Page 1

© KROHNE 7.02568.21.00

18.10.2005

Installation and

operating instructions

BATCHCONTROL 5014 C

Compact Electromagnetic

Flowmeters with CANopen bus interface

Please note!

Do not open the housing of the BATCHCONTROL 5014C.

Danger of contamination with substances likely to destroy the

moisture barrier of the electronic equipment (e.g. if CIP or SIP

cleaned from the outside).

Therefore, please contact your KROHNE Service engineer before

you open the housing.

Page 2

Contents

System description 4

Standards and approvals 4

Product liability and warranty 4

Functional description BATCHCONTROL IFM 5014C 5

Part A System installation and start-up 6 - 15

1 Installation in the pipeline 6 - 12

1.1 Important information 6

1.2 Suggestions for installation 7

1.3 Installation requirements 8

1.3.1 Position of flange 9

1.3.2 Example: centering and sealing the primary head 9

1.3.3 Grounding 9

1.4 Installation of the primary head 10

1.4.1 Device description 10

1.4.2 Installation of the IFM 5014C 10

1.5 Size of connections 11 - 12

1.5.1 Fastening with tie bolts 11

1.5.2 Fastening with bolts (option) 12

2 Electrical connection 13 - 14

2.1 Important information 13

2.2 Attachment plugs 13

2.3 Power supply and CAN bus 14

2.4 Input and output 14

2.5 Block circuit diagram 14

3 Start-up 15

3.1 Checking for availability 15

3.2 Factory settings 15

Part B IFC 014 batch controller 16 - 20

4 Description of functions 16 - 20

4.1 Contact outputs 16

4.2 Voltage input 16

4.3 Contact input 16

4.4 CAN bus and parameter 16 - 17

4.5 Temperature sensors 17

4.6 Flow sensor 17

4.7 An example for a filling process 17 - 20

Part C Service 21

5 Illustrations of printed circuit boards 21

Part D Technical Data, block diagram and measuring principle 22 - 28

6 Technical data 22 - 26

6.1 Flow during filling and fill volume 22

6.2 Flowmeters 22

6.3 Signal converter 23

6.4 Error limits at reference conditions 24

6.5 Dimensions and weights 25 - 26

6.6 Instrument nameplates 26

7 Block diagram 27

Installation and operating instructions 2 BATCHCONTROL

Page 3

8 Measuring principle 28

Part E Annex 29 - 47

E1 Index 29

E2 CAN parameter 30 - 45

E3 Form to accompany returned device 46

Please note!

Do not open the housing of the BATCHCONTROL IFM 5014C.

Danger of contamination with substances likely to destroy the moisture barrier of the electronic

equipment (e.g. if CIP or SIP cleaned from the outside).

Therefore, please contact your KROHNE Service engineer before you open the housing.

Installation and operating instructions

BATCHCONTROL

3

Page 4

System description

The BATCHCONTROL IFM 5014C compact electromagnetic flowmeter is a precision instrument

designed for the linear flow measurement of liquid products and c ontrolling the filling process.

The products need to be electrically conductive:

> 5 µS/cm (except for water)

> 20 µS/cm (for water)

The full-scale range Q

DN 2.5 – 40 and

This is equivalent to a flow velocity of 0.2 - 12 m/s.

1

/10” – 11/2” Q

can be set as a function of the meter size:

100%

= 0.0015 - 15 l/s

100%

Standards and approvals

BATCHCONTROL IFM 5014C with the IFC014 signal converter meets the EU-EMC Directives

•

and bears the CE and 3A symbol.

The 3A approval covers only the meter without adapter.

•

All factories and production sequences are ISO 9001 certified.

•

Product liability and warranty

The compact BATCHCONTROL IFM 5014C electromagnet ic flowmeter is des igned exclusivel y for

measuring the volumetric flowrate of electrically conductive, liquid process produc ts.

The compact flowmeter is not suitable for use in hazardous areas. Other flowmeter series are

available for such applications.

Responsibility as to suitability and intended use of this compact electromagnetic flowmeter rests

solely with the operator.

Improper installation and operation of the flowmeters (systems) may lead to loss of warranty.

In addition, the “General conditions of sale“ forming the basis of the purchase contract are

applicable.

If BATCHCONTROL 5014C flowmeters need to be returned to KR OHNE, please note the infor-

mation given on the last-but-one page of these instructions. KROHNE regret that they cannot

repair or check your flowmeter(s) unless these are accompanied by the completed form sheet.

Installation and operating instructions 4 BATCHCONTROL

Page 5

Functional description

BATCHCONTROL IFM 5014C

The volume to be filled into the container is measured “in line“ by means of the electromagnetic

flowmetering system. The BATCHCONTROL closes the filling valve once the pres et filling volume

has been reached. It is always the preset target volume that is filled into the container.

The signal converter converts the measured flowrate signa l into volume that are transfered to the

integrated batch controller.

The influence of valve closing times and ot her dynamic factors can be corrected by the adaptive

correction formalism of the BATCHCONTROL 5014C.

The use of state-of-the-art microprocessor electronics and the high-speed anal og/digital converter

also enables changes in the flowrate to be sensed precisely. This technology ensures high

reproducibility and long-term stability.

Installation and operating instructions

BATCHCONTROL

5

Page 6

1

Part A System installation and start-up

1 Installation in the pipeline

1.1 Important information

The following recommendations should be observed to ensure proper functioning of the

flowmeter – PLEASE NOTE.

Measuring tube must be filled

•

completely at all times.

Direction of flow: the blue arrow on the

•

housing of the primary head must point in

the direction of flow. If for structural

reasons the flowmeter can only be installed

invers to the direction of flow, the direction

of flow measurement can be reprogrammed.

Stud bolts and nuts: to fit, make sure

•

there is sufficient room next to the pipe

flanges.

Vibration: support the pipeline on both

•

sides of the flowmeter. Vibration level to

IEC 068-2-34: below 2,2g in the

20 - 2000 Hz frequency range.

Radiant heat: avoid e.g. from hot product

•

tanks, insulate if necessary.

Avoid strong electromagnetic fields

•

in vicinity of flowmeter.

Straight Inlet run ≥ 5 x DN and straight

•

outlet run ≥ 2 x DN, measured from the

electrode axis (DN = meter size).

Vortex or corkscrew flow: increase

•

length of inlet and outlet runs or install flow

straighteners.

Mixing different process liquids: install

•

flowmeter upstream of mixing point or at an

adequate distance downstream, minimum

of 30 x DN (DN = meter size), otherwise

display may be unsteady.

Plastic pipes and internally coated metal

•

pipes: grounding rings required, see

“Grounding“, Section 1.3.3.

Heat-insulated pipelines: do not insulate

•

flowmeter.

Zero setting: not required. For checking

•

purpose, it should be possible to set “zero“

flow velocity in the completely filled

measuring tube. Shutoff valves should

therefore be provided either downstream or

upstream and downstream of the

flowmeter.

Ambient temperature

•

-25°C to +60°C

Process temperature

•

max. 140 °C

Transport and storage temperature

•

-25°C to +60°C

Limits imposed by the material used for the

measuring tube for process temperature,

thermal shock limit, pressure and vacuum, see

Section D page 22.

Please note!

The ceramic measuring tube must not contac t

metal parts (flange, pipeline). This can destroy

the flowmeter!

Installation and operating instructions 6 BATCHCONTROL

Page 7

A

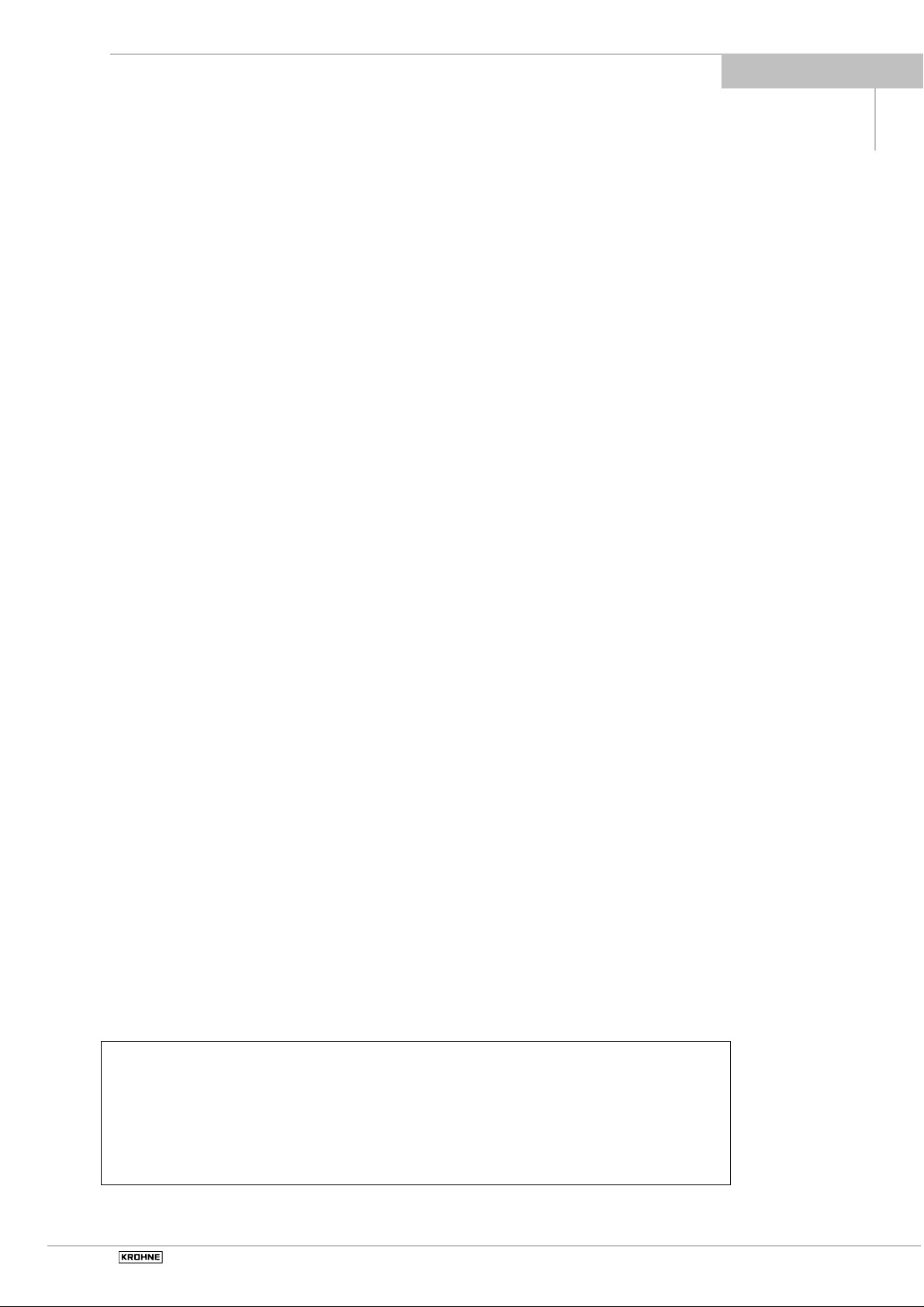

1.2 Suggestions for installation

To avoid measuring errors due to

air inclusion and vacuum, please

observe the following:

Highest point of pipe run

(Air bubbles collect in measuring

tube - faulty measurements!)

Preferred

locations

downpipe

(open discharge)

void draining or partial filling of

the measuring tube. Faulty

measurements.

1

Pumps

Do not install flowmeter on pump suction side

Open feed or discharge

Install meter in low section of pipe

open discharge

Selecting the installation location

Location and position as required, but

electrode axis (X – – – – X

must be approximately horizontal in a

horizontal pipe run.

Horizontal pipe run

Install in slightly descending pipe section to

prevent air from collecting, so avoiding faulty

measurements and that meter can drain.

Control and shutoff valves: always install

behind the flowmeter

x

Direction of flow The blue arrow on the

primary head housing must point in the flow

direction.

On high-temperature pipes and

where process temperatures

exceed 100 °C, provide facilities to

compensate for longitudinal

expansion on heat-up of the pipeline.

Use flexible pipe elements (e.g.

elbows).

x

Installation and operating instructions

BATCHCONTROL

7

Page 8

1

1.3 Installation requirements

Items supplied with flowmeter

BATCHCONTROL IFM 5014C compact

•

flowmeter in the version as ordered

Installation and operating instructions,

•

as agreed

Certificate of system calibration data

•

(as agreed)

Excluding fitting accessories. Stud bolts,

gaskets, etc., to be provided b y customer.

All operating data and function values

are factory set according to your order

specifications.

Requirements

Use in the food industry

The IFM 5014C is specifically suitable for us e

in the food and beverage industry or similar

sterile processes.

The IFM 5014C is steam-resistant.

The measuring tube can be SIP or CIP

cleaned when in installed condition. During the

cleaning the meter(s) must be switched off to

maintain the reliability of the unit(s).

• Operating pressure, type, and space

between pipe flanges: see Table.

