Page 1

Handbook

Handbook

BATCHFLUX 5500 C

BATCHFLUX 5500 C

BATCHFLUX 5500 CBATCHFLUX 5500 C

Electromagnetic flowmeter for volumetric filling

machines

HandbookHandbook

© KROHNE 05/2014 - 4000827703 - HB BATCHFLUX 5500 R03 en

Page 2

: IMPRINT :::::::::::::::::::::::::::::::::::::::

All rights reserved. It is prohibited to reproduce this documentation, or any part thereof, without

the prior written authorisation of KROHNE Messtechnik GmbH.

Subject to change without notice.

Copyright 2014 by

KROHNE Messtechnik GmbH - Ludwig-Krohne-Str. 5 - 47058 Duisburg (Germany)

2

www.krohne.com 05/2014 - 4000827703 - HB BATCHFLUX 5500 R03 en

Page 3

BATCHFLUX 5500 C

CONTENTS

1 Safety instructions 5

1.1 Intended use ..................................................................................................................... 5

1.2 Safety instructions from the manufacturer ..................................................................... 5

1.2.1 Disclaimer ............................................................................................................................... 5

1.2.2 Information concerning the documentation........................................................................... 5

1.2.3 Warnings and symbols used................................................................................................... 6

1.3 Safety instructions for the operator................................................................................. 6

2 Device description 7

2.1 Scope of delivery............................................................................................................... 7

2.2 Device description ............................................................................................................ 8

2.3 Nameplate ........................................................................................................................ 9

3 Installation 10

3.1 General notes on installation ......................................................................................... 10

3.2 Storage ........................................................................................................................... 10

3.3 Pre-installation requirements ....................................................................................... 10

3.4 General requirements .................................................................................................... 11

3.5 Installation conditions ....................................................................................................12

3.5.1 Inlet and outlet...................................................................................................................... 12

3.5.2 Control valve ......................................................................................................................... 12

3.5.3 Pump ..................................................................................................................................... 12

3.5.4 Open feed or discharge......................................................................................................... 13

3.5.5 Mounting position.................................................................................................................. 13

3.5.6 Mounting ............................................................................................................................... 14

3.5.7 Installation location .............................................................................................................. 14

3.5.8 Flange deviation.................................................................................................................... 14

3.5.9 Temperatures ....................................................................................................................... 15

3.5.10 Hot filling............................................................................................................................. 15

4 Electrical connections 16

4.1 Safety instructions.......................................................................................................... 16

4.2 Grounding ....................................................................................................................... 16

4.3 Electrical connection......................................................................................................17

4.3.1 Cable connector M12 - 5 pin ................................................................................................. 17

4.3.2 Cable connector M12 - 8 pin (with status output) ................................................................ 18

5 Service 19

5.1 Spare parts availability...................................................................................................19

5.2 Availability of services .................................................................................................... 19

5.3 Returning the device to the manufacturer..................................................................... 19

5.3.1 General information.............................................................................................................. 19

5.3.2 Form (for copying) to accompany a returned device............................................................ 20

5.4 Disposal .......................................................................................................................... 20

www.krohne.com05/2014 - 4000827703 - HB BATCHFLUX 5500 R03 en

3

Page 4

CONTENTS

BATCHFLUX 5500 C

6 Technical data 21

6.1 Measuring principle........................................................................................................21

6.2 Technical data................................................................................................................. 22

6.3 Dimensions and weights ................................................................................................ 26

6.4 Counter Flanges ............................................................................................................. 29

7 Notes 31

4

www.krohne.com 05/2014 - 4000827703 - HB BATCHFLUX 5500 R03 en

Page 5

BATCHFLUX 5500 C

1.1 Intended use

The electromagnetic flowmeter is designed exclusively for measuring the volumetric flowrate of

electrically conductive, liquid process products.

Needed electrical conductivity for products:

• > 5 µS/cm (except for water)

• > 20 µS/cm (for water)

1.2 Safety instructions from the manufacturer

1.2.1 Disclaimer

The manufacturer will not be liable for any damage of any kind by using its product, including,

but not limited to direct, indirect or incidental and consequential damages.

This disclaimer does not apply in case the manufacturer has acted on purpose or with gross

negligence. In the event any applicable law does not allow such limitations on implied warranties

or the exclusion of limitation of certain damages, you may, if such law applies to you, not be

subject to some or all of the above disclaimer, exclusions or limitations.

SAFETY INSTRUCTIONS 1

Any product purchased from the manufacturer is warranted in accordance with the relevant

product documentation and our Terms and Conditions of Sale.

The manufacturer reserves the right to alter the content of its documents, including this

disclaimer in any way, at any time, for any reason, without prior notification, and will not be liable

in any way for possible consequences of such changes.

1.2.2 Information concerning the documentation

To prevent any injury to the user or damage to the device it is essential that you read the

information in this document and observe applicable national standards, safety requirements

and accident prevention regulations.

If this document is not in your native language and if you have any problems understanding the

text, we advise you to contact your local office for assistance. The manufacturer can not accept

responsibility for any damage or injury caused by misunderstanding of the information in this

document.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device. Special considerations and precautions are also described in the

document, which appear in the form of underneath icons.

www.krohne.com05/2014 - 4000827703 - HB BATCHFLUX 5500 R03 en

5

Page 6

1 SAFETY INSTRUCTIONS

1.2.3 Warnings and symbols used

Safety warnings are indicated by the following symbols.

DANGER!

This warning refers to the immediate danger when working with electricity.

DANGER!

This warning refers to the immediate danger of burns caused by heat or hot surfaces.

DANGER!

This warning refers to the immediate danger when using this device in a hazardous atmosphere.

DANGER!

These warnings must be observed without fail. Even partial disregard of this warning can lead to

serious health problems and even death. There is also the risk of seriously damaging the device

or parts of the operator's plant.

