Konica 7920 Wiring Diagram fs133e

FrameMaker Ver.5.5(PC) FS-133/FS-134 OPTION FOR 7915/7920

01.02.09

FS-133/FS-134

SERVICE MANUAL

14413

FrameMaker Ver.5.5(PC) FS-133/FS-134 OPTION FOR 7915/7920

01.02.09

CONTENTS

GENERAL,

MECHANICAL/ELECTRICAL

1. SPECIFICATIONS ........................................................................................... M-1

2. PARTS IDENTIFICATION ........................................................... ....................M-3

3. CROSS-SECTIONAL VIEW ............................................................................M-4

4. DRIVE SYSTEM ..............................................................................................M-5

5. ELECTRICAL COMPONENTS LAYOUT ........................................................M-6

6. PAPER TRANSPORT ..................................................................................... M-8

6-1. Paper Transport Mechanism ...................................................................M-8

(1) Entrance Section Paper Transport Mechanism ...............................M-8

(2) 1st Tray Paper Transport Mechanism .............................................M-9

(3) Finisher Tray Paper Transport Mechanism .....................................M-10

(4) Elevator Tray Paper Transport Mechanism .....................................M-11

6-2. Paper Switchback Mechanism .................................................................M-12

6-3. Roller/Rolls Spacing Mechanism .............................................................M-13

(1) Storage Roller/Rolls Spacing Mechanism .......................................M-13

(2) Exit Roller/Rolls Spacing Mechanism ..............................................M-13

7. PUNCH MECHANISM (FS-134) ......................................................................M-14

8. FINISHER TRAY .............................................................................................M-16

8-1. Paper Aligning Mechanism ......................................................................M-17

(1) Aligning Plate ...................................................................................M-17

(2) Paddles ............................................................................................M-18

9. STAPLING ....................................................................................................... M-19

9-1. Stapling Mechanism ................................................................................M-19

9-2. Stapling Unit Moving Mechanism ............................................................M-20

9-3. Staple Sheet Empty Detection .................................................................M-21

10. ELEVATOR TRAY ............................................ ........................... ....................M-22

10-1.Elevator Tray Ascent/Descent Mechanism ..............................................M-22

10-2.Elevator Tray Shifting Mechanism ...........................................................M-24

11. HORIZONTAL TRANSPORT UNIT ............................... ..................................M-25

11-1.Paper Transport Mechanism ...................................................................M-26

(1) Paper Path Switching Mechanism ...................................................M-26

(2) Finisher Paper Transport Mechanism .............................................M-27

SWITCHES ON PWB, TEST MODE

1. SWITCHES ON PWB ......................................................................................S-1

2. TEST MODE ........................ ........................... ........................... ......................S-2

2-1. Test Mode Setting Procedure ..................................................................S-2

2-2. Test Mode Operations .............................................................................S-2

2-3. Operation in Each Test Mode Operation .................................................S-3

(1) 1st Tray Exit .....................................................................................S-3

(2) Elevator Tray Exit .............................................. ..............................S-3

(3) Finisher Tray Exit .............................................................................S-3

(4) Shifting Operation ............................. ........................... ....................S-3

(5) Aligning Plate Operation ..................................................................S-4

i

FrameMaker Ver.5.5(PC) FS-133/FS-134 OPTION FOR 7915/7920

01.02.09

(6) Stapling Unit CD Movement ............................................................S-4

(7) Exit Roller/Rolls Spacin g ............................................... ..................S-4

(8) Storage Roller/Rolls Spacing ...........................................................S-4

(9) Elevator Tray Operatio n ............................................................... ...S-5

(10) Hole Punch Operation (FS-134) ......................................................S-5

(11) Hole Position Selection (FS-134) U.S.A. and Canada ....................S-5

(12) Se n sor Test ........... ........................... ........................... ....................S-5

DIS/REASSEMBLY, ADJUSTMENT

1. DISASSEMBLY AND REASSEMBLY ............ ........................... ......................D-1

1-1. Maintenance Schedule ..................................................................... .. .... .D-1

1-2. Removal of the Exterior Parts .................................................................. D-1

1-3. Removal of the Punch Unit ......................................................................D-2

1-4. Removal of the Stapling Unit ...................................................................D-2

2. ADJUSTMENTS ..............................................................................................D-3

2-1. Check and Adjustment of the Hole Punch Positions ...............................D-3

2-2. Adjustment of the Solenoids ....................................................................D-4

(1) Adjustment of the Upper/Lower Entrance Switching Solenoid

(SL1) .............................................................................................D-4

(2) Adjustment of the 1st Tray Entrance Selecting Solenoid (SL2) .......D-4

2-3. Timing Belt Tension Adjustment ..............................................................D-5

(1) Adjustment of the Upper Entrance Motor (M4) Timing Belt .............D-5

(2) Adjustment of the Lower Entrance Motor (M2) Timing Belt .............D-5

(3) Adjustment of the Exit Motor (M3) Timing Belt ............................... .D-5

2-4. Adjustment of the Elevator Tray Upper Limit Sensor ...............................D-6

TROUBLESHOOTING

1. SENSOR CHECK ............................................. ........................... ....................T-1

1-1. Sensor Check Scre en ......................... ........................... ..........................T-1

1-2. Sensor Check List ............................... .............. ............................ ...........T-2

1-3. Sensor Check Proc edu re .......................... ........................... ....................T-4

2. MISFEED DETECTION AND TROUBLESHOOTING PROCEDURES ...........T-5

2-1. Misfeed Detecting Sensor Layout ............................................................T-5

2-2. Misfeed Detection ....................................................................................T-6

2-3. Misfeed Troubleshooting Procedures ......................................................T-7

(1) Transport misfeed ............................................................................T-7

(2) Misfeed at the 1st Tray exit .............................................................T-7

(3) Misfeed at the Elevator Tray exit .....................................................T-8

(4) Paper stack exit misfeed ....... ..........................................................T-8

(5) Staple misfeed .................................................................................T-8

3. MALFUNCTION DETECTION AND TROUBLESHOOTING

PROCEDURES ...............................................................................................T-9

3-1. Malfunction Detection ..............................................................................T-9

3-2. Malfunction Troubleshooting Procedures ................................................T-10

(1) C0B20 .............................................................................................T-10

(2) C0B30 .............................................................................................T-10

(3) C0B48 .............................................................................................T-10

(4) C0B4A .............................................................................................T-10

ii

FrameMaker Ver.5.5(PC) FS-133/FS-134 OPTION FOR 7915/7920

01.02.09

(5) C0B50 .............................................................................................T-11

(6) C0B54 (FS-134) ..............................................................................T-11

(7) C0B73 (FS-134) ..............................................................................T-11

(8) C0B78 (FS-134): U.S.A. and Canada .............................................T-11

