Konica 7920 Wiring Diagram 7920fv4e

FrameMaker Ver.5.5(PC) 7915/7920 Unit Replacement Manual

01.02.09

UNIT REPLACEMENT

MANUAL

18605

FrameMaker Ver.5.5(PC) 7915/7920 Unit Replacement Manual

01.02.09

CONTENTS

1. The Unit Life Manual ........................................................................................1

2. The Indication of Replacement for CRU/TFU/FRU .......................................... 1

3. Unit Replacement Manual ................................................... .... .. .... ....... .. .... .. ...1

3-1. Unit Layout ................................. .......................... ............ ............. ...........1

3-2. Replacing the Units ............................... ............ .......................... ............ .2

(1) Replacing the Fusing Web Unit ....................... ............ ....................2

(2) Replacing the Oil Coating Unit ........................................................6

(3) Replacing the Imaging Unit (C, M, Y) ..................................... .........11

(4) Replacing the Waste Toner Bottle .................................... ...............19

(5) Replacing the Imaging Unit Bk .................... ....................................21

(6) Replacing the Fusing Unit ........................ .......................... .............22

(7) Replacing the Paper Dust Remover, Image Transfer Roller Unit,

Image Transfer Belt Unit, and Ozone Filter .....................................26

APPENDIX

7915/7920 OVERALL WIRING DIAGRAM (1/4) .....................................................A-1

7915/7920 OVERALL WIRING DIAGRAM (2/4) .....................................................A-2

7915/7920 OVERALL WIRING DIAGRAM (3/4) .....................................................A-3

7915/7920 OVERALL WIRING DIAGRAM (4/4) .....................................................A-4

7915/7920 ELECTRICAL PARTS LAYOUT............................................................A-5

7915/7920 CONECTORS LAYOUT........................................................................A-6

9020/7915/7920 CIRCUIT DIAGRAM (1/5)............................................................A-7

9020/7915/7920 CIRCUIT DIAGRAM (2/5)............................................................A-8

9020/7915/7920 CIRCUIT DIAGRAM (3/5)............................................................A-9

9020/7915/7920 CIRCUIT DIAGRAM (4/5)............................................................A-10

9020/7915/7920 CIRCUIT DIAGRAM (5/5)............................................................A-11

7915/7920 ADJUSTMENT ITEM LIST....................................................................A-12

DF-331 OVERALL DIAGRAM.................................................................................A-13

ST-134 OVERALL DIAGRAM.. ...............................................................................A-14

PF231 OVERALL DIAGRAM ..................................................................................A-15

DB-431 OVERALL DIAGRAM.................................................................................A-16

FS-133/FS-134 OVERALL DIAGRAM ....................................................................A-17

AD-231 OVERALL DIAGRAMA-18

i

1. The Unit Life Manual

NOTES

• The life specifications values represent the number of copies made or figures equivalent to it when given conditions are met. They can be more or less depending on the copier operating conditions

of each individual user.

• The initiation of a new copy cycle is inhibited upon 1K after a near life condition has been detected for all units (except the Toner Bottle and Waste Toner Bottle).

1

Unit Life Spec. Value

Toner Bottle – B/E An approximate life value is 10K under the specified conditions. – 10K

Waste Toner Bottle 40K B/C/D/E/F

Fusing Web Unit 17K B/C/D/F

20-cpm copier Oil Coating Unit 33K

15-cpm copier Oil Coating Unit 26K 26K 27K

Fusing Unit 101K B/C/D/F The life specifications value is based on A4C or Letter C. 101K

Transfer Belt Unit 120K A/B/C/D/F The life specifications value is based on A4C or Letter C.

20-cpm copier Imaging Unit (C, M, and Y) 30K

15-cpm copier Imaging Unit (C, M, and Y) 27K

20-cpm copier Imaging Unit (Bk) 50K

15-cpm copier Imaging Unit (Bk) 47k

Copying Condition

Code

A/B/C/D/F

A/B/C/D/F

Description Near Life Value Life Value

A waste toner full condition is detected when about 4.5K copies are made after a

waste toner near-full condition has been detected.

The life specifications value is based on A4C or Letter C. A near life condition is

detected when a web empty condition is detected or a predetermined number of

copies are made, whichever arrives earlier.

