Page 1

© KROHNE 7.30925.31.00

07.03.2003

Installation and

operating instructions

BATCHFLUX 5015 K

Compact electromagnetic

flowmeters

Please note!

Do not open the housing of the BATCHFLUX IFM 5015 K.

Danger of contamination with substances likely to destroy the

moisture barrier of the electronic equipment (e.g. if CIP or SIP

cleaned from the outside).

Therefore, please contact your KROHNE Service engineer

before you open the housing.

Page 2

Contents

System description 4

Standards and approvals 4

Product liability and warranty 4

Functional description BATCHFLUX IFM 5015 K 5

Part A System installation and start-up 6 - 16

1 Installation in the pipeline 6 - 11

1.1 Important information 6

1.2 Suggestions for installation 7

1.3 Installation requirements 8-9

1.3.1 Position of flange 9

1.3.2 Example: centering and sealing the primary head 9

1.3.3 Grounding 9

1.4 Installation of the primary head 10

1.4.1 Device description 10

1.4.2 Installation of the IFM 5015 K 10

1.5 Size of connections 11-12

1.5.1 Fastening with tie bolts 11

1.5.2 Fastening with tie bolts (option) 12

2 Electrical connection 13 - 14

2.1 Important information 13

2.2 Attachment plugs 13

2.3 Power supply and outputs 14

3 Start-up 15 - 16

3.1 Checking for availability 15

3.2 Factory settings 16

Part B IFC 015 signal converter 17 - 34

4 Operator control of signal converter with the HHT 010 17 - 27

4.1 Operator control concept 17

4.2 Operating and check elements 18

4.3 Function of keys 18 - 19

4.4 Table of settable functions 20 - 24

4.5 Error messages in measuring mode 25

4.6 Resetting totalizers and deleting error messages, RESET / QUIT menu 26

5 Description of functions 28 - 35

5.1 Full-scale range Q

5.2 Time constant 28

5.3 Low-flow cutoff 28

5.4 Display with HHT 010 29

5.5 Internal electronic totalizer 30

5.6 Current output I 30

5.7 Pulse output P 30 - 31

5.8 Status output S (option) 32

5.9 Language 32

5.10 Entry code 33

5.11 Primary head 33

5.12 User-definable unit 34

5.13 F/R mode, forward / reverse flow measurement 35

5.14 Characteristic of outputs 35

28

100%

Installation and operating instructions 2 BATCHFLUX

Page 3

Part C Special applications, functional checks, and service 36 - 42

6 Special applications 36

6.1 RS 232 adapter and KROHNE software (option) 36

6.2 Operation via HHT 010 hand-held terminal (option) 36

7 Functional checks 37 - 39

7.1 Zero check with signal converter IFC 015 37

7.2 Test of measuring range Q, Fct. 2.1 38

7.3 Hardware information and error status, Fct. 2.2 39

8 Service 40 - 41

8.1 Important advice for removing the flowmeter from the pipeline – PLEASE NOTE 40

8.2 Removal from the pipe system 40

8.3 Removal of the electronics unit 41

8.4 Restart 41

9 Illustrations of printed circuit boards 42

Part D Technical Data, block diagram and measuring principle 43 - 49

10 Technical data 43 - 47

10.1 Flow during filling and fill volume 43

10.2 Flowmeters 43

10.3 Signal converter 44

10.4 Error limits at reference conditions 45

10.5 Dimensions and weights 46 - 47

10.6 Instrument nameplates 47

11 Block diagram 48

12 Measuring principle 49

Part E Annex 50 - 52

E1 Index 50 - 51

E2 Form to accompany returned device 52

Please note!

Do not open the housing of the BATCHFLUX IFM 5015 K.

Danger of contamination with substances likely to destroy the moisture barrier of the electronic

equipment (e.g. if CIP or SIP cleaned from the outside).

Therefore, please contact your KROHNE Service engineer before you open the housing.

Installation and operating instructions

BATCHFLUX

3

Page 4

System description

The BATCHFLUX IFM 5015 K compact electromagnetic flowmeter is a precision instrument

designed for the linear flow measurement of liquid products.

The products need to be electrically conductive:

> 5 µS/cm (except for water)

> 20 µS/cm (for water)

The full-scale range Q

DN 2.5 – 40 and

This is equivalent to a flow velocity of 0.3 - 12 m/s.

Standards and approvals

BATCHFLUX IFM 5015 K with the IFC 015 signal converter meets the EU-EMC Directives and

•

bears the CE and 3A symbol.

The 3A approval accepts only adapters shown in Sect. 1.5.

•

All factories and production sequences are ISO 9001 certified.

•

1

/10” – 11/2” Q

can be set as a function of the meter size:

100%

= 0.0015 - 15 l/s

100%

Product liability and warranty

The compact BATCHFLUX IFM 5015 K electromagnetic flowmeter is designed exclusively for

measuring the volumetric flowrate of electrically conductive, liquid process products.

The compact flowmeter is not suitable for use in hazardous areas. Other flowmeter series are

available for such applications.

Responsibility as to suitability and intended use of this compact electromagnetic flowmeter rests

solely with the operator.

Improper installation and operation of the flowmeters (systems) may lead to loss of warranty.

In addition, the “General conditions of sale“ forming the basis of the purchase contract are

applicable.

If BATCHFLUX IFM 5015 K flowmeters need to be returned to KROHNE, please note the

information given on the last-but-one page of these instructions. KROHNE regret that they cannot

repair or check your flowmeter(s) unless these are accompanied by the completed form sheet.

Installation and operating instructions 4 BATCHFLUX

Page 5

Functional description

BATCHFLUX IFM 5015 K

The volume to be filled into the container is

measured “in line“ by means of the

electromagnetic flowmetering system. The

batch controller closes the filling valve once

the preset filling volume has been reached.

It is always the preset target volume that is

filled into the container.

The signal converter converts the measured

flowrate signal into volume pulses that are

intelligible to the batch controller. For a filling

volume of 1000 ml, for example, this could

be 10 pulses per ml; in other words, the

batch controller switches the valve off after

1000 pulses have been received.

The influence of valve closing times and

other dynamic factors can be corrected by

the adaptive corrector of the batch controller.

The use of state-of-the-art microprocessor

electronics and the high-speed analog/digital

converter also enables changes in the

flowrate to be sensed precisely. This

technology ensures high reproducibility and

long-term stability.

Feed tank

(pressurized if liquid

contains CO2)

Flowmeter

BATCHFLUX

Valve

Container

bottle, tin, keg, paper or

plastic container

(pressurized if liquid

contains CO2)

e.g. 10 pulses per ml

pulses per

volumes

valve control signal

on

off

open

valve

filling time t

Start command

when container is ready

for filling

F

close

valve

External communication

(preselection,

measuring error correction)

Installation and operating instructions

BATCHFLUX

5

Page 6

1

Part A System installation and start-up

1 Installation in the pipeline

1.1 Important information

The following recommendations should be observed to ensure proper functioning of the

flowmeter – PLEASE NOTE.

Measuring tube must be completed

•

filled at all times.

Direction of flow: the red arrow on the

•

housing of the primary head must point in

the direction of flow. If for structural

reasons the flowmeter can only be installed

counter to the direction of flow, the direction

of flow measurement can be

reprogrammed.

Stud bolts and nuts: to fit, make sure

•

there is sufficient room next to the pipe

flanges.

Vibration: support the pipeline on both

•

sides of the flowmeter. Vibration level to

IEC 068-2-34: below 2,2g in the

20 - 2000 Hz frequency range.

Radiant heat: avoid e.g. from hot product

•

tanks, insulate if necessary.

Avoid strong electromagnetic fields

•

in vicinity of flowmeter.

Straight Inlet run ≥ 5 x DN and straight

•

outlet run ≥ 2 x DN, measured from the

electrode axis (DN = meter size).

Vortex or corkscrew flow: increase

•

length of inlet and outlet runs or install flow

straighteners.

Mixing different process liquids: install

•

flowmeter upstream of mixing point or at an

adequate distance downstream, minimum

of 30 x DN (DN = meter size), otherwise

display may be unsteady.

Plastic pipes and internally coated metal

•

pipes: grounding rings required, see

“Grounding“, Section 1.3.3.

Heat-insulated pipelines: do not insulate

•

flowmeter.

Zero setting: not required. For checking

•

purpose, see Section. 7.1, it should be

possible to set “zero“ flow velocity in the

completely filled measuring tube. Shutoff

valves should therefore be provided either

downstream or upstream and downstream

of the flowmeter.

Ambient temperature

•

-25°C to +60°C

Process temperature

•

max. 140 °C

Transport and storage temperature

•

-25°C to +60°C

Limits imposed by the material used for the

measuring tube for process temperature,

thermal shock limit, pressure and vacuum, see

Section 10.2 “Limits“.

Please note!

The ceramic measuring tube must not contact

metal parts (flange, pipeline). This can destroy

the flowmeter!

Installation and operating instructions 6 BATCHFLUX

Page 7

A

1.2 Suggestions for installation

To avoid measuring errors due to

air inclusion and vacuum, please

observe the following:

Highest point of pipe run

(Air bubbles collect in measuring

tube - faulty measurements!)

Preferred

locations

downpipe

(open discharge)

void draining or partial filling of

the measuring tube. Faulty

measurements.

1

Pumps

Do not install flowmeter on pump suction side

Open feed or discharge

Install meter in low section of pipe

open discharge

Selecting the installation location

Location and position as required, but

electrode axis (X – – – – X

must be approximately horizontal in a

horizontal pipe run.

