KROHNE 70 User Manual

DIN A4: 7.02182.37.00

©

KROHNE 11/2000 US size: 7.02182.77.00

GR/LP

Status: 05-1998

Installation and operating instructions

(Reference Manual)

Level Radar

BM 70 A / BM 70 P

Non-contact level gauging

using electromagnetic waves

Variable area flowmeters

Vortex flowmeters

Flow controllers

Electromagnetic flowmeters

Ultrasonic flowmeters

Mass flowmeters

Level measuring instruments

Communications engineering

Engineering systems & solutions

Contents:

General advice on safety ................................3

Product liability and warranty .........................3

Items included with supply ..............................3

Software history ..............................................4

1. Range of application ................................6

2. Mode of operation and system structure.6

2.1 Operating principle ...................................6

2.2 Signal processing (digital) .........................7

2.3 Modularity (signal converter, flange,

antenna)....................................................7

3. Input...........................................................8

3.1 Measured variable (distance, level,

volume, reflection) ....................................8

3.2 Measuring range [0.5-35/40 m

(1.64-115/131 ft)] .....................................8

3.3 Block distance...........................................8

3.4 Out-of-range performance.........................8

4. Output........................................................9

4.1 Variants.....................................................9

4.2 Ex-e current output HART

4.3 Ex-i current output HART

(type of protection: Ex de [ia]) ................10

4.4 HART

®

communication............................11

®

....................10

®

4.5 Current output (non-communicable) .......11

4.6 Digital interface RS 485 .........................11

4.7 Breakdown signal .................................... 13

4.8 Digital input.............................................13

8. User interface ..........................................35

8.1 Local display .........................................35

8.2 Function of the keys ...............................36

8.3 Operator control concept........................37

8.4 Table fo settable functions

(Version 3.00, 3.03, 4.02, 4.03) .............39

8.5 Configuration examples..........................42

8.6 Description of functions..........................44

8.7 Functional checks...................................55

8.8 Pointers and error messages during

measurements.......................................56

8.9 Messages on start-up.............................58

8.10 Faults and symptoms during start-up

and measurement .................................58

8.11 Calculation of the measured value .......61

8.12 User program PC-CAT

for Windows .........................................62

9. Power supply ..........................................63

9.1 Options, technical data...........................63

9.2 Fuses ....................................................63

9.3 Changeover of operating voltage and

replacement of fuses .............................63

9.4 Advice on safety.....................................64

10. Certificates and approvals....................66

10.1 Hazardous-duty approvals.....................66

10.2 Other approvals and certificates ...........66

10.3 Explosion proof acc. to ATEX ...............67

10.4 Radio approval .....................................68

10.5 CE manufacturer’s declaration...............69

5. Measuring accuracy................................14

5.1 Reference conditions...............................14

5.2 Error of measurement ............................14

5.3 Repeatability ...........................................15

5.4 Measured value resolution/hysteresis .....15

5.5 Transient recovery time ..........................16

5.6 Turn-on drift / turn-on characteristics ......16

5.7 Long-term drift .......................................16

5.8 Effect of ambient temperature ................16

6. Operating conditions .............................17

6.1 Installation conditions .............................17

6.2 Ambient conditions..................................25

6.3 Product conditions................................... 26

6.4 Maintenance ......... .................................27

7. Design......................................................28

7.1 Models ..... .............................................28

7.2 Dimensions and weights .........................29

7.3 Replacement of the signal converter .......30

7.4 Field assembly ........................................ 30

Selection of antenna type and size..............31

7.5

7.6 Materials of construction .........................32

7.7 Process connection .................................32

7.8 Electrical connection ...............................33

7.9 Terminating resistor for the

RS 485 interface .....................................34

11. Order information .................................70

12. External standards, codes and

directives .............................................. 71

13. Quality assurance .................................71

Annex

Annex A: Technical Data ............................72

Annex B: Type code / nameplates...............74

Annex C: Spare parts .................................77

Annex D: Signed declaration to accompany

a device returned to KROHNE ....80

Annex E: Table on documentation of

device configuration....................81

Annex F: Index............................................82

BM 70 A/P Montage- und Betriebsanleitung Seite: 2 11/00

General advice on safety:

• To carry: the device will weigh between approx. 16 kg (35.5 lb) and 30 kg (66.1 lb) or more! To

carry, use both hands to lift the device carefully by the converter housing. If necessary, use lifting

gear.

• When handling the BM 70 A/P, avoid hard blows, jolts, impacts, etc.

Product liability and warranty:

The BM 70 A/P level gauge is designed solely for measuring the distance, level, volume and

reflection of liquids, pastes, slurries, solids and particulate materials.

The BM 70 A/P level gauge does not form part of an overfill protection system as defined in WHG.

Special codes and regulations apply to its use in hazardous areas.

Responsibility as to suitability and intended use of these level gauges rests solely with the user.

Improper installation and operation of our level gauges may lead to loss of warranty.

In addition, the "General conditions of sale", forming the basis of the purchasing contract, are appli-

cable.

If you need to return the level gauge to the manufacturer or supplier, please refer to the information

given in Annex D.

Items included with supply:

The scope of supply encompasses, in the version as ordered:

• Signal converter bolted to waveguide window and antenna

Optionally: antenna extension, sunshade (with fastening material in each case)

• Shielding material with strap retainer (not for the US market)

• Report on factory settings for the signal converter

• Bar magnet for operator control / parameter assignment (only in version with local display)

• Wrench for the covers

Installation material (stud bolts, flange gasket and cabling) not supplied, to be provided by customer!

Documentation supplied:

• Condensed instructions: installation, connection, start-up and safety advice in condensed form,

but sufficient for most applications. Please read through these instructions first!

• Instruction card: overview of the configuration menu and meaning of the markers in cheque card

format.

• Installation and operating instructions (this manual): detailed user manual and reference book,

including description of special versions and functions. This documentation is structured on lines

similar to those given in the DIN V 19259 Standard.

• Approval documents, unless reproduced in the installation and operating instructions.

Installation and operating instructions BM 70 A/P Page: 3 11/00

Software history

Signal Converter Firmware

For BM 70 A:

Introduction

Mth./Yr

06/97 3.00PREnn 06/97 Test versions

01/98 3.00 11/97-11/00 First serial version. Errors when empty spectrum recorded

05/98 3.01 11/97-11/00 Elimination of errors in V. 3.00; improved application of empty

07/99 3.02 05/98-11/00 Implementation of the ModBus protocol; adaptation to

11/99 3.03 05/98-11/00 Correction of a bug in the mode "Hold on Error" (output

Firmware

Version

Device

Instructions

Remarks

with WAVE-STICK; automatic reset when signal is extremely

weak.

spectrum at tank bottom.

PROFIBUS interface; improved application of empty

spectrum at tank bottom; improvement of PC-CAT protocol

switching in multidrop operation; definition of 3.6 mA as lower

error current for the IS current output; improved tank bottom

tracing; improved spectrum evaluation at tank heights > 15

m.

current went to 1 mA or 3.6 mA; only V. 3.02); Adaption of the

HART protocol for operation with the program AMS, and

some smaller error corrections; Improved "tank bottom

recognition" (measured value now always goes to the

programmed tank bottom position); If no measured value is

found after start-up, the instrument goes directly into "tank

bottom recognition" and the local display to level = 0, if Fct.

3.2.5 Error Messages = NO is set.

For BM 70 P:

Introduction

Mth./Yr

05/98 4.00PREnn

07/99 4.02 05/98-11/00 First serial version.

11/99 4.03 05/98-11/00 Correction of a bug in the mode "Hold on Error" (output

Firmware

Version

4.01PREnn

4.02PREnn

Device

Instructions

05/98 Test versions

Remarks

current went to 1 mA or 3.6 mA; only V. 4.02); Adaption of the

HART protocol for operation with the program AMS, and

some smaller error corrections; Improved "tank bottom

recognition" (measured value now always goes to the

programmed tank bottom position); If no measured value is

found after start-up, the instrument goes directly into "tank

bottom recognition" and the local display to level = 0, if Fct.

3.2.5 Error Messages = NO is set.

Installation and operating instructions BM 70 A/P Page: 4 11/00

Compatibility between PC-CAT Software and BM 70x Level-Radar Instruments

I N S T R U M E N T S

Software

(1)

Operating

System

BM 70

BM 70

Nautic

BM 70 A

BM 70 P

BM 700 BM 702

PC-CAT (DOS) 1.00

PC-CAT (DOS) 2.00

(4)

PC-CAT (DOS) 2.10/2.11

PC-CAT (DOS) 2.30

(4)

DOS ≥ 3.00

DOS ≥ 3.00

DOS ≥ 3.00

DOS ≥ 5.00

(7)

(2)

YES

(3)

YES

YES NO NO NO

YES Up to firmw.

3.02/4.02

PC-CAT (DOS) 3.00

DOS ≥ 5.00

(7)

YES Up to firmw.

3.02/4.02

PC-CAT (DOS) 3.01

DOS ≥ 5.00

PC-CAT Windows 4.00/4.01 Windows

(7)

YES YES YES YES

NO YES YES YES

95,98,2000,NT

PC-CAT Windows Lite 4.01 Windows

NO YES YES YES

95,98,2000,NT

(1)

table is not including PRE versions of PC-CAT

(2)

limited to configuration parameters up to firmware 2.02/2.10

(3)

limited to configuration parameters up to firmware 2.20

(4)

Attention!! Does not run on fast PCs !!

(5)

with reduced display and configuration capability

(6)

not with firmware 7.00/PRE0x

(7)

or DOS-Window in Windows 3.1x, 9x (not Windows NT, 2000)

NO NO NO

NO NO NO

(5)

Up to

firmw.

5.02

Up to

(5)

NO

NO

firmw. 5.02

(6)

Installation and operating instructions BM 70 A/P Page: 5 11/00

1 Range of application

The BM 70 A/P Level-Radar level gauging system is designed to measure the distance, level, volume

and reflection of liquids, pastes, slurries, solids and particulate materials. It can be operated on

storage and process tanks and also on stilling wells.

BM 70 P is specially designed for applications on storage tanks with highest precision requirements.

BM 70 A/P Ex hazardous-duty versions are suitable for use in Ex-Zone 0, 1 and 2.

In Germany (and, depending on the respective radio approval, in some other countries as well) its use

is restricted to closed tanks or containers made of metal or concrete. Because of the low output

involved, however, the microwaves are not harmful to human beings.

2 Mode of operation and system structure

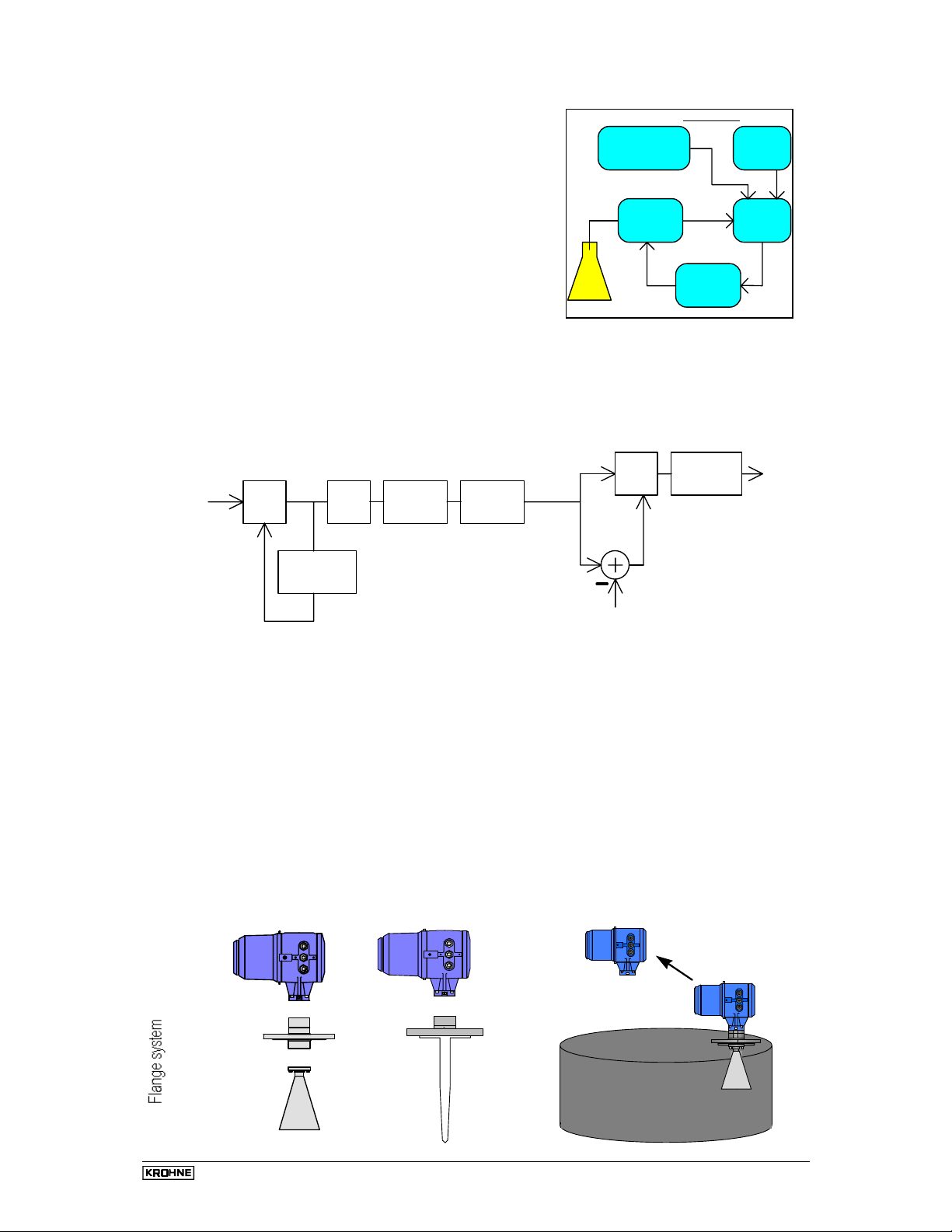

2.1 Operating principle (FMCW-Radar)

A radar signal is given via an antenna, reflected on the measuring surface and received after a delay

time t.

