Page 1

3. ADJUSTMENTS

NOTE

After the copier has exited the Service mode, be sure to turn OFF and ON the Power

Switch to let the copier run an image stabilizer sequence.

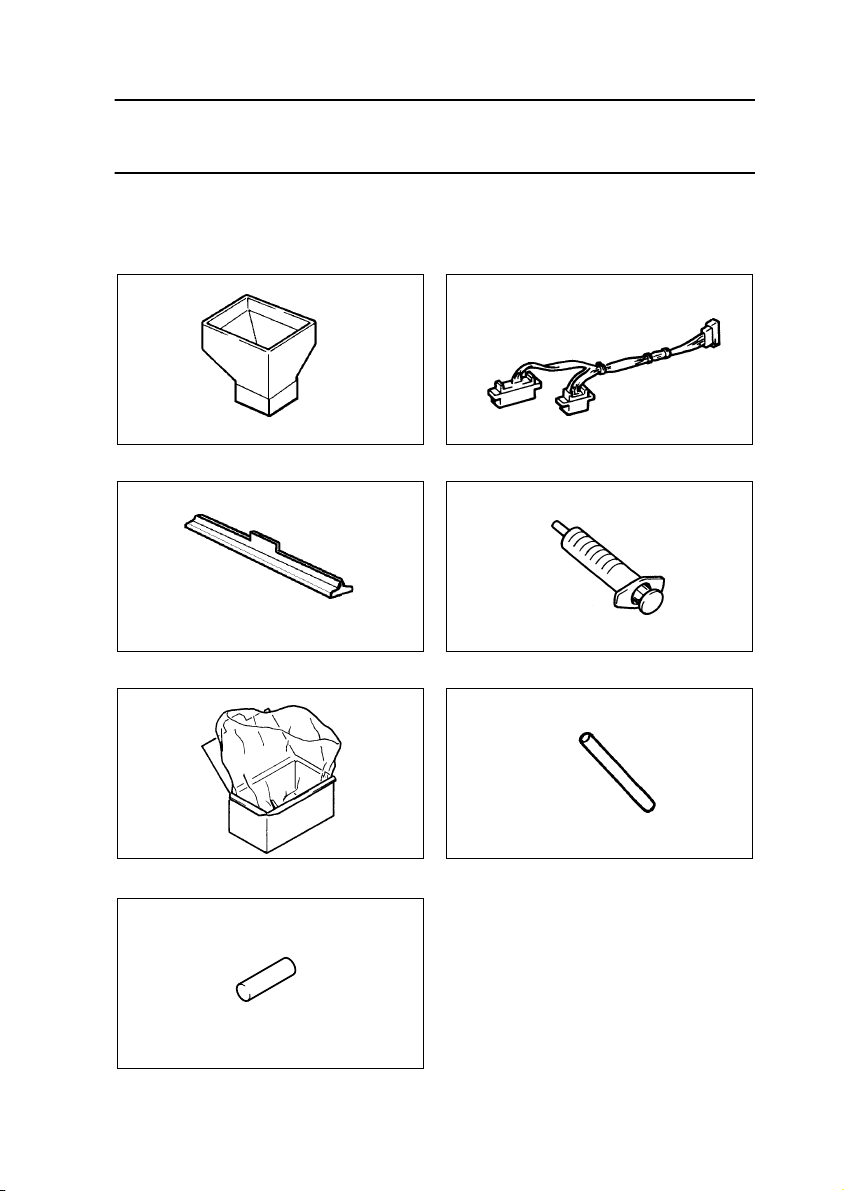

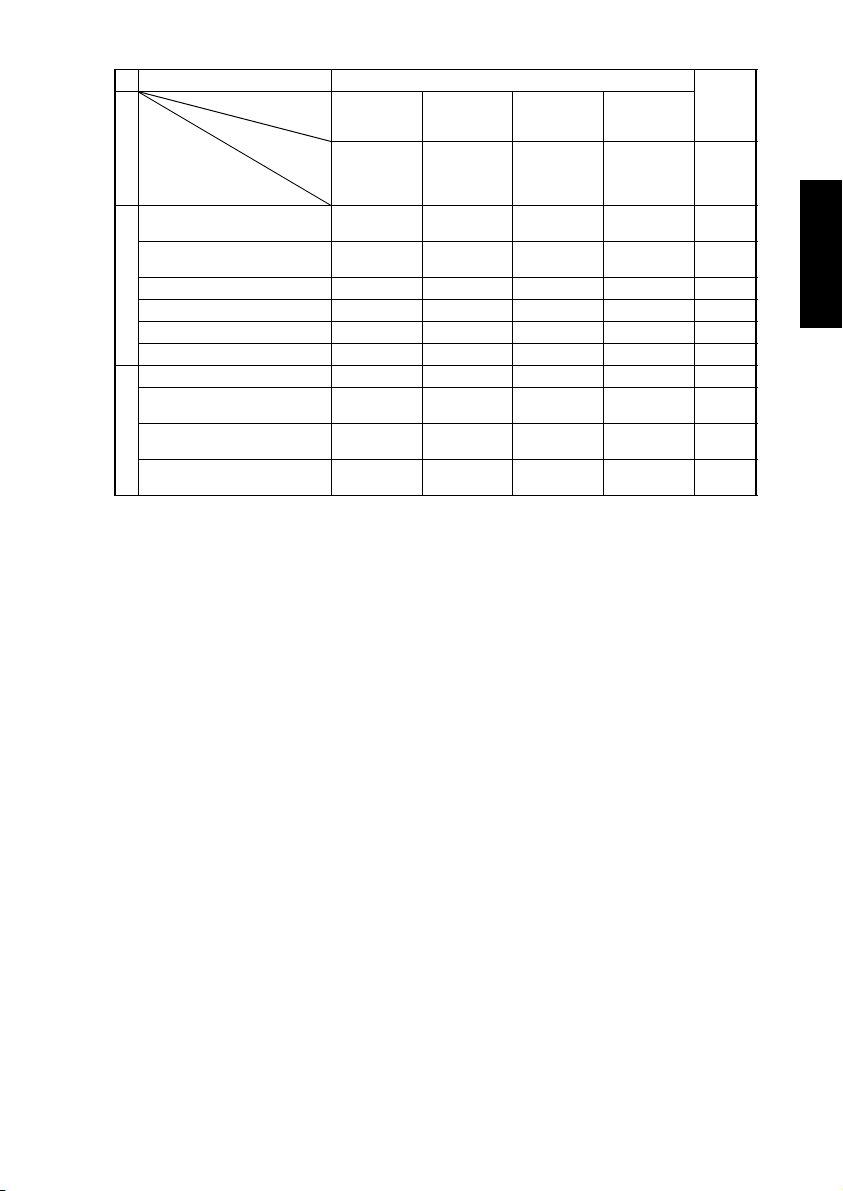

3-1. JIGS AND TOOLS USED

(1) Tools for Setting-up and PM

Part No. 25TU00460 Part No. 11ZT00440

× 4

1144D228YA

1

Developer Chute

✽

Jumper Harness

Part No. 25TU00470 Part No. 25TU00450

× 4

1144D269YA

Mag. Roller Shield Fuser Oil Syringe

Part No. 25TU00330 Part No. 25TU00370

1154D209AA

Developer Collecting Bag & Box Rubber Tube

✽

Part No. 11UM01250

1: New jumper harness (Part No.

11ZT00440) can use both 7823 and

7832.

× 2

But current jumper harness (Part No.

11UM00440) can use only for 7823.

1154D217AA

1154D211AA

1154D216AA

Pin

1154D261AA

D-94

Page 2

(2) Miscellaneous Jigs

Part No. 11ZT00540 Part No. 11ZT00040

1144D229AA

4002D503AA

Db Gap Adjusting Jigs Cable Holding Jigs

Part No. 25TU00400

Part No. 25TU00340

25TU00410

1144D235AA

1144D326AA

Scanner/Mirrors Carriage Positioning Jigs Transfer Adjusting Jig

Part No. 25TU00420 Part No. 25TU00350

1144D233AA

1144D231AA

AIDC Sensor Positioning Jig Interlock Switch Actuating Jig

D-95

Page 3

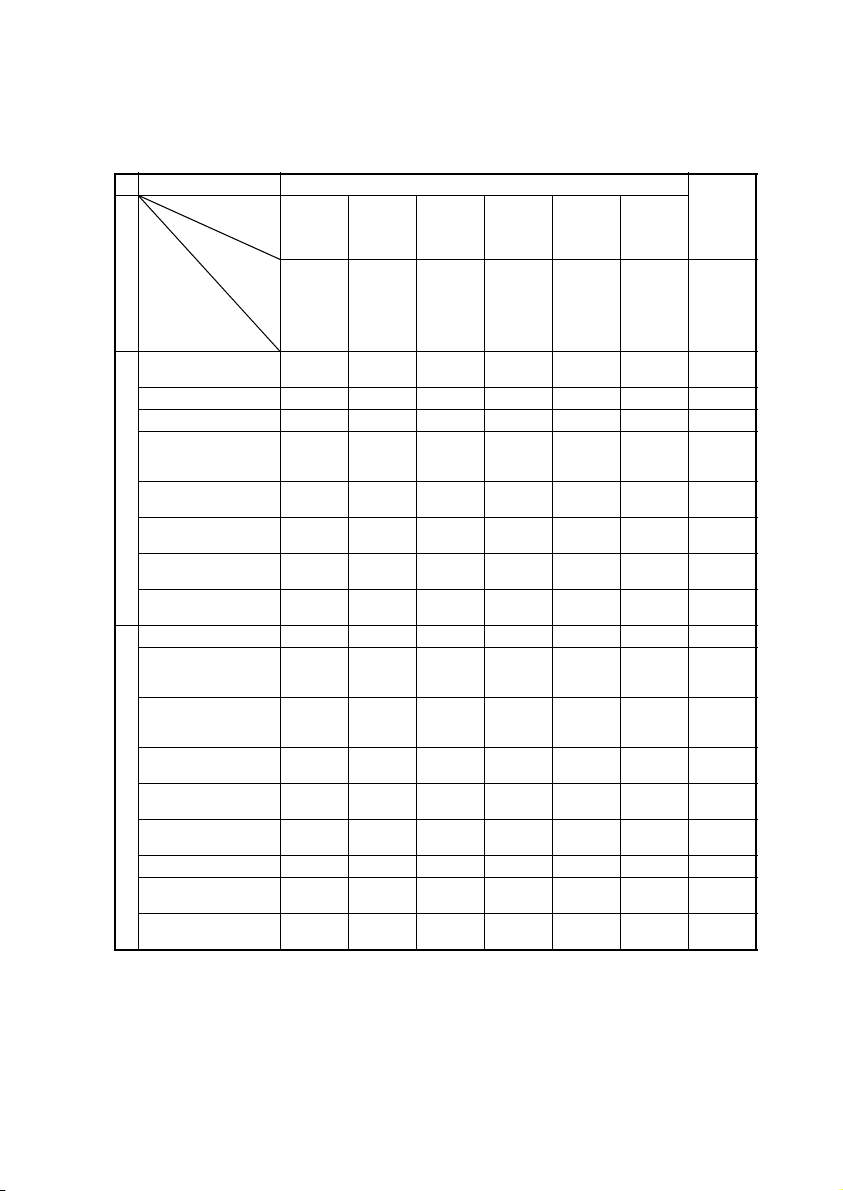

3-2. ADJUSTMENT REQUIREMENTS FOR CLEANING/REPLACE-

MENT OF EACH PART

When any of the jobs listed in the Parts List column is performed (replacement or cleaning),

make the adjustments in numerical order 1, 2, ...

Job Type Developer Change

Job item Developer

Check

Use jig. Use jig. Reference

Section

Parts List

Developing Unit replacement

Developer change 2 1 3 4 5 6 7

Ds rolls cleaning ––(1) (1) –––

Toner Scattering Preven tion Plate (M, C, Bk)

cleaning

Toner Scattering Preven tion Seal 1 (Y) cleaning

Developing Unit

ATDC window replacement

ATDC Adj. Unit replacement

High Voltage Unit 4

replacement

PC Drum replacement ––12––3

PC Drum Charge

Corona Assy replacement

PC Drum Charge

Corona wire/grid cleaning/replacement

PC Drum Charge

Corona housing cleaning

Cleaning Pad replacement

Main Erase Lamp cleaning

PC Unit and associated parts

AIDC Sensor cleaning ––12–– 3

Surface Potential Detection Sensor cleaning

Toner Scattering Preven tion Seal 2 cleaning

✽

(1) Check.

Developer

Filling

Discharge

1 – 23456

––(1) (1) –––

––(1) (1) –––

2134567

21345– 6

21345– 6

––––––1

––––––1

––––––1

––––––1

––––––1

––––––1

––––––1

AIDC Sensor adjust-

ment

voltage 4.0

±0.3V

AIDC Sen-

sor offset

level

adjustment

Auto

adjustment

ATDC Sen-

sor adjust-

5.0 ±0.2% After auto

ment

Bk unit-tounit vari a-

tions

adjustment

adjust-

ment,

check cor-

rection

value.

Gradation

Adjust

Run three

times.