BATCHFLUX 5500 C

WARNING!

Disregarding this safety warning, even if only in part, poses the risk of serious health problems.

There is also the risk of damaging the device or parts of the operator's plant.

CAUTION!

Disregarding these instructions can result in damage to the device or to parts of the operator's

plant.

INFORMATION!

These instructions contain important information for the handling of the device.

LEGAL NOTICE!

This note contains information on statutory directives and standards.

• HANDLING

HANDLING

HANDLINGHANDLING

This symbol designates all instructions for actions to be carried out by the operator in the

specified sequence.

i RESULT

RESULT

RESULTRESULT

This symbol refers to all important consequences of the previous actions.

1.3 Safety instructions for the operator

WARNING!

In general, devices from the manufacturer may only be installed, commissioned, operated and

maintained by properly trained and authorized personnel.

This document is provided to help you establish operating conditions, which will permit safe and

efficient use of this device.

6

www.krohne.com 05/2014 - 4000827703 - HB BATCHFLUX 5500 R03 en

Page 7

BATCHFLUX 5500 C

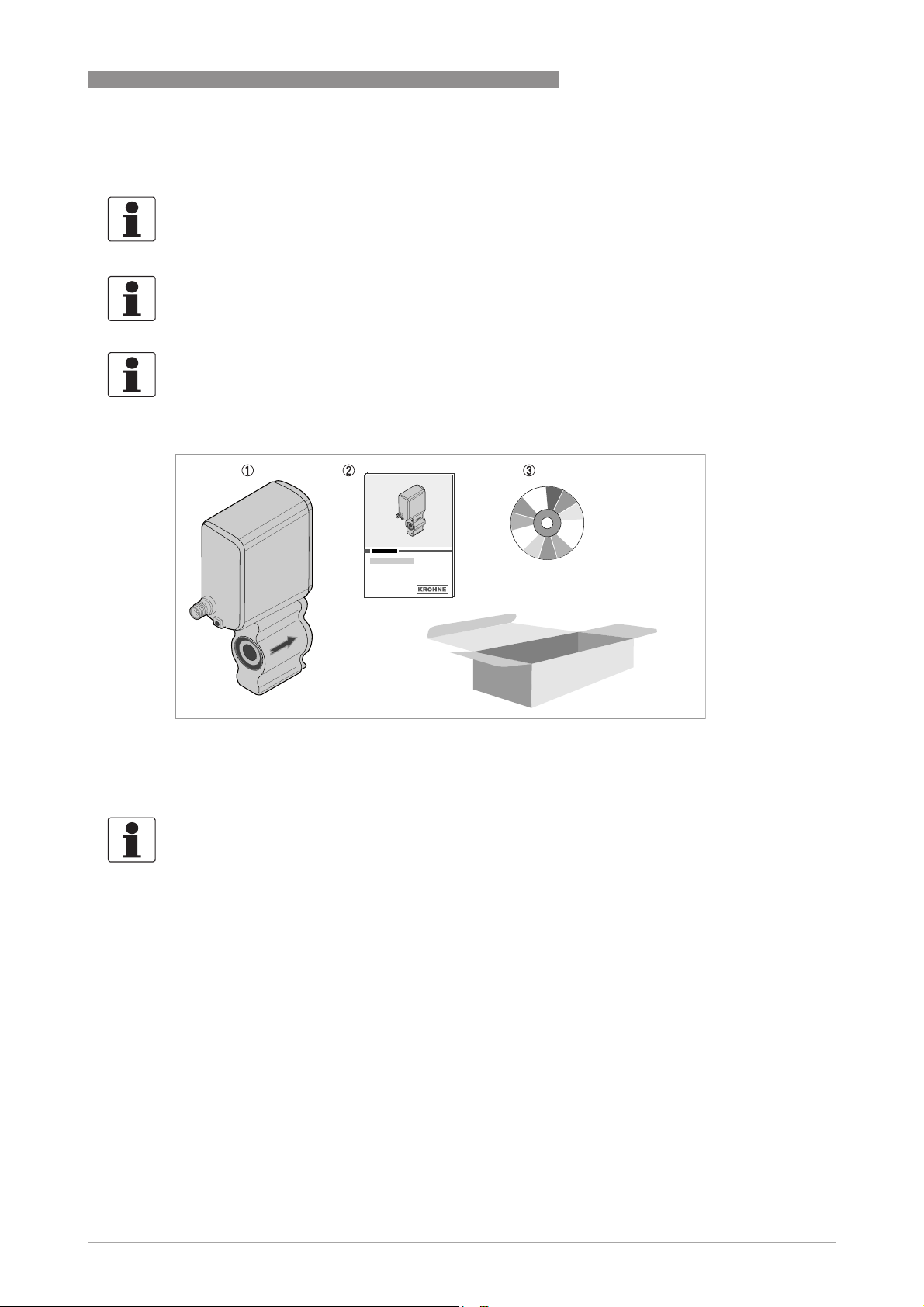

2.1 Scope of delivery

INFORMATION!

Inspect the packaging carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

DEVICE DESCRIPTION 2

Figure 2-1: Scope of delivery

1 Flowmeter in ordered size

2 Product documentation (on request)

3 CD-ROM with product documentation

INFORMATION!

Assembly materials and tools are not part of the delivery. Use the assembly materials and tools

in compliance with the applicable occupational health and safety directives.

www.krohne.com05/2014 - 4000827703 - HB BATCHFLUX 5500 R03 en

7

Page 8

2 DEVICE DESCRIPTION

2.2 Device description

Your measuring device is supplied ready for operation. The factory settings for the operating

data have been made in accordance with your order specifications.