The life specifications value is based on A4C or Letter C. A near life condition or a

life condition is detected when the Oil Coating Roller has turned a predetermined

period of time or a predetermined number of copies are made, whichever arrives

earlier.

The near life and life time values are detected when the PC Drum has turned or the

Developing Unit has been energized for a predetermined period of time, whichever

arrives earlier.

– 40K

16K 17K

33K 34K

2 120K

✽

(17400M)

3 4415M

✽

(30K)

3 4415M

✽

(27K)

3 6972M

✽

(50K)

3 6972M

✽

(47K)

1 102K

✽

2 121K

✽

(17545M)

3 4562M

✽

(31K)

3 4562M

✽

(28K)

3 7122M

✽

(51K)

3 7122M

✽

(48K)

M: minutes

✽

1: As a rule, the Fusing Unit is to be replaced at the same time that the Fusing Web Unit is replaced a sixth time (17K × 6 = 102K). If the Fusing Web Unit is replaced before 17K is reached, there

will be a discrepancy in the replacement cycle, resulting in a near life and life value ranging between 90K and 110K.

✽

2: The life of the Transfer Belt Unit is controlled based on the number of copies made. The life counter gives a time value display.

✽

3: The life of the Imaging Unit is controlled based on a time value. The life counter gives a time value display.

• Conditions for Life Specifications Values

Copying Condition 7920 7915

Job Type A Making two copies per job

Paper Size B A4 or Letter

Color Ratio C C (color) : Bk (black) = 5 : 1 C (color) : Bk (black) = 2.5 : 1

CV/M D 6K 3.5K

Original Density E B/W = 5% for each color

No. of Operating Days per Month F 20 days (Power Switch turned ON and OFF 20 times per month)

FrameMaker Ver.5.5(PC) 7915/7920 Unit Replacement Manual

01.02.09

2. The Indication of Replacement for CRU/TFU/FRU

✽

K=1,000 copies

✽

The contents of the this list are subject to change without notice.

✽

For details, see the unit life manual about the PM cycle.

