Konica 7920 Wiring Diagram st134e

FrameMaker Ver.5.5(PC) ST-134 OPTION FOR 7915/7920

01.02.09

ST-134

SERVICE MANUAL

11563

FrameMaker Ver.5.5(PC) ST-134 OPTION FOR 7915/7920

01.02.09

CONTENTS

GENERAL,

MECHANICAL/ELECTRICAL

1. SPECIFICATIONS ........................................................................................... M-1

2. COMPONENTS IDENTIFICATION .................................................................M-2

3. CROSS-SECTIONAL VIEW ............................................................................M-3

4. DRIVE SYSTEM ..............................................................................................M-4

5. ELECTRICAL COMPONENTS LAYOUT ........................................................M-5

6. PAPER TRANSPORT .....................................................................................M-6

6-1. Paper Transport Mechanism ...................................................................M-7

(1) Entrance Section Paper Transport Mechanism ...............................M-7

(2) Non-Sort Bin Paper Transport Mechanism . .....................................M-8

(3) 2nd to 10th Bin Paper Transport Mechanism ..................................M-9

6-2. Paper Exit Detection ................................................................................M-12

6-3. Paper Empty Detection . ...........................................................................M-12

6-4. Paper Full Detection . ...............................................................................M-13

7. Horizontal Unit .................................................................................................M-14

7-1. Paper Transport Mechanism ...................................................................M-14

(1) Paper Path Switching Mechanism ...................................................M-14

(2) Sorter Paper Transport Mechanism ................................................M-15

TEST MODES

1. OUTLINE OF THE TEST MODES ...................................................................S-1

1-1. Test Mode Setting Procedure ..................................................................S-1

(1) Starting of Test Mode ......................................................................S-1

(2) Running Different Test Mode Operations ........................................S-1

(3) Exiting Test Mode ............................................................................S-1

1-2. Description of Each Test Mode Operation ...............................................S-2

(1) Initial Display ................................................................................... S-2

(2) Sensor Input Check .........................................................................S-3

(3) Transport Speed Setting ..................................................................S-4

(4) Initial Operation ...............................................................................S-4

(5) Paper Size Input: Not used ..............................................................S-4

(6) Sorting Check ........................... ........................... ............................S-4

(7) Solenoid Check ...............................................................................S-5

(8) Paper Entrance Switching Check ....................................................S-5

DIS/REASSEMBLY, ADJUSTMENT

1. DIS/REASSEMBLY .........................................................................................D-1

1-1. Maintenance Schedule ............................................................................D-1

1-2. Removal of the External Covers ..............................................................D-1

2. ADJUSTMENT .................................................................................................D-2

2-1. Adjusting the Solenoid ................................................... ..........................D-2

(1) Adjusting the Non-So rt Bin Solenoid .................................... ...........D-2

(2) Entrance Switching Solenoid Adjustment ........................................D-2

2-2. Adjustment of Tension of Timing Belts .................... ........................... .....D-3

(1) Transport Motor Ti ming Be lts ........................................ ............... ...D-3

i

FrameMaker Ver.5.5(PC) ST-134 OPTION FOR 7915/7920

01.02.09

(2) Drive Mechanism Timing Belt ..........................................................D-3

2-3. Adjustment of the Ex it Se n sor ................................. ........................... .....D-4

2-4. Adjustment of the Bin Empty Sensors ..................... ................................D-5

TROUBLESHOOTING

1. SENSOR CHECK ............................................. ........................... ....................T-1

1-1. Sensor Check Scre en ......................... ........................... ..........................T-1

2. MISFEED DETECTION AND TROUBLESHOOTING .....................................T-2

2-1. Missfeed Detecting Sensor Layout ..........................................................T-2

2-2. Missfeed Detection ..................................................................................T-3

2-3. Misfeed Troubleshooting Procedures ......................................................T-4

3. MALFUNCTION DETECTION AND TROUBLESHOOTING

PROCEDURES ...............................................................................................T-5

3-1. Malfunction Detection ..............................................................................T-5

3-2. Malfunction Troubleshooting Procedures ................................................ T-5

4. Time chart .................................... ............... ........................... ..........................T-6

4-1. Paper Path Switching/Non-sort Mode ......................................................T-6

