Page 1

©

KROHNE 12/2004 7.02391.22.00

Technical Data Sheet

GR

Subject to change without notice.

Electromagnetic flowmeters

Variable area flowmeters

Mass flowmeters

Ultrasonic flowmeters

Vor tex flowmeters

Flow controllers

Level measuring instruments

Pressure and temperature

Heat metering

Communications technology

Switches, counters, displays and recorders

Engineering systems & solutions

ALTOSONIC III

3-Beam ultrasonic flowmeter

for custody transfer of

liquid hydrocarbons

Designed for custody transfer of light

products

Long-term stability and high reliability

Eliminates maintenance

Non-intrusive

No wear

No pressure loss

Bi-directional

Compliant with OIML R-117, API

Page 2

2ALTOSONIC III

Custody transfer of light

hydrocarbon products

Fiscal metering

Duty metering

(with the ALTOSONIC V as

reference meter)

Allocation metering

Pipeline leak detection

Fields of application

Refineries

Pipeline systems for refined

products

Terminal loading and offloading

of refined products

Truck and rail loading

ALTOSONIC III

The flow metering

solution for the oil

and petrochemical

industry

ALTOSONIC III

3-Beam ultrasonic flowmeter for custody transfer

of liquid hydrocarbons

Eliminates maintenance

KROHNE is innovation

The introduction of the ALTOSONIC V, the highly accurate, five-beam liquid ultrasonic

flowmeter in the 1990's for multiple products was a true revolution in the flow market for

custody transfer and master metering.

Over the past years ultrasonic flowmeters have gained full acceptance and have become

the fastest growing flow metering technology in the world. KROHNE's UFM 3030, the first

truly universal and easy to use ultrasonic flowmeter for process applications, created a

breakthrough in the widespread application of ultrasonic flowmeters worldwide.

Introducing ALTOSONIC III

Now, KROHNE is proud to introduce the ALTOSONIC III, an innovative and economical

solution for custody transfer of light oil products. The 3-beam ALTOSONIC III is the outcome

of our revolutionary development of liquid multiple beam ultrasonic flowmeters. It combines

innovative technology with long-term experience to guarantee superior performance at an

attractive price.

KROHNE is experience

The ALTOSONIC III is the result of years of experience in the field with ultrasonic

flowmeters for custody transfer including fiscal metering for a very wide range of

applications.

25 Years ago KROHNE was already one of the pioneers in ultrasonic flow metering. In line

with our vision, we continue to develop and perfect a wide range of single and multiple

beam ultrasonic flowmeters for liquids and gases. Since 1980 over 30,000 KROHNE

ultrasonic flowmeters have been installed showing reliable and trouble-free operation.

KROHNE is quality

It is KROHNE's policy to calibrate each flowmeter that leaves our factory by means of wet

calibration to guarantee the highest possible accuracy and quality. Therefore KROHNE

owns accredited calibration rigs that comply with the most stringent demands (according to

IEC-ISO 17025).

Page 3

ALTOSONIC III

3ALTOSONIC III

A cost effective ultrasonic flowmeter concept for custody transfer

Excellent repeatability

Reliable flow measurement with long-term stability

Large dynamic range: measures from zero flow up to 20 m/s.

Light, compact and robust flowmeter

Bi-directional

Compliant with OIML R-117 and API

Integrated diagnostics

ALTOSONIC III

The alternative for conventional flowmeters

The ALTOSONIC III offers decisive advantage over mechanical flowmeters

like turbine meters and PD meters.

No obstructions in the pipeline

ALTOSONIC III has no parts protruding the flow, in other words no

risks of flow obstruction or blockage.

No moving parts

ALTOSONIC III has not a single internal moving part that can break

down or suffer neither from wear caused by corrosive or abrasive

fluids, gas and solids or from build-up like wax. This means maintenance-free and excellent long term stability.

No filters

For ALTOSONIC III filters are not required, which results in costs

savings on regular inspection, maintenance and cleaning of filters

and no additional pressure drop.

Low pressure drop

Unrestricted flow means no loss of pressure. Reducing pressure drop

means smaller pump capacity, improved pipeline efficiency, and

savings on energy costs.

Minimal maintenance

and substantial savings in cost of ownership.

Multi-channel ultrasonic flow measurement

Like all KROHNE ultrasonic flowmeters,

ALTOSONIC III operates by the transit-time

differential method. The measurement principle

is based on a simple physical principle. Imagine

two canoes crossing a river diagonally, one with

the flow and one against the flow. Naturally the

canoe that is travelling with the flow will reach the opposite side sooner than

the canoe that is travelling upstream. Acoustic signals behave in a comparable

way.