Horizontal pipe run

Install in slightly descending pipe section to

prevent air from collecting, so avoiding faulty

measurements and that meter can drain.

Control and shutoff valves: always install

behind the flowmeter

x

Direction of flow The red arrow on the

primary head housing must point in the flow

direction.

On high-temperature pipes and

where process temperatures

exceed 100 °C, provide facilities to

compensate for longitudinal

expansion on heat-up of the pipeline.

Use flexible pipe elements (e.g.

elbows).

x

Installation and operating instructions

BATCHFLUX

7

Page 8

1

1.3 Installation requirements

Items supplied with flowmeter

BATCHFLUX IFM 5015 K compact

•

flowmeter in the version as ordered

Installation and operating instructions,

•

as agreed

Certificate of system calibration data

•

(as agreed)

Excluding fitting accessories. Stud bolts,

gaskets, etc., to be provided by customer.

All operating data and function values

are factory set according to your order

specifications.

its conical in/outlet.

DIN 2501

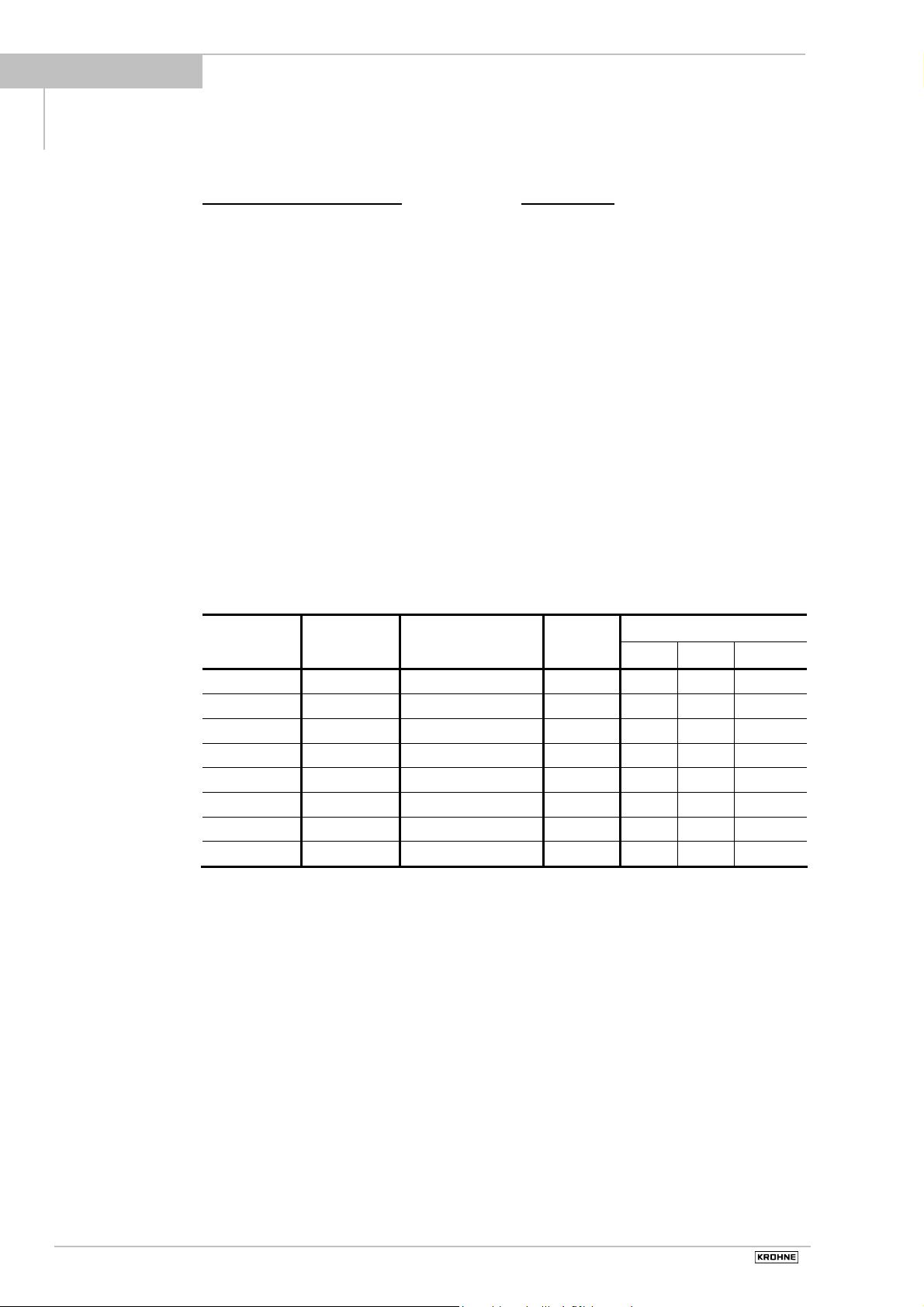

and JIS pipe flanges Nm kpm ft × lbf

DN 2.5

DN 4

DN 6 1/4" 51.8 mm (2.04") 4 x M12 10 1.0 7.2

DN 10 3/8" 51.8 mm (2.04") 4 x M12 10 1.0 7.2

DN 15 1/2" 51.8 mm (2.04") 4 x M12 10 1.0 7.2

DN 25 1" 58.0 mm (2.28") 4 x M12 10 1.0 7.2

DN 32 11/4“ 83.0 mm (3.27“) 4 xM16 43 4.3 31.0

DN 40 1 1/2" 83.0 mm (3.27") 4 x M16 43 4.3 31.0

ANSI B 16.5 Space between Bolts Max torque

1

1

/10" 51.8 mm (2.04") 4 x M12 10 1.0 7.2

/8" 51.8 mm (2.04") 4 x M12 10 1.0 7.2

Requirements

Use in the food industry

The IFM 5015 K is specifically suitable for use

in the food and beverage industry or similar

sterile processes.

The IFM 5015 K is steam-resistant and can be

pigged.

The measuring tube can be SIP or CIP

cleaned when in installed condition. During the

cleaning the meter(s) must be switched off to

maintain the reliability of the unit(s).

• Operating pressure, type, and space

between pipe flanges: see Table.

• Tighten stud bolts uniformly down to the

metal stop in diagonally opposed

sequence. See Table for type and number

of stud bolts.

• Install meter vertically or in a slope due to

On DN 15 (

BATCHFLUX with straight ceramic tube is

available.

1

/2”) and DN 32 (11/4”), a

Installation and operating instructions 8 BATCHFLUX

Page 9

R

1.3.1 Position of flanges

Install flowmeter in line with the pipe axis. Pipe

flange faces must be parallel to each other,

max. allowable deviation:

L

– L

max

1.3.2 Example: centering and sealing

The primary head is centered between the pipe

flanges with the aid of the precise geometric

fitting (guide collar on primary head).

Detail drawings see Sect. 1.5.

≤ 0.5 mm ≤ 0.02"

min

the primary head

1.3.3 Grounding

V

R

FE

FE Functional ground, wire > 4 mm

R Pipeline

RF Pipe flanges

V Interconnecting wires,

bolted to the housing

Grounding is carried out via the functional

ground that is connected to the U-clamp

terminal (9). See also Section 2 “Electrical

connection“.

When connected to functional extra-low

voltages,

24 V DC, protective separation (PELV)

must be ensured (VDE 0100/VDE 0106 or

IEC 364/IEC 536).

All flowmeters must be properly

•

grounded.

The grounding wire should not

•

transmit any interference

voltages. Therefore do not ground

any other electrical device

simultaneously with this

conductor.

RF RF

V

2

Cu.

1

Installation and operating instructions

BATCHFLUX

9

Page 10

9

1

1.4 Installation of the primary head

1.4.1 Device description

4

10

8

5

11

12

13

14

BATCHFLUX IFM 5015 K

•

4 Cover, signal converter

5 Primary head

8 Connector for power and pulse output

(optionally: and status output)

9 U-clamp terminal for functional ground

10 Fastening screws for cover

11 Locating collar, primary head

Accessories from system manufacturer

•

12 O-ring gasket

13 Special pipe flange

14 Stud bolt with lock washer,

plain washer and nut

To facilitate servicing of the

primary head, please note the

following points:

It must be possible to shut off the flow

•

through the pipeline upsteam of the primary

head (provide shutoff valve),

Drain the pipe system before removing the

•

primary head (provide drain valve),

Support the pipeline on both sides of the

•

flowmeter when located in a long, freely

suspended section to facilitate removal of

the primary head.

6

1.4.2 Installation of the IFM 5015 K

Position gaskets (12) in the pipe flanges.

•

Type and location of gaskets as specified

•

by the manufacturer of the filling machine

(see Sect. 1.3.2 “Centering of the primary

head”).

Insert primary head (5) between the pipe

•

flanges (13) in line with the pipe axis.

For spacing and location of the pipe

•

flanges, see Sect. 1.3 “Position of flanges”.

Press pipe flanges against flowmeter.

•

Centering ring of pipe flanges must

snap into place in the guide collar

(11) of the primary head.

Insert stud bolts (14) with washers into the

•

holes in the pipe flanges. Fit nuts to stud

bolts with lock washer.

Tighten stud bolts and nuts down to the

•

metal stop symmetrically. Check all bolts

after starting up the pipe system, and

retighten when any leaks show.

Connect ground conductor to U-clamp

•

terminal (9).

Connect power supply and passive pulse

•

output to connector plugs (7, 8) on signal

converter housing (4).

See Section 2.2 and 2.3 for details of

electrical connection.