(9) C0B80 .............................................................................................T-11

(10) C0BA0 .............................................................................................T-12

4. TIME CHART ....................................... ....................................................... .....T-13

4-1. Non-Sort Mode/Sort Mode .......................................................................T-13

4-2. Sort staple Mode/Hole Punch Mode ........................................................T-14

iii

FrameMaker Ver.5.5(PC) FS-133/FS-134 OPTION FOR 7915/7920

01.02.09

GENERAL,

MECHANICAL/ELECTRICAL

FrameMaker Ver.5.5(PC) FS-133/FS-134 OPTION FOR 7915/7920

01.02.09

1. SPECIFICATIONS

Type : Multi Staple Finisher (FS-134)

Single Staple Finisher (FS-133)

Installation : Freestanding

Modes : Non-Sort Copier

Non-Sort, Sort, Gr oup

Sort Staple, Group Staple PC Print

Hole Punch (FS-134)

Copy Medium

Mode Paper Type Paper Size Paper Weight Capacity

Plain paper

Thick paper

Transparen-

Non-Sort

Sort, Group

Sort Staple,

Group

Staple

Hole Punch Plain paper

✽

: 20 sheets if originals of high ID (Color Wise 3) is used.

cies

Translucent

paper

Postcards

Envelopes

Plain paper A3L to B5L/C

Thick paper

Plain paper

A3L to A6L

11

17 to

×

5-1/2

8-1/2

×

11

17 to

×

8-1/2

11

×

A3L to B5L

17 to

11

×

8-1/2

11

×

64 to 209 g/m

17 to 55-1/2 lb

64 to 209 g/m

17 to 55-1/2 lb

64 to 90 g/m

17 to 24 lb

250 sheets

2

20 sheets

FS-134:

2

3,000 sheets

(A4L or

smaller);

1,500 sheets

(B4L or larger)

FS-133:

1,000 sheets

(A4L or

2

smaller);

500 sheets

(B4L or larger)

Finishing

Tray

st

Tray

1

Elevator

Tray

st

Tray,

1

Elevator

Tray

Max. No. of

Sheets to be

Stapled

FS-134:

50 sheets

(64 to 90 g/m2,

17 to 24 lb)

FS-133:

30 sheets

(64 to 80 g/m2,

17 to 21 lb)

: 35 sheets when using Color Copy 90 paper (FS-134).

: 15 sheets when using Color Copy 90 paper (FS-133).

: 20 sheets when using Radiant White paper (FS-133).

✽

✽

M-1

FrameMaker Ver.5.5(PC) FS-133/FS-134 OPTION FOR 7915/7920

01.02.09

Registration : Center

No. of Holes : 2, 3 or 4 holes

Power Requirements : DC 24 V (supplied from copier)

DC 5 V (generated by Finisher)