FMCW: Frequency Modulated Continuous Wave

The FMCW-radar uses a high frequency signal (~10 GHz) which transmit frequency increasing

linearly 1 GHz during the measurement (frequency sweep) (1). The signal is emitted, reflected on the

measuring surface and received time-delayed (2).

For further signal processing the difference ∆f is calculated from the actual transmit frequency and

the receive frequency (3). The difference is directly proportional to the distance i.e. a large frequency

difference correspond to a large distance and vice versa.

The frequency difference is transformed via a Fourier transformation (FFT) into a frequency spectrum

and then the distance is calculated from the spectrum. The level results from the difference between

tank height and distance.

Linearity of frequency sweeps

The measuring accuracy of a FMCW radar is determined from the linearity of the frequency sweeps

and their reproducibility. The linearity correction is deduced via reference measurement of the

oscillator.

The non-linearity is corrected up to 98% (BM 700/BM 70 A).

An immediate frequency regulation is necessary with the BM 70 P device because of the higher

demand on the measuring accuracy.

With the PLL technology (Phase Locked Loop) the signal frequency is directly recorded as a digital

data and the converter oscillator locks automatically on the right frequency.

3) differential frequency

formed

f

∆∆f

1) radar frequency

linearly changed

non-linear sweep linear sweep

f

Stop

∆∆f

antenna

2) delay time due to wave

propagation

t

f

Start

Installation and operating instructions BM 70 A/P Page: 6 11/00

As the transmit frequency is changed during a short time

interval by FMCW radar the transmitted frequency has to

follow the nominal frequency within micro seconds. This

ensues via modern, fast electronic and processors.

Microprocessor

control

PLL structure

Reference

oscillator

Microwave

oscillator

Loop

filter

Antenna

Phase

detector

2.2 Signal processing (digital)

The radar signals are digitally processed by a microprocessor. The processing system is based on

intelligent procedures that allow for plausibilities and history.

The following diagram describes the path of internal signal processing:

measurement

signal

gain

switch

V

gain

control

filter

analog to

digital

conversion

Fourier

transform

spectrum

empty tank spectrum

plausi-

bility

After automatic gain control, the measuring signal is filtered, digitized and converted into a frequency

spectrum by means of the Fourier transform. Plausibility of the value obtained is assessed with the

aid of the so-called empty-tank spectrum, which contains information about constant interference

reflectors. Interpolation of the spectrum helps to improve resolution of the measured value.

spectrum

interpolation

corrected

spectrum

distance

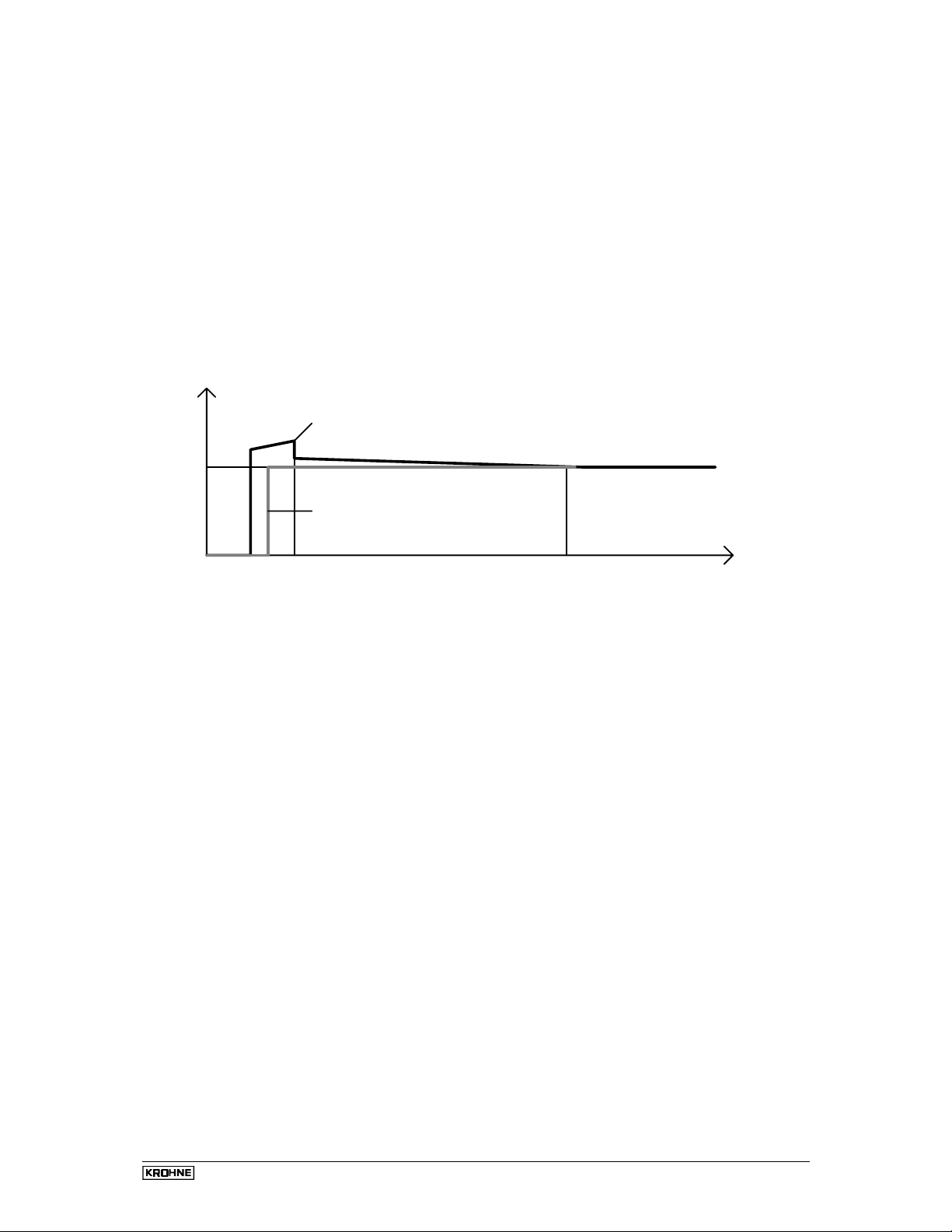

2.3 Modularity (signal converter, flange, antenna)

The measuring system consists of the flange system and the signal converter.

The flange system contains the microwave window separating product from pressure, and the

antenna system.

The compact signal converter contains the microwave generator and the entire signal processing

system, including provision of a standardized output signal (4 - 20 mA or digital interface).

The signal converter can be separated from the flange system under process conditions, without loss

of pressure or escape of product.

OO

Converter

OO

Flange with microwave window

Antenna system

Installation and operating instructions BM 70 A/P Page: 7 11/00

3 Input

3.1 Measured variable (distance, level, volume, reflection)

The primary measured variable is the distance between a reference point (as standard: tank mounting

flange) and a reflecting surface (e.g. surface of the liquid).

The filling level is determined by allowing arithmetically for the entered tank height.

Volume measurements are possible by entering a conversion table (max. 50 points).

The strength of the reflected signal can be measured for qualitative assessment of the tank product or

its surface.

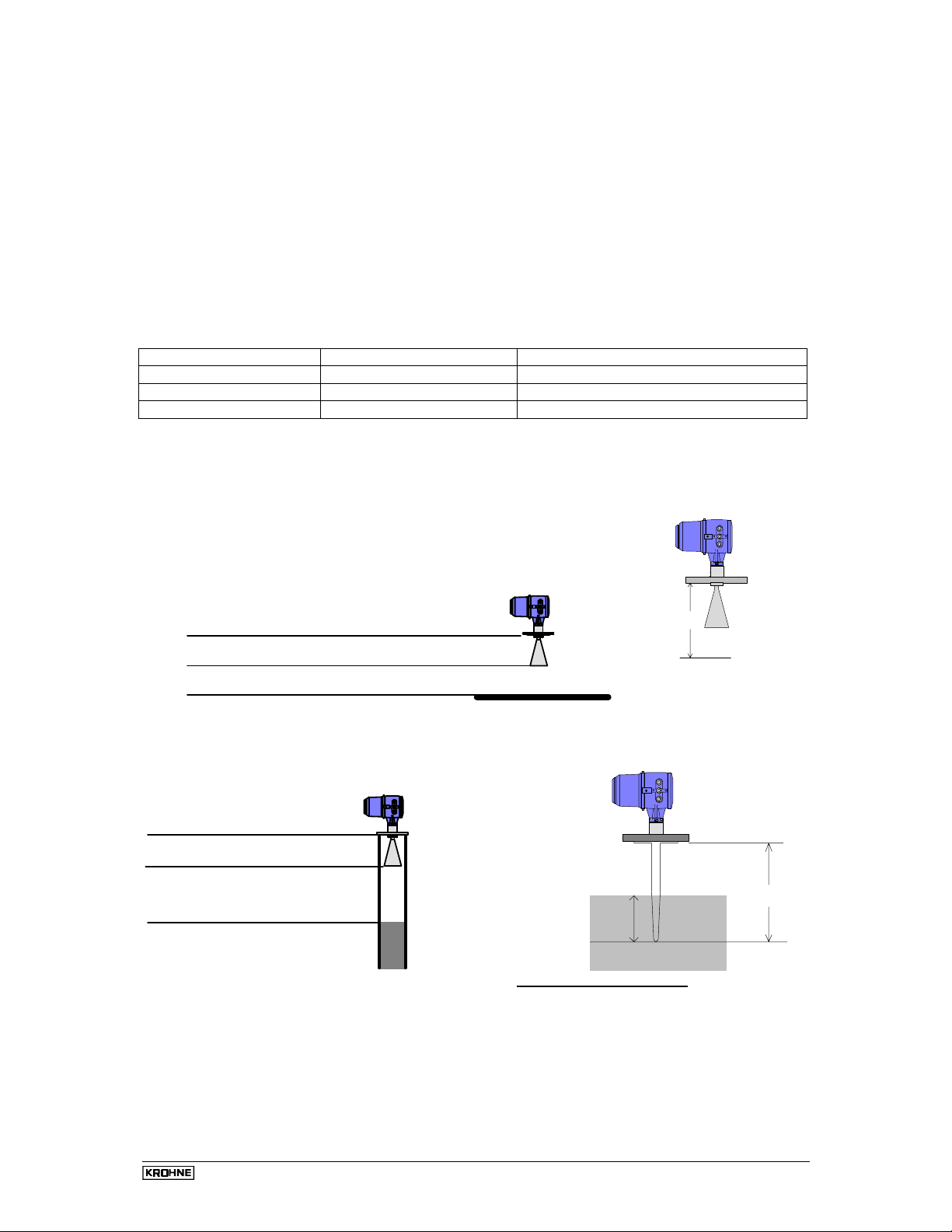

3.2 Measuring range [0.5-35/40 m (1.64-115/131 ft)]

Minimum tank height 0.5 m (1.64 ft)

Maximum measuring BM 70 A 40 m (131 ft) / optionally 100 m (328 ft)

BM 70 A mit Wave-Stick 20 m (65.62 ft)

BM 70 P 35 m (115 ft)

The useful range will depend on the antenna size, the reflection properties of the tank product, the

installation position, and the presence of interference reflectors (see Sections 6.1 and 7.5).

3.3 Block distance

The block distance is the minimum measured distance between the mounting

flange (reference point) and surface of the tank product.

Recommended minimum values: see following sketches.