• Tighten stud bolts uniformly down to the

metal stop in diagonally opposed

sequence. See Table for type and number

of stud bolts.

• Ins tall meter vertically or in a slope due to

its conical in/outlet.

On DN 15 (1/2”) and DN 32 (11/4” ) a

BATCHCONTROL with straight ceramic

tube is avaible.

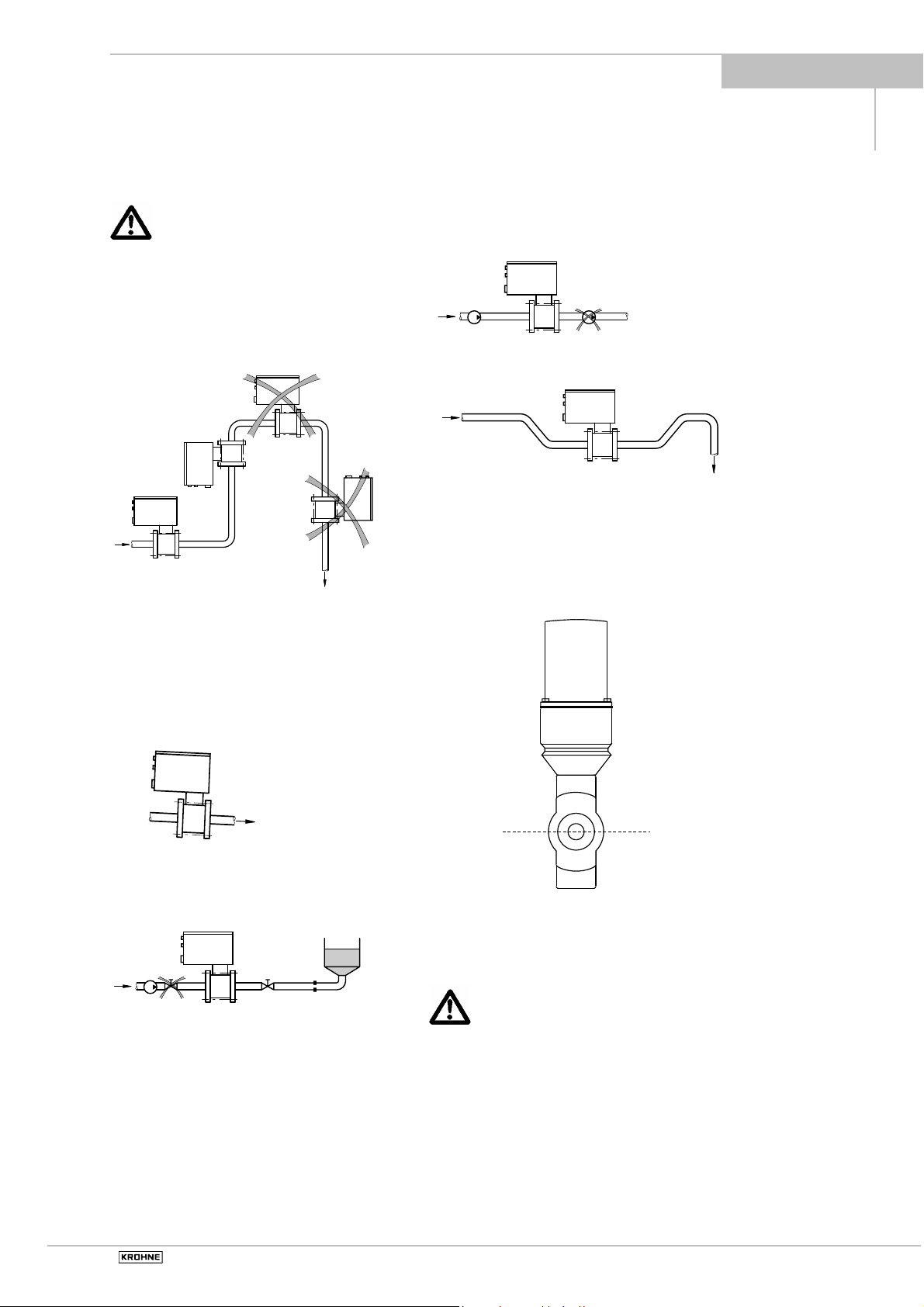

DIN 2501

and JIS pipe flanges Nm kpm ft × lbf

DN 2.5

DN 4

DN 6 1/4" 51.8 mm (2.04") 4 x M12 10 1.0 7.2

DN 10 3/8" 51.8 mm (2.04") 4 x M12 10 1.0 7.2

DN 15 1/2" 51.8 mm (2.04") 4 x M12 10 1.0 7.2

DN 25 1" 58.0 mm (2.28") 4 x M12 10 1.0 7.2

DN 32 11/4“ 83.0 mm (3.27“) 4 xM16 43 4.3 31.0

DN 40 1 1/2" 83.0 mm (3.27") 4 x M16 43 4.3 31.0

ANSI B 16.5 Space between Bolts Max torque

1

1

/10" 51.8 mm (2.04") 4 x M12 10 1.0 7.2

/8" 51.8 mm (2.04") 4 x M12 10 1.0 7.2

Installation and operating instructions 8 BATCHCONTROL

Page 9

y

R

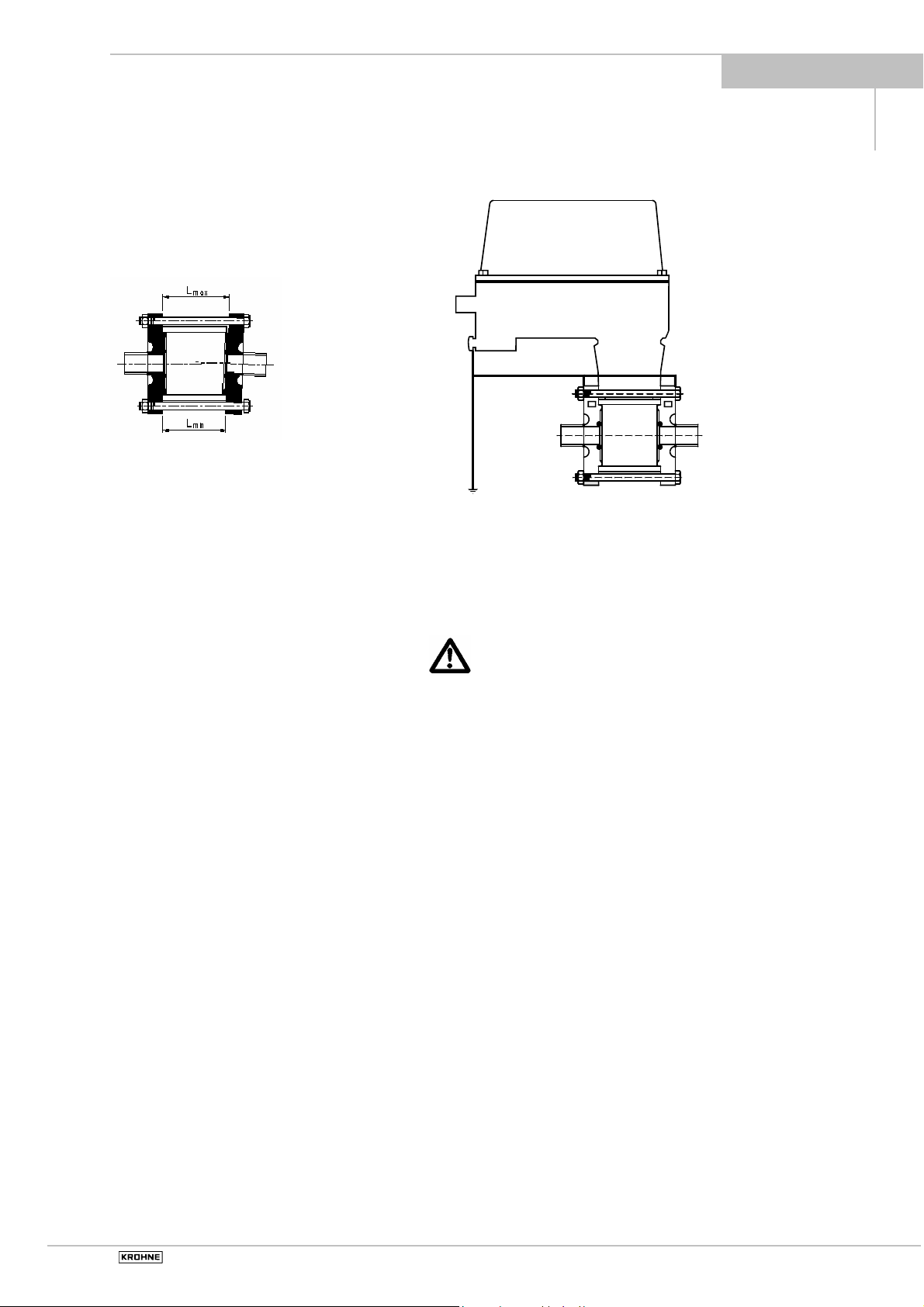

1.3.1 Position of flanges

Install flowmeter in line with the pipe axis. Pipe

flange faces must be parallel to each other,

max. allowable deviation:

L

– L

max

1.3.2 Example: centering and sealing

The primary head is centered between the pipe

flanges with the aid of the precise geometric

fitting (guide collar on primary head).

Detail drawings see Sect. 1.5.

≤ 0.5 mm ≤ 0.02"

min

the primary head

1.3.3 Grounding

V

R

FE

FE Functional ground, wire > 4 mm

R Pipeline

RF Pipe flanges

V Interconnecting wires,

bolted to the housing

Grounding is carried out via the functional

ground that is connected to the U-clamp

terminal (9). See also Section 2 “Electrical

connection“.

When connected to functional extra-low

voltages,

24V DC, protective separation (PELV)

must be ensured (VDE 0100/VDE 0106 or

IEC 364/IEC 536).

All flowmeters must be properly

•

grounded.

The grounding wire should not

•

transmit any interference voltage.

Therefore do not ground any other

electrical device simultaneousl

with this conductor.

RF RF

V

2

Cu.