Power Consumption : 63 W

Dimensions : Width: 538 mm, 21-1/4

Depth: 629 mm, 24-3/4

Height: 978 mm, 38-1/2

Mass : FS-134: 39.2 kg, 86-1/2 lb

FS-133: 35.5 kg, 78-1/4 lb

Environmental Require-

ments

Supplies : Staple Cartridge

: Same as copier

M-2

FrameMaker Ver.5.5(PC) FS-133/FS-134 OPTION FOR 7915/7920

01.02.09

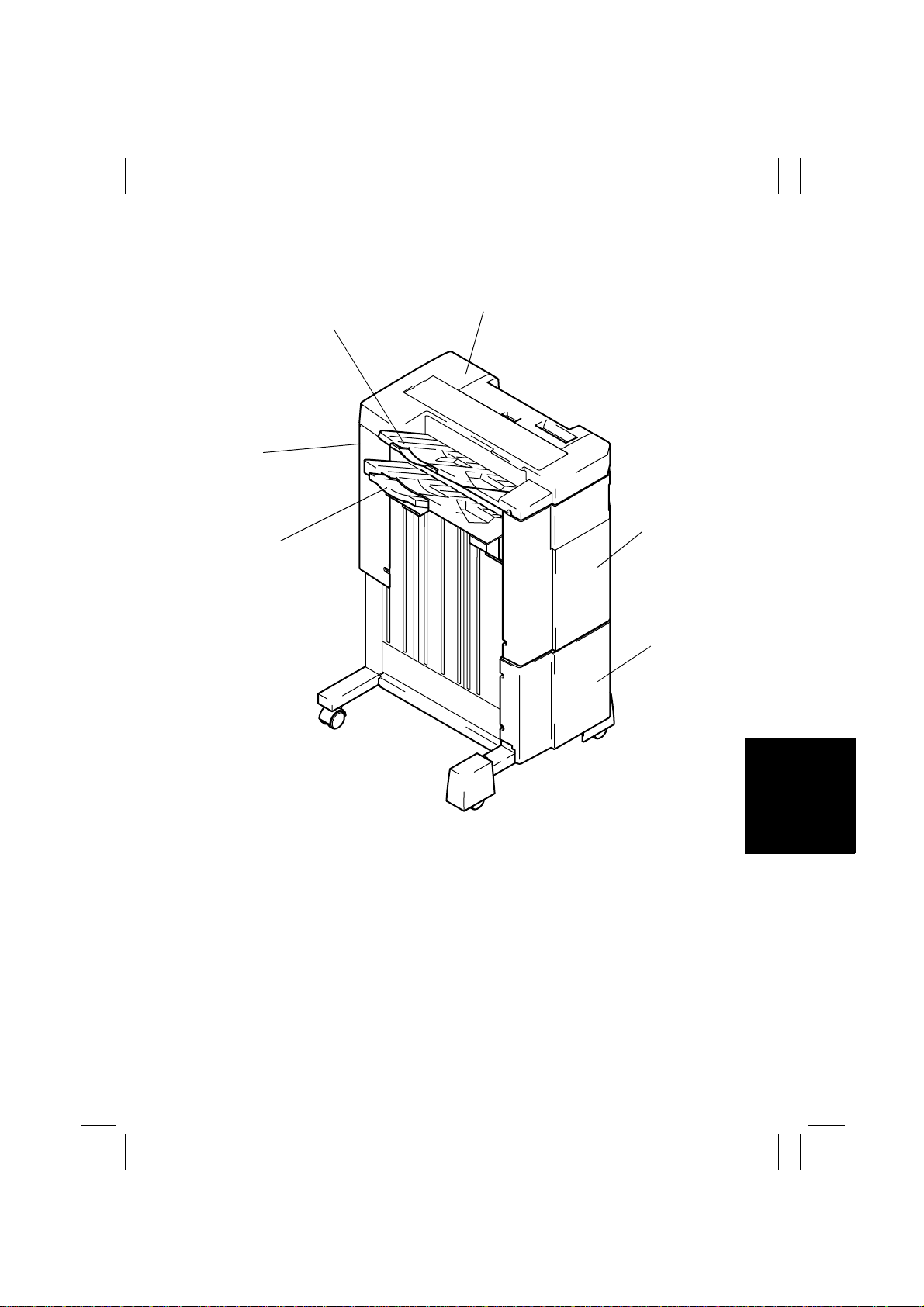

2. PARTS IDENTIFICATION

2

1

6

5

1. 1st Tray

2. Upper Cover

3. Upper Front Cover

3

4

4643M001AA

4. Lower Front Cover

5. Elevator Tray

6. Rear Cover

M-3

FrameMaker Ver.5.5(PC) FS-133/FS-134 OPTION FOR 7915/7920

01.02.09

3. CROSS-SECTIONAL VIEW

13

13

2

14

12

11

10

4

9

5

8

6

7

1. 1st Tray Exit Roll

st

2. 1

Tray Exit Roller

3. Upper Path Transport Roller

4. Upper Path Transport Roll

5. Entrance Roller

6. Transport Rolls

7. Transport Rollers

4853M001AB

8. Entrance Roll

9. Lower Path Transport Roll

10. Lower Path Transport Roller

11. Storage Roller

12. Storage Roll

13. Exit Roller

14. Exit Roll

M-4

FrameMaker Ver.5.5(PC) FS-133/FS-134 OPTION FOR 7915/7920

01.02.09

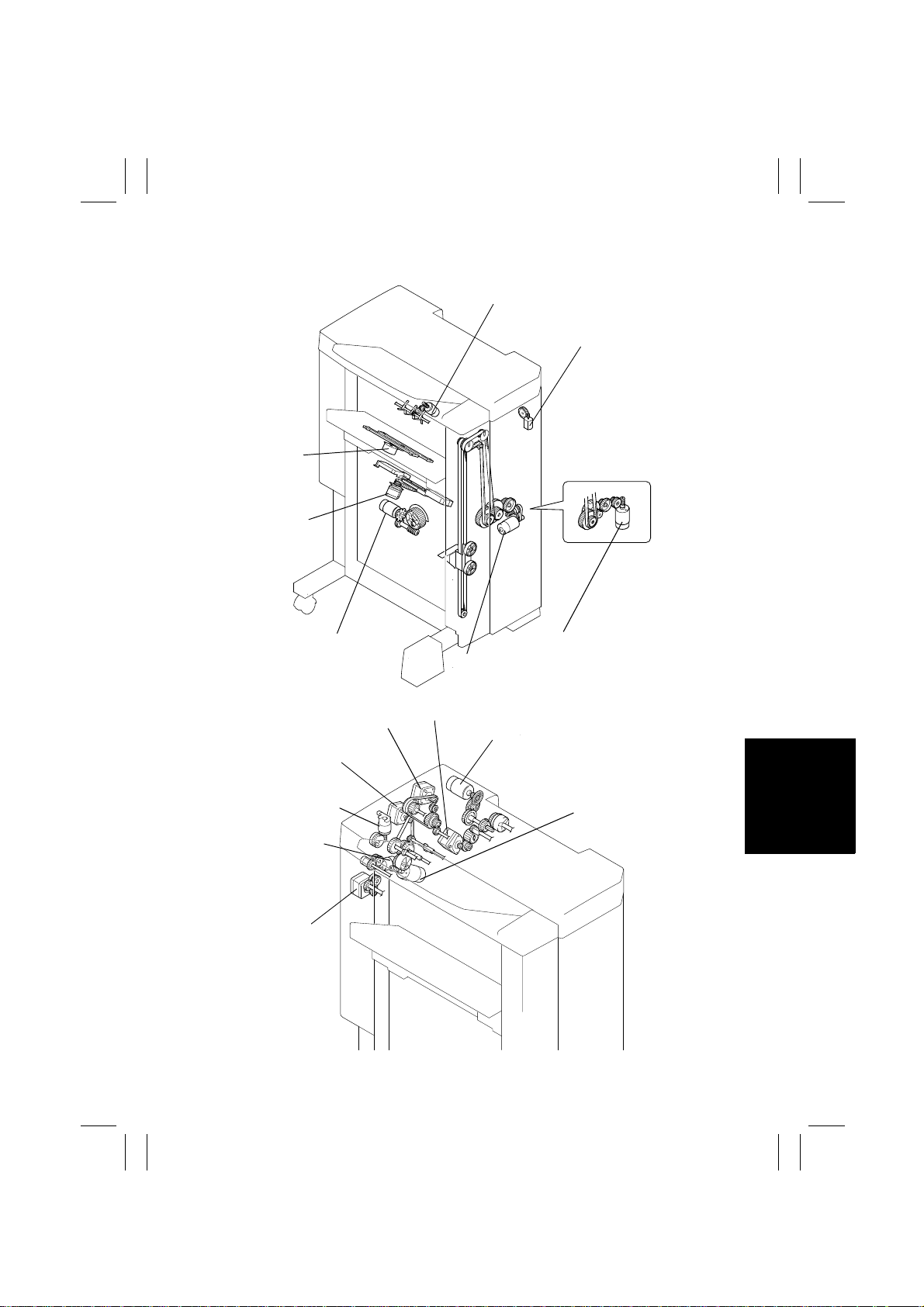

4. DRIVE SYSTEM

Lower Paddle Motor (M9)

Hole Position Selector Motor (M14):

FS-134 (U.S.A. and Canada)

CD Aligning

Motor (M5)

Stapling Unit

Moving Motor (M6)

Shift Motor (M8)

Upper Entrance Motor (M4)

Lower Entrance Motor (M2)

Exit Roller/Rolls

Spacing Motor (M13)

Upper Paddle

Motor (M15)

Exit Motor (M3)

Elevator Motor (M7): FS-133

Elevator Motor (M7): FS-134

Entrance Motor (M1)

Punch Motor (M11): FS-134

4643M003AC

Storage Roller/Rolls

Spacing Motor (M12)