Installation and operating instructions 10 BATCHFLUX

Page 11

A

A

1.5 Size of connections

1.5.1 Fastening with tie bolts

All dimensions in mm (inches)

Flange-material: AISI 300 series

O-ring material: 3A standard 18-03

Meter size Centering device, pipe connection O-Ring Dimensions

DN inches d

1

2.5

/10 6 25.5 30

1

4

/8 7 25.5 30

1

6

/4

3

10

/8 12 25.5 30

1

15

/2 14 25.5 30

i

(0.24) (1.00) (1.18

(0.28) (1.00) (1.18

9 25.5 30

(0.35) (1.00) (1.18

(0.47) (1.00) (1.18

(0.55) (1.00) (1.18

25 1 26 37.5 71.3

(1.02) (1.48) (2.81

1

32

1

/

4

on request

40 11/2 on request

D1 D2 h 75 Shore k d

1.5

-0.05/-0.15

-0.05/-0.15

-0.05/-0.15

-0.05/-0.15

-0.05/-0.15

) (0.06

-0.002/-0.006

1.5

) (0.06

-0.002/-0.006

1.5

) (0.06

-0.002/-0.006

1.5

) (0.06

-0.002/-0.006

1.5

) (0.06

-0.002/-0.006

2

-0.1

) (0.08

–0.004

on request 60 8.5

-0.05/-0.15

-0.05/-0.15

-0.05/-0.15

-0.05/-0.15

-0.05/-0.15

) on request (2.36) (0.33)

-0.002/-0.006

on request 60 8.5

) on request (2.36) (0.33)

-0.002/-0.006

on request 60 8.5

) on request (2.36) (0.33)

-0.002/-0.006

on request 60 8.5

) on request (2.36) (0.33)

-0.002/-0.006

Ø 16×5 60 8.5

) (Ø 0.47×0.20) (2.36) (0.33)

-0.002/-0.006

Ø 28×5 80 8.5

+0.1

) (Ø 1.10×0.20) (3.15) (0.33)

+0.04

1

DN 2.5 - 15 / 1/10“ - 1/2“

DN 25 / 1“

A-A

DN 32-40 /

1

1

/4“-11/2“

Dimensions

on request

Installation and operating instructions

BATCHFLUX

11

Page 12

1

1.5.2 Fastening with bolts (option)

All dimensions in mm (inches)

* Flange-material : AISI 300 series

O-ring material : 3A standard 18-03

Meter size Centering device, pipe connection O-ring Screw thread (option)

gaskets 2× M4 4× M6

inches

DN

1

2.5

1

4

1

6

3

10

1

15

(0.55) (1.00) (1.18

d

D1 D2 h 75 Shore k d k d

/10 6 25.5 30

/8 7 25.5 30

/4 9 25.5 30

/8 12 25.5 30

/2 14 25.5 30

i

(0.24) (1.00) (1.18

(0.28) (1.00) (1.18

(0.35) (1.00) (1.18

(0.47) (1.00) (1.18

-0.05/-0.15

-0.002/-0.006

-0.05/-0.15

-0.002/-0.006

-0.05/-0.15

-0.002/-0.006

-0.05/-0.15

-0.002/-0.006

-0.05/-0.15

-0.002/-0.006

1.5

) (0.06

1.5

) (0.06

1.5

) (0.06

1.5

) (0.06

1.5

) (0.06

on request 60 8.5 56 6.4

-0.05/-0.15

-0.05/-0.15

-0.05/-0.15

-0.05/-0.15

-0.05/-0.15

) on request (2.36) (0.33) (2.20) (0.25)

-0.002/-0.006

on request 60 8.5 56 6.4

) on request (2.36) (0.33) (2.20) (0.25)

-0.002/-0.006

on request 60 8.5 56 6.4

) on request (2.36) (0.33) (2.20) (0.25)

-0.002/-0.006

on request 60 8.5 56 6.4

) on request (2.36) (0.33) (2.20) (0.25)

-0.002/-0.006

-0.002/-0.006

Ø 16×5

)

(Ø 0.47×0.20)

60 8.5 56 6.4

*

(2.36) (0.33) (2.20) (0.25)

*

Installation and operating instructions 12 BATCHFLUX

Page 13

2 Electrical connection

2.1 Important information

Be sure to take note of the following

information in order to ensure proper

functioning of the signal converter.

Please note:

1) Overvolta

In conformity with VDE 0120, equivalent

to IEC 664, the compact flowmeters are

designed for overvoltage category III in

the supply circuits and overvoltage

category II in the output circuits.

2) Safet

The compact flowmeters must be

provided with an isolating facility.

Electrical connection and repairs may only

be carried out by qualified personnel.

2.2 Attachment plugs

Manufacturer Series and type Description

Binder Series 715 Moulded plug, straight or

Series 763 Integrally extruded plug

Hirschmann E-Series

ELKA 4012 and

ELKA KV 4412

Lumberg RK-Series

RKC and RKCW Moulded plug, straight or

RKT and RKWG Integrally extruded plug

Amphenol Series C 164 P Moulded plug, straight or

Series C 164 P

Coninvers Series BC Moulded plug, straight

ge class:

y isolation:

ELWIKA 4012

and ELWIKA KV

4412

compact

angle-entry form

with cable in various

lengths

Moulded plug, straight or

angle-entry form

Integrally extruded plug

with cable in various

lengths

angle-entry form

with cable in various

lengths

angle-entry form

Integrally extruded plug

with cable in various

lengths

form, especially suitable

for high-interference

environments (keyword:

EMC)

Protect the flowmeter from direct radiant

•

heat (e.g. hot-product tanks), insulate if

necessary.

Do not expose flowmeter to intense

•

vibration. If necessary, support the

pipeline to the right and left of the

flowmeter. Level of vibration in accordance

with IEC 068-2-34: below 2.2g in the 20 2000 Hz frequency range.

Note information given on the instrument

•

nameplate, voltage.

The FE functional ground for the supply

•

power should for measurement reasons be

connected to the separate U-clamp

terminal on the signal converter housing.

When connected to a functional extra-

•

low voltage of 24 V DC, protective

separation (PELV) must be ensured (VDE

0100 / VDE 0106 or IEC 364 / IEC 536 or

equivalent national regulations)..

Pin-assignment and

alignment of

cable entry body

Detail

o

p

n

q

2

Installation and operating instructions

BATCHFLUX

13

Page 14

2

2.3 Power supply and outputs

Standard 4-pin connector M12x1 for 24 V DC power supply and passive pulse output

Pin Standard

1

2

3

4

Pin assignment

Pulse output

passiv

U

ext.

I

max

The pulse output is

galvanically isolated from

the 24 V power supply.

Pulse output

•

•

See also Sect. 3.2 “factory settings“.

•

•

counters connected, allow for minimum counting interval: counter gate time [s]

•

pulses per m³, litres, US gallons or user-defined unit

•

> 10 Hz: - automatic, pulse width

- symmetrical 1:1

Status output

•

•

See also Sect. 3.2 “factory settings“.

•

+ 24 V

pulse output

pulse output ⊥

ground

ground

pulse output

≤ 30 V DC / ≤ 24V AC

≤ 20 mA

All operating data and functions are settable (see Sect. 6).

All data and functions are factory-set to your specifications.

Connection of electronic totalizers.

Digital pulse division. Interpulse period non-uniform, therefore if frequency meters or cycle

Pulse rate for Q = 100% max. 10 kHz, fixed or optionally in

Pulse width ≤ 10 Hz: 50, 100, 200 or 500 ms

All operating data and functions are settable (see Sect. 6).

All data and functions are factory-set to your specifications.

Can be set to signal direction, errors or trip points.

power

24 Volt DC

p

o

q

n

=

f21×

100%

1000

≥

100%

[Hz]P

Installation and operating instructions 14 BATCHFLUX

Page 15

3 Start-up

Before powering the system, check that it has

been correctly installed according to Sections 1

and 2.

The compact flowmeter is delivered ready for

operational use. All operating data have been

factory set in accordance with your

specifications.

Power the unit, and the flowmeter will

immediately start process flow measurement.

3.1 Check for availability

Please note!

Do not open the housing of the BATCHFLUX IFM 5015 K.

Danger of contamination with substances likely to destroy the moisture barrier of the electronic

equipment (e.g. if CIP or SIP cleaned from the outside).

Therefore, please contact your KROHNE Service engineer before you open the housing.

The measurement status is signalled by the

•

light-emitting diodes (LED) below the cover

of the converter housing (see amplifier

board on right).

LED 1 LED 2 Function

flashing off in order

flashing flashing overdriving

on flashing Fatal Error

(defective operating

parameter)

off on defective hardware

off off no supply voltage

or hardware

is defective

LED 2

LED 1

3

Refer to Section 6 for operator control.

•

Furthermore, external facilities (hand-held

communicator HHT 010, PC, etc.) can be

connected on the pc board of the control

electronics via the IMoCom interface. This will

enable precise checking of the correct mode of

operation of the Batchflux IFM 5015 K.

All operating data can be set and stored by

means of a personal computer via the IMoCom

interface. The digital IMoCom interface allows

the complete filling procedure to be graphically

represented on the PC, thus providing

visualization of system and valve properties.

Installation and operating instructions

BATCHFLUX

15

Page 16

3

3.2 Factory settings

All operating data are factory-set according to

your order specifications.

To facilitate easy and rapid initial start-up,

pulse output is - unless specified otherwise set to process flow measurement in “2 flow

directions“ so that the current flowrate is

displayed and the volumetric flow counted

independent of the direction of flow.