1

Installation and operating instructions

BATCHCONTROL

9

Page 10

1

1.4 Installation of the primary head

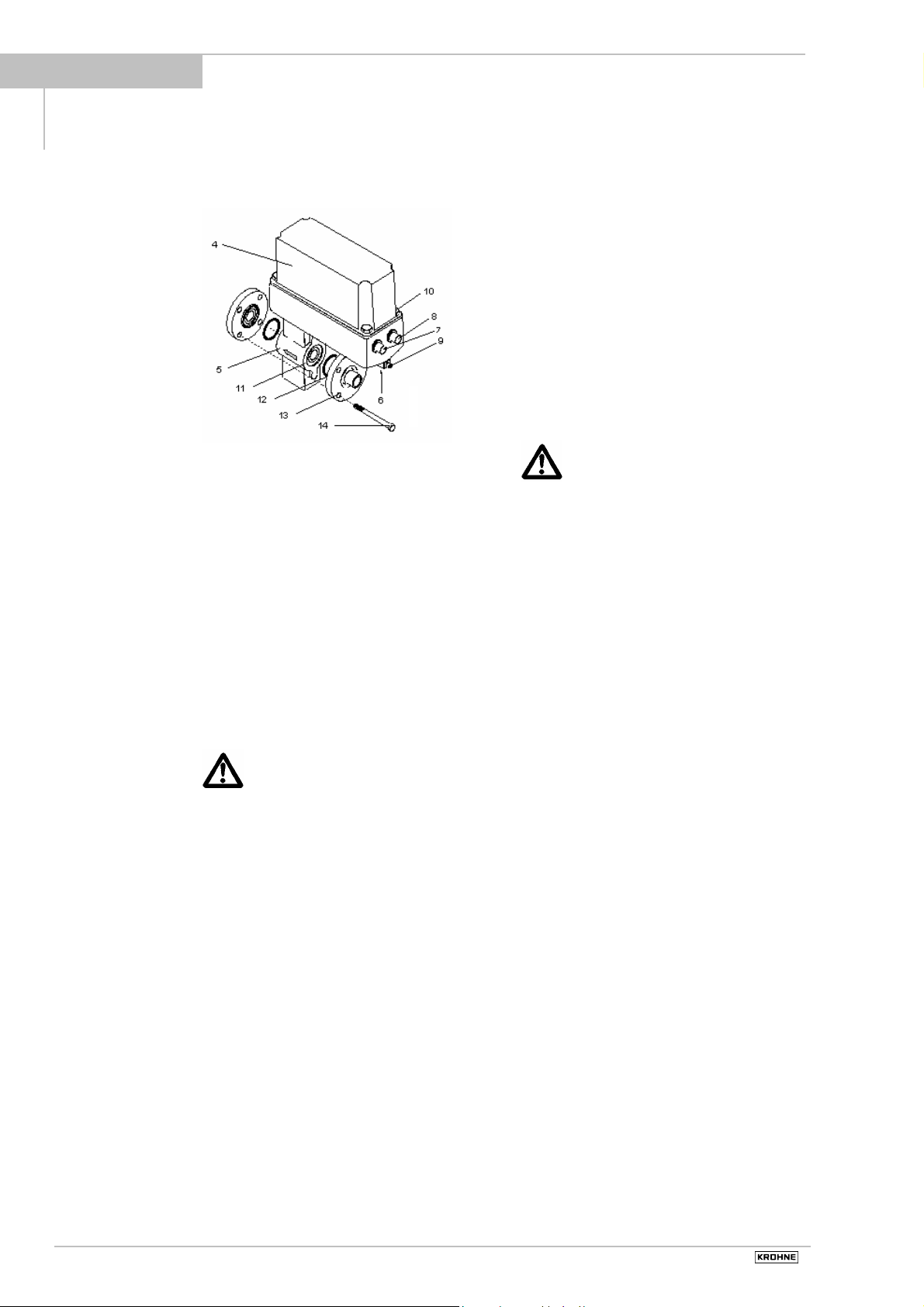

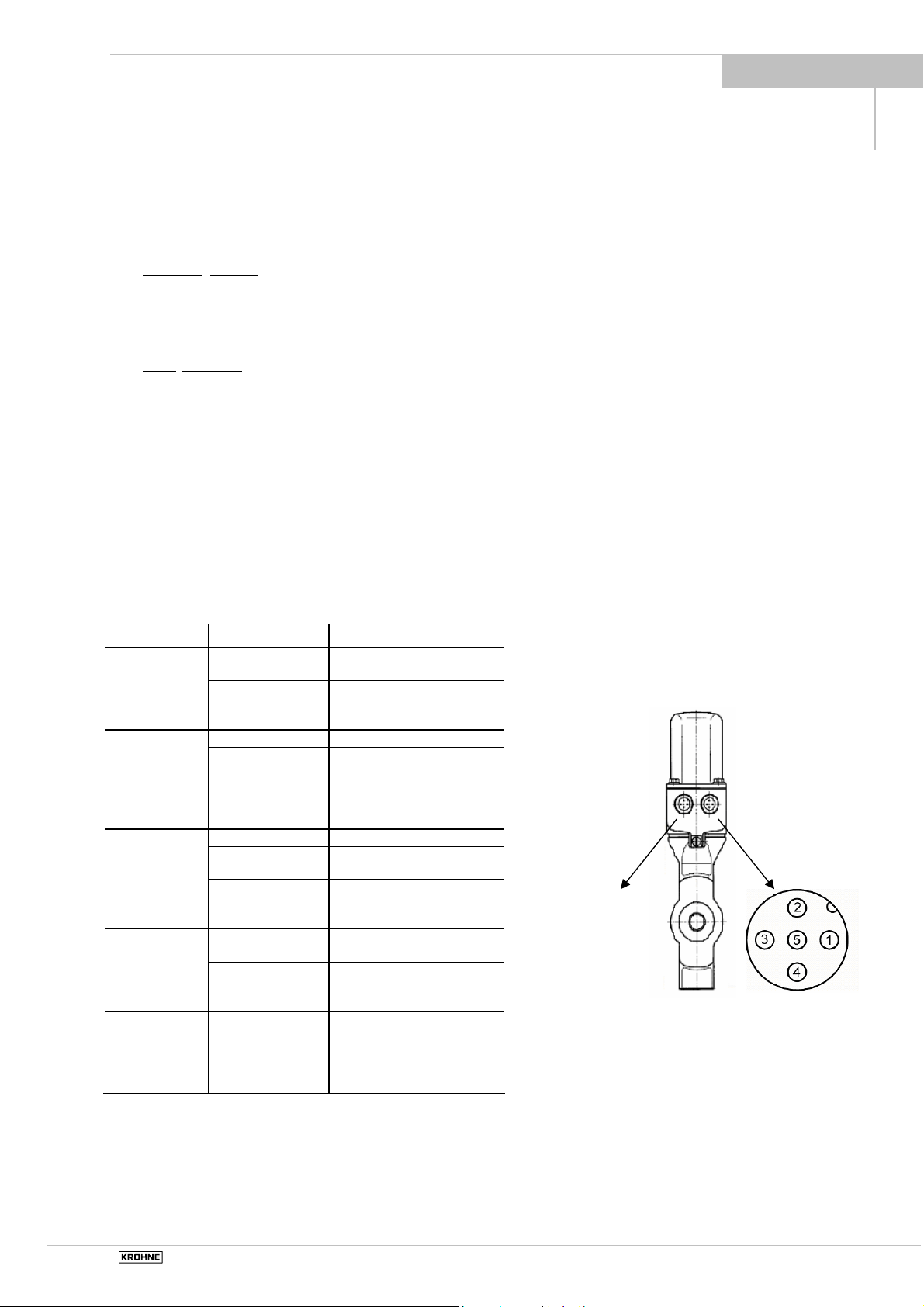

1.4.1 Device description

BATCHCONTROL IFM 5014C

•

4 Cover, signal converter

5 Primary head

7 Connector for the six in-/outputs

8 Connector for power and CAN Bus

9 U-clamp terminal for functional ground

10 Fastening screws for cover

11 Locating collar, primary head

Accessories from system manufacturer

•

12 O-ring gasket

13 Special pipe flange

14 Stud bolt with lock washer,

plain washer and nut

To facilitate servicing of the

primary head, please note the

following points:

It must be possible to shut off the flow

•

through the pipeline upsteam of the primary

head (provide shutoff valve),

Drain the pipe system before removing the

•

primary head (provide drain valve),

Support the pipeline on both sides of the

•

flowmeter when located in a long, freely

suspended section to facilitate removal of

the primary head.

1.4.2 Installation of the IFM 5014C

Position gaskets (12) in the pipe flanges.

•

Type and location of gaskets as specified

•

by the manufacturer of the filling machine

(see Sect. 1.3.2 “Centering of the primary

head”).

Insert primary head (5) between the pipe

•

flanges (13) in line with the pipe axis.

For spacing and location of the pipe

•

flanges, see Sect. 1.3 “Position of flanges”.

Press pipe flanges against flowmeter.

•

Centering ring of pipe flanges must

snap into place in the guide collar

(11) of the primary head.

Insert stud bolts (14) with washers into the

•

holes in the pipe flanges. Fit nuts to stud

bolts with lock washer.

Tighten stud bolts and nuts down to the

•

metal stop symmetrically. Check all bolts

after starting up the pipe system, and

retighten when any leaks show.

Connect ground conductor to U-clamp

•

terminal (9).

Connect power supply, CAN bus and

•

outputs to connector plugs (7, 8) on signal

converter housing (4).

See Section 2.2 and 2.3 for details of

electrical connection.

Installation and operating instructions 10 BATCHCONTROL

Page 11

A

A

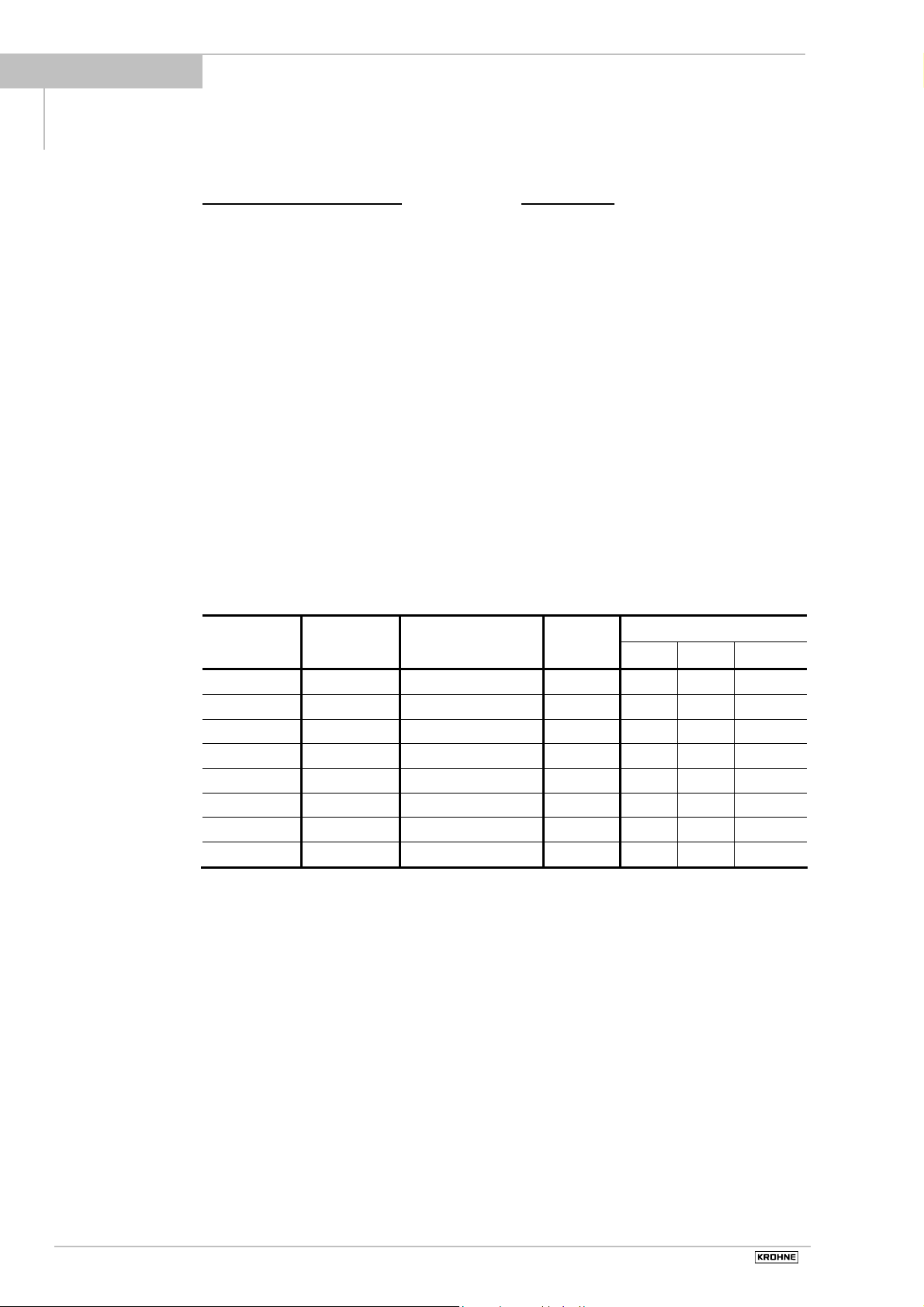

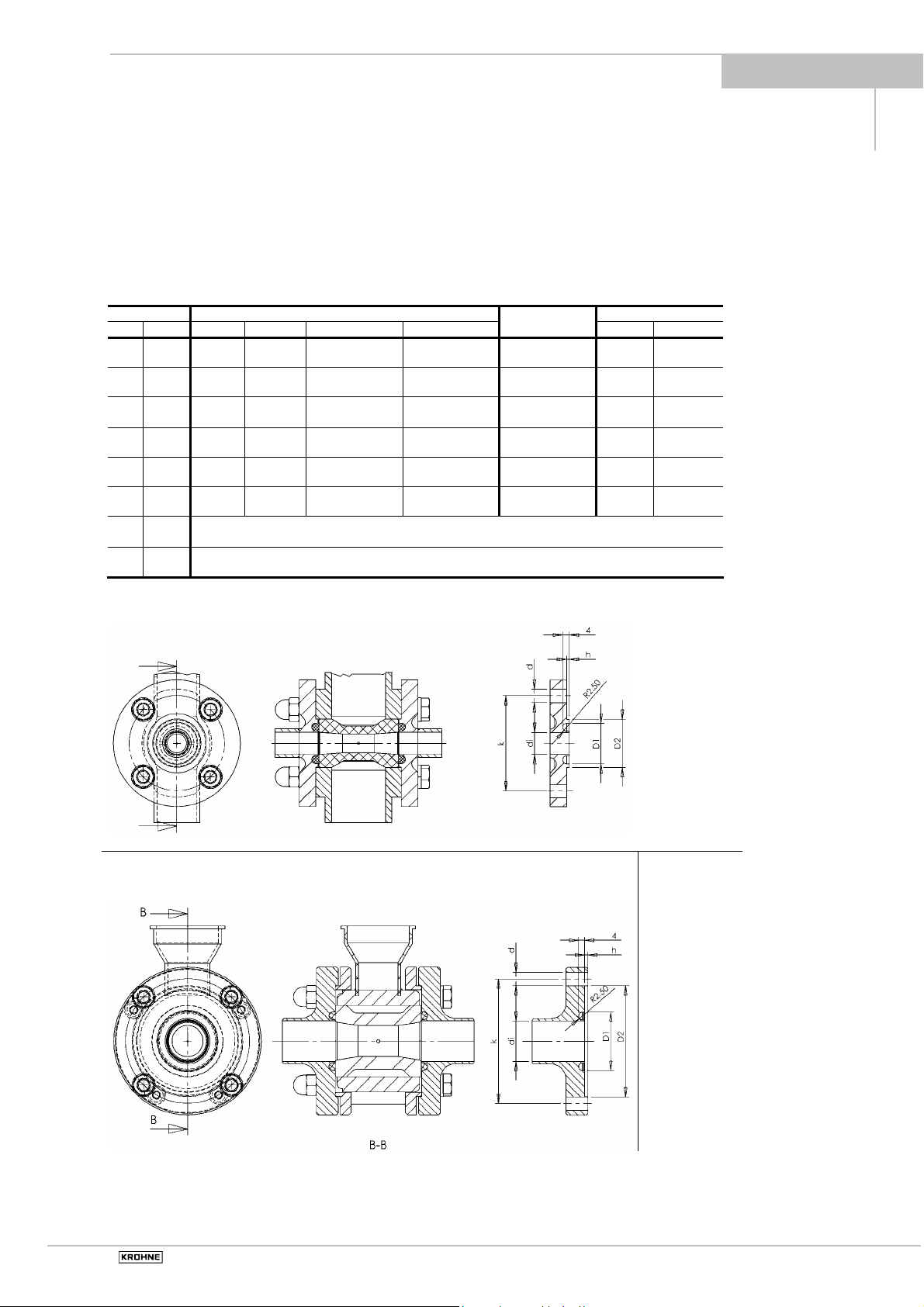

1.5 Size of connections

1.5.1 Fastening with tie bolts

All dimensions in mm (inches)