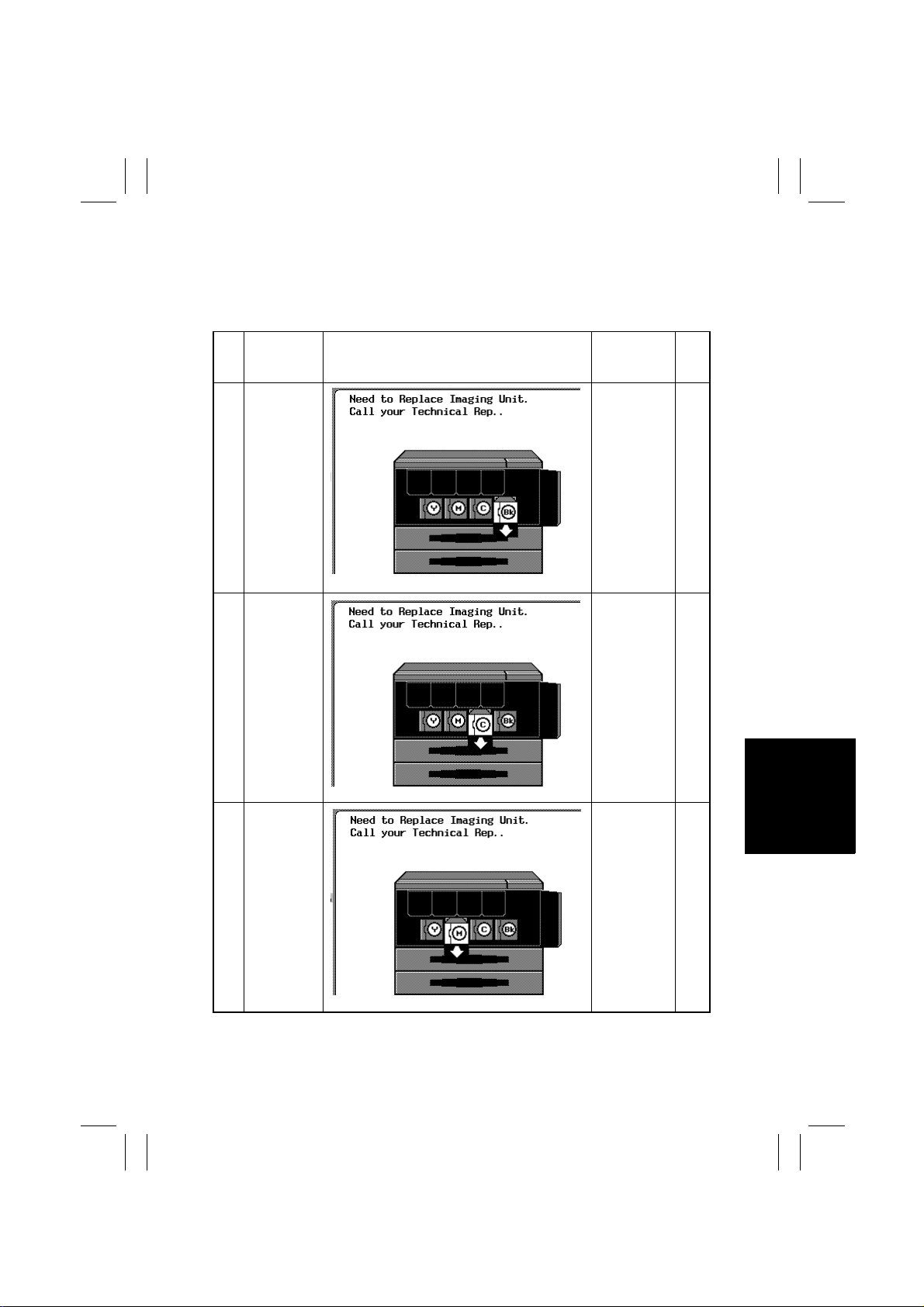

No. Unit Name Maintenance Message Display

Imaging Unit

1.

(Bk)

Imaging Unit

2.

(C)

PM Cycle

CF2001/

CF1501

7122 min

(51K/48K)

4562 min

(31K/28K)

Page

No.

P-21

P-11

Imaging Unit

3.

(M)

1

4562 min

(31K/28K)