Horn antenna without stilling well:

Antenna size* = Type3: 22cm/8.7"; Type4: 34cm/13";

* Hastelloy: +3cm / 1,2 "

Recommended antenna distance:

Storage tanks: 10cm/4"; Process tanks: 20cm/8"

Product surface

The length of any antenna extension used must be added on!

Stilling well / Wave-Guide Wave-Stick

Antenna size * = Type1: 11cm/4";

Type2: 15cm/5.5"; Type3: 22cm/8.7"

Wave-Stick SW: 6cm/2.4"

(Wave-Guide: no antenna)

Recommended antenna distance =

30 cm / 12"

Product

* Hastelloy: 3 cm (0.4")

Minimum block distance =

Standard: 184 mm

Normal: Rod length - 200 mm (7.87")

3.4 Out-of-range performance

max.

200 mm

8"

Product

Block

distance

Maximum

level

Standard:

384 mm/15.1"

When the level measuring range is exceeded (including flooding) the measured value will stick at the

(adjustable) block distance (see Sect. 8.6.14).

If the measured value drops below the level range, it will stay put at the set lower range limit (distance

= tank height).

Installation and operating instructions BM 70 A/P Page: 8 11/00

4 Output

4.1 Variants

Variants Remarks Described

in Section

Ex-e current output HART®Ex-e; active; HART® protocol;

together with switching output and digital input

Ex-i current output HART®intrinsically safe; passive; HART® protocol

(optionally with intrinsically safe switching output)

Current output Ex-e; active; non-communicable 4.5

RS 485 + current output BM70 protocol or ModBus-RTU or HART

®

PROFIBUS-PA intrinsically safe; see Supplementary Instructions Foundation Fieldbus (FF) intrinsically safe; see Supplementary Instructions -

All versions with HART® or BM70 protocols can be operated with the PC-CAT PC program (see Section 8.12).

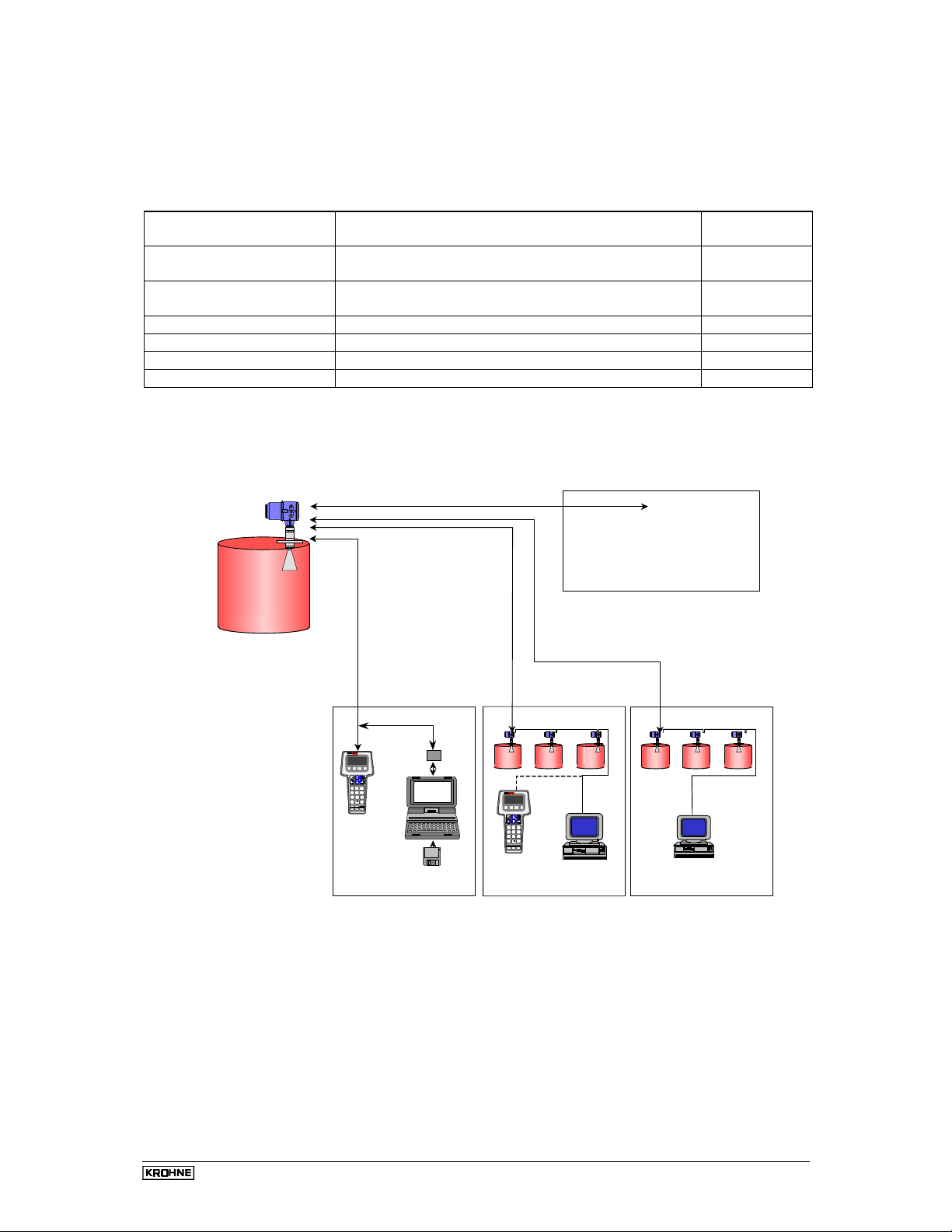

Overview of digital Communication possibilities:

BM 70 A

RS 485

communication interfaces

Modbus

PROFIBUS-PA

...........

Other

4.2 + 4.4

4.3 + 4.4

4.6 + 4.5

RS 485

4 ... 20mA

+ HART ®

Converter

HART

FIELD COMMUNICATIONS PROTOCOL

F1 F2 F3 F4

HART Communicator

I

>>>>>>

O

A B C D E F G H I

7 8 9

J K L M N O P Q R

4 5 6

S T U V W X Y Z /

1 2 3

# % & < > : +

*

0 . _

HART-

HHC

PC-CAT

or

HART specific software

and operating devices

4mA (Ex i)

+ HART®

HART

FIELD COMMUNICATIONS PROTOCOL

F1 F2 F3 F4

HART Communicator

I

>>>>>>

O

A B C D E F G H I

7 8 9

J K L M N O P Q R

4 5 6

S T U V W X Y Z /

1 2 3

# % & < > : +

*

0 . _

HART-

HHC

HART-Master

Point-to-point Multidrop

Tank Inventory System

Installation and operating instructions BM 70 A/P Page: 9 11/00

4.2 Ex-e current output HART

®

Function Level, distance, volume (conversion table) or reflection,

and error identification;

galvanically isolated from digital input and switching output

Current 4-20 mA; without or with error message (2 mA and 22 mA)

Accuracy/linearity 0.05

% (rel. 20 mA; at T = 20°C, 100Ω load impedance and nominal operating voltage)

Temperature drift < 100 ppm/K (typically 30 ppm/K)

Load impedance < 500 Ω

Effect of load impedance < 0.02 % (rel. 20 mA for RB = 0...500 Ω)

Effect of power < 0.02 % (rel. 20 mA for UB within limits of tolerance)

Hazardous-duty version: Ex e

Note: together with switching output and digital input

Digital input (terminals 81/82):

Can be used to suspend the entire measurement procedure, i.e. measurements are "frozen" (standard

setting), or to hot start the device (reprogra mming by KROHNE Service).

Applicable voltage: 5...28 V DC

Input resistance: > 1 kΩ

Switching output (terminals 41/42):

Can be progra mmed as a limit switch, alarm contact or error message.

The contact is open in the de-energized condition.

Operating data: max. 100 mA / 30 V DC or 30 V AC.

Internal resistance: < 20 Ω

4.3 Ex-i current output HART® (type of protection: Ex de [ia])

Function Level, distance, volume (conversion table) or reflection;

and error identification;

passive output (current sink)

Current 4-20 mA; without or with error message (3.6 mA / 22 mA);

4 mA constant, adjustable for HART

Temperature drift < 100 ppm/K (typically 30 ppm/K)

Accuracy/linearity 0.05 % (rel. 20 mA; at T = 20°C, 10 V supply voltage and nominal operating voltage)

Supply voltage U 8-30 V (between terminals 31 and 32)

Load impedance < (U

- 8V) / 22 mA (US = external supply voltage)

S

Effect of supply voltage < 0.02 % (rel. 20 mA for U = 8...30 V)

Effect of power < 0.02 % (rel. 20 mA for UB within limits of tolerance)

Note: Digital input not available.

-Multidrop

Optional switching output (terminals 41/42):

can be progra mmed as limit switch, alarm contact or error message.

The contact is open in the de-energized condition.

Operating data: 6...30 V; I

< 110 mA; U

Low

Low

< 2V; I

< 900 µA (U=30V) and I

High

High

Ex-i safety limits

Signal circuit in type of protection: Intrinsic Safety EEx ia IIC/IIB or EEx ib IIC/IIB

for connection to a certified intrinsically safe circuit with the following peak values:

Uo = 30 V; Ik = 250 mA

Effective inner capacitance ≈ 0; effective inner inductance ≈ 0

Installation and operating instructions BM 70 A/P Page: 10 11/00

= 200 µA (U=8V)

4.4 HART® communication

The HART Communications protocol can, in accordance with the Rosemount Standard, be used with

a BM 70 A/P.

Electrical connection: see Section 7.8.

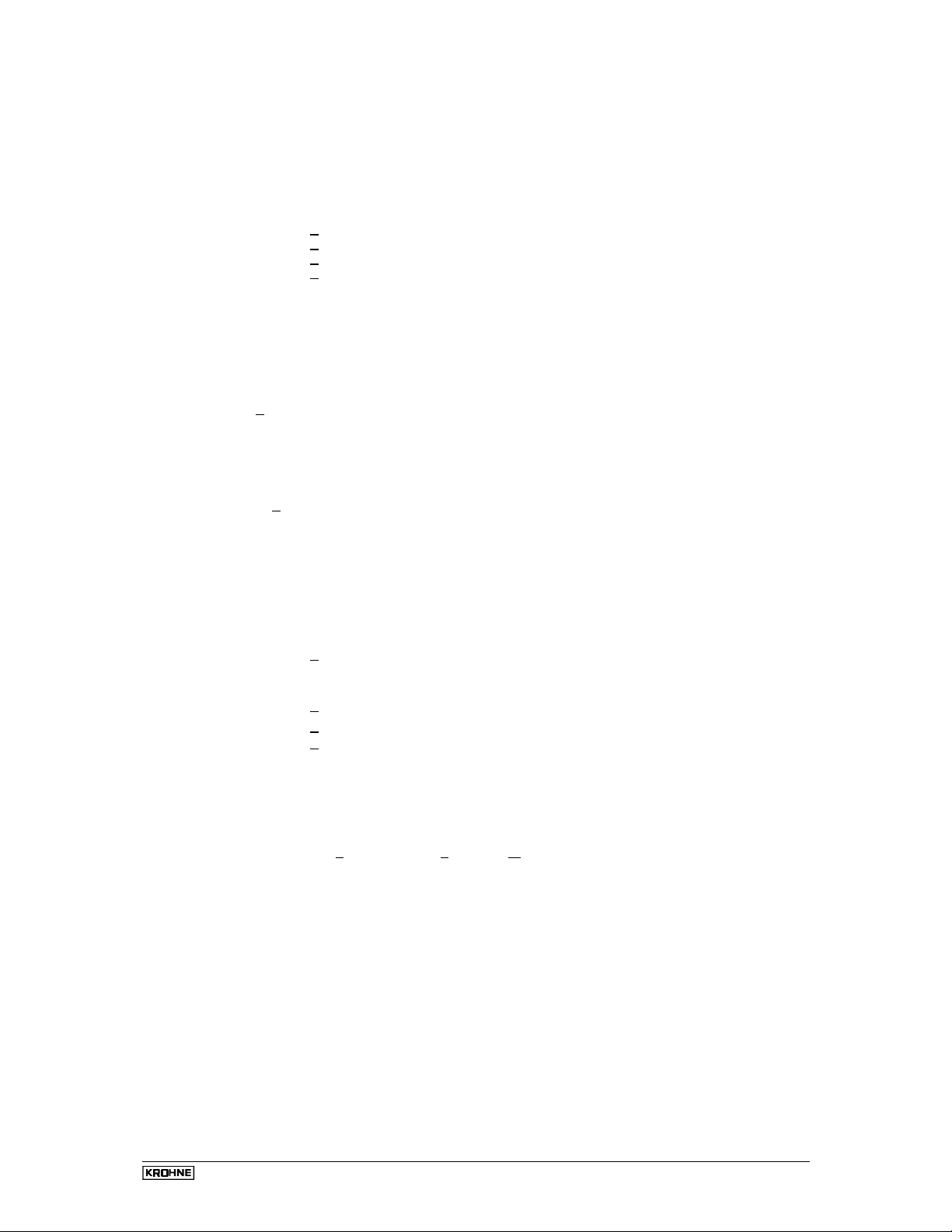

There are two ways of using the HART

®

Communication:

a) As a point-to-point connection between the BM 70 A/P and the HART

A BM 70 A/P can be used either with an Ex-e current output HART

®

master equipment.