Flange-material: AISI 300 series

O-ring material: 3A standard 18-03

Meter size Centering device, pipe connection O-Ring Dimensions

DN inches d

1

2.5

/10 6 25.5 30

1

4

/8 7 25.5 30

1

6

/4

3

10

/8 12 25.5 30

1

15

/2 14 25.5 30

i

(0.24) (1.00) (1.18

(0.28) (1.00) (1.18

9 25.5 30

(0.35) (1.00) (1.18

(0.47) (1.00) (1.18

(0.55) (1.00) (1.18

25 1 26 37.5 71.3

(1.02) (1.48) (2.81

1

32

1

/

4

on request

40 11/2 on request

DN 2.5 - 15 / 1/10“ - 1/2“

D1 D2 h 75 Shore k d

1.5

-0.05/-0.15

-0.05/-0.15

-0.05/-0.15

-0.05/-0.15

-0.05/-0.15

) (0.06

-0.002/-0.006

1.5

) (0.06

-0.002/-0.006

1.5

) (0.06

-0.002/-0.006

1.5

) (0.06

-0.002/-0.006

1.5

) (0.06

-0.002/-0.006

2

-0.1

) (0.08

–0.004

on request 60 8.5

-0.05/-0.15

-0.05/-0.15

-0.05/-0.15

-0.05/-0.15

-0.05/-0.15

) on request (2.36) (0.33)

-0.002/-0.006

on request 60 8.5

) on request (2.36) (0.33)

-0.002/-0.006

on request 60 8.5

) on request (2.36) (0.33)

-0.002/-0.006

on request 60 8.5

) on request (2.36) (0.33)

-0.002/-0.006

Ø 16×5 60 8.5

) (Ø 0.47×0.20) (2.36) (0.33)

-0.002/-0.006

Ø 28×5 80 8.5

+0.1

) (Ø 1.10×0.20) (3.15) (0.33)

+0.04

1

DN 25 / 1“

A-A

Installation and operating instructions

DN 32-40 /

1

1

/4“-11/2“

Dimensions

on request

BATCHCONTROL

11

Page 12

1

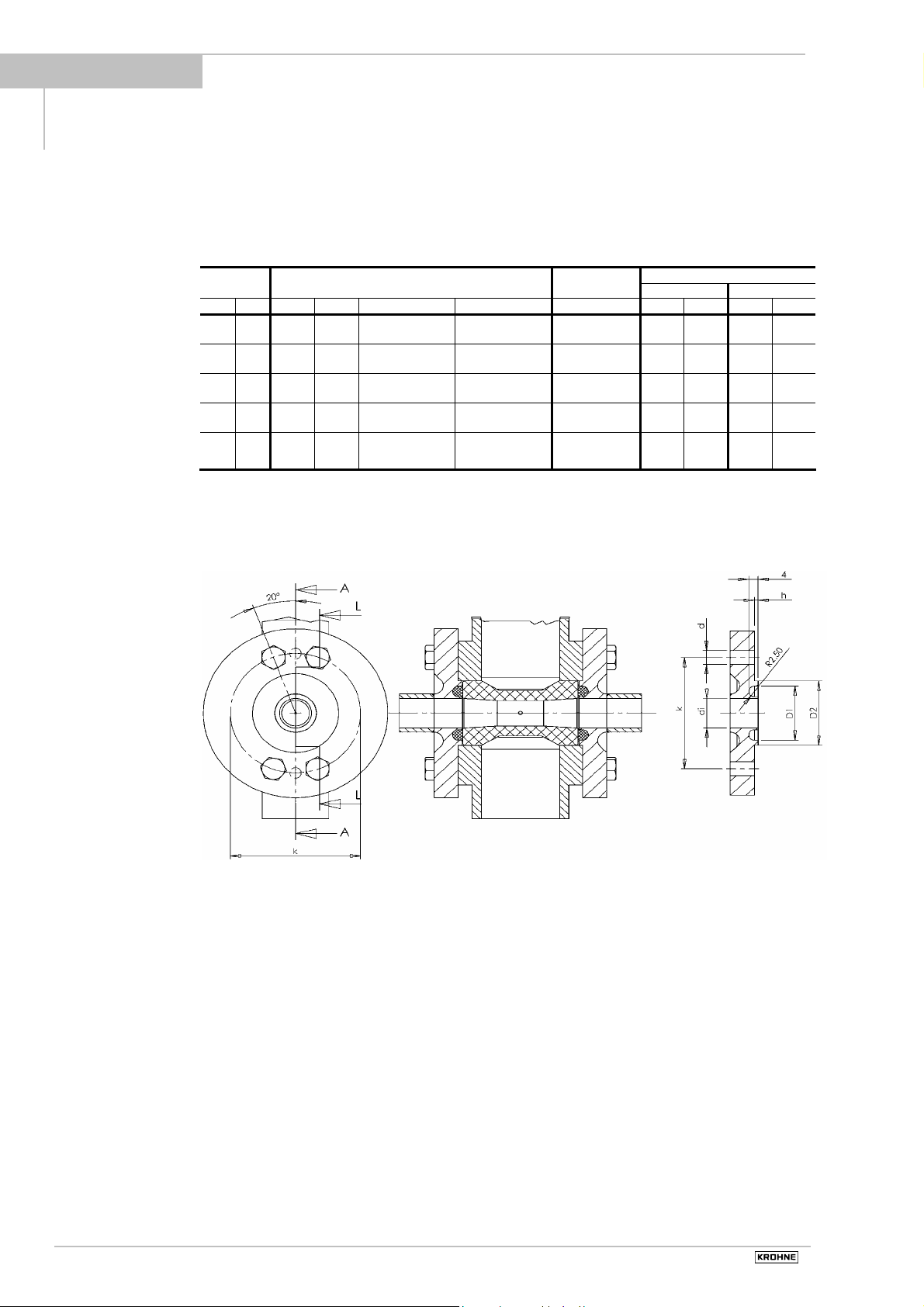

1.5.2 Fastening with bolts (option)

All dimensions in mm (inches)

* Flange-material : AISI 300 series

O-ring material : 3A standard 18-03

Meter size Centering device, pipe connection O-ring Screw thread (option)

gaskets 2× M4 4× M6

inches

DN

1

2.5

1

4

1

6

3

10

1

15

(0.55) (1.00) (1.18

d

D1 D2 h 75 Shore k d k d

/10 6 25.5 30

/8 7 25.5 30

/4 9 25.5 30

/8 12 25.5 30

/2 14 25.5 30

i

(0.24) (1.00) (1.18

(0.28) (1.00) (1.18

(0.35) (1.00) (1.18

(0.47) (1.00) (1.18

-0.05/-0.15

-0.002/-0.006

-0.05/-0.15

-0.002/-0.006

-0.05/-0.15

-0.002/-0.006

-0.05/-0.15

-0.002/-0.006

-0.05/-0.15

-0.002/-0.006

1.5

) (0.06

1.5

) (0.06

1.5

) (0.06

1.5

) (0.06

1.5

) (0.06

on request 60 8.5 56 6.4

-0.05/-0.15

-0.05/-0.15

-0.05/-0.15

-0.05/-0.15

-0.05/-0.15

) on request (2.36) (0.33) (2.20) (0.25)

-0.002/-0.006

on request 60 8.5 56 6.4

) on request (2.36) (0.33) (2.20) (0.25)

-0.002/-0.006

on request 60 8.5 56 6.4

) on request (2.36) (0.33) (2.20) (0.25)

-0.002/-0.006

on request 60 8.5 56 6.4

) on request (2.36) (0.33) (2.20) (0.25)

-0.002/-0.006

-0.002/-0.006

Ø 16×5

)

(Ø 0.47×0.20)

60 8.5 56 6.4

*

(2.36) (0.33) (2.20) (0.25)

*

Installation and operating instructions 12 BATCHCONTROL

Page 13

2 Electrical connection

2.1 Important information

Be sure to take note of the following

information in order to ensure proper

functioning of the signal converter.

Please note:

1) Ov ervolta

In conformity with VDE 0120, equivalent

to IEC 664, the compact flowmeters are

designed for overvoltage category III in

the supply circuits and overvoltage

category II in the output circuits.

2) Safety isolation:

The compact flowmeters must be

provided with an isolating facility.

Electrical connection and repairs may only

be carried out by qualified personnel.

ge class:

2.2 Attachment plugs

Manufacturer Series and type Description

Binder Series 715 Moulded plug, straight or

angle-entry form

Series 763 Integrally extruded plug

with cable in various

lengths

Hirschmann E-Series

ELKA 4012 and

ELWIKA 4012

ELKA KV 4412

and ELWIKA KV

4412

Lumberg RK-Series

RKC and RKCW Moulded plug, straight or

RKT and RKWG Integrally extruded plug

Amphenol Series C 164 P Moulded plug, straight or

Series C 164 P

compact

Coninvers Series BC Moulded plug, straight

Moulded plug, straight or

angle-entry form

Integrally extruded plug

with cable in various

lengths

angle-entry form

with cable in various

lengths

angle-entry form

Integrally extruded plug

with cable in various

lengths

form, especially suitable

for high-interference

environments (keyword:

EMC)

Protect the flowmeter from direct radiant

•

heat (e.g. hot-product tanks), insulate if

necessary.

Do not expose flowmeter to intense

•

vibration. If necessary, support the

pipeline to the right and left of the

flowmeter. Level of vibration in accordance

with IEC 068-2-34: below 2.2g in the 20 2000 Hz frequency range.

Note information given on the instrument

•

nameplate, voltage.

The FE functional ground for the supply

•

power should for measurement reasons be

connected to the separate U-clamp

terminal on the signal converter housing.

When connected to a functional extra-

•

low voltage of 24 V DC, protective

separation (PELV) must be ensured (VDE

0100 / VDE 0106 or IEC 364 / IEC 536 or

equivalent national regulations)..