D-96

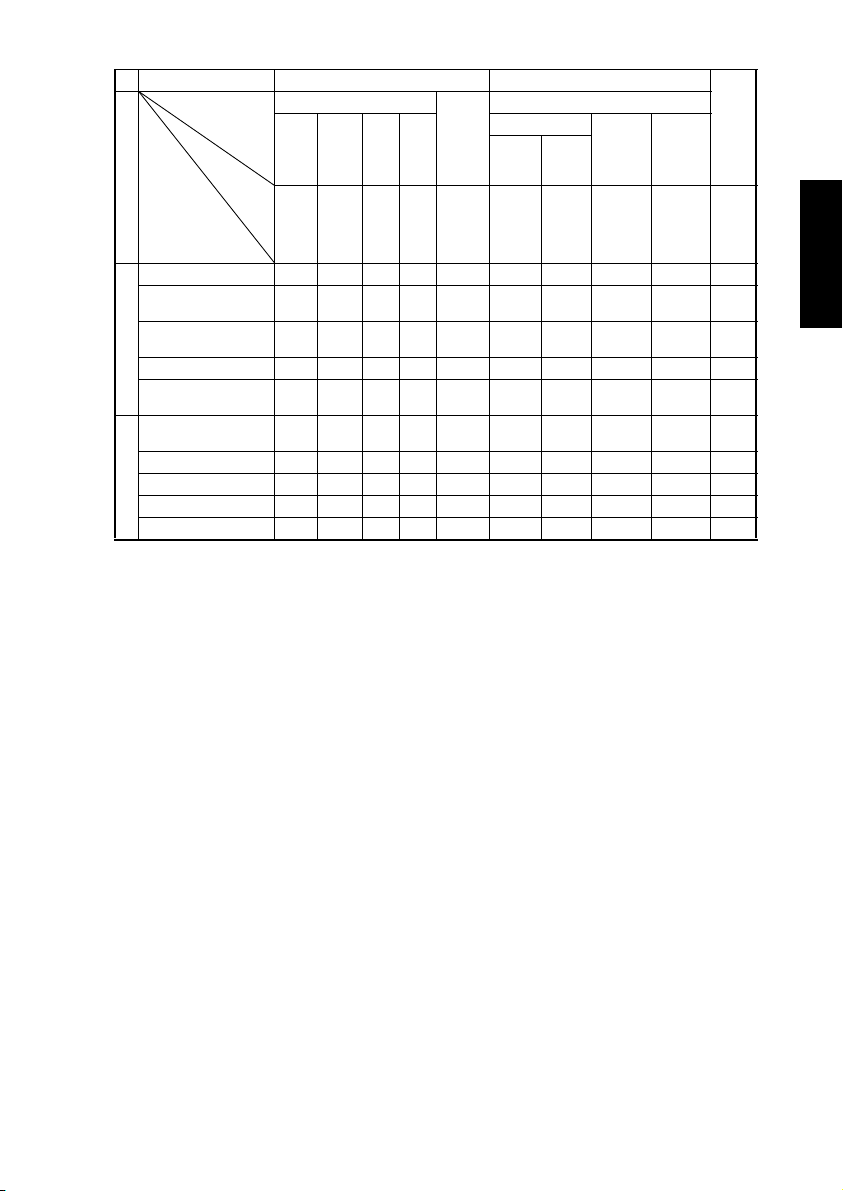

Page 4

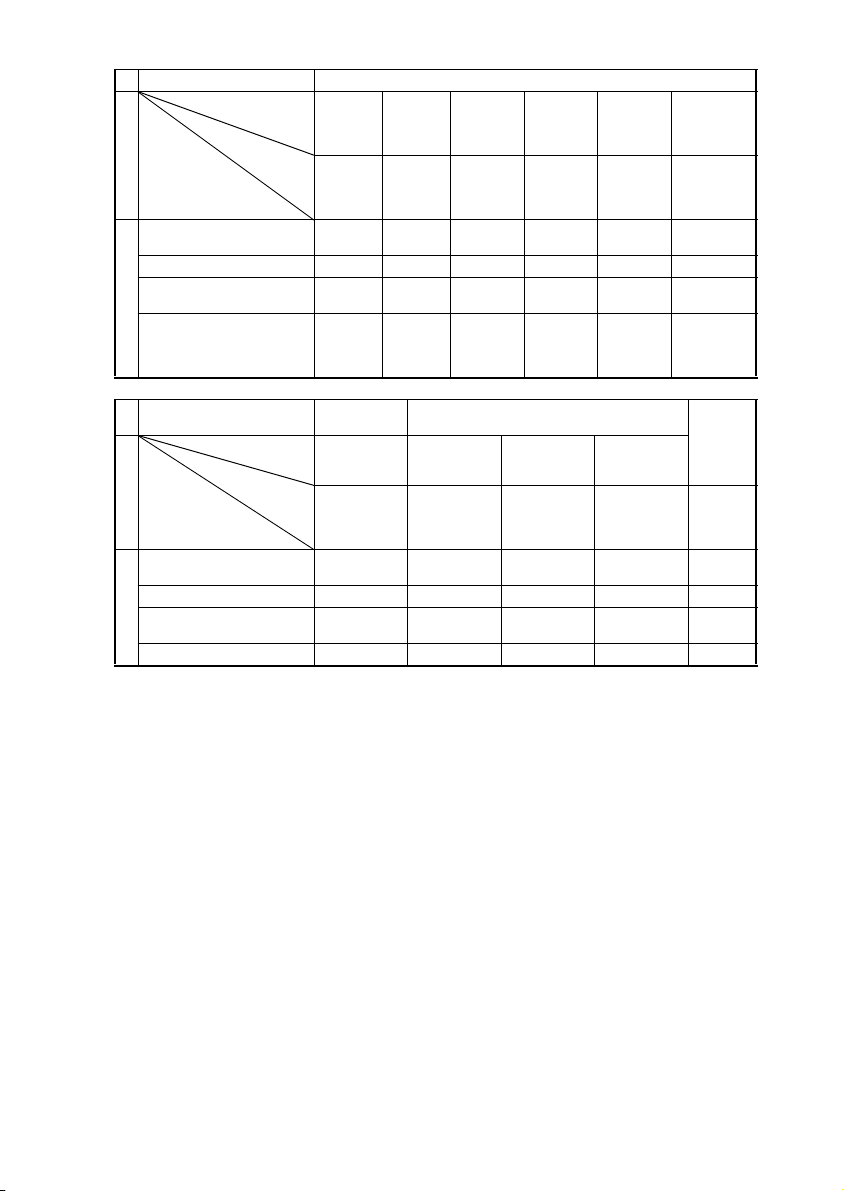

Job Type Machine Adjust 2 Machine Adjust 1 Grada-

Job item IR Area Org.

Left

Top

Image

Refer-

ence

position 10

±1 mm

CD-

Mag.

200

±1

mm

Image

Section

Parts List

CCD Assy replacement 2 1 3 4 ––– – –5

Mirror/lens/Original

Glass cleaning

Exposur e Lamp

IR

replacement

Cable coming unwound 2 1 3 4 ––– – –5

Original Size Detecting

Sensor replacement

PH Upper/Lower Assy

replacement

Window 1 cleaning ––––– – – – – 1

PH

Window 2 cleaning ––––– – – – – 1

Window 3 cleaning ––––– – – – – 1

Window 4 cleaning ––––– – – – – 1

Check

Lead-

ing

edge

0 ±1

mm

––––– – – – – 1

––––– – – – – 1

––––1 –– – – –

6578– 34 1 2 9

FD-

Mag.

300

±1.5

mm

Detect

Sensor

Check

OK after

adjust-

ment.

Top Margin Left Mar-

Image

Start

Position

5 ±0.25 mm0 ±0.5 mmVoid

auto

Lead

Edge

Position

PRT Area

image on

left/right:

3 ±1.5

gin

mm

Dup. Left

Margin

Void

image on

left/right:

3 ±1.5

mm

tion

Adjust

Run

three

times.

D-97

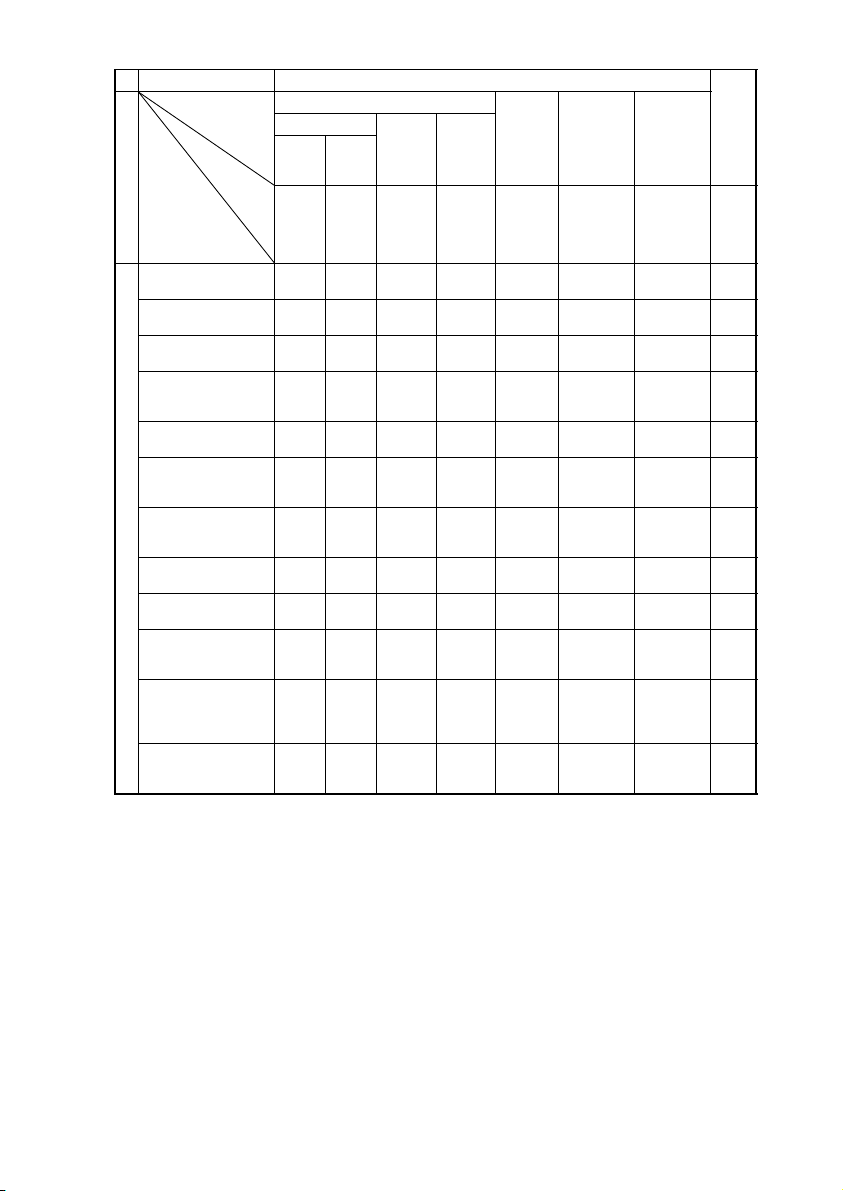

Page 5

Job Type Machine Adjust 1 Grada-

Job item PRT Area Jam Sen-

Section

Parts List

Transfer Unit replacement

Transfer Film replacement

Image Transfer Corona

unit replacement

Image Transfer Corona

wire cleaning/replacement

Image Transfer Corona

housing cleaning

Paper Bonding Failure

Detection Board 1 sensor cleaning

Paper Bonding Failure

Detection Board 2 sensor cleaning

Transfer

Sensor Adj. Board

replacement

High Voltage Unit 3

replacement

Pre-Image Transfer

Corona Assy replacement

Pre-Image Transfer

Corona Comb Electrode/grid cleaning/

replacement

Pre-Image Transfer

Corona housing cleaning

Top Margin Left Mar-

Image

Start

Position

Check

5 ±0.25 mm0 ±0.5 mmVoid

45 2 3 1 ––6

45 2 3 1 ––6

–– – – – – – 1

–– – – – – – 1

–– – – – – – 1

–– – – 1 –––

–– – – 1 –––

–– – – 1 –––

–– – – – 1 ––

–– – – – – – 1

–– – – – – – 1

–– – – – – – 1

Lead

Edge

Position

gin

image on

left/right:

3 ±1.5

mm

Dup. Left

Margin

Void

image on

left/right:

3 ±1.5

mm

adjust-

Point at

which

LED1 and

2 go out.

sor

ment

Transfer

Output

adjustment

Transfer out-

put should

not be more

or less than

required.

Feed Motor

Speed

adjustment

Color image

registration

deviation

within 0.5

dots

tion

Adjust

Run

three

times.

D-98

Page 6

Job Type Machine Adjust 1 Grada-

Job item Transfer Out-

put adjustment

Check

Section

Parts List

Paper Take-Up/Feed Roll Assy

cleaning/replacement

Paper Separator Roll cleaning/

replacement

Synchronizing Roller cleaning – 1 –––

Transport Roller cleaning – 1 –––

Paper take-up

Vertical Transport Roller cleaning – 1 –––

Copy paper not recommended 2 1 ––3

Fusing Unit replacement ––21–

Fusing Roller (Upper/Lower)

replacement

Fusing Roller bushing (upper/

lower) replacement

Fusing Unit

Coil Collecting Blade cleaning/

replacement

Transfer output

should not be

more or less

than required.

– 1 –––

– 1 –––

––21–

––21–

––21–

Feed Motor

Speed adjust-

ment

Color image

registration

deviation within

100 µm

Fuser Speed

adjustmen t

Magenta image

should not be

brushed or

blurred.

Fuser Nip

adjustment

8.5 ±0.3 mm at

center; right-

left difference

0.5 mm

tion

Adjust

Run three

times.

D-99

Page 7

Job Type Developer Change

Job item Developer

Check

Section

Parts List

Paper Take-Up Motor replacement

Fusing Motor replacement –– – – – –

PC Drum Drive Motor replacement

Control

RAM Pack replacement

Use jig. Use jig. Reference

Bk Developing Unit

Developer

Filling

Discharge

–– – – – –

–– – – – –

2

Bk Developing Unit

only

only

1

AIDC Sensor adjust-

voltage 4.0

±0.3V

AIDC Sen-

ment

sor offset

level adjust-

Auto adjust-

456 3

ATDC Sen-

sor adjust-

ment

5.0 ±0.2% After auto

ment

ment

Bk unit-to-unit

variations

adjustment

adjustment,

check correc-

tion valu e.

Job Type

Section

Parts List

Paper Take-Up Motor replacement

Fusing Motor replacement ––(1) ––

PC Drum Drive Motor replace-

Control

ment

RAM Pack replacement 7 ––––

✽

(1) Check.

Machine Adjust

2

Job item Org. Detect

Sensor adjust-

ment

Check

Check OK after

auto adjust-

ment.

– (1) –––

––(1) ––

Feed Motor

Speed adjust-

ment

Color image

registration

deviation within

100 µm

Machine Adjust 1

Fuser Speed

adjustment

Magenta image

should not be

brushed or

blurred.

Fuser Nip

adjustment

8.5 ±0.3 m m at

center; right-left

difference 0.5

mm

Gradation

Adjust

Run three

times.

