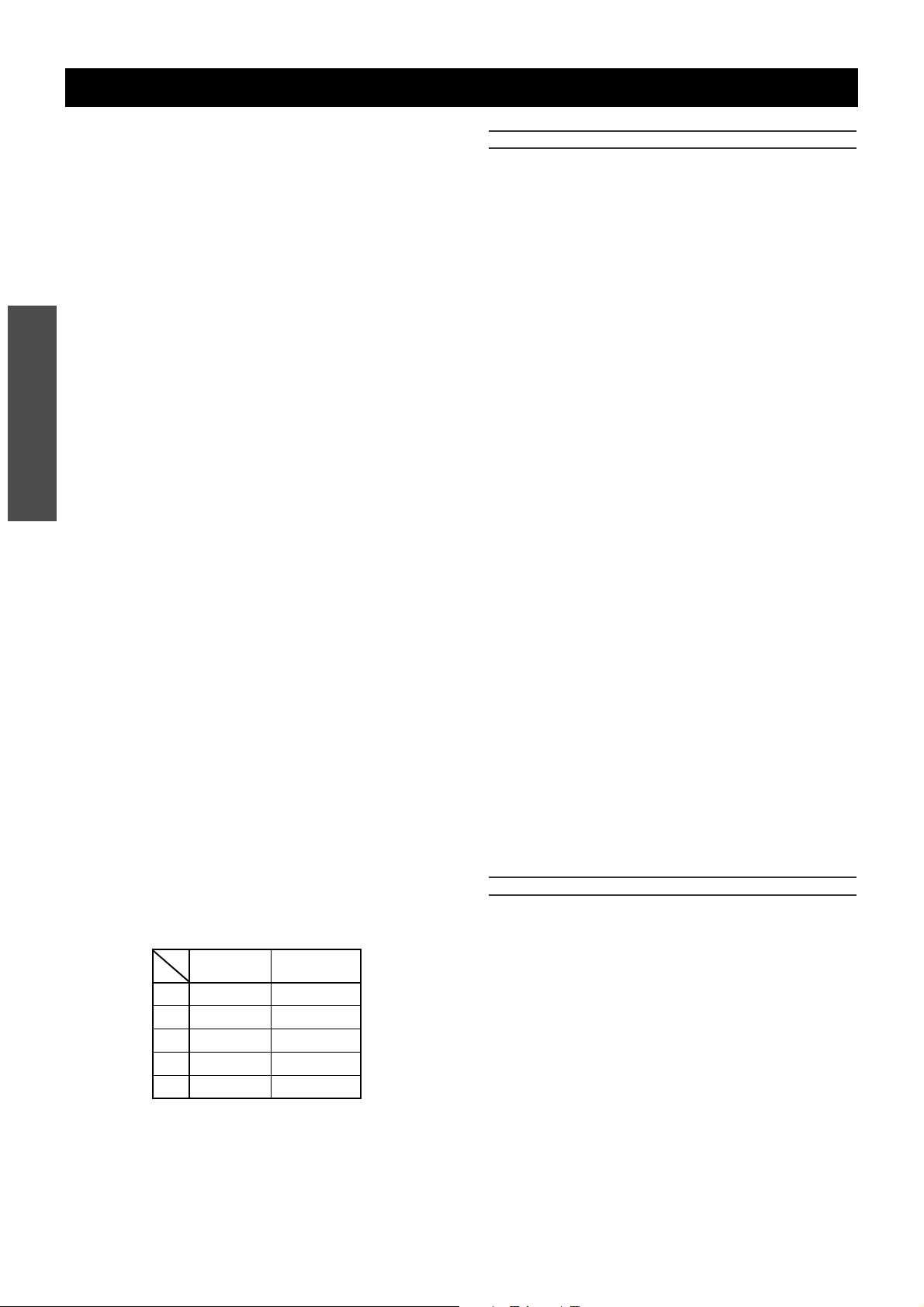

Checking chain tension

To check, jack up the motorcycle on the center stand or frame until it no

longer touches the ground.

Press the chain up approx. 30 mm behind the end of the chain sliding

component. The chain should barely touch the swing arm when the upper

chain part

A is tensioned. If not, correct the chain tension.

WARNING

–I

F CHAIN TENSION IS TOO GREAT

, PARTS WITHIN THE SECONDARY POWER TRANS-

MISSION (CHAIN, CHAIN SPROCKETS, TRANSMISSION AND REAR WHEEL BEARINGS)

WILL BE SUBJECTED TO UNNECESSARY STRESS, RESULTING IN PREMATURE WEAR AND

EVEN CHAIN BREAKAGE

.

