Page 1

CMD

©

KROHNE 07/2005 7.30950.31.00

Variable area flowmeters

Vortex flowmeters

Flow controllers

Electromagnetic flowmeters

Ultrasonic flowmeters

Mass flowmeters

Level measuring instruments

Communications technology

Engineering systems & solutions

Switches, counters, displays and recorders

Heat metering

Pressure and temperature

Installation and

operating instructions

ALTOSONIC III

3-beam ultrasonic flowmeters

for custody transfer

of liquid hydrocarbons

UFC III F/...EEx ultrasonic flow converter

UFS III F/...EEx ultrasonic flow sensor

Subject to change without notice.

●●

Long term stability; high reliability

●●

Eliminates maintenance

●●

Non-intrusive

●●

No wear

●●

No pressure loss

●●

Bi-directional

●●

Compliant with OIML R-117, API

Page 2

General advice on safety

• Do not install, operate or maintain this flowmeter without reading, understanding and following the factory-supplied

instructions, otherwise injury or damage may result.

• Read these instructions carefully before starting installation and save them for future reference.

• Observe all warnings and instructions marked on the product.

• Use only mains supply with protective earthing connected.

• Do not use the product with removed covers under wet conditions.

• Consider handling and lifting instructions to avoid damage.

• Install the product securely and stable.

• Install and connect cabling proper to exclude damage or harmful situations.

• If the product does not operate normally, refer to the service instructions or refer to qualified KROHNE service

engineers. There are no operator-serviceable parts inside the product.

The following symbols may appear in this manual or on the product.

Attention: Refer to operating and installation instructions!

Disclaimer

Product liability

and warranty

Items included with order

Danger: Risk of electric shock!

Protective Earth (PE) conductor terminal!

These terms may appear in this manual or on the instrument:

Warning statement: Identify conditions or practice that could result in injury or loss of life.

or

Caution statement: Identify conditions or practice that could result in damage to the instrument or other property.

• This document contains important information on the instrument. KROHNE attempts to be as accurate and up-to-

date as possible but assumes no responsibility for errors or omissions. Nor does KROHNE make any commitment

to update the information contained herein. This manual and all other documents are subject to change without

prior notice.

• KROHNE will not be liable for any damage of any kind by using its instrument, including, but not limited to direct,

indirect, incidental, punitive and consequential damages.

• This disclaimer does not apply in case KROHNE has acted on purpose or with gross negligence. In the event any

applicable law does not allow such limitations on implied warranties or the exclusion of limitation of certain

damages, you may, if such law applies to you, not be subject to some or all of the above disclaimer, exclusions or

limitations.

• Any instrument purchased from KROHNE is warranted in accordance with the relevant product documentation and

our Terms and Conditions of Sale.

• KROHNE reserves the right to alter the content of its documents, including this disclaimer in any way, at any time,

for any reason, without prior notification, and will not be liable in any way for possible consequences of such

changes.

• Responsibility for suitability and intended use of this ultrasonic flowmeter rests solely with the user. Improper

installation and operation of the flowmeter (syste m) may lead to loss of warranty.

• In addition, the Terms and Conditions of Sale are applicable and are the basis for the purchase contract.

• If flowmeters need to be returned to KROHNE, please note the information given on the last pages of the

installation and operating instructions. KROHNE regrets that they cannot repair or check flowmeter(s) unless

accompanied by the completed form (see last pages of the installation and operating instructions).

• ALTOSONIC III ultrasonic flowmeter, consisting of a flow sensor (UFS III) and a flow converter (UFC III) either built

together as a compact system or supplied as two separate pieces, in the size as indicated on the packaging box.

• Signal cable (only in case of a separate system).

• Special tool for opening the converter housing.

ALTOSONIC III 2

Page 3

Installation and operating instructions

Documentation supplied

• Handbook; manual and installation and operation instructions

• Approval documents and certificates

• Report of factory settings of the flow converter

• Certificate of flowmeter calibration data

This instrument is developed and manufactured by:

KROHNE Altometer

Kerkeplaat 12

3313 LC Dordrecht

The Netherlands

For information, maintenance or service, please contact your nearest local KROHNE representative.

See www.krohne.com.

WARNING!

No changes may be made to the devices. Unauthorized changes might affect the explosion safety of the devices.

Be sure to follow these instructions!

IMPORTANT!

• The prescriptions and regulations as well as the electrical data described in the EC type examination certificate

must be obeyed.

• Beside the instructions for electrical installations in non-hazardous locations according to the applicable national

standard (equivalent of HD 384 or IEC 364, e.g. VDE 0100), especially the regulations in EN 60079-14 "Electrical

installations in hazardous locations" or equivalent national standard (e.g. DIN VDE 0165 Part 1) must be strictly

followed.

• Installation, establishment, utilization and maintenance are only allowed to be executed by personnel with an

education in explosion safety!

WARNING!

When removing the front or rear cover of the converter any sealing will be broken.

3 ALTOSONIC III

Page 4

Table of contents

1. Introduction.....................................................................................................................................................5

1.1 Cautions................................................................................................................................................................................................................ 5

1.2 Unpacking and inspection.................................................................................................................................................................................. 5

1.3 System description.............................................................................................................................................................................................. 5

1.4 Approvals.............................................................................................................................................................................................................. 5

2. Mechanical Installation...................................................................................................................................6

2.1 Handling the flowmeter....................................................................................................................................................................................... 6

2.2 Installation location and position....................................................................................................................................................................... 6

2.3 Accessibility and environmental precautions .................................................................................................................................................. 8

2.4 Special installation requirements....................................................................................................................................................................... 8

2.5 Pipe flanges.......................................................................................................................................................................................................... 9

2.6 Pipes with cathodic protection........................................................................................................................................................................... 9

3. Connecting the signal converter..................................................................................................................10

3.1 Safety instructions............................................................................................................................................................................................. 10

3.2 Installation in hazardous areas ........................................................................................................................................................................ 10

3.3 Converter terminal box...................................................................................................................................................................................... 10

3.4 Power supply connection .................................................................................................................................................................................10

3.5 Connection of sensor cables............................................................................................................................................................................ 11

3.6 Electrical connection of the signal inputs and outputs................................................................................................................................. 12

3.7 Connection diagram examples......................................................................................................................................................................... 12

3.8 Start-up ............................................................................................................................................................................................................... 14

3.9 Operating the signal converter......................................................................................................................................................................... 14

3.10 Menu structure and function of operating keys ............................................................................................................................................. 15

3.11 Description of functions.................................................................................................................................................................................... 20

4. Functional checks and service....................................................................................................................26

4.1 Functional checks.............................................................................................................................................................................................. 26

4.2 Device information............................................................................................................................................................................................. 26

4.3 Measuring zero flow value................................................................................................................................................................................ 26

5. Installation in hazardous areas, zone 1 and zone 2 ...................................................................................27

5.1 Approvals............................................................................................................................................................................................................ 27

5.2 Compact flowmeter............................................................................................................................................................................................ 27

5.3 Flow sensor........................................................................................................................................................................................................ 27

5.4 Flow converter.................................................................................................................................................................................................... 28

5.5 Technical data.................................................................................................................................................................................................... 29

6. Electrical installation....................................................................................................................................30

6.1 General................................................................................................................................................................................................................ 30

6.2 Connecting cables............................................................................................................................................................................................. 30

6.3 Connection diagrams........................................................................................................................................................................................ 30

7. Service and maintenance.............................................................................................................................33

7.1 Introduction........................................................................................................................................................................................................ 33

7.2 Replacement of electronics unit or power fuse(s) ......................................................................................................................................... 33

7.3 Replacement of electronics unit....................................................................................................................................................................... 34

7.4 Replacement of mains fuse .............................................................................................................................................................................. 34

7.5 Returning the flowmeter to KROHNE for service or repair............................................................................................................................ 35

ALTOSONIC III 4

Page 5

Installation and operating instructions

1. Introduction

1.1 Cautions

For flowmeters supplied with a voltage over 50 V AC:

• Refer all maintenance or service to trained KROHNE service engineers.

• Mains power shall be disconnected from the product before performing any maintenance.

• This product is prepared for and can only function with the rated AC mains or DC supply voltage as indicated on

the type plate.

For 100 – 240 V AC supplied flowmeters:

• This product is a Class 1 device (earthed) and requires a correct connection to protective earth. The protective

earth conductor of the main power shall be properly connected to the marked protective earth terminal to ensure

safety from electric shock for the operator and its environment.

1.2 Unpacking and

inspection

• The product has been thoroughly inspected and tested before shipment and is ready for operation.

• After carefully unpacking, inspect for shipping damage before attempting to operate. If any indication of mechanical

damage is found, immediately contact the responsible transport service and your local KROHNE representative.

• A simple operating check of the electronics after unpacking and before permanent installation is advisable to

ascertain whether it has suffered damage during shipment.

• Confirm for the correct mains voltage printed on the type plate. If it differs from the ordered product please contact

your local KROHNE representative.

• After connecting to the mains, check if there is any indication on the display and if the backlight of the display is

lighted. If not, contact your local KROHNE representative.

1.3 System description

The ALTOSONIC III ultrasonic flowmeter is a precision instrument designed for linear, bi-directional flow measurement

of liquids. Flow measurement values can be outputted via the standard analog and-or pulse/frequency outputs. Via a

user friendly operator interface (HMI) the flow can be read. Next to actual volumetric flow measurement the converter

can be configured to perform measurement and output of the liquid sonic velocity and acoustic signal attenuation.

1.4 Approvals

CE Approvals

EMC, Electromagnetic Compatibility Directive

EMC directive 89/336/EEC.

Low Voltage Directive

73/23/EEC and is designed in accordance with EN IEC 61010-1 first and second edition.

Pressure Equipment Directive 97/23/EC / Module H

The KROHNE organization complies with the requirements of Module H of the Pressure Equipment Directive 97/23/EC

(full quality assurance).

ATEX directive ATEX Directive 94/9/EC

Both the flow sensor and the flow converter are in compliance with the European Directive 94/9 EG (i.e. ATEX 100A).