D-100

Page 8

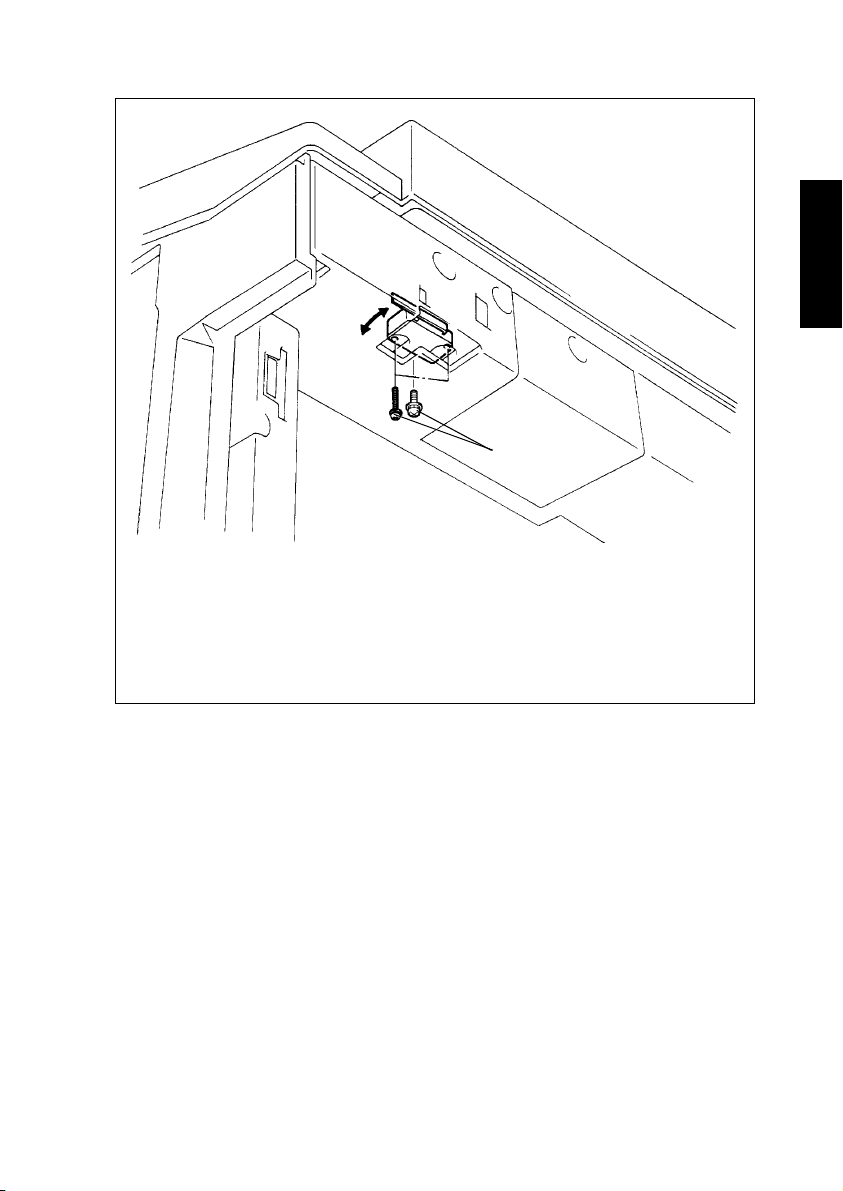

3-3. ADJUSTMENT OF SWITCHES

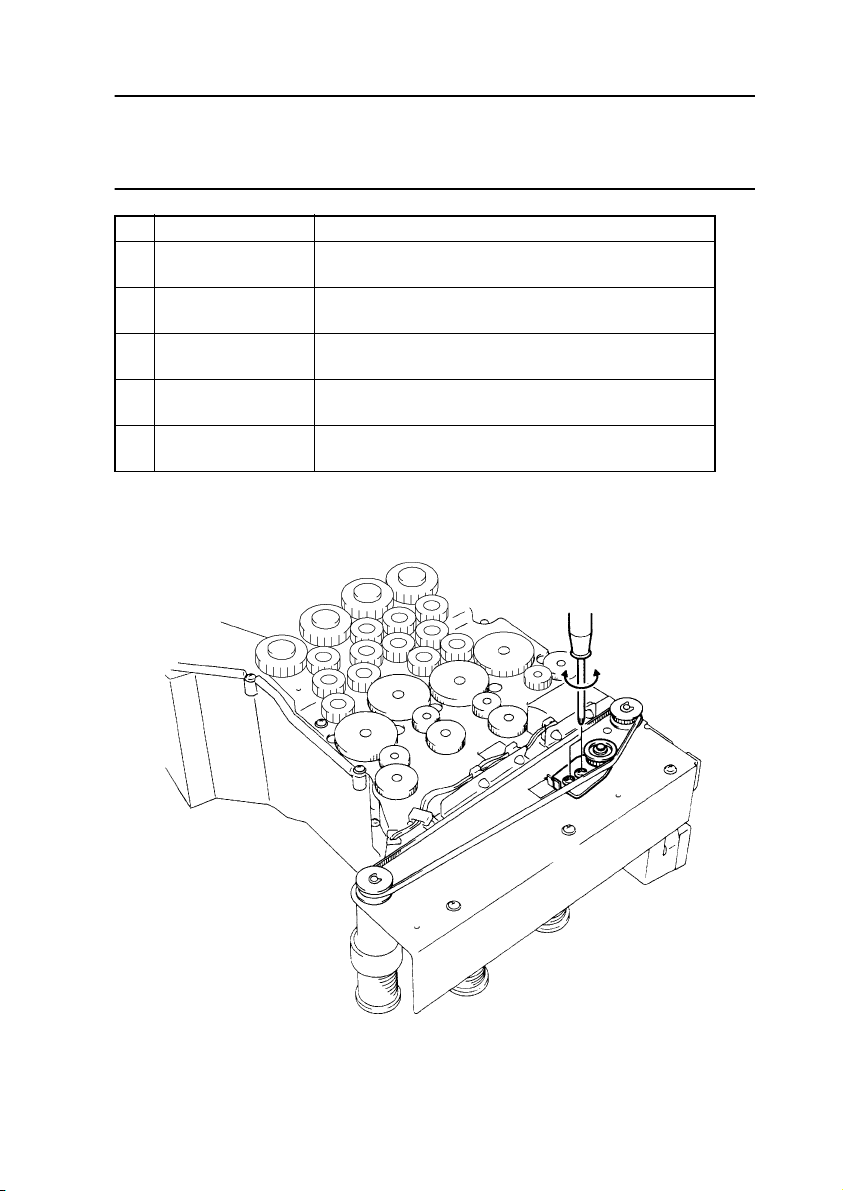

Adjusting screws

1179D071AA

1. Open the Front Door.

Loosen the Front Door Interlock Switch assy adjusting screws.

2. If the Front Door Interlock Switch is in the deactuated position when the Front Door is

closed, move the Front Door Interlock Switch assy to the front.

If the Front Door Interlock Switch remains actuated because it is located too far forward, move the Front Door Interlock Switch assy towards the rear.

D-101

Page 9

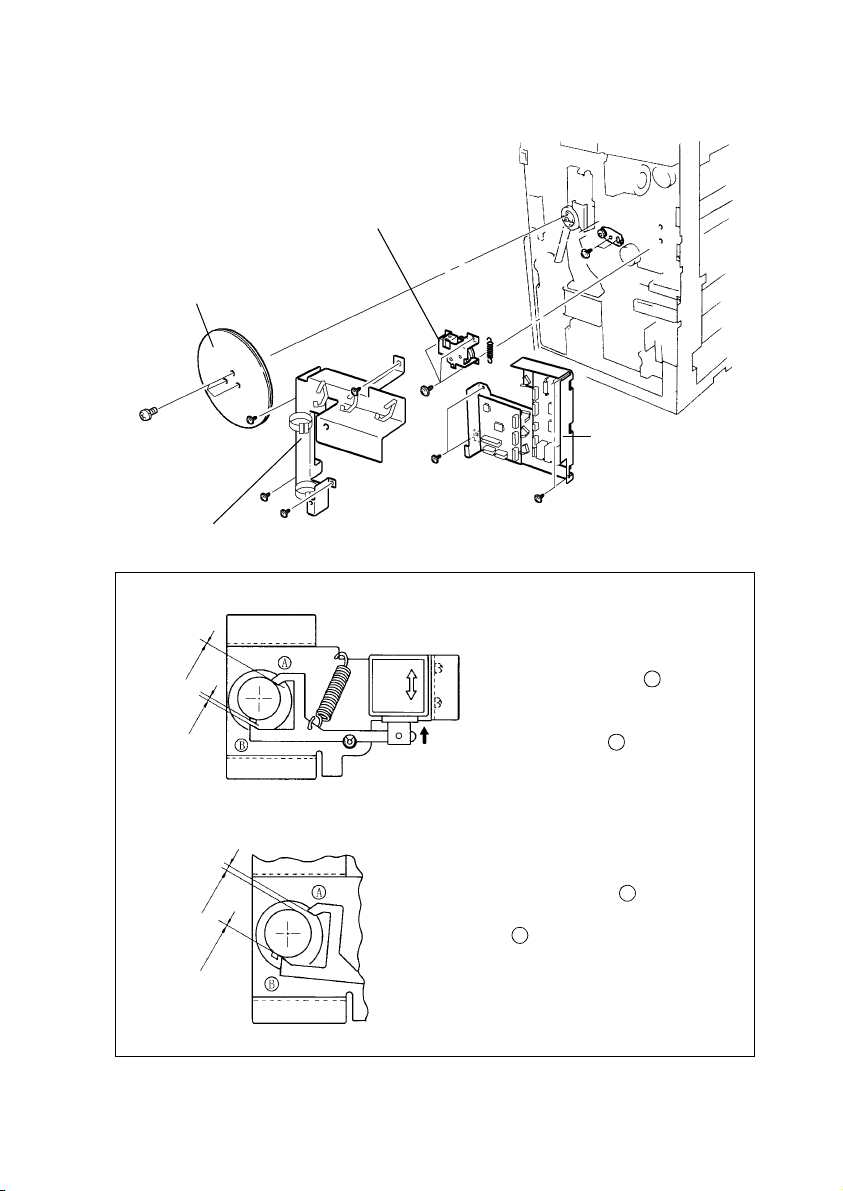

3-4. ADJUSTMENT OF SOLENOIDS

(1) Adjustment of the Transfer Drum Retract Solenoid

4. Transfer Drum

Retract Assy

Fig. 1

1. Flywheel

3. Cover

Fig. 1 Transfer Drum Retract Solenoid Adjusting Procedure

1. Loosen the adjusting screw.

0 mm

2 ±1 mm

2. Manually move the solenoid into

the energized position. The clear-

ance between pawl and ratchet

should be 2 ±1 mm.

At this time, allowing “0” clearance

between pawl and ratchet,

secure the solenoid.

2. Paper Take-Up

Board/Engine

Power Supply

Board Assy

1154D262AD

B

A

1 mm or more

0 mm

1144D196AA

1144D195AA

3. With the solenoid in the deenergized position,

turn the ratchet.

4. The clearance between pawl and ratchet

should be 1 mm or more when the clearance

between pawl and ratchet is “0” (the solenoid

is in the deenergized position).

B

A

D-102

Page 10

(2) Adjustment of the Static Charge Roller Solenoid

1. Transfer Unit cover

Static Charge

Roller Solenoid

Fig. 1

2. Synchronizing/Static

Charge Roller Assy

Fig. 1 Static Charge Roller Solenoid Adjusting Procedure

1144D197AA

Static Charge Roller Solenoid

Adjusting screw

1. Loosen the adjusting screw.

Solenoid energized

Ratchet flat

portion

Solenoid

2. Manually move the solenoid into

3. Secure the solenoid where the

4. Deenergized the solenoid and

Ratchet

Pawl

1144D198AA

tooth

1179D058AA

the energized position.

pawl engages halfway or more

with a tooth, but is not in contact

with the flat portion of the

ratchet.

ensure that the tip of the pawl

does not contact the ratchet

tooth.

D-103

Page 11

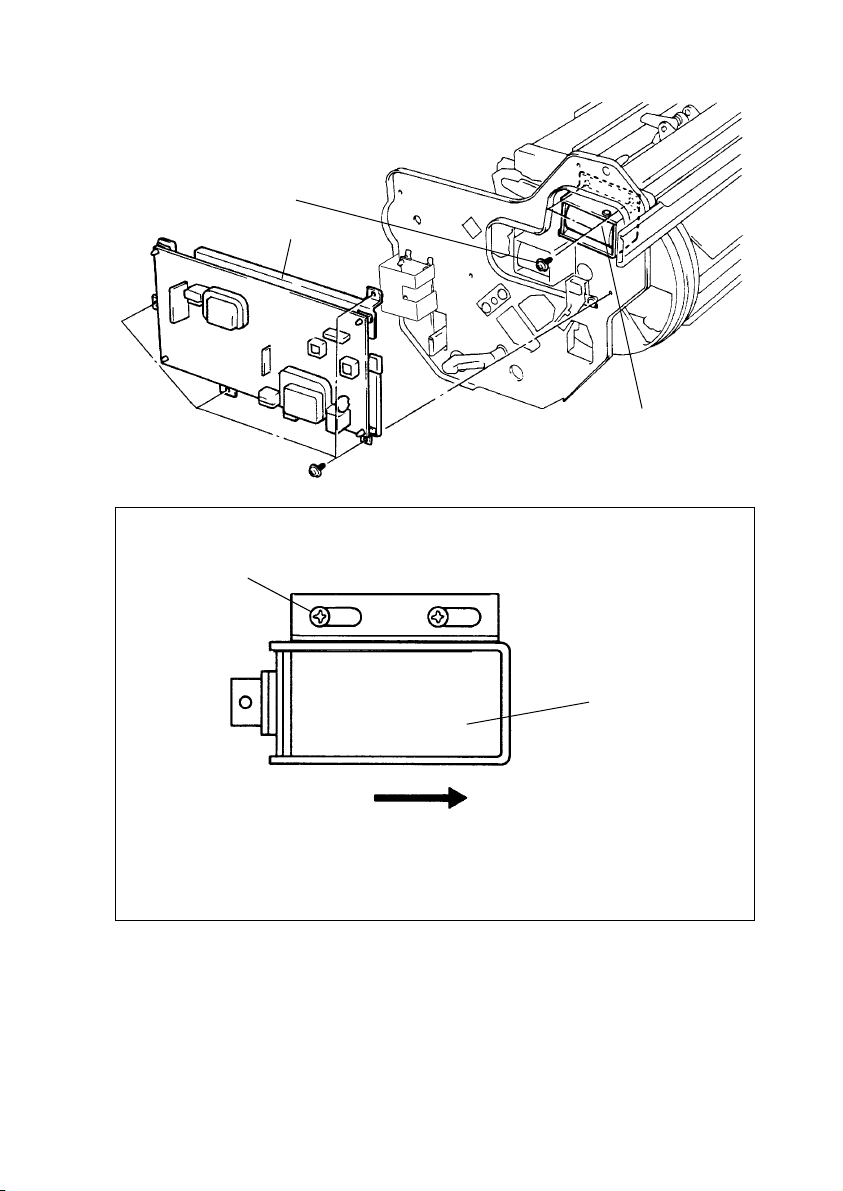

(3) Adjustment of the Paper Separator Finger Solenoid

Adjusting screw

High Voltage Unit 2 Assy

Fig. 1 Paper Separator Finger Solenoid Mounting Position

Screw position

Paper Separator

Finger Solenoid

Fig. 1

1154D259AA

1154D260AA

Slide the solenoid as far as it will go in the slot in the

direction of the arrow before tightening the screws.

D-104

Paper Separator

Finger Solenoid

Page 12

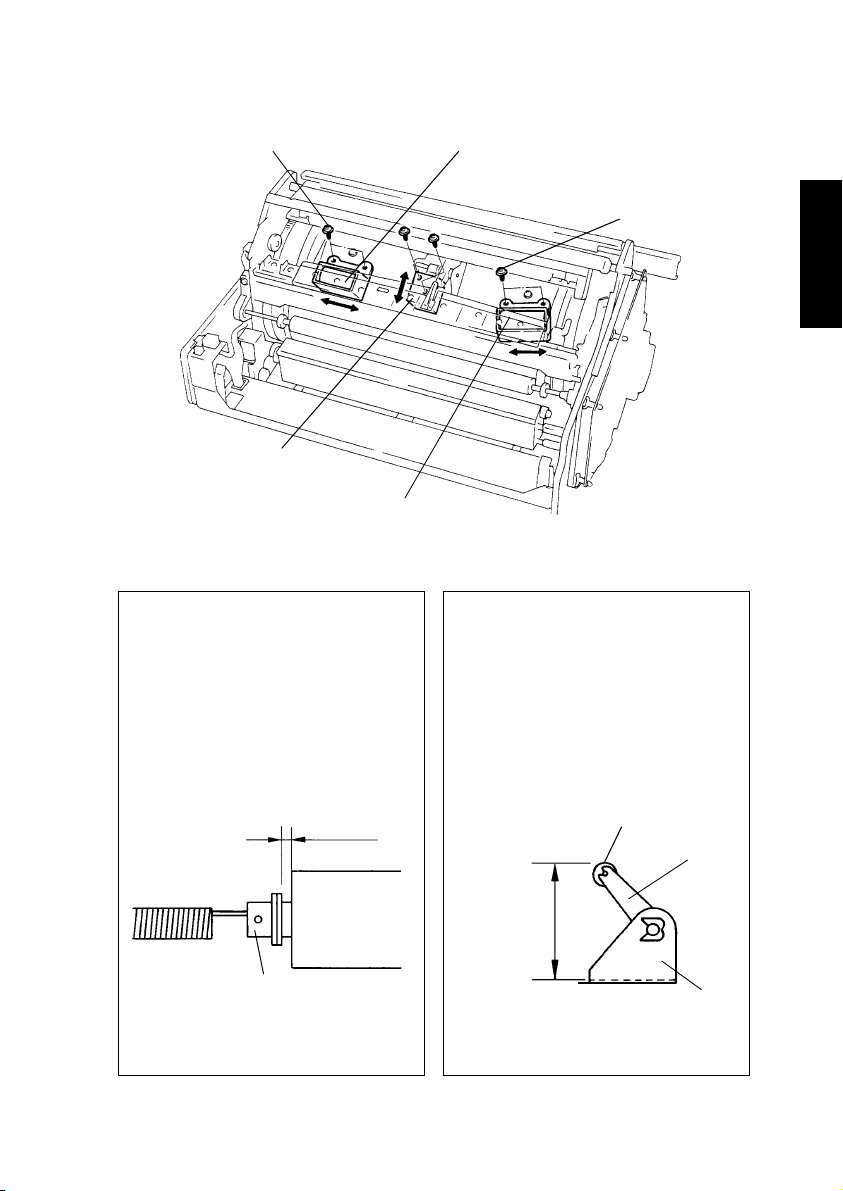

(4) Adjustment of the Internal Fur Brush Solenoid, Backup Brush Solenoid, and

Lifting Finger Solenoid

Adjusting screw

Lifting Finger Solenoid

Fig. 2

Internal Fur Brush Solenoid

Fig. 1

Fig. 1 Internal Fur Brush Solenoid/

Backup Brush Solenoid Adjusting Procedure

1. Loosen the adjusting screw of the

solenoid.