®

or with an Ex-i current output

HART®.

HART

Master

b) As a multipoint connection (multidrop) with up to 15 devices (BM 70, BM 70 A/P or other

HART

®

equipment), in parallel on a 2-wire bus:

4...20 mA

A BM70 A/P is normally used with Ex-i current output, but an Ex-e current output can also be used

(constant 4 mA in both cases.)

HART

Master

4mA 4mA 4mA 4mA

other

HART

device

other

HART

device

4.5 Current output (non-communicable)

Function Level, distance, volume (conversion table) or reflection,

Current 4-20 mA; without or with error message (2 mA and 22 mA)

Accuracy/linearity 0.3

Temperature drift < 200 ppm/K (typically 70 ppm/K)

Load impedance < 250 Ω

Effect of load impedance < 0.1 % (rel. 20 mA for RB = 0...250 Ω)

Effect of power < 0.1 % (rel. 20 mA for UB within limits of tolerance)

Hazardous-duty version: Ex e

and error identification

% (rel. 20 mA; at T = 20°C, 100 Ω load impedance and nominal operating voltage)

When operated as a switching output (digital output):

Function limit switch, alarm contact or error message

Low status current < 2 mA

High status current = 22 mA (when load < 250 Ω)

No-load voltage < 18 V

4.6 Digital interface RS 485

RS 485 is a bus that allows two-way Communication (half-duplex operation) with the BM 70 A/P

Level-Radar. When the computer system sends out a request, the BM 70 A/P transmits: level,

distance; volume (conversion table), reflection, setting parameters and status.

A PC can configure any BM 70 A/P via the bus (RS 485/RS232 converter required) by means of the

PC-CAT program, provided no master is active. The maximum cable length - excluding amplifier - is

2000 m.

Installation and operating instructions BM 70 A/P Page: 11 11/00

Transmission rate: 1200 to 38400 bauds

)

120 ohms

120 ohms

Address: 0 to 255

Protocols: KROHNE Protocol, HART

®

, Modbus RTU (from firmware

V.3.02/4.02)

Additional information: see "BM 70 A/P Communication RS 485"

instructions

Additional current output: The current output is conductively coupled to the RS 485 interface.

Technical data: see Section 4.5

Note: Switching contact and digital input are not available. However, the

current output can be configured as a switching output.

Various bus configurations

A) Connection of a BM 70 A/P as a single RS 485 user:

Computer

system

RS485 connection must

be terminated with 120 ohms

(if necessary insert resistor

between A and B

Bus line (2 shielded wires)

with termination

resistance

120 ohms

B) Connection of several BM 70 A/P in the RS 485 bus system via stubs to the bus cable:

Computer

system

RS485 connection must

be terminated with 120 ohms

(if necessary insert resistor

between A and B)

Bus line (2 shielded wires)

without

termination

resistance

without

termination

resistance

...........

without

termination

resistance

with termination

resistance

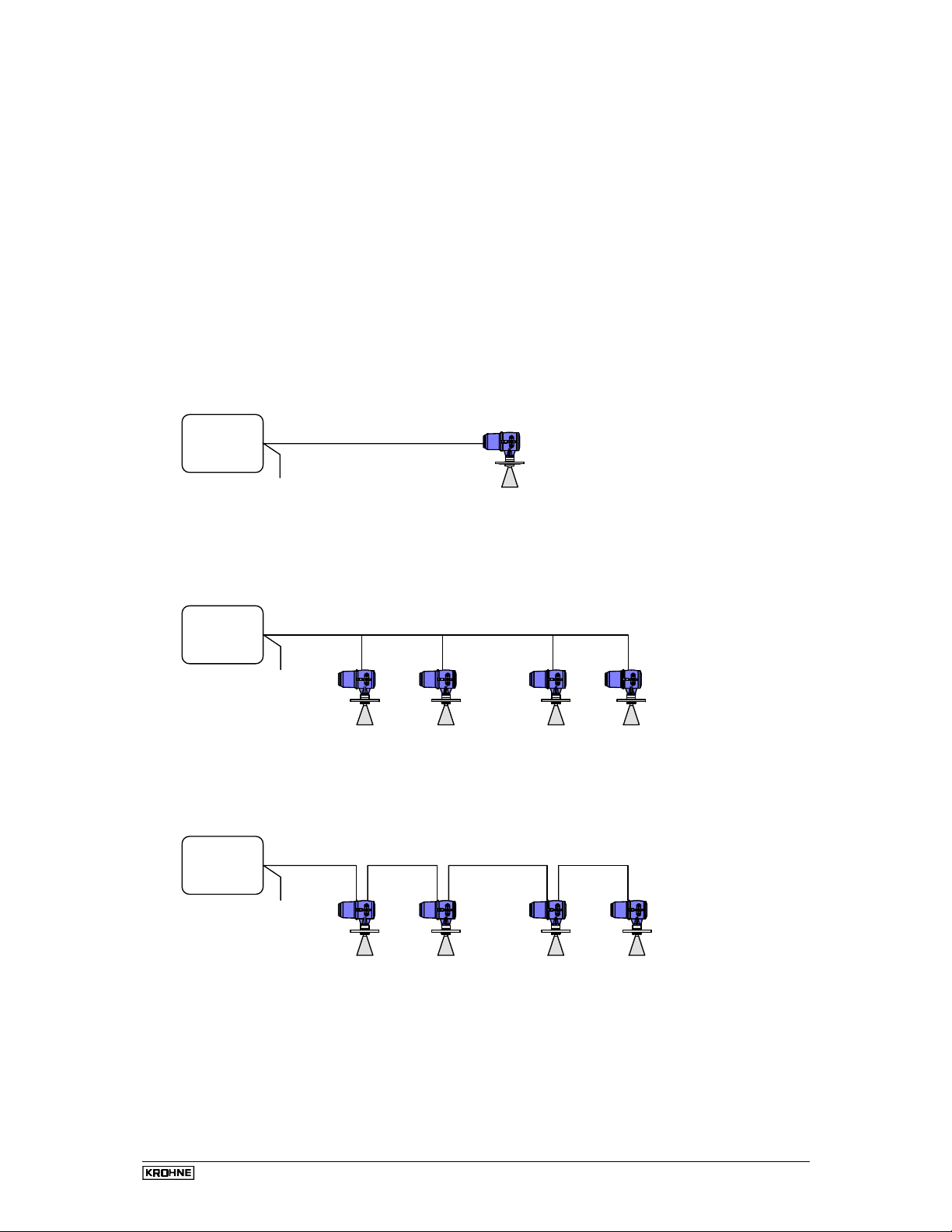

C) Connection of several BM 70 A/P in the RS 485 bus system, with bus cable looped through to

further field instruments:

Computer

system

Bus line (2 shielded wires)

RS485 connection must

be terminated with 120 ohms

(if necessary insert resistor

between A and B)

without

termination

resistance

without

termination

resistance

...........

without

termination

resistance

with termination

resistance

Notes:

• If other devices are operated together with the BM 70 A/P Level-Radar on one bus, all devices

must use the same Communications protocol (e.g. ModBus devices of different makes or BM 70

A/P and TTM 70 with KROHNE Protocol).

• When "HART

®

" is set as the protocol type, use only the protocol in keeping with the "HART

®

Specification". The "Hardware Implementation RS 485" does not conform to the HART® Standard

(see Sections 4.2 and 4.3).

Installation and operating instructions BM 70 A/P Page: 12 11/00

• Since signal reflections at the line ends can interfere with Communication, both the line beginning

(at the computer system) and the line end (at the last device) should be terminated with the typical

surge impedance of the cable (120 Ω). To do this inside the BM 70 A/P: see Section 7.9.

4.7 Breakdown signal

Breakdown information can be called up via the following interfaces:

• Local display: flashing display, plain text information

• Current output: error signal 2 mA (Exi = 3.6 mA) or 22 mA

• Switching output: contact opens or closes

• Digital interfaces: interrogation of error flags

4.8 Digital input

The digital input (for electrical data: see Section 4.2) can be used for temporarily "freezing" measurements or for carrying out a hot start. It is only available in the "Ex-e current output HART

The "freeze" function can be used to blank out larger, temporary interferences, e.g. very slow agitator,

slide gate, ball valve in the stilling well. The last measured values in each case are present at outputs

I and S, and in the display. The digital input is also taken into account when the empty-tank spectrum

is being recorded (totalizer does not continue). marker 6 in the display indicates that the digital input

is active in the "freeze" function.

NOTE: The function of the digital input is set as standard to "freeze". To switch the function to "hot

start" or to deactivate it completely, the setting will need to be changed in the Service menu of the

BM 70 A/P

®

" version.

Installation and operating instructions BM 70 A/P Page: 13 11/00

5 Measuring accuracy

5.1 Reference conditions

• Temperature = +20°C / +68°F

• Pressure = 1013 mbar abs. / 14.5 psia

• Air humidity = 65%

• Highly reflecting product (e.g. water) with calm surface

• Tank diameter > 5 m / 16.4 ft

• Mounted at least 1/7 x tank height away from tank edge (BM 70 P: 1/5 x tank height)

• No interference reflections inside the radiation lobe (± 6...9°; see Section 6.1.1)

5.2 Error of measurement

Since the measuring process primarily determines distance, measuring accuracy can only be

specified as a function of the distance. For that reason, all figures given in this Section 5 refer to the

measured distance.

BM 70 A: With antenna type 3 (139 mm / 5.47") or type 4 (200 mm / 7.87") or stilling well or WaveGuide

Accuracy

inch cm

12

4.8

10

4

8

3.2

6

2.4

4

1.6

2

0.8

± 1 cm (0.4")

0 5 10 15 20 25 30 35 40 m

1

block

16 33 49 66 82 98 1153

-0.8

-1.6

-2.4

-3.2

-4.8

0

0

-2

-4

-6

-8

-4

-10

-12

distance

± 0.3 %

Distance to flange

131ft

BM 70 A Wave-Stick:

Accuracy

inch cm

12

4.8

10

4

8

3.2

6

2.4

4

1.6

2

0.8

± 1.5 cm (0.6")

0 5 10 15 20 25 30 35 40 m

1

0.18

0.6

Installation and operating instructions BM 70 A/P Page: 14 11/00

-0.8

-1.6

-2.4

-3.2

-4

-4.8

0

0

-2

-4

-6

-8

-10

-12

± 0.3 %

16 33 49 66 82 98 1153

Distance to flange

131ft

BM 70 A Precision (with special calibration and certificate):

Only with antenna type 4 (200 mm / 7.87") or stilling well 80 - 200 mm dia. (3 - 8")

Accuracy

inch cm

12

4.8

10

4

8

3.2

6

2.4

4

1.6

0.8

2

0

0

-0.8

-2

-1.6

-4

-2.4

-6

-3.2

-8

-4

-10

-4.8

-12

0 5 10 15 20 25 30 35 40 m

block

distance

± 5 mm (0.2")

1

16 33 49 66 82 98 1153

± 0.1 %

Distance to flange

= calibration range = not verified by calibration

BM 70 P

Only with antenna type 4 (200 mm / 7.87") or stilling well 100 - 200 mm dia. (4 - 8")

Accuracy

inch mm

12

0.48

10

0.4

0.32

0.24

0.16

0.08

0

-0.08

-0.16

-0.24

-0.32

-0.4

-0.48

±

8

20

...

6

30

4

mm

2

0

-2

-4

-6

-8

-10

-12

± 1 mm (0.04")

0 5 10 15 20 25 30 35 40 m

Block-

distance

1

16 33 49 66 82 98 1153

Distance to flange

± 0.01 %

131ft

131ft

5.3 Repeatability

Repeatability is equal to half the value for the error of measurement.

5.4 Measured value resolution/hysteresis

Measured value resolution is: 1 mm / 0.04" for BM 70 A, and 0.1 mm / 0.004" for BM 70 P

Hysteresis is at least 20 times less than the error of measurement.

Installation and operating instructions BM 70 A/P Page: 15 11/00

5.5 Transient recovery time

The transient recovery time is determined by the setting parameter "time constant" (1 ... 100 s).

The transient recovery time relative to 1% deviation from the steady-state value is approx. 4.6 times

the time constant.

However, in the case of unusually rapid changes in level, the transient recovery time may deviate

from this figure.