Table of standard factory settings

Function Setting

1.1 Full-scale range Q

1.2 Time constant 3 s, for S (option)

1.3 Low-flow cutoff SMU

(do not change setting!)

1.4 Display

1.5 Current output I (NO HARDWARE !)

(function must be set to “OFF“!)

1.6 Pulse output P

Function

Pulse value

Pulse width

1.7 Status output (NO HARDWARE !)

(function must be set to “OFF“!)

3.1 Language for display only English (or other)

3.2 Flowmeter

Size

Flow direction (see arrow on primary head)

3.4 Entry code no

3.5 User-definable unit Liter/h

100%

The factory setting for the current and pulse

outputs may occasionally cause measuring

errors, particularly in the case of volume flow

counting. For example, if pumps are switched

off and a “backflow“ occurs that is not within

the range of the low-flow cutoff (SMU), or if

separate displays and counts are required for

both flow directions. To avoid faulty

measurements, therefore, it may be necessary

to change the factory setting of some or all of

the following functions:

low-flow cutoff SMU, Fct. 1.3

•

pulse output P, Fct. 1.6

•

see instrument

nameplate

ON: 4 %

OFF: 5 %

OFF

1 direction

1000 pulses/s

automaticly

OFF

see instrument

nameplate

+ direction

Installation and operating instructions 16 BATCHFLUX

Page 17

↑

↵

↵

Part B IFC 015 signal converter

4 Operator control of signal converter with

HHT 010 (option)

4.1 Operator control concept

Please note!

Do not open the housing of the BATCHFLUX IFM 5015 K.

Danger of contamination with substances likely to destroy the moisture barrier of the electronic

equipment (e.g. if CIP or SIP cleaned from the outside).

Therefore, please contact your KROHNE Service engineer before you open the housing.

136.49

m3/hr

→

Measuring mode

CodE 1

When this displayed, press following

keys: → → → ↵ ↵ ↵ ↑ ↑ ↑

4

Menu column Function column Data column

3.0 INSTALL.

2.2 HARDW. INFO

2.0 TEST

3.5 USER UNIT

3.4 ENTRY CODE

3.3 ZERO SET

3.2 FLOWMETER

3.1 LANGUAGE

2.1 TEST Q

1.7 IND.OUTP. S

1.6 PULS.OUTP. P

1.5 CUR.OUTP. I

1.4 DISPLAY

1.3 L.F.CUTOFF

no

HARDWARE!

no

HARDWARE!

1.0 OPERATION 1.1 FULLSCALE

Direction of movement

↑

1.2 TIMECONST.

↓

Installation and operating instructions

→

See

↓

→

Sect.

4 + 5

BATCHFLUX

17

Page 18

↵

4

4.2 Operating and check

elements

The following operating elements are featured

on the hand-held communicator HHT 010:

HHT 010

+ –

Totalizer

190.47

m3/hr

I P

Overrange

→

M M M M M M

Flow-

rate

← → ↵ ↑ ↓

Display, 1st line

Display, 2nd line

Display, 3rd line: arrows to

identify

display

Flowrate current flowrate

Totalizer + totalizer

– totalizer

∑ sum totalizer (+ and –)

Overrange I overranging, current output

I

P overranging, pulse output P

Keys for operator control of signal

converter

Compass field, signals actuation of a key

4.3 Function of the keys

The cursor, flashing part of display, has a

y background in the following descriptions.

gre

To start operator control

Measuring mode

Operator

control mode

O P E R A T I O N

PLEASE NOTE: when “YES“ is set

under Fct. 3.4 ENTRY CODE,

“CodE 1 - - - - - - - - - “ appears in the

display after pressing key

Now enter the 9-keystroke Entry Code 1:

→ → → ↵ ↵ ↵ ↑ ↑ ↑

(each keystroke acknowledged by “ * “).

To terminate o

perator control

Press key ↵ repeatedly until one of the

following menus Fct. 1.0 OPERATION, Fct.

2.0 TEST

or Fct. 3.0 INSTALL. is displayed.

Press key

↵

S T O R E Y E S

Store new parameters:

Confirm by pressing key

continued with the new parameters.

Do not store new

Press key

↑

parameters:

to display “STORE.NO“.

Measuring mode continued with the “old“

parameters after pressing key

1 3 . 5 7 1

3

/ h r

m

→

F c t . 1. 0

→ .

F c t . 3. 0

I N S T A L L.

↵ . Measuring mode

↵ .

Installation and operating instructions 18 BATCHFLUX

Page 19

↑

←

↑

←

↵

↵

To chan

Increase number

Decrease number

To shift cursor

Shift to right

Shift to left

To alter texts

For units, the numerical value is

converted automatically

Select previous text

To transfer from text

Change to number setting

Return to text setting

To transfer to subfunction

Subfunctions do not have a “Fct. No.“ and are identified by a “→“.

To revert to function dis

ge numbers

(flashing position)

(units)

3 9 7. 3 5

m3 / h r

3 9 7. 3 5

m3 / h r

Select next text

3. 7 6 9 9

L i t e r / S e c

(unit) to number setting

1 3. 5 7 1

3

m

/ h r

1 D I R.

play

1 0. 3

S e c

↓

→

↓

→

3 9 7. 4 5

m3 / h r

3 9 7. 3 5

m3 / h r

9 3. 3 6 5

U S. G a l / m i n

1 3. 5 7 1

3

m

/ h r

→

R A N G E I

F c t. 1. 2

T I M E C O N S T.

4

Installation and operating instructions

BATCHFLUX

19

Page 20

4

4.4 Table of settable functions

100%

100%

100%

100%

/ max. full-scale range

max

) at v

) at v

= 12 m/s

max

/ min. full-scale range

min

= 0,3 m/s

min

Abbreviatioins used

DN Nominal size, meter size

F

Highest frequency of the pulse output

max

F

Lowest frequency of the pulse output

min

FM Conversion factor volume for any unit,

see Fct. 3.5 “FACT.VOL.“

F

Conversion factor time for any unit,

T

see Fct. 3.5 “FACT.TIME“

GKL Primary constant

I Current output (no HARDWARE)

P Pulse output

= F

P

max

max

/ Q

P

min

= F

min

/ Q

Q actual flow rate

Q

100% flow =

100%

full-scale range

Q

max

(Q

Q

min

(Q

π

= DN2 × v

4

π

= DN2 × v

4

S Status output (no HARDWARE)

SMU Low-flow cutoff for I and P

v Flow velocity

v

Max. flow velocity (12 m/s)

max

at Q

100%

Min. flow velocity (0,3 m/s)

v

min

at Q

100%

F/R Forward/reverse flow in F/R mode

Fct. Text Description and settings

1.0 OPERATION Operations menu

1.1 FULL.SCALE

→ VALUE P

1.2 TIME CONST. Time constant

Full-scale range for

flowrate Q

Select unit

3

• m

/hr • Liter/Sec

• US.Gal/min

• user unit,

factory set is “Liter/hr“

(see Fct. 3.5)

Press key → to transfer to

number setting!

g ranges

Settin

The ranges are dependent on

the meter size (DN) and the

flow velocity (v):

= DN2 x v

Q

min

Q

= DN2 x v

max

• BATCHFLUX IFM 5015 K :

0.0053 – 54 m

0.0015 – 15 Liter/Sec

0.02377 – 237.7619

US.Gal/min

Press key ↵ to return to

Fct. 1.1 FULL SCALE.

Change pulse value

(see Fct. 1.6 “VALUE P“)

Appears only when

“PULSE/VOL.“ set under

Fct. 1.6 “SELECT. P“ and the

output frequency (F) has been

over- or undershot:

P

= F

min

P

= F

max

Selection:

• ALL (applies to display and

all outputs)

• ONLY I+S (display, current

and status outputs only, no

current output)

Press key ↵ to transfer to

number setting!

ge:

Ran

• 0.2 – 99.9 Sec

Press key ↵ to return to

Fct.1.2 TIMECONST.

100%

π

4

π

4

min

max

/ Q

/ Q

100%

100%

min

max

3

/hr

Installation and operating instructions 20 BATCHFLUX

Page 21

Fct. Text Description and settings

1.3 L.F.

CUTOFF Low-flow cutoff (SMU)

• OFF (fixed values:

1.4 DISPLAY Display functions

→

DISP.

FLOW.

→

DISP.

TOTAL.

→

DISP.

MSG.

ON = 0.1% /

OFF = 0.2%,

at 100 Hz - 1000 Hz,

see Fct.1.6, 1% and 2%)

• PERCENT

(variable values)

ON 1 – 19%

OFF 2 – 20%

Press key → to transfer to

number setting!

cutoff “off“ value must be

Note:

greater than cutoff “on“ value!

Press key ↵ to return to

Fct. 1.3 L.F.CUTOFF

Select flow display

(only HHT 010)

• NO DISP.

• user unit, factory set is

“Liter/hr“ (see Fct. 3.5)

3

/hr • PERCENT

• m

• Liter/Sec • US.Gal/min

• BARGRAPH (value and

bargraph display in %)

Press key ↵ to transfer to

subfunction “ DISP.TOTAL“.

Select totalizer display

• NO DISP.

(totalizer switched on but

not displayed)

• OFF (totalizer switched off)

3

• Liter • US.Gal

• m

• user unit, factory set is “Liter“

(see Fct. 3.5)

Press key → to transfer to

format setting!

Format settin

• Auto (exponent notation)

• # . ####### • ##### . ###

• ## . ###### • ###### . ##

• ### . ##### • ####### . #

• #### . #### • ########

Press key ↵ to transfer to

subfunction “DISP.MSG.“.