5 ALTOSONIC III

Page 6

2. Mechanical

Installation

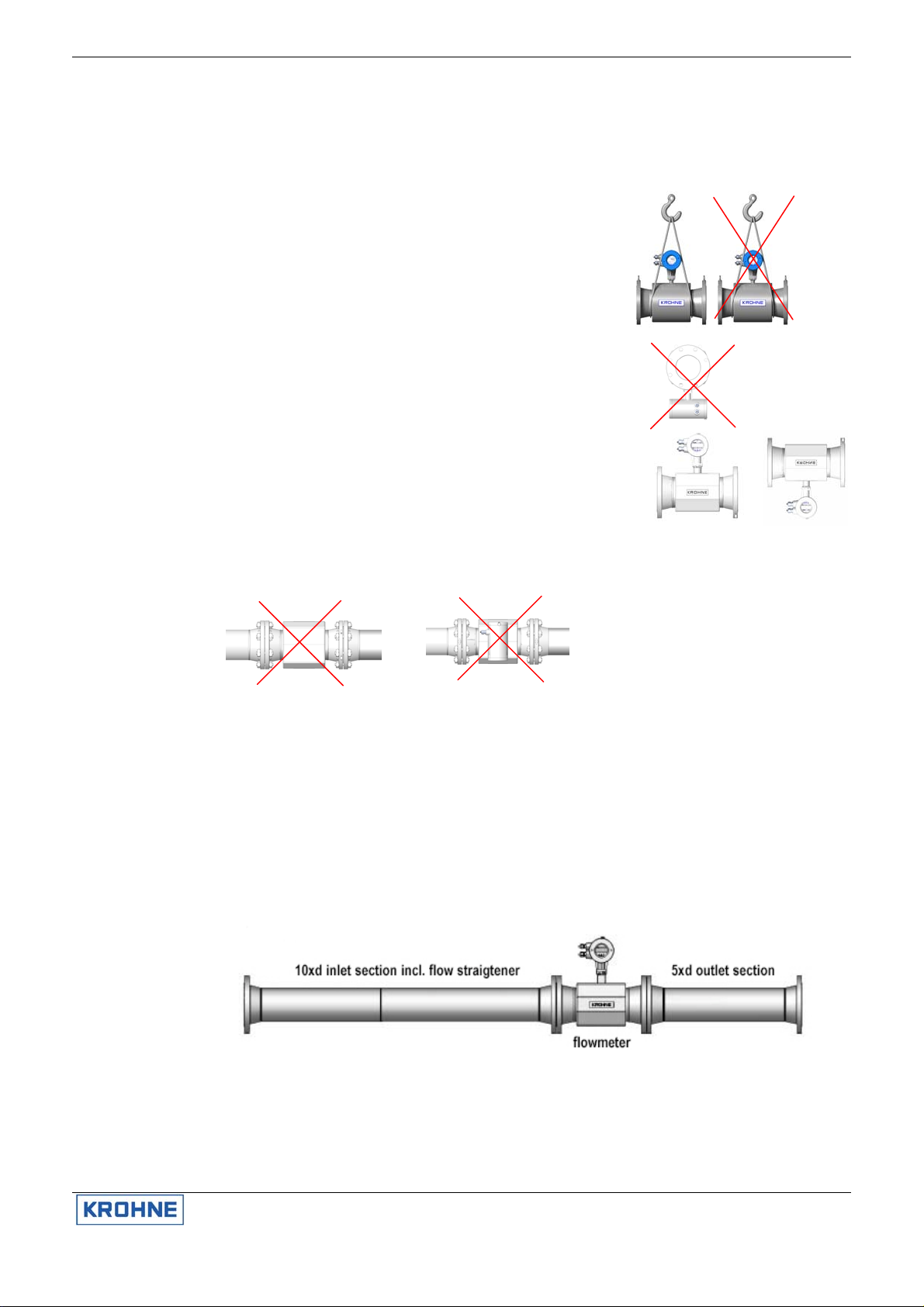

2.1 Handling the

flowmeter

Important: Do not lift the flowmeter by the signal converter housing or the

terminal box. Check the weight of the flowmeter as indicated on the type

plate before handling the unit. When handling the flowmeter avoid hard

blows, jolts or impacts.

2.2 Installation location

and position

Do not place the flowmeter on the signal converter housing.

As the ALTOSONIC III is used in hydrocarbon pipelines, be aware of

potentially explosive atmospheres. Local standards and regulations must be

respected.

The flow sensor must be completely filled at all times for proper flow

measurement. Non-wetted sensors show loss of signal. There is no damage

when this occurs.

The sensor must be installed in a horizontal or vertical position. A correct

position of the unit guarantees a completely filled flow sensor and accurate

flow measurement.

Inlet and outlet sections

For functioning within stated accuracy the flow sensor has to be installed with specified inlet flow conditioner and outlet

sections. The flow conditioner is delivered as a part of the flowmeter as the flow sensor and flow conditioner are calibrated

together for optimal performance.

Inlet configurations (upstream): Straight inlet section, length 10 D with ISO tube bundle flow conditioner.

Outlet configuration (downstream): Straight outlet section, length 5 D.

D = nominal diameter of the flow sensor.

It is advised to keep length of 5 D straight pipe section upstream between flow conditioner and upstream disturbances.

ALTOSONIC III 6

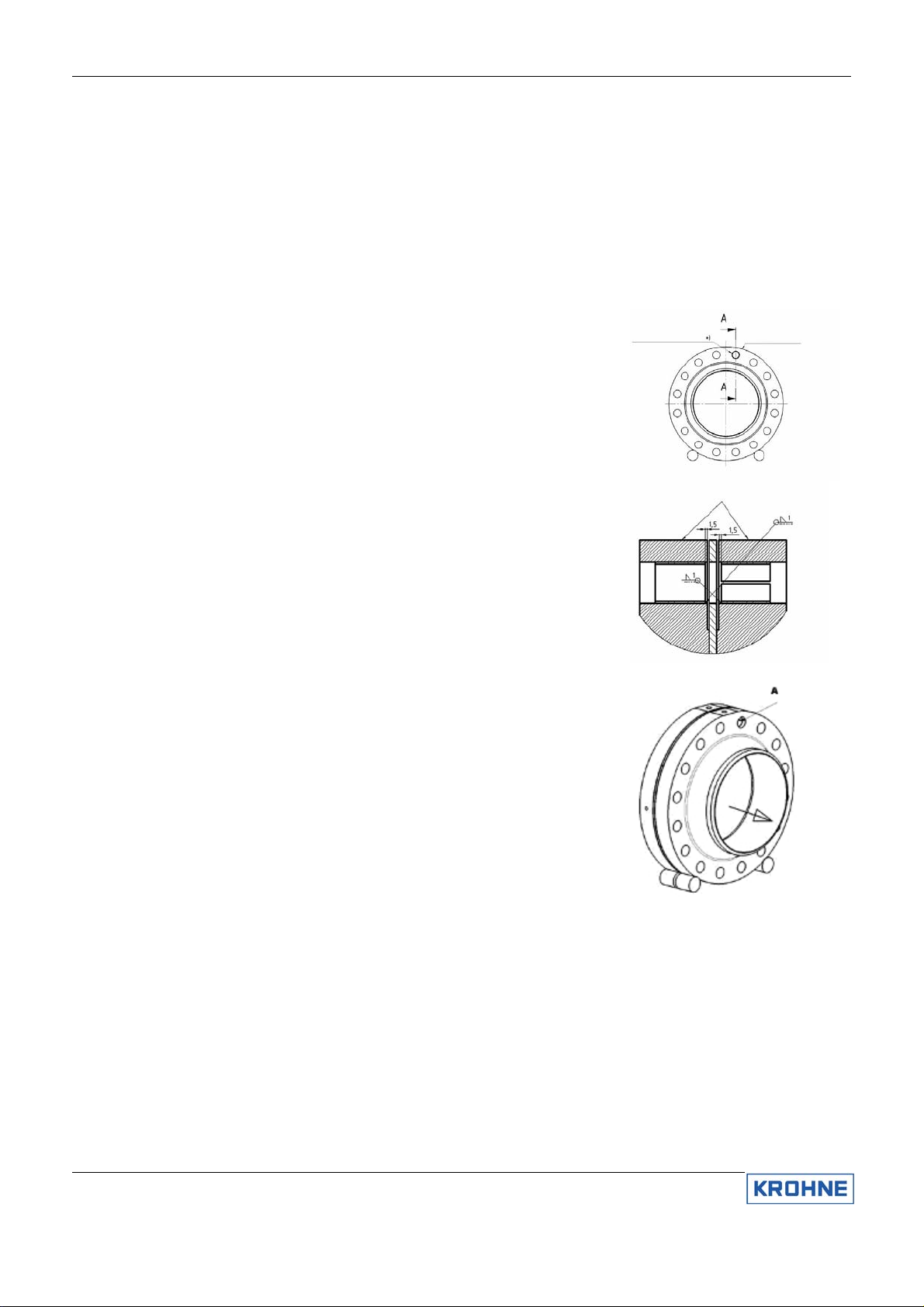

Bush guides

Every ALTOSONIC III is calibrated in combination with a dedicated inlet flow

conditioner. To minimize the installation effects on the performance of the

ALTOSONIC III a provision is made to assure that the flow conditioner

versus the ALTOSONIC III have the same position at operation as during the

initial calibration.

Page 7

Installation and operating instructions

During the mechanical installation of the ALTOSONIC III and the flow

conditioner it is absolutely required that both parts are aligned with high

accuracy.

“Bush Guides” are permanently welded in one of the top bolt holes of the

inlet flange of the ALTOSONIC III and the outlet flange of the flow

conditioner. The position of these “Bush Guides” is marked on the flange

with “BG”. This provision is integrated to assure the position and to align the

ALTOSONIC III in combination with the flow conditioner as accurate as

possible. If the ALTOSONIC III is used bi-directionally the outlet flange is

provided with a ”Bush Guide” as well.

Seen upstream, only the right top hole is fitted with a bush guide. When the

flowmeter is bidirectional, both flanges of the flowmeter are fitted with a bush

guide, which are placed collinear.

Mark the location of the bush guide in both flanges

Flow direction

Please note to the forward direction of the flow sensor indicated by the

direction arrow on the body. If the flow has this direction the output indication

will be positive.

Bolts and nuts

Use the specified bolts and nuts and gaskets, according to the ordered

flange type and pressure rating and mount according the general or local

requirement.

Vibration

Do not expose the sensor unit to intensive vibrations. Support of the flow

sensor is only allowed at the in- and outlet sections near the flowmeter.

7 ALTOSONIC III

Page 8

2.3 Accessibility and

environmental

precautions

2.4 Special installation

requirements

Gas inclusion

To avoid measuring errors due to gas inclusion, adequate measures have to

be taken. Gas inclusion should be limited to the lowest possible value and

shall be < 1 vol. % according to OIML R117 for accurate measuring.