P-11

FrameMaker Ver.5.5(PC) 7915/7920 Unit Replacement Manual

01.02.09

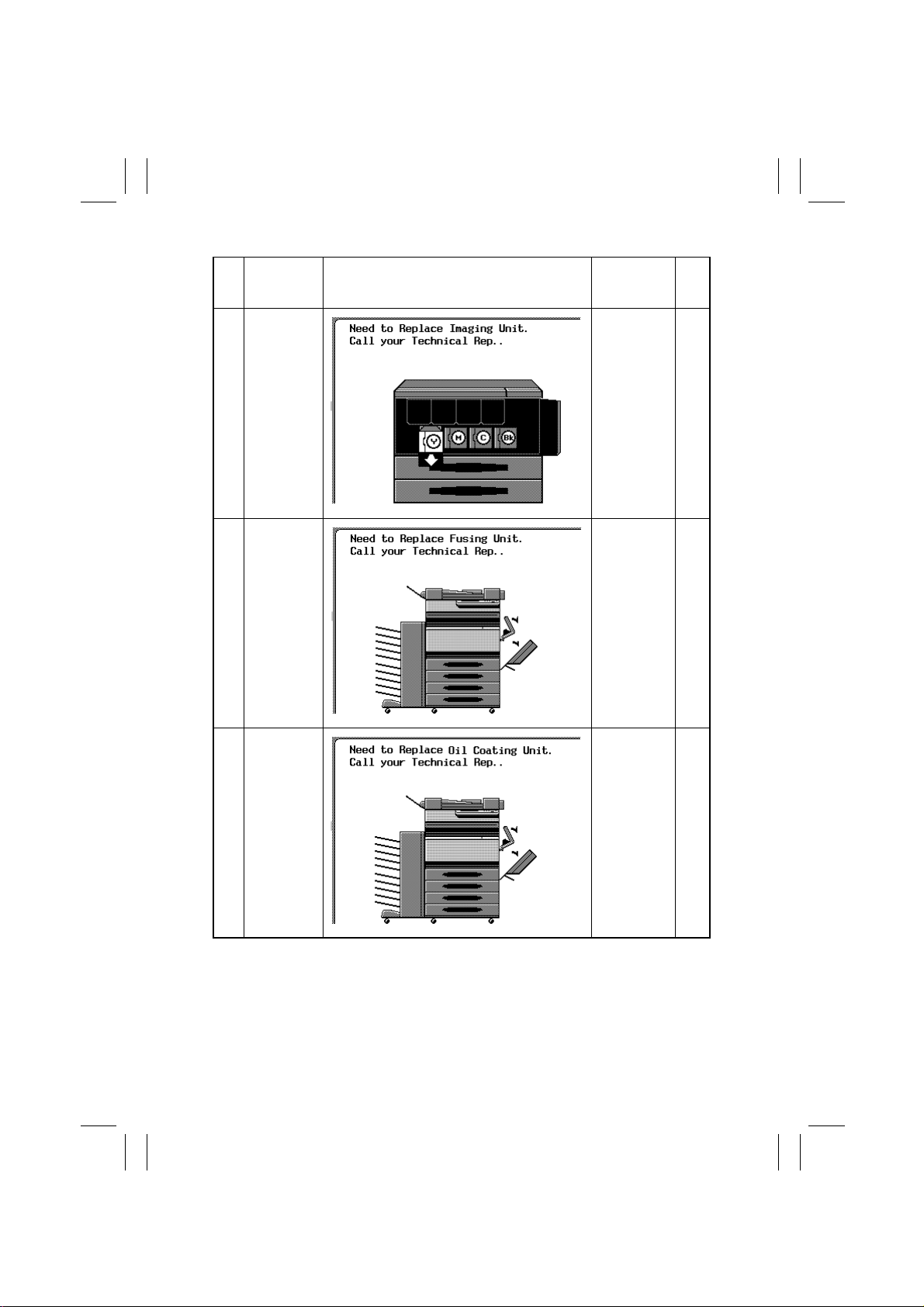

No. Unit Name Maintenance Message Display

Imaging Unit

4.

(Y)

5. Fusing Unit 102K/102K P-22

PM Cycle

CF2001/

CF1501

4562 min

(31K/28K)

Page

No.

P-11

Oil Coating

6.