4-2. Sort Mode ................................................................................................T-7

ii

FrameMaker Ver.5.5(PC) ST-134 OPTION FOR 7915/7920

01.02.09

GENERAL,

MECHANICAL/ELECTRICAL

FrameMaker Ver.5.5(PC) ST-134 OPTION FOR 7915/7920

01.02.09

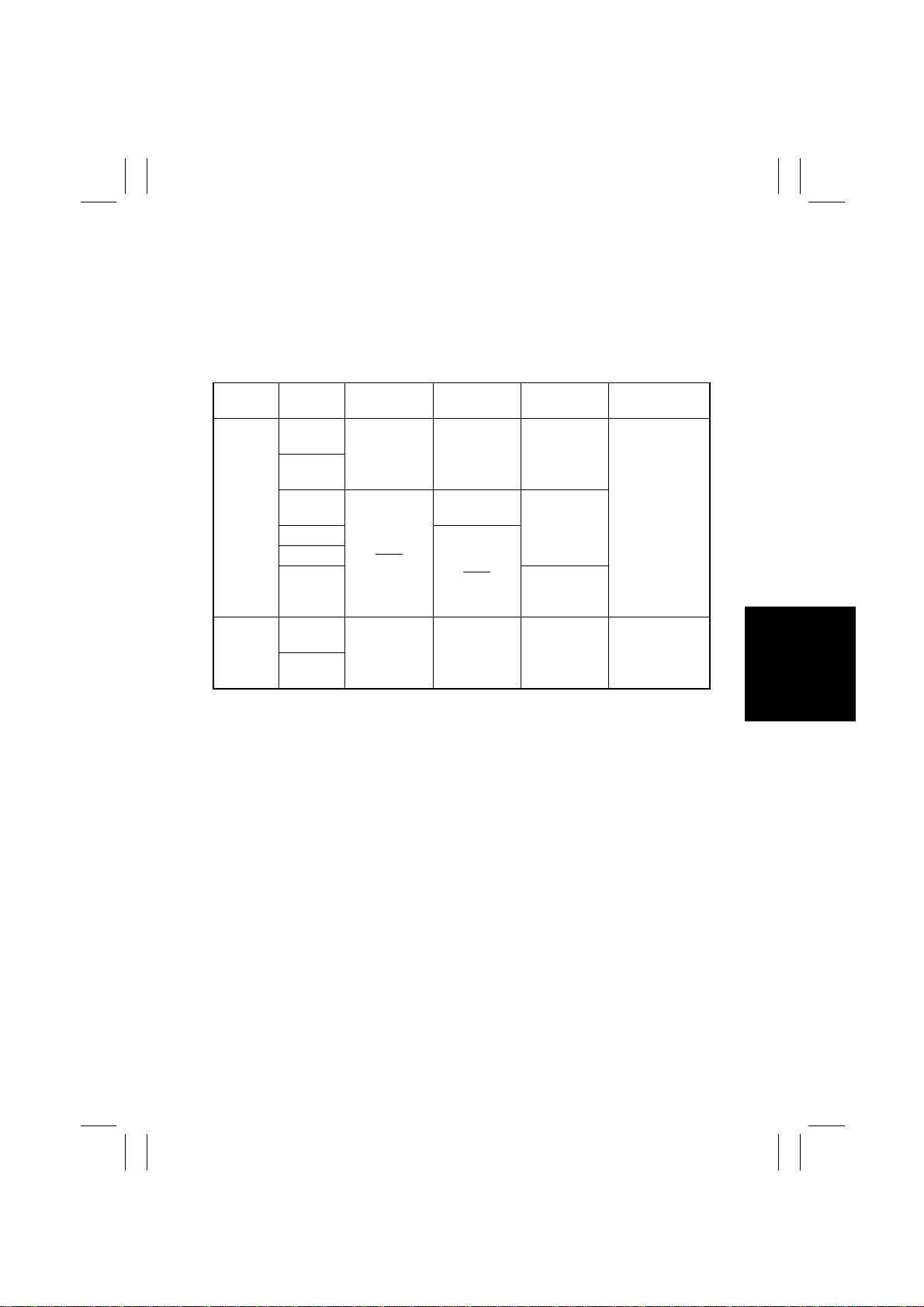

1. SPECIFICATIONS

Type : 10-Bin Mailbin Sorter

Installation : Freestanding

Modes : Non-Sort

Mail Sort

Copy Medium

Mode

Non-Sort

Mail Sort

*: (Recommend paper)

Paper

Type

Plain

paper

Recycled

paper

Thick

paper

Postcards

Envelopes

OHP

Transpar-

encies

Plain

paper

Recycled

paper

Paper Size Paper Weight Capacity Exit Bin

A3L to A6L

11 × 17 to

5-1/2 × 8-1/2

A3L to A5L

11 × 17 to

5-1/2 × 8-1/2

60 to 90 g/m

16 to 24 lb

91 to 209 g/m

60 to 90 g/m

16 to 24 lb

2

200 sheets*

2

20 sheets

2

200 sheets*

32 mm

1 sheet

32 mm

Non-Sort Bin

Non-Sort Bin to

th

Bin

10

Registration : Center

Power Requirements : DC24 V (supplied from copier)

Power Consumption : 32 W

Dimensions : Width: 554 mm

Mass : 10-Bin Mailbin Sorter: 29 kg

Environmental Requirements

DC5 V (generated by sorter)