Particle inclusion

To avoid measuring errors due to particle inclusion, adequate measures

have to be taken. Particle inclusion should be limited to the lowest possible

value and shall be < 5 % for accurate measurement.

Cavitation

In order to prevent cavitation in the following formula should be applied to

calculate the minimum required back pressure:

Pb ≥ 2.65 10E-5 ρL* vL

Pb Back pressure [bar]

ρL Liquid density [kg/m3]

vL Liquid velocity [m/s]

Pv Vapour pressure [bar] (at operational temperature)

If required the position of the signal converter can be modified by turning the

display through 90° or 180°.

In case of direct sunlight, we recommend installation of a sunshield to

prolong the life of the meter. No direct damage will occur without a sunshield.

Do not expose the signal converter to excessive vibration. For this, support

the pipeline on either side of the flowmeter.

Ambient temperature: -40°C to +70°C/ -40°F to +158°F

Product temperature: -25°C to +180°C/ -13°F to +356°F

Storage temperature: -40°C to +80°C/ -40°F to +176°F

Keep a minimum distance between pipe centerline and adjacen t wall of at

least 0.5 m (1.6 ft).

To avoid measuring errors and malfunctioning of the flowmeter due to gas or

air inclusions or an empty pipe, please observe the following precautions:

Since gas will collect at the highest point of a pipe, installation of the

flowmeter at that location should be avoided at all times. Also installation in a

down going pipe should be avoided since a completely filled pipe may no t be

guaranteed due to cascading affects. Additionally flow profile distortion is

possible.

2

+ 1.25 Pv

Long horizontal pipes

Install in slightly ascending pipe section. If not possible, ensure adequate

velocity to prevent air, gas or vapor from collecting in upper part of flow tube

As a partially filled meter will report higher than actual flow rates, or not

measure (as transducer pairs become non-wetted).

Mixing different fluid products

Install the flowmeter upstream of mixing point or at minimum distance of 30

D (D = flowmeter diameter) downstream of the mixing point, otherwise the

flow measurement may be unstable.

ALTOSONIC III 8

Page 9

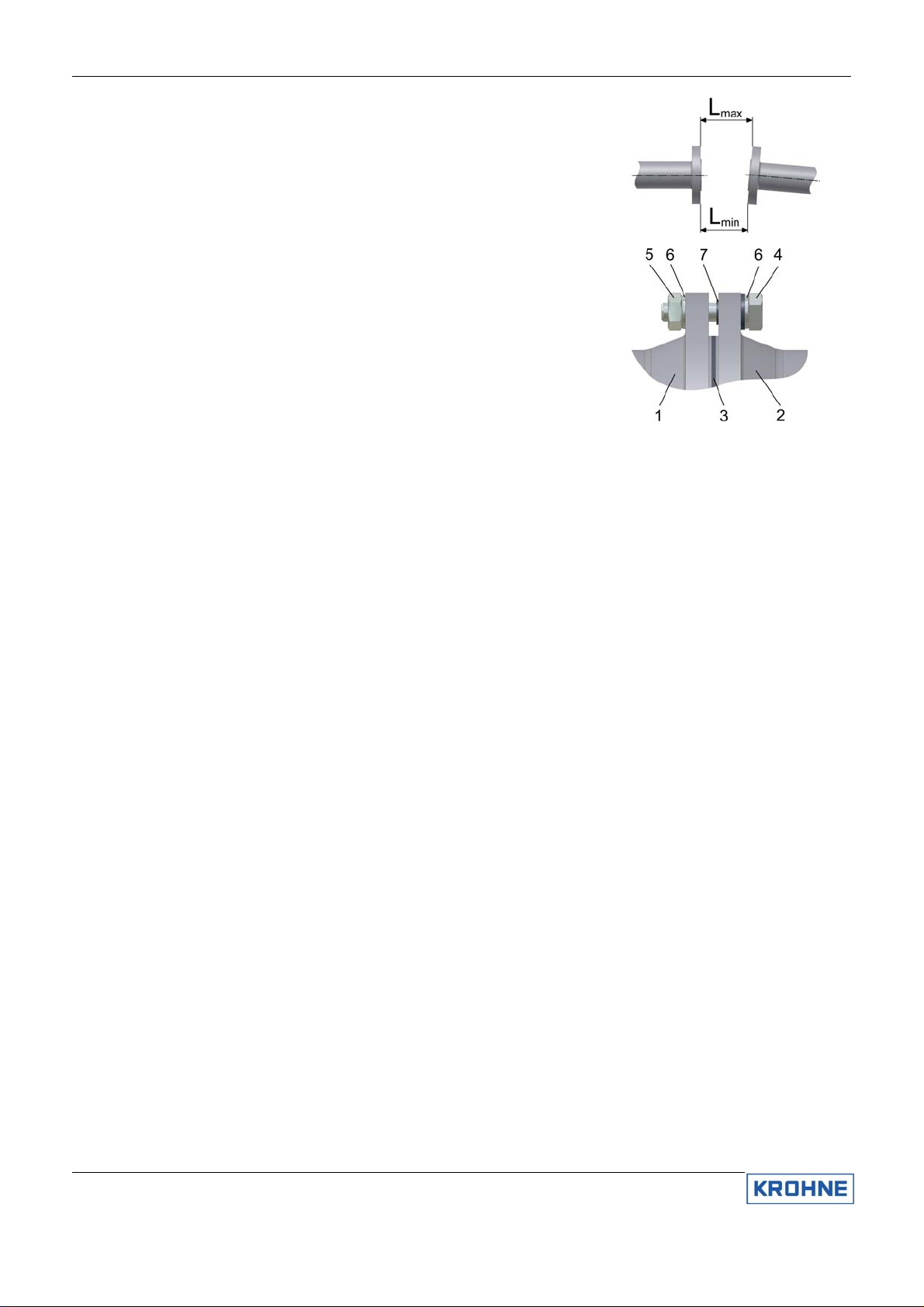

2.5 Pipe flanges

Installation and operating instructions

Refer to dimensional drawings for flange spacing and in addition allow for

thickness of gaskets. Install flowmeter in line with pipe axis. Pipe flange

faces must be parallel to each other, max.

Permissible deviation: Lmax - Lmin ≤ 0.5 mm (0.02").

2.6 Pipes with cathodic

protection

Pipes with electric corrosion protection

are generally insulated inside and

outside so that the fluid has no

conductive connection to ground. The

flowmeter must be insulated from the

pipe. Note the following when installing

the flowmeter:

The pipe flanges must be connected to

each other using a copper cable (L), but

must not be connected to the flowmeter.

The bolts for the flange connections and

the gaskets must be insulated. Use

sleeves and washers that are made of

insulating material (these must be

provided by customer).

Follow grounding instructions.

Use ≥ 4 mm² (≥ AWG 11 cable).

Note: No earthing cables are supplied by KROHNE.

1. Flange of flow sensor

2. Pipe flange

3. Gasket

4. Bolt

5. Nut

6. Washer

7. Insulating sleeve

9 ALTOSONIC III

Page 10

3. Connecting

the signal

converter

3.1 Safety

instructions

3.2 Installation in

hazardous

areas

3.3 Converter

terminal box

3.4 Power supply

connection

This product is designed for use in accordance with EN IEC 61010-1 for Installation Category 2 and Pollution Degree 2.

Hazardous voltages are present within this product during normal operation.

The product is designed for Protection Class I and should never be operated without protective earthing.

The product shall also never be operated with covers removed unless equivalent protection of the operator and its environment

from accidental contact with hazardous internal voltages is provided. Always follow basic and local safety precautions when

using this product to reduce risk of injury from electrical shock, spread of fire or other dangerous situations.

All ultrasonic flowmeters of the ALTOSONIC III series must always be incorporated within the equipotential bonding system of

the hazardous area. For this purpose it is provided with an external PE-terminal. The external PE-terminal is located on the

connecting flange at the bottom of the flow converter housing and on top of the support of the flow sensor, just below the junction

box.

A separate bonding conductor must be at least 4 mm

Clause 413 of HD 384.4.41 or IEC 364-4-41. Make sure that the core of the bonding wire is properly mounted under the U-clamp

of the PE-terminal and that the screw is tightly fixed.

• The converter terminal box is accessible after removing the rear (blind) cover of the electronics section using the special

wrench supplied with the flowmeter.

• Do not damage the screw thread and the gasket, never allow dirt to accumulate, and make sure that the screw thread is well

greased, using Teflon grease at all times. A damaged gasket must be replaced immediately!

• Do not cross or loop the cables in the terminal box of the signal converter. Use separate cable entries for power supply and

signal cables.

Environmental conditions

The ALTOSONIC III is designed to operate safely under the following conditions:

• Suitable for indoor and outdoor use, the instrument is usable up to protection category IP 67 (IEC 60529).

• Use up to an altitude of 2000 m above sees.

• Suitable for an operation ambient temperature range: - 40°C to +70°C / - 40°F to +158°F.

• Suitable for an storage temperature range: -40°C to + 80°C / -40°F to + 176°F.

• Suitable for use in atmospheres with a relative humidity up to 80%.

• Mains supply voltage fluctuations up to -15 and +10% of the specified voltage range.

• Over voltages up to category II on the main supply voltage (IEC 60364-4-443).

• Connected to protective earth conductor (Protection Class I).

• Rated pollution degree 2.

• This instrument is intended for permanent connection to the mains. It is required (for example for service) to mount an

external switch or circuit breaker near the product for disconnection from the mains. It must be easily reachable by the

operator and marked as the disconnecting device for this product. The switch or circuit breaker has to be suitable for the

application and shall also be in accordance with to local (safety) requirements and of the building installation (IEC 60947-1/-

3).

• The protective conductor clamp terminal size M5, press-fitted in the terminal compartment (near the main connection

terminals), shall always to be connected to the protective earth conductor of the mains supply. Conductors up to 4 mm² (11

AWG) be connected to this terminal. The diameter of the conductors of the mains supply, including the protective earth

conductor shall be in accordance with the general and local requirements.

• It is not allowed to use the protective conductor terminal for any other connection than the protective earth conductor.

• IP 67 is only warranted when using suitable cabling with the cable glands and covers mounted as specified.