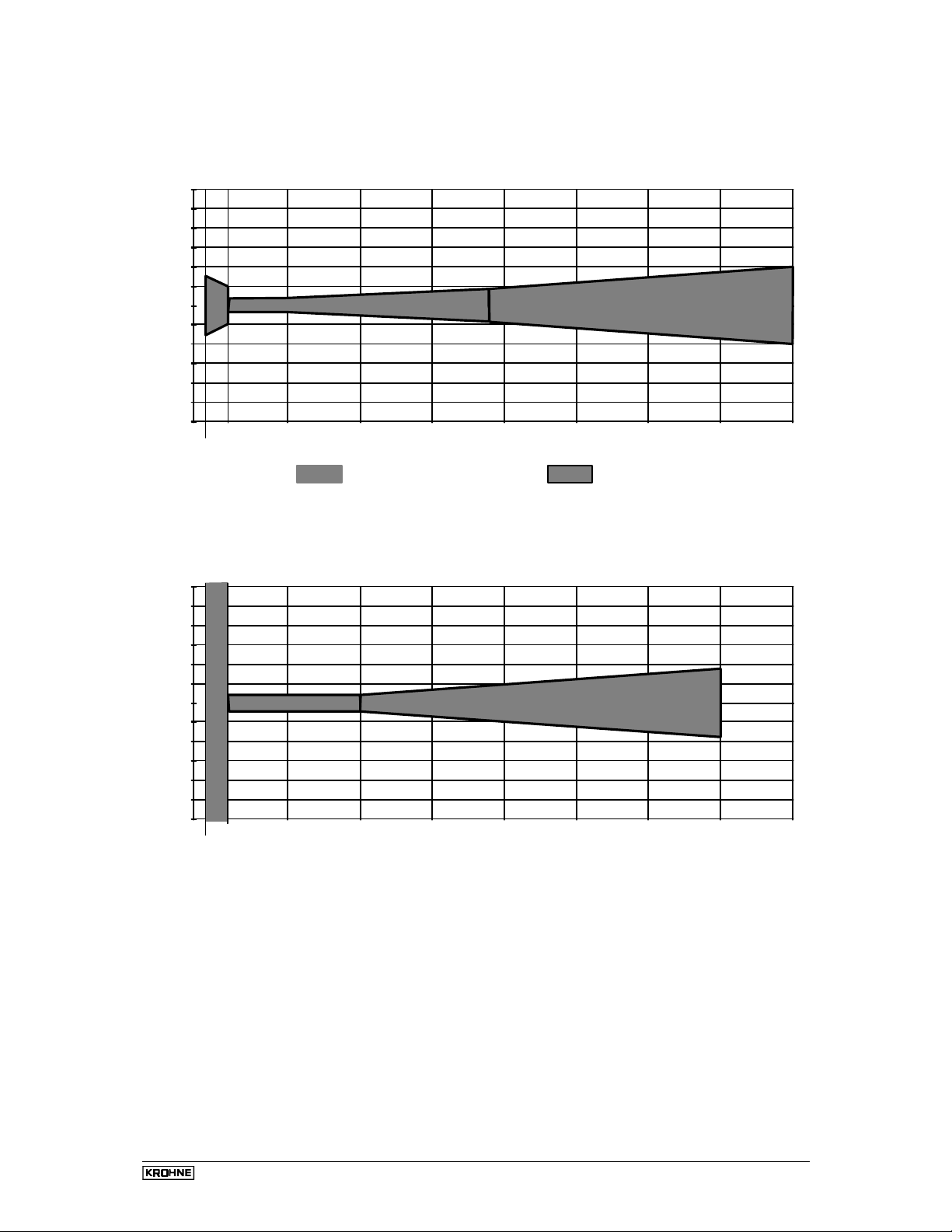

5.6 Turn-on drift / turn-on characteristics

A rough measured value is initially displayed about 1 minute after the BM 70 A has been switched on.

The first self-calibration is completed after about 2 minutes. Full measuring accuracy is attained after

30 minutes operating time.

The measured value from the BM 70 P is accurate directly after the startup phase (approx. 1.5

minutes).

Typical turn-on drift (example):

Measured value

BM 70 A

BM 70 P

Time/min012 30

5.7 Long-term drift

The long-term drift is within the specified error of measurement.

5.8 Effect of ambient temperature

Temperature coefficient, signal output:

Ex-e current output HART

Ex-i current output HART

Current output: < 200 ppm/°C (typically: 70 ppm/°C)

Digital interfaces: no temperature effect

The temperature has no effect on the measured value as the device carries out a regular self-calibration.

The effect of temperature of the atmosphere above the liguid product results theoretically in 1ppm/°C for air.

In respect of proof of temperature effect with the aid of reference measurements in liquid tanks, it

needs to be borne in mind that liquids generally have a high coefficient of cubic expansion (organic

liquids: typically 0.15 %/°C)!

®

: < 100 ppm/°C (typically: 30 ppm/°C)

®

: < 100 ppm/°C (typically: 30 ppm/°C)

Installation and operating instructions BM 70 A/P Page: 16 11/00

6 Operating conditions

Hazardous-duty systems

• The BM 70 A/P is certified in conformity with European Standard (ATEX) for use in Zone 0, 1 and

2 hazardous locations.

• The BM 70 A/P also has FM Approval (Factory Mutual) for CLASS I, DIV 1, GROUPS B,C,D;

CLASS II/III, DIV 1, GROUPS E,F,G.

• Attention is drawn to the information given on the nameplate and the specifications in the

approval certificates.

• When carrying out installation, dismantling work or making electrical connections in the

hazardous area, be sure to observe the pertinent wiring and installation regulations, e.g. as

specified in VDE 0165.

• Within the scope of routine checks required to be carried out on systems operated in hazardous

areas (maintaining the system in good working order), the "flameproof enclosure" (large cover on

signal converter) should also be visually inspected for signs of external damage and corrosion.

• Before opening the "flameproof enclosure" (e.g. to inspect the inside or for repair purposes)

make absolutely certain in the hazardous location:

- that the BM 70 A/P Level-Radar is disconnected from voltage, and then allow the prescribed

waiting time of 22 minutes to elapse first,

- and that there is no explosion hazard (gas-free certificate!).

Safety

• Operator control via the keys: on electrical safety grounds, operator control of the keys (below

the display, with the housing open) may only be carried out by specialist personnel for service and

repair work, on no account, however, when there is risk of explosion!

• Surface temperature: the housing of the signal converter can, in extreme ambient conditions,

assume temperatures of more than 70°C (158°F)!

6.1 Installation conditions

Refer to Section 7.5 for selection of the optimum antenna type

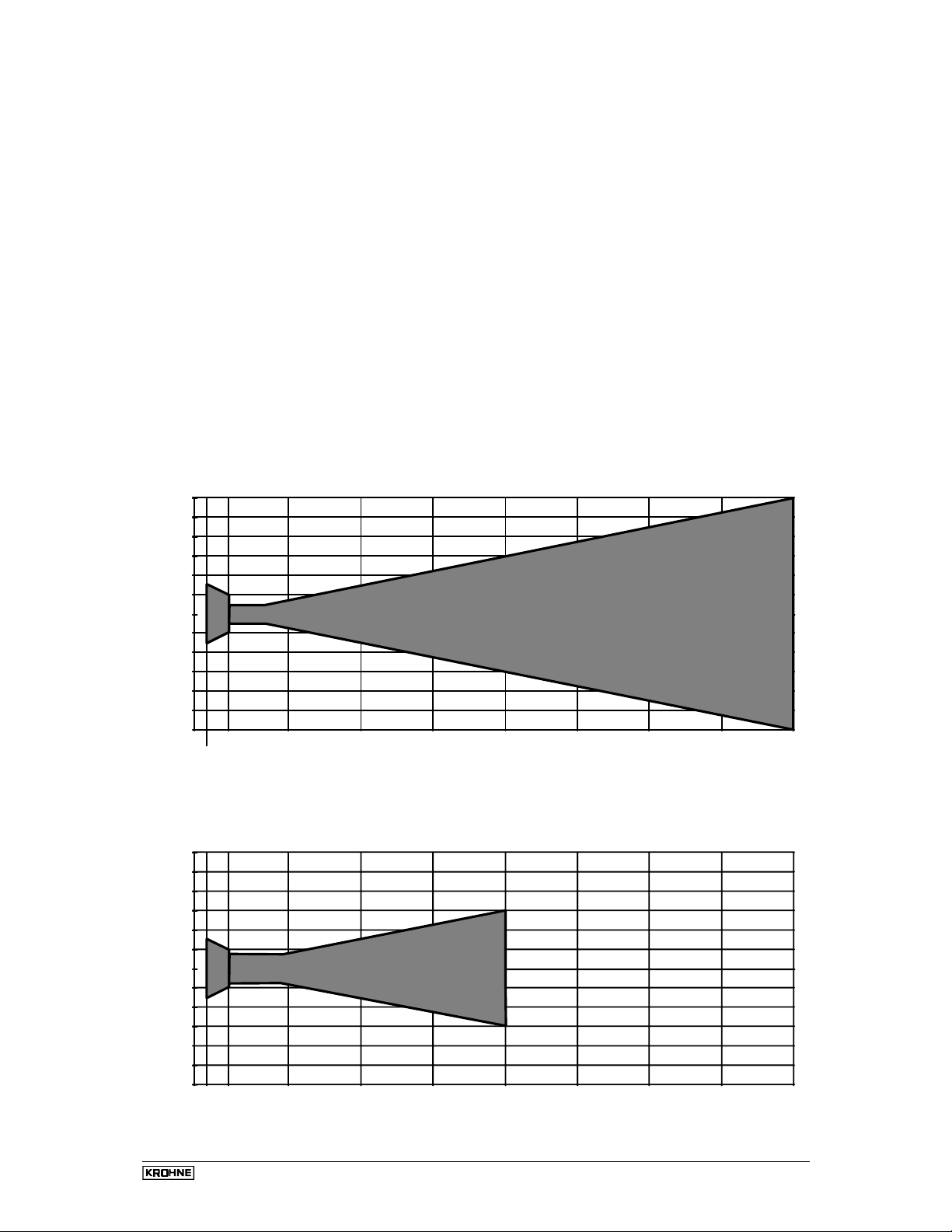

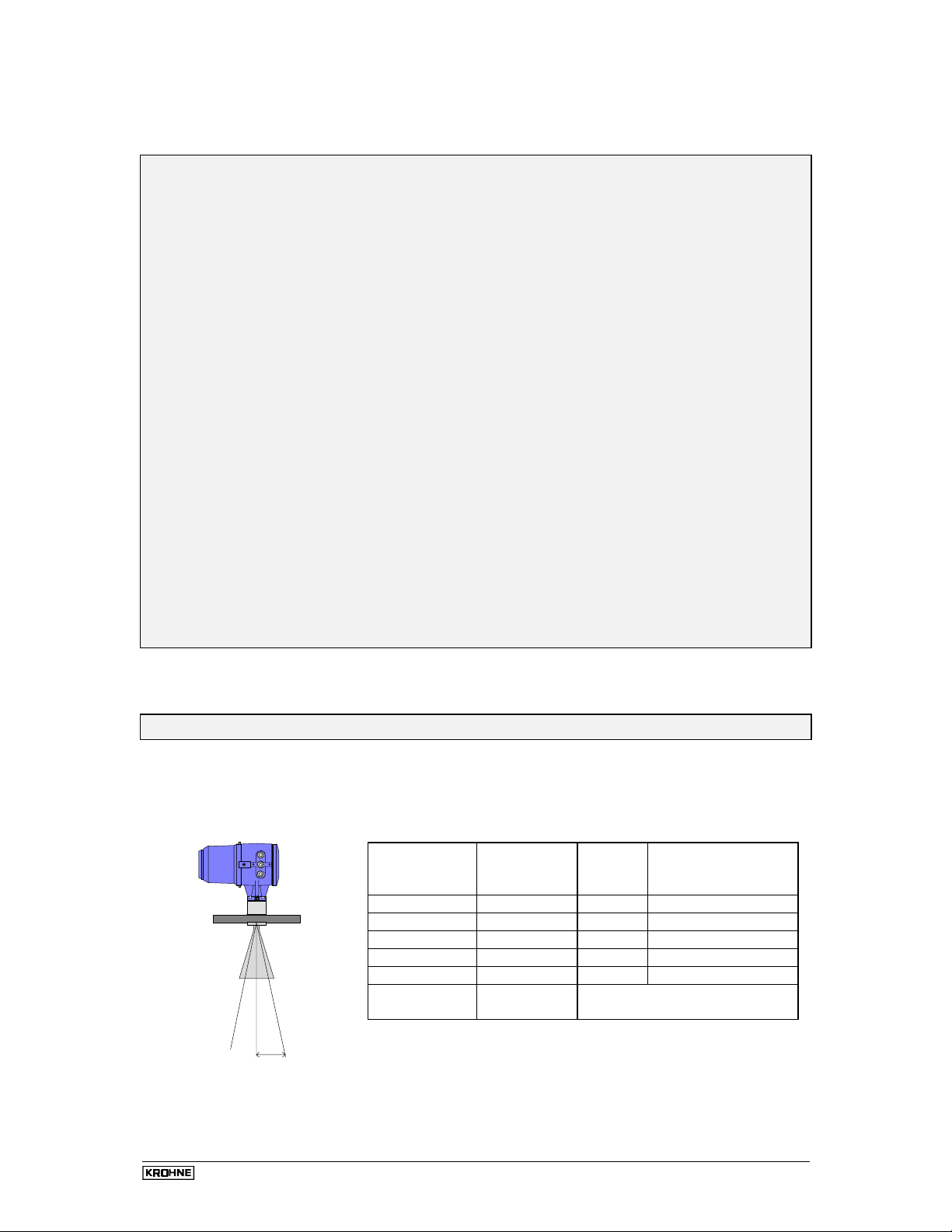

6.1.1 Transmission angle

The transmission angle is defined as the angle α to the vertical, in which the power density of the

radar waves assumes half the value of the maximum power density (half-power beamwidth):

Antenna Type Diameter

mm (inches)

Type 4 200 (7.87) 6° 10 cm (3.94”)

Type 3 140 (5.51) 8° 14 cm (5.51”)

Type 2 * 100 (3.94) 12° * 22 cm (8.67”)

Type 1 * 80 (3.15) 16° * 30 cm (11.8”)

Wave-Stick 25 (0.98) 9° 16 cm (6.3”)

Wave-Guide /

stilling well

αα

s

* Should only be used in stilling wells; the transmission angle given

applies to line-of-sight propagation, i.e. without stilling well.