Depth: 512 mm

Height: 874 mm

Horizontal Transport Unit: 2.6 kg

: Same as copier

M-1

FrameMaker Ver.5.5(PC) ST-134 OPTION FOR 7915/7920

01.02.09

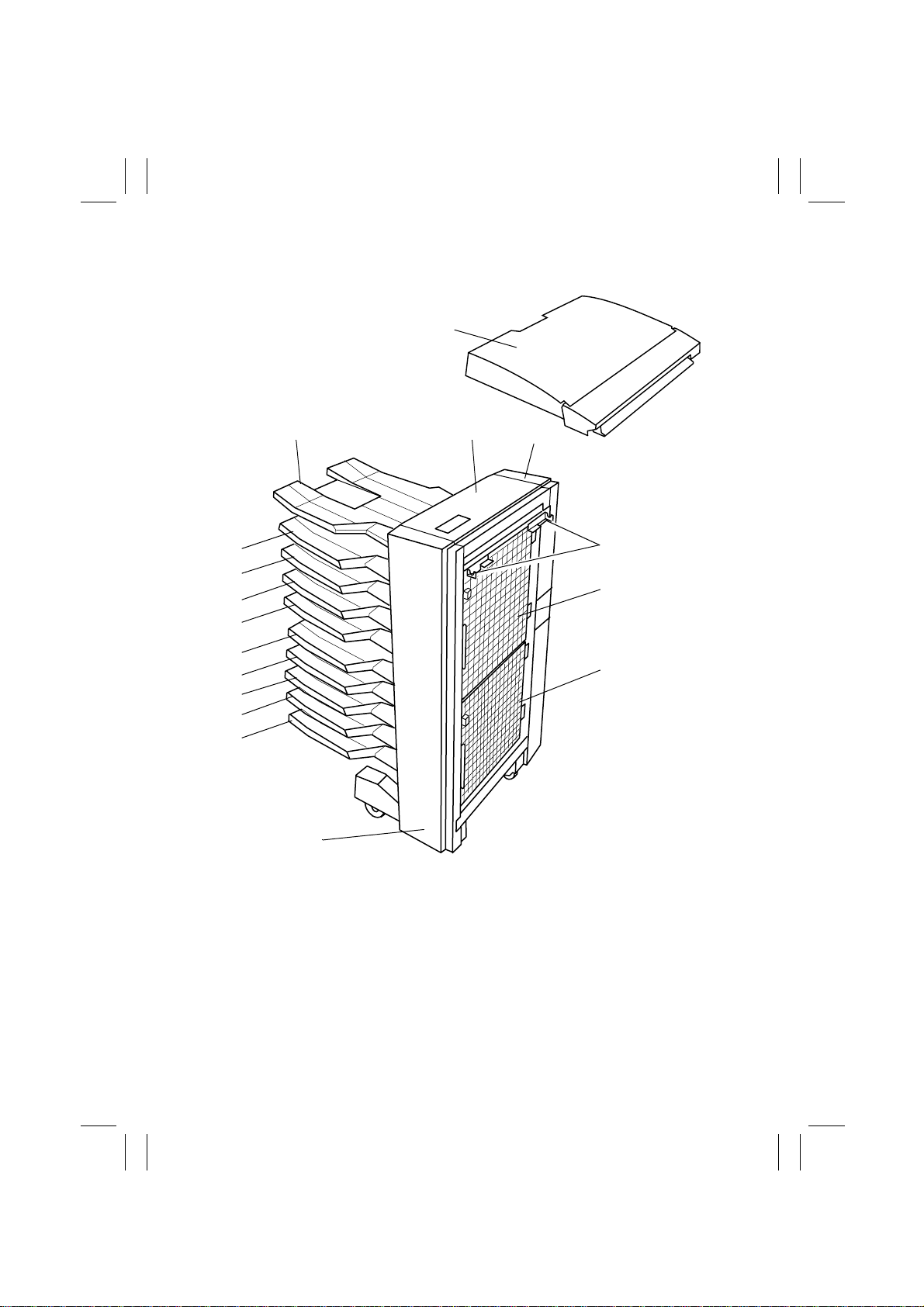

2. COMPONENTS IDENTIFICATION

Horizontal Transport Unit

17

10-Bin Mailbin Sorter

1

2

3

4651M507AA

16

15

14

13

12

11

10

9

8

7

1. Non-Sort Bin

2. Upper Cover

3. Rear Cover

4. Horizontal Unit Mounting Bracket

5. Upper Door

6. Lower Door

7. Front Cover

th

Bin

8. 10

th

9. 9

Bin

4651M501AA

th

10. 8

Bin

th

11. 7

Bin

th

12. 6

Bin

th

13. 5