2. Adjust to obtain a clearance of 1 ±0.5

mm for the gap shown below when

the solenoid is manually moved into

the energized position.

1 ±0.5 mm

Backup Brush Solenoid

Fig. 1

Adjusting screw

1154D257AA

Fig. 2 Lifting Finger Solenoid Adjusting

Procedure

1. Loosen the adjusting screw of the

solenoid.

2. Adjust to obtain a lift of 57 ±0.5 mm

from the joint face for the Lifting Finger when the solenoid is manually

moved into the energized position.

Lifting Finger

Arm

Manually move solenoid

into energized position.

1144D201AA

Check for correct clearance when

the spring is not stretched.

Amount of lift

57 ±0.5 mm

Mounting

bracket

1154D258AA

D-105

Page 13

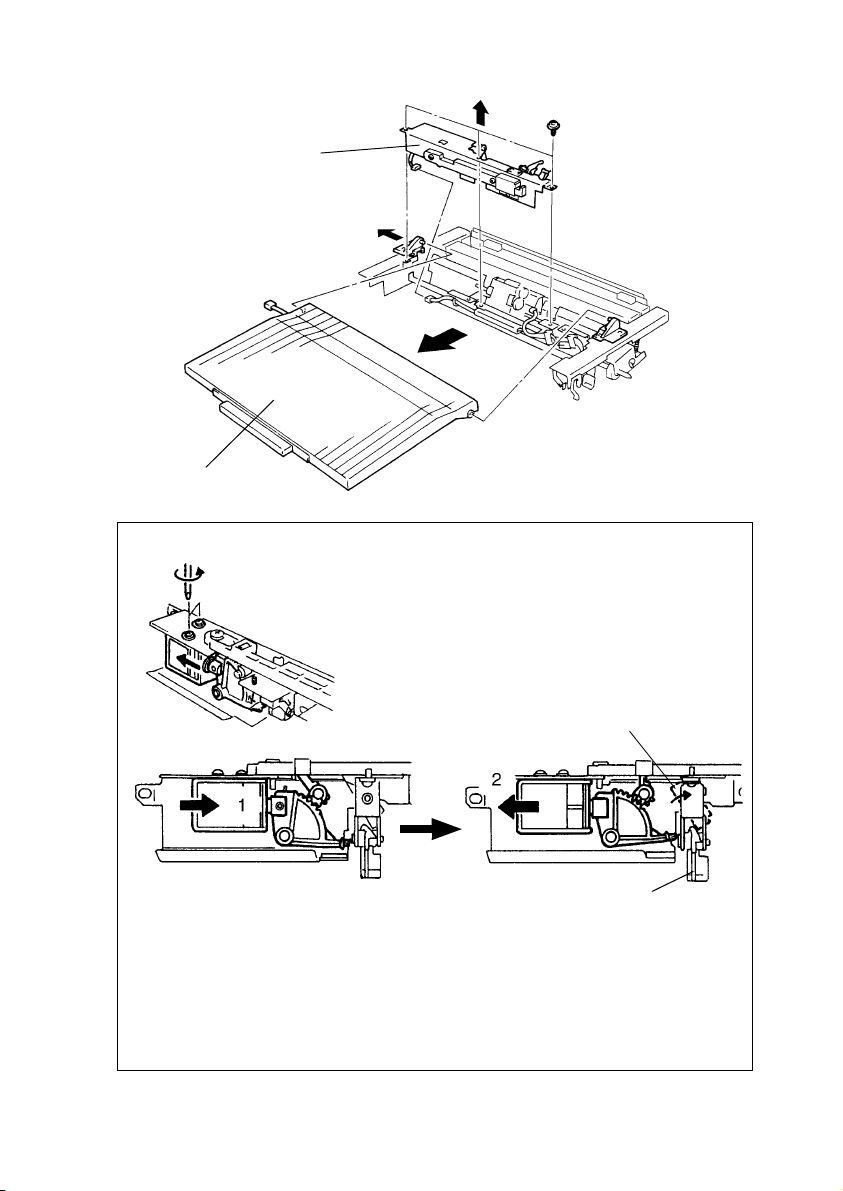

(5) Adjustment of the Manual Feed Paper Pick-Up Solenoid

Manual Feed Paper PickUp Solenoid assy

Fig. 1

Multi Bypass Table assy

1179D018AA

Fig. 1 Manual Feed Paper Pick-Up Solenoid Adjusting Procedure

1. Manually move the solenoid into the energized

position.

2. Loosen the adjusting screws.

Lock lever

1075D155AA

1075D156AB

Paper Stopper

1075D157AB

3. Move the solenoid in the direction of arrow 1 and then move it slowly in the direction

of arrow 2.

4. Move the solenoid to a position at which the Paper Stopper lock levers are in the

upright position (at which the Paper Stoppers are locked).

If the solenoid is moved too far, it will be released from the SET position. If it is

released from the SET position, energize the solenoid and start the procedure over.

5. Tighten the two screws that secure the solenoid in position.

D-106

Page 14

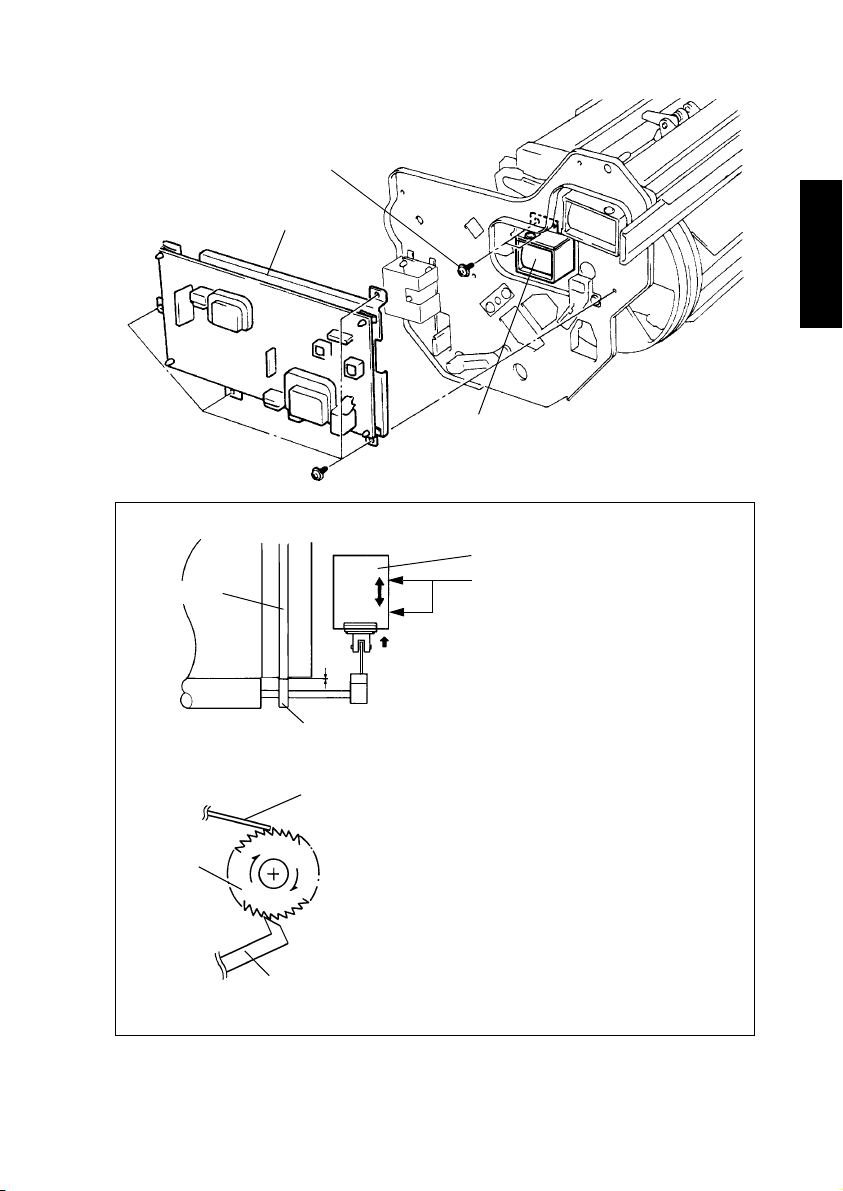

(6) Adjustment of the Oil Roller Solenoid

Adjusting screw

High Voltage Unit 2 assy

Fig. 1 Oil Roller Solenoid Adjusting Procedure

Rubber Ring

Oil Roller Solenoid

Fig. 1

1154D255AA

Oil Roller Solenoid

1. Loosen the adjusting screws.

Oil Collecting Roller

Ratchet

Lever

1154D256AA

0

Roll

Flat spring

1144D207AA

2. Manually move the solenoid into the

energized position and, where the

clearance between the rubber ring of

the Transfer Drum and the front and

rear roll of the Oil Collecting Roller

becomes “0,” secure the solenoid in

position.

3. When the solenoid is manually energized and deenergized, it should click

twice or more.

D-107

Page 15

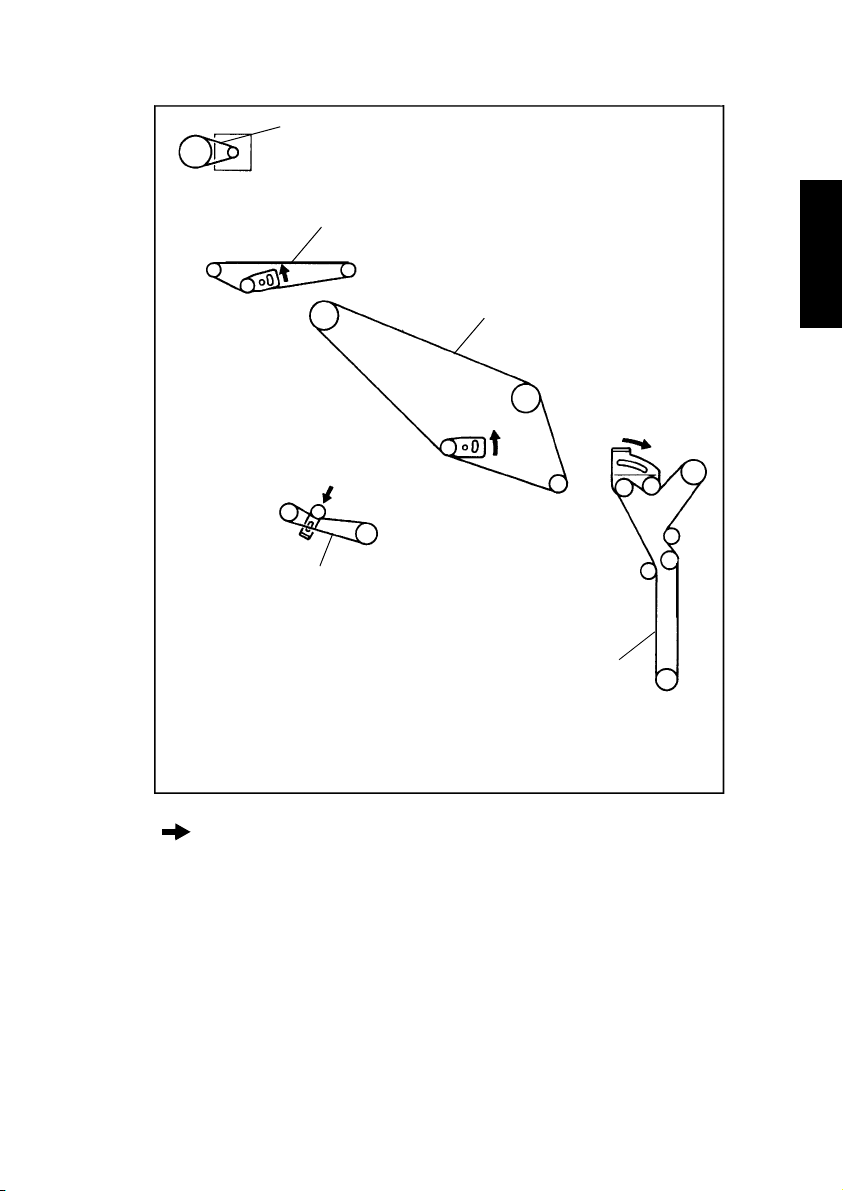

3-5. ADJUSTMENT OF BELT TENSION

Tip

A given tension is being applied to the torsion spring or tension spring fitted to the tension

plate that keeps each timing belt taut. Simply loosening and tightening the mounting

screw(s) therefore allows belt tension to be adjusted.

No. Driven Mechanism Adjusting Procedure

1 Developing Unit

2 Hopper

3 Paper Take-Up

4 Cleaning Unit

5 Scanner Drive

(Example) Adjustment of Hopper Unit Timing Belt

Loosen the two tension plate mounting screws and then tighten them again.

Loosen one tension plate mounting screw and then

tighten it again.

Loosen two tension plate mounting screws and then

tighten them again.

Loosen one tension plate mounting screw and then

tighten it again.

Loosen two tension plate mounting screws and then

tighten them again.

Loosen three Scanner Motor assy mounting screws

and then tighten them again.