4643M004AA

M-5

FrameMaker Ver.5.5(PC) FS-133/FS-134 OPTION FOR 7915/7920

01.02.09

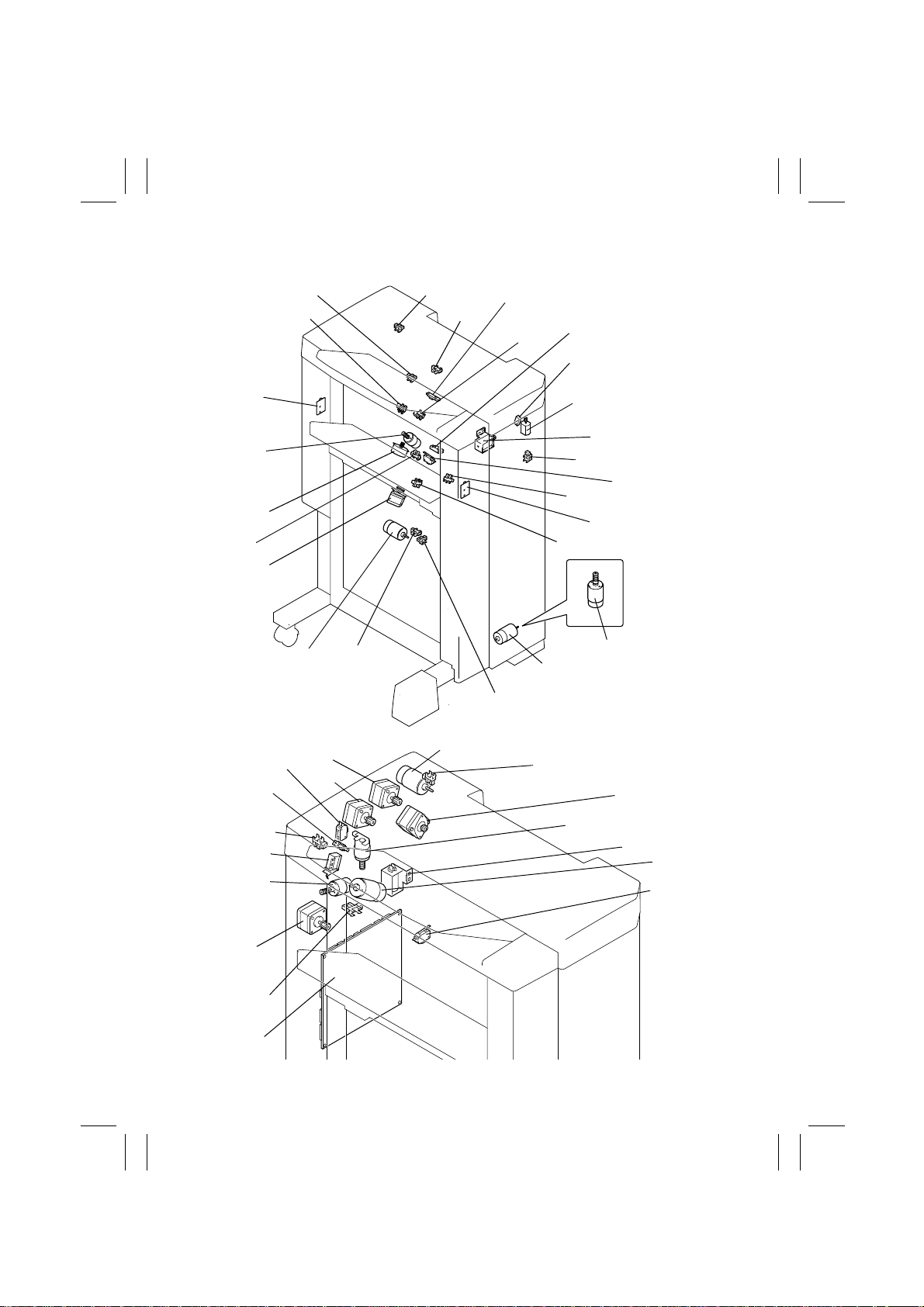

5. ELECTRICAL COMPONENTS LAYOUT

PWB-D

M9

PC8

M5

M6

PC6

PC4

M8

PC11

PC18

PC1

PC2

PC10

PC3

PC5

S4 (✽1): U.S.A. and

Canada

M14 (✽1):U.S.A. and

Canada

SL2

PC17

S2

PC9

PWB-C

PC14

M7 (✽2)

M7 (✽1)

4643M005AC

PC13

SL3

M15

M3

PC12

PWB-A

PC7

S3

M4

M2

M11 (✽1)

PC15 (✽1)