Bin

th

14. 4

Bin

rd

15. 3

Bin

nd

16. 2

Bin

17. Horizontal Unit Door

4

5

6

M-2

FrameMaker Ver.5.5(PC) ST-134 OPTION FOR 7915/7920

01.02.09

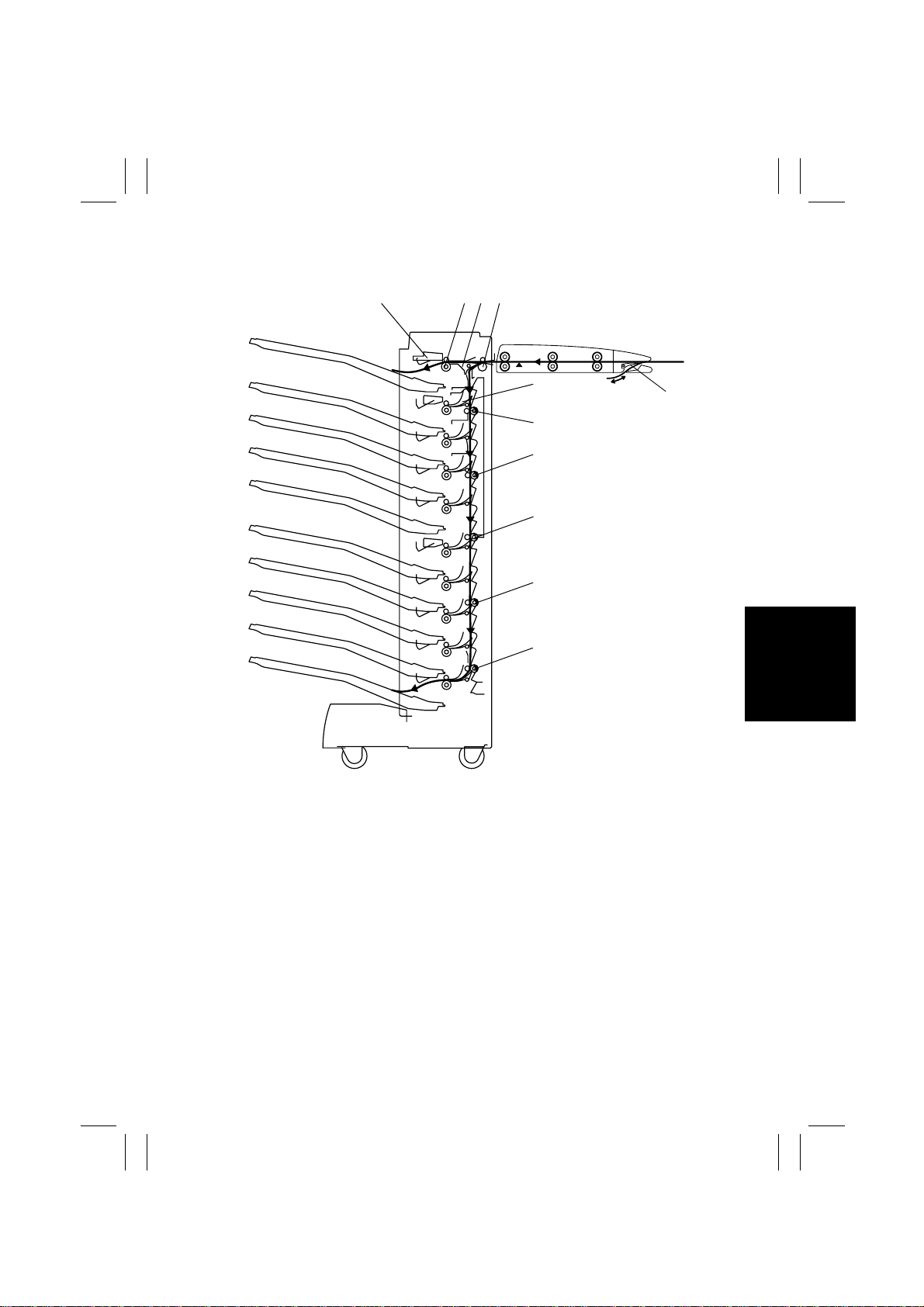

3. CROSS-SECTIONAL VIEW

3

1

2 4

Horizontal Unit10-Bin Mailbin Sorter

5

11

6

7

8

9

1. Sensor Board: Non-Sort Bin to 10th Bin

2. Exit Roller: Non-Sort Bin to 10

3. Switching Deflector A: Non-Sort Bin

4. Entrance Roller

5. Switching Deflector B: 2

th

Bin

nd

Bin to 10th Bin

10

4651M502AA

6. Transport Roller 1

7. Transport Roller 2

8. Transport Roller 3