D-108

1154D210AB

Page 16

Timing Belt Locations (Viewing Copier from the Back)

5

2

1

4

Tensioning Direction

3

1179D059AA

D-109

Page 17

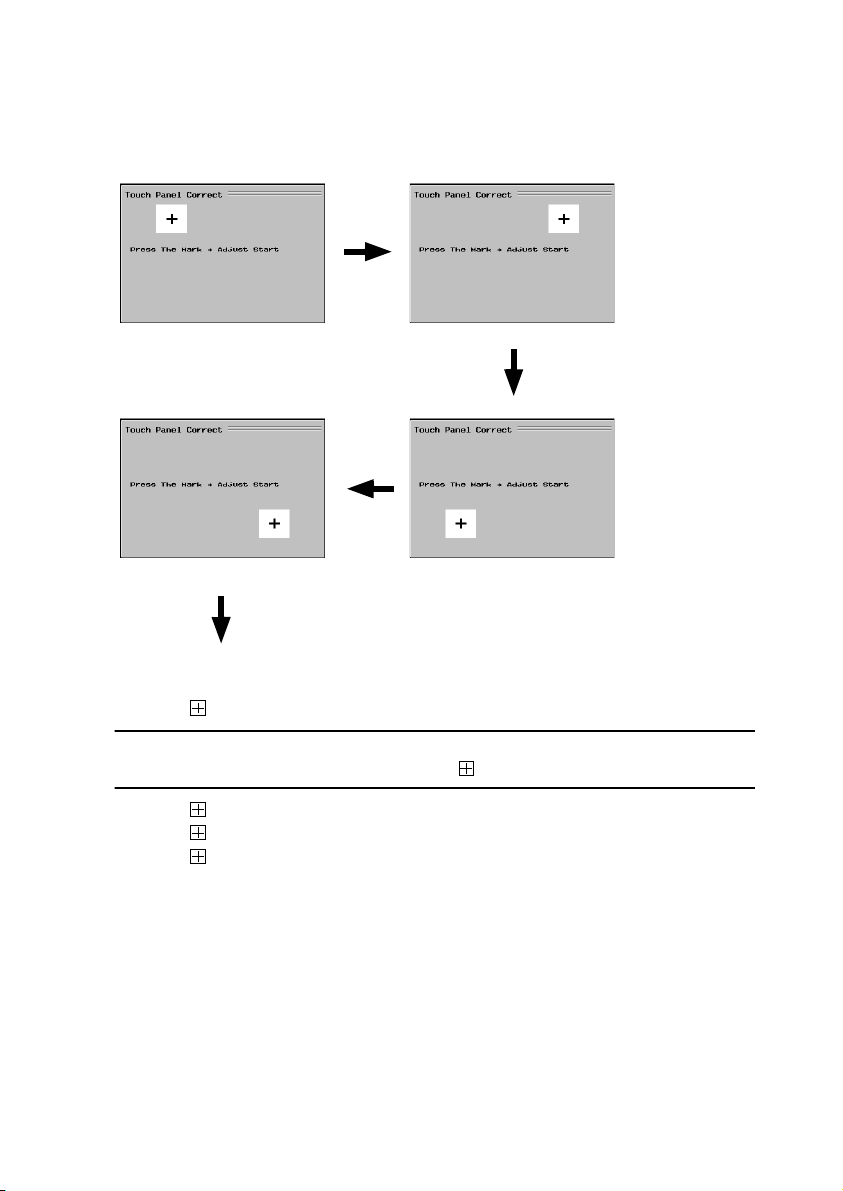

3-6. TOUCH PANEL CORRECTION MODE

1. Press the following keys in this order to set the copier into the Touch Panel Correct

mode: Stop → 0 → Stop → 3.

12

1144S009CA

1144S010CA

43

1144S012CA

1144S011CA

Basic Screen

2. Touch on screen 1.

NOTE

At this time, be sure to touch the exact center of . (The same is true with the following.)

3. Touch on screen 2.

4. Touch on screen 3.

5. Touch on screen 4.

D-110

Page 18

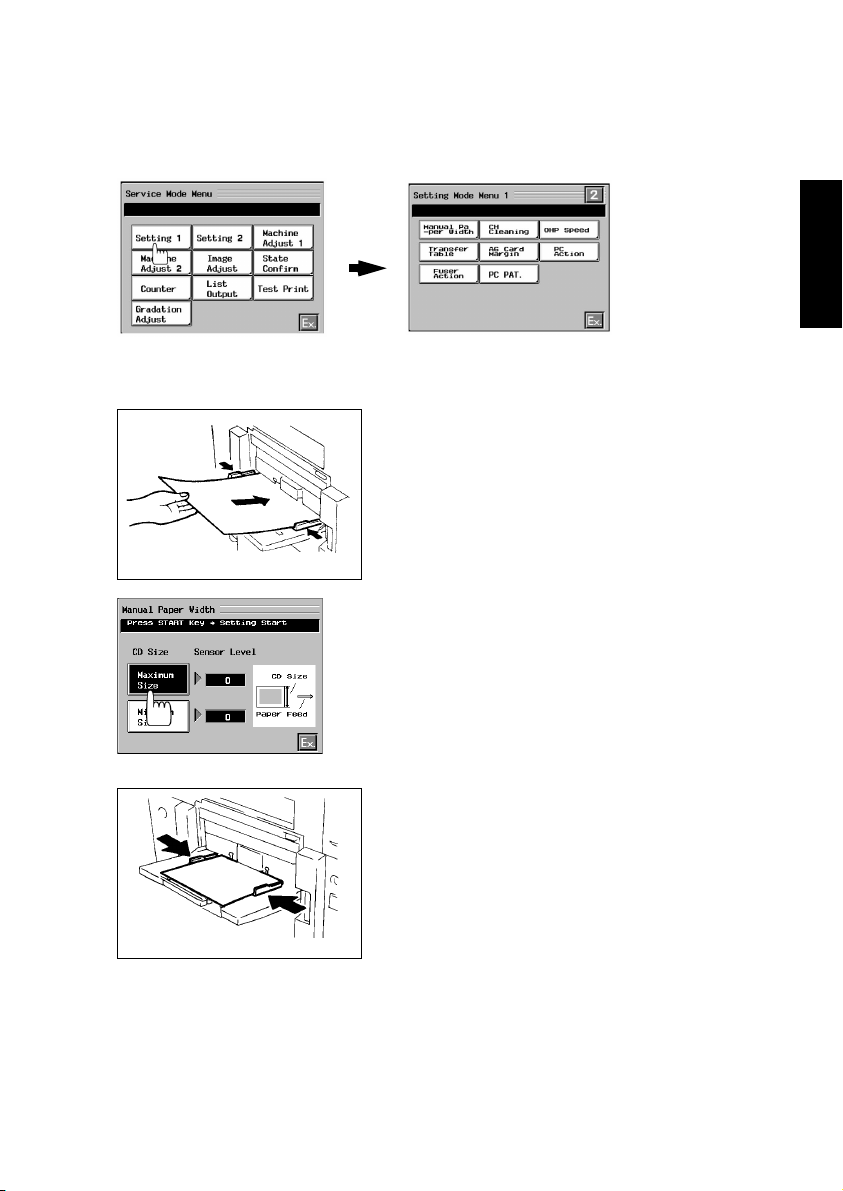

3-7. SETTING MODE

1. Press the Utility key and then select “Meter Count” to open the Meter Count screen.

2. Press the following keys in this order to show the Service Mode Menu screen: Stop → 0

→

0 → Stop → 0 → 1.

3. Select “Setting 1.”

1179P439CA

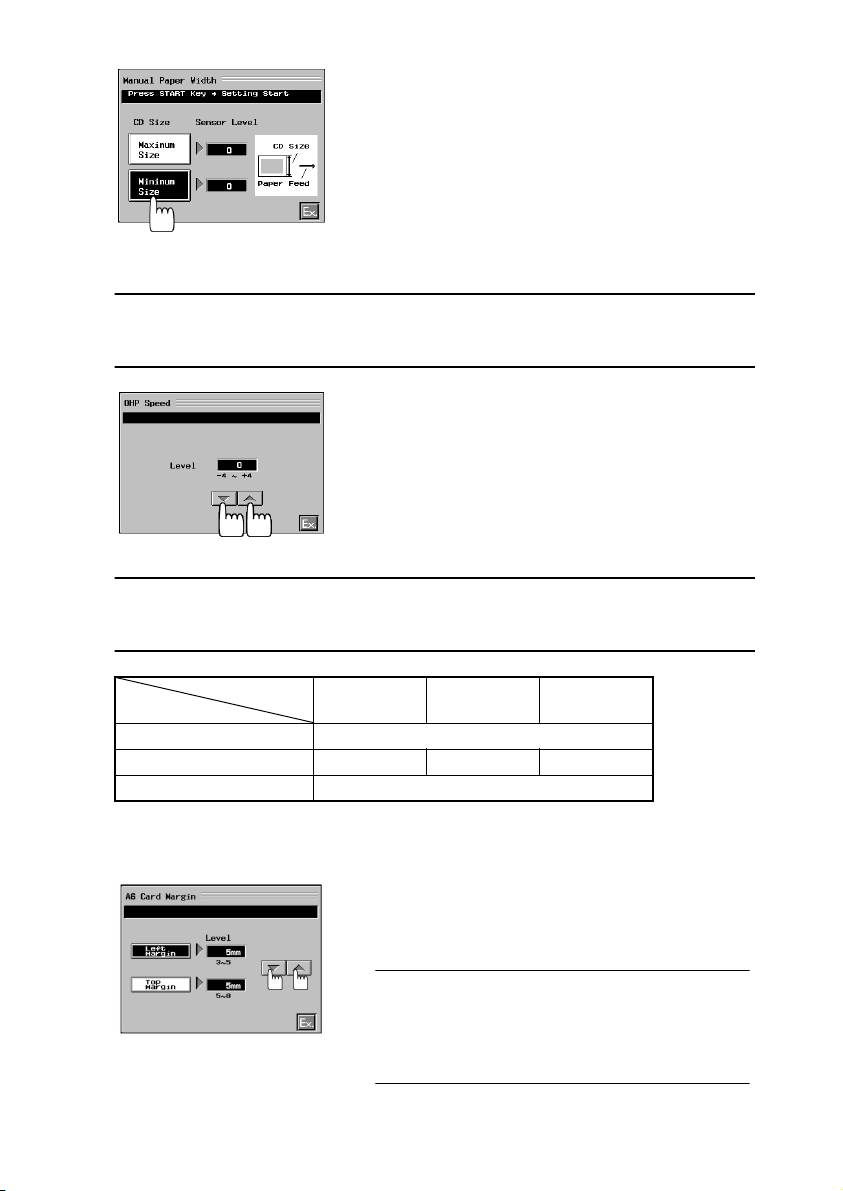

(1) Manual Paper Width

1144D268AA

1154D075CA

1179P440CA

1. Place several sheets of A3 wide (305 mm × 457

mm) or 12 × 18 paper on the Multi Bypass Table.

2. Select “Manual Paper Width.”

3. Select “Maximum Size” and press the Start key.

(This will start an automatic adjustment

sequence.)

4. Remove the A3 wide (305 mm × 457 mm) or 12 ×

18 paper from the Multi Bypass Table and,

instead, place several sheets of B5 lengthwise or

5-1/2 × 8-1/2 paper on the table.

1144O013YA

D-111

Page 19

5. Select “Minimum Size” and press the Start key.

(This will start an automatic adjustment

sequence.)

6. After the adjustments have been made, touch

“Ex.”

1154D076CA

(2) OHP Speed

Adjustment

• If lines appear in the CD direction (paper separation failure), increase the setting value.

• If OHP transparency is low, decrease the setting value.

1. Select “OHP Speed.”

2. Change the setting value using the shift keys.

3. After the adjustments have been made, touch

“Ex.”

1154D108CA

NOTE

Whenever a change is made in the Fuser Temp. setting under Machine Adjust 1, OHP

Speed is automatically adjusted so that the OHP fusing efficiency does not change.

Paper

Fuser Temp.

155 °C 160 °C 165 °C

Standard Paper 168 mm/s

OHP 80 mm/s 90 mm/s 100 mm/s

Heavy Stock 2 70 mm/s

(3) A6 Card Margin (4 × 6 Paper Margin)

Given in ( ) is the function name for the inch areas.

1. Select “A6 Card Margin” or “4 × 6 Paper Margin.”

2. Change the setting value using the shift keys.

3. After the adjustments have been made, touch

“Ex.”

Setting Range

Left Margin (void image width on right and left

edges): 3 to 5 mm

1179P441CA

Top Margin (void image width on leading edge): 5 to

8 mm

D-112

Page 20

3-8. MACHINE ADJUST MODE

1. Press the Utility key and then select “Meter Count” to open the Meter Count screen.

2. Press the following keys in this order to show the Service Mode Menu screen: Stop → 0

→

0 → Stop → 0 → 1.

3. Select “Machine Adjust 1” or “Machine Adjust 2.”

Machine

Adjust 1

1179P443CA

1179P442CA

Machine

Adjust 2

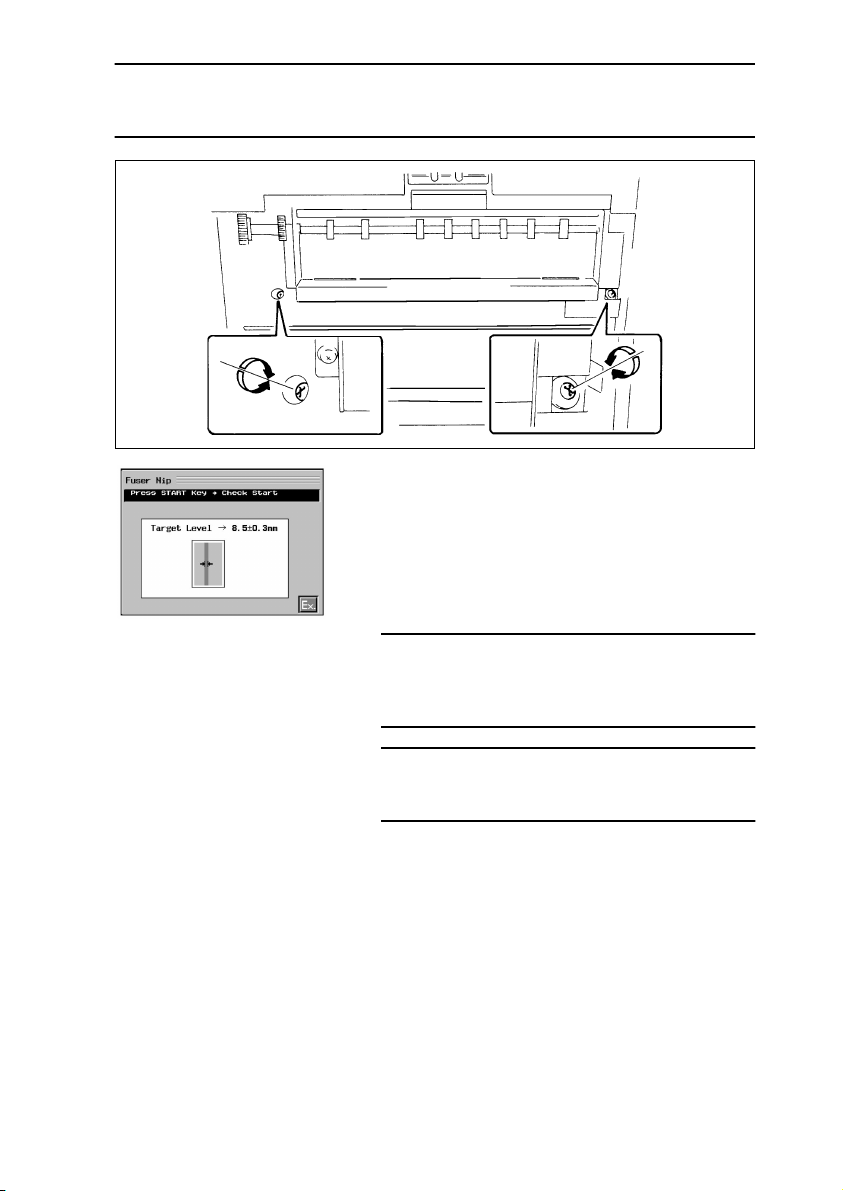

(1) Fuser Nip

NOTE

After Fuser Nip has been adjusted, Fuser Speed must also be adjusted.

1. Load any one of the drawers or the Multi Bypass

Table with A4 crosswise or 8-1/2 × 11 crosswise

paper.

2. Open the Front Door and slide out the Transfer

Unit.

3. From the position where the Fusing Roller pressure adjusting screws are fully tightened, back

1144U017AA

them off four turns, while ensuring uniform pressure on the front and rear ends.

4. Slide the Transfer Unit back into the copier.

5. Close the Front Door.

1179P444CA

D-113

Page 21

Reference

The Fusing Roller pressure adjusting screws can be adjusted by removing the Middle Left

Cover.

1144D254AA

6. Select “Fuser Nip” from the “Machine Adjust 1”

menu.