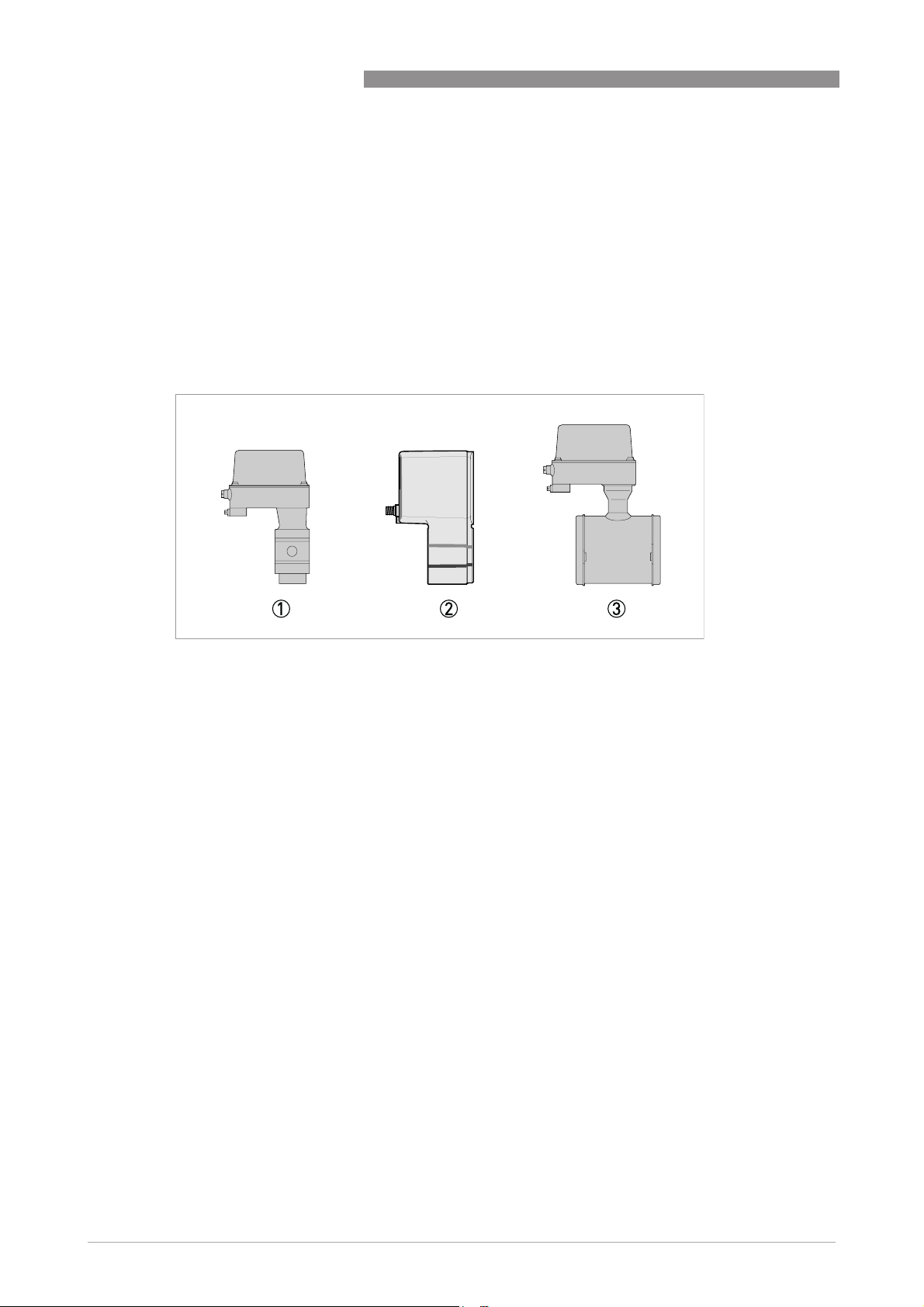

The following compact versions are available:

• Version 1: converter directly mounted on cast sensor housing in size DN2.5..6

• Version 2: converter and sensor in solid cast BNG construction for DN10 and DN 15

• Version 3: converter mounted on conventional sensor construction (DN25 and DN40)

BATCHFLUX 5500 C

Figure 2-2: Device version

1 DN2.5 - 4 - 6 (

2 DN10 - DN15 (

3 DN25 - DN40 ( 1 - 1

1

/10 -1 /6 -1 /4 " ).

3

/8 -1 /2 " ).

1

/2 " ).