–T

OO MUCH SLACK IN THE CHAIN, ON THE OTHER HAND, CAN RESULT IN THE CHAIN

JUMPING OFF THE CHAIN WHEELS

. IF THIS HAPPENS

, THE CHAIN COULD ALSO BLOCK

THE REAR WHEEL OR DAMAGE THE ENGINE

.

–I

N EITHER CASE THE OPERATOR IS LIKELY TO LOSE CONTROL OF THE MOTORCYCLE

.

Correct chain tension

Loosen collar nut 1, loosen counter nuts 2, and turn right and left

adjusting screws

3 equally far. Tighten counter nuts 2.

Before tightening the wheel spindle, verify that the chain adjusters

4 are

sitting close to the adjusting screws and that the rear wheel has been

aligned with the front wheel.

Tighten collar nut

1 with 80 Nm.

WARNING

I

F YOU DON

’T HAPPEN TO HAVE A TORQUE WRENCH AT HAND

,

MAKE SURE YOU HAVE

THE TIGHTENING TORQUE CORRECTED BY A

KTM DEALER AS SOON AS POSSIBLE. A

LOOSE AXLE MAY LEAD TO AN UNSTABLE DRIVING BEHAVIOR OF YOUR MOTORCYCLE.

NOTE: The large adjusting range of the chain adjusters 32mm (1.28 in)

allows you to use different secondary ratios in combination with the same

chain length. The chain adjusters

4 can be rotated by 180°.

!

CAUTION

!

ALWAYS MOUNT THE CHAIN TENSIONER EQUALLY ALIGNED.

4

1

4

2

3

A

Page 25

ENGLISH

24

Chain maintenance

For long chain life, good maintenance is very important. X-ring chains

require only modest maintenance. The best way is to use lots of water, but

never use brushes or solvents. After letting the chain dry, you can use a

special X-ring chain spray (Motorex Chainlube Racing).

WARNING

N

O LUBRICATION IS ALLOWED TO REACH THE REAR TIRE OR THE BRAKE DISK, EITHERWISE

THE ROAD ADHERENCE AND THE REAR WHEEL BRAKING EFFECTS WOULD BE STRONGLY

REDUCED AND THE MOTORCYCLE COULD EASILY GET OUT OF CONTROL

.

!

CAUTION

!

WHEN MOUNTING THE CHAIN JOINT, THE CLOSED SIDE OF THE SAFETY DEVICE MUST

POINT IN RUNNING DIRECTION

.

Also check sprockets and chain guides for wear, and replace if necessary.

Chain wear

In order to check the chain wear, regard the following instructions:

Shift the gear into idling and pull the upper chain strand with approx. 10-15

kilogramm (33 lb) upwards (see figure). Now one can measure a space of

18 chain reels at the lower chain strand. The chain should be replaced at the

latest when a space of 272 mm (10.88 in) is measured. Chains do not

always wear off evenly, therefore repeat the measurement at different

places on the chain.

NOTE: If you mount a new chain, the sprockets should also be replaced.

New chains wear faster if used on old used sprockets.

✓

15 KG

max. 272 mm

1 2 3

16 17 18

Page 26

ENGLISH

25

General informations about KTM disc brakes

BRAKE CALIPERS (LC4):

The brake calipers of this series “float“. This means that the brake calipers

are not solidly attached to the caliper support. Thus, the brake pads are

always in optimum contact with the brake disc. Secure the screws of the

caliper support with Loctite 243 and tighten to 25 Nm.

BRAKE CALIPERS (LC4 SUPERMOTO):

The front brake caliper

1 has 4 brake pistons and is rigidly connected to

the fork leg. The rear brake caliper has one brake piston and "floats", which

means that it is not rigidly connected to the brake caliper support. The

resulting lateral adjustment ensures that the brake pads

2 optimally rest

against the brake disk at any time. Secure the screws

3 of the caliper

support with Loctite 243 and tighten to 40 Nm.

BRAKE PADS:

The motorcycles are delivered with organic brake pads and have also been

type-coded with these pads. Said pads are suitable for almost the entire

range of application of these motorcycles.It is only for competitive racing in

extremely dirty conditions (e.g., water in combination with sand and mud)

that we recommend brake pads that have sintered linings. However, take

notice of the fact that brake pads with sintered linings have not been type

coded! Besides, they may cause greater wear on the brake discs.