2

(11 AWG) or 2,5 mm2 (14 AWG) in case it is mechanical protected, see

ALTOSONIC III 10

Page 11

Installation and operating instructions

100-240 V AC supply:

The mains voltage

power supply terminal

has two connections

L Live power supply

N

Neutral power supply

Mains voltage AC supply: 100…240 V AC +10%/-15%,

48 - 63 Hz, 11 W

PE: Protective ground connection

FE: Functional ground connection

Protective conductor clamp terminal. Conductors up to 4

mm² (11 AWG) need to be connected to this terminal.

24 V AC/DC supply:

The low voltage

AC/DC power supply

terminal has two

connections

L

L

Live power supply

Neutral power supply

FE: Functional ground connection

SELV AC/DC supply:

24 V AC +10%/-15%, 48 - 63 Hz, 8 W of

24 V DC +33%/-25%, 8 W

3.5 Connection of

sensor cables

The sensors of the separate flowmeter must be connected using the factory supplied MR06 cable between the flow sensor

terminal box and the converter housing terminal box. For compact flowmeters these are connected at the factory.

Both the flow sensor terminals and the converter sensor terminals should be connected between the appropriate numbers

indicated on the sensor cable and in the terminal boxes

Cable diameter: 11 mm (0,433 inch), minimum bending radius: 8 x cable diameter.

3.2 3.1

2.2 2.1

1.2 1.1

11 ALTOSONIC III

Page 12

3.6 Electrical

connection of

the signal

inputs and

outputs

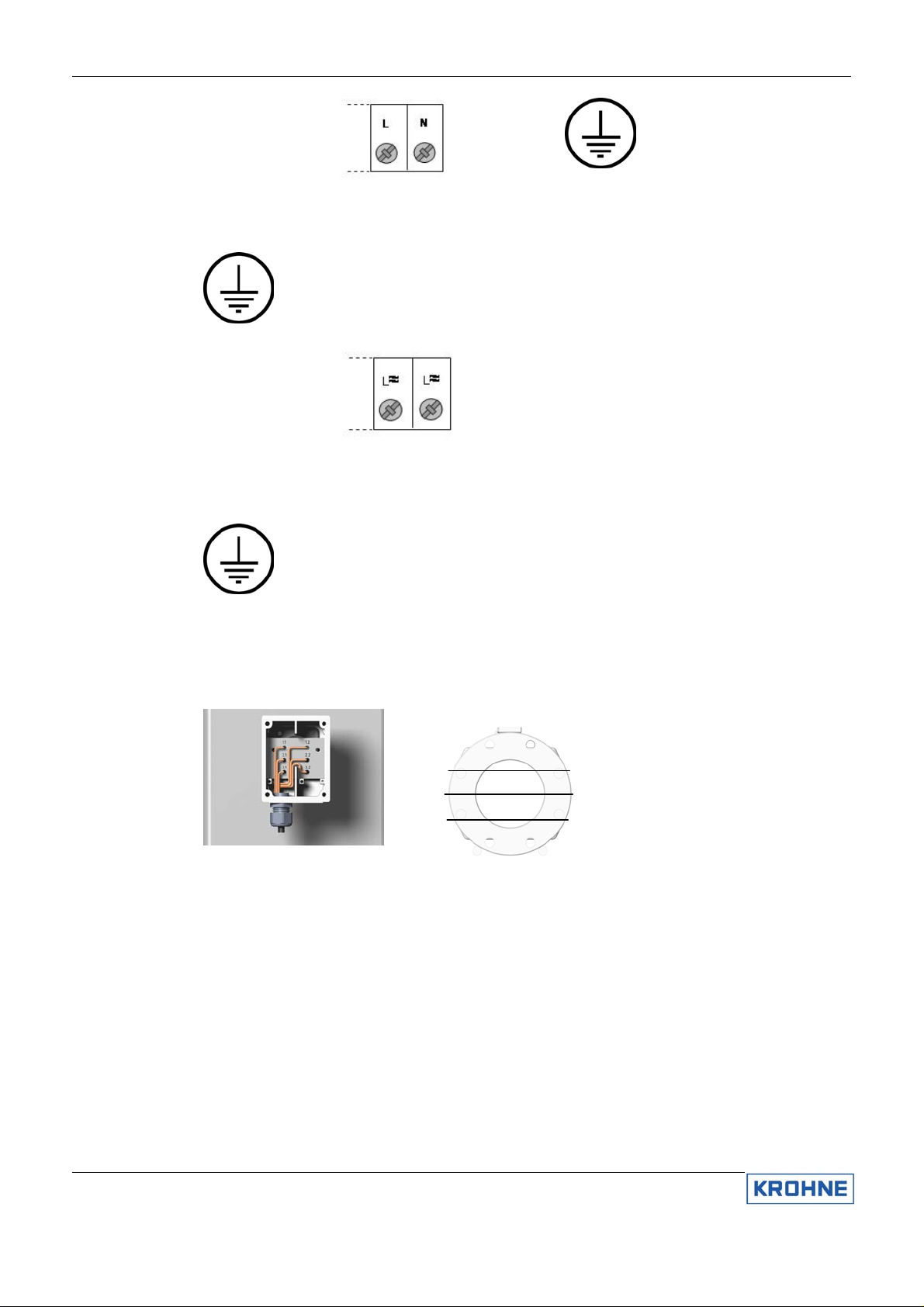

The terminal to connect the electrical signal inputs

and outputs consist of 6 connections. For wiring of

the signal inputs and outputs it is advised to use

unshielded twisted pairs.

Terminal Function Specification

⊥

P1 Pulse output 1, passive open collector output. Pulse

P2 Pulse output 2, passive open collector output. 90° or

S Status output. Function can be set via menu option

I/C Current output (I), 0(4) to 20 mA

Common ground -

output to flow computer for volume counting.

Function can be set via menu option.

180° phase shifted from P1. For pulse fidelity checking

P1 and P2 should be connected to 2 separate inputs of

a flow computer.

Function can be set via menu option.

3.5.0.

Passive open collector current sink output. Digital input

(C)

Function can be set via menu option 3.4.0. and 3.6.0.

: 150 mA

I

max

: 32V DC, 24V AC

U

max

Max frequency: 1,5 kHz

: 150 mA

I

max

U

: 32V DC, 24V AC

max

Max frequency: 1,5 kHz

I

: 150 mA

max

U

: 32V DC, 24V AC

max

Current output (I): I ≤ 22 mA,

≤ 680 Ohm. U

R

load

Digital input (C): low = 0-5 V DC, high = 15-32 V DC.

Will be switched off when current output activated.

max

The electrical input and output signals can be connected in passive mode. Please observe instrument polarity:

current (I) is always flowing towards P1, P2, S, I/C, terminals (current sink).

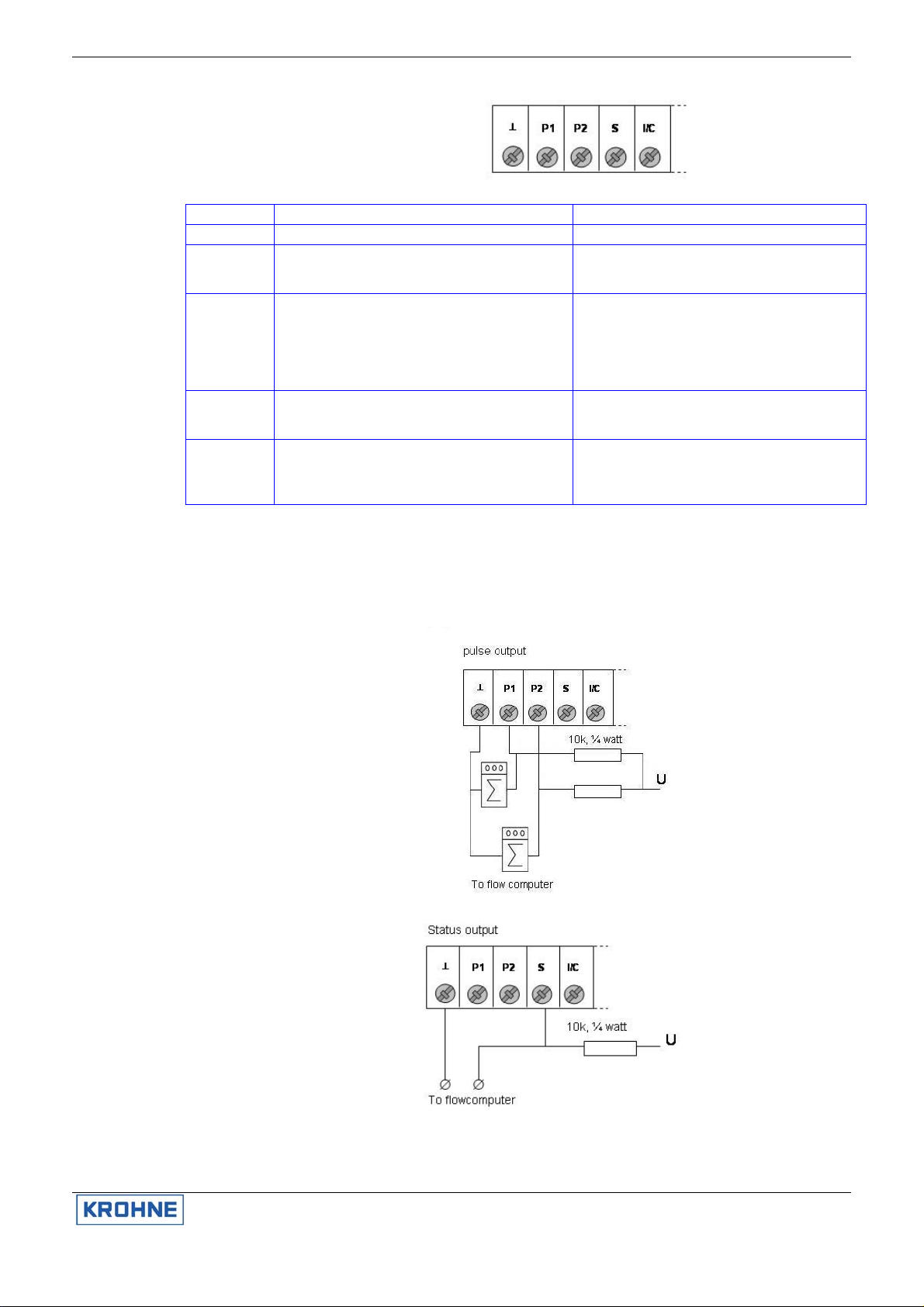

3.7 Connection

diagram

examples

Pulse output, P1,

P2

For supply:

U ≤ 32V DC, ≤

24V AC

= 15V DC.