8

www.krohne.com 05/2014 - 4000827703 - HB BATCHFLUX 5500 R03 en

Page 9

BATCHFLUX 5500 C

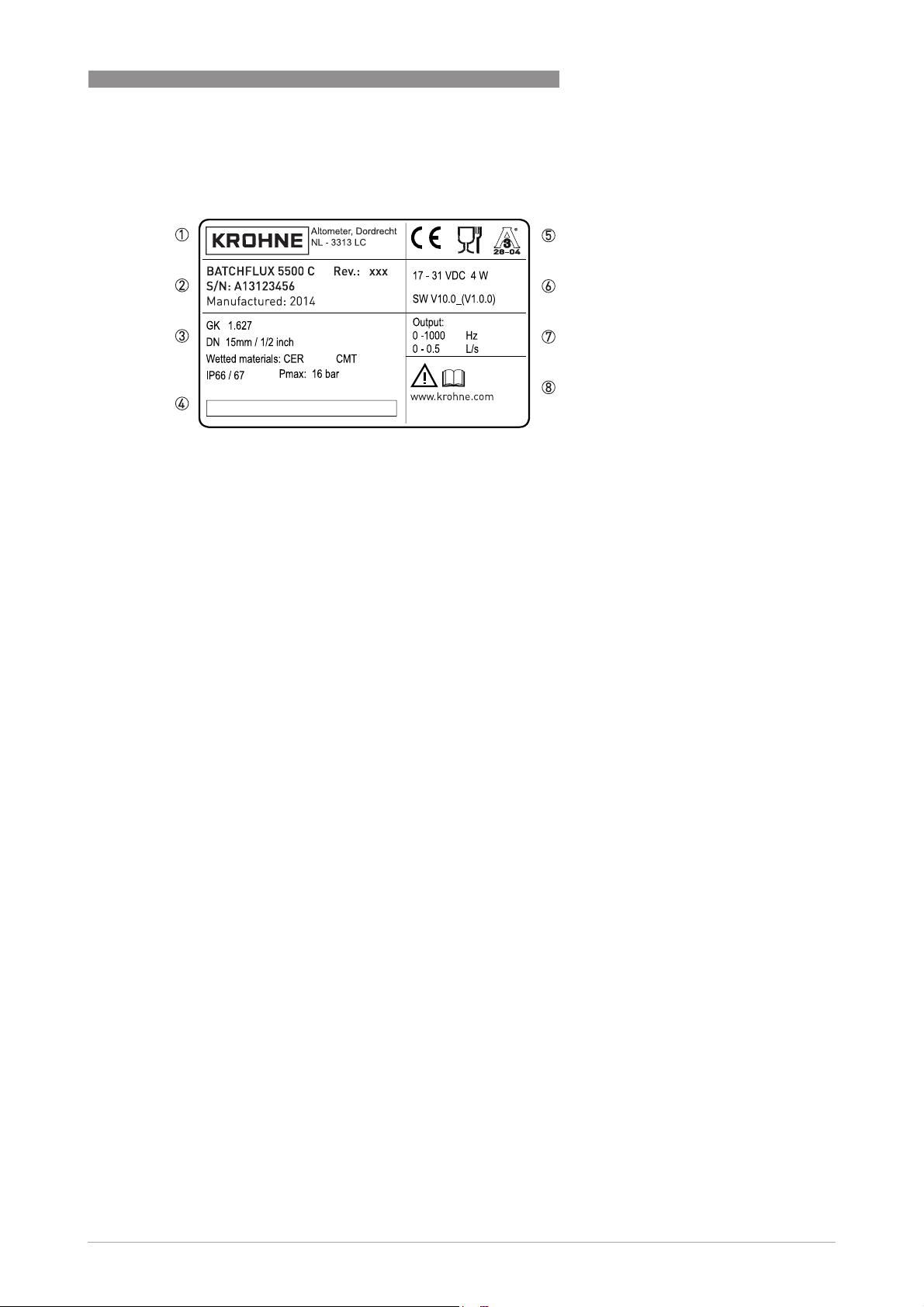

2.3 Nameplate

Figure 2-3: Nameplate

1 Name and address of the manufacturer

2 Type designation, S/N nr and year of manufacturing

3 Calibration and device data

4 Tag number

5 Marking ( ao. CE and 3-A logo )

6 Electrical values and software revision nr.

7 Output data

8 Additional info ( e.g. manufacturer website)

DEVICE DESCRIPTION 2

www.krohne.com05/2014 - 4000827703 - HB BATCHFLUX 5500 R03 en

9

Page 10

3 INSTALLATION

3.1 General notes on installation

INFORMATION!

Inspect the packaging carefully for damages or signs of rough handling. Report damage to the

carrier and to the local office of the manufacturer.

INFORMATION!

Do a check of the packing list to make sure that you have all the elements given in the order.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

3.2 Storage

• Store the device in a dry and dust-free location.

• Avoid lasting direct exposure to the sun.

• Store the device in its original packaging.

• Storage temperature: -50 ...+70°C / -58...+158°F

BATCHFLUX 5500 C

3.3 Pre-installation requirements

Make sure that you have all necessary tools available:

• Small wrench (M5) for connection to ground

• Torque wrench for installing flowmeter in pipeline

Assecoires necessary for the correct installations are available on request at the manufacturer

Make sure that these accesoires are available before starting installation;

• O- ring / L-ring gasket

• Special pipe flanges

• Stud bolt with lockwasher, plain washer and nut

INFORMATION!

To facilitate servicing and/or exchanging of the device, please note that:

it must be possible to shut off the flow through the pipeline ( control valve upstream in pipeline).

Drain the pipeline before removing device ( provide drain valve)

10

www.krohne.com 05/2014 - 4000827703 - HB BATCHFLUX 5500 R03 en

Page 11

BATCHFLUX 5500 C

3.4 General requirements

INFORMATION!

The following precautions must be taken to ensure reliable installation.

•

Make sure that there is adequate space to the sides.

•

Protect the signal converter from direct sunlight and install a sun shade if necessary.

•

Support the pipeline on both side of the flowmeter.

•

Do not expose the signal converter to intense vibration. The flowmeters are tested for a

vibration level in accordance with IEC 60068-2-64.

INSTALLATION 3

Figure 3-1: Avoid vibrations

Figure 3-2: Avoid strong magnetic fileds

Figure 3-3: Horizontal piperun

CAUTION!

Install in a slightly descending pipe section to prevent air from collecting and to avoid faulty

measurements (meter can drain).

www.krohne.com05/2014 - 4000827703 - HB BATCHFLUX 5500 R03 en

11

Page 12

3 INSTALLATION

3.5 Installation conditions

3.5.1 Inlet and outlet

Figure 3-4: Inlet and outlet section

1 ≥ 5 DN

2 ≥ 2 DN

3 Drain valve (to empty pipeline)

BATCHFLUX 5500 C

3

3.5.2 Control valve

Figure 3-5: Installation before control valve

3.5.3 Pump

12

Figure 3-6: Installation after pump

∠α > 2°

1. Drain valve (to empty pipeline)

www.krohne.com 05/2014 - 4000827703 - HB BATCHFLUX 5500 R03 en

Page 13

BATCHFLUX 5500 C

3.5.4 Open feed or discharge

Figure 3-7: Installation before an open discharge

3.5.5 Mounting position

INSTALLATION 3

Figure 3-8: Installation in bending pipes

∠α ; > 2°

1. Drain valve ( to empty pipeline)

CAUTION!