WARNING

B

RAKE PADS AVAILABLE IN THE ACCESSORY TRADE ARE OFTEN NOT AUTHORIZED FOR

OPERATION OF YOUR

KTM MOTORCYCLE IN ROAD TRAFFIC

. THE BRAKE PADS DESIGN

AND FRICTION FACTOR AND THEREFORE THE BRAKING POWER CAN DEVIATE

SIGNIFICANTLY FROM ORIGINAL

KTM BRAKE PADS. IF YOU USE DIFFERENT BRAKE PADS

THAN THOSE PROVIDED WITH THE ORIGINAL EQUIPMENT

, IT CANNOT BE WARRANTED

THAT THEY ARE AUTHORIZED FOR USE IN ROAD TRAFFIC

. Y

OUR MOTORCYCLE WILL NOT

LONGER COMPLY WITH THE REGULATIONS AUTHORIZING THE USE OF VEHICLES FOR

ROAD TRAFFIC AND THE WARRANTY WILL BE VOID

.

BRAKE FLUID:

KTM fills the brake systems with „Motorex Brake Fluid DOT 5.1“ brake

fluid, one of the best brake fluids that is currently available. We recommend

that you continue to use it. DOT 5.1 brake fluid is based on glycol ether

and of an amber color. If you do not have any DOT 5.1 for refilling, you

may use DOT 4 brake fluid. However, you should replace it as soon as

possible by DOT 5.1.

Never use DOT 5 braking fluid. It is based on silicone oil and has a purple

color. Gaskets and brake hoses are not compatible with it.

WARNING

H

AVE THE BRAKE FLUID CHANGED AT LEAST ONCE ANNUALLY. IF YOU WASH YOUR

MOTORCYCLE OFTEN

, THE BRAKE FLUID SHOULD BE CHANGED EVEN MORE FREQUENTLY.

BRAKE FLUID TENDS TO ABSORB WATER

. T

HEREFORE

, VAPOR POCKETS MAY FORM IN

"OLD" BRAKE FLUIDS EVEN AT LOW TEMPERATURES, CAUSING THE BRAKE SYSTEM TO

FAIL

.

BRAKE FLUID RESERVOIRS:

The brake fluid reservoirs on the front and rear wheel brakes have been

designed in such a way that even if the brake pads are worn it is not

necessary to top up the brake fluid. If the brake fluid level drops below the

minimum either the brake system has a leak or the brake pads are

completely worn down. In this case, consult an authorized KTM dealer

immediately.

BRAKE DISCS:

Wear reduces the thickness of the brake disc in the area of contact

4 with

the brake pads. At its thinnest spot

A, the brake disc must not be more

than 0.4mm thinner than its nominal dimension

B. The nominal dimension

can be gaged in a location beyond the area of contact with the brake pads.

Check wear in several spots.

WARNING

–B

RAKE DISCS SUFFERING FROM WEAR GREATER THAN 0.4 MM CONSTITUTE A SAFETY

HAZARD

. HAVE THE BRAKE DISC REPLACED IMMEDIATELY AS SOON AS IT REACHES ITS

WEAR LIMIT

.

–A

SAMATTER OF PRINCIPLE, HAVE ANY REPAIR OF THE BRAKE SYSTEM CARRIED OUT

BY A LICENSED

KTM MECHANIC.