Additional messages

required in measuring mode?

• NO • YES

(cyclic change with

meas. value displays)

Press key ↵ to return to

Fct.1.4 DISPLAY.

g

Fct. Text Description and settings

1.5 CURRENT I Current output I

No hardware available

→

FUNCTION I

• OFF (must be set, as

→

RANGE I

→

I ERROR

1.6 PULS.OUTP. P Pulse output P

→

FUNCTION P

→

SELECT. P

→

PULSWIDTH

Select function for current

output I

hardware not available!)

• 1 DIR. (1 direction of flow)

• 2 DIR. (forward/reverse flow,

F/R flow measurement)

Press key ↵ to transfer to

subfunction “RANGE I“.

Select measuring range

• 0 - 20 mA

• 4 - 20 mA

Press key ↵ to transfer to

subfunction “I ERROR“.

Select error value

• 0 mA

• 3.6 mA (only possible in

4 - 20 mA range)

• 22 mA

Press key ↵ to return to

Fct. 1.5 CURRENT I.

Select function for pulse

output P

• OFF (switched off)

• 1 DIR.

(1 direction of flow)

• 2 DIR.

(forward/reverse flow,

F/R flow measurement)

Press key ↵ to transfer to

subfunction “SELECT P“.

Select pulse type

• 100-1000 Hz • PULSE/VOL

(pulses per unit volume,

flow)

• 100-1000 Hz • PULSE/TIME

(pulses per unit time for

100% flow)

Press key ↵ to transfer to

subfunction “PULSWIDTH“.

When 100 Hz - 1000 Hz

selected, return to Fct.1.6

PULS.OUTP. P, (pulse width

50%, cyclic).

Select pulse width

• 50 mSec • 100 mSec

• 200 mSec • 500 mSec

Press key ↵ to transfer to

subfunction “VALUE P“.

4

Installation and operating instructions

BATCHFLUX

21

Page 22

4

Fct. Text Description and settings

1.6

→

VALUE P

→

VALUE P

1.7

STATUS. S Status output S

Set pulse value per unit

volume (appears only when

“PULSE/VOL.“ set under

“SELECT.P“ above)

• xxxx PulS/m3

• xxxx PulS/Liter

• xxxx PulS/US.Gal

• xxxx PulS/ user unit, factory

set is “Liter“ (see Fct. 3.5)

Setting range “xxxx“ depends

on the pulse width and the fullscale range:

= F

= F

min

max

/ Q

/ Q

100%

100%

P

min

P

max

Press key ↵ to return to

Fct.1.6 “PULS.OUTP.P“.

Set pulse value per unit time

(appears only when

“PULSE/TIME“ set under

“SELECT. P“ above)

• xxxxx PulSe/Sec (=Hz)

• xxxx PulSe/min

• xxxx PulSe/hr

• xxxx PulSe/user unit,

factory set is “hr“

(see Fct. 3.5)

Setting range “xxxx“ depends

on pulse width, see above.

Press key ↵ to return to

Fct. 1.6 “PULS.OUTP. P“.

No hardware available

ALL ERROR

• FATAL ERROR

• OFF

• ON

• F/R INDIC. (F/R indication

for forward/reverse

measurement)

• TRIP.POINT

Setting range:

002 - 115 PERCENT

Press key ↵ to transfer to

number setting!

Press key ↵ to return to

Fct. 1.7 “STATUS. S“.

Fct. Text Description and settings

2.0 TEST Test menu

2.1 TEST Q Test of range Q

2.2 HARDW.

INFO

→

MODUL

ADC

→

MODUL

I/O

→

MODUL

DISP.

Precautionar

• SURE NO

Press key ↵ to return to

Fct. 2.1 “TEST Q“.

• SURE YES

Press key ↵ and select value

with keys ↑ and ↓:

-110 / -100 / -50 / -10 / 0 / +10 /

+50 / +100 / +110 PCT.

of set measuring range

Q

100%

Displayed value present at

outputs I and P.

Press key ↵ to return to

Fct. 2.1 “TEST Q“.

Hardware information and

error status

Please note down all 6 codes

before consulting factory.

X . X X X X X . X X

Y Y Y Y Y Y Y Y Y Y

Press key ↵ to transfer to

“MODUL I/O“.

X . X X X X X . X X

Y Y Y Y Y Y Y Y Y Y

Press key ↵ to transfer to

“MODUL DISP“.

X . X X X X X . X X

Y Y Y Y Y Y Y Y Y Y

Press key ↵ to return to

Fct. 2.2 “HARDW. INFO“.

y query

in each case.

Installation and operating instructions 22 BATCHFLUX

Page 23

Fct. Text Description and settings

3.0 INSTALL. Installation menu

3.1 LANGUAGE Select language for

3.2 FLOWMETER

→

DIAMETER

→

FULL

SCALE

→

VALUE P

→

GKL

VALUE

display texts

• GB / USA (English)

• F (French)

• D (German)

• others on request

Press key ↵ to return to

Fct. 3.1 “LANGUAGE“.

Set data for primary head

Select size from table of

meter sizes

• BATCHFLUX IFM 5015 K

DN 2.5 - 40 mm

equivalent to

1

/10 - 11/2 inches

Select with key ↑ or ↓.

Press key ↵ to transfer to

subfunction “FULL SCALE“.

Full scale range for flow

Q

100%

To set, refer to Fct. 1.1

“FULL SCALE“ above.

Press key ↵ to transfer to

subfunction “GKL VALUE“.

Change pulse value

(see Fct. 1.6 “VALUE P“)

Appears only when “PULSE/

VOL.“ has been set under

Fct. 1.6 “SELECT. P“ and the

output frequency (F) has

been over- or undershot:

P

= F

/ Q

/ Q

100%

100%

min

min

P

= F

max

max

Set primary constant GKL

see instrument nameplate for

primary head

ge: • 1.0000 - 9.9999

Ran

Press key ↵ to transfer to

subfunction “FLOW DIR.“.

Fct. Text Description and settings

→

FIELD

FREQ.

→

FLOW DIR.

Magnetic field frequency

Do not change setting !

Values 1/2

of 50 Hz or 60 Hz,

see nameplate.

Press key ↵ to transfer to

subfunction “FLOW DIR.“.

Define direction of flow

(in F/R mode: forward flow)

Set according to direction of

arrow on primary head.

• + DIR. • – DIR.

Select with key ↑ or ↓ .

Press key ↵ to return to

Fct. 3.2 “FLOWMETER“.

, 1/6 and 1/18

4

Installation and operating instructions

BATCHFLUX

23

Page 24

4

Fct. Text Description and settings

3.3 ZERO

SET

3.4 ENTRY

CODE

3.5 USER

UNIT

→

TEXT

VOL.

→

FACT.

VOL.

Zero calibration

Note:

Carry out only when flow

is “0“ and measuring tube is

completely filled!

Precautionar

• CALIB. NO

Press key ↵,

return to Fct. 3.3 “ZERO“.

• CALIB. YES

Press key ↵

to start calibration.

Duration approx. 10 seconds.

Current flowrate displayed in

the selected unit (see Fct. 1.4

“DISP.FLOW“)

A “WARNING“ sign appears

when flowrate “> 0“.

Confirm with key ↵.

• STORE NO (do not store

new zero value)

• STORE YES (store

(store new zero value)

Press key ↵ to return to

Fct. 3.3 “ZERO SET “.

Entry code required to enter

setting mode?

• NO (= entry with → only)

• YES (= entry with → and

Code 1: → → → ↵ ↵ ↵ ↑ ↑ ↑ )

Press key ↵ to return to

Fct. 3.4 “ENTRY CODE“.

Set any required unit for

flowrate and counting

Set text for required

flowrate unit

(max. 5 characters)

Factory-set: “Liter“ (= Liters).

Characters assi

each

• A-Z, a-z, 0-9, or „ – “

(= blank character)

Press key ↵ to transfer to

subfunction “FACT. VOL.“.

Set conversion factor (FM)

for volume

Factory set: “1.00000 E+3“ for

“Liter“ (exponent notation,

here:10

Factor F

Settin

• 1.00000 E-9 to 9.99999 E+9

(= 10

Press key ↵ to transfer to

subfunction “TEXT TIME“.

y query

place:

g range

-9

to 10+9)

gnable to

3

).

= volume per 1m3.

M

Fct. Text Description and settings

→

TEXT

TIME

→

FACT.

TIME

Set text for required flow

unit (max. 3 characters)

Factory-set: “hr“ (= hour).

Characters assi

each place:

• A-Z, a-z, 0-9, or “ – “

(= blank character)

Press key ↵ to transfer to

subfunction “FACT.TIME“.

Set conversion factor (FT)

for time

Factory set: “3.60000 E+3“

for “hour“ (exponent notation,

here: 3.6 x 10

Factor F

g range

Settin

• 1.00000 E-9 to 9.99999 E+9

-9

bis 10+9)

(= 10

Press key ↵ to return to

Fct. 3.5 “USER UNIT“.

gnable to

3

).

: set in seconds.

T

Installation and operating instructions 24 BATCHFLUX

Page 25

4.5 Error messages in measuring mode

The following list gives all errors that are likely

to occur during process flow measurement.

Errors are shown in the display when “YES“ is

set in Fct. 1.4 DISPLAY, subfunction

“DISP.MSG.“.

Error message Discription of error Error clearance

LINE INT.

PULS.OUTP. P

ADC

FATAL. ERROR

TOTALIZER Totalizer has been reset.