Avoid draining or partial filling of the flow sensor.

WARNING!

Vertical down position only in conjunction of a control valve

www.krohne.com05/2014 - 4000827703 - HB BATCHFLUX 5500 R03 en

13

Page 14

3 INSTALLATION

3.5.6 Mounting

3.5.7 Installation location

Figure 3-9: Installation location

CAUTION!

Mount the flow sensor in such a way that the electrode axis

(X--------X) is approximately in a horizontal pipe run.

BATCHFLUX 5500 C

3.5.8 Flange deviation

Figure 3-10: Mounting position and flange deviation

1 L

max

2 L

min

CAUTION!

Max. permissible deviation of pipe flange faces:

- L

L

max

≤ 0.5 mm / 0.02"

min

14

www.krohne.com 05/2014 - 4000827703 - HB BATCHFLUX 5500 R03 en

Page 15

BATCHFLUX 5500 C

3.5.9 Temperatures

Process temperature vs ambient temperature

1 Ambient temperature

2 Process temperature

3.5.10 Hot filling

INSTALLATION 3

Installation position

Figure 3-11: In case of hot fluids

INFORMATION!

Avoid installation near hot product tanks. If possible, try to insulate the flowmeter from radiant

heat sources.

CAUTION!

°

On high temperature pipes and where temperatures exceed 100

C, provide facilities to

compensate for longditudinal expansion of pipeline (due to heat-up). Use flexible pipe elements

(e.g. elbows).

www.krohne.com05/2014 - 4000827703 - HB BATCHFLUX 5500 R03 en

15

Page 16

4 ELECTRICAL CONNECTIONS

4.1 Safety instructions

DANGER!

All work on the electrical connections may only be carried out with the power disconnected. Take

note of the voltage data on the nameplate!

DANGER!

Observe the national regulations for electrical installations!

WARNING!

Observe without fail the local occupational health and safety regulations. Any work done on the

electrical components of the measuring device may only be carried out by properly trained

specialists.

INFORMATION!

Look at the device nameplate to ensure that the device is delivered according to your order.

Check for the correct supply voltage printed on the nameplate.

BATCHFLUX 5500 C

4.2 Grounding

CAUTION!

The grounding wire should not transmit any interference voltage. Therefore do not ground any

other electrical device at the same conductor.

CAUTION!

When connecting to functional extra-low voltages (24VDC) , ensure that you use protective

separation (PELV) according to IEC 364/IEC 536 or VDE 0100/VDE 0106.

16

www.krohne.com 05/2014 - 4000827703 - HB BATCHFLUX 5500 R03 en

Page 17

BATCHFLUX 5500 C

4.3 Electrical connection

4.3.1 Cable connector M12 - 5 pin

All operating data for the BATCHFLUX 5500 C are preset at the factory. For changing the

parameters and diagnostic purposes BATCHMon plus operation software can be used.

ELECTRICAL CONNECTIONS 4

1 +24 VDC

2 Frequency output

3 Frequency output (ground)

4 Ground

5 To be connected for servicing only

Use one of the following attachment plug types to connect the flowmeter to a third

party system:

• moulded plug, straight or angle-entry form

• integrally extruded plug with cable in various lengths

• moulded plug, straight form, especially suitable for high-interference environments

Possible vendors of these plugs are:

• Binder

• Hirschmann

• Lumberg

• Amphenol

• Coninvers

www.krohne.com05/2014 - 4000827703 - HB BATCHFLUX 5500 R03 en

17

Page 18

4 ELECTRICAL CONNECTIONS

4.3.2 Cable connector M12 - 8 pin (with status output)

The 8 pin electric connection has a status output. This status output, is configurable to customer

specifications and offers either the flow direction (of the medium) or an error signal.

1 + 24 VDC

2 Not Connected

3 To be connected for servicing only

4 Ground

5 Frequency output

6 Ground common I/O

7 Status output

8 Not Connected

BATCHFLUX 5500 C

Options on status output 7; Off / Error / Flow direction

Mode

• Status output On / Off

• Flow direction

- Default value :Flow Direction

- Forward flow : status output; open

- Reversed flow ; status output ; closed

• Error software / application failure

Error signaling for following events: software failure or application failure (detection of empty

pipe only). No error ; status output open

18

www.krohne.com 05/2014 - 4000827703 - HB BATCHFLUX 5500 R03 en

Page 19

BATCHFLUX 5500 C

5.1 Spare parts availability

The manufacturer adheres to the basic principle that functionally adequate spare parts for each

device or each important accessory part will be kept available for a period of 3 years after

delivery of the last production run for the device.

This regulation only applies to spare parts which are subject to wear and tear under normal

operating conditions.

5.2 Availability of services

The manufacturer offers a range of services to support the customer after expiration of the

warranty. These include repair, maintenance, technical support and training.

INFORMATION!

For more precise information, please contact your local sales office.

5.3 Returning the device to the manufacturer

SERVICE 5

5.3.1 General information

This device has been carefully manufactured and tested. If installed and operated in accordance

with these operating instructions, it will rarely present any problems.

CAUTION!

Should you nevertheless need to return a device for inspection or repair, please pay strict

attention to the following points:

•

Due to statutory regulations on environmental protection and safeguarding the health and

safety of our personnel, manufacturer may only handle, test and repair returned devices that

have been in contact with products without risk to personnel and environment.