7. Press the Start key.

8. Measure the nip width at the front and rear ends

of the copy fed out onto the Exit Tray.

9. If the measurement falls outside the specified

range, turn the Fusing Roller pressure adjusting

1179P445CA

screws as necessary.

Specifications

Nip width: 8.5 ±0.3 mm

Difference in nip width between front and rear: Within

0.5 mm

Adjustments

8.8 mm <: Loosen the adjusting screw.

8.2 mm >: Tighten the adjusting screw.

10. After the adjustments have been made, touch

“Ex.”

D-114

Page 22

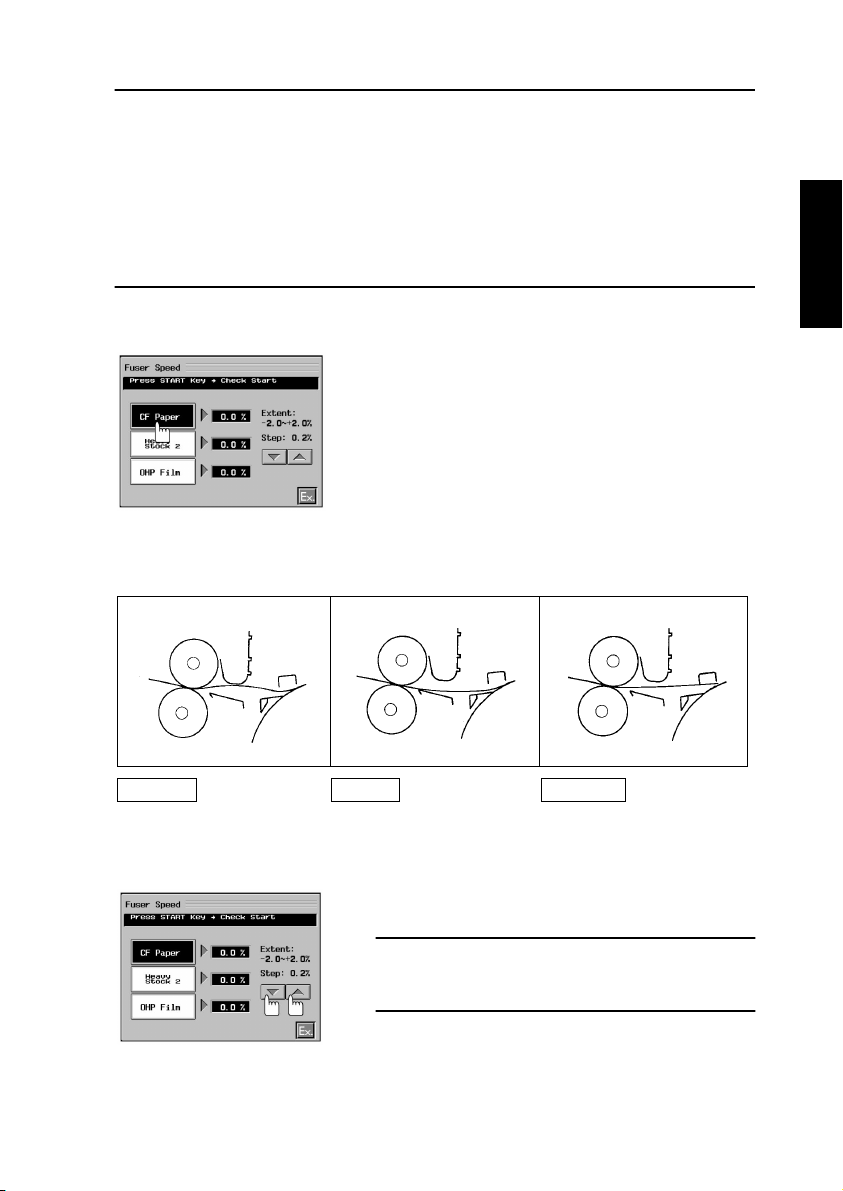

(2) Fuser Speed

NOTES

1. This adjustment should be made after Fuser Nip has been adjusted.

2. A specific paper source and type of paper must be used for each type of paper available

on the Touch Panel as follows.

• CF Paper: Load any of the drawers with A3 or 11 × 17 paper.

• Heavy Stock 2: Load the Multi Bypass Table with A3 or 11 × 17 paper weighing 129 to

2

209 g/m

.

• OHP Film: Load the Multi Bypass Table with A4 lengthwise or 8-1/2 × 11 lengthwise

paper.

3. Open the Front Door and remove the Transfer Unit cover.

4. Install the Interlock Switch Actuating Jig.

5. Select “Fuser Speed” and then “CF Paper.”

1179P446CA

6. Press the Start key and check to see if an adequate length of loop is formed before the

Fusing Rollers.

1154D215AA 1154D212AA 1154D213AA

Retarded Correct Advanced

The loop length is too long

causing the paper to have

too much slack.

A good length of loop is

formed as the paper moves

into the Fusing Rollers.

No loop is formed causing

the paper to be taut.

7. If the timing is advanced or retarded, change the

setting of Fuser Speed.

Adjustments

Retarded: Increase the setting.

Advanced: Decrease the setting.

8. Check the length of the loop again and repeat the

1179P447CA

above steps until a good length of loop is

obtained.

D-115

Page 23

1179P448CA

1179P449CA

9. Touch “Ex.” Twice to go back to the Service Mode

Menu screen. Then, touch “Test Print” and then

“Halftone” → “4 Color.”

10. Press the Clear key and enter “200” for TD (Test

Data). Then, check the length of the loop before

the Fusing Rollers and check the test print for

“brush effect.”

11. If the loop length is long and “brush effect” is evident on the test print, increase the setting until

“brush effect” disappears.

NOTE

If no “brush effect” is evident on the test print, no

adjustments are necessary and steps 10 and 11 may

be omitted.

12. Select “Cyan” for Test Print/Halftone.

13. Press the Clear key, enter “0” for TD (Test Data),

and check the loop length before the Fusing Rollers.

14. Make the necessary adjustments for Heavy Stock

2 and OHP Film by following steps 4 through 6.

15. After the adjustments have been made, touch

“Ex.”

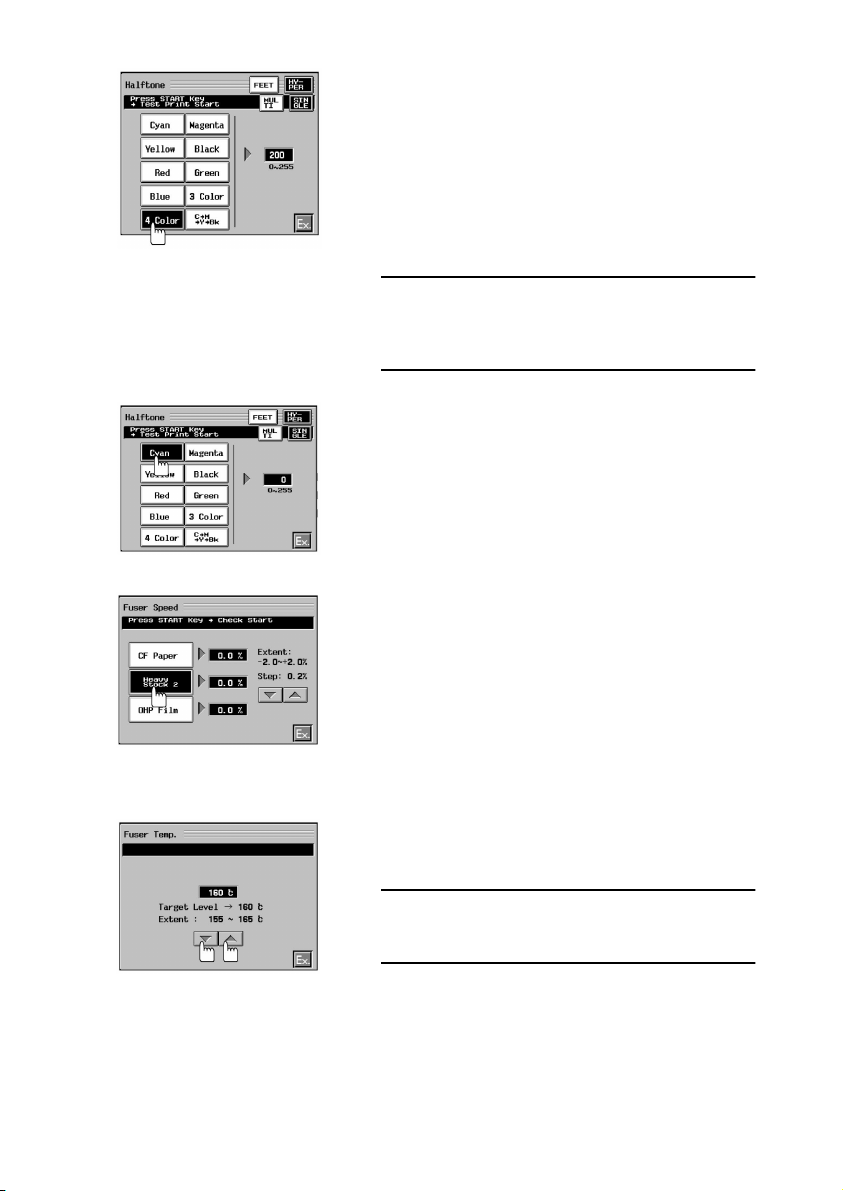

(3) Fuser Temp.

1179P450CA

1. Select “Fuser Temp.” from the “Machine Adjust 1”

menu.

2. Change the setting value using the shift keys.

Setting Range: 155 to 165 °C

Initial Setting: 160 °C

Step: 5 °C

1179P451CA

D-116

Page 24

(4) AIDC Offset

NOTES

• This adjustment should not be made individually.

• It must be made as part of a series of operations run in Developer Change Mode.

(5) Transfer Output

1. Load a drawer with A3 or 11 × 17 paper.

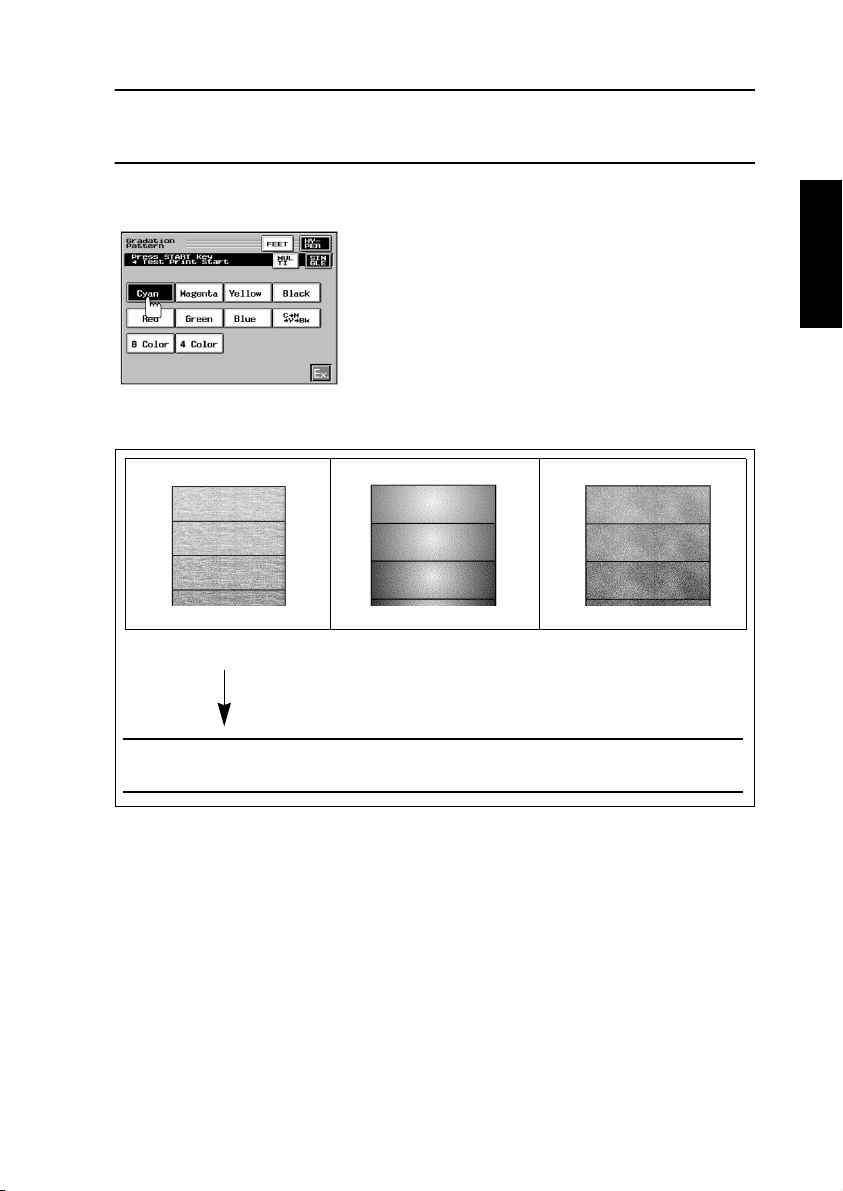

2. From the Service Mode Menu, select “Test Print.”

Then, select “Gradation Pattern” → “Cyan.” Now,

press the Start key.

1179P452CA

3. Check the test print produced for the following.

<Low T/C> <Poor Image Transfer>

1144D244AA1144D242AA

<Excessive Image Transfer>

1144D243AA

<Low T/C> <Poor Image Transfer> <Excessive Image Transfer>

Entire image has a lightly

brushed effect with uneven,

irregular low image density.

Even, high image density

at the edges with lower

density inside.

If the entire image has a heavily brushed effect, select “Copying Status” from “State

Confirm” and press the Start key to check for T/C of each color of toner.

D-117

Page 25

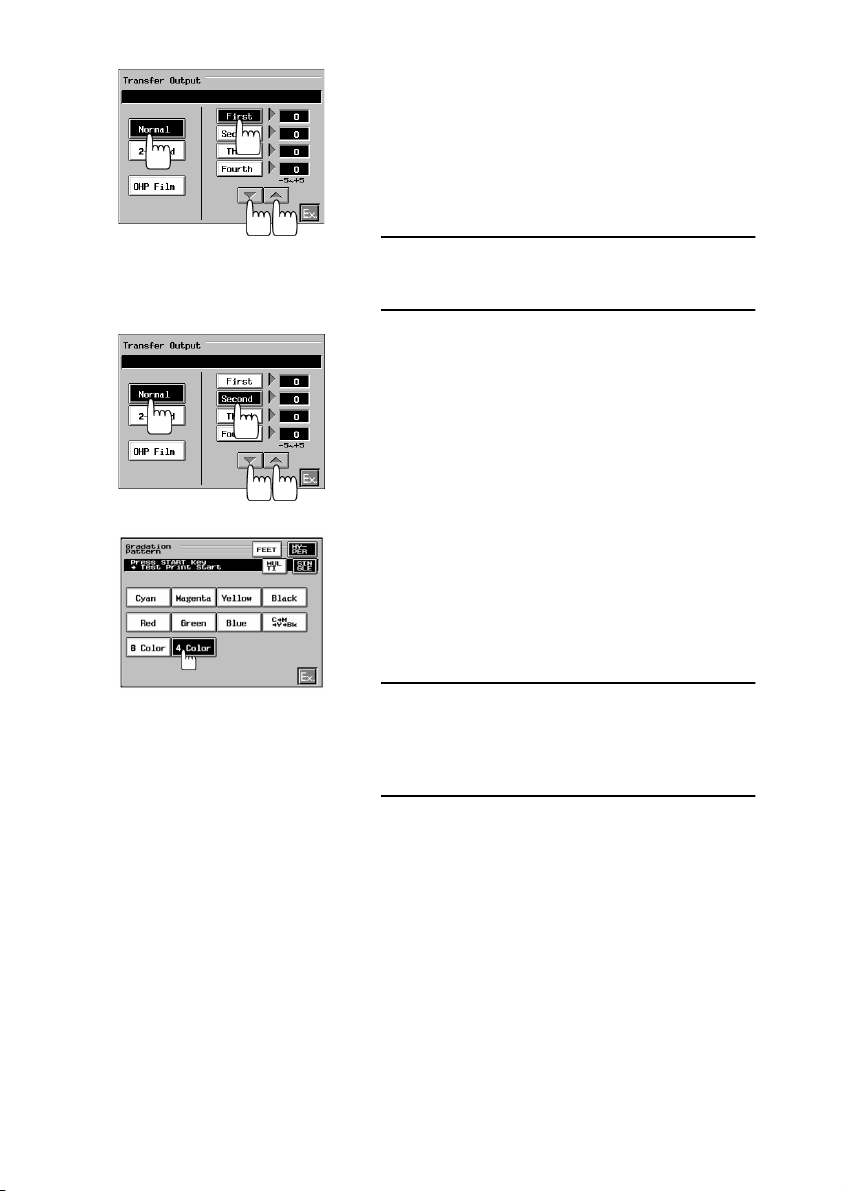

1154D086CA

1154D087CA

4. For Poor Image Transfer or Excessive Image

Transfer, touch “Ex.” twice to return to the Service

Mode Menu screen.