Status output, S

For supply:

U ≤ 32V DC, ≤

24V AC

ALTOSONIC III 12

Page 13

Installation and operating instructions

Current output /

control input, I/C

For supply:

U = 15…24V

DC, ≥ 22mA

For supply:

15 – 30V DC, I ≥

1,5 mA

Connection to

Omni 3000/6000

flow computer

Single flow pulse

connection

Omni 6000,

Omni 3000

A/B type combo

module

Channel 3 or 4

on A type

Channel 3 only

on B type

13 ALTOSONIC III

Dual pulse

connection

for pulse fidelity

checking

Omni 6000,

Omni 3000

E type combo

module

Page 14

Flowmeter status

connection

Omni 6000,

Omni 3000

Digital I/O

module

3.8 Start-up

• Check that the flowmeter has been correctly installed. With separate systems, check before initial start-up that the correct

converter (UFC III F) is used with the correct flow sensor (UFS III F).

• Order No., see instrument type plates

• Meter size, Function 3.1.5

• Primary constant GK, Function 3.1.6

• Flow direction, Function 3.1.7

• When powered, the signal converter operates in the measuring mode. TEST, NO ERROR and IDENT NO. _ _ _ _ _ _ _ of the

signal converter appear in succession on the display. This is followed by display of the actual flow rate and/or the internal

count on a continuous or alternating basis (depending on setting, see Function 3.03 Display or Function 1.02 Display).

3.9 Operating the

signal

converter

Front panel and operating keys

The front panel and its operating keys are accessible after removing the front (glass) cover of the electronics section using the

special wrench supplied with the flowmeter.

When removing the cover, do not damage the screw thread and the gasket, never allow dirt to accumulate, and make sure that

they are well greased using Teflon grease at all times. A damaged gasket must be replaced immediately!

The converter can display several types of measured values (depending on the programming), indicated by the markers at the

display bottom line. They can be selected manually at any time by pressing the ↑ key or they are automatically cycled at 5 second

intervals.

Errors are indicated by flashing display lines and/or by the compass field. For a description of the errors and what to do, see main

“error” menu.

1. Display 1st (top) line, measured value

2. Display 2nd (middle) line, units of measured value

3. Display 3rd (bottom) line with markers ▼

to identify actual displayed value, from left to right:

Flow rate

Velocity Of Sound VOS

4. Compass field for error indication

5. Operating keys for programming the signal converter

6. Magnetic sensors to program the signal converter by means of a hand-held bar magnet

(optional) without having to open the housing. To prevent change of settings with the

cover in place sensors are only fitted for the 2 right most keys.

The function of the sensors is as follows: the right most sensor is equivalent to the right

key and the top sensor is equivalent to the center key.

ALTOSONIC III 14

Page 15

3.10 Menu

structure and

function of

operating

keys

The menu structure consists of shows the available functions for system check and configuration. Function block 0 can be

accessed with the display cover in place. For access to function block 1 to 4 the display cover has to be removed as it requires the

leftmost key for operation.

• Function block 0 Function is accessible without removing display cover. System info and error reset, can be accessed from

the measuring mode and provides detailed information on errors occurred during operation. It allows for fast and easy

resetting of the errors. System information like software version numbers can be displayed using this function. Also a display

test can be performed using this function.

• Function block 1 Operation contains a subset of options from function block 3, Installation. The options in function block 1

are selected so that the most commonly used functions can be selected quickly from this menu. In most cases only function

block 1 needs to be accessed in order to perform the required setting or programming task.

• Function block 2 Test contains all available test functions. This block can be accessed to check proper functioning off all

converter hard- and software.

• Function block 3 Installation contains all other set-up parameters for the converter. In general the converter is factory-

preset. See Service Handbook for modification instructions.

• Function block 4 Parameter Error becomes active automatically when non-plausible values have been programmed, e.g. a

too high a flow rate in too small a diameter. If this is the case menu 4 will indicate that either FULL SCALE or METER SIZE

needs to be changed.

The figure below shows the main operation structure of the converter. The cursor or flashing part of the display is shown as

underlined text.

Installation and operating instructions

15 ALTOSONIC III

Page 16

Key Measuring mode Menu mode Data level

Go to the parameter setting mode, function 1.00.00

→

OPERATION. If access CODE 1 is activated, CODE 1 must be

entered first. Using function 3.07.02 access CODE 1 can be

activated or deactivated.

Go to the error/Totalizer reset mode (via "CODE 2") Return to the previous (higher)

↵

Cycle through measured values, see Function 3.03.07 CYCL

↑

DISP

Function Text Description and settings

0.00.00 ERROR/TOT Main menu 0.00.00

0.00.01 VIEW ERR View error messages list

0.00.02 RST ERR Reset error messages

0.00.03 UP2 SW NO Software version micro processor 2

0.00.04 DSP SW NO Software version digital signal processor

0.00.05 DISPLAY Display test, all display items on

0.00.06 EXIT Leave menu 0.00

1.00.00 OPERATION Main menu 1.00.00 Operation

1.01.00 FLOW Submenu 1.01.00 Flow

1.01.01 FULL SCALE Full-scale value for 100% volume flow rate, see Function 3.01.01

1.01.02 ZERO VALUE Zero value, see Function 3.01.02

1.01.03 ZERO CAL Zero calibration, see Function 3.01.03

1.01.04 MASTER TC Master time constant, see Function 3.01.04

1.01.05 LF CUTOFF Low-flow cut-off, see Function 3.01.05

1.01.06 CUTOFF ON Cut-off active, see Function 3.01.06

1.01.07 CUTOFF OFF Cut-off de-active, see Function 3.01.07

1.02.00 DISPLAY Submenu 1.02.00 Display

1.02.01 DISP FLOW Display of flow, see Function 3.03.01

1.03.00 PULSE OUTP Submenu 1.03.00 Pulse output

1.03.01 PULSE RATE Pulse frequency value for 100% scale, see Function 3.05.08

1.03.02 PULSE/UNIT Pulse value per volume flow unit, see Function 3.05.09

2.00.00 TEST Main menu 2.00.00 Test functions

2.01.00 DISPLAY Submenu 2.01.00 Display

2.01.01 DISPLAY

2.02.00 OUTPUTS Submenu 2.02.00 Outputs

2.02.01 CURRENT Test current output

2.02.02 PULSE Test pulse/frequency output

2.03.00 INPUTS Submenu 2.03.00 Inputs

2.03.03 DIG INPUT Test digital input

2.04.00 DEV INFO Submenu 2.04.00 Device information

2.04.01 MANUFACT Display manufacturer

2.04.02 MODEL NO Display model number

2.04.03 SERIAL NO Display serial number

2.04.04 UP2 HW NO Display µP2 hardware number

2.04.05 UP2 SW NO Display µP2 software number

2.04.06 FRNT HW NO Display front end hardware number

2.04.07 DSP HW NO Display D.S.P. hardware number

2.04.08 DSP SW NO Display D.S.P. software number

2.04.09 TIME COUNT Display time counter

3.00.00 INSTALL Main menu 3.00.00 Installation

3.01.00 FLOW Submenu 3.01.00 Volume flow parameters

ALTOSONIC III 16

Test display, lights all pixels. End with ↵ key

0 mA 4 mA

12 mA 20 mA

22 mA

Use up arrow to advance. Displayed value directly present at current output. Actual value present at

output after pressing ↵ key.

1 Hz 10 Hz

100 Hz 1000 Hz

2000 Hz

Use the up arrow to advance. Displayed value directly present at Pulse output. Actual value present at

output after pressing ↵ key

Measure level at digital input. End with ↵ key.

Go to the next, lower menu level. Go to the next character or change line

(only when 2 lines are displayed)

Accept entered value

menu level or leave the menu

mode.

Cycle through menu options

within actual menu level.

Cycle active digit up to new values

Page 17

Installation and operating instructions

3.01.01 FULL SCALE Full-scale value for 100% volume and flow rate units (see Function 1.01.01). The selection of units may

be limited to SI units only.

m³/s, m³/min, m³/hr, L/s, L/min, L/hr,

US Gal/s, US Gal/min, US Gal/hr, bbls/hr, bbls/day,

********** (free user configurable unit).

3.01.02 ZERO VALUE Zero value (see Function 1.01.02)

FIXED (factory zero setting)

MEASURED (zero calibration possible, see Function 3.01.03)

3.01.03 ZERO CAL Zero calibration (see Function 1.01.03)

Carry out only at “zero” flow and with completely filled measuring tube. Duration approximately 15s with

display indicating "BUSY". STORE NO (preserve old zero value)

STORE YES (store new zero value)

3.01.04 MASTER TC Master time constant of display and current output (see Function 1.01.04)

Range: 0.02 through 99.99 s

3.01.05 LF CUTOFF Low-flow cut-off for display and outputs (see 1.01.05)

NO (fixed tripping points: ON = 0.1%, OFF = 0.2%)

YES (see Function 3.01.06 and 3.01.07)

3.01.06 CUTOFF ON Cut off “active” value

Range: 1 through 19% of Q100%

3.01.07 CUTOFF OFF Cut off “de-active” value

Range: 2 through 20% of Q100%

Value "off" must be greater than value "on"

3.01.08 METER SIZE Meter size

Selection of size from meter size table: 25-3000 mm equivalent to 1-120 inch

3.01.09 GK VALUE Flow sensor constant (GK)

Must equal flow sensor type plate value

Range: 0.02 through 20

3.01.10 FLOW DIR Definition of forward flow direction

POSITIVE

NEGATIVE

Setting in accordance with direction of arrow on flow sensor

3.01.11 MIN VOS Minimum velocity of sound (VOS)

Value used for I0% or P0% when function "VOS" selected in Function 3.04.01 or 3.05.01

Unit: m/s or feet/s

Range: 0 through 4999 m/s (0 through 15000 feet/s)

3.01.12 MAX VOS Maximum velocity of sound

Value used for I100% or P100% when function "VOS" selected in Function 3.04.01 or 3.05.01

Unit: m/s or feet/s

Range:1 through 4999 m/s (0 through 15000 feet/s)

Maximum value must be greater than minimum value

3.02.00 VERSION Submenu 3.02.00 Version

3.02.01 FUNCTION Function of converter

CUSTODY. This is factory set and can not be changed.