DOT

5.1

DOT

5

✓

✕

A

B

4

1

2

3

LC4

LC4 SUPERMOTO

Page 27

ENGLISH

26

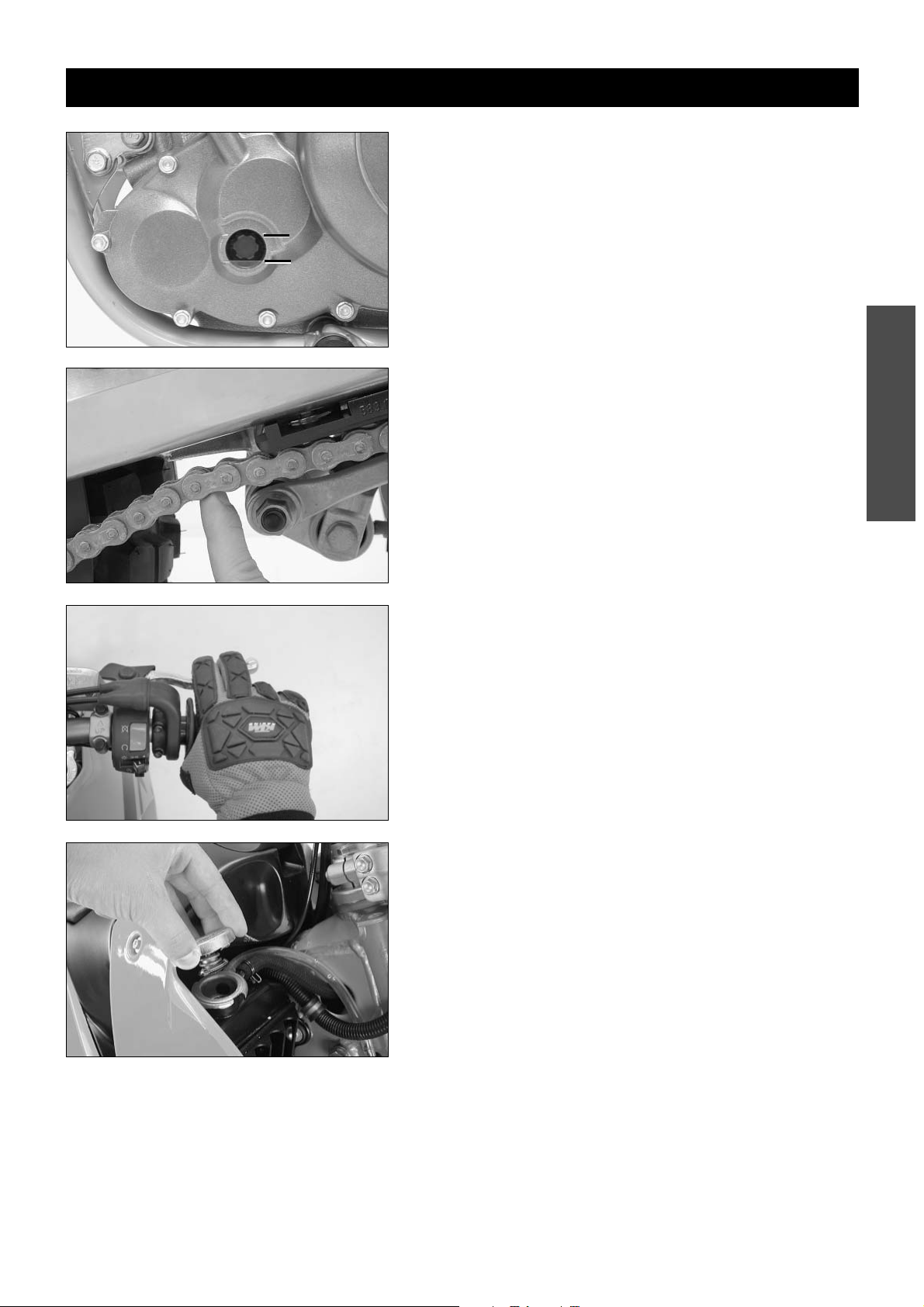

Adjusting of free travel at the hand brake lever (LC4)

Free travel at the hand brake lever may be readjusted by using adjusting

screw

1. In this way, the position of the point of pressure (i.e., the

resistance you feel on the hand brake lever when the brake pads are

pressed against the brake disc) can be adjusted for any hand size. When

you press the hand brake lever forwards, you should have at least 3 mm

(0.12 in) free travel. Turn the adjusting screw

1 if necessary.

!

CAUTION

!

AT THE HAND BRAKE LEVER, FREE TRAVEL MUST AT LEAST BE 3 MM (0.12 IN). ONLY

THEN MAY THE PISTON IN THE HAND BRAKE CYLINDER BE MOVED

(TO BE RECOGNIZED BY

THE GREATER RESISTANCE OF THE HAND BRAKE LEVER

). IF THIS FREE TRAVEL IS NOT

PROVIDED

, PRESSURE WILL BUILD UP IN THE BRAKING SYSTEM, AND THE FRONT WHEEL

BRAKE MAY FAIL DUE TO OVERHEATING

.

Changing the basic position of the handbrake lever (LC4

Supermoto)

The adjusting screw 2 allows you to change the basic position of the handbrake lever

3.

Press the handbrake lever's outer end forward, and, at the same time, turn

the adjusting screw.

Checking of brake fluid level - front brake

The brake fluid reservoir is linked with the hand brake cylinder at the

handlebar and the reservoir is provided with an inspection glass. With the

reservoir in a horizontal position, the brake fluid level should not go below

middle of the glass.