M1

M13

SL1

M12

S1

4643M006AA

M-6

FrameMaker Ver.5.5(PC) FS-133/FS-134 OPTION FOR 7915/7920

01.02.09

Symbol Name Symbol Name

PWB-A Control Board PC1

PWB-C Elevator Tray Upper Limit Sen-

PWB-D Elevator Tray Upper Limit Sen-

M2 Lower Entrance Motor PC6

M3 Exit Motor PC7 Elevator Tray Full Detecting

M4 Upper Entrance Motor

M5 CD Aligning Motor PC8 Elevator Tray Paper Detecting

M6 Stapling Unit Moving Motor

M7 (✽1, ✽2) Elevator Motor PC9 CD Aligning Home Position

M8 Shift Motor

M9 Lower Paddle Motor PC10 Shift Home Position Sensor

M11 (✽1) Punch Motor PC11 Shift Motor Pulse Sensor

M12 Storage Roller/Rolls Spacing

M13 Exit Roller/Rolls Spacing

M14 (✽1) Hole Position Selector Motor PC14 Staple Home Position Sensor

M15 Upper Paddle Motor PC15 (✽1) Punch Motor Pulse Sensor

SL1 Upper/Lower Entrance Switch-

SL2

SL3 Upper Paddle Solenoid

(✽1): Parts used exclusively for FS-134

(✽2): Parts used exclusively for FS-133

sor LED

sor PQ

Motor

Motor

ing Solenoid

st

Tray Entrance Selecting

1

Solenoid

PC2 Lower Entrance Sensor

PC3 Storage Sensor

PC4 Upper Entrance Sensor

PC5 Finisher Tray Paper Detecting

PC12 Storage Roller Home Position

PC13 Exit Roller Home Position Sen-

PC17 Front Door Detecting Sensor

PC18 Upper Cover Detecting Sensor

S1 Set Switch

S2 Elevator Tray Upper Limit

S3 Elevator Tray Lower Limit

S4 (✽1) Hole Punch Position Switch

st

1

Tray Exit Sensor

SensorM1 Entrance Motor

st

Tray Full Detecting Sensor

1

Sensor

Sensor

Sensor

Sensor

sor

Switch

Switch

M-7

FrameMaker Ver.5.5(PC) FS-133/FS-134 OPTION FOR 7915/7920

01.02.09

6. PAPER TRANSPORT

6-1. Paper Transport Mechanism

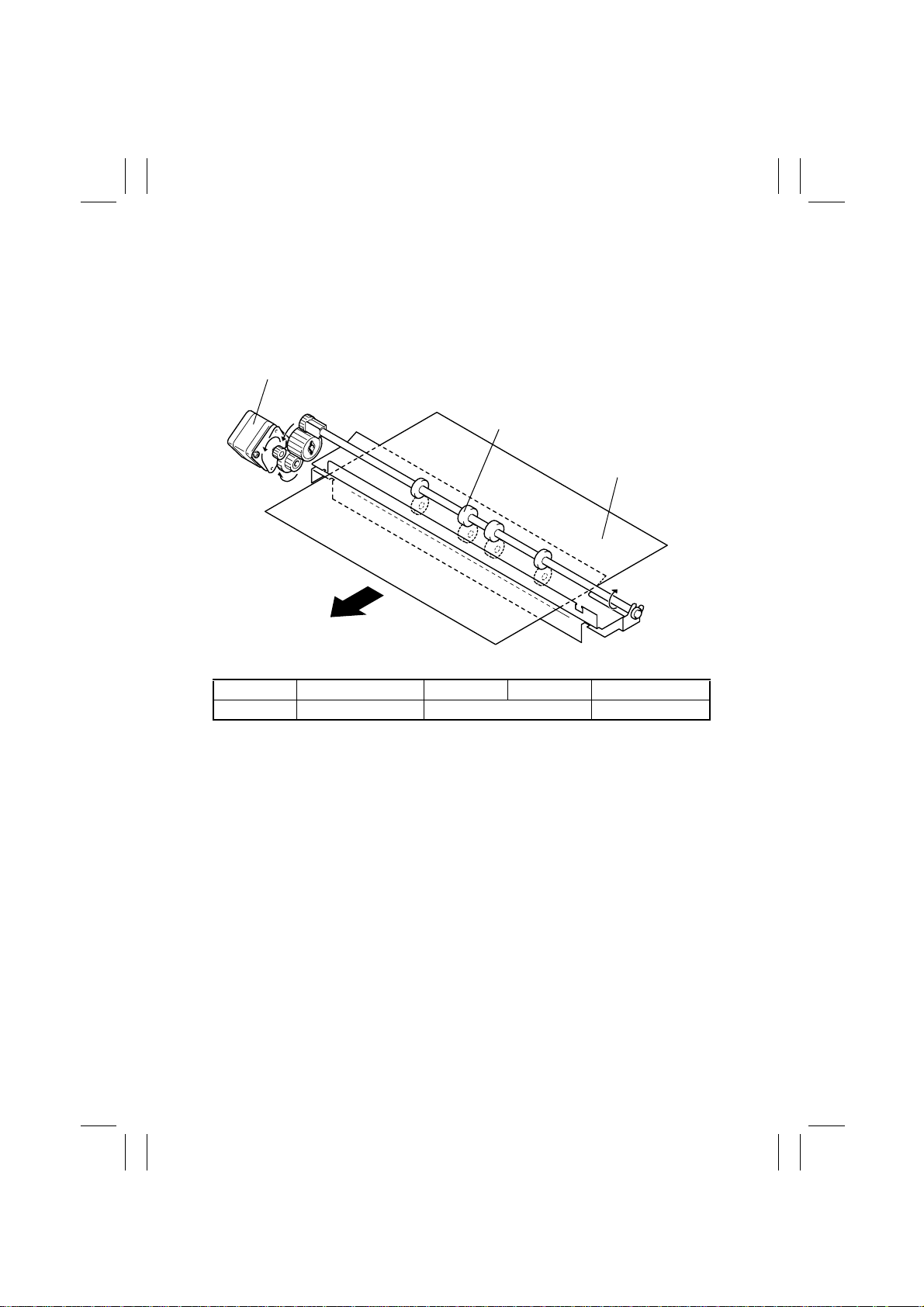

(1) Entrance Section Paper Transport Mechanism

• The Entrance Roller is turned to transport the paper into the Finisher as the Entrance

Motor is energized.

Entrance Motor (M1)