Pin-assignment and

alignment of cable entry

body

Installation and operating instructions

BATCHCONTROL

13

Page 14

2

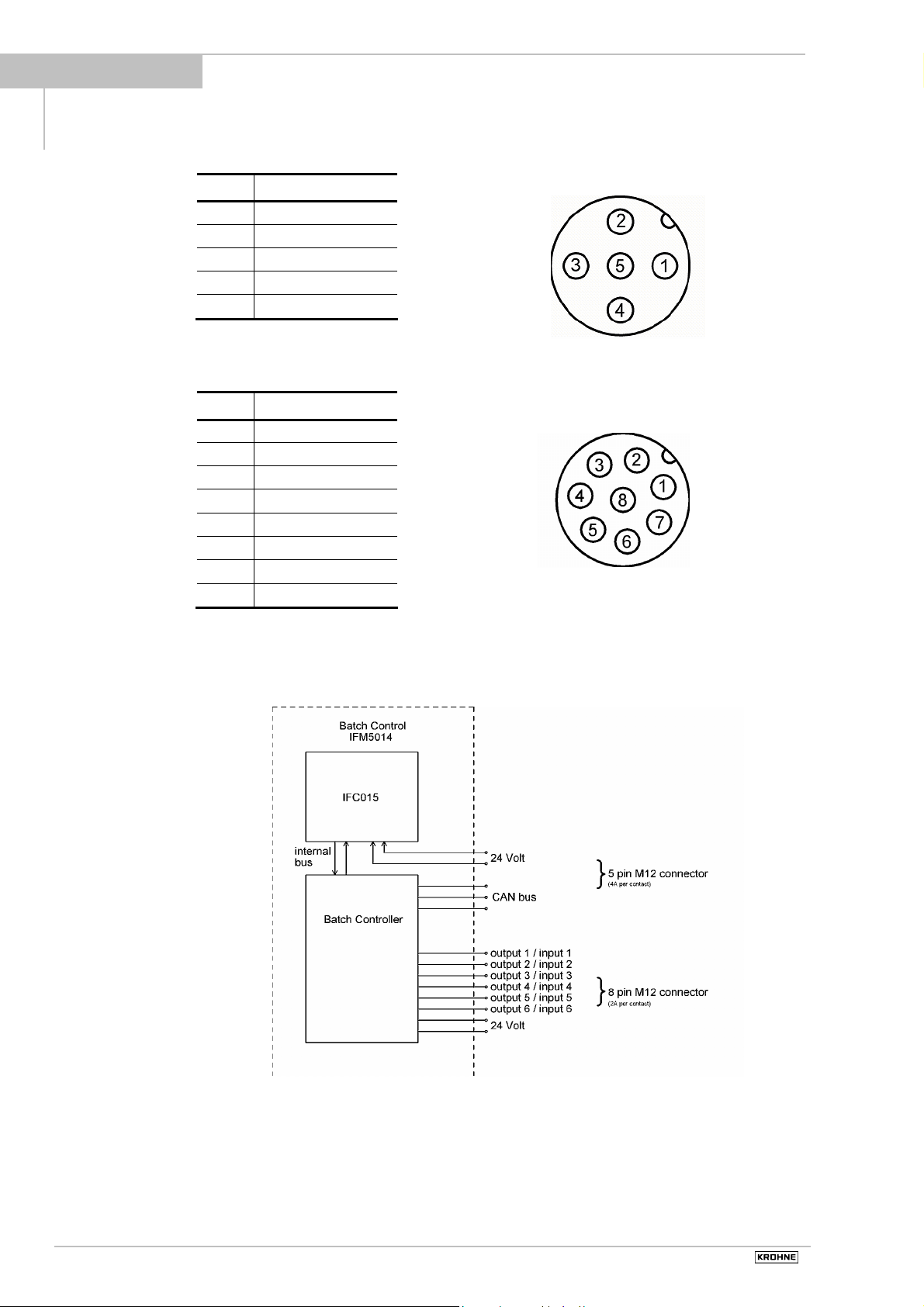

2.3 Power supply and CAN bus

5-pin connector M12x1 for 24V DC power supply and CAN bus

Pin Description

1 ground CAN bus

2 +24 V power

3 ground

4 CAN high level

5 CAN low lev el

Pin assignment

2.4 Input and output

8-pin connector M12x1 for 24V DC power supply and input / output signals

Pin Description

1 input / output 1

2 input / output 2

3 input / output 3

4 input / output 4

5 input / output 5

6 input / output 6

7 +24 V power

8 ground

Pin assignment

2.5 Block circuit diagram

The following picture shows the block circuit diagram of the BATCHCONTROL 5014C:

The individual functions of inputs and outputs are described in detail in the following chapter.

Installation and operating instructions 14 BATCHCONTROL

Page 15

3 Start-up

Before powering the system, check that it has been installed c orrectly according to Sections 1 an d

2.

The compact flowmeter is delivered ready for operat io nal us e. All oper atin g data hav e b een fac t ory

set in accordance with your specifications.

Power the unit, and the flowmeter will start process flow measurement immediately.

3.1 Check for availability

Please note!

Do not open the housing of the BATCHCONTROL IFM 5014C.

Danger of contamination with substances likely to destroy the moisture barrier of the electronic

equipment (e.g. if CIP or SIP cleaned from the outside).

Therefore, please contact your KROHNE Service engineer before you open the housing.

3

The measurement status is signalled by the light-emitting diodes (LED) belo w the cover of the

•

converter housing (see amplifier board on right).

LED 1 LED 2 Function

flashing off in order

flashing flashing overdriving

on flashing Fatal Error

(defective operating

parameter)

off on defective hardware

off off no supply voltage

or hardware

is defective

All operating data can be set and stored by means of a personal computer via the CAN bus

interface. The digital CAN bus interface allows the complete filling procedure to be graphically

represented on the PC, thus providing visualization of system and valve properties.

LED 2

LED 1

3.2 Factory settings

All operating data are factory-set according to your order specifications.

The table of standard factory settings is shown at the end of the manual.

Installation and operating instructions

BATCHCONTROL

15

Page 16

4

Part B IFC 014 batch controller

4 Description of functions

Six contacts are available for the different functions. Every contact can be switched over as a

switching output, switching input or analogous by software. In addition, the d evice has one CAN

bus interface for communication, two internal temperature sensors and one flo w s ensor .

4.1 Contact outputs

Up to six power outputs (24V / I < 200mA), switch over to ground (low side driver) or to the 2 4V

supply voltage (high side driver), can be pr ogrammed by software. The drivers communicate via

the internal data bus with the logic and the other c ontrol and monitoring functions: undervoltage,

overvoltage, overtemperature and failure detection. When commutating inductive loads, the

dissipated power peak is be significantly reduced by the internal freewheeling diode. All power

drivers are connected to the supply voltage. These are monitored by overvoltage and underv oltage

comparators with hysteresis, so that the correct function can be checked in the applicat ion at any

time. They are short-circuit resistant (I

Consumer are controlled for disconnections (cable break) by the outputs, indication by the Bus

interface.

All valve outputs are on equal basis. The following functions can be adjusted:

• Without use (off)

• Permanentl y on (breakdown identification)

• Binary output controlled by the bus

• Switch on after time or after reaching target volume or after reaching a defined volume flow

• Turn off after time or reaching target volume or after reaching a defined volume flow

• Automatically, regulation for target filling volume

• Customers specific programming

2A). Overcharge is indicated by the bus interface.

max

4

4.2 Voltage input

Up to six voltage inputs with common ground for 24V supply voltage are available. The voltage

range is from 0 volts up to 11 volts with a res olution of 8 bits . The input impedanc e of the i nputs ‘1’

and ‘2’ is 220kOhm, for the inputs ‘3’ up to ‘ 6’ is 22kOhm. T he update rate is 8ms . For every input

scaling factors and offsets can be defined. To us e this functionality the corresponding output has to

be switched off. Each voltage input can be programmed for the following functions:

• Without use (off)

• Voltage input for the bus

• Start of filling process

• Emergency off

• Customers specific programming

4.3 Contact inputs

Up to six inputs with common ground for 24V supply voltage. To use this functionality the

corresponding output has to be switched off. Each control input can be programmed for the

following functions:

• Without use (off)

• Binary input for the bus

• Starting of filling process

• Emergency off

• Customers specific programming

4.4 CAN bus and parameter

For the interface the CAN bus is used. Baud rates within the range 20k up to 1M Baud are

possible. For the protocol CANopen is appli ed. The interfac e has a galvanic c onnection to the 24V

supply! The possible functions are described in one of the following chapter.

Default Baud rate is 20k Baud.

Installation and operating instructions 16 BATCHCONTROL

Page 17

The object dictionary for the parameters is subdivided into the following groups:

Object number range Description

10xxH CAN open parameter

300xH Flow sensor parameter

301xH Electronic temperature sensor

302xH Liquid temperature sensor

303xH Function block 1

304xH Function block 2

305xH Function block 3

306xH Function block 4

307xH Function block 5

308xH Function block 6

309xH Batching

30AxH CAN parameter

32xxH Customer specific 1 bit memory

33xxH Customer specific 8 bit memory

34xxH Customer specific 16 bit memory

35xxH Customer specific 32 bit memory

The complete list of all parameters can be found at the end of the manual.

To be able to represent the variety of all possible messages on the bus , the CANopen definition

hasn't been used at the definition of the TPDOs and RPDOs. If this function is programmed, then

the device sends at every message in the firs t data byte a description and in the following bytes

the data. This shall be explained at an example:

The user needs every flow measurement for the anal ysis of the valve. With the parameter

3002.02 the PDO is defined. After this parameter was stored in the BATCHCONTROL

5014C, it sends the actual volume flow every 20 ms. The Telegramm starts in the first byte

with the descriptor (in this case 01H) followed by the meas urement value in float format.

Many parameters can use the same PDO. The distinction of the data is made by the first

byte (called descriptor in the parameter list at the end of the manual).

This function shouldn't be used in CANopen nets.

4

4.5 Temperature sensors

Two temperature sensors are installed inside the BATCHCONTROL 5014C. The first one is

mounted on the BATCHCONTROL print board. This one measures the electronic temperature.

The information can be important during the CIP process or in hot filling application. If the

temperature is higher then 70°C the life time of the electronic compone nts are reduced. An upper

and lower setpoint can be programmed. If one of this po ints are reached, an alarm message is

send via the CAN bus. Alternativly this information can be programmed for an output, which is

used as an alarm output.

The second sensor is mounted on the outside of the c eramic pipe. It has the same functionalit y as

the electronic temperature sensor. Since the temperature s ensor doesn' t have direct contact to the

liquid, the temperature measurement is delayed. The delay time depends on the temperature

gradient and the temperature difference between outside housing and liquid. The delay time can

be a few seconds.

Each sensor can be programmed for the following functions:

• Without use (off)

• Temperature value for the bus

• Temparature alarm for the bus

• Customers specific programming

4.6 Flow Sensor

The integrated flow sensor measures precisely the flow velocity. From this signal the device

generates the information for the internal electronic volume counter. Furthermore the flow values

and the counter are actualized every 20ms. It can be programmed for the following functions:

• Without use (off)

• Volume flow value for the bus

• Totalized Volume value for the bus

4.7 An example for a filling process

The function of the device shall be represented at the example of a t wo-stage filling device. The

following order is used:

Output ‘1’ is for the low speed fluid valve. This valve is opene d during the complete filling

time. The target volume is 1000ml.

Output ‘2’ is for the high speed fluid valve. This valve switch off 50ml before the target

Installation and operating instructions

BATCHCONTROL

17

Page 18

A

4

volume.

Output ‘3’ is used for the carbonizing of the bottle. This valve is t used at the beginning of

the filling process. It opens for 0,6 second.

Output ‘4’ is used for unpreasurizing the bottle at the end of the filling process. It opens for

1 second.

Output ‘5’ an ‘6’ are not used.

CAN PARAMETER

Letter Object No. Description

output 1 3031.01 Function of the block

3034.01 Output hardware function

output 2 3041.01 Function of the block

3044.01 Output hardware function

output 3 3051.01 Function of the block

3054.01 Output hardware function

output 4 3061.01 Function of the block

3064.01 Output hardware function

output 5 3071.01 Function of the block

output 6 3081.01 Function of the block

The following graphic shows the timing diagram of the filling process.

time parameter

0,16

output 4

output 3

output 2

output 1

0,14

0,12

0,10

0,08

Q[l/s]

0,06

0,04

0,02

0,00

0,00 2,00 4,00 6,00 8,00 10,00 12,00 14,00 16,00 18,00

-0,02

B

C D E F G H I J

t[s]

At the time of ‘A’ the filling starts. The bottle gets pressurized with CO2 (‘B’ – ‘C’). After this both

product valves opens at the time of 'D'. The high speed valve is clos ed after 950ml (‘E’) is filled.

The low speed valve is closed at the time of 'F' and the filling is completed to 'G'. The las t step is to

depressurize the bottle ('H' – ‘I’). The next filling starts after 'J'.

CAN PARAMETER

Letter Object No. Description

A 3091.05 Controlling batching process

B 3054.02 Output 3 on function definitio n

3054.03 On value (output 3)

C 3054.05 Output 3 off function definition

3054.06 Off value (output 3)

D 3091.02 Forward run time

3034.02 Output 1 on function definition

3044.02 Output 2 on function definition

E 3044.05 Output 2 off function definition

3044.06 Off value (output 2)

F 3034.05 Output 1 off function definition

G 3091.07 Function select ‘switch off calculation’

3091.08 Function data 1

3091.0A Volume flow value for switch off

3091.0B Number of measurements

3091.0C Definition for shut-down

Installation and operating instructions 18 BATCHCONTROL

Page 19

A

H 3064.02 Output 4 on function definition

3064.03 On value (output 4)

I 3064.05 Output 4 off function definition

3064.06 Off value (output 4)

G – J 3091.03 Time out

There are parameters similar as in the cas e of the time representation, for the supervision of the

volume flow.

volume flow parameter

0,16

0,15

B

0,14

C

0,13

0,12

0,11

0,10

0,09

0,08

0,07

Q[l/s]

0,06

0,05

0,04

0,03

0,02

0,01

0,00

0,00 2,00 4,00 6,00 8,00 10,00 12,00 14,00 16,00 18,00

-0,01

-0,02

flow max. limit flow max. flow Q100%

t[s]

‘A’ is the full scale range of the flow meter. An overload of +50% is permitted. If the flow should get

even bigger, then the value is limited to150%. The v alue 'B' is an emergency switch off value for

the valve. The value 'C' corresponds to the maximum volume flow during the filling process.