Unit

34K/27K P-6

2

FrameMaker Ver.5.5(PC) 7915/7920 Unit Replacement Manual

01.02.09

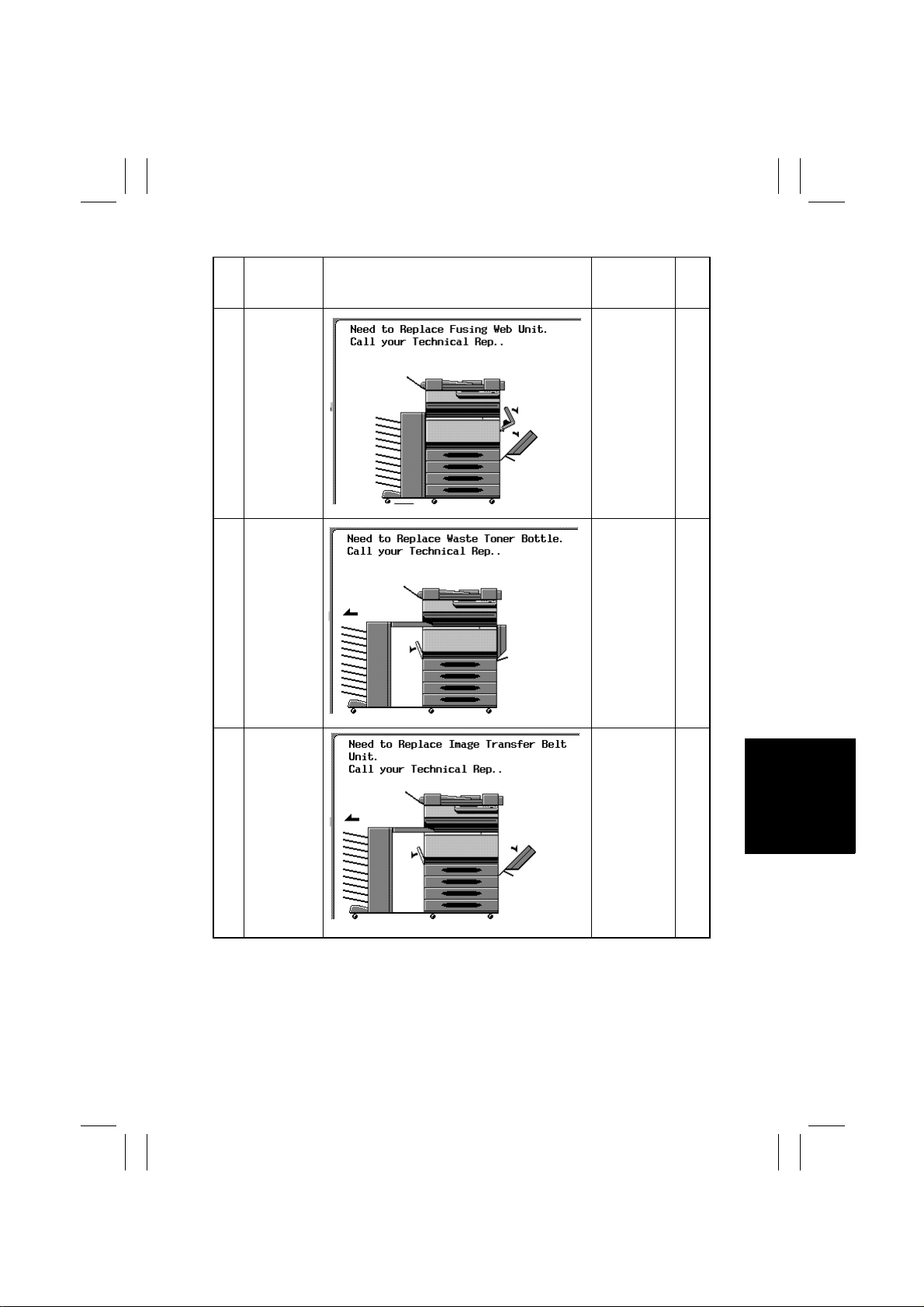

No. Unit Name Maintenance Message Display

Fusing Web

7.

Unit

Waste Toner

8.

Bottle

PM Cycle

CF2001/

CF1501

17K/17K P-2

40K/40K P-19

Page

No.

Image

9.

Transfer Belt

Unit

3

17545 min

(121K/121K)

P-26

FrameMaker Ver.5.5(PC) 7915/7920 Unit Replacement Manual

01.02.09

No. Unit Name Maintenance Message Display

Image

10.

Transfer

Roller Unit

Paper Dust

11.

Cleaner

12. Ozone Filter Nothing to indicate 121K/121K P-26

Nothing to indicate 121K/121K P-26

Nothing to indicate 121K/121K P-26

PM Cycle

CF2001/

CF1501

Page

No.

4

FrameMaker Ver.5.5(PC) 7915/7920 Unit Replacement Manual

01.02.09

3. Unit Replacement Manual

3-1. Unit Layout

Image Transfer Belt Unit

Replace every 121 K.

Replace the waste toner

bottle about 4.5 K prints

after WASTE TONER

BOTTLE NEARLY FULL

is detected.

Ozone Filter

Replace every 121 K.

Fusing Web Unit

Replace the web unit every 17 K prints,

or about 1 K prints after WEB UNIT

NEARLY EMPTY is detected.

4004D301AA

Imaging Unit

C, M, Y: Replace every 4,562 M.

Bk: Replace every 7,204 M.

Fusing Unit

Replace every 102 K.

1

Oil Coating Unit

Replace every 34 K or

325,000 sec.

Paper Dust Remover

Replace every 121 K.

Image Transfer Roller Unit

Replace every 121 K.