Entrance Roller

Paper

4643M007AD

CONTROL SIGNAL Energized Deenergized WIRING DIAGRAM

M1 PWB-A PJ9A-1~-4 Pulse output 4-B

M-8

FrameMaker Ver.5.5(PC) FS-133/FS-134 OPTION FOR 7915/7920

01.02.09

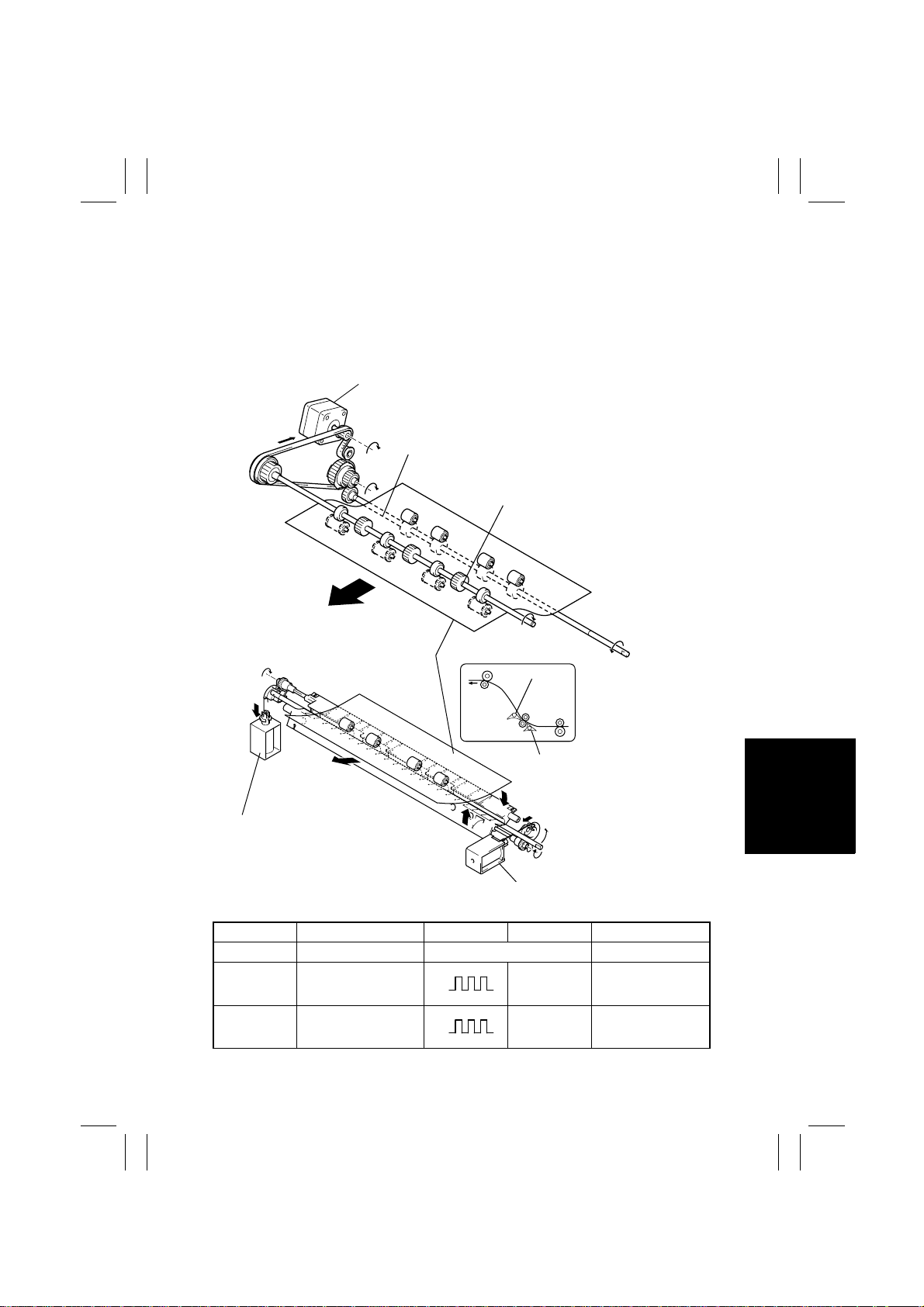

(2) 1st Tray Paper Transport Mechanism

• Paper transport to the 1

• The Upper Path Transport Roller and 1

st

the 1

Tray as the motor is energized.

st

• The 1

Tray Entrance Selecting Solenoid and Upper/Lower Entrance Switching Solenoid

are energized to select the paper path into the 1

st

Tray takes place when the Finisher is in the Non-Sort mode.

st

Tray Exit Roller turn to transport the paper into

st

Tray.

Upper Entrance Motor (M4)

Upper Path Transport Roller

1st Tray Exit Roller

Paper

SL2

SL1

Upper/Lower Entrance Switching

Solenoid (SL1)

1st Tray Entrance Selecting Solenoid (SL2)

CONTROL SIGNAL Energized Deenergized WIRING DIAG RAM

M4 PWB-A PJ9A-5~-8 Pulse output 4-B

SL1 PWB-A PJ18A-2 H 8-E

SL2 PWB-A PJ18A-4 H 9-E

H

L

H

L

M-9

4643M008AB

4643M011AE

FrameMaker Ver.5.5(PC) FS-133/FS-134 OPTION FOR 7915/7920

01.02.09

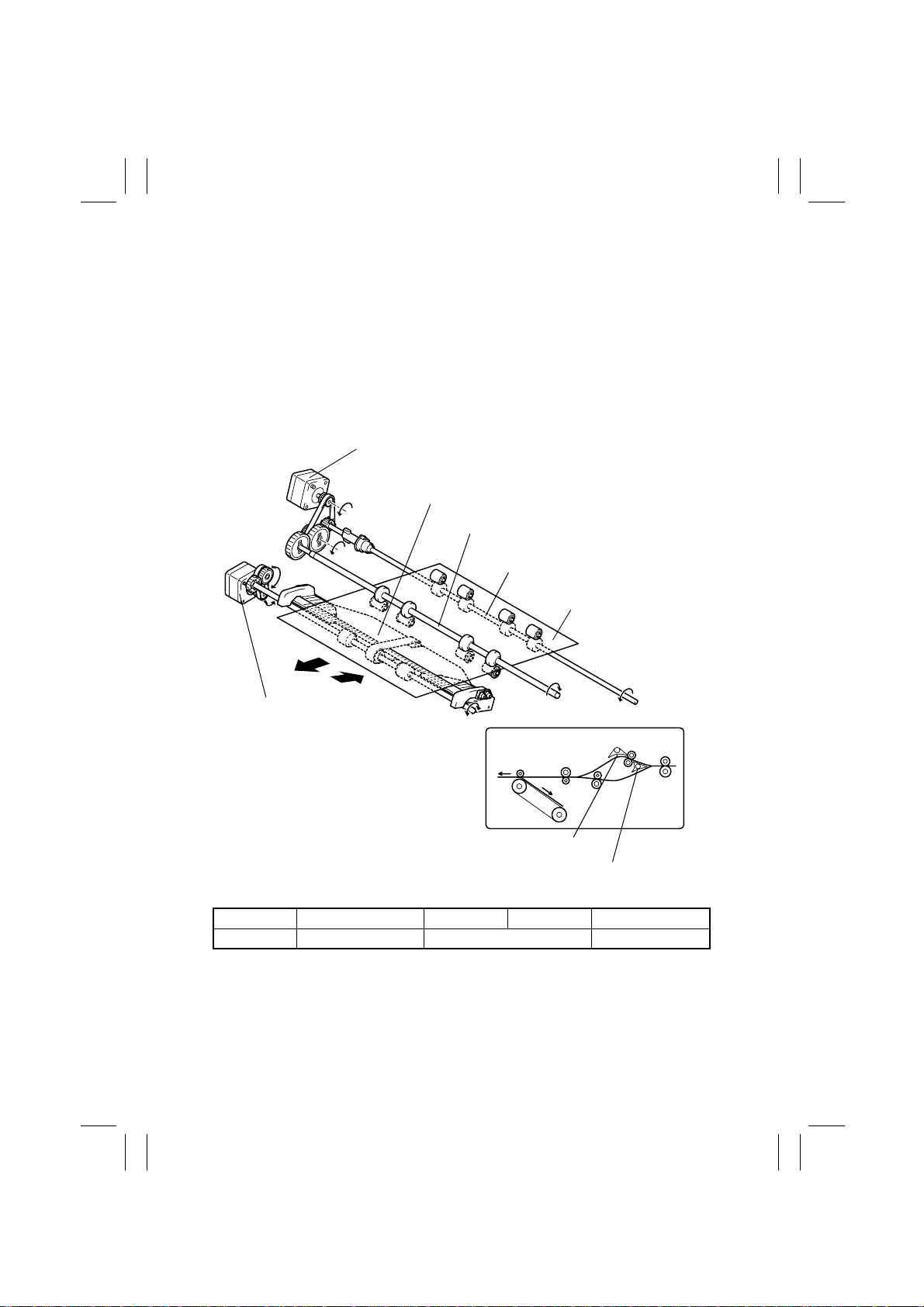

(3) Finisher Tray Paper Transport Mechanism

• Paper transport to the Finisher Tray takes place when the Finisher is in the Staple mode.

• As the Lower Entrance Motor is energized, the Storage Roller turns to transport the

paper toward the exit direction.

• By turning the Exit Motor backward, paper is transported onto the Finisher Tray.