Power failure

Note:

no counting during power failure

Pulse output overranged.

Note:

totalizer deviation possible.

Analog/digital converter

overranged.

Fatal Error; all outputs set to

“Min. values“.

Delete error message in RESET/QUIT

menu. If necessary, reset totalizer.

Check instrument parameters and

correct, if necessary. After cause has

been eliminated, error message is

deleted automatically.

After cause has been eliminated, error

message is deleted automatically.

Please consult factory.

Delete error message in RESET/QUIT

menu.

4

Installation and operating instructions

BATCHFLUX

25

Page 26

4

4.6 Resetting totalizer and deleting error messages, RESET / QUIT

menu

Cancel error messa

Key Display Description

- - - - - - - - - - - - / - - - Measuring mode

↵

↑→

→

↑

↵

↵

Reset totalizer

ges in RESET / QUIT menu

CodE 2

- - - - - - - - - - - - / - - - Return to measuring mode

(s) in RESET / QUIT menu

- -

ERROR QUIT.

QUIT. NO

QUIT. YES

ERROR QUIT.

Key in Entry Code 2 for RESET/QUIT

menu:

→ ↑

Menu for error acknowledgement

Do not delete error messages.

Press

↵ twice = return to measuring

mode.

Delete error messages

Error messages deleted

Key Display Description

- - - - - - - - - - - - / - - - Measuring mode

↵

↑→

↑

→

↑

↵

↵

CodE 2

- - - - - - - - - - - - / - - - Return to measuring mode

- -

ERROR QUIT.

TOTAL. RESET

RESET NO

RESET. YES

RESET QUIT.

Key in Entry Code 2 for RESET/QUIT

→ ↑

menu:

Menu for error acknowledgement

Menu for resetting totalizer

Do not reset totalizer.

Press

↵ twice = return to measuring

mode.

Reset totalizer

Totalizer reset

Installation and operating instructions 26 BATCHFLUX

Page 27

Notes

Installation and operating instructions

BATCHFLUX

27

Page 28

5

5 Description of functions

Please note!

Do not open the housing of the

BATCHFLUX IFM 5015 K.

Danger of contamination with substances

likely to destroy the moisture barrier of the

electronic equipment (e.g. if CIP or SIP

cleaned from the outside).

Therefore, please contact your KROHNE

Service engineer before you open the

housing.

5.1 Full-scale range Q

Fct. 1.1 FULL SCALE

Press key

Selection of unit for

full-scale ran

m3/hr (cubic metres per hour)

•

Liter/Sec (litres per second)

•

US.Gal/min (US gallons per minute)

•

user-defined unit; factory-set is here

•

“Liter/hr“ (litres per hour), see Sect.

5.12

Select with keys

Use key

setting, 1st digit (cursor) flashes.

Set full-scale range Q

The setting range is dependent on the

meter size (DN) and the flow velocity (v):

Q

min

(refer to flow table in Sect. 10.1)

Change flashing digit (cursor) with keys

and

cursor 1 place to right or left.

Press key

SCALE.

Note: if “VALUE P“ is displayed after

pressing key

Fct. 1.6 PULS.OUTP. P, subfunction

“SELECT P“. Due to the changed fullscale range Q

(F) of the pulse output is over- or

undershot:

P

min

Change pulse value accordingly, see

Sect. 5.7 pulse output P, Fct. 1.6.

→ .

ge Q

→ to transfer to numerical

π

= DN2 × v

4

↓ . Use keys → and ← to shift

↵ to return to Fct. 1.1 FULL

↵ . PULSE/VOL is set under

100%

= F

min

/ Q

100%

↑ and ↓.

100%

Q

min

, the output frequency

P

100%

= DN2 × v

max

= F

max

π

4

100%

max

/ Q

100%

max

↑

5.2 Time constant

Fct. 1.2 TIMECONST.

Press key

Selection

•

and all outputs)

•

current and status outputs,

no current output,

no hardware)

Select with keys ↑ and ↓.

Transfer to number setting with key ↵,

1st digit. (cursor) flashes.

Set numerical value

•

Change flashing digit (cursor) with keys ↑ and

↓ . Use keys → and ← to shift cursor 1 place

to right or left.

Press key ↵ to return to Fct. 1.2 TIMECONST.

5.3 Low-flow cutoff

Fct. 1.3 L.F.CUTOFF (do not change

setting!)

Press key

Selection

•

•

Select with keys ↑ and ↓. Transfer to number

setting with key

selected), 1st digit (cursor) flashes.

Setting the numerical value when

“PERCENT“ selected

•

•

Change flashing digit (cursor) with keys

↓ . Shift cursor 1 place to right or left with keys

→ and ← . Press key ↵ to return to Fct. 1.3

L.F.CUTOFF.

Note: the cutoff “off“ value must be greater

than the cutoff “on“ value.

→ .

ALL (applies to HHT 010-display

ONLY I + S (only valid for HHT 010 display,

0.2 - 99.9 Sec (seconds)

↵ .

OFF

(fixed trip points: ON = 0.1 % / OFF =

0.2 %, at 100 - 1000 Hz, see Fct.1.6, 1%

and 2%)

PERCENT

(variable trip points: ON = 1-19% /OFF =

2-20%)

→ (only when “PERCENT“

01 to 19 (cutoff “on“ value, left of hyphen)

02 to 20 (cutoff “off“ value, right of hyphen)

↑ and

Installation and operating instructions 28 BATCHFLUX

Page 29

5.4 Display with HHT 010

Fct. 1.4 DISPLAY

Press key

→ DISP.FLOW = Select unit for display

of flowrate

• NO DISP. (not displayed)

• m

• Liter/Sec (litres per second)

• US.Gal/min (US gallons per minute)

• User-defined unit; factory-set is

„Liter/hr“ (litres per

hour), see Sect. 5.12

• PERCENT (percentage display)

• BARGRAPH (numerical value and

Select with keys

Press key

“DISP.COUNT“

→ DISP.COUNT = Select unit for totalizer

display, press key →

• NO DISP. (not displayed)

• OFF (internal totalizer

• m

• Liter (litres)

• US.Gal (US gallons)

• user-defined unit; factory-set is “Liter“,

Select with keys

Transfer to totalizer format setting with key

Settin

• Auto (exponent notation)

• # . ####### • ##### . ###

• ## . ###### • ###### . ##

• ### . ##### • ####### . #

• #### . #### • ########

Select with keys

Transfer to subfunction “DISP.MSG.“

key

↵ .

3

/hr (cubic metres per hour)

bar graph display in %)

↵ to transfer to subfunction

switched off)

3

(cubic metres)

see Sect. 5.12

g of totalizer format

↵ .

, press key →

↑ and ↓.

↑ and ↓.

→ .

↑ and ↓.

with

→ DISP.MSG. = Additional messages

required in measuring mode, press key →

• NO (no other messages)

• YES (display other messages,

e.g. errors, in sequence with the

measured values)

Select with keys

Press key

Note: “BUSY“ is displayed in the measuring

mode when all displays are set to “NO DISP.“

and “NO“. Sequencing of displays is automatic.

However, in the measuring mode, manual

sequencing can be carried out with keys

and ↓ . Return to automatic sequencing after

approx. 3 minutes.

Please refer to Sect. 3.2

“Factory settings“.

↑ and ↓.

↵ to return to Fct. 1.4 DISPLAY.

↑

5.5 Internal electronic totalizer

The internal electronic totalizer counts in m

regardless of the unit set under Fct. 1.4,

subfunction “DISP.FLOW“.

The counting range is dependent upon the

meter size and has been selected such that

the totalizer will count for a minimum of 1 year

without overflow:

Meter size Counting range

DN mm inches in m3

2,5 - 40 1/10 - 11/2 0 - 999 999.99999999

Only part of the totalizer count is shown in the

display because it is not possible to output a

14-digit number. Unit and format of the display

are freely selectable, see Fct. 1.4, subfunction

“DISP.COUNT“ and Sect. 5.4. This determines

which part of the count is to be displayed.

Display overflow and totalizer overflow are

independent of one another.

Exam

ple

Internal count 0000123 . 7654321 m3

Format,

display unit XXXX . XXXX Liter

Internal count

in unit 0123765 . 4321000 Liter

Displayed 3765 . 4321 Liter

3

,

5

Installation and operating instructions

BATCHFLUX

29

Page 30

5

5.6 Current output I

No HARDWARE!

Function must be set to “OFF”.

Fct. 1.5 CUR.OUTP. I (not available, no

HARDWARE !)

Press key

→ FUNCTION I = Select function for the

current output, press key →

• OFF (switched off,

do not change setting,

no hardware available)

• 1 DIR. (1 flow direction)

• 2 DIR. (2 flow directions, F/R mode,

forward/reverse)

Select with keys ↑ and ↓.

Transfer to subfunction “RANGE I“

↵. Exception: when “OFF“ selected, return to

Fct. 1.5 CUR.OUTP. I.

→ RANGE I = Select measuring range,

press ke

• 0 - 20 mA

• 4 - 20 mA

Select with keys ↑ and ↓.

Transfer to subfunction “I ERROR“ with key

↵.

→ I ERROR = Set error value,

press key →

• 0 mA

• 3.6 mA (only possible when

range “4 - 20 mA“

selected)

• 22 mA

Select with keys ↑ and ↓.

Press key

I.

Please refer to Sect. 3.2

“Factory settings“.

Refer to Sect. 2.3 for connection diagrams,

and to Sect. 5.14 for characteristics.

→ .

with key

y →

↵ to return to Fct. 1.5 CUR.OUTP.