CAN PARAMETER

Letter Object No. Description

A 3001.01 Full scale range

B 3003.01 Maximum volume flow

C 3094.06 Maximum flow velocity

The internal volume counter adds up the measurement values. As in the case of the two prev ious

representations the counter has own parameters.

volume parameter

1,20

1,00

F

G

H

I

(internal counter)

4

0,80

0,60

volume [ml]

0,40

0,20

0,00

0,00 2,00 4,00 6,00 8,00 10,00 12,00 14,00 16,00 18,00

A

B

C D E

t[s]

At the time of ‘A’ the filling starts. The bottle gets pres surized with C O2. After this both val v es open

for the product at the time of 'B'. The valve reduces the flow speed at the position of 'C' and the

Installation and operating instructions

BATCHCONTROL

19

Page 20

A

4

filling is completed to 'D'. The parameter ‘I’ is the s witch point for lower speed and ‘H’ is the target

volume. ‘E’, ‘F’ and ‘G’ are alarm and emergency shutoff values.

CAN PARAMETER

Letter Object No. Description

B 3091.02 Forward run time

E 3093.04 Maximum batching time

F 3003.05 Maximum volume

G 3093.01 Maximum tail volume

H 3091.01 Target volume

I 3044.06 Off value

As a rule, valves don't close directly and completel y. It comes to vibrations if the liquid i s suddenl y

stopped. The vibrating amount of liquid is measured. If the oscillation amplitude is in a

programmable area for a predefined number of meas uring, then the filling is regarded as ended.

The following picture shows this process:

end of filling

0,009

0,007

0,005

flow min. value max. value

0,003

Q[l/s]

0,001

12,10 12,20 12,30 12,40 12,50

-0,001

B

-0,003

-0,005

counter : 0 1 0 1 2 0 1 2 3 4 5

start againstart start again filling process finished

C

t[s]

CAN PARAMETER

Letter Object No. Description

A + B 3091.0A Volume flow value for switch off

C 3091.0B Number of measurements

In addition to the described functions alarm and emergency off functions can be progra mmed. The

individual phases of the filling process, changes of state and the filling results can be sent by the

device automatically. The Krohne configuration program represents a good summary of the

possibilities for the BATCHCONTROL 5014C.

If the possibilities shouldn't suffice, then customer specific functions can be down loaded in the

device.

Installation and operating instructions 20 BATCHCONTROL

Page 21

5

Part C Service

5 Illustration of printed circuit board

Please note!

Do not open the housing of the

BATCHCONTROL IFM 5014C.

Danger of contamination with substances likely

to destroy the moisture barrier of the electronic

equipment (e.g. if CIP or SIP cleaned from the

outside).

Therefore, please contact your KROHNE

Service engineer before you open the housing.

1

2

3

4

5

11

12

13

14

6

10

7

8

9

1 Cover, signal converter

2 Gasket

3 Electronic unit, signal converter

4 Housing, signal converter

5 Primary head

7 Printed circuit board

8 Plug connector power supply and

pulse output

9 U-clamp terminal for functional ground

10 Fastening screws for cover

11 Guide collar, primary head

12 O-ring gasket

13 Special pipe flange

14 Stud bolt with lock washer,

plain washer and nut

LED 2

LED 1

5

Installation and operating instructions

BATCHCONTROL

21

Page 22

6

Part D Technical Data, block diagram

and measuring principle

6 Technical data

6.1 Flow during filling, and fill volume

Meter size Optimum flowrate for filling

DN mm inches ml/s US Gal/min ml US Gal

2.5

4

6

10

15

1

/10 3 - 10 0.048 - 0.159

1

/8 10 - 30 0.159 - 0.476

1

/4 20 - 60 0.317 - 0.951

3

/8 60 - 200 0.951 - 3.170

1

/2 150 - 500 2.378 - 7.925

25 1 400 - 1200 6.340 - 19.020

32 11/4 650 - 2250 10.300 - 35.663

40 11/2 1000 - 3000 15.850 - 47.551

6.2 Flowmeter

Meter sizes

with venturi measuring tube DN 2.5, 4, 6, 10, 15, 25, 40 and 1/10", 1/8", 1/4", 3/8", 1/2", 1",11/2"

with straight tube (option) DN 15, 32 and 1/2", 11/4"

Connection sandwich (flangeless) type with precisely defined sealing faces,

centering devices and metallic stop face

Electrical conductivity ≥ 5 µS/cm (≥ 20 µS/cm for demineralized cold water)

Ambient temperature Process temperature

-25 to +40 °C / -13 to +104 °F -60 to +140 °C / -76 to +284 °F

-25 to +60 °C / -13 to +140 °F -60 to + 60 °C / -76 to +140 °F

(information on higher provided on request)

steam cleaning up to +150 °C / +302 °F (max. 1 hour)

Temperature shock resistance Temperature rising Temperature falling

sudden change ∆T = 120 °C = 216 °F ∆T = 90 °C = 162 °F

Temperature gradient 1 K/s = 1.8 °F/s

Operating pressure 40 bar / 580 psig

(10 bar / 145 psig for DN 15, 32 and 1/2", 11/4"

with straight measuring tube)

Electrode design fused-in-place electrodes

Protection category IP 67, equivalent to NEMA 6

(EN 60 529/IEC 529) (overall device, incl. signal converter)

Materials of construction

Housing stainless steel 1.4408 or 1.4404

Measuring tube fine-grain-stabilized, high-density HiTec ceramics,

Electrodes Cermet

purity 88 % Al2O3 + 12%ZrO2, CIP- and SIP-proof

Cover seal EPDM

Filling times > 1.5 s,

filling volume .....

≥

≥

≥

≥

≥

≥

≥

≥

10

20

40

100

200

600

975

1500

0.003

≥

0.005

≥

0.011

≥

0.026

≥

0.053

≥

0.159

≥

0.257

≥

0.396

≥

Installation and operating instructions 22 BATCHCONTROL

Page 23

6.3 Signal converter

Power supply

Voltage 24 V DC, ± 20%

Power consumption ≤ 5 W excl. external loads

Electrical connection two M12 plug-in connector

Operator control All operating data factory-set to your specifications.

Available as option for change of operating data:

- KROHNE software for operator control via PC.

Options connected to the CAN bus interface

6 Valve outputs low or high side activ

Function programmable to control valves,

short and cable broken detect

Voltage 24 V DC, ± 20%

Load rating I

Load short I

6 Analogue inputs alternative to the outputs

Function programmable for alarm messages,

to control the filling process

Voltage 0 – 11 V DC, resolution of 8 bit

Impedance input 1 and 2: 220 kOhm

Input 3 to 6: 22 kOhm

Electronic temperature sensor

Function programmable for alarm messages

Range -20°C … +100°C

Error ± 3 K

Fluid temperature sensor

Function programmable for alarm messages

Range -20°C … +140°C

Error ± 3 K

CAN bus

Baud rate 20k … 1M baud

max

short

≤ 200 mA

≤ 2 A

6

Installation and operating instructions

BATCHCONTROL

23

Page 24

6

6.4 Error limits at reference conditions

F = Error in % of MV

MV = measured value

Pulse output DN 2.5 – 6 /

1

/10“ – 1/

“ DN 10 – 40 /

4

at flow velocity of ...

v ≥ 1 m/s ≥ 3.3 ft/s F < ± 0.5 % of MV F < ± 0.3 % of MV

v < 1 m/s < 3.3 ft/s F < ± 0.4 % of MV + 1 mm/s F < ± 0.2 % of MV + 1 mm/s

< ± 0.4 % of MV + 0.04 inch/s < ± 0.2 % of MV + 0.04 inch/s

Repeatability Filling time TF Standard deviation σ

1.5 s < TF ≤ 3 s ≤ 0.4 %

3.0 s < T

5.0 s < T

≤ 5 s ≤ 0.2 %

F

≤ 0.1 %

F

Reference conditions (similar to EN 29 104)

Liquid product water +20 °C / +68 °F

Straight inlet/outlet runs 10× DN / 5 × DN (DN = meter size)

Valve closing time variation < 1 ms

Flow velocity 1 m/s = 3.3 ft/s

Volumetrically wet calibration on EN 17025 accredited calibration rigs.

3

/8“ – 11/2“

Installation and operating instructions 24 BATCHCONTROL

Page 25

6.5 Dimensions and weights

in mm (inches)

DN 2.5 –15 /

1

/10“ – ½“

flow direction

M12

connector

series 713,

5 and 8-pin

6

X2

M6

option: 4 x M6 bolt hole on both sides

(section M-M)

Meter size Diameter d

DN inches mm (inches) kg lb

2.5

4

6

10

15

1

/10 6 (0.24) 1.6 (3.6)

1

/6 7 (0.28) 1.6 (3.6)

1

/4 9 (0.35) 1.6 (3.6)

3

/8 12 (0.47) 1.6 (3.6)

1

/2 14.3 (0.56) 1.6 (3.6)

Weight

1

Installation and operating instructions

BATCHCONTROL

25

Page 26

6

DN 25 – 40 / 1“ – 1½“

Meter size Dimensions in mm (inches) Weight

DN inches a b f g kg (lb)

25 1 58 (2.28) 200 (7.87) 66 (2.68) 34 (1.34) 1.6 (3.6)

32 1 1/4 83 (3.27) 215 (8.46) 81 (3.19) 42 (1.65) 2.3 (5.1)

40 11/2 83 (3.27) 215 (8.46) 81 (3.19) 42 (1.65) 2.3 (5.1)

6.6 Instrument nameplates

Type designation

Serial No.

Insulation class of field coils

Protection category to IEC529/EN60529

M12

connector

series 713,

5 and 8-pin

IFM 5014 K /B /2

Pressure rating/flange class

Electrode material: platinum

Measuring tube material: Al

Meter size: DN mm and inches

Measuring range Primary constant

l

Installation and operating instructions 26 BATCHCONTROL

28-03

aluminium oxide

2O3

Page 27

7 Block diagram

The IFC 014 signal converter consists of 2 functional groups.

Functional group 1 contains an input amplifier, and a high-resolution analog/digital conv erter that

is controlled and monitored by microprocessor CPU 1. It controlled also the direct current for the

field coils of the primary head.

Functional group 2 is the batch controller board. It is supdevided in the six IO-function blocks, the

CAN bus interface and the temperature sensors. All functions are controlled by the CPU 2.

Block diagram IFC 014

7

Installation and operating instructions

BATCHCONTROL

27

Page 28

8

8 Measuring principle

Flowmeter for electrically conductive

liquids.

Measurement is based on Faraday’s law

of induction, according to which a voltage

is induced in an electrically conductive

body passing through a magnetic field.

The following expression applies:

U = K × B × v × D

K an instrument constant

B magnetic field strength

v mean velocity

D tube diameter

U

B

v

D

U

Thus, the induced voltage is proportional to the

mean flow velocity, when the field strength is

constant. Inside the electromagnetic flowmeter,

the liquid passes through a magnetic field

applied perpendicular to the direction of flow.

An electric voltage is induced by the movement

of the liquid (which must have a minimum

electrical conductivity), which is proportional to

the mean flow velocity and thus to the volume

of flow.

The induced voltage signal is picked up by two

electrodes that are in conductive contact with

the liquid, and transmitted to a signal converter

for a standardized output signal.

Installation and operating instructions 28 BATCHCONTROL

Page 29

E E

E 1 Index

Part E Annex

Keyword Section-No. Fct-No.

A

Ambient temperature 1.1, 6.2

B

Block diagram IFC 014 C 6, 7

C

Cleaning 1.3, 6.2

Connection diagrams

– outputs 2.4

– power supply 2.3

Connection points

– grounding 1.3.3

D

Data, Technical 6

Device description 1.4.1

DN = meter size in mm 6.1, 6.2

E

Electrical connection

– outputs 2.4

– power supply 2.3

– status output 2.5

– current output 2.5

– pulse output 2.5

Electrodes 6.2, 8

Errors 1.2

Error (messages) 4.5

F

Factory settings 3.2

Fatal Error 3.1

FE = functional ground 5

Flanges 1.3

Flanges, Position of 1.3.1

Flow (Q) 1.1, 1.4.1, 4,

Flow velocity v 4.4, 6.4, 8

Flow, direction of 1.2

Frequency output S

– pulse output P 2.3.3, 4.4, 5.7 1.6

4.6, 6

Functional description page 5

Function(s) 4.4

Functional ground FE 1.3.2, 2.1

– measuring range 6.6

H

Hardware info 4

I

Impulse output =

pulse output P

(frequency output) 5.6

Instrument nameplates 6.6

L

Limits 1.1, 6.4

M

Measuring principle 6, 8

Measuring tube 1.1, 1.3

Meter size (DN) = nominal dia.

of measuring tube in mm or 1.1, 1.5, 6.1, 3.2

inches 1.5, 6.1, 6.5

Keyword Section-No. Fct-No.