3.03.00 DISPLAY Submenu 3.03.00 Display (see Function 1.02.01)

3.03.01 DISP FLOW Display of flow

RATE (full-scale units)

Percent (percentage of full-scale, 0% - 100%)

NO DISPLAY (no flow display)

3.03.06 VOS Unit for Velocity Of Sound

NO DISPLAY, m/s, feet/s

3.03.07 CYCL DISP Cyclic display of measured values

NO, YES

3.03.08 ERROR MSG Display error messages

NO, YES

3.03.11 SIGN LEVEL Display signal level

NO, YES

3.04.00 CURR OUTP Submenu 3.04.00 Current output

3.04.01 FUNCTION Function of current output

OFF (switched off)

ACT FLOW (actual flow)

F/R IND (forward/reverse indication of actual flow)

VOS (velocity of sound, range is defined in Function 3.01.11 and 3.01.12)

GAIN (sensor signal gain, range is 0 dBV through 100 dBV)

3.04.02 DIRECTION Direction of current output

FORWARD (forward flow measurement)

17 ALTOSONIC III

Page 18

BOTH (forward and reverse flow measurement indicating both in the same range)

F/R SPEC (forward and reverse flow measurement indicated in different range see Function 3.04.04)

3.04.03 RANGE Range of current output

OTHER (user defined, see Function 3.04.04 through 3.04.06)

0-20/22 mA (0 pct - 100 pct / limit)

4-20/22 mA(0 pct - 100 pct / limit)

3.04.04 0 pct Current value for 0% scale

Range: 0 through 16 mA

3.04.05 100 pct Current value for 100% scale

Range: 4 through 20 mA

Value must be at least 4 mA greater than current value for 0% scale

3.04.06 LIMIT Limitation of current value

Range: 20 through 22 mA

3.05.00 PULSE OUTP Submenu 3.05.00 Pulse output

3.05.01 FUNCTION Function of pulse output

OFF (switched off)

ACT FLOW (actual flow)

VOS (velocity of sound, range defined in Function 3.01.11 and 3.01.12)

GAIN (sensor signal gain, range is 0 dBV through 100 dBV)

3.05.02 DIRECTION Direction of pulse output

FORWARD (forward flow measurement)

BOTH (forward and reverse flow measurement indicating both in the same range)

3.05.06 TIME CONST Time constant of pulse output

25 ms

MASTER TC (see Function 3.01.04)

3.05.07 OUTPUT Unit of pulse output (see Function 1.03.00)

PULSE FREQUENCY, pulses per unit time, see Function 3.05.08)

PULSE/UNIT, Totalizer pulse output, pulses per unit volume, see Function 3.05.09

3.05.08 PULSE RATE Pulse rate (frequency) value for 100 % scale

pulse/s, pulse/hr, pulse/min

Range: 1 pulse/hr through 2000 pulse/s

3.05.09 PULSE/UNIT Pulse value per volume unit for totalization

pulse/m³, pulse/l, pulse/US Gal, pulse/bbl,

free user definable unit

3.06.00 DIG INPUT Submenu 3.06.00 Digital input

3.06.01 FUNCTION Function of digital input

OFF (switched off)

RST ERROR (reset error messages)

3.07.00 USER DATA Submenu 3.07.00 User data

3.07.01 LANGUAGE Language for display texts

GB/USA (English)

D (German)

F (French)

3.07.02 ENTRY CODE Entry code for setting mode

NO (entry with key only)

YES (entry with key and code 1, factory set on 9 x key, see Function 3.07.03)

3.07.03 CODE 1 Code 1

Press any 9-keystroke combination and th en press the same combination again. Each keystroke is

acknowledged by "Ж" in the display. If both combinations are equal, "CODE OK" appears and the new

code can be stored, else "WRONG CODE" appears and the desired code has to be entered again.

3.07.04 LOCATION Tag name setting

Free settable tag for identification, maximum 10 characters.

Characters assignable to each place: A..Z / blank character / 0..9

Factory setting: KROHNE

3.07.05 UNIT TEXT Text for user-defined unit

Definition: volume/time

Characters assignable to each place: A..Z / blank character / 0..9

Fraction bar "/" in 5th place is unalterable

Factory setting: XXXX/YYY

3.07.06 UNIT VOL User-defined unit volume

Quantity of user-defined volume per m³.

Range: 10-5 through 107

Factory setting: 1

3.07.07 UNIT TIME User-defined unit time

Amount of user-defined time in seconds

Range: 10-5 through 107

Factory setting: 1

ALTOSONIC III 18

Page 19

Installation and operating instructions

3.10.01 DIG OUTPUT Function of digital status output

CUST ERR (Only errors related to custody transfer operation, also see error list)

ALL ERR (indication of all errors)

F/R IND (forward/reverse flow indication)

OVERRANGE (overrange indication)

TRIP POINT (trips when actual flow (Q) goes over a set limit, see 3.10.02 and 3.10.03 for settings)

3.10.02 TRIP PNT 1 First trip point

Range: 0 through 120% of Q100%

3.10.03 TRIP PNT 2 Second trip point

Range: 0 through 120 % of Q100%

4.00.00 PARAM ERR Main menu 4.00.00 Parameter error

4.01.00 FLOW VELOC Volume flow velocity (v) value incorrect. The flow speed is calculated from the full scale volume flow and

the meter size.

Ensure condition 0.5 m/s ≤ v ≤ 20 m/s (1,5 to 66 feet/s) is met!

4.01.01 FULL SCALE Full-scale value for 100% volume flow rate, see Function 3.01.01

4.01.02 METER SIZE Meter size, see Function 3.01.08

4.02.00 CURR OUTP Current output range incorrect. Setting for 100% is compared with setting for 0%. Ensure condition 100

pct-0 pct ≥ 4 mA is met!

4.02.01 RANGE Range of current output, see Function 3.04.03

4.02.02 0 pct Current value for 0% scale, see Function 3.04.04

4.02.03 100 pct Current value for 100% scale, see Function 3.04.05

4.03.00 LF CUTOFF Low-flow cut-off range incorrect: If low flow cut-off is set to on, the value for CUTOFF-OFF is compared

with the value of CUTOFF-ON on.

Ensure condition CUTOFF-OFF – CUTOFF-ON ≥ 1% is met!

4.03.01 LF CUTOFF Low-flow cut-off, see Function 3.01.05

4.03.02 CUTOFF ON Cut off “on” value, see Function 3.01.06

4.03.03 CUTOFF OFF Cut off “off” value, see Function 3.01.07

4.05.00 PULSE/VOS Unit of pulse output for velocity of sound function incorrect

Ensure "PULSE RATE" is selected for "VOS"!

4.05.01 PULS FUNCT Function of pulse output, see Function 3.05.01

4.05.02 PULSE OUTP Unit of pulse output, see Function 3.05.07

4.06.00 VOS Velocity of sound range incorrect:

Ensure condition MAX VOS - MIN VOS ≥ 1 m/s (3.3 ft/sec) is met

4.06.01 MIN VOS Minimum velocity of sound, see Function 3.01.11

4.06.02 MAX VOS Maximum velocity of sound, see Function 3.01.12

4.07.00 PULSE OUTP Pulse output frequency value (f) incorrect. The max frequency is calculated from the pulse/unit setting

and the max value of the measured value.

Ensure condition 1 pulse/hr ≤ f ≤ 2000 pulse/s is met.

4.07.01 PULSE/UNIT Pulse value for volume flow rate unit, see Function 3.05.09

4.08.00 PULS WIDTH Pulse output pulse width incorrect

Ensure condition pulse width ≤ 0.5 x pulse period time is met.

4.08.01 PULS WIDTH

4.09.01 CURR RANGE Range of current output, see Function 3.04.03

4.09.02 CURR 0 pct Current value for 0% scale, see Function 3.04.04

4.10.00 INP/OUTP The digital input (C) and current output (I) are not allowed to be switched on simultaneously. The current

4.10.01 INP FUNCT Function of digital input, see Function 3.06.01

4.10.02 CURR FUNCT Function of current output, see Function 3.04.01

4.10.03 CURR RANGE Range of current output, see Function 3.04.03

4.10.04 PULS FUNCT Range of pulse output, see F uncti on 3.05.01

4.13.00 EPROM EPROM checksum error, reset device.

Pulse width for frequencies ≤ 10 Hz, see Function 3.05.11

output is deactivated by setting the function of current output to off en setting the range of current output

to 0-20mA.

19 ALTOSONIC III

Page 20

3.11 Description of

functions

3.11.1 Main menu 0.00.00

Error

This menu is accessible from the measuring mode by pressing the ← key and entering "CODE 2" (↑→).

Depending on the programming of Function 3.03.08 ERROR MSG, errors occurring during process flow measurement

are represented with flashing display lines and/or a compass field. Depending on the programming of Function 3.03.07

CYCL DISP, the error messages alternate with the display of the measured value(s) every 5 seconds, or they can be

manually selected by pressing the ↑ key.

Indication of measuring path errors:

1, 2, 3: for measuring path 1,2 and 3, open or shorted sensor no measured value from

path.

4. Noise error, to much noise on measuring path(s). Flowmeter functions outside

specification.

The following list gives an alphabetical overview of error messages that can occur during process flow measurement

and what to do. The error messages only appear when Function 3.03.08 ERROR MSG is YES. Errors indicated with

“YES” in the column “via status output” the status output is activated when the error occurs

Function 0.00.01 through 0.00.06 View error messages list / Reset error messages

All occurred error messages are stored in an error messages list and can be viewed using Function 0.00.01 VIEW

ERR. The messages are kept in this list until the cause of the errors has been removed and the error messages have

been reset using Function 0.00.02 RST ERR. Errors that have been reset, but whose cause has not been removed, are

kept in the list but are displayed without bar. This allows identification of previously acknowledged and unacknowledged

errors. See table below.

1. Flashing line with number of errors that have occurred.

2. Flashing line with description of error message(s).

3. Flashing bar, indicating "new" errors, not yet

acknowledged.

4. Compass field, indicating measuring path error(s):

ALTOSONIC III 20

Page 21

3.11.2 Main menu 1.00.00

Operation

3.11.3 Main menu 2.00.00

Test functions

Error message Description of error message OIML error

CURR > MAX Current output overflow (> 22 mA) No Check flow velocity

DSP Digital signal processor (DSP) internal

error

EE MENU Menu parameters corrupted Yes Contact KROHNE representative

EE SERVICE Service parameters internal error Yes Contact KROHNE representative

EMPTY PIPE Measuring tube not completely filled,

flow reading to 0, error on all 3 paths.