5.7 Pulse output P

Fct. 1.6 PULS.OUTP. P

Press key

→ .

→ FUNCTION P = Select function for the

pulse output, press key →

• OFF (switched off, no function)

• 1 DIR. (1 flow direction)

• 2 DIR. (2 flow directions, F/R mode,

forward/reverse)

Select with keys ↑ and ↓.

Transfer to subfunction “SELECT P“

↵. Exception: when “OFF“ selected, return to

Fct. 1.6 PULS.OUTP. P.

→ SELECT P = Select pulse type,

press ke

• 100-1000 Hz

• PULSE/VOL. (pulses per unit volume,

• PULSE/TIME (pulses per unit time

Select with keys ↑ and ↓.

Transfer to subfunction “PULSEWIDTH“

with key

Note: when 100-1000 Hz selected,

return to Fct. 1.6 PULS.OUTP. P.

y →

flow)

for 100 % flow)

↵.

→ PULSEWIDTH = Select pulse width,

press ke

• 50 mSec F

• 100 mSec F

• 200 mSec F

• 500 mSec F

for all F

(= 20 pulses / hr)

Select with keys

Transfer to subfunction “VALUE P“ with key

or return to Fct. 1.6 PULS.OUTP. P,

depending on selected pulse type in

subfunction “SELECT P“.

y →

= 10 Hz

max

= 5 Hz

max

= 2.5 Hz

max

= 1 Hz

max

= 0.0056 Hz

min

↑ and ↓.

with key

↵

Installation and operating instructions 30 BATCHFLUX

Page 31

→ VALUE P = Set pulse value per unit volume,

(a

ppears only when “PULSE/VOL.“ has been set under “SELECT P“) press key →

• XXXX PulS/m

• XXXX PulS/Liter

• XXXX PulS/US.Gal

• XXXX PulS/ user-defined unit,

factory-set is “Liter“, see Sect. 5.12.

Select with keys

Transfer to number setting with key

Set numerical value

• XXXX (Setting range depends on

pulse width and full-scale range:

P

P

Change flashing digit (cursor) with keys

Shift cursor 1 place to right or left with keys → und ← .

Press key

3

↑ and ↓.

→, 1st digit (cursor) flashes.

= F

/ Q

min

min

= F

max

max

↵ to return to Fct. 1.6 PULS.OUTP. P.

/ Q

100%

100%

)

↑ and ↓ ,

or

→ VALUE P = Set pulse value per unit time,

(appears only when “PULSE/TIME“ has been set under “SELECT P“), press key →

• XXXXX PulSe/Sec (max. 10 kHz)

• XXXX PulSe/min

• XXXX PulSe/hr

• XXXX PulSe/ user-defined unit,

factory-set is “hr“, see Sect. 5.12.

Select with keys ↑ and ↓.

Transfer to number setting with key →, 1st digit (cursor) flashes.

Set numerical value

• XXXX (Setting range depends on

pulse width)

Change flashing digit (cursor) with keys

Shift cursor 1 place to right or left with keys → and ←.

Press key

Please refer to Sect. 3.2

“Factory settings“

Refer to Sect. 2.3 for connection diagrams,

and to Sect. 5.14 for characteristics.

↵ to return to Fct. 1.6 PULS.OUTP. P.

↑ and ↓ ,

5

Installation and operating instructions

BATCHFLUX

31

Page 32

5

5.8 Status output S (option)

No HARDWARE!

Function must be set to “OFF”.

Fct. 1.7 IND. OUTP. S

Press key

Select function for the status output,

press ke

• OFF (switched off,

no function)

• ON (indicates that

flowmeter is operative)

• V/R INDIC. (indicates direction for

current output and

pulse output, F/R mode)

• TRIP.POINT (setting range: 002 -

115 PERCENT of Q

full-scale range)

endwert)

• ALL ERROR (indicates all errors)

• FATAL.ERROR (indicates

Fatal Error only)

Characteristics of

status output

OFF

ON (e.g. operation indicator)

F/R INDIC. Forward flow Reverse flow

TRIP.POINT

ALL ERROR

FATAL. ERROR

For factory settings, please refer to the report on settings and to Sect. 3.2.

Connection diagrams: see Sect. 2.2.

→ .

y → .

100%

Switch open Switch closed

no function

Power OFF Power ON

Inactive Active

Error(s) No error(s)

Error No error

5.9 Language

Fct. 3.1 LANGUAGE

Press key

Select lan

• D (German)

• GB (English)

• F (French)

• others available on request

→ .

guage for texts in display

Transfer to number setting with key

digit (cursor) flashes. Change flashing digit

(cursor) with keys

place to right or left with keys

Press key

Fct. 1.7 IND. OUTP. S.

,

↵ to return to

↑ and ↓, shift cursor 1

↵, 1st

→ and ←.

Select with keys

Press key

↵ to return to Fct. 3.1 LANGUAGE.

↑ and ↓.

Installation and operating instructions 32 BATCHFLUX

Page 33

5.10 Entry Code

Fct. 3.4 ENTRY CODE

Press key

Selection

• NO (no code, press key →

to enter setting mode)

• YES (enter setting mode with key

and Code 1:

Select with keys

Press key

→ .

↵ to return to Fct. 3.4 ENTRY CODE.

5.11 Primary head

Fct. 3.2 FLOWMETER

Press key

→ DIAMETER = Set the meter size

(see instrument nameplate) press key → .

Select size from table of meter sizes:

• BATCHFLUX IFM 5015 K : DN 2,5 - 40

mm equivalent to 1/10 - 11/2 inches

Select with keys ↑ and ↓.

Transfer to subfunction “FULL SCALE“

with key

→ FULL SCALE = Set the full-scale range,

press key →.

Set as described in Sect. 5.1.

Transfer to subfunction “GKL VALUE

with key

Note: if “VALUE P“ is displayed after

pressing key

PULSE/VOL. has been set under Fct. 1.6

PULS.OUTP. P, subfunction “SELECT P“.

Because the full-scale range Q

changed, the output frequency (F) of the pulse

output is over- or undershot:

P

P

Change pulse value accordingly, see Sect. 5.7

Pulse output P, Fct. 1.6.

↵.

↵.

min

max

→ .

= F

= F

↵ .

min

max

→ → → ↵ ↵ ↵ ↑ ↑ ↑)

↑ and ↓.

100%

/ Q

/ Q

100%

100%

→

“

has been

→ GKL VALUE = Set the primary

constant GK

• 1.0000 - 9.9999 (note information on

instrument nameplate, do not change

setting !)

Change flashing digit (cursor) with keys

↓ . Shift cursor 1 place to right or left with keys

→ and ←.

Transfer to subfunction “FLOW DIR.“ with

key ↵.

→ FIELD FREQ. = Magnetic field

frequency, press key → .

• 1/2 (1/2, 1/6 or 1/18 or 50 Hz

or 60 Hz,

• 1/6 see instrument nameplate,

• 1/18 do not change setting !)

The magnetic field frequency is determined by

the program.

Select with keys

Transfer to subfunction “FLOW DIR.“

↵.

key

→ FLOW DIR. = Set the direction of flow,

press key → .

• + DIR.

• - DIR. (for identification of flow

direction see “+“ arrow on primary head, in

F/R mode this identifies the “positive“ flow

direction)

Select with keys

Press key

FLOWMETER.

Zero check: see Fct. 3.3 and Sect. 7.1.

Please refer to Sect. 3.2

“Factory settings“

, press key → .

↑ and

↑ and ↓.

with

↑ and ↓.

↵ to return to Fct. 3.2

5

Installation and operating instructions

BATCHFLUX

33

Page 34

5

5.12 User-definable unit

Fct. 3.5 USER UNIT

Press key

→ .

→ TEXT VOL. = Set the text for user-

defined flow unit, press key →

• Liter (max. 5 characters, factory-set is

“Liter“) Characters assi

each place: A-Z, a-z, 0-9, or

“–“ (= blank)

Change flashing place (cursor) with keys

↓ . Shift cursor 1 place to right or left with

and

→ and ←. Transfer to subfunction

keys

“FACT.VOL“ with key ↵.

→ FACT. VOL. = Set factor F

press key →

• 1.00000 E+3 (factory-set is “1000“ /

Factor FM = volume per

1 m

1.00000 E-9 to 9.99999 E+9

( = 10-9 to 10+9)

Change flashing place (cursor) with keys

and ↓ . Shift cursor 1 place to right or left with

→ and ←. Transfer to subfunction

keys

“TEXT TIME

3

) Setting range:

“ with key ↵.

gnable to

↑

for volume,

M

↑

→ TEXT TIME = Set text für required time,

press key →

• hr (max. 3 places, factory-set is “hr =

hour“)

Characters assi

gnable to each place:

A-Z, a-z, 0-9, or “–“ (= blank)

Change flashing place (cursor) with keys ↑

and ↓ . Shift cursor 1 place to right or left with

→ and ←. Transfer to subfunction

keys

“FACT.TIME“ with key ↵.

→ FACT. TIME = Set Factor F

press ke

y →

for time,

T

• 3.60000 E+3 (factory-set is “3600“ /

set Factor F

in seconds)

T

Setting range:

1.00000 E-9

to 9.99999 E+9

( = 10-9 to 10+9)

Change flashing place (cursor) with keys

↑

and ↓ . Shift cursor 1 place to right or left with

→ and ←. Press key ↵ to return to

keys

Fct. 3.5 USER UNIT.