By means of patented ultrasonic transducers, the transit time of acoustic

signals that travel upstream and downstream are measured. The difference in

transit time is proportional to the mean liquid flow velocity and is transformed

into an output signal and display of volumetric liquid flow rates.

The 3 measuring beams of the ALTOSONIC III make a 3-dimensional crosssection of the velocity distribution, or flow profile of the medium that flows

through the flow sensor. These measuring beams are positioned such that the

influence of the flow profile is strongly reduced.

ALTOSONIC III

eliminates maintenance in flow metering

Page 4

4ALTOSONIC III

The responsibility as to the suitability, intended use and corrosion-resistance of the materials used in

their construction rests solely with the purchaser.

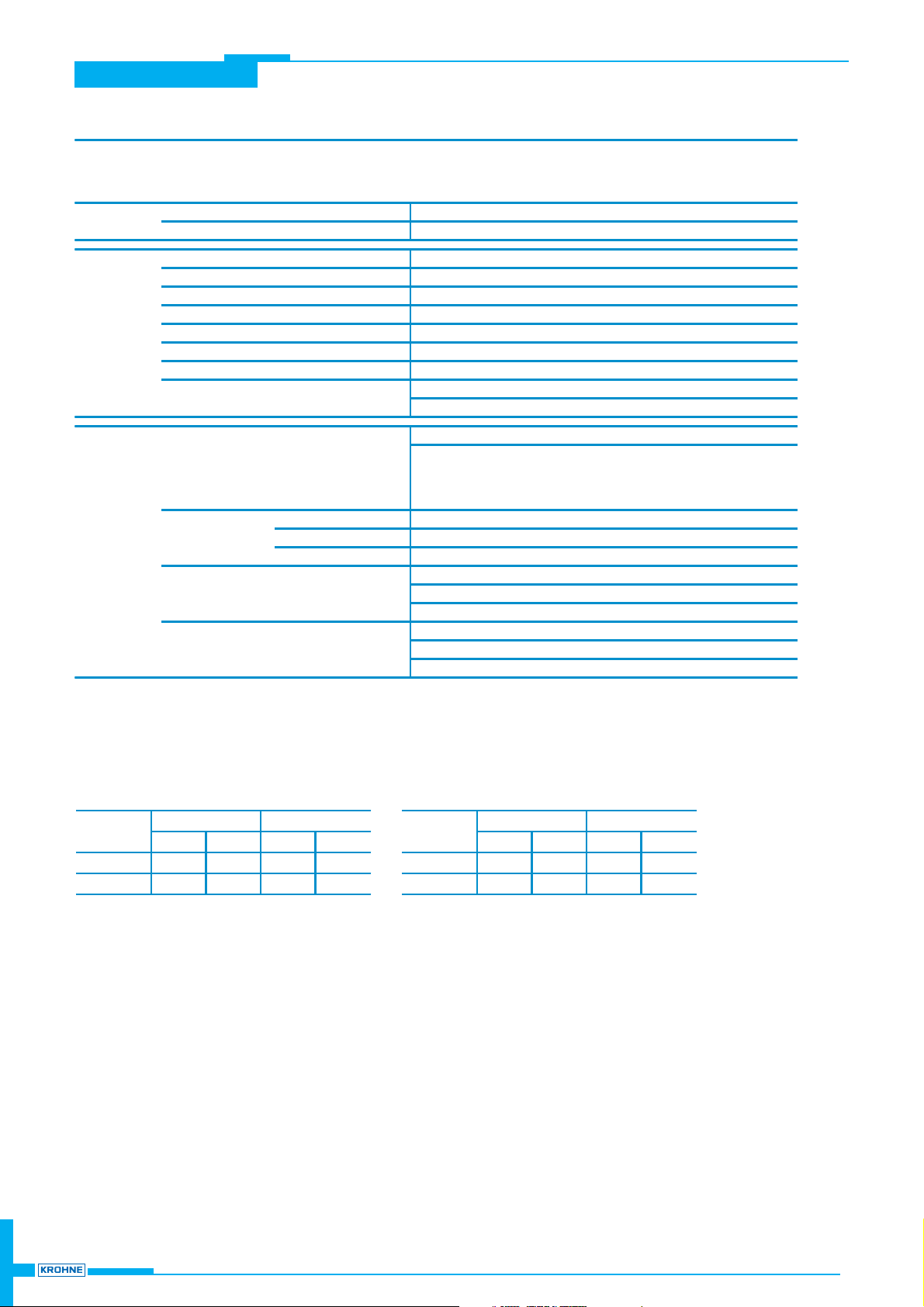

Versions

ALTOSONIC III/C-EEx

UFS-III/F-EEx

UFC-III/F-EEx

Approvals

Maximum solid particle content < 5% (by v olume)