FLOW > MAX Measuring range overflow (flow > 2 x

)

Q

max

FRONT END Front end internal error Yes Only checked at power-up. Switch

RESTART Flowmeter restarted No Reset errors

UNRELIABLE Flow data disturbed, same as right

compass field (4)

PATH 1 Measuring path 1 error Yes Check flow conditions

PATH 2 Measuring path 2 error Yes Check flow conditions

PATH 3 Measuring path 3 error Yes Check flow conditions

PULS > MAX Pulse output overflow (> 120 %) No Check flow velocity

UP2 µP2 internal error Yes Contact KROHNE service

VOS path 1 Deviation > 5% from average VOS of

3 measuring paths

VOS path 2 Deviation > 5% from average VOS of

3 measuring paths

VOS path 3 Deviation > 5% from average VOS of

3 measuring paths

Flow calc. Algorithm check error Yes Reset error

Cal data Yes Contact KROHNE representative

System stp System error Yes Power on/off. Contact KROHNE

Function 0.00.03 Reset Totalizer

Reset display totalizer(s). Only available when Function 3.07.08 RST ENABLE is YES. Note that all totalizer values are

reset.

The functions in this menu are a subset of Main menu 3.00.00 Installation, and are selected in this menu as most

commonly used functions for a quick installation. Note that parameters set in these functions are automatically set in

both menus.

This menu is for testing the display, the in- and outputs and for information on hard- and software numbers. See

chapter on functional checks and service.

Installation and operating instructions

What to do?

(set function

3.10.1 to CUST.

ERR)

Yes Only checked at power-up. Switch

off and on the flowmeter. If the

error still exists, contact KROHNE

representative

Yes Fill measuring tube completely

No Check flow velocity

off and on the flowmeter. If the

error still exists, contact KROHNE

representative

Yes Check flow conditions

Yes Check VOS of each path

Yes Check VOS of each path

Yes Check VOS of each path

representative when message

remains

21 ALTOSONIC III

Page 22

3.11.4 Main menu 3.00.00

Installation

Submenu 3.01.00 Volume flow parameters

Function 3.01.01 Full-scale value for 100% volume flow rate

The following units can be applied:

m³/s - cubic meter per second – US Gal/s - US gallons per second

m³/min- cubic meter per minute – US Gal/min - US gallons per minute

m³/hr- cubic meter per hour – US Gal/hr - US gallons per hour

L/s - liter per second - bbls/hr - barrels per hour

L/min -liter per minute - bbls/day - barrels per day

L/hr -liter per hour - free unit, a user-definable unit, which can be defined using Function 3.07.05 to 3.07.07.

Range depends on diameter (D) and volume flow velocity (v):

[m³/h] = 0,9 x D² (v

Q

min

[m³/h] = 31,25 x D² (v

Q

max

[US GPM]= 3,9 x D² (v

Q

min

[US GPM] = 138 x D² (v

Q

max

= 0.5 m/s)

min

max

min

max

Function 3.01.02 through 3.01.03 Zero value / Zero calibration

Although zero calibrated at the factory the flow sensor might still give an offset flow reading, at "zero" flow in the

pipeline (measuring tube completely filled with medium. Function 3.01.02 ZERO VALUE can be used for zero

calibration. It can be set to either FIXED, which will give a factory zero setting, or MEASURED, which will allow to

compensate for the small signal using Function 3.01.03 ZERO CAL.

Function 3.01.04 Master time constant of display and outputs

This is the time that it takes for the display and the current and pulse outputs to reach 66% of the end value, after a

change in the flow rate. The time constant does not apply for totalization. The time constant does not apply for the

current output in F/R setting. If required, a different time constant value can be set for the pulse/frequency output under

Function 3.05.06 TIME CONST.

Function 3.01.05 through 3.01.07 Low-flow cut off for display and outputs / Cut off "on" value/ Cut off "off"

value

Due to the extreme low flow sensitivity of the ALTOSONIC III, it will detect the slightest movement of fluid, even at zero

flow. To avoid these measurements causing outputs and totalizer changes, the low flow cut-off can be used to force

reading to zero. These are set as a percentage of Full Scale, as configured in Fct.1.01.01 or 3.01.01.

When the flow rate decreases below the "on" value, the display and outputs are set to their "zero" values. When the

flow increases above he "off" value, measurements are resumed. The "off" value must be larger than the "on" value by

at least 1%. With Function 3.01.05 LF CUTOFF set to NO, factory settings are used for the "on" and "off" values.

Function 3.01.08 Meter size

The nominal diameter of the measuring tube. See the flow sensor nameplate. This value can be entered In mm or in

inches.

Function 3.01.09 Flow sensor constant GK

At the factory, each flow sensor is calibrated and supplied with a calibration constant. This constant can be found on the

flow sensor nameplate.

Function 3.01.10 Definition of forward flow direction

The forward flow direction is indicated with an arrow on the flow sensor. If the actual flow is in the direction of the arrow

then the flow is in the positive direction and the converter will have a positive flow reading. By setting this function to

NEGATIVE, the converter's reading can be reversed. This can be useful when the process flow direction is changed so

the flow sensor will not need to be reversed.

Function 3.01.11 through 3.01.12 Minimum/Maximum velocity of sound

In media of varying composition, the ultrasonic wave speed will vary, like in oil-water mixtures. This is identifiable by

means of measuring the velocity of sound. The current output and the pulse output can be programmed to indicate the

velocity of sound, see Function 3.04.01 and 3.05.01. Their "zero" values (0% scale) will then correspond with the

velocity of sound set in Function 3.01.11 MIN VOS, where their "full-scale" values (100% scale) will correspond with the

velocity of sound set in Function 3.01.12 MAX VOS. See also Function 3.03.06 VOS for the display of the velocity of

sound. NOTE: Only necessary for setting span for outputting VOS, is not needed to measure flow!

Submenu 3.02.00 Version

Function 3.02.01 Function of converter

The function of the converter is factory preset to CUSTODY and can not be altered.

= 20 m/s)

= 1.5 feet/s)

= 20 m/s)

ALTOSONIC III 22

Page 23

Submenu 3.03.00 Display

Function 3.03.01 Display of flow

To display the flow, three options are available

Rate; flow is shown with the unit as set in function 3.01.01

Percentage; flow is shown as a percentage of the full scale as set in 3.01.01

No display; no flow is shown.

Function 3.03.06 Unit for velocity of sound

The display of the velocity of sound, as described in Function 3.01.11 through 3.02.12.

The following units can be applied:

NO DISPLAY no display of velocity of sound

m/s meter per second

feet/s feet per second

Function 3.03.07 Cyclic display of measured values

Whenever more than one measured value is to be displayed (e.g. flow rate and totalizer), each value can be selected

manually by pressing the ↑ key, or the values can be alternately displayed each 5 seconds by turning the cyclic display

function on. This also includes the display of various readings as described in Function 3.03.08 through 3.03.11.

Function 3.03.08 Display error messages

Enable/disable the display of error messages as described in section 5.1. When enabled, the converter display will

FLASH when an error occurs, and the error code will be displayed. It will continue to flash until the alarm is

acknowledged or cleared. An unacknowledged alarm will be displayed with 3 horizontal lines in front of the error

message. Acknowledging the alarm will remove the lines. If the alarm is acknowledged but the cause is not removed

the error will stay in the error list. To remove the error from the list the cause must be removed and the error must be

reset. When it is turned off, the compass display indicates errors are present, but the display will not flash.

Function 3.03.11 Display gain

Enable/disable the display of the signal level from the sensors. For each measuring path this level is displayed as a

gain value 0 dBV through 80 dBV at the input amplifier.

Submenu 3.04.00 Current output

Function 3.04.01 Function of current output

The current output can be programmed for the following functions:

• OFF switched off, current output steady at current value for 0 % scale, see Function 3.04.03 ACT FLOW

proportional with the actual volume flow, see Function 3.01.0.1 FULL SCALE.

• F/R IND forward/reverse flow indication, see Function 3.01.10, 100 pct mA value for forward flow, 0 pct mA value

for reverse flow, see Function 3.04.03 through 3.04.05.

• VOS proportional with the velocity of sound, see Function 3.01.11 through 3.01.12.

• SIGN LEVEL proportional with the signal level, see Function 3.03.11.

Function 3.04.02 Direction of current output

Only available when ACT FLOW is selected in Function 3.04.01. When FORWARD is selected, the current output will

only be active when the flow is in the forward flow direction as defined in Function 3.01.10 FLOW DIR, while when

BOTH is selected, the current output will be active forward and reverse flow direction. Use F/R SPEC to indicate the

reverse flow in the range from 0 mA through 0 pct mA (see Function 3.04.04 0 pct). I.e. when the flow goes from the

forward direction to the negative direction, the current output will pass the "0 pct" mA value down to 0 mA, where it

stops.

Installation and operating instructions

23 ALTOSONIC III

Page 24

Abbreviations used:

I Current output

QF Forward volume flow rate

Current output at 0 % scale

I

0%

Current output at 100 % scale

I

100%

QR Reverse volume flow rate

Current output maximum

I

max

When VOS or signal gain is set, only the forward characteristic applies.

Function 3.04.03 Range of current output

The range of the current output can be set to standard 0-20mA or 4-20 mA or to “other” for other user specified spans.

Max reading is 22 mA. The range for “other” is set using functions 3.04.04 to 3.04.06.

Function 3.04.04 0 pct

mA setting for 0 percent of the range. It can be set between 0 and 16 mA. Default is 4 mA.

Function 3.04.05 100 pct

mA setting for 100 percent of the range. It can be set between 4 and 20 mA. Default is 20 mA.

Function 3.04.06 Limit

Limit of current output. Max setting and default setting: 22 mA. Limit it to 20mA when safety systems reserve highe r

currents as Fault Codes.

Submenu 3.05.00 Pulse / frequency output

Function 3.05.01 Function of pulse output

The pulse output can be programmed for the following functions:

• OFF switched off, contact closed.

• ACT FLOW proportional with the actual volume flow, see Function 3.01.01 FULL SCALE.

• CORR FLOW proportional with the corrected volume flow, availability depending on version, see Function 3.02.01.

• F/R IND forward/reverse flow indication, see Function 3.01.10, contact closed for forward flow, contact open for

reverse flow.

• VOS proportional with the velocity of sound, see Function 3.01.11 through 3.01.12.