9. Transport Roller 4

10. Transport Roller 5

11. Entrance Switching Deflector

M-3

FrameMaker Ver.5.5(PC) ST-134 OPTION FOR 7915/7920

01.02.09

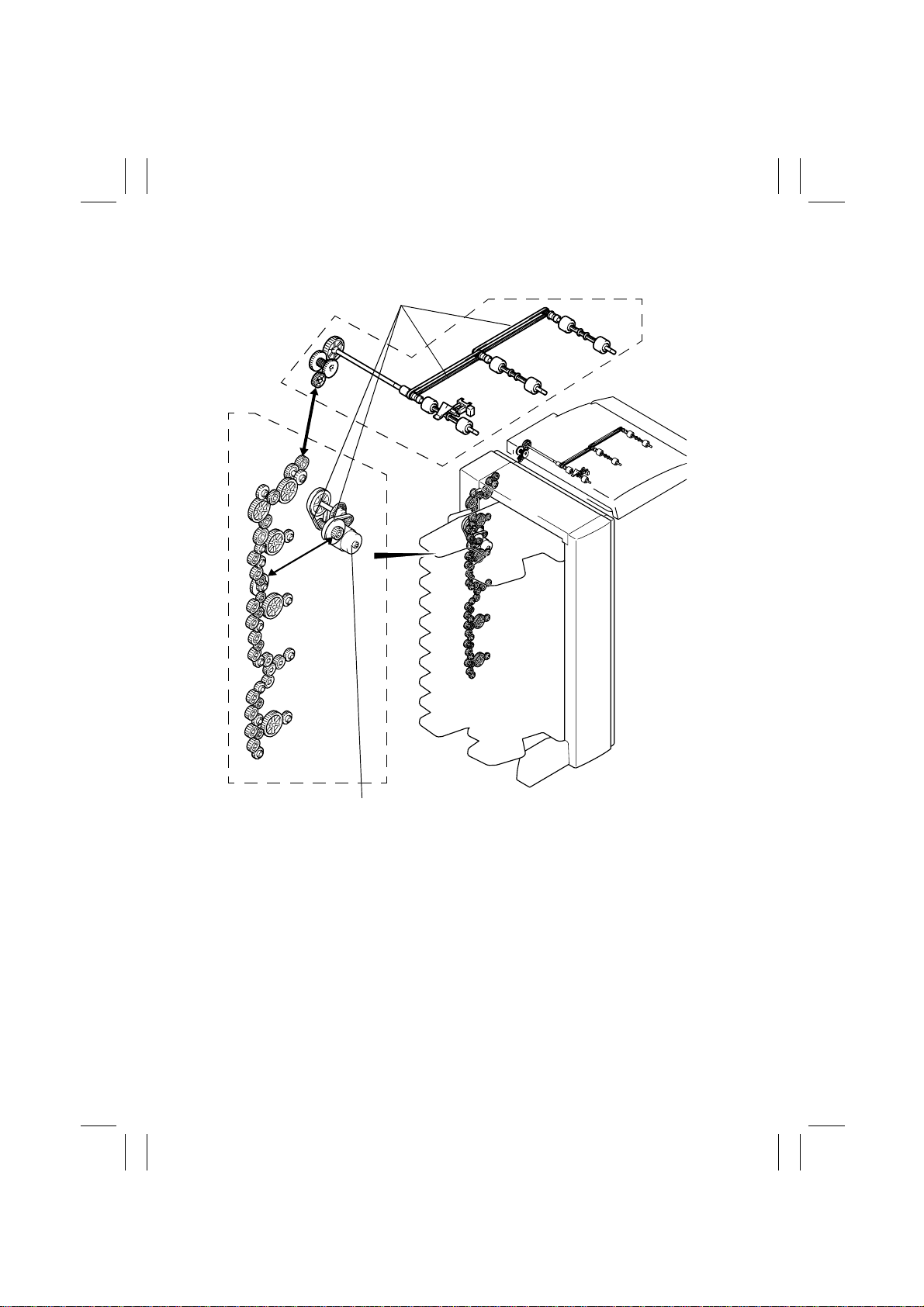

4. DRIVE SYSTEM

Timing Belt

Horizontal

Unit

Transport Motor M1

10-Bin Mailbin Sorter

4651M503AA

M-4

FrameMaker Ver.5.5(PC) ST-134 OPTION FOR 7915/7920

01.02.09

5. ELECTRICAL COMPONENTS LAYOUT

PC6

PC4

SL1

PC1

M1

S1

PWB-A

PWB-B

PWB-D1

PWB-D2

PWB-D3

PWB-D4

PWB-D5

PWB-D6

PWB-D7

PWB-D8

PWB-D9

PWB-C

SL1

Horizontal Unit

(Assy)

SL2

(Assy)