•

This means that the manufacturer can only service this device if it is accompanied by the

following certificate (see next section) confirming that the device is safe to handle.

CAUTION!

If the device has been operated with toxic, caustic, flammable or water-endangering products,

you are kindly requested:

•

to check and ensure, if necessary by rinsing or neutralising, that all cavities are free from

such dangerous substances,

•

to enclose a certificate with the device confirming that is safe to handle and stating the

product used.

www.krohne.com05/2014 - 4000827703 - HB BATCHFLUX 5500 R03 en

19

Page 20

5 SERVICE

5.3.2 Form (for copying) to accompany a returned device

Company: Address:

Department: Name:

Tel. no.: Fax no.:

Manufacturer's order no. or serial no.:

The device has been operated with the following medium:

BATCHFLUX 5500 C

This medium is: water-hazardous

toxic

caustic

flammable

We checked that all cavities in the device are free from such

substances.

We have flushed out and neutralized all cavities in the

device.

We hereby confirm that there is no risk to persons or the environment through any residual media

contained in the device when it is returned.

Date: Signature:

Stamp:

5.4 Disposal

CAUTION!

Disposal must be carried out in accordance with legislation applicable in your country.

20

www.krohne.com 05/2014 - 4000827703 - HB BATCHFLUX 5500 R03 en

Page 21

BATCHFLUX 5500 C

6.1 Measuring principle

An electrically conductive fluid flows inside an electrically insulated pipe through a magnetic

field. This magnetic field is generated by a current, flowing through a pair of field coils.

Inside of the fluid, a voltage U is generated:

U = v * k * B * D

U = v * k * B * D

U = v * k * B * DU = v * k * B * D

in which:

v = mean flow velocity

k = factor correcting for geometry

B = magnetic field strength

D = inner diameter of flow meter

The signal voltage U is picked off by electrodes and is proportional to the mean flow velocity v

and thus the flow rate q. A signal converter is used to amplify the signal voltage, filter it and

convert it into signals for totalising, recording and output processing.

TECHNICAL DATA 6

Figure 6-1: Measuring principle

1 Induced voltage (proportional to flow velocity)

2 Electrodes

3 Magnetic field

4 Field coils

www.krohne.com05/2014 - 4000827703 - HB BATCHFLUX 5500 R03 en

21

Page 22

6 TECHNICAL DATA

6.2 Technical data

INFORMATION!

•

The following data is provided for general applications. If you require data that is more

relevant to your specific application, please contact us or your local sales office.

•

Additional information (certificates, special tools, software,...) and complete product

documentation can be downloaded free of charge from the website (Download Center).

Measuring system

Measuring principle Faraday's law

Application range Electrically conductive fluids

Measured value

Measured value

Measured valueMeasured value

Primary measured value Flow velocity

Secondary measured value Volume flow

Design

Features Tube: Zirconium oxide

Modular construction The measurement system consists of a flow sensor and a signal

Compact version BATCHFLUX 5500 C

Nominal diameter DN2.5...40 / 0.1...1½"

Measurement range -12...+12 m/s / -39...+39 ft/s

User interface

User interface

User interfaceUser interface

Operating data Factory set to customer specification.

Human Machine Interface (HMI) Option: BATCHMon Plus software

Cable connections Standard; 1x M12, 5-pin connector

BATCHFLUX 5500 C

Electrodes: Fused-in cermet (DN2.5...15) / Platinum (DN25...40)

Standard wet calibration

converter. It is only available as compact version.

With status output; 1x M12, 8-pin connector

22

www.krohne.com 05/2014 - 4000827703 - HB BATCHFLUX 5500 R03 en

Page 23

BATCHFLUX 5500 C

Measuring accuracy

Reference conditions Medium: water

Error limits at reference conditions for tap water, 400

Error limits at reference conditions for tap water, 400 µS/cm, 20

Error limits at reference conditions for tap water, 400Error limits at reference conditions for tap water, 400

Maximum measuring error DN2.5...6:

Repeatability DN2.5...6 / DN25...40:

Error limits at reference conditions for hot water, 400

Error limits at reference conditions for hot water, 400 µS/cm, 80

Error limits at reference conditions for hot water, 400Error limits at reference conditions for hot water, 400

Maximum measuring error DN10...15:

Repeatability DN10...15:

TECHNICAL DATA 6

Inlet / outlet section: 10 DN / 5 DN

Valve closing time variation: < 1 ms

Flow velocity: 1 m/s, flow conditions similar to EN 29104

Operating pressure: 1 bar / 14.5 psi

S/cm, 20°C / 68

S/cm, 20S/cm, 20

DN2.5...6:

DN2.5...6:DN2.5...6:

v ≤ 1 m/s: ±0.4% of measured value + 1 mm/s

v > 1 m/s: ±0.5% of measured value

DN10...15:

DN10...15:

DN10...15:DN10...15:

±0.2% of measured value + 1 mm/s

DN25...40:

DN25...40:

DN25...40:DN25...40:

v ≤ 1 m/s: ±0.2% of measured value + 1 mm/s

v > 1 m/s: ±0.3% of measured value

DN2.5...6 / DN25...40: Standard deviation:

DN2.5...6 / DN25...40:DN2.5...6 / DN25...40:

Filling time 1.5...3 s: ≤ 0.4%

Filling time 3...5 s: ≤ 0.2%

Filling time > 5 s: ≤ 0.1%

DN10...15:

DN10...15: Standard deviation:

DN10...15:DN10...15:

Filling time 1.5...3 s: ≤ 0.3%

Filling time 3...5 s: ≤ 0.15%

Filling time > 5 s: ≤ 0.08%

S/cm, 80°C / 176

S/cm, 80S/cm, 80

DN10...15:

DN10...15:DN10...15:

±0.2% of measured value + 1 mm/s

DN10...15: Standard deviation:

DN10...15:DN10...15:

Filling time 1.5...3 s: ≤ 0.3%

Filling time 3...5 s: ≤ 0.2%

Filling time > 5 s: ≤ 0.1%

C / 68°FFFF:

C / 68C / 68

Standard deviation:

Standard deviation:Standard deviation:

Standard deviation:

Standard deviation:Standard deviation:

C / 176°FFFF:

C / 176C / 176

Standard deviation:

Standard deviation:Standard deviation:

www.krohne.com05/2014 - 4000827703 - HB BATCHFLUX 5500 R03 en

23

Page 24

6 TECHNICAL DATA

Operating conditions

Temperature

Temperature

TemperatureTemperature

Process temperature Dependent on ambient temperature. See chapter "Temperatures".