O

Operating pressure 11.3, 6.2

Option 1.5.2, 6.2,

P

P = pulse output 6.4

Power supply (= line voltage) 1.4.1, 2.3,

– frequency 2.2, 10.5

– power consumption 6.3

– voltage 6.3

Primary constant, see GKL 6.6 3.2

Primary head

– installation 1.1 - 1.4

Process temperature 1.1, 6.2

Pulse output P / pulse width 5.6 1.6

Q

Q = flowrate 6.1 1.1, 3.2

R

Removal of

– device (total) 1.4.1

S

Signal converter IFC 015

– operator control 6.3

– error limits 6.4

Software 4, 6.3

Start-up 3

Straight outlet run 1.1

Straight inlet run 1.1

Storage 1.1

Standards

– ANSI . . . 1.3,

– DIN . . . 1.3,

– EN . . 2.2

– EMC page 4

– IEC . . . 1.1,1.3.3,

2.1, 6.2

– VDE . . . 1.3.3, 2.1,

T

Technical data 6

– dimensions + weights 1.5.1, 6.5

– error limits 6.4

– limits for

– signal converter IFC 015 K 6.3, 8

– primary head 1.1, 1.3.2,

Temperatures

– ambient 1.1, 6.2

Totalizer (internal electronic) 4.6, 5.7 1.6

Transport 1.1

V

v = flow velocity 4.6, 4.7 3.2

6.2, 6.5

6.3

6.3

1.4

Installation and operating instructions

BATCHCONTROL

Page 30

E

E 2 C AN parameter

Object No

Index

Value (default)

10xxH CANopen parameter

1000H 00H Device type without long 0 r - - 0x00000014 (const. value)

1008H 00H Manufacturer Device Name without string - - r - - “IFC “

1009H 00H

1010H Parameter save

1010H 00H 1 Number of entries without byte - - r - -

1010H 01H

1011H Parameter recall

1011H 00H 1 Number of entries without byte - - r - -

1011H 01H 1

1017H 00H 250 Consumer heartbeat time ms word 0 65535 r/w - d

1018H Identity Object

1018H 00H 4 Number of entries without byte - - r - -

1018H 01H Vendor Id without long - - r - -

1018H 02H Product code without long - - r - -

1018H 03H Revisionsnumber without long - - r - -

1018H 04H Serialnumber without long - - r - -

300xH Flow sensor parameter

3001H Sensor parameter

3001H 00H 7 Number of entries without byte - - r - 3001H 01H 1 Full scale range l/s float 0,0015 15,1 r/w - d

3001H 02H 1 Time constant S float 0,1 99 r/w - as

3001H 03H 15 Meter size mm float 2,5 40 r/w - as Meter size of tube

3001H 04H 3,3 Sensor constant without float 0,5 9,9 r/w - as Calibration constant of Sensor

3001H 05H 0 Zero point l/s float -1,0 +1,0 r/w - as Zero point of Sensor

3001H 06H 0 Flow direction without byte 0 1 r/w - as

3001H 07H 0 Auto zero function - byte 0 1 r/w - d Zero point calculation

Bit 0: Activation of function

3002H M easurement values and PDO definition

3002H 00H 6 Number of entries without byte - - r - 3002H 01H 0,0

3002H 02H 4

Bit 1-0: Priority

00 = PDO 0

01 = PDO 1

10 = PDO 2

11 = PDO 3

Bit 2: Activation of function

Manufacturer Hardware

Version

Save all parameters in

EEPROM

Recall all parameters from

EEPROM to RAM

Volume flow without time

constant

Sending function for Index

01H

Description

Dimension

without string - - r - - “014 “

without long - - r/w - d

without long - - r/w - d

l/s float -15,1 15,1 r 01H -

without byte 0 4 r/w - d

Format

min

max

access

Descriptor

transfer

Save databytes: 65H 76H 61H 73H

Read: 00H 00H 00H 01H

Recall databytes: 64H 61H 6FH

6CH

Read: 00H 00H 00H 01H

Full scale value, basis for values

given as percentage values

Time constant for output value, of

no significance for

BATCHCONTROL

Actual measurement flow value

without time constant

Sending function measurement

value without time constant

Description

0 = as printed on

instrument

1 = contrary to

imprint

1 = function

active

0 = function

switched off

Installation and operating instructions 30 BATCHCONTROL

Page 31

Object No

Index

Value (default)

3002H 03H 0,0

3002H 04H 4

Bit 1-0: Priority

00 = PDO 0

01 = PDO 1

10 = PDO 2

11 = PDO 3

Bit 2: activation of function

3002H 05H 0,0 Currently measured volume l float -1000 1000 r 03H d Currently totalized volume

3002H 06H 4

Bit 1-0: Priority

00 = PDO 0

01 = PDO 1

10 = PDO 2

11 = PDO 3

Bit 2: activation of function

3003H Alarm values and PDO definition

3003H 00H 8 Number of entries without byte - - r - -

3003H 01H 1 Maximum volume flow l/s float 0,0001 15,1 r/w - d

3003H 02H 0 Definition for shut-down without byte 0 63 r/w - d

3003H 03H - Actual status without byte 0 1 r 04H 3003H 04H 4

00 = PDO 0

01 = PDO 1

10 = PDO 2

11 = PDO 3

Bit 2: activation of function

3003H 05H 1,0 Maximum volume l float 0,0001 100,0 r/w - d

3003H 06H 0 Definition for shut-down without byte 0 63 r/w - d Bit 0: 1 = output 1 switch off if

Volume flow with time

constant

Sending function for Index

03H

Sending function for Index

05H

Sending function for Index

03H

Description

Dimension

l/s float -15,1 15,1 r 02H -

without byte 0 4 r/w - d

without byte 0 4 r/w - d

without byte 0 4 r/w - d Bit 1-0: Priority

Format

min

max

access

Descriptor

transfer

actual measurement flow value with

time constant

Sending function Measurement

value with time constant

Bit 2-0: Sending function volume

counter

Limit value for volume flow (without

time constant) with emergency

shut-down

Bit 0: 1 = output 1 switch off if

volume flow is to high, 0 = no

influencing of t he output

Bit 1: 1 = output 2 switch off if

volume flow is to high, 0 = no

influencing of t he output

Bit 2: 1 = output 3 switch off if

volume flow is to high, 0 = no

influencing of t he output

Bit 3: 1 = output 4 switch off if

volume flow is to high, 0 = no

influencing of t he output

Bit 4: 1 = output 5 switch off if

volume flow is to high, 0 = no

influencing of t he output

Bit 5: 1 = output 6 switch off if

volume flow is to high, 0 = no

influencing of t he output

Bit 0: 1 = Limit value exceeded, 0 =

okay

Limit value for counted volume with

emergency shut-down

Description

1 = no message

output

0 = activation of

message output

1 = no message

output

0 = activation of

message output

1 = no message

output

0 = activation of

message output

1 = no message

output

0 = activation of

message output

Installation and operating instructions

BATCHCONTROL

Page 32

Object No

Index

Value (default)

3003H 07H - Actual status without byte 0 1 r 05H 3003H 08H 4

00 = PDO 0

01 = PDO 1

10 = PDO 2

11 = PDO 3

Bit 2: activation of function

Sending function for Index

07H

Description

Dimension

without byte 0 4 r/w - d Bit 1-0: Priority

Format

min

max

access

Descriptor

transfer

volume is to high, 0 = no

influencing of t he output

Bit 1: 1 = output 2 switch off if

volume is to high, 0 = no

influencing of t he output

Bit 2: 1 = output 3 switch off if

volume is to high, 0 = no

influencing of t he output

Bit 3: 1 = output 4 switch off if

volume is to high, 0 = no

influencing of t he output

Bit 4: 1 = output 5 switch off if

volume is to high, 0 = no

influencing of t he output

Bit 5: 1 = output 6 switch off if

volume is to high, 0 = no

influencing of t he output

Bit 0: 1 = Limit value exceeded, 0 =

okay

Description

1 = no message

output

0 = activation of

message output

301xH Electronic temperature sensor

3011H Sensor parameter

3011H 00H 2 Number of entries without byte - - r - -

1000,

3011H 01H 1.0 Factor for scaling without float 0,001

3011H 02H 0.0 Offset for scaling °C float -100,0 100,0 r/w - d

3012H M easurement values and PDO definition

3012H 00H 3 Number of entries without byte - - r - 3012H 01H 0,0 Measuring value °C float -10 +100 r 11H - actual measured temperature

3012H 02H 4

Bit 1-0: Priority

00 = PDO 0

01 = PDO 1

10 = PDO 2

11 = PDO 3

Bit 2: activation of function

3012H 03H 250 Repeat time ms word 50 5000 r/w - d Repeat time for the value

3013H Alarm values and PDO definition

3013H 00H 4 Number of entries without byte - - r - 3013H 01H 20 Lower limit value °C float -10 +80 r/w - d

3013H 02H 70 Upper limit value °C float 0 +100 r/w - d

3013H 03H 0 Status of measuring input without byte 0 15 r 12H -

Bit 2: 1 = sensor cable break

Bit 3: 1 = sensor short circuit

3013H 04H 4

Sending function for index

01H

Sending function for index

03H

without byte 0 4 r/w - d

without byte 0 4 r/w - d Sending function change of status

r/w - d

0

Sending function of temperature

output (repeat time depends on

index 3)

1 = no message

output

0 = activation of

message output

Warning message when value

remains below limit

Warning message when value

exceeds limit

Bit 0: 1 = lower limit value is

exceeded

Bit 1: 1 = upper limit value is

exceeded

Installation and operating instructions 32 BATCHCONTROL

Page 33

Object No

Index

Value (default)

Bit 1-0: Priority

00 = PDO 0

01 = PDO 1

10 = PDO 2

11 = PDO 3

Bit 2: activation of function

302xH Liquid temperature sensor

3021H Sensor parameter

3021H 00H 2 Number of entries without byte - - r - 3021H 01H 1.0 Factor for scaling without float 0,001 1000 r/w - d

3021H 02H 0.0 Offset for scaling °C float -100,0 100,0 r/w - d

3022H M easurement values and PDO definition

3022H 00H 3 Number of entries without byte - - r - 3022H 01H 0,0 Measuring value °C float -10 +150 r 21H - actual measured temperature

3022H 02H 4

Bit 1-0: Priority

00 = PDO 0

01 = PDO 1

10 = PDO 2

11 = PDO 3

Bit 2: activation of function

3022H 03H 250 Repeat time ms word 50 5000 r/w - d Repeat time for the value

3023H Alarm values and PDO definition

3023H 00H 4 Number of entries without byte - - r - 3023H 01H 20 Lower limit value °C float -10 +140 r/w - d

3023H 02H 70 Upper limit value °C float 0 +150 r/w - d

3023H 03H 0 Status of measuring input without byte 0 15 r 22H -

Bit 2: 1 = sensor cable break

Bit 3: 1 = sensor short circuit

3023H 04H 4

Bit 1-0: Priority

00 = PDO 0

01 = PDO 1

10 = PDO 2

11 = PDO 3

Bit 2: activation of function

30yxH Functi on bl ocks (3 <= y <= 8)

30y1H Functi on block definition

30y1H 00H 1 Number of entries without byte - - r - 30y1H 01H 0 Function of the block without byte 0 5 r/w - D Bit 3 - 0: function definition

Sending function for index

01H

Sending function for index

03H

Description

Dimension

without byte 0 4 r/w - d

without byte 0 4 r/w - d Sending function change of status

Format

min

max

access

Descriptor

transfer

Sending function of temperature

output (repeat time depends on

index 3)

Warning message when value

remains below limit

Warning message when value

exceeds limit

Bit 0: 1 = lower limit value is

exceeded

Bit 1: 1 = upper limit value is

exceeded

Description

0 = activation of

message output

1 = no message

output

1 = no message

output

0 = activation of

message output

0 = activation of

message output

1 = no message

output

Installation and operating instructions

BATCHCONTROL

Page 34

Object No

Index

Value (default)

0000 = off

30y2H Bi nary input parameter and PDO definition (only valid if 30y1.1 = 01H)

30y2H 00H 4 Number of entries without byte - - r - 30y2H 01H 0 Function of Input without byte 0 20 r/w - D Bit 3 - 0: Function of Input

Bit 4: Polarity of Input

0 = high active

1 = low active

30y2H 02H 0 Definition for shut-down without byte 0 63 r/w - d

30y2H 03H 0 Status of Input without byte 0 1 r y1H - Bit 0: actual status of Input

0 = Input is off

1 = Input is on

30y2H 04H 4

Bit 1-0: Priority

00 = PDO 0

01 = PDO 1

10 = PDO 2

11 = PDO 3

Bit 2: activation of function

30y3H Analog ue i nput and PDO definition (only valid if 30y1.1 = 02H)

30y3H 00H 10 Number of entries without byte - - r - 30y3H 01H 0 Function of Input without byte 0 20 r/w - d Bit 3 - 0: Function of Input

Sending function for Index

03H

Description

Dimension

without byte 0 4 r/w - d

Format

min

max

access

Descriptor

transfer

Description

0001 = binary

input

0010 = analogue

input

0011 = binary

output

0100 = pulse

width modulated

output

0101 = customer

program

0000 = without

function (off)

0001 = Start of

batching

0010 = Stop of

batching

(emergency shutdown)