25-200

(0.98-7.87)

Transmission

angle α

Propagation only inside the

Lobe expansion s per

metre distance

stilling well

Installation and operating instructions BM 70 A/P Page: 17 11/00

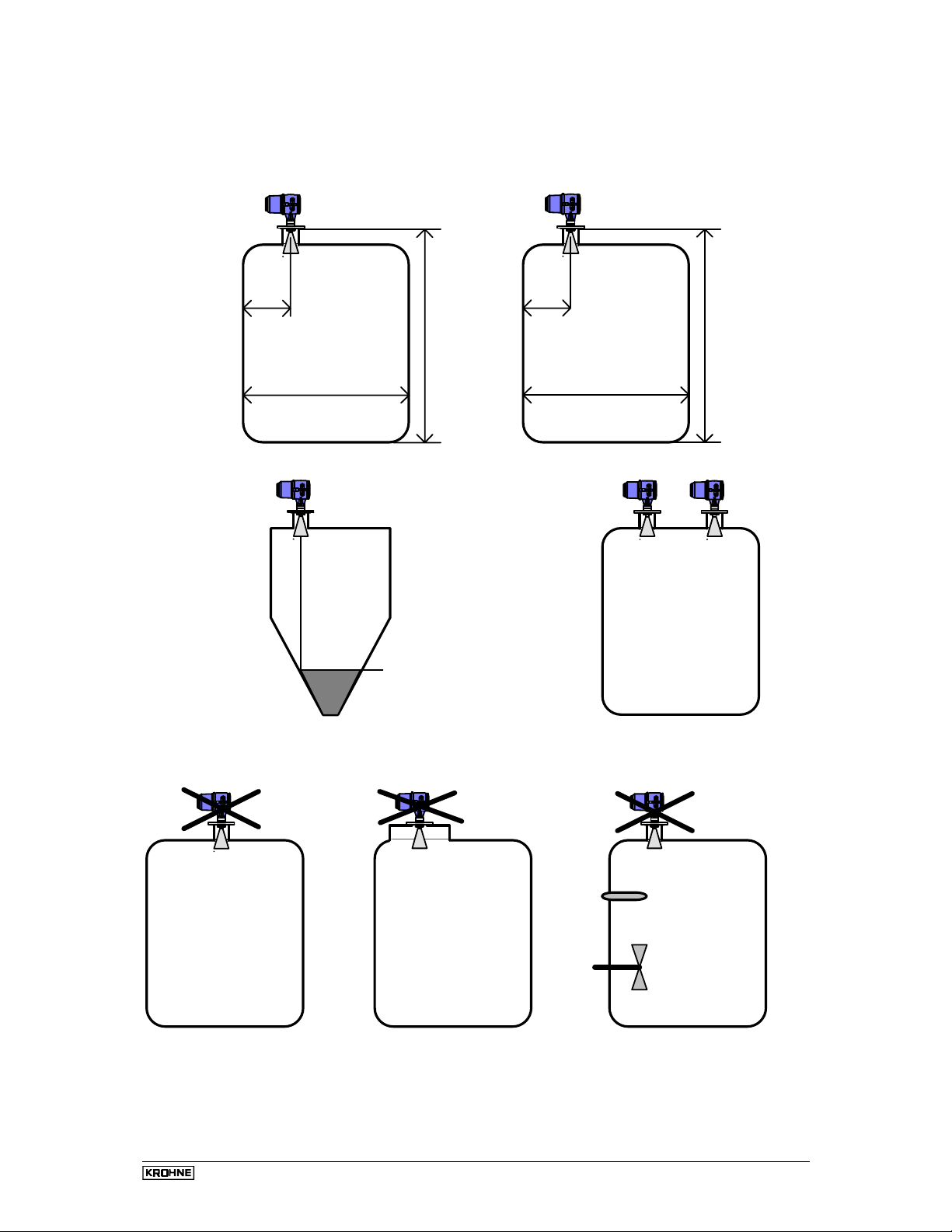

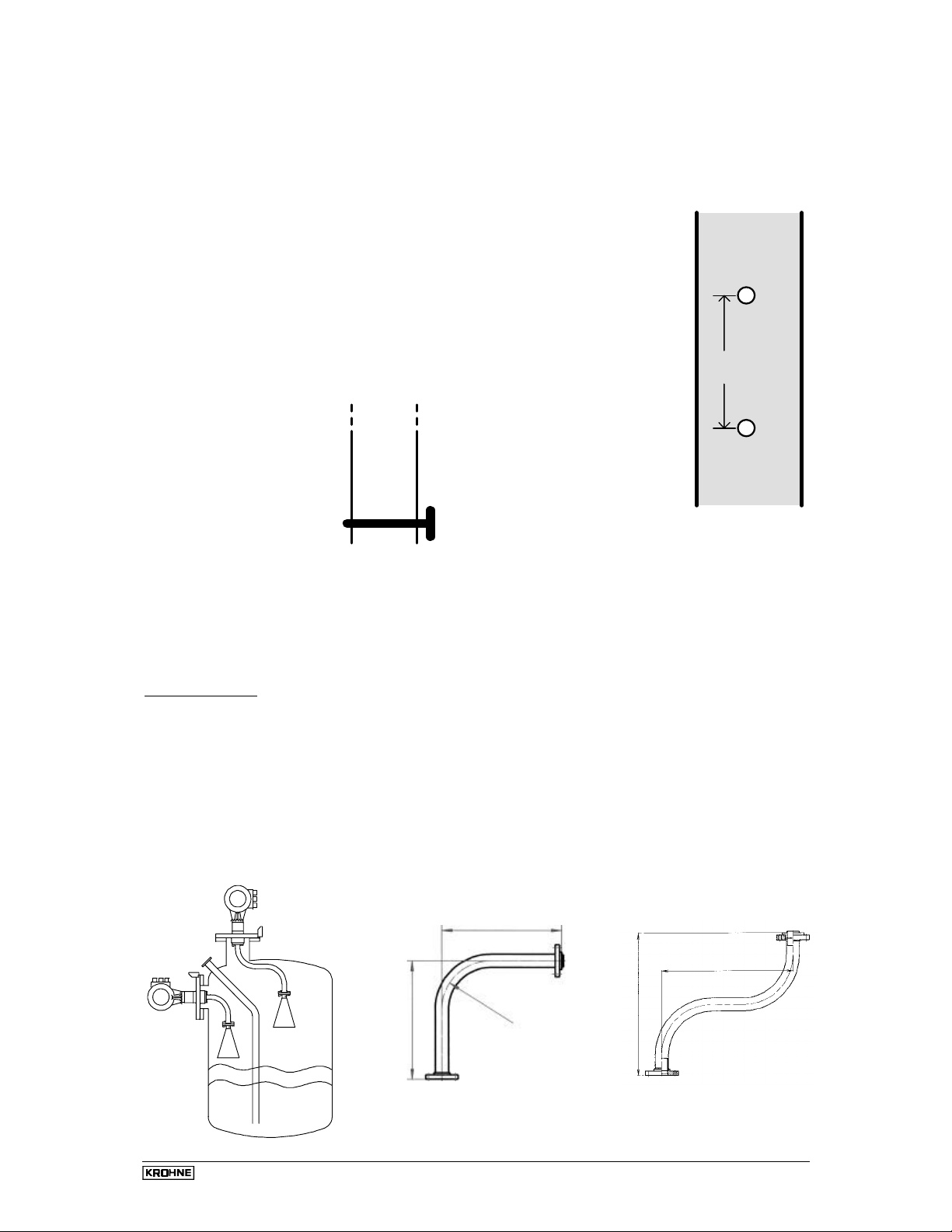

6.1.2 Recommendations for positioning on the tank

A) Horn antenna or Wave-Stick without stilling well

Recommended

distance

from the tank

wall:

Antenna Type 3

or Wave-Stick

>1/7×H, but max. 1/3×D

D

H

min.

measurable

level

Antenna Type 4

>1/10×H, but max. 1/3×D

BM 70 P : > 1/5 x H

D

H

Lower measuring range limited Several BM 70 A/P can be operated

when tank has tapered bottom. in one tank.

Do not position in Do not mount dead centre Do not position

tank centreline!onmanhole cover! above internals!

(multiple reflections!) (multiple reflections!) (interference reflections!)

If these recommendations cannot be followed because of the tank geometry, please consult

KROHNE.

Installation and operating instructions BM 70 A/P Page: 18 11/00

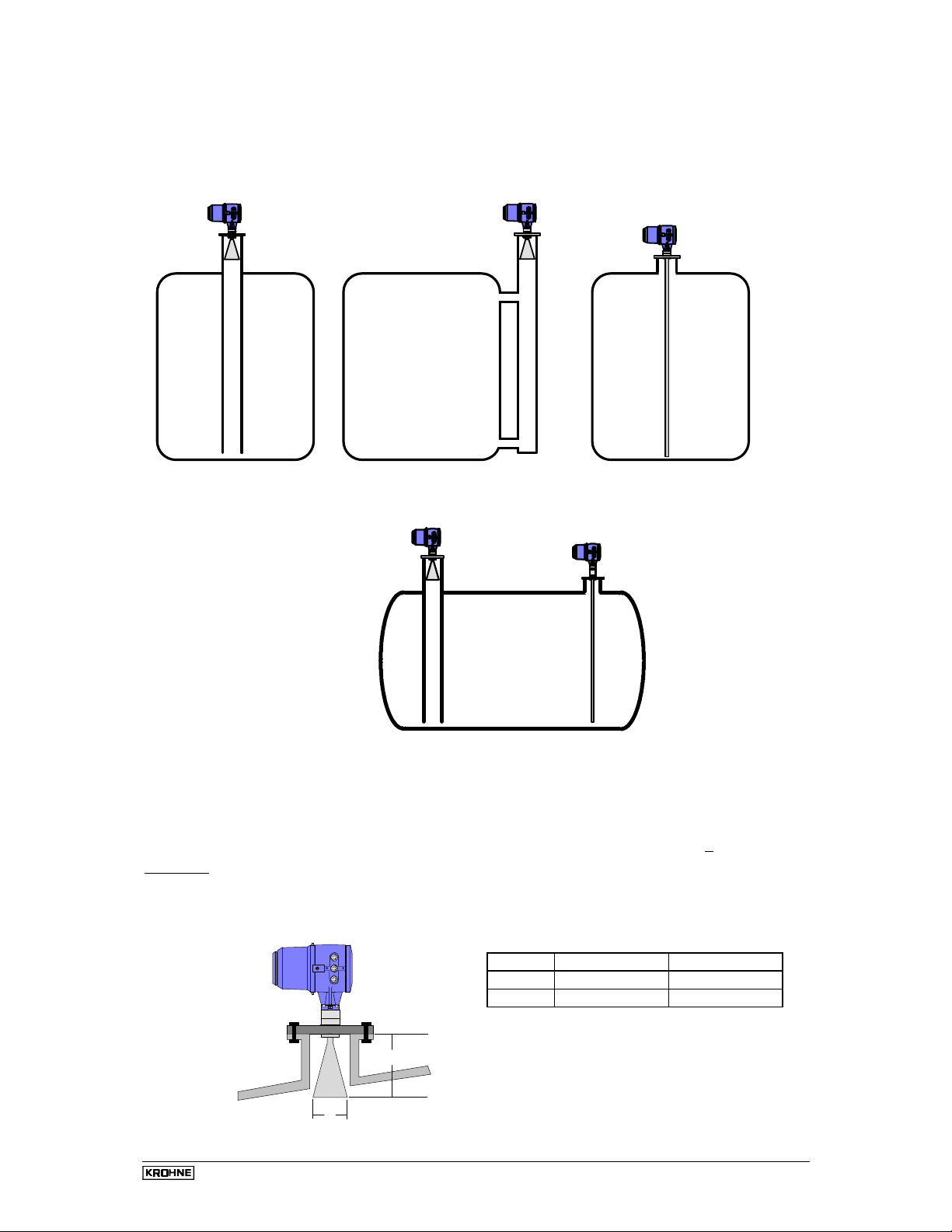

B) Stilling well or Wave-Guide

A stilling well or Wave-Guide may be mounted in any position on the tank.