Cleaning temperature SIP: Maximum 1 hour at 150°C / +302°F

Shock ≤ 3K/s

Ambient temperature -40…+60°C/ -40…+140°F

Storage temperature -50…+70°C/ -58…+158°F

Pressure

Pressure

PressurePressure

Ambient Atmospheric

Process pressure up to 16 bar / 232 psi for DN10...15

Vacuum load 0mbara / 0psig

Chemical properties

Chemical properties

Chemical propertiesChemical properties

Physical condition Liquids

Electrical conductivity ≥ 5 μS/cm (≥ 20 μS/cm for demineralised water)

Recommended flow velocity -12...+12 m/s / -39...+39 ft/s

BATCHFLUX 5500 C

CIP: Maximum 1 hour at 140°C / +284°F

up to 40 bar / 580 psi for DN2.5...6 / DN25...40

Installation conditions

Installation For detailed information see chapter "Installation".

Inlet run ≥ 5 DN

Outlet run ≥ 2 DN

Dimensions and weights For detailed information see chapter "Dimensions and weights".

Materials

Sensor- and converter housing Stainless steel 1.4404 / 1.4408

Measuring tube Fused in-place

Measuring electrodes DN2.5...15: Cermet

DN25...40: Platinum

Process connections

Connection Sandwich design

Optional: Pressure relief groove at flange facing of the sensor

Construction drawings of recommenced counter flanges are

available from download centre.

24

www.krohne.com 05/2014 - 4000827703 - HB BATCHFLUX 5500 R03 en

Page 25

BATCHFLUX 5500 C

Electrical connections

Power supply 24 VDC ± 25%

Power consumption ≤ 3 W

Switch on current ≤ 5 A (< 100 μs) at 24 VDC

Voltage loss Possible for a maximum of 20 ms according to NAMUR NE21.

BATCHMON Plus For parameter setting and diagnostic purposes, communication via

Status output Configurable; error, flow direction, on/off

Frequency output

Frequency output

Frequency outputFrequency output

Type Frequency (passive) / galvanically isolated from power supply

Function All operating data preset at factory.

Interval Counter gate time ≥ 1000 / (P

Frequency output ≤ 10 kHz

Pulse width at full scale value ≤ 10 Hz: 50, 100, 200 or 500 ms

Passive operation Connection of electronic or electromechanical counters.

Low flow cut-off Threshold: 0...20%

TECHNICAL DATA 6

PC with a single device (optional)

[Hz])

100%

> 10 Hz: automatic, pulse width = 1 / (2 x f

External voltage: ≤ 30 VDC / ≤ 24 VAC

Load: I

Hysteresis: 0...20%

Hysteresis ≤ threshold

Depending on customers specifications.

max

≤ 20 mA

) or symmetrical, 1:1

100%

Approvals and certifications

CE

CE

CECE

This device fulfills the statutory requirements of the EC directives.

The manufacturer certifies successful testing of the product by

applying the CE mark.

Electromagnetic compatibility Directive: 2004/108/EC

Harmonized standard: EN 61326-1: 2006

Low voltage directive Directive: 2006/95/EC

Harmonized standard: EN 61010: 2010

Pressure equipment directive Directive: 97/23/EC

Category SEP

Fluid group 1

Production module H

Other approvals and standards

Other approvals and standards

Other approvals and standardsOther approvals and standards

Protection category acc. to

IEC 529 / EN 60529

Shock test IEC 60068-2-27

Vibration test IEC 60068-2-64

Hygienic DN2.5...15: 3A

DN2.5...6 / DN25...40: IP 66/67

DN10...15: IP 69K

FDA approved materials

www.krohne.com05/2014 - 4000827703 - HB BATCHFLUX 5500 R03 en

25

Page 26

6 TECHNICAL DATA

6.3 Dimensions and weights

DN2.5...6

Figure 6-2: Dimensions

1 (Grounding)

2 M12; 5 - 8 pins connector

BATCHFLUX 5500 C

Nominal

size

Dimensions [mm] Weight

[kg]

a b c d e f g h i

DN2.5 50 156 206 6 → 2.5 44 88 141 128 54 1.5

DN4 50 156 206 7 → 3.2 44 88 141 128 54 1.6

DN6 50 156 206 9 → 4.8 44 88 141 128 54 1.6

Note on dimension d: As the diameter reduces to the middle, the diameter is specified for the inlet and

for the middle

Nominal

size

Dimensions [inches] Weight

[lb]

a b c d e f g h i

1/10" 1.97 6.14 8.11 0.24 → 0.10 1.73 3.46 5.55 5.0 2.13 3.4

1/6" 1.97 6.14 8.11 0.28 → 0.13 1.73 3.46 5.55 5.0 2.13 3.6

1/4" 1.97 6.14 8.11 0.35 → 0.19 1.73 3.46 5.55 5.0 2.13 3.6

Note on dimension d: As the diameter reduces to the middle, the diameter is specified for the inlet and

for the middle

26

www.krohne.com 05/2014 - 4000827703 - HB BATCHFLUX 5500 R03 en

Page 27

BATCHFLUX 5500 C

DN10...15

1 (Grounding)