0011 = Input for

Bus

0100 = customer

program

Bit 0: 1 = output 1 switch off if input

is high, 0 = no influencing of the

output

Bit 1: 1 = output 2 switch off if input

is high, 0 = no influencing of the

output

Bit 2: 1 = output 3 switch off if input

is high, 0 = no influencing of the

output

Bit 3: 1 = output 4 switch off if input

is high, 0 = no influencing of the

output

Bit 4: 1 = output 5 switch off if input

is high, 0 = no influencing of the

output

Bit 5: 1 = output 6 switch off if input

is high, 0 = no influencing of the

output

Bit 3-0: Sending function change of

status

1 = no message

output

0 = activation of

message output

0000 = without

function (off)

0001 = input for

bus

Installation and operating instructions 34 BATCHCONTROL

Page 35

Object No

Index

Value (default)

Bit 4: Calculation function

30y3H 02H 1,0

30y3H 03H 0,0

30y3H 04H 0,0

30y3H 05H 4

Bit 1-0: Priority

00 = PDO 0

01 = PDO 1

10 = PDO 2

11 = PDO 3

Bit 2: activation of function

30y3H 06H 250 Repeat time ms word 50 5000 r/w - d Repeat time for the value

30y3H 07H 10 Maximum voltage V float 0,0001 12,0 r/w - d

30y3H 08H 0 Definition for shut-down without byte 0 63 r/w - d

30y3H 09H 0 Actual status without byte 0 1 r y3H 30y3H 0AH 4

00 = PDO 0

01 = PDO 1

10 = PDO 2

11 = PDO 3

Bit 2: activation of function

30y4H Bi nary output parameter and PDO definition (only valid if 30y1.1 = 03H)

30y4H 00H 9 Number of entries without byte - - r - -

30y4H 01H 0 Output hardware function without byte 0 3 r/w - d

Scaling factor for analogue

input

Scaling offset for analogue

input

Measured voltage (with

scaling)

Sending function for Index

04H

Sending function for Index

09H

Description

Dimension

without float 0,0001 1000 r/w - as

V float -1000 1000 r/w - as

V float 0,0 1000 r y2H - actual measured voltage

without byte 0 4 r/w - d

without byte 0 4 r/w - d Bit 1-0: Priority

Format

min

max

access

Descriptor

transfer

The measured analogue voltage [V]

is multiplied with this factor

The offset is added to the

measured analogue voltage [V]

(voltage = offset + factor*real

voltage)

Sending function of analogue value

(repeat time depends on index 6)

Limit value for voltage with

emergency shut-down

Bit 0: 1 = output 1 switch off if

voltage is to high, 0 = no

influencing of t he output

Bit 1: 1 = output 2 switch off if

voltage is to high, 0 = no

influencing of t he output

Bit 2: 1 = output 3 switch off if

voltage is to high, 0 = no

influencing of t he output

Bit 3: 1 = output 4 switch off if

voltage is to high, 0 = no

influencing of t he output

Bit 4: 1 = output 5 switch off if

voltage is to high, 0 = no

influencing of t he output

Bit 5: 1 = output 6 switch off if

voltage is to high, 0 = no

influencing of t he output

Bit 0: 1 = Limit value exceeded, 0 =

okay

Bit 0: definition for high or low side

driver

Description

0010 = start of

batching

0011 = stop of

batching

(emergency shutdown)

0100 = customer

program

0 = input >

parameter

1 = input <

parameter

1 = no message

output

0 = activation of

message output

1 = no message

output

0 = activation of

message output

0 = output

switching to

Installation and operating instructions

BATCHCONTROL

Page 36

Object No

Index

Value (default)

Bit1: output polarity

0 = high active

1 = low active

30y4H 02H 0

30y4H 03H

30y4H 04H 0 Input channel for on signal without byte 0 31 r/w - d

0000 = function 1

0001 = function 2

0010 = function 3

0011 = function 4

0100 = function 5

0101 = function 6

Bit 4: Calculation function

30y4H 05H 0

Output on funct ion

definition

0,001

On value

s

Output off function

definition

Description

Dimension

without byte 0 11 r/w - d

l or s or V or

°C

without byte 0 11 r/w - d

float

Format

0s

0l

0l/s

0V

-20°C

min

max

100s

100l

15l/s

r/w - d

11V

120°C

access

Descriptor

transfer

Bit 0-3: definition for switching the

output on

According to selected function: on

time or volume or volume flow or

temperature or voltage

Bit 0-3: input channel for output on

function

Bit 0-3: definition for switching the

output off

Description

ground

1 = output

switching to +24V

0000 = without

function (off)

0001 = switch on

by input

0010 = switch on

by bus

0011 = switch on

by time

0100 = switch on

by volume

0101 = switch on

by volume flow

0110 = switch on

by fluid

temperature

0111 = switch on

by electronic

temperature

1000 = switch on

by analogue

voltage

1001 = switch on

by batch program

1010 = switch on

by error detected

1011 = switch on

by customer

program

0 = input >

parameter

1 = input <

parameter

0000 = without

function (off)

0001 = switch off

by input

0010 = switch off

by bus

0011 = switch off

by time

0100 = switch off

by volume

0101 = switch off

by volume flow

0110 = switch off

by fluid

temperature

0111 = switch off

by electronic

temperature

Installation and operating instructions 36 BATCHCONTROL

Page 37

Object No

Index

Value (default)

30y4H 06H

30y4H 07H 0 Input channel for off signal without byte 0 21 r/w - d

0000 = function 1

0001 = function 2

0010 = function 3

0011 = function 4

0100 = function 5

0101 = function 6

Bit 4: Calculation function

30y4H 08H 0 Status of output without byte 0 7 r/w y4H - Bit 0: actual status of output

0 = output is off

1 = output is on

Bit 2-1: error status of output

00 = no error

30y4H 09H 4

Bit 1-0: Priority

00 = PDO 0

01 = PDO 1

10 = PDO 2

11 = PDO 3

Bit 2: activation of function

0,001

Off value

s

Sending function for Index

08H

Description

Dimension

l or s or l/s

or V or °C

without byte 0 4 r/w - d

float

Format

min

0s

0l

0l/s

0V

-20°C

max

100s

100l

15l/s

r/w - d

11V

120°C

access

Descriptor

transfer

According to selected function: off

time or volume or volume flow or

temperature or voltage

Bit 0-3: input channel for output off

function

Bit 3-0: Sending function change of

status

Description

1000 = switch off

by analogue

voltage

1001 = switch off

by batch program

1010 = switch off

by error detected

1011 = switch off

by customer

program

0 = input >

parameter

1 = input <

parameter

01 = short circuit

(only detected if

output is on)

10 = interruption

(only detected if

output is on)

11 = chip

temperature to

high

1 = no message

output

0 = activation of

message output

309xH Batching

3091H Filling parameter

3091H 00H 15 Number of entries without byte - - r - d

3091H 01H 0,5 Target volume l float 0,0001 200 r/w - d

3091H 02H 0,02 Forward run time s float 0.01 10 r/w - d

3091H 03H 0,5 Time out s float 0.01 10 r/w - d

3091H 04H 1 Counter control without byte 0 3 w - d

Bit 0: Start/Stop Counter

0 = stop counter

Automatic output controls on this

parameter

Time after starting, before opening

of valve

Time after filling, before a new run

instruction is accepted

Counter control (only active on

manual control output))

Installation and operating instructions

BATCHCONTROL

Page 38

Object No

Index

Value (default)

Bit 1: Counter reset

0 = no function

3091H 05H 0

3091H 06H 0 Learning function - byte 0 3 r/w - d Self learning function

Bit 1-0: Activation of function

0 = function off

1 = not allowed

3091H 07H 0

3091H 08H 0 Function data 1 - byte 0 5 r/w - d

3091H 09H 0 Function data 2 - byte 0 255 r/w - d

3091H 0AH 0,001

3091H 0BH 10 Number of measurements byte 1 100 r/w - d Parameter for the function 3091.10

3091H 0CH 0 Definition for shut-down without byte 0 63 r/w - d

3091H 0DH 100 Fixed tail volume 1 ml byte 0 255 r/w - d

3091H 0EH 100 Fixed tail volume 2 ml byte 0 255 r/w - d

3091H 0FH 10

3092H Status values and PDO definition

3092H 00H 2 Number of entries without byte - - r - d

3092H 01H 0 Actual status of batching without byte 0 5 r 91H -

Bit 0-3: actual status of batching

0 = stop

Controlling batching

process

Function select for ‘switch

off calculation’

Volume flow value for

switch off

Percentage of target

volume

Description

Dimension

without byte 0 3 w - d

- byte 0 1 r/w - d

l/s float 0 15,1 r/w - d

% byte 0 50 r/w - d

Format

min

max

access

Descriptor

transfer

Description

1 = counter

operates

1 = reset the

counter

Bit 0: 1 = Start filling through bus,

only at batching process = CAN

Bus (0 = without function)

Bit 1: 1 = Stop filling through bus,

independent from other inputs (0 =

without function)

2 = function on,

no other action

3 = function on

and the next

filling starts the

self learning cycle

Programm select for switch off

calculation

0 = switch off point depends from

the last 1 to 5 tail volumes

1 = switch off point depends from

the actual flow and the last 1 to 5

tail volumes

First data for the function ‘switch off

calculation’

Fct = 0: number of tail volumes for

switch off calculation (1 to 5)

Fct = 1: number of tail volumes for

switch off calculation (1 to 5)

Second data for the function ‘switch

off calculation’

(for future use)

If the volume flow is lower then this

value, the filling will stop after

number of measurements

Bit 0: 1 = output 1 switch off if

3091_05 Bit 1 = 1 , 0 = no

influencing of t he output

Bit 1: 1 = output 2 switch off if

3091_05 Bit 1 = 1, 0 = no

influencing of t he output

Bit 2: 1 = output 3 switch off if

3091_05 Bit 1 = 1 , 0 = no

influencing of t he output

Bit 3: 1 = output 4 switch off if

3091_05 Bit 1 = 1, 0 = no

influencing of t he output

Bit 4: 1 = output 5 switch off if

3091_05 Bit 1 = 1, 0 = no

influencing of t he output

Bit 5: 1 = output 6 switch off if

3091_05 Bit 1 = 1, 0 = no

influencing of t he output

this tail volume is used for the next

filling (if the bit 4 is set in RPDO1)

and after power on

this tail volume is used for the next

filling (if the bit 5 is set in RPDO1)

this tail volume is used for the next

filling (if the bit 6 is set in RPDO1)

Installation and operating instructions 38 BATCHCONTROL

Page 39

Object No

Index

Value (default)

1 = wait

2 = fill

3 = tail

4 = pause

5 = break

Bit 4 - 7: not used

3092H 02H 4

Bit 1-0: Priority

00 = PDO 0

01 = PDO 1

10 = PDO 2

11 = PDO 3

Bit 2: Activation of function

3093H Alarm values and PDO definition

3093H 00H 20 Number of entries without r

3093H 01H 0,05 Maximum tail volume l float 0,0001 1,0 r/w - d

3093H 02H 0 Actual status without byte 0 1 r 92H 3093H 03H 4

Bit 1-0: Priority

00 = PDO 0

01 = PDO 1

10 = PDO 2

11 = PDO 3

Bit 2: Activation of function

3093H 04H 10 Maximum batching time s float 0,01 100 r/w - d

3093H 05H 0 Definition for shut-down without byte 0 63 r/w - d

3093H 06H 0 Actual status without byte 0 1 r 93H 3093H 07H 4

Bit 1-0: Priority

00 = PDO 0

01 = PDO 1

10 = PDO 2

11 = PDO 3

Bit 2: Activation of function

1 = no message

Sending function for Index

01H

Sending function for Index

02H

Sending function for Index

06H

Description

Dimension

without byte 0 4 r/w - D

without byte 0 4 r/w - d

without byte 0 4 r/w - d

Format

min

max

access

Descriptor

transfer

Description

Sending function at change of

status

1 = no message

output

0 = activation of

message output

Limit value tail volume, status info

only

Bit 0: 1 = Limit value overstepped,

0 = okay

Sending function at change of

status

1 = no message

output

0 = activation of

message output

Limit value for batching time with

emergency shut-down

Bit 0: 1 = output 1 switch off if

batching time is to high, 0 = no

influencing of t he output

Bit 1: 1 = output 2 switch off if

batching time is to high, 0 = no

influencing of t he output

Bit 2: 1 = output 3 switch off if

batching time is to high, 0 = no

influencing of t he output

Bit 3: 1 = output 4 switch off if

batching time is to high, 0 = no

influencing of t he output

Bit 4: 1 = output 5 switch off if

batching time is to high, 0 = no

influencing of t he output

Bit 5: 1 = output 6 switch off if

batching time is to high, 0 = no

influencing of t he output

Bit 0: 1 = Limit value overstepped,

0 = okay

Sending function at change of

status

Installation and operating instructions

BATCHCONTROL

Page 40

Object No

Index

Value (default)

3093H 08H 0,3 Maximum tail time s float 0,005 10 r/w - d

3093H 09H 0 Actual status without byte 0 1 r 94H 3093H 0AH 4

Bit 1-0: Priority

00 = PDO 0

01 = PDO 1

10 = PDO 2

11 = PDO 3