Maximum gas content < 2% (by v olume)

OIML R-117 Class 0.3

ANSI/API MPMS 5.8-2004

Performance

Custody transfer

API MPMS Chapter 5 Section 8, M easurement of Liquid H y drocarbons by

Ultrasonic Flowmeters U sing Transit Time Technology

Viscosity

Up to 10 cS t for standard operation. For higher v iscosities contact KROH N E

< 1 mm/s

< ± 0.027% conforms to AP I standard

UFC III C flow converter directly mounted on UFS III C flow sensor

Process conditions

Zero stability

ALTOSONIC III is available in a separate and in a compact v ersion and consists of a UFS III ultrasonic flow sensor combined

with a UFC III ultrasonic flow conv erter to make a complete flowmeter. Both the sensor and conv erter are approv ed for use in

hazardous areas.

Measurement functionality

Measuring range

< ± 0.15% of measured v alue (under reference conditions)

Linearity

ALTOSONIC III C (compact)

ALTOSONIC III F (separate)

Uncertainty

Repeatability

CSA Class I, Div . 1 & 2, G roups A, B, C & D

UFC III F flow converter remotely mounted from UFS III F flow sensor

Standard actual volume

0 to 20 m/s (0 ft/s to 66 ft/s), higher flow v elocities on request

< ± 0.05%

EEx zone 1 (ATEX)

CSA Class II, Div. 1 & 2, Groups E, F & G

II 2 G EEx d [ib] IIC T6 …T3 or II 2 G EEx de [ib] II C T6 … T3

II 2 G EEx ib IIC T6 …T3

II 2 G EEx d [ib] IIC T6

FM Class I, Div . 1 & 2, G roups B, C & D

Standard Optional - On request

ALTOSONIC III Ultrasonic flowmeter

FM

CSA

CSA Class III, Div. 1

FM Class II, Div. 1, Groups E, F & G and Div . 2, Groups F & G

FM Class III, Div. 1 & 2

ALTOSONIC III

min. max. min. max. min. max. min. max.

Compact -25°C 140°C -40°C 70°C Compact -13°F 284°F -40°F 158°F

Separate -25°C 180°C -40°C 70°C Separate -13°F 356°F -40°F 158°F

Process temp.

Ambient temp.

°C

Process temp.

Ambient temp.

°F

Temperature Limits

Page 5

5ALTOSONIC III

2"3"4"6"8"

10"

12"

14"

16"

18"

20"

24"

28"

32"

36"

40"

150 lbs RF

300 lbs RF

600 lbs RF/ RTJ -------

900 lbs RF/ RTJ ---------

Pressure rating according to ASME B16.5 Group 2.3 materials. Other combinations of diameter/pressure class are av ailable on request.

UFS III C (compact)

UFS III F (separate)

Flanges

Measuring tube

Housing

Connection box

Blasted

Offshore paint sy stem, silv er

6 points, 1 point 3 repeats, w ith w ater

According to OIML:

6 points, each point 3 repeats, w ith water

Witnessed calibration

RVA certificate

Calibration with hy drocarbon

Protection category

to IEC 529

IP 67 / IP 66 eq. NEMA 4/4X / 6

M20 x 1,5

1/2" N PT

PF 1/2

5 m / 15 ft

10 m / 30 ft

15 m / 45 ft

20 m / 60 ft

25 m / 75 ft

30 m / 90 ft

For a detailed ov erview , see the dimensions and w eights tables in this datasheet.

UFC III C flow converter directly mounted on UFS III C flow sensor.

UFC III F flow converter remotely mounted from UFS III F flow

Versions

Stainless steel A ISI 316 L (1.4408)

Stainless steel A ISI 316 L (1.4404)

Materials used

Other materials (e.g. Duplex)

available o n req uest

Stainless steel A ISI 316 L (1.4404)

Stainless steel A ISI 316 L (1.4404)

Finish

Other f inishes on request

Ultrasonic flow sensor UFS III

Sensor cable connection

for separate v ersions only

Pressure cl ass

Nominal diameter [inch]

ASME B16.5

ASME B16.47, A

Standard Optional - On request

Sensor cable length

for separate v ersions only

Cable ty pe MR06,

O.D. = 11 mm / 0.43"

Calibration

Calibration options

ALTOSONIC III

The responsibility as to the suitability, intended use and corrosion-resistance of the materials used in

their construction rests solely with the purchaser.