WARNING

I

F THE BRAKE FLUID LEVEL DROPS BELOW THE MINIMUM EITHER THE BRAKE SYSTEM HAS A

LEAK OR THE BRAKE PADS ARE COMPLETELY WORN DOWN

. IN THIS CASE, CONSULT AN

AUTHORIZED

KTM DEALER IMMEDIATELY.

Refilling the front brake fluid reservoir *

Loosen screws 4 and remove lid 5 and membrane 6.

If necessary, dismount the mirror and loosen the throttle grip.

Place hand brake cylinder in a horizontal position and fill the brake fluid

reservoir to 5 mm (0.2 in) below the rim with brake fluid DOT 5.1 (Motorex

Brake Fluid DOT 5.1). Replace membrane and lid, tighten screws. Rinse off

spilled or overflowing brake fluid with water.

WARNING

–N

EVER USE DOT5 BRAKE FLUID! ITISBASED ON SILICONE OIL AND OF A PURPLE

COLOR

. SEALS AND BRAKE HOSES MUST BE ESPECIALLY ADAPTED TO IT.

–S

TORE BRAKE FLUID OUT OF REACH OF CHILDREN.

–BRAKE FLUID CAN CAUSE SKIN IRRITATION. AVOID CONTACT WITH SKIN AND EYES. IF

YOU GET BRAKE FLUID IN YOUR EYES

, RINSE WITH PLENTY OF WATER AND CONSULT

A DOCTOR

.

!

CAUTION

!

–DON’T LET BRAKE FLUID GET IN CONTACT WITH PAINT, IT IS AN EFFECTIVE PAINT

REMOVER

.

–U

SE ONLY CLEAN BRAKE FLUID TAKEN FROM A TIGHTLY SEALED CONTAINER.

5 mm

min. 3 mm

2

3

1

6

5

4

Page 28

ENGLISH

27

Checking the front brake pads (LC4)

The brake pads can be inspected from below. The linings must be at least

1 mm (0.04 in) thick.

WARNING

A

T THEIR MOST WORN POINT BRAKE PAD LININGS SHOULD NOT BE THINNER THAN

1

MM, OTHERWISE THEY COULD LEAD TO BRAKE FAILURE. FOR YOUR OWN SAFETY

DON

’T PUT OFF HAVING YOUR BRAKE PADS CHANGED.

!

CAUTION

!

IF THE BRAKE PADS ARE REPLACED TOO LATE SO THAT THE LINING IS PARTLY OR ENTIRELY

WORN AWAY

, THE STEEL COMPONENTS OF THE BRAKE PAD WILL RUB AGAINST THE BRAKE

DISC

, IMPAIRING THE BRAKING EFFECT AND DESTROYING THE BRAKE DISC.

Checking the front brake pads (LC4 Supermoto)

The brake pads can be inspected from behind. Always inspect the brake pad

linings before taking off on your motorcycle. They should not be thinner

than 1 mm (0.04 in) which is the case when the notch

A is no longer

discernable.

WARNING

A

T THEIR MOST WORN POINT BRAKE PAD LININGS SHOULD NOT BE THINNER THAN

1

MM, OTHERWISE THEY COULD LEAD TO BRAKE FAILURE. FOR YOUR OWN SAFETY DON’T

PUT OFF HAVING YOUR BRAKE PADS CHANGED

.

!

VORSICHT

!

IF THE BRAKE PADS ARE REPLACED TOO LATE SO THAT THE LINING IS PARTLY OR ENTIRELY

WORN AWAY

, THE STEEL COMPONENTS OF THE BRAKE PAD WILL RUB AGAINST THE BRAKE

DISC

, SIGNIFICANTLY IMPARING THE BRAKING EFFECT AND DESTROYING THE BRAKE DISC.

Changing the basic position of the foot brake pedal *

The basic position of the foot brake pedal can be altered by turning the stop

roller

1. The free play at the foot brake pedal must then be adjusted by

means of the piston rod

2.

Measured on the outside, the foot brake pedal must have 3-5 mm

(0.12–0.20 in) of free play, before the piston rod can move the piston in the

brake cylinder (to be recognised from the resistance on the foot

brake pedal).

NOTE: To prevent the stop roller from turning when tightening, counteract

by inserting a hexagon socket wrench in hole

B provided for this purpose.

!

CAUTION

!

IF THIS FREE PLAY IS NOT PRESENT

, THEN PRESSURE CAN BUILD UP IN THE BRAKE SYSTEM

WHEN DRIVING

, CAUSING CONSTANT FRICTION OF THE BRAKE PADS.THE BRAKING SYSTEM