5. Select “Machine Adjust 1” and then “Transfer Output.”

6. Select “Normal” and “First” (image transfer number), in that order, and change the setting as necessary using the shift keys.

Adjustments

Excessive Image Transfer: Decrease the setting.

Poor Image Transfer: Increase the setting.

7. Select again “Test Print” → “Gradation Pattern” →

“Cyan” and then press the Start key.

8. Check the test print produced.

9. After the adjustment has been made, select

“Transfer Output” again and, using the shift keys,

set the same value as that for “First” of “Normal”

for “Second,” “Third,” and “Fourth.”

10. Select “Test Print” → “Gradation Pattern” → “4

Color” and then press the Start key.

11. Make the final check on the test print produced.

12. If Poor Image Transfer or Excessive Image Transfer is evident on magenta, yellow, or black on the

test print, make an independent setting for Second, Third, or Fourth.

1179P453CA

Transfer Output Order (Transfer Number)

First: Cyan

Second: Magenta

Third: Yellow

Fourth: Black

13. Using these procedures, make adjustments for

“2-Sided” and “OHP Film.”

14. After the adjustments have been made, touch

“Ex.”

D-118

Page 26

(6) Jam Sensor

1. Open the Front Door, remove the Transfer Unit

cover, and then lock the Transfer Unit back into

position.

2. Install the Interlock Switch Actuating Jig.

3. Select “Machine Adjust 1” and “Jam Sensor.”

Then, press the Start key.

1144D284CA

4. After the Transfer Drum has stopped turning, turn RT1 on the Failure Sensor Adj. Board

clockwise until LED1 (red) turns ON and then turn it counterclockwise until LED1 turns

OFF.

LED2

LED1

S1

RT1

RT2

S2

RT1: LED1: S1: For sensor on Paper Bonding Failure Detection Board 2

RT2: LED2: S2: For sensor on Paper Bonding Failure Detection Board 1

5. If LED1 (red) does not light up in step 4:

LD1 LD2

1. Flip DIP switch S1-1 on the Failure Sensor Adj. Board to

the OFF position and then perform step 4 again.

2. If LED1 does not still light up, flip DIP switch S1-1 to the

ON position again and flip S1-2 to OFF. Then, perform

S1

S1-1

S1-2

RT1

ON

OFF

ON

OFF

S2

S2-1

RT2

S2-2

step 4 again.

3. If LED1 does not still light up, flip S1-1 to OFF and, with

S1-2 in the OFF position, carry out step 4 again.

1179D060AB

For sensor on Paper Bonding Failure Detection Board 1

For sensor on Paper Bonding Failure Detection Board 2

D-119

1179D075AA

Page 27

6. Turn RT2 on the Failure Sensor Adj. Board clockwise until LED2 (green) turns ON and

then turn it counterclockwise until LED2 turns OFF.

7. If LED2 (green) does not light up in step 6, change the DIP switch S2 key positions as

necessary to make an adjustment.

8. After the adjustment has been made, press the Stop key and touch “Ex.”

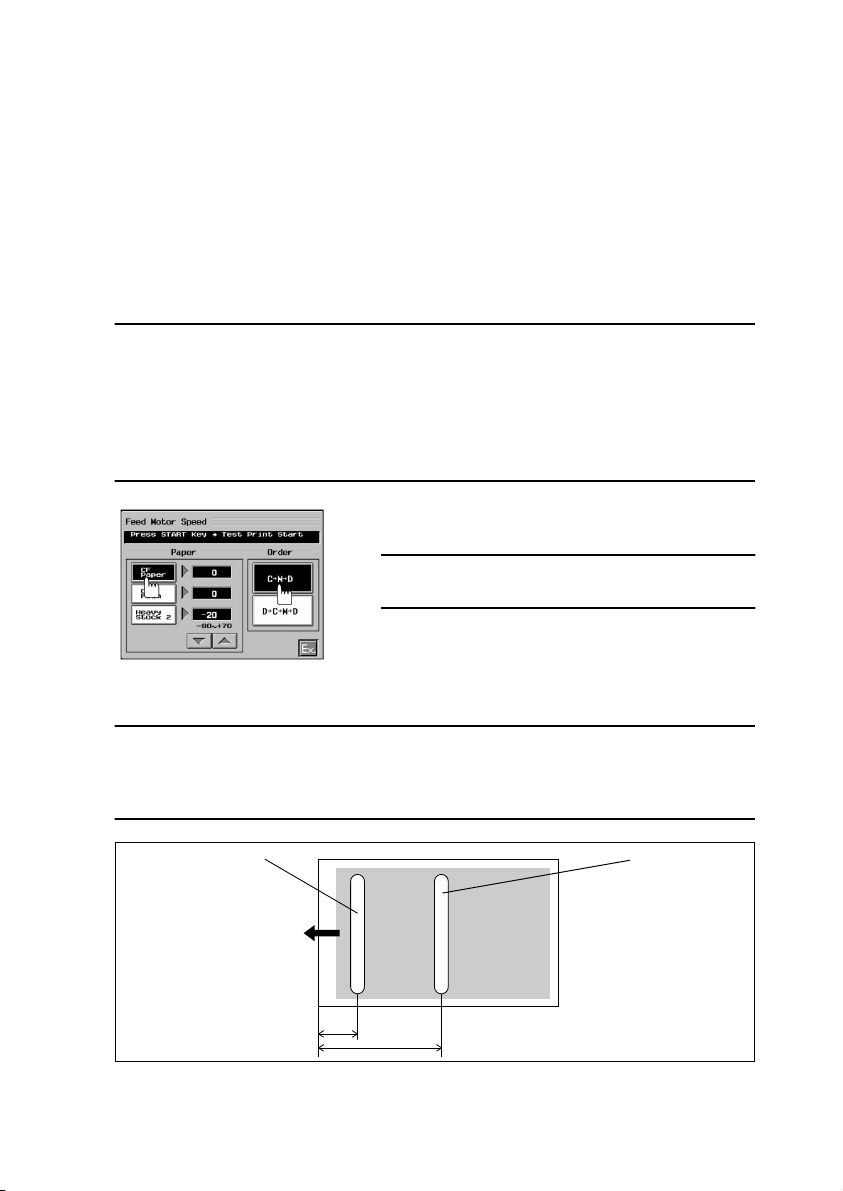

(7) Feed Motor Speed

<Normally>

The amount of color overlay deviation between C and M is uniform throughout the entire

print area.

<When faulty>

The amount of color overlay deviation between C and M varies from one point to another on

the image.

NOTE

A specific paper source and type of paper must be used as detailed below according to the

paper type selection made on the Touch Panel.

• CF Paper: Load the drawer with A3 or 11 × 17 paper.

• OHP Film: Place A4L or 8-1/2 × 11L OHP transparencies on the Multi Bypass Table.

2

• Heavy Stock 2: Place A3 or 11 × 17 paper weighing 129 to 209 g/m

on the Multi Bypass

Table.

1. Select “Feed Motor Speed” of “Machine Adjust

1.” Then, select “CF Paper” and “C → M → D.”

NOTE

Do not select “D → C → M → D.”

2. Press the Start key.

1179P454CA

3. Using a loupe, measure the amount of color overlay deviation of the test copy produced.

Specifications

m max.

100

µ

Tip:

Check especially at the leading edge and at the center.

Leading Edge

Center

Feeding

Direction

50

mm

200 mm

1179D073AB

D-120

Page 28

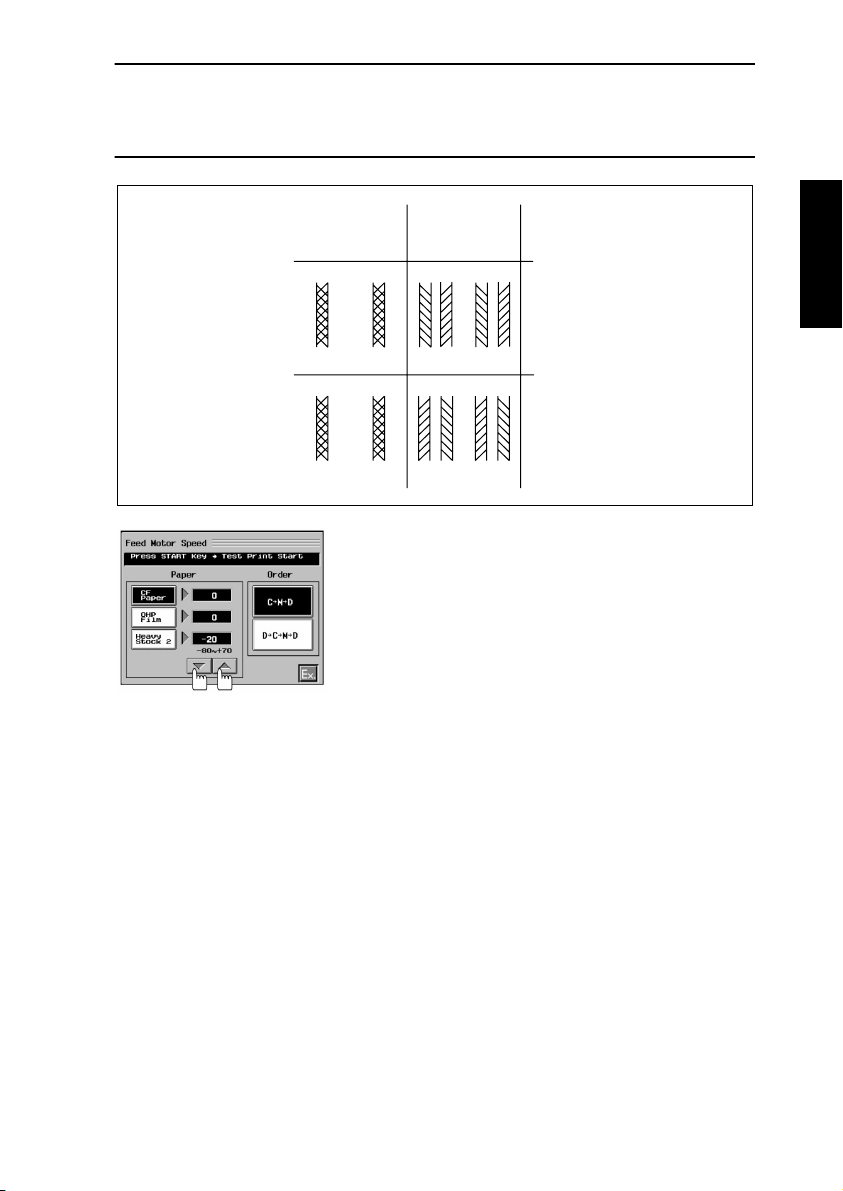

Criteria

Deviation at Center, but not at Leading Edge:

M (magenta) is relatively advanced → Feed Motor speed is faster.

M (magenta) is relatively retarded → Feed Motor speed is slower.

Out-of-Phase Example:

Leading

Edge

Center

C M C M

M C M C

1154D222AA

Criteria

→

Too slow

→

Too fast

4. If the specifications are not met, change the setting using the shift keys.

1179P455CA

5. Make a check again by making another test copy.

6. Using the same procedure, adjust for “OHP Film” and “Heavy Stock 2.”

7. After the adjustments have been made, touch “Ex.”

D-121

Page 29

(8) PRT Area

Top Margin

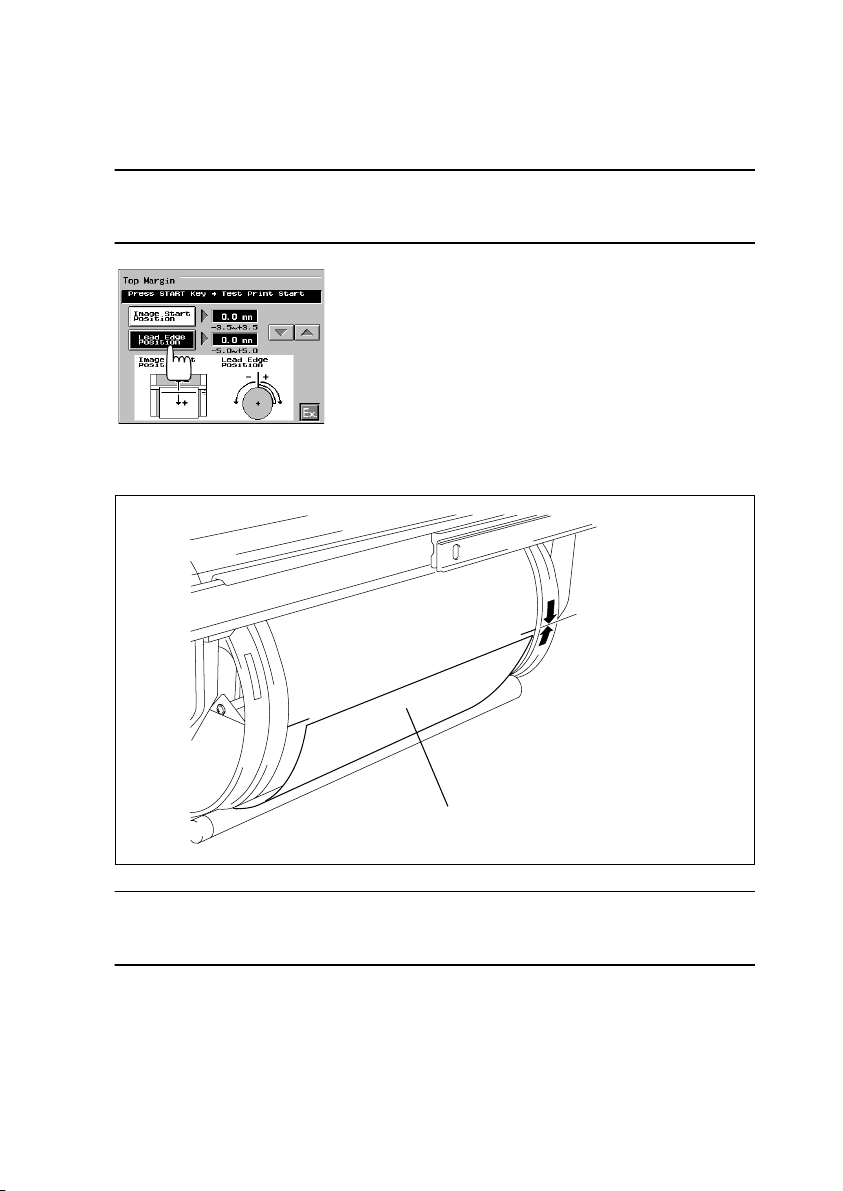

This function permits adjustments of the print start position (Image Start Position) on the

paper which is not affected by the image signal sent from the IR and the point at which the

paper is attracted onto the surface of the Transfer Drum (Lead Edge Position).