2 M12; 5 - 8 pins connector

TECHNICAL DATA 6

Nominal

size

Dimensions [mm] Weight

[kg]

a b c d e f g h i

DN10 50 140 179 10.5 → 8 45.4 60 106.5 88 54 1.4

DN15 50 140 179 14 → 12 45.4 60 106.5 88 54 1.4

Note on dimension d: As the diameter reduces to the middle, the diameter is specified for the inlet and

for the middle

Nominal

size

Dimensions [inches] Weight

[lb]

a b c d e f g h i

3/8" 1.97 5.51 7.05 0.41 → 0.31 1.79 2.36 4.19 3.46 2.13 3.1

1/2" 1.97 5.51 7.05 0.55 → 0.47 1.79 2.36 4.19 3.46 2.13 3.1

Note on dimension d: As the diameter reduces to the middle, the diameter is specified for the inlet and

for the middle

www.krohne.com05/2014 - 4000827703 - HB BATCHFLUX 5500 R03 en

27

Page 28

6 TECHNICAL DATA

DN25..40

Figure 6-3: Dimensions

1 (Grounding)

2 M12; 5 - 8 pins connector

BATCHFLUX 5500 C

Nominal

Dimensions [mm] Weight [kg]

size

a b c d e f g h i

DN25 50 170 204 26 → 20 68 102 141 128 58 1.6

DN40 50 177 219 39 → 30 84 117 141 128 83 2.3

Note on dimension d: As the diameter reduces to the middle, the diameter is specified for the inlet and

for the middle

Nominal

Dimensions [inches] Weight [lb]

size

a b c d e f g h i

1" 1.97 6.69 8.03 1.02 → 0.79 2.68 4.02 5.55 5.04 2.28 3.6

1 1/2" 1.97 6.97 8.62 1.54 → 1.18 3.30 4.61 5.55 5.04 3.27 5.1

Note on dimension d: As the diameter reduces to the middle, the diameter is specified for the inlet and

for the middle

28

www.krohne.com 05/2014 - 4000827703 - HB BATCHFLUX 5500 R03 en

Page 29

BATCHFLUX 5500 C

6.4 Counter Flanges

The BATCHFLUX 5500 can be mounted between various types of counter flanges.

TECHNICAL DATA 6

Sizes of flanges

DN a [mm] b [mm] c [mm] d [mm] O-ring

Flange 1 2,5...10 * see table

below

Flange 2 15 Ø 14.2 Ø 19.2 Ø 26.6 Ø 30.4 15.47 *

Flange 3 25 Ø 25 Ø 31.3 Ø 41.2 Ø 49.2 15.47 *

Size DN

2,5 Ø 10 Ø 6.2 Ø 11.1 Ø 18.4

4 Ø 10 Ø 7.2 Ø 12.1 Ø 19.4

6 Ø 10 Ø 9.2 Ø 14.2 Ø 21.5

10 Ø 10 Ø 10.7 Ø 15.7 Ø 23

a1[mm] a2 [mm]

* see table below * see table

below

b [mm] c [mm]

Ø 30.4 Special L-

ring

3.53

3.53

Note; flanges must be fully welded and surface roughness, grinded and polished ( roughness

0,8). See for more information the 3A CCE 2007-2 Coordination Bulletin.

INFORMATION!

The O-rings require periodic inspection and replacement. As the interval depends on processspecific variables, the length of the interval cannot be specified.

The O-rings are not part of the portfolio of KROHNE.

INFORMATION!

For 3A applications, O-rings must conform to the requirements of the 3A sanitary standard for

Flow meters, number 28-04 Class I or Class II (max. 8% milk fat).

The used O-rings must also withstand the processing, sterilization and chemical conditions for

the intended use ( for more information, contact the manufacturer)

www.krohne.com05/2014 - 4000827703 - HB BATCHFLUX 5500 R03 en

29

Page 30

6 TECHNICAL DATA

Reference to specific dimensions and drawing numbers

Size DN Pcd [mm] D [mm] W [mm] Drawing number

2,5 Ø 56 Ø 68 14.5 4000587801

4 Ø 56 Ø 68 14.5 4000587807

6 Ø 56 Ø 68 14.5 4000587810

10 Ø 56 Ø 68 14.5 4000587815

15 Ø 56 Ø 68 14.9 4000587818

25 Ø 84 Ø 104 16.5 4000587824

40 # # # #

# Dimensions for DN40; on request

INFORMATION!

Detailed construction drawings of the above sketches are available from the download centre

( see table for drawing numbers)

BATCHFLUX 5500 C

30

www.krohne.com 05/2014 - 4000827703 - HB BATCHFLUX 5500 R03 en

Page 31

BATCHFLUX 5500 C

NOTES 7

www.krohne.com05/2014 - 4000827703 - HB BATCHFLUX 5500 R03 en

31

Page 32

KROHNE product overview

• Electromagnetic flowmeters

• Variable area flowmeters

• Ultrasonic flowmeters

• Mass flowmeters

• Vortex flowmeters

• Flow controllers

• Level meters

• Temperature assemblies

• Pressure transmitters

• Analysis products

• Products and systems for the oil & gas industry

• Measuring systems for the marine industry

Head Office KROHNE Messtechnik GmbH

Ludwig-Krohne-Str. 5

47058 Duisburg (Germany)

Tel.:+49 203 301 0

Fax:+49 203 301 103 89

info@krohne.com

© KROHNE 05/2014 - 4000827703 - HB BATCHFLUX 5500 R03 en - Subject to change without notice.

The current list of all KROHNE contacts and addresses can be found at:

www.krohne.com

Loading...

Loading...