Page 6

6ALTOSONIC III

2"3"4"6"8"

10"

12"

14"

16"

18"

20"

24"

28"

32"

36"

40"

150 lbs RF

300 lbs RF

600 lbs RF/ RTJ -------

900 lbs RF/ RTJ ---------

Silver

Offshore paint sy stem, silv er

Typ ical flowmeter configuration

ASME B16.5

Pressure rating according to AS M E B16.5 G roup 2. 3 materials.

For a detailed ov erv iew , see the dimensions and w eights section of this datasheet.

Standard Optional - On request

Nominal diameter [inch]

ASME B16.47, A

Inlet flow conditioner and outlet section

The flow sensor is deliv ered as standard w ith a 10D inlet flow conditioner. For optimal performance the flow sensor and flow conditioner are calibrated

together. The flow sensor has to be installed w ith a straight outlet section w ith a minimum length of 5D.

Finish*

Other paint systems on request

Materials used

Other materials (e.g. Duplex)

available o n req uest

Pressure cl ass

Carbon steel ASTM A 105 / C arbon steel A S TM A106

Stainless steel A ISI 316 L (1.4404)

Flange / Tube

10D

5D

ALTOSONIC III

Installation

General

For specific information please consult the operating and installation instructions or contact KRO H NE.

Position

The flow meter can be installed in a horizontal or v ertical position. In a horizontal pipeline ensure that

the acoustic channels are alw ay s in the horizontal plane.

Completely filled flow sensor

Install the UFS III ultrasonic flow sensor at a location where it will be completely filled under all

circumstances, including at zero flow v elocity .

Flow conditioning

Standard a 10D inlet section w ith ISO tube bundle flow conditioner must be installed upstream of the

flow meter. A fter the meter a straight outlet section of 5D should be installed.

Zero checking

Zero setting is not required w ith ultrasonic flow meters. For zero checking it is adv ised to install shutoff

valves before or after the flow sensor.

Cavitation

At operation sufficient backpressure is required to prev ent cav itation

Page 7

ALTOSONIC III

7ALTOSONIC III

General

UFC III C (compact) UFC III C flow converter directly mounted on UFS III C flow sensor.

UFC III F (separate) UFC III F flow converter remotely mounted from UFS III F flow sensor.

Materials used Conv erter housing Stainless steel AISI 316 L (1.4408)

Blasted

Offshor e paint system, silv er

Protection category

to IEC 529

IP 67 / IP 66

eq. N EM A 4/4X / 6

Operation

Cover remov ed: All display operations, including changing of settings and parameters can

be done by using the push buttons.

Cover in place: M easured v alues and (error) messages can be v iew ed. Resetting of errors

is still possible using a hand-held bar magnet.

Units

Actual flow rate in liter/s, m3/h, US gall/min or user-defined unit (e.g. U S million gall/day).

English (GB)

English (U S )

German

French

Gal van ic isolation

Time constant

Mains supply 100 – 240 V AC (48-63 Hz) +10% / -15%

Low v oltage supply 24 V (AC or DC ), A C : -10% / +15% , DC : 18 - 35 V

M20 x 1,5

1/2" N PT

PF 1/2

Standard Optional - On request

Ultrasonic flow converter UFC III

All inputs and outputs are galv anically isolated from the power supply , but not from each other

Finish

Other paint systems on request

Versions

Overall functionality /

Measurem ents available

Self diagnostics, e.g. v elocity of sound w ithin range, reliability of received acoustic signal, flow sensor not filled

Errors (flashing display and error code)

0.025 - 99 seconds (programmable in increments of 0.01; 0.1 and 1.0 seconds)

The conv erter has a backlit local display with 3 push buttons.

1st line 8 character 7 segment alphanumeric display and sy mbols for key

acknowledgement

2nd line 10 character, 14 segment text display

3rd line 5 markers to identify display in measuring mode

3-field

LC D

Actual v olume flow rate (continuous measurement) in m3, liters, U S gallons, Bbl or user defined v olume unit per hour,

minute, second, or user defined time unit

Flow direction (forw ard or rev erse)

Velocity of sound in m/s or ft/s, per acoustic channel

Signal attenuation (in dB), per acoustic channel

Low-flow cut-off

Power consumption approx . 10 V A (A C ) or approx. 10 W (DC )

Cut-off activ e value 1 - 19% programmable in increments of 1%

Cut-off de-activ e v alue 2 - 20%

The conv erter is fully digital. M easured v alues are obtained using DSP (Digital Signal Processing) to ensure accurate and

highly repeatable measurements.