SL3

10-Bin Mailbin Sorter

PC1

4651M504AA

10-Bin Mailbin Sorter

Code Name Code Name

M1 Transport Motor PWB-D1 Non-Sor t Bin Sensor Board

PC1 Transport Motor Pulse Sensor PWB-D2

S1 Set Switch PWB-D3

SL1 Non-Sort Bin Solenoid PWB-D4

SL2 Upper Entrance Switching Solenoid PWB-D5

SL3 Lower Entrance Switching Solenoid PWB-D6

PWB-A Control Board PWB-D7

PWB-B Exit Sensor Board PWB-D8

PWB-C

th

Bin Sensor Board

10

PWB-D9

nd

Bin Sensor Board

2

rd

Bin Sensor Board

3

th

Bin Sensor Board

4

th

Bin Sensor Board

5

th

Bin Sensor Board

6

th

Bin Sensor Board

7

th

Bin Sensor Board

8

9th Bin Sensor Board

Horizontal Unit

Code Name Code Name

SL1 Entrance Switching Solenoid PC4 Horizontal Unit Door Sensor

PC1 Paper Sensor PC6 Turnover Empty Detecting Sensor

M-5

FrameMaker Ver.5.5(PC) ST-134 OPTION FOR 7915/7920

01.02.09

6. PAPER TRANSPORT

• The paper transport mechanism transports copies fed from the copier through the Horizontal Unit into the designated bin.

1. Non-Sort Mode

• All copies are fed into the Non-Sort Bin.

2. Mail Sort Mode

• Copies are sorted into different bins.

The sequence of bins through which copies are fed can be designated in the order from

the Non-Sort to 10th Bin or from the 10th to Non-Sort Bin.

Horizontal Unit10-Bin Mailbin Sorter

Non-Sort Bin

nd

2

Bin

rd

Bin

3

Copier

4651M506AA

M-6

FrameMaker Ver.5.5(PC) ST-134 OPTION FOR 7915/7920

01.02.09

6-1. Paper Transport Mechanism

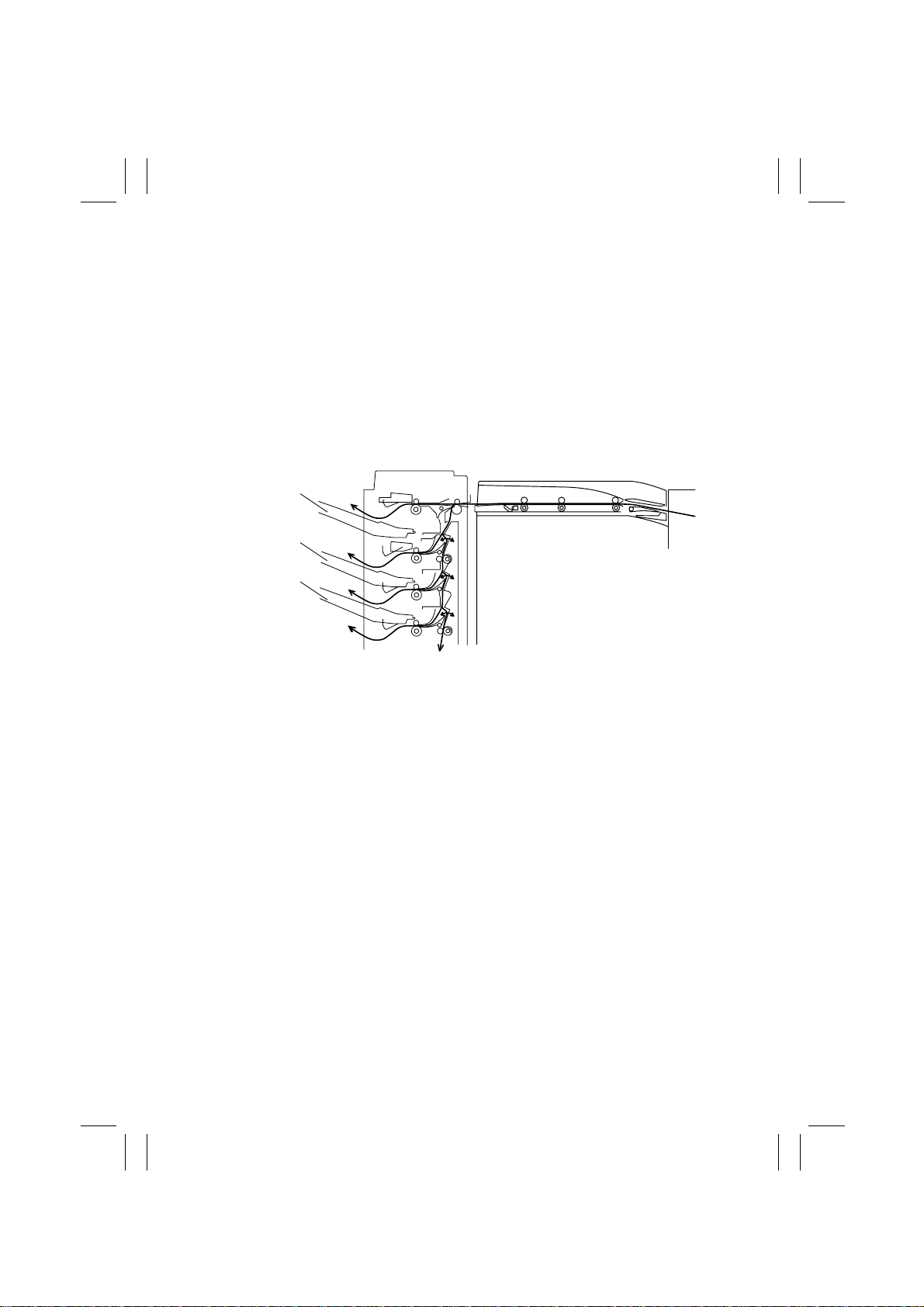

(1) Entrance Section Paper Transport Mechanism

• Drive from the Transport Motor turns the Entrance Roller so that the copy can be fed into

the Sorter.