Factors for volume F

Volumetric unit Text examples Factor FM Setting

Cubic metres m3 11 111.0 1.00000 E+0

Litres Liter 1 000 1.00000 E+3

Hectolitres h Lit 10 1.00000 E+1

Decilitres d Lit 10 000 1.00000 E+4

Centilitres c Lit 100 000 1.00000 E+5

Millilitres m Lit 1 000 000 1.00000 E+6

US gallons USGal 22 264.172 2.64172 E+2

Millions US gallons USMG 0.000264172 2.64172 E-4

Imperial gallons GBGal 22 219.969 2.19969 E+2

Mega imperial gallons GBMG 0.000219969 2.19969 E-4

Cubic feet Feet3 333 35.3146 3.53146 E+1

Cubic inches inches3 61 024.0 6.10240 E+4

US barrels, liquid US BaL 88 888.36364 8.38364 E+0

US barrels, ounces US BaO 33 813.5 3.38135 E+4

(Factor FM = volume per 1 m3)

M

Factors for time F

Time unit Text examples Factor FT (seconds) Setting

Seconds Sec 1 1.00000 E+0

Minutes min 60 6.00000 E+1

Hours hr 3 600 3.60000 E+3

Day DAY 86 400 8.64000 E+4

Year (= 365 days) YR 31 536 000 3.15360 E+7

(Factor FT in seconds)

T

Installation and operating instructions 34 BATCHFLUX

Page 35

5.13 F/R mode, forward / reverse flow measurement

Refer to Sect. 2.3 for electrical

•

connection of the outputs.

Define direction of forward (normal)

•

flow, see Fct. 3.2, subfunction “FLOW

DIR.“:

in conjunction with F/R operation, set the

direction for the forward flow here.

“+“ signifies the same direction as shown

by the arrow on the primary head, “-“

signifies the opposite direction.

5.14 Characteristic of outputs

P Pulse output

P

Pulses at Q

100%

QF 1 flow direction, or forward flow in

F/R mode

Q

Reverse flow in F/R mode

R

Q

Full-scale range

100%

1 direction of flow

P

P

max

P = 0 Hz QF

Q

R

% 100 Max %

0

, full-scale range

100%

115%

P

100%

Set the status indication output to

•

“F/R INDIC.“, see Fct. 1.7.

Set the current and / or pulse output to

•

“2 DIR.“, see Fct. 1.5 and 1.6, subfunctions

“FUNCTION I“ and “FUNCTION P“.

2 directions of flow F/R mode

P

P

115%

max

P

100%

Q

P = 0 Hz QF

R

% Max 100 100 Max %

0

5

Installation and operating instructions

BATCHFLUX

35

Page 36

6

Part C Special applications, functional

checks and service

6 Special applications

Please note!

Do not open the housing of the BATCHFLUX IFM 5015 K.

Danger of contamination with substances likely to destroy the moisture barrier of the electronic

equipment (e.g. if CIP or SIP cleaned from the outside).

Therefore, please contact your KROHNE Service engineer before you open the housing.

6.1 RS 232 adapter and KROHNE

software (option)

For operator control of the signal converter

with MS-DOS PC, an RS 232 adapter (on

request, with Imo monitor software) is available

as an option. Detailed directions for use of the

software are included.

Switch off

housing !

1) Detach the 4 hex. screws and remove

cover.

2) Plug the RS 232 adapter into the IMoCom

jack on the printed circuit board of the

signal converter (see Sect. 9), and connect

to PC or laptop.

3) Switch on the power.

4) As described in the CONFIG directions,

change data, parameters and measured

values and/or have them called up for

display.

5) Switch off the power.

6) Remove the RS 232 adapter from the

amplifier board.

7) Replace the cover and tighten down the 4

screws.

Please refer to Sect. 3.2

“Factory settings“.

power source before opening the

6.2 Operation via HHT 010 handheld terminal (option)

The HHT 010 hand-held terminal is available

as an option for operation of the signal

converter.

Switch off

housing !

1) Detach the 4 hex. screws and remove

cover.

2) Plug the HHT 010 connector into the

IMoCom jack on the printed circuit board of

the signal converter, see Sect. 9.

3) Power the unit.

4) Change data, parameters and measured

values as described in Sect. 4 and 5 of

these Instructions, and display.

5) Disconnect from power.

6) Detach HHT connector from the mother

board.

7) Replace cover and tighten down the

4 screws with a torque of max.2 Nm.

Please refer to Sect. 3.2

“Factory settings“.

power source before opening the

Installation and operating instructions 36 BATCHFLUX

Page 37

7 Functional checks

7.1 Zero check with signal converter IFC 015

Please note!

Do not open the housing of the

BATCHFLUX IFM 5015 K.

Danger of contamination with substances likely

to destroy the moisture barrier of the electronic

equipment (e.g. if CIP or SIP cleaned from the

outside).

Therefore, please contact your KROHNE

Service engineer before you open the housing.

Key Displayed Description

→

Fct. 1.0 OPERATION

2x ↑

→

2x ↑

→

↑

↵

Zero measurement in progress, duration approx. 10

When flow “> 0“, “WARNING“ notice appears, confirm

STORE NO

↑

↵

(2x) 3x ↵

If “YES“ is set under Fct. 3.4 ENTRY CODE, key-in the 9-

keystroke CODE 1:

Fct. 3.0 INSTALL.

Fct. 3.1 LANGUAGE

Fct. 3.3 ZERO SET

CALIB. NO

CALIB. YES

0.00 - - - - - / - - - Flowrate set in displayed unit, see Fct. 1.4 DISPLAY,

subfunction “DISP.FLOW“.

seconds.

with key

If new value not to be stored, press key ↵ (3x) 4x =

return to measuring mode.

STORE YES

Fct. 3.3 ZERO SET Store new zero value.

- - - - - - - - - - - - / - - - Measuring mode with new zero.

Switch off

before o

Set “zero“ flow in the pipeline, but make

•

sure that the measuring tube is

completely filled with fluid.

Switch on the system and wait 15 minutes.

•

Press the following keys for zero

•

measurement

↵ .

power source

pening the housing

→ → → ↵ ↵ ↵ ↑ ↑ ↑

7

Installation and operating instructions

BATCHFLUX

37

Page 38

7

7.2 Test of measuring range Q, Fct. 2.1

Please note!

Do not open the housing of the

BATCHFLUX IFM 5015 K.

Danger of contamination with substances

likely to destroy the moisture barrier of the

electronic equipment (e.g. if CIP or SIP

cleaned from the outside).

Therefore, please contact your KROHNE

Service engineer before you open the

housing.

Keys Displayed Description

→

Fct. 1.0 OPERATION

↑

→

→

↑

↵

± 10 PERCENT

↑ or ↓

± 100 PERCENT

± 110 PERCENT

↵

(2x) 3x ↵

If “YES“ is set under Fct. 3.4 ENTRY CODE, key-in the

9-keystroke CODE 1:

Fct. 2.0 TEST

Fct. 2.1 TEST Q

SURE NO

SURE YES

0 PERCENT Current, pulse and status outputs indicate the

corresponding values.

± 50 PERCENT

Fct. 2.1 TEST Q End of test; actual measured values again present at

- - - - - - - - - - - - / - - - Measuring mode

Select with keys ↑ and ↓

outputs.

Switch off

before o

•

•

•

power source

pening the housing

For this test a measured value can be

simulated in the range of -110 to +110

percent of Q

see Fct. 1.1 FULL SCALE).

Power the system.

Press the following keys for this test:

(for set full-scale range

100%

→ → → ↵ ↵ ↵ ↑ ↑ ↑

Installation and operating instructions 38 BATCHFLUX

Page 39

7.3 Hardware information and error status, Fct. 2.2

Please note!

Do not open the housing of the

BATCHFLUX IFM 5015 K.

Danger of contamination with substances likely

to destroy the moisture barrier of the electronic

equipment (e.g. if CIP or SIP cleaned from the

outside).

Therefore, please contact your KROHNE

Service engineer before you open the housing.

Key Displayed Description

→

Fct. 1.0 OPERATION

↑

→

↑

→ → MODUL ADC -.- - - - -.- -

- - - - - - - - - Sample status code

↵ → MODUL I/O -.- - - - -.- -

- - - - - - - - -

↵ → MODUL.DISP. -.- - - - -.- -

- - - - - - - - -

↵

(2x) 3x ↵

If you need to return your flowmeter to KROHNE, please refer to the

last-but-one page of these Instructions !

If “YES“ is set under Fct. 3.4 ENTRY CODE, key-in

Fct. 2.0 TEST

Fct. 2.1 TEST Q

Fct. 2.2 HARDW. INFO

PLEASE NOTE DOWN ALL 6 STATUS CODES !

Fct. 2.2 HARDW. INFO End of hardware information

- - - - - - - - - - - - - / - - - Measuring mode

Switch off power source

before o

•

•

•

•

the 9-keystroke CODE 1:

1st window

2nd window 3.25105.02 ( 8-character code,

3rd window

pening the housing

Before consulting the factory about

errors/faults or flow measurement

problems, please invoke Fct. 2.2 HARDW.

INFO (hardware information).

An 8-character and a 10-character status

code are stored under this function in each

of 3 “windows“. These 6 status codes will

enable rapid and simple diagnosis of your

compact flowmeter.

Power the system.

Press the following keys for display of the

status codes:

→ → → ↵ ↵ ↵ ↑ ↑ ↑

1st line)

3A47F01DB1 (10-character code,

2nd line)

7

Installation and operating instructions

BATCHFLUX

39

Page 40

4

9

8

8 Service

Please note!

Do not open the housing of the BATCHFLUX IFM 5015 K.