Power supply

Local display

Cable connecti on

(for power supply and

signal cables)

Languages

Page 8

ALTOSONIC III

8ALTOSONIC III

Ex-connection (standard)

⊥ Common ground

P1 Pulse, frequency output

P2 Pulse, frequency output

90 or 180 degrees phase shifted from P1

S Status output

I/C 0(4) ... 20mA current output

N / L~ Neutral power supply

L/ L~ Live power supply

SizingElectrical connections

Please refer to the instruction manual in the

Dowload Center of the KROHNE internet site on

www.krohne.com for detailed information on how to

connect signal inputs and outputs.

1 m/ s 10 m/s 1 m/s 10 m/s 1 m/s 10 m/s

3.3 ft/s 30 ft/s 3.3 ft/s 30 ft/s 3.3 ft/s 30 ft/s

(m3/h) (m3/h)

(GPM) (GPM) (BBL/hr) (BBL/hr)

2" 7 73 32 321 46 459

3" 16 164 72 723 103 1033

4" 29 292 129 1285 184 1836

6" 66 657 289 2891 413 4132

8" 117 1167 514 5140 735 7345

10" 182 1824 803 8032 1148 11477

12" 263 2627 1157 11565 1653 16527

14" 358 3575 1574 15742 2249 22495

16" 467 4670 2056 20561 2938 29381

18" 591 5910 2602 26022 3719 37186

20" 730 7297 3213 32126 4591 45908

24" 1051 10507 4626 46261 6611 66108

28" 1430 14301 6297 62967 8998 89980

32" 1868 18679 8224 82243 11752 117525

36" 2364 23641 10409 104088 14874 148742

40" 2919 29186 12850 128504 18363 183632

Nominal

diameter

Choosing the correct size is v ery simple due to the extremely wide range of possible

velocities. Typical flow rates for 1 m/s (3,3 ft/s) and 10 m/s (33 ft/s) are specified in the

attached table. P ending on the application the ALTOS ON I C III has a virtually unlimited

flow v elocity range.

Q = 0 % 0 - 16 mA programmable in increments of 1 mA

Q = 100 % 4 – 20 mA

Connection Passive External v oltage 18 - 24 V DC , load ≤ 680 Ohm, (current limit 22 mA)

Pulse duty cy cle 50%

Connection

Alarm trip point (high and low ) based on actual v olume flow rate

Settings

Connection

Flow direction indication (forw ard or rev erse)

Velocity of Sound (VOS )

Tr ansducer signal amplification

Settings

Function

Dual pulse output, 90° or 180° phase shifted from each other

Pulse/unit (max . 1500Hz) (ex ample: 1000 pulses/barrel)

Pulse per v olumetric unit (m3, liters, U S gallons, Bbl or user defined v olume unit)

Current output

Settings

Function

Actual v olume flow rate (continuous measurement)

Status output

Function

Pulse output

Passive mode connection to electronic counter (EC ). E x ternal v oltage ≤ 19 - 32 V DC / I ≤ 150 mA

Diagnostics alarm path errors, all errors

Flow direction indication (forw ard or rev erse)

Passive mode connection to electronic input. E x ternal v oltage ≤ 19 - 32 VD C / I ≤ 150 mA

On or Off

Outputs

Page 9

ALTOSONIC III

9ALTOSONIC III

Dimensions and weights

78 (3.07)

w

Flow direction

a

j

98 (3.86)

ØDi

h

71 (2.8)

e

Flow direction

a

j

160 (6.3)

ØDi

h

165 (6.5)

e

Ø122 (4.8)

206 (8.11)