4004D351CA

FrameMaker Ver.5.5(PC) 7915/7920 Unit Replacement Manual

01.02.09

3-2. Replacing the Units

(1) Replacing the Fusing Web Unit

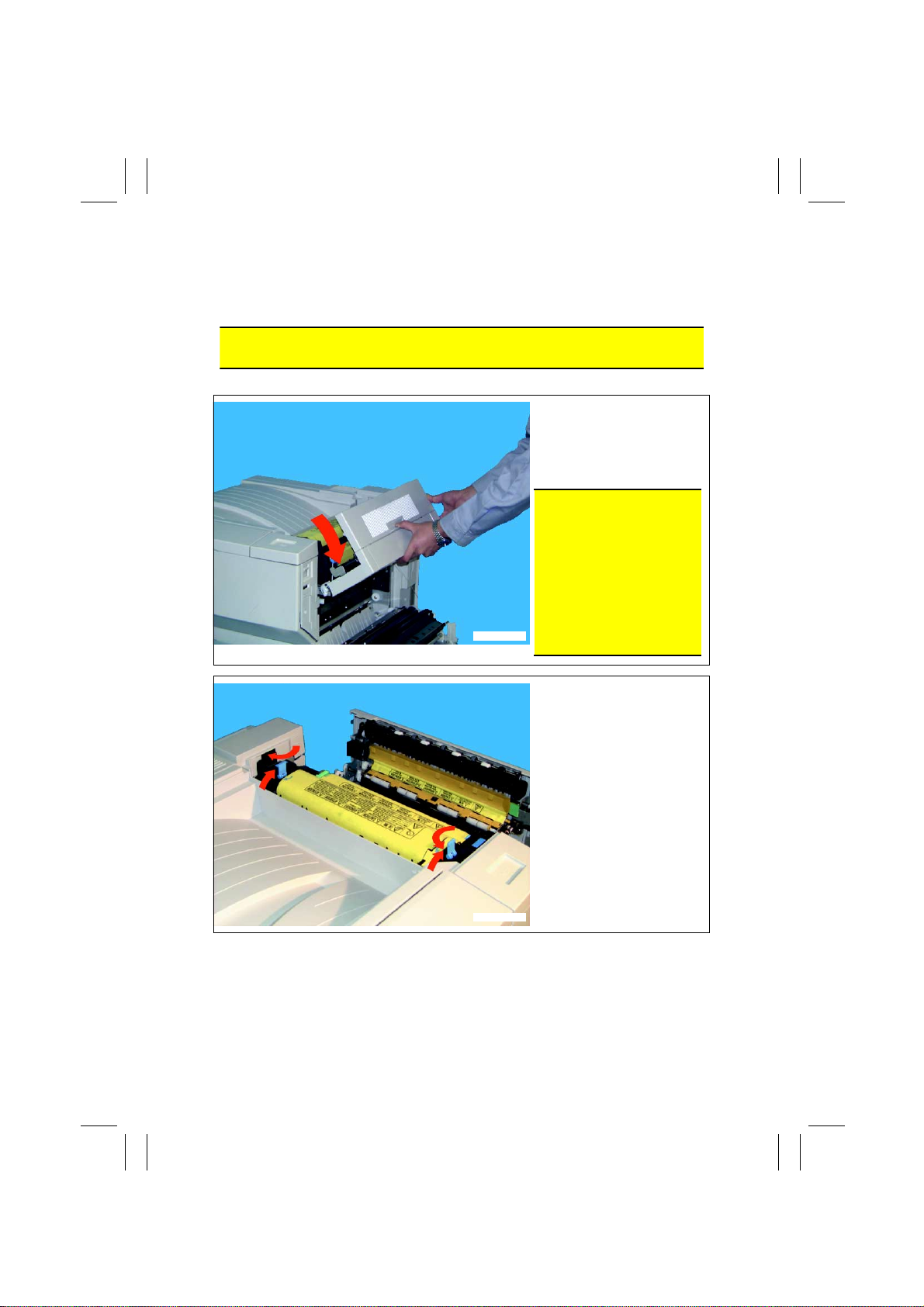

Removal method

NOTE

• Before replacing the fusing web unit, ensure that it is not hot.

1. Turn OFF the main switch,

2. Open the Upper Right

NOTE

• When opening the upper

4004D352CA

then wait for about 20 minutes.

Door.

right door, be sure to support it with your hand until it

is in the fully open position.

If you remove your hand

from the upper right door, it

may drop, and the resulting

impact may cause the

hinges to bend.

➀

➁

➁

➀

2

4004D305AA

3. Release the two blue lock

levers.

➀

(

: Push up, ➁: Rotate)

FrameMaker Ver.5.5(PC) 7915/7920 Unit Replacement Manual

01.02.09

4004D306AA

Terminals (metal)

4. Grasp the two blue lock

levers, and remove the

fusing web unit.

NOTE

• Do not touch the metal ter-

minals beneath the fusing

web unit (on the fusing unit

side).

Failure to observe this precaution may cause an electrostatic discharge, resulting

in a breakdown.