• Either the upper paper path or lower paper path is used to transport paper onto the

Finisher Tray.

• The upper paper path is selected when the Upper/Lower Entrance Switching Solenoid is

st

energized, while the 1

Tray Entrance Selecting Solenoid is deenergized.

• The lower paper path is selected when the Upper/Lower Entrance Switching Solenoid is

deenergized.

Lower Entrance Motor (M2)

Finisher Tray

Storage Roller

Lower Path Transport Roller

Paper

Exit Motor (M3)

1st Tray Entrance Selecting Solenoid (SL2)

4643M009AG

Upper/Lower Entrance Switching Solenoid (SL1)

CONTROL SIGNAL Energized Deenergized WIRING DIAGRAM

M2 PWB-A PJ9A-9~-12 Pulse output 4-A

M-10

FrameMaker Ver.5.5(PC) FS-133/FS-134 OPTION FOR 7915/7920

01.02.09

(4) Elevator Tray Paper Transport Mechanism

• Paper transport to the Elevator Tray takes place when the Finisher is in the Sort or Group

mode.

• As the motor is energized, the Exit Roller turns to transport the paper into the Elevator

Tray.

• Either the upper paper path or lower paper path is used to transport paper onto the

Elevator Tray.

• The upper paper path is selected when the Upper/Lower Entrance Switching Solenoid is

st

energized, while the 1

Tray Entrance Selecting Solenoid is deenergized.

• The lower paper path is selected when the Upper/Lower Entrance Switching Solenoid is

deenergized.

Exit Motor (M3)

Finisher Tray

Exit Roller

Paper

Elevator Tray

4643M010AF

1st Tray Entrance Selecting Solenoid (SL2)

Upper/Lower Entrance Switching Solenoid (SL1)

4643M012AD

CONTROL SIGNAL Energized Deenergized WIRING DIAGRAM

M3 PWB-A PJ8A-1~-4 Pulse output 3-A

M-11

FrameMaker Ver.5.5(PC) FS-133/FS-134 OPTION FOR 7915/7920

01.02.09

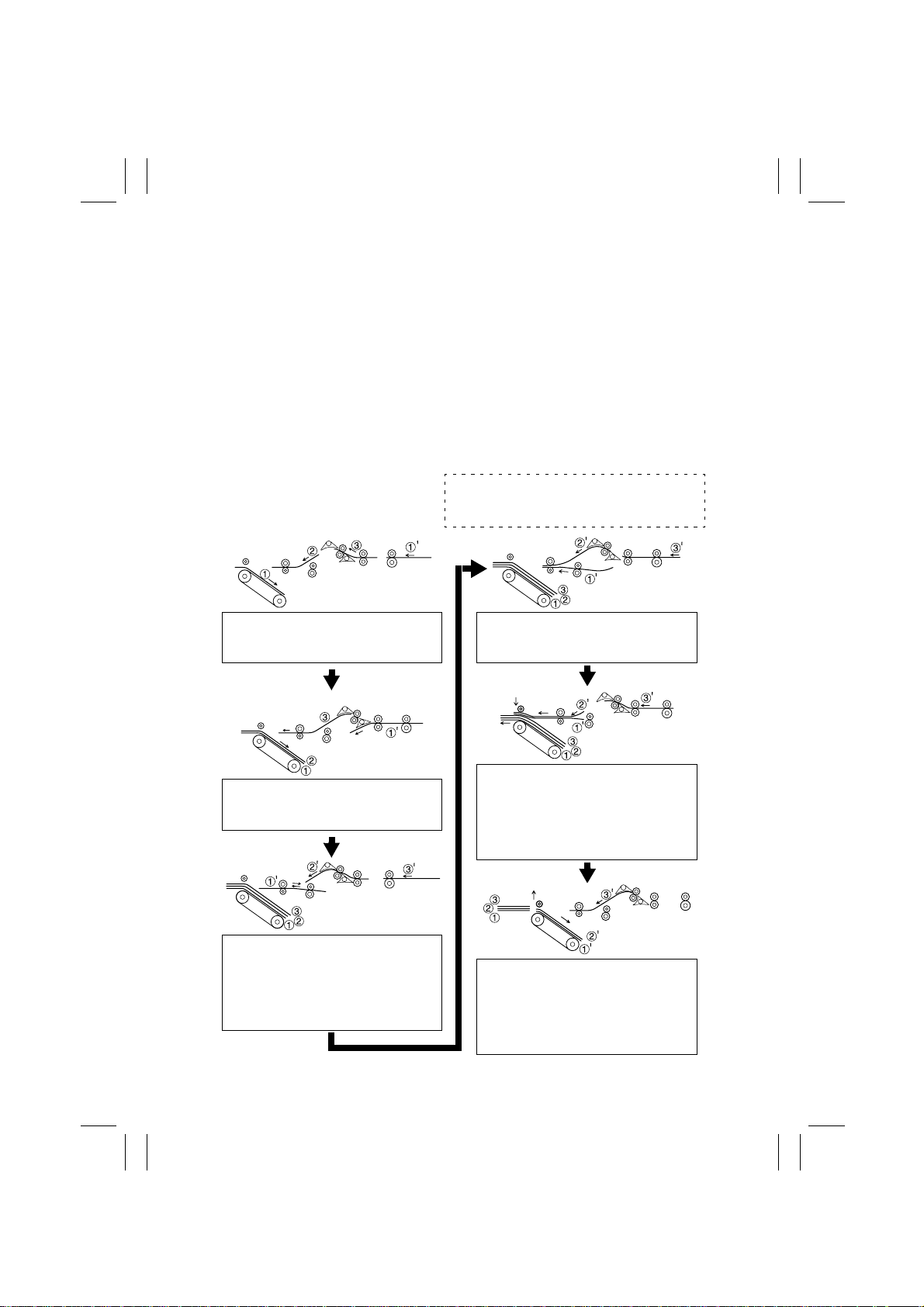

6-2. Paper Switchback Mechanism

• When the last paper of the first copy set is transported onto the Finisher Tray during a

multi-copy cycle in the Sort Staple mode, the first paper of the subsequent copy set,

which is to be next transported, undergoes a switchback sequence. The paper for the

switchback is transported via the lower paper path.

• The second paper of the second copy set is placed over the paper which has undergone

the switchback sequence. After the first copy set has been fed into the Elevator Tray, the

first and second sheets of paper of the second copy set are together transported onto the

Finisher Tray.

• The switchback sequence of the paper is performed by turning the motor backward,

which turns the Lower Path Transport Roller and Storage Roller backward.

• The sheet of paper to be transported next to the one subjected to the switchback

sequence is transported via the upper paper path.

• No switchback sequence is carried out if the interval between sheets of paper is wide as

when using paper of a large size.