w

aDih j ew aDih j ew

2" 290 49.2 180 139 100 150 14 11.42 1. 94 7.09 5.47 3.94 5. 91 31

3" 330 73.7 215 170 130 200 26 12.99 2. 90 8.45 6.69 5.12 7. 87 57

4" 380 97.2 247 190 155 220 33 14.96 3. 83 9.74 7.48 6.10 8. 66 73

6" 440 154.1 301 240 210 270 45 17.32 6. 07 11. 84 9.45 8.27 10.63 99

8" 600 202.7 358 370 260 370 72 23.62 7. 98 14. 09 14. 57 10.24 14.57 159

10" 640 254.5 417 415 315 420 105 25.20 10.02 16.41 16.34 12.40 16. 54 231

12" 710 304.7 480 465 365 470 145 27.95 12.00 18.91 18.31 14.37 18. 50 320

14" 770 336.5 522 495 395 500 179 30.31 13.25 20.53 19.49 15.55 19. 69 395

16" 830 387.3 579 550 445 550 221 32.68 15.25 22.78 21.65 17.52 21. 65 487

18" 900 438.1 623 595 500 600 256 35.43 17.25 24.53 23.43 19.69 23. 62 564

20" 950 484.0 680 645 550 650 335 37.40 19.06 26.78 25.39 21.65 25. 59 739

24" 1080 579. 6 788 745 650 750 500 42.52 22.82 31.03 29. 33 25. 59 29.53 1102

28" 1140 691. 2 896 865 750 870 577 44.88 27.21 35.28 34. 06 29. 53 34.25 1272

32" 1260 792. 8 1014 955 855 960 786 49.61 31. 21 39. 91 37.60 33.66 37.80 1733

36" 1400 884. 4 1118 1055 955 1060 1136 55.12 34.82 44.03 41.54 37.60 41.73 2504

40" 1500 986.0 1230 1150 1055 1150 1359 59.06 38.82 48.41 45.28 41.54 45.28 2996

a = flange to flange

Di = inner diameter

h = height flow sensor

Approx.

weight

in kg*

ANSI 150 lbs

dimensions in mm

Nominal

diameter

For compact (C) v ersion: add 6.4 kg (14.1 lbs).

*Approx. w eight of flow sensor in separate (F) v ersion.

Weight conv erter incl. w allmount separate (F) v ersion: 14 kg (30.9 lbs).

Approx.

weight

in lbs*

ANSI 150 lbs

dimensions in inch

Inner diameters based on schedule standard.

j = length housing

e = height housing

w = width housing

aDi

weight

in kg

aDi

Approx.

weight

in kg

aDi

weight

in lbs

aDi

Approx.

weight

in lbs

2" 508 54.8 8 254 54.8 6 20.00 2.16 17. 6 10. 00 2.16 13

3" 762 77.9 20 381 77.9 13 30.00 3.07 44.1 15.00 3.07 29

4" 1016 104.7 32 508 104.7 18 40.00 4.12 70.5 20.00 4.12 40

6" 1524 158.7 65 762 158.7 31 60.00 6.25 143. 3 30.00 6.25 68

8" 2032 206.3 125 1016 206. 3 60 80.00 8.12 275.6 40. 00 8.12 132

10" 2540 260.2 190 1270 260. 2 89 100.00 10.24 418. 9 50.00 10.24 196

12" 3048 309.6 325 1524 309. 6 141 120. 00 12.19 716.5 60.00 12.19 311

14" 3556 339.8 490 1778 339. 8 197 140. 00 13.38 1080.3 70.00 13.38 434

16" 4064 390.6 560 2032 390. 6 255 160. 00 15.38 1234.6 80.00 15.38 562

18" 4572 441.4 700 2286 441. 4 307 180. 00 17.38 1543.2 90.00 17.38 677

20" 5080 489.0 1080 2540 489.0 431 200.00 19.25 2381.0 100.00 19. 25 950

24" 6096 590.6 1425 3048 590.6 615 240.00 23.25 3141.6 120.00 23. 25 1356

28" 7112 695.4 1725 3556 695.4 766 280.00 27.38 3803.0 140.00 27. 38 1689

32" 8128 797.0 2400 4064 797.0 1054 320.00 31.38 5291. 1 160.00 31. 38 2324

36" 9144 898.6 3055 4572 898.6 1338 360.00 35.38 6735. 2 180.00 35. 38 2950

40" 10160 996. 0 4235 5080 996.0 1895 400.00 39. 21 9336. 6 200.00 39. 21 4178

Nominal

diameter

ANSI 150 lbs

dimensions in inch

ANSI 150 lbs

dimensions in mm

10D inlet spoolpiece

5D outlet spoolpiece

10D inlet spoolpiece

5D outlet spoolpiece

Dimensions in mm (inch)