3

4004D307AA

FrameMaker Ver.5.5(PC) 7915/7920 Unit Replacement Manual

01.02.09

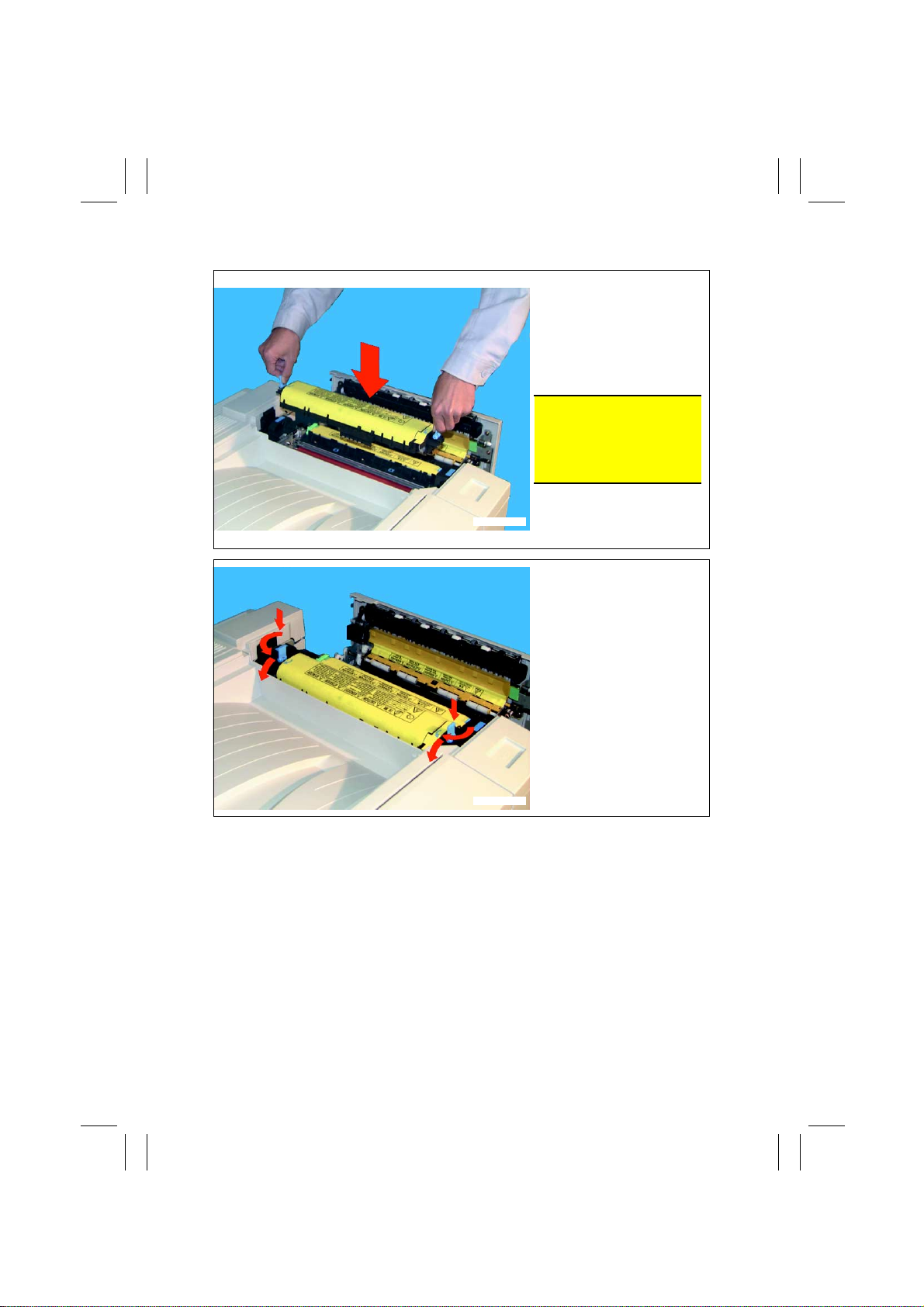

Installation method

4004D308AA

➀

➁

1. Remove the fusing web

unit from its box, and

remove the packing material.

2. Grasp the two blue lock

levers, and set the fusing

web unit in place.

NOTE

• When setting the fusing web

unit, align the ▼ mark on

the fusing web unit with the

▼

mark on the fusing unit.

3. Lock the two blue lock

levers.

➀

: Push, ➁: Rotate,

(

➂

: Push down)

➂

➂

➀

➁

4004D309AA

4

FrameMaker Ver.5.5(PC) 7915/7920 Unit Replacement Manual

01.02.09

4004D353CA

4. Close the Upper Right

Door.

5

Loading...

Loading...