(For design layout: see also Section 6.1.4; for block distance: see Section 3.3).

Stilling well application In a side vessel BM 70 A Wave-Guide

A stilling well or Wave-Guide

is positively recommended for

horizontal cylindrical tanks

(to avoid multiple reflections):

6.1.3 Mounting on tank fitting

A) Horn antenna

Should be mounted on the tank fitting as close to the horizontal as possible (deviation < ± 2°).

Exception: if product surface is not horizontal, (e.g. particulate materials) the flange can be aligned

roughly parallel to it.

The antenna should project out of the fitting:

Antenna Diameter D Length l*

Type 4 200 mm (8”) 335 mm (13.2”)

Type 3 140 mm (5.5”) 223 mm (8.8”)

* Hastelloy: + 30 mm (1.2”)

(subject to change without notice)

Tank nozzle

L

D

Installation and operating instructions BM 70 A/P Page: 19 11/00

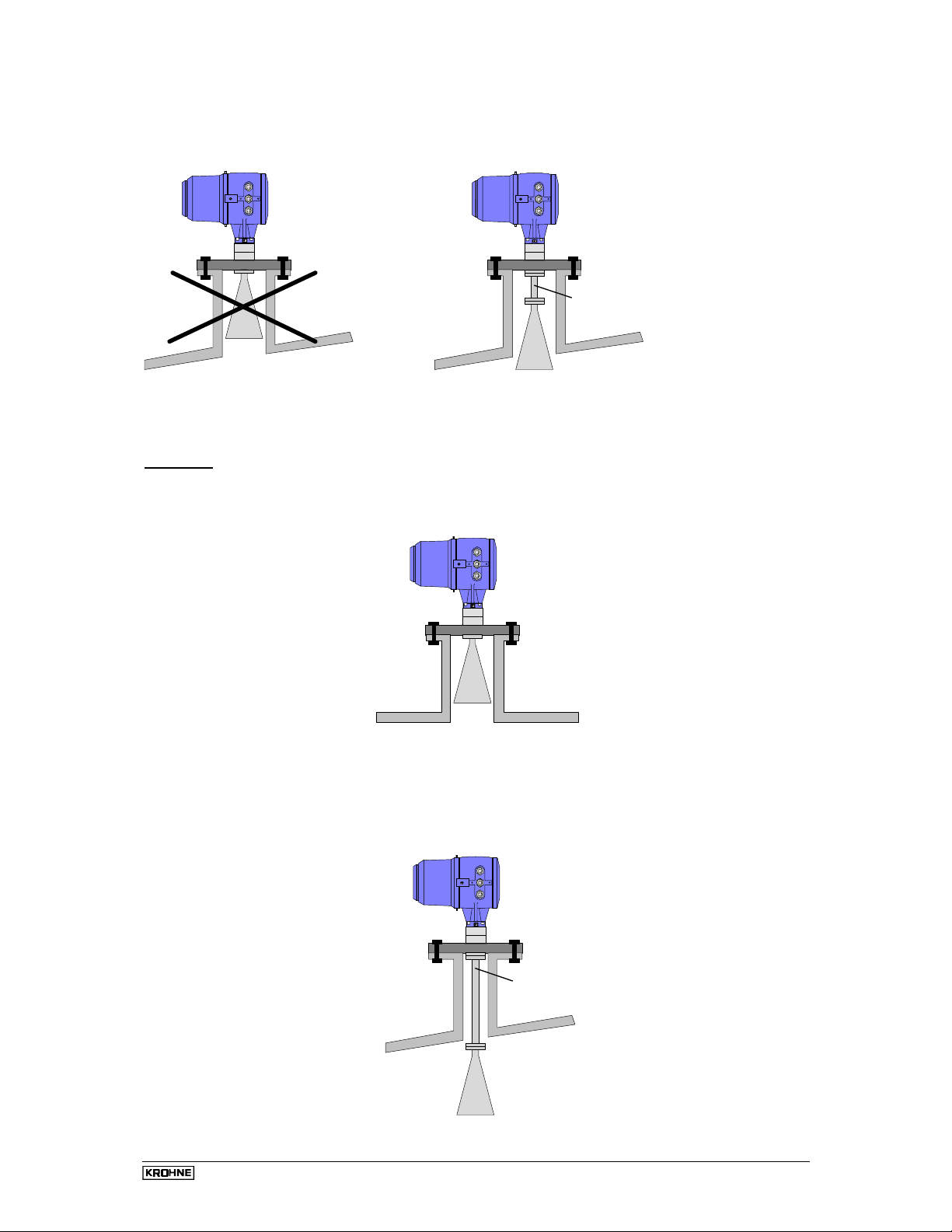

An antenna extension should be added if the antenna does not project out of the fitting:

Antenna

Tank nozzle

extension

Antenna extensions are available from 100 to 2000 mm (3.94" to 78.74") in steps of 100 mm (3.94").

Several extensions can be joined up:

Exception:

When the tank fitting is sy mmetrical, the antenna may end in the fitting so as to enlarge the

measuring range (minimum dead zone to tank cover, see Sect. 3.3 "block distance" and Sect. 5.2

"error of measurement"):

Tank nozzle

Narrow tank fitting

If the inside diameter of the fitting is smaller than the diameter of the antenna, and the fitting is

accessible from inside the tank for mounting purposes, the antenna with extension can be mounted

from the inside (not for versions made of titanium or tantalum). The antenna extension should be

about 100 mm (3.94") longer than the height of the fitting.

Antenna

Tank nozzle

extension

Installation and operating instructions BM 70 A/P Page: 20 11/00

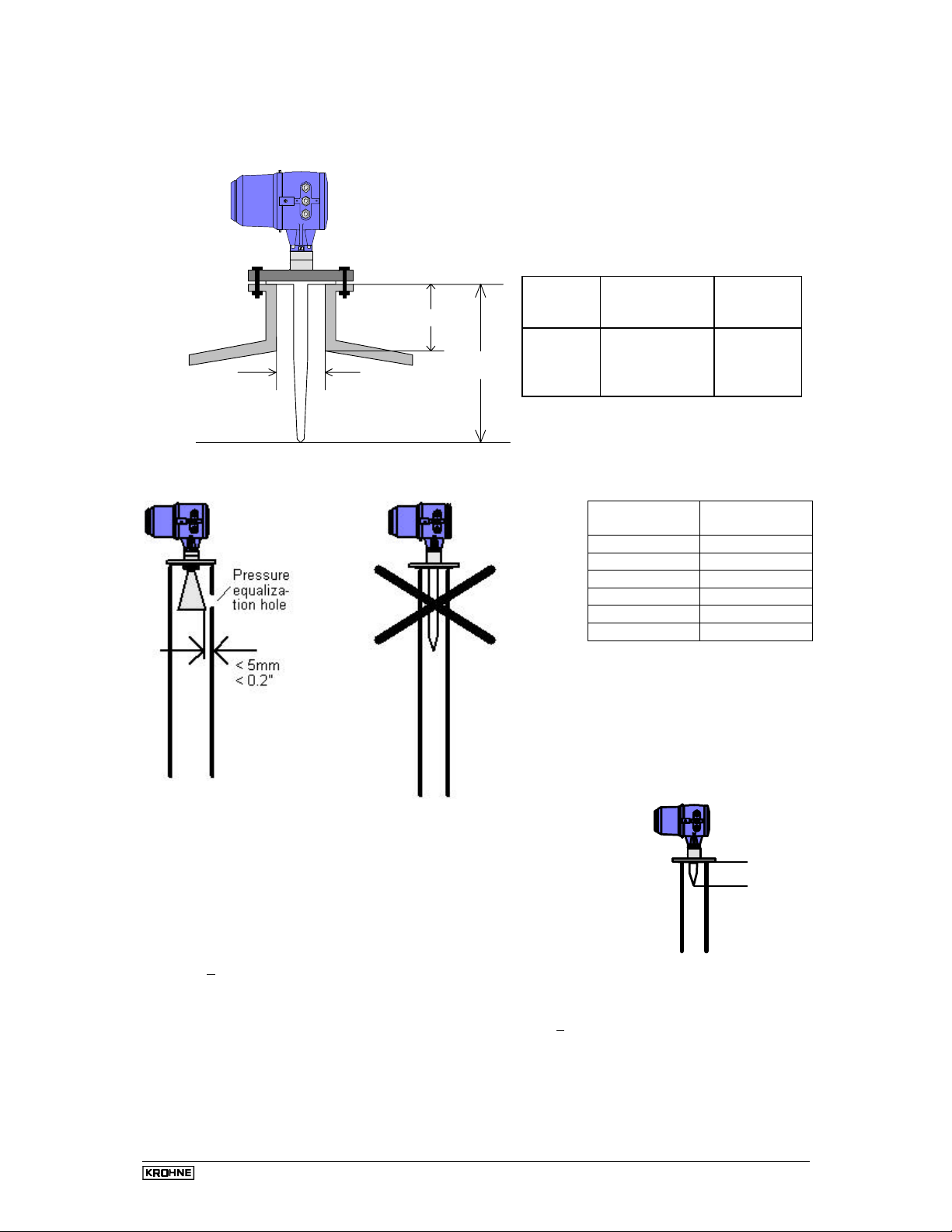

B) Wave-Stick

Note the requirements pertaining to diameter and length of the tank fitting:

Version Length L max.

Tank nozzle

min. 50 mm/2"

max. X

Standard 384 mm

L

Option 500...1000 mm

(19.7” - 39.4”)

6.1.4 Mounting on stilling wells

Antenna Type Outside

height of

fitting X

150 mm

(15.12”)

(15.12”)

L - 234 mm

(L - 9.2”)

diameter

1 80 mm (3.15”)

1s 76 mm (2.99”)

2, 2s 100 mm (3.94”)

3 140 mm (5.51”)

3s 152 mm (5.98”)

4, 4s 200 mm (7.87”)

If necessary, turn antenna

to size!

Antenna size must match inside

diameter

A standard Wave-Stick will not

function in a stilling well! For

stilling wells 40-55 mm a type

Wave-Stick SW can be used.

60mm

Further requirements concerning stilling wells:

• The well must be electrically conductive.

• Minimum inside diameter of well: 40 mm (1.57"). (BM 70 P: 80 mm,

better > 100 mm).

• If possible, use only smooth walled, straight stilling wells. If nevertheless an assembled stilling well

is necessary, abrupt changes in diameter along the pipe should be less than 1 mm (0.04"). Surface

roughness of the inside of the pipe should not be more than + 0.1 mm (0.004").

• For the BM 70 P the antenna types 1s, 2s, 3s or 4s have to be used to achieve a high measuring

accuracy.

Installation and operating instructions BM 70 A/P Page: 21 11/00

It is possible to measure through a full-bore open ball valve if the valve and the pipe adapters above

and below the valve are relatively smooth-walled.

• It is not possible to measure levels below the end of the stilling well.

• To ensure equalization of pressure, drill one or two small holes in the stilling well above the

maximum filling level.

• If necessary, several holes can be drilled along the

whole length of the pipe. All holes must be

deburred. The holes should be as small as

possible and spaced wide apart (Recommendation: see drawing on the right).

• It is advisable to fit a reference point at the end of

Ø max.

10 mm

/ 0.4"

the stilling well in the form of a rod or screw of

approx. 6 mm (0.24") diameter. See drawing

below.

Ø 6 mm

6 mm Ø

Ø 0.24"

min.

50 mm

/ 1.97"

6.1.5 Wave-Guide

The "Wave-Guide" is a pipe with an outside diameter of 30 mm (1.18") and an inside diameter of 25

mm (0.98"), that is bolted direct to the BM 70 A flange system (in the same way as an antenna

extension). It functions like a stilling well and can be used for clean products. The Wave-Guide is not

practical in conjunction with the BM 70 P as it will not provide high measuring accuracy.

maximum length:

Ex: max. 3 m (9.84 ft) (except tantalum: max. 1 m (3.28 ft)).