Page 10

ALTOSONIC III

10 ALTOSONIC III

Dimensions and weights

aDih j ew aDih j ew

2" 300 49.2 185 139 100 150 15 11.81 1.94 7. 28 5.47 3. 94 5.91 33

3" 350 73.7 224 170 130 200 30 13.78 2.90 8. 83 6.69 5. 12 7.87 66

4" 400 97.2 260 190 155 220 42 15.75 3.83 10.24 7. 48 6.10 8.66 93

6" 470 146.4 320 240 210 270 69 18.50 5.76 12.59 9. 45 8.27 10.63 152

8" 620 193.7 377 370 260 370 115 24.41 7.63 14.84 14.57 10.24 14.57 254

10" 670 247.6 436 415 315 420 156 26.38 9.75 17.16 16.34 12.40 16.54 344

12" 750 298.4 499 465 365 470 213 29.53 11.75 19.66 18.31 14.37 18.50 470

14" 810 325.6 547 495 395 500 290 31.89 12.82 21.53 19.49 15.55 19.69 639

16" 870 376.4 604 550 445 550 358 34.25 14.82 23.78 21.65 17.52 21.65 789

18" 940 417.2 661 595 500 600 482 37.01 16.43 26.03 23.43 19.69 23.62 1063

20" 1000 468.0 718 645 550 650 578 39.37 18. 43 28. 28 25. 39 21.65 25.59 1274

24" 1110 569.6 839 745 650 750 811 43.70 22. 43 33. 03 29. 33 25.59 29.53 1788

28" 1300 661.2 950 865 750 870 1223 51.18 26.03 37.41 34. 06 29. 53 34.25 2696

32" 1440 752.8 1058 955 855 960 1714 56.69 29.64 41.66 37.60 33.66 37.80 3779

36" 1580 854.4 1169 1055 955 1060 2131 62.20 33.64 46. 03 41. 54 37.60 41.73 4698

40" 1580 946.0 1204 1150 1055 1150 2100 62.20 37.24 47.41 45. 28 41.54 45.28 4630

Inner diameters based on schedule standard.

*Approx . w eight of flow sensor in separate (F) v ersion.

j = length housing

w = width housing

e = height housing

a = flange to flange

Di = inner diameter

h = height flow sensor

Nominal

diameter

For compact (C) v ersion: add 6. 4 kg (14.1 lbs).

Weight conv erter incl. w allmount separate (F) v ersion: 14 kg (30.9 lbs).

Approx.

weight

in lbs*

Approx.