<Three A4C originals for two copy sets>

➀, ➁, ➂

➀

: Sheets of paper for the first copy set

’, ➁’, ➂’: Sheets of paper for the second

copy set

4643M027AD

The sheets of paper for the first copy

are transported via the upper paper

path onto the Finisher Tray.

4643M031AH

The first sheet of paper of the second

copy set is transported via the lower

paper path.

4643M028AG

The first sheet of paper of the second

copy set undergoes the switchback

sequence and stops. The second

sheet of paper stops as soon as its

trailing edge leaves the Entrance

Roller.

4643M029AG

The first and second sheets of paper

of the second copy set are transported

together, one on top of the other.

4643M030AH

The Exit Rolls are pressed against the

Exit Roller to feed the sheets of paper

of the first copy set out. At the same

time, the first and second sheets of

paper of the second copy set are

transported toward the exit.

4643M032AE

When the first copy set is fed out, the

Exit Roller starts turning backward to

transport the first and second sheets

of paper of the second copy set to the

Finisher Tray. The Exit Rolls leave the

Exit Roller.

M-12

FrameMaker Ver.5.5(PC) FS-133/FS-134 OPTION FOR 7915/7920

01.02.09

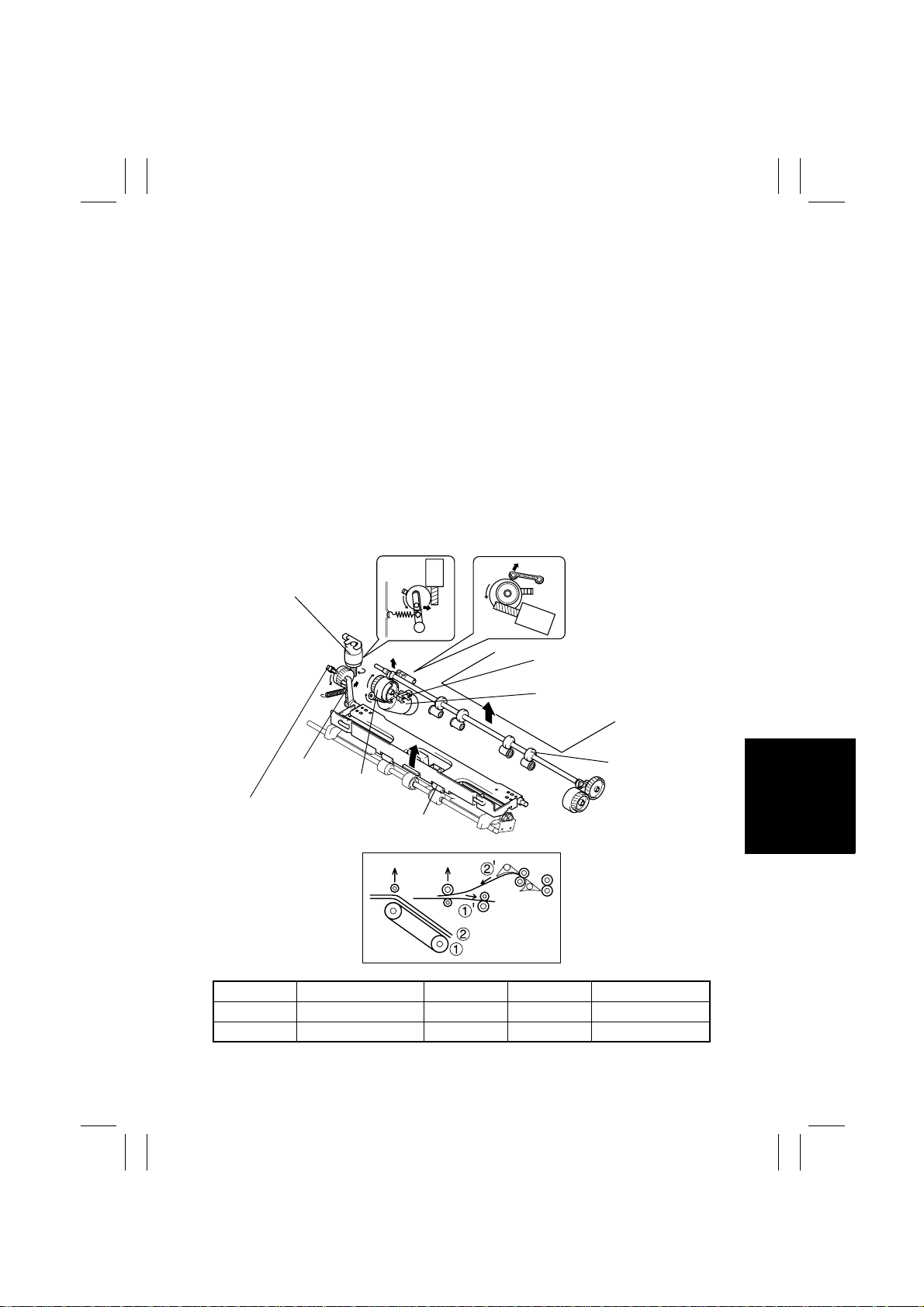

6-3. Roller/Rolls Spacing Mechanism

(1) Storage Roller/Rolls Spacing Mechanism

• The Storage Roller briefly stops when the first sheet of paper completes a switchback

sequence during a multi-copy cycle in the Sort Staple mode. If, however, paper measures 217 mm or more in the FD direction, the leading edge of the second sheet of paper

reaches the Storage Roller before the roller stops turning. The Storage Roller is therefore

raised up to allow a given clearance from the Storage Rolls.

• The Storage Roller is spaced from the Storage Rolls as a cam is turned by the corresponding motor.

(2) Exit Roller/Rolls Spacing Mechanism

• Paper needs to be temporarily transported to the Finisher Tray in the Staple mode, which

makes it necessary to raise the Exit Rolls to provide a given clearance from the Exit

Roller.

• After the stapling sequence has been completed, the Exit Rolls are lowered and pressed

against the Exit Roller so that the paper can be fed out.

• The Exit Rolls are spaced from the Exit Roller as a lever is moved to the right and left by

the cam which is rotated by the motor.

Exit Roller/Rolls

Spacing Motor (M13)

Storage Roller Home Position

Sensor (PC12)

Storage Roller/Rolls Spacing

Motor (M12)

Lever

Cam

Exit Rolls Home Position

Sensor (PC13)

Exit Rolls

4643M033AD

CONTROL SIGNAL Energized Deenergized WIRING DIAGRAM

M12 PWB-A PJ8A-6 Pulse output L 3-A

M13 PWB-A PJ16A-2 H L 9-D

M-13

Storage Roller

4643M013AE

Loading...

Loading...