Non-Ex: up to 3 m (9.84 ft) without additional support

Pipes longer than 3 m (9.84 ft) need to be fixed at two points.

6.1.6 Curved antenna extensions

Rectangular and S-shaped extensions are available for particularly difficult operating conditions. Such

extensions can be used in cases where the antenna is exposed to especially high temperatures and

where there are problems of space, (e.g. to avoid internals; positioning the antenna away from the

centre of sy mmetry; lateral mounting of the signal converter).

Standard sizes (others on request):

271 (10.67")

271 (10.67")

R 110 (4.33")

323 (12.72")

300 (11.81")

Dimensions in mm (inches)

Installation and operating instructions BM 70 A/P Page: 22 11/00

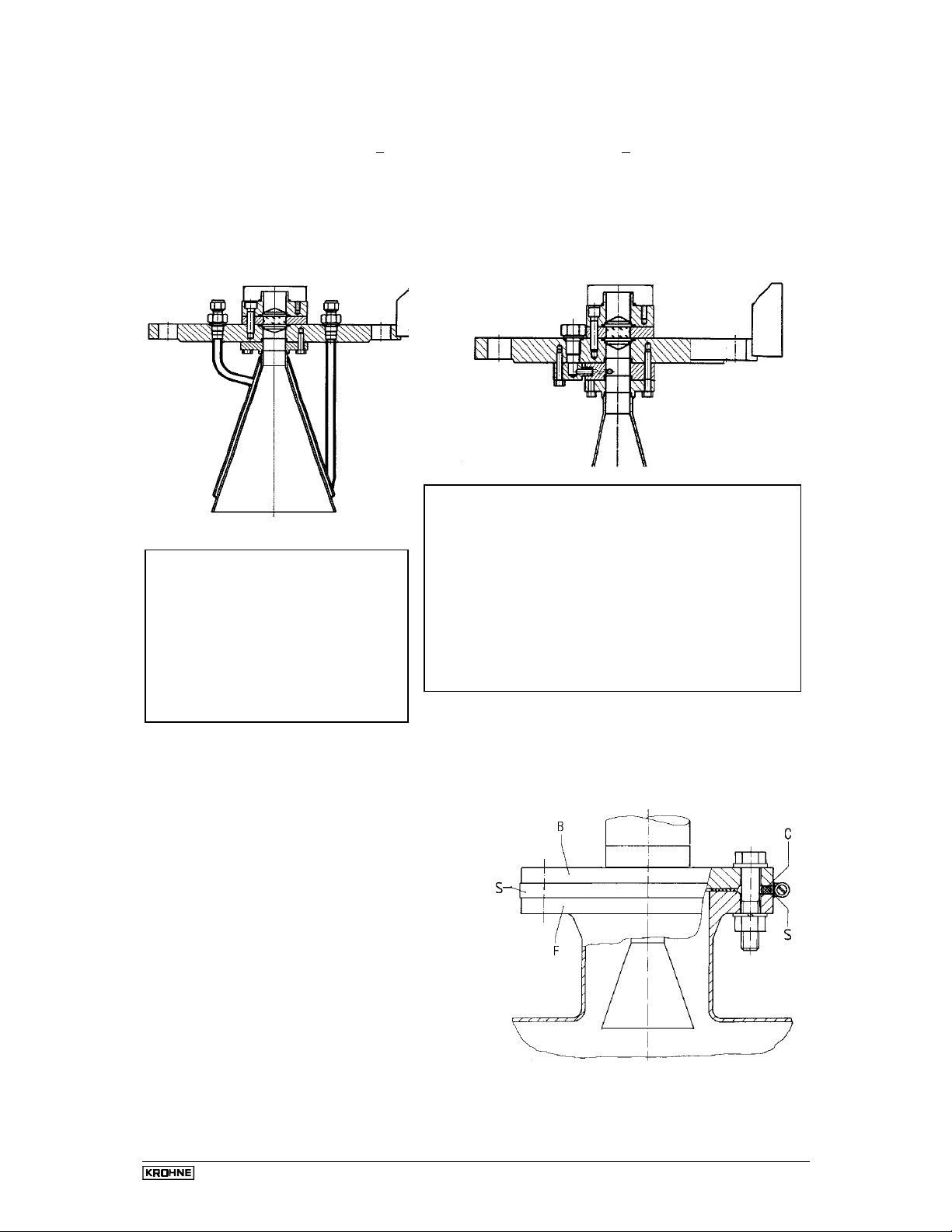

6.1.7 Special options for the flange

y p

g

y

p

p

Antenna heating/cooling device (> DN150/6") Purging device (>

DN100)

Double-walled antenna for cooling or heating, With connection for purging the inside surface

e.g. to avoid condensation (recommended for of the antenna to prevent heavy deposits of

liquid sulphur). product or to heat or cool the antenna.

max. differential pressure at antenna:

Standard DN150

= 6 bar (87 psig) (information on other pressure

levels provided on request)

If a liquid is used for purging, this may interfere with the

functioning of the BM 70 A/P during the process.

Continuous purging with gas is not a problem as it does

Hazardous-duty systems:

1. In Zone 0, the temperature of the

heating system and antenna may

not exceed 80 % of the ignition

temperature of the stored material.

2. Continuous monitoring shall

ensure, and operational inspections

shall verify, that the 80% level of

not interfere with measurements.

The purge connection is closed off by the manufacturers

with a ¼" screw. When this screw is removed to connect

up a purging system, the operator is responsible for

ensuring conformity with "Ex" requirements in

connection with the purging circuit (e.g. fitting a flame

trap).

the ignition temperature stated in

Point 1 above is not exceeded.

6.1.8 Ultimate installation on the tank

• After carefull

tank fittin

ositioning the BM 70 A/P on the

flange (not forgetting the gasket),

align the BM 70 A/P and the gasket.

• Insert stud bolts and tighten nuts slightly (b

hand). (These items not included with supply).

• Press shielding strip C* in the gap between

tank flange and the BM 70 A/P flange and

secure with stra

retainer S* (both items

included with supply).

• Strap retainer S* must fit closely and overla

both flanges.

* only required for European radio approvals

• Tighten down stud bolts and nuts firmly. The

torque is dependent on the strength properties

of the stud bolts and the pressure rating of the

tank.

Installation and operating instructions BM 70 A/P Page: 23 11/00

C* = shielding strip B = BM 70 A/P flange

S* = strap retainer F = tank flange

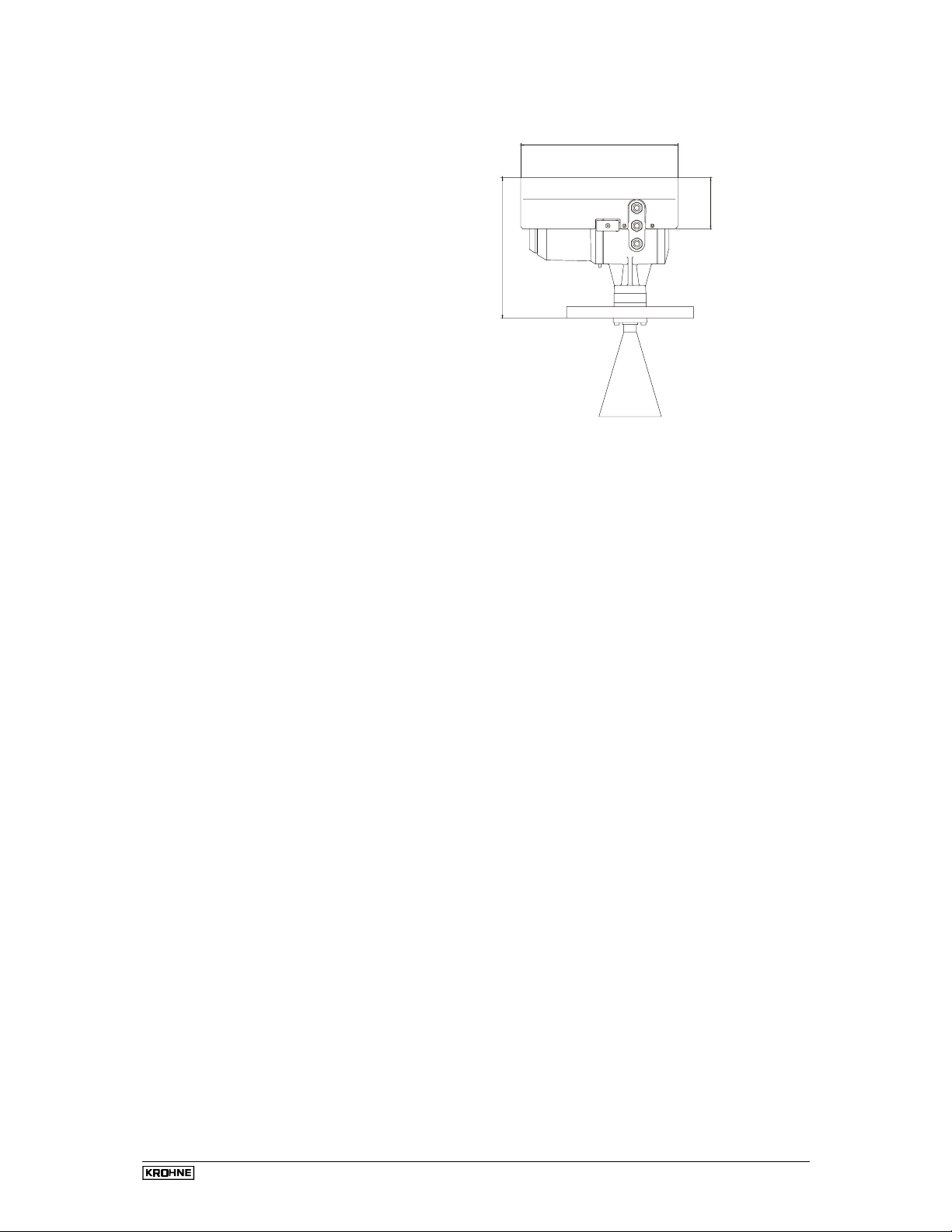

6.1.9 Sunshade

315 (12.40")

A sunshade SD is recommended to protect the

signal converter from the effects of direct sunshine

from above. This will increase the overall installation height by approx. 20 mm.

The sunshade is easily fitted/dismantled with the

aid of 4 screws S (included). An Allen key (size 4

mm) is required.

Dimensions in mm (inches)

353 (13.89")

Installation and operating instructions BM 70 A/P Page: 24 11/00

6.2 Ambient conditions

6.2.1 Hazardous locations

BM 70 A/P Ex is suitable for use in hazardous locations of the following zones: 0, 1, 2

Temperature classes: T6...T2; danger groups: IIA...IIC

For further information: see Section 10.

6.2.2 Ambient temperature of signal converter

BM 70 A/P with horn antenna or Wave-Guide: -20 ... +55°C (-4 ... +131°F)

A "BM 70 sunshade" should be fitted if the converter is located in the open with the likelihood of

strong insolation (see Section 6.1.9).

6.2.3 Flange temperature

Horn antenna, Wave-Guide (T

Horn antenna, Wave-Guide (T

High-temperature version with distance piece and

amb* ≤ 50°C): -30 ... +130°C (-22 ... +266°F)

amb* ≤ 55°C): -30 ... +120°C (-22 ... +248°F)

FFKM gasket (Kalrez 4079

or Parofluor V3819-75): -30 ... +250°C ** (-22 ... +482°F)

Kalrez 2035 gasket: -30 ... +210°C (-22 ... +410°F)

Viton gasket: -30 ... +200°C (-22 ... +392°F)

FEP-sheathed gasket: -30 ... +200°C (-22 ... +392°F)

Wave-Stick, permanently: -20 ... +100°C (-4 ... +218°F)

Wave-Stick, pressure-dependent (see 6.3.5), with no mechanical

loading radial to the rod: bis +150°C (302°F)

Wave-Stick, steam cleaning (CIP, SIP) for 30 minutes: max. +160°C (320°F)

* Tamb is the ambient temperature of the signal converter

** Safety limit: +280°C (536°F)

6.2.4 Ambient temperature limits

Signal converter:

Measuring function OK, but LCD "freezes up": min. - 40°C (-40°F)

Functional upper limit, for max. 2 hours: max. +70°C (+158°F)

Flange system:

see Section 6.2.3

6.2.5 Storage temperature

-20 ... +60°C (-4 ... +140°F)

6.2.6 Environment class

Locations exposed direct to open-air climate, D1 Severity in conformity with EN 60654-1

6.2.7 Protection category

Signal converter: IP 66 / IP 67 (equivalent to NEMA 6)

Installation and operating instructions BM 70 A/P Page: 25 11/00

Loading...

Loading...