• DIG OUTPUT digital output, see Function3.05.03.

• SIGN GAIN, gain of sensor amplifier, proportional with the signal level, see Function 3.03.11.

Function 3.05.02 Direction of pulse output

Only available when ACT FLOW is selected in Function 3.05.01. When FORWARD is selected, the pulse output will

only be active when the flow is in the forward flow direction as defined in Function 3.01.10 FLOW DIR, while when

BOTH is selected, the pulse output will be active in both flow directions.

Function 3.05.06 Time constant of pulse output

The time constant of the pulse output can be set to 25 ms, which is the lowest value, or MASTER TC, which will result

in the value, set in Function 3.01.04 MASTER TC. The time constant setting only applies to actual flow and corrected

flow.

Function 3.05.07 pulse output function

The function of the pulse output can be set to either PULSE RATE (frequency) or PULSE/UNIT (Totalizer pulse).

PULSE RATE: Is set by entering a frequency at 100 % volume flow rate.

PULSE/UNIT: Is set by entering a value for the number of pulses for each volume (or energy) unit. Each pulse having a

fixed volume, i.e. 1 pulse / 0.1 liter. This is the best method of remote totalizing, as pulses simply need to be counted,

i.e. 10 pulses = 1 liter. See Function 3.05.08 through 3.05.10.

Function 3.05.08 Pulse rate

If the function of 3.05.07 is set to pulse rate, the frequency of the pulse can be set that will be available at 100% flow.

The frequency can be set to: pulse/s, pulse/min, pulse/hr. The default setting is 1000 pulses/second (Hz), the max

setting is 1500.

Function 3.05.09 Pulse/unit

If the function of 3.05.07 is set to pulse/unit, the unit and number of pulses per unit can be set for the flow measurement

using this function. Options are; pulse/m³, pulse/l, pulse/US Gal., pulse/bbl. Also a user definable unit can be set. The

max number of pulses per unit is 7870000, the default setting is 1. NOTE: Check that the max. flow span will not cause

the number of pulses generated per second to exceed the maximum of 2 000 Hz.

ALTOSONIC III 24

Page 25

Submenu 3.06.00 Digital input

Function 3.06.01 Function of digital input

The digital input terminal is the same as the current output terminal. Therefore, when the digital input function is

selected, the function of the current output (see Function 3.04.01) needs to be set to OFF and the current output range

has to be set to 0-20mA (see Function 3.04.03).

The digital input can programmed for the following functions:

• OFF switched off, no function

• RST ERROR reset error messages, see also Function 0.00.02 RST ERR

Submenu 3.07.00 User data

Function 3.07.01 Through 3.07.04 Language for display texts / Entry code for setting mode / Code 1 / Tag name

setting

Function 3.07.05 through 3.07.07 User-defined unit for volume flow rate

Instead of choosing from pre-defined units for the volume flow as in Function 3.01.01 FULL SCALE, a user-defined unit

can be programmed. This unit is to be defined as a volume unit per time unit. In Function 3.07.05 UNIT TEXT the text

can be defined, in Function 3.07.06 UNIT VOL the amount of volume units that will fit in one m³ must be programmed,

and in Function 3.07.07 UNIT TIME the amount of seconds that will fit in a time unit must be programmed.

Example: to program barrels per day, program in Function 3.07.06 6,289 (= 1/0,159) and in 3.07.07 8,640E4

(=24*60*60).

3.11.5 Main menu 4.00.00

Parameter error

For description see under main menu 0.00.00.

Installation and operating instructions

25 ALTOSONIC III

Page 26

4. Functional

checks and

service

4.1 Functional checks

4.1.1 Display test Function 2.01.01 Display test

4.1.2 Current output test Function 2.02.01 Test, current output I

4.1.3 Frequency output

test

4.1.4 Status output test 2.03.03 Test of the status inputs (if applicable)

4.2 Device information 2.04.00 Device info

4.3 Measuring zero flow

value

The signal converter has several different test functions (Function 2.01.01 to 2.01.05).

Select function 2.01.01 as described above.

Press right arrow to start.

All segments in the 3 lines of the display are activated sequentially. The test can be terminated by pressing ← key.

WARNING – This will affect the current output, and will no longer be process output!

A milliamp-meter must be connected between terminals V+ and I for this test, see the connection diagrams.

Select current value with ↑ key:

0 mA - 4 mA

12 mA - 20 mA

22 mA

The milliamp-meter indicates the current value selected. Press the ← key to terminate the test and display the actual

value again

Function 2.02.02 Test, frequency output F

WARNING – this will affect the pulse/frequency output, and will no longer be process output!

An electronic totalizer (EC) must be connected to terminal P. for this test.

Select function 2.02.02. Select frequency value with ← key:

1 Hz - 10 Hz

100 Hz - 1000 Hz

1500 Hz

The totalizer indicates the frequency value selected. Press the ← key to terminate the test and display the actual value

again.

Connect a voltage source to terminal I/GND.

Select Function 2.03.03.

Apply a voltage < 5 V and check if the display indicates a '0' level as value.

Apply a voltage >15 V and check if the display indicates a '1' level as value.

Press '<-' to terminate.

Select the 2.04 menu. The various sub-menus (2.04.01 to 2.04.09) will show:

• manufacturer

• model no.

• serial no.

• uP2 hardware no.

• uP2 Software no.

• Front Hardware no.

• DSP Hardware no.

• DSP software no.

• Time count

Set zero flow in the pipeline. Make sure the flow sensor is completely filled with liquid.

Select function 1.01.02 or 3.01.02, ZERO VALUE and set this to MEASUREMENT

Select 1.01.03 or 3.01.03, ZERO CAL, zero calibration will start upon entry of this function.

the zero measurement will take approximately 15 seconds, display indicating BUSY. At the end the display shows

"STORE NO". Use the '^' to select "STORE YES" if desired use the "<-" to store and exit the zero calibration routine.

Remark: if fixed zero value is selected (1.01.02 or 3.01.02) a zero calibration routine is not possible.

ALTOSONIC III 26

Page 27

Installation and operating instructions

5. Installation in

hazardous

areas, zone 1

and zone 2

5.1 Approvals

5.2 Compact flowmeter

5.3 Flow sensor

27 ALTOSONIC III

The ALTOSONIC III ultrasonic flowmeters in compact and separate design are in accordance with the European

Directive 94/9 EC (ATEX 100a) and approved for hazardous classified locations of Zone 1 and 2 by the PTB conform to

the European Standards of the EN 500xx series, approval number: PTB 03 ATEX 2021 X.

The standard ALTOSONIC III C-EEx compact flowmeter is designed for ambient temperatures (i.e. Ta) in the range of

-40°C / 104°F up to +70°C/158°F. The maximum allowed process liquid (medium) temperature is restricted by the

combustible atmosphere that (possibly) surrounds the apparatus, determined by the temperature class of the

atmosphere, see table below.

Temperature class Maximum process liquid temperature at

Ta ≤ 40°C / 104°F Ta ≤ 50°C / 122°F Ta ≤ 60°C / 140°F

T6

T5

T4

T3

The ALTOSONIC III K/…-EEx compact flowmeter consists of the UFC III…-EEx flow converter that is screwed on top of

the UFS III-EEx flow sensor by four hexagonal socket head cap screws of size M6. The standard compact flowmeter is

marked with one of the codes below:

Standard: II 2G EEx de [ib] IIC T6…T3 for the terminal compartment of the flow converter housing in type of protection

increased safety "e" according to EN 50019.

Optional: II 2G EEx d [ib] IIC T6…T3 for the terminal compartment of the flow converter housing designed as

flameproof enclosure "d" according to EN 50018.

The UFS III…-EEx flow sensor is the measuring unit of the ALTOSONIC III (3-beam) ultrasonic flowmeters. It contains

the ultrasonic sensor (three pairs of opposite transducers) in type of protection intrinsic safety category "ib" according to

EN 50020. All sensor circuits are wired by separate coaxial cables and connected through SMB connectors, which are

marked by the respective numbers 1.1, 1.2, 2.1, 2.2, 3.1 and 3.2. The flow sensors are available in size DN25 (1”) up to

DN1000 (40”) in diameter.

The UFS III…-EEx flow sensor is used in combination with the flow converter unit type UFC III…-EEx, which is either

directly mounted on top of the flow sensor (compact meter) or installed on a distance and connected via a cable

(separate version). In the last case the flow sensor as well as the flow converter unit are both provided with a junction

box, in which the SMB connectors are mounted.

The UFS III F/…-EEx flow sensor in separate design is the measuring unit of the separate flowmeter system. The

sensor is suitable for process liquid temperatures from -25°C/-13°F up to +180°C/356°F and designed for an ambient

temperature in the range of -40°C/-40°F up to +70°C/158°F.

The UFS III F/…-EEx flow sensors in separate design are classified according to the temperature classification table

below.

Temperature class Maximum process liquid temperature at Ta = 60°C / 140°F

T6

T5

T4

T3

The UFS III F/…-EEx flow sensors are marked with the explosion safety codes: UFS III F-EEx: II 2G EEx ib IIC T6…T3.

The intrinsically safe "ib" ultrasonic sensor circuits inside the UFS III…-EEx flow sensor have the following maximum

values (i.e. entity parameters):

Maximum input voltage : V

80°C / 176°F 80°C / 176°F 80°C / 176°F

95°C / 203°F 95°C / 203°F 95°C / 203°F

130°C / 266°F 130°C / 266°F 125°C / 257°F

180°C / 356°F 165°C / 329°F 125°C / 257°F

80°C / 176°F

95°C / 203°F

130°C / 266°F

180°C / 356°F

= 13.1 V

max

Page 28

Maximum input current : Imax = 600 mA

Maximum internal capacitance : Ci = 13.1 nF (maximum, 3 sensor circuits)

Maximum internal inductance : Li = 134 µH (maximum, 3 sensor circuits)

The intrinsically safe sensor circuits of the ALTOSONIC III C/…-EEx compact flowmeter are only internal circuits and

not accessible for the user.

5.4 Flow converter

The UFC III…-EEx flow converter consists of an approved cylindrical housing, made of a stainless steel (type VX-EEx

with PTB No. Ex-96.D.1068 U). It contains two separate compartments, divided from each other by wall with an

integrated encapsulated flameproof terminal feed-through. The housing of the compact version is screwed on top of the

flow sensor, the housing of the separate version is screwed on an aluminium or stainless steel wall-mounting bracket. A