weight

in kg*

ANSI 300 lbs

dimensions in mm

ANSI 300 lbs

dimensions in inch

aDi

weight

in kg

aDi

weight

in kg

aDi

weight

in lbs

aDi

weight

in lbs

2" 508 53.9 10 254 53.9 7 20.00 2.12 22.0 10.00 2.12 15

3" 762 77.9 24 381 77.9 16 30.00 3.07 52.9 15.00 3.07 35

4" 1016 104.7 40 508 104.7 26 40.00 4.12 88.2 20.00 4.12 57

6" 1524 154.1 95 762 154.1 54 60.00 6.07 209. 4 30.00 6.07 119

8" 2032 206.4 150 1016 206. 4 84 80.00 8. 13 330. 7 40.00 8.13 185

10" 2540 257.4 250 1270 257. 4 137 100.00 10.13 551. 2 50. 00 10.13 302

12" 3048 307.0 390 1524 307. 0 204 120.00 12.09 859. 8 60. 00 12.09 450

14" 3556 339.8 500 1778 339. 8 270 140.00 13.38 1102.3 70.00 13.38 595

16" 4064 387.3 710 2032 387. 3 376 160.00 15.25 1565.3 80.00 15.25 829

18" 4572 434.9 1000 2286 434.9 509 180.00 17.12 2204.6 90.00 17.12 1122

20" 5080 482.6 1280 2540 482.6 672 200.00 19.00 2821.9 100.00 19. 00 1482

24" 6096 581.1 2065 3048 581.1 1047 240.00 22. 88 4552. 6 120.00 22. 88 2308

28" 7112 679.4 3023 3556 679.4 1543 280.00 26. 75 6664. 6 140.00 26. 75 3402

32" 8128 781.0 3995 4064 781.0 2035 320.00 30. 75 8807. 5 160.00 30. 75 4486

36" 9144 876.3 5635 4572 876.3 2877 360.00 34. 50 12423.1 180. 00 34.50 6343

40" 10160 976. 0 6665 5080 976.0 3103 400.00 38.43 14693.9 200.00 38. 43 6841

Nominal size

ANSI 300 lbs

dimensions in inch

ANSI 300 lbs

dimensions in mm

10D inlet spoolpiece

5D outlet spoolpiece

10D inlet spoolpiece

5D outlet spoolpiece

Page 11

ALTOSONIC III

11ALTOSONIC III

aDih j ew aDih j ew

2" 320 49.2 185 139 100 150 17 12.60 1. 94 7.28 5.47 3. 94 5.91 37

3" 370 73.7 224 170 130 200 33 14.57 2. 90 8.83 6.69 5. 12 7.87 73

4" 440 97.2 270 190 155 220 53 17.32 3. 83 10. 62 7.48 6.10 8. 66 117

6" 530 131.8 339 240 210 270 111 20. 87 5.19 13.34 9.45 8.27 10.63 245

8" 660 189.1 396 370 260 370 165 25. 98 7.44 15.59 14. 57 10.24 14.57 364

10" 770 233.0 468 415 315 420 272 30. 31 9.17 18.41 16. 34 12.40 16.54 600

12" 830 273.8 518 465 365 470 359 32. 68 10. 78 20.41 18.31 14.37 18.50 791

14" 880 305.6 556 495 395 500 423 34. 65 12. 03 21.91 19.49 15.55 19.69 933

16" 960 346.4 623 550 445 550 603 37. 80 13. 64 24.53 21.65 17.52 21.65 1329

Approx.

weight

in lbs*

Approx.

weight

in kg*

ANSI 600 lbs

dimensions in mm

ANSI 600 lbs

dimensions in inch

Nominal

diameter

aDi

weight

in kg

aDi

weight

in kg

aDi

weight

in lbs

aDi

weight

in lbs

2" 508 52.5 11 254 52.5 9 20. 00 2.07 24.3 10.00 2.07 20

3" 762 77.9 26 381 77.9 19 30.00 3.07 57.3 15.00 3.07 42

4" 1016 102.3 55 508 102.3 38 40.00 4.03 121.3 20.00 4.03 84

6" 1524 146.4 140 762 146.4 92 60. 00 5.76 308. 6 30.00 5.76 203

8" 2032 193.7 250 1016 193. 7 154 80.00 7.63 551.2 40. 00 7.63 340

10" 2540 242.8 445 1270 242. 8 268 100.00 9.56 981.1 50.00 9.56 591

12" 3048 295.3 570 1524 295. 3 339 120.00 11.62 1256.6 60.00 11.62 747

14" 3556 325.4 760 1778 325. 4 432 140.00 12.81 1675.5 70.00 12.81 952

16" 4064 373.1 1105 2032 373.1 618 160. 00 14.69 2436.1 80.00 14.69 1362

ANSI 600 lbs

dimensions in inch

ANSI 600 lbs

dimensions in mm

10D inlet spoolpiece

5D outlet spoolpiece

10D inlet spoolpiece

5D outlet spoolpiece

Nominal

diameter

a Di h j e w a Di h j e w

2" 380 49.2 210 139 100 150 27 14.96 1. 94 8.27 5.47 3. 94 5.91 60

3" 420 66.7 240 170 130 200 46 16.54 2. 63 9.45 6.69 5. 12 7.87 101

4" 470 87.3 279 190 155 220 69 18.50 3. 44 10. 99 7.48 6.10 8. 66 152

6" 570 131.8 352 240 210 270 138 22. 44 5.19 13.84 9.45 8.27 10.63 304

8" 750 169.1 422 370 260 370 256 29. 53 6.66 16.59 14. 57 10.24 14.57 564

10" 840 213.0 487 415 315 420 385 33. 07 8.39 19.16 16. 34 12.40 16.54 849

12" 920 263.8 544 465 365 470 507 36. 22 10. 39 21.41 18.31 14.37 18.50 1118

Nominal

diameter

Approx.

weight

in lbs*

Approx.

weight

in kg*

ANSI 900 lbs

dimensions in mm

ANSI 900 lbs

dimensions in inch

aDi

weight

in kg

aDi

weight

in kg

aDi

weight

in lbs

aDi

weight

in lbs

2" 508 49.3 22 254 49.3 19 20.00 1.94 48.5 10.00 1.94 42

3" 762 73.7 40 381 73.7 30 30.00 2.90 88.2 15.00 2.90 66

4" 1016 97.2 70 508 97. 2 51 40.00 3.83 154.3 20.00 3.83 112

6" 1524 146.4 165 762 146.4 116 60.00 5.76 363.8 30.00 5.76 256

8" 2032 182.6 350 1016 182.6 231 80.00 7.19 771. 6 40.00 7.19 509

10" 2540 230.2 580 1270 230.2 371 100. 00 9.06 1278.7 50.00 9.06 818

12" 3048 280.9 815 1524 280.9 514 120. 00 11. 06 1796.8 60.00 11.06 1133

Nominal

diameter

ANSI 900 lbs

dimensions in inch

ANSI 900 lbs

dimensions in mm

10D inlet spoolpiece

5D outlet spoolpiece

10D inlet spoolpiece

5D outlet spoolpiece

Loading...

Loading...