Transport Motor M1

CONTROL SIGNAL ENERGIZED DEENERGIZED WIRING DIAGRAM

M1 PWB-A PJ3A-2 L H 2-G

Entrance Roller

Paper

4651M508AA

M-7

FrameMaker Ver.5.5(PC) ST-134 OPTION FOR 7915/7920

01.02.09

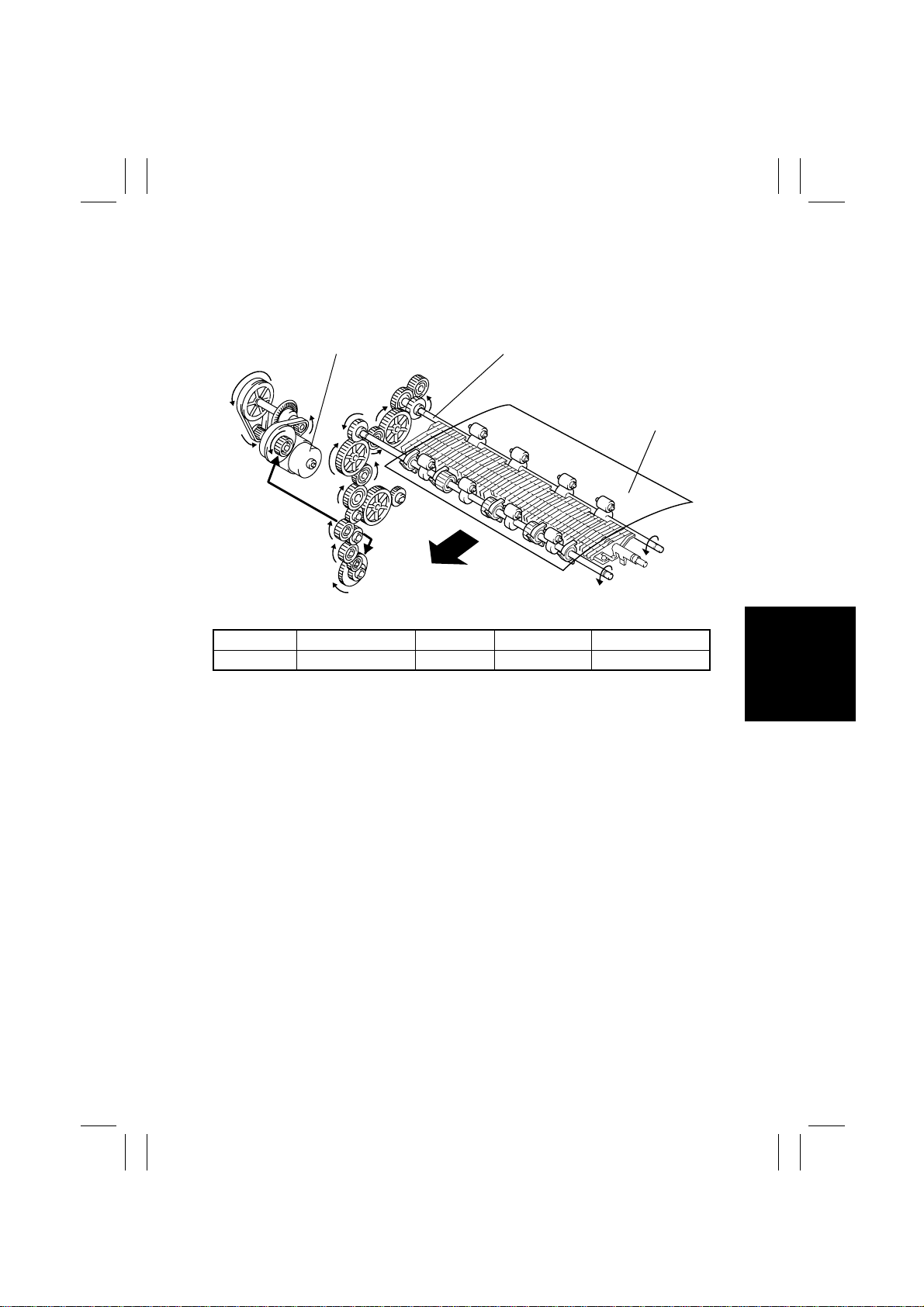

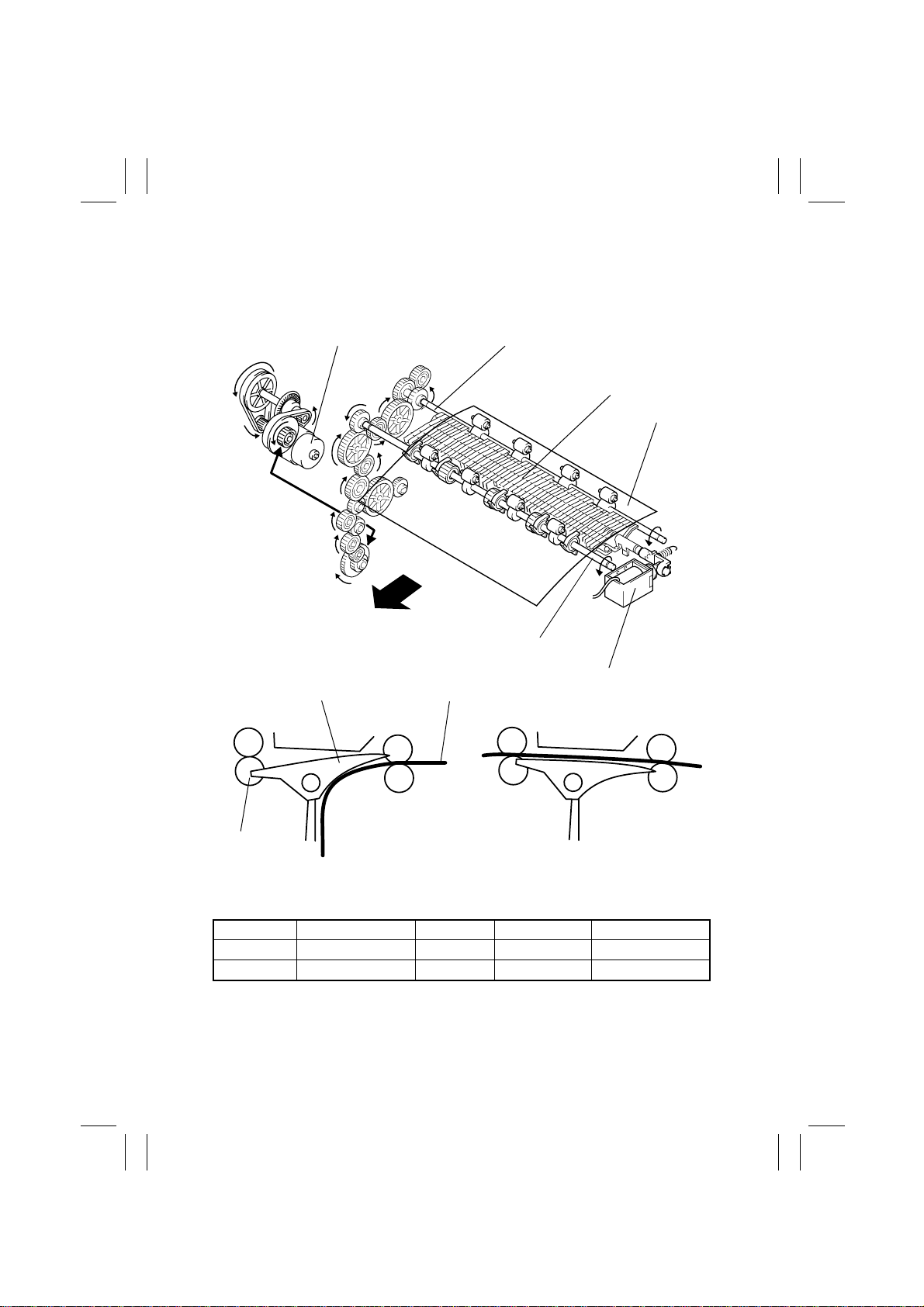

(2) Non-S or t B i n Pa per Transport Mechanism

• In the Non-Sort mode, copies are fed into the Non-Sort Bin.

• Drive from the motor turns the Exit Roller, which feeds the copy into the Non-Sort Bin.

• The path into the Non-Sort Bin is selected when the Non-Sort Bin Solenoid is energized.

Entrance RollerTransport Motor M1

Switching Deflector A

Paper

Exit Roller

Switching Deflector A

Paper

Non-Sort Bin Solenoid

SL1

Exit Roller

Non-Sort Bin Solenoid deenergized

Transport to 2

nd

Bin to 10th Bin

Non-Sort Bin Solenoid energized

Transport to Non-Sort Bin

CONTROL SIGNAL ENERGIZED DEENERGIZED WIRING DIAGRAM

M1 PWB-A PJ3A-2 L H 2-G

SL1 PWB-A PJ4A-2 L H 2-H

4651M509AA

4651M516AA

M-8

Loading...

Loading...