NOTES

• This adjustment should be made after Feed Motor Speed has been adjusted.

• Lead Edge Position must be adjusted before Image Start Position.

1. Load the drawer with A3 or 11 × 17 paper.

2. Select “PRT Area” of “Machine Adjust 1.”

3. Select “Top Margin” and then “Lead Edge Position.” Then, press the Start key.

4. After a misfeed message has appeared, open the

Front Door.

1154D090CA

5. Slide out the Transfer Drum and measure the distance between the leading edge of the

paper attracted to the drum and the white line on the Transfer Film.

Leading Edge Position

Standard:

0 ±0.5 mm

Paper

1154D199AB

Specifications

Distance between the leading edge of the paper attracted to the Transfer Drum and the

white line on the Transfer Film: 0 ±0.5 mm

D-122

Page 30

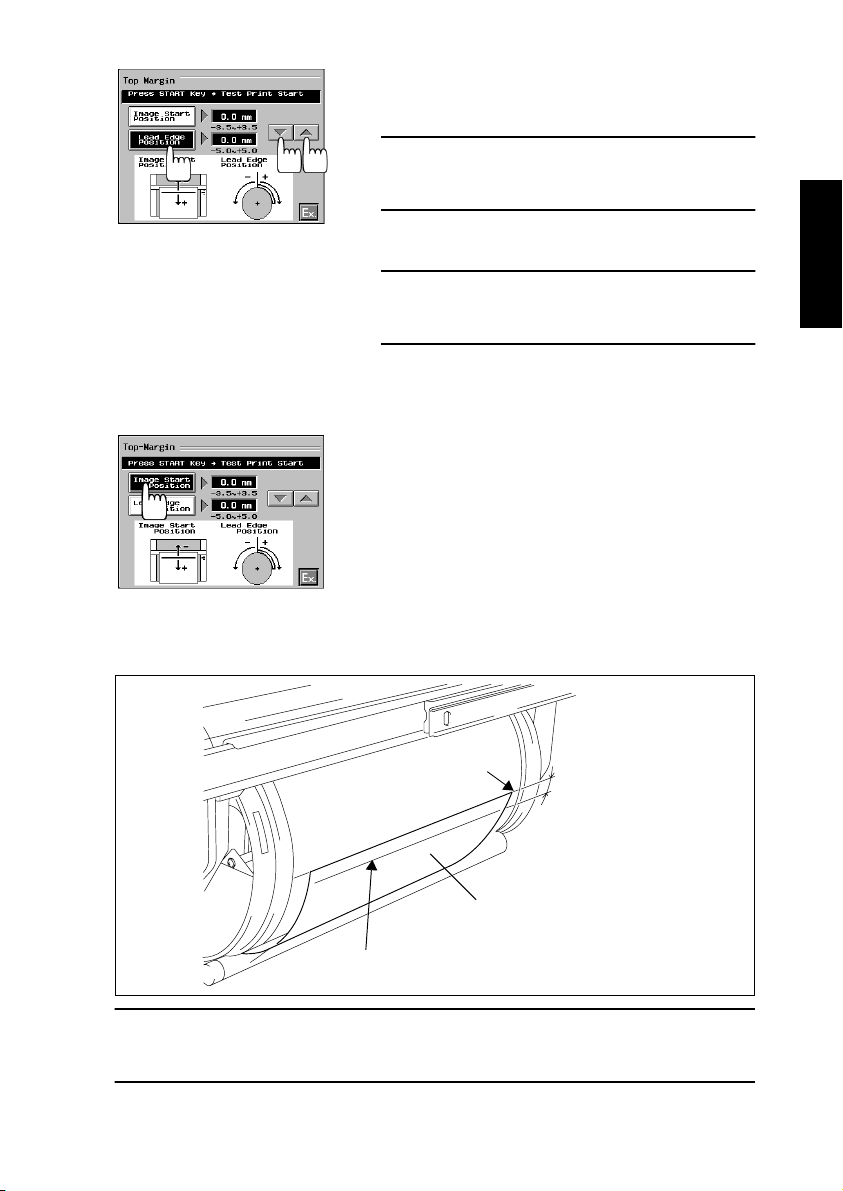

6. If the specifications are not met, slide the Transfer

Unit back into the copier and close the Front

Door.

NOTE

At this time, be sure to remove the paper, as the

copier does not perform predrive.

1154D091CA

7. Select “Lead Edge Position” and change the setting using the shift keys.

Adjustments

+0.5 mm <: Increase the setting.

-0.5 mm >: Decrease the setting.

8. After the adjustment has been made, check the

position of the leading edge of the paper

attracted to the Transfer Drum three times.

9. Select “Image Start Position” and press the Start

key.

10. After the misfeed message has appeared, open

the Front Door.

1154D110CA

11. Slide out the Transfer Drum and measure the distance between the leading edge of the

paper attracted to the drum and the white line on the Transfer Film.

White line

5 ±0.25 mm

Paper

Image Start Position Line

1179D077AA

Specifications

Distance between the image start position line on the paper and the white line on the Transfer Film: 5 ±0.25 mm

D-123

Page 31

12. If the specifications are not met, slide the Transfer

Unit back into the copier and close the Front

Door.

NOTE

At this time, be sure to remove the paper, as the

copier does not perform predrive.

1154D111CA

13. Select “Image Start Position” and change the setting using the shift keys.

Adjustments

5.25 mm <: Decrease the setting.

4.75 mm >: Increase the setting.

14. Check the image start position again.

15. After the adjustments have been made, touch

“Ex.”

Left Margin

This function is used after the PH has been replaced or when the reference positions of the

drawer and Multi Bypass Table deviate due to variations in size of paper.

1. Select “PRT Area” of “Machine Adjust 1.”

2. Select “Left Margin” and then “Upper.”

3. Press the Start key.

3 ±1.5mm

1154D093CA

4. Measure the width of the void image on the test

copy as shown on the left.

Specifications:

Void image width: 3 ±1.5 mm

1144D238AA

D-124

Page 32

5. If the measurement falls outside the specified

range, change the setting using the shift keys.

Adjustments

4.5 mm <: Decrease the setting.

1.5 mm >: Increase the setting.

1154D094CA

6. Make a test copy to check again.

7. Using these steps, adjust the remaining drawers

and the Multi Bypass Table (A4C or 8-1/2 × 11C).

8. After the adjustments have been made, touch

“Ex.”

Dup. Left Margin

This function is used after the PH has been replaced or when the reference position of the

Duplex Unit deviates due to variations in size of paper.

1. Select “PRT Area” of “Machine Adjust 1.”

2. Select “Dup. Left Margin” and then “Upper.”

3. Press the Start key.

1154D095CA

4. Measure the width of the void image on the test

copy as shown on the left.

Specifications:

Void image width: 3 ±1.5 mm

3 ±1.5mm

1144D238AA

5. If the measurement falls outside the specified

range, change the setting using the shift keys.

1179P456CA

Adjustments

4.5 mm <: Decrease the setting.

1.5 mm >: Increase the setting.

6. Make a test copy to check again.

7. Using these steps, adjust the remaining drawers.

8. After the adjustments have been made, touch

“Ex.”

D-125

Page 33

(9) A6 Card Passage (4 × 6 Paper Passage)

✽

Shown in ( ) are the display messages for the inch areas.

NOTE

This function is concerned with the adjustment procedure, in which the position of the spur

wheel (sprocket) is checked by examining test copies. The spur wheel (sprocket) position

is, however, rather hard to tell and it is recommended that “Adjustment of Sprocket Unit

Position” contained in “OTHER ADJUSTMENTS” be used.

1. Load thick paper B5L or 5-1/2 × 8-1/2L in the

Multi Bypass Table.

2. Select “A6 Card Passage” of “Machine Adjust 1."

3. Press the Start key to make a test copy.

1179P457CA

4. Determine the position of the spur wheel

Spur Wheel

Position

Feeding Direction

(sprocket) as measured from the edge of the

image on the test copy.

Specifications

A6 Card: 5.5 ±1 mm

4 × 6 Paper: 8 ±1 mm

1179D068AD

5. If the specifications are not met, adjust with the

adjusting screw.

Adjusting

Screw

(10) Paper Loop

1179D067AB

1179P458CA

Adjustments

A6 Card

6.5 mm <: Turn the adjusting screw counterclock-

wise.

4.5 mm >: Turn the adjusting screw clockwise.

4 × 6 Paper

9 mm <: Turn the adjusting screw counterclockwise.

7 mm >: Turn the adjusting screw clockwise.

6. After the adjustments have been made, touch

“Ex.”

1. Select “Paper Loop” of “Machine Adjust 1.”

2. Change the setting using the shift keys.

Setting range: -3 to +3

Initial setting: 0 (target loop length: 8.9 mm)

1 step: 1 (2.4 mm)

D-126

Page 34

(11) IR Area

NOTES

• This function is used to adjust the document scanning position. The check should be

made using a test copy, not a regular copy.

• After this adjustment has been made, be sure to make the IR Lamp adjustment.

• A malfunction of C0660 could result depending on the values set for “Top Image” and

“FD-Mag.”

Left Image and Top Image

1. Load the drawer with A3 paper.

2. Place scales on the Original Glass as shown on

the left and lower the Original Cover.

1144D239AA

3. Select “IR Area” of “Machine Adjust 2.”

4. Press the Start key to make a test copy.

1179P459CA

10 ±1

mm

5. Check the image on the test copy to see where

20

10

5

0~1mm

the graduations of the scales start.

Specifications

Left Image (left edge of the image): 0 ±1 mm

Top Image (leading edge of the image): 10 ±1 mm

1144D240AB

D-127

Page 35

6. If the specifications are not met, select “Left

Image” and change the setting using the shift

keys.

Adjustments

Edge of image +1 mm <: Increase the setting.

Edge of image -1 mm >: Decrease the setting.

1179P460CA

CD-Mag and FD-Mag

1179P459CA

Zoom Ratio

Error

200 190 180

200 190 180

1144D239AA

Scale on

Test Copy

1144D241AA

7. Using the same procedure, adjust “Top Image.”

8. Make a check again by making another test copy.

9. After the adjustments have been made, touch

“Ex.”

1. Load the drawer with A3 or 11 × 17 paper.

2. Place scales on the Original Glass as shown on

the left and lower the Original Cover.

3. Select “IR Area” of “Machine Adjust 2.”

4. Press the Start key to make a test copy.

5. Measure the scale on the test copy.

Specifications

CD zoom ratio: 200 ±1 mm

FD zoom ratio: 300 ±1.5 mm

6. If the specifications are not met, calculate the

zoom ratio error.

Calculation Formula:

Specifications / Measurement Taken on Copy =

Zoom Ratio Correction Factor

D-128

Page 36

7. Select “CD-Mag” and, using the shift keys, input

the correction factor calculated in step 6.

Example:

If the 200-mm position on the copy is 198 mm on the

actual scale, calculate the correction factor as follows:

200 mm

= 1.01

1179P461CA

(12) Orig. Detect Sensor

NOTE:

This adjustment must be made after following:

• Memory clear

• Original size has been incorrectly detected

• An Original Size Detection Sensor has been added or replaced.

198 mm

Using the shift keys, set × 1.01 for the correction factor.

8. Using the same procedure, adjust “FD-Mag.”

9. After the adjustments have been made, touch

“Ex.”

1. Place a blank sheet of A3 or 11 × 17 paper on the

Original Glass and lower the Original Cover.

2. Select “Orig. Detect Sensor” of “Machine Adjust

2.”

3. Press the Start key to run the Orig. Detect Sensor sequence.

1179P462CA

NOTE

During the adjustment sequence, the Start key stays

lit up orange. It turns to a green steady light as soon

as the adjustment is completed.

4. Check that the message “All .. OK” is shown.

Then, touch “Ex.”

D-129

Page 37

3-9. DEVELOPER CHANGE MODE

(1) Developer Change (Developer Discharge

tating)

NOTE

Although functions are available to perform Developer Discharge, Developer Filling, or

Developer Agitating individually, perform “Developer Change” that covers all these in a

given sequence.

1. Turn OFF the Power Switch.

2. Open the Front Door, remove the Toner Antispill Plate, and Toner Hopper Unit.

3. Remove the Developing Unit Cover and slide out the Developing Unit.

4. Install the Jumper Harness and four Mag. Roller Shields.

Jumper Harness

5. Turn ON the Power Switch.

6. Press the following keys in this order to set the

copier into the Developer Change mode: Stop →

0 → Stop → 2.

7. Install the Interlock Switch Actuating Jig.

8. Select “Developer Change.”

→→→→

Developer Filling

Mag. Roller Shield ×4

1179D061AA

→→→→

Developer Agi-

1154D097CA

D-130

Page 38

9. Assemble the Developer Collecting Bag. Using two clips, secure the bag to the Developing Unit (Fig. 1).

10. Remove the ATDC assy from the Developing Unit or Units to be discharged (Fig. 2).

11. Pull the bag up over the front end and clip it with two more clips (Fig. 3).

Fig. 1

Developer Collecting Bag

NOTE

Use care not to damage the lower edge of

the vinyl bag (Developer Collecting Bag)

1144D328AA

when putting the

inner box into it.

Fig. 2 Fig. 3

1154D205AA

Clip ×2

1154D204AA

Clip ×2

1144D323AA

1154D114CA

12. Touch “On” for the color or colors of developer to

be discharged (two or more colors may be

selected).

13. Press the Start key to discharge the developer.

(It takes about 5 min. to discharge all four colors

of developer.)

14. After these steps have been completed, touch

“Ex.” and select “Developer Filling.”

D-131

Page 39

15. Remove the supply port of the Developing Unit which is to be charged with developer

-

and then install the Developer Chute. (In the illustration, the Bk Developing Unit is

selected.)

1154D115CA

1179U017AA

1154D098CA

1144U053AA

1144U054YA

16. Select the color of developer and press the Start

key.

17. Pour in developer through the Developer Chute.

18. When all the developer has been poured in the

Developing Unit, press the Stop key.

Following the same procedure, pour developer of

other colors.

19. After the developer of all colors has been poured,

touch “Ex.”

20. Touch “On” for the color of the developer charged.

(Two or more colors may be selected.)

21. Press the Start key to agitate the developer

selected in step 20.

NOTE

If three or more colors have been selected, the agita

tion sequence takes place twice.

22. The Developing Unit stops automatically when

agitation is completed. Then, touch “Ex.”

23. Turn OFF, then ON, the Power Switch to return to

the initial screen.

D-132

Page 40

(2) After Dev. (C/M/Y/Bk) Has Been Changed

[ATDC Sensor Adjust (Auto) → AIDC Sensor Adjust (Auto) → AIDC Offset → Black ATDC

Adjust]

NOTES

• Although functions are available to perform ATDC Sensor Adjust (Auto), AIDC Sensor

Adjust (Auto), AIDC Offset, or Black ATDC Adjust individually, perform “After Dev. (C/M/Y/

Bk) has been changed” that covers all these in a given sequence.

• If the PC Drum has been replaced at the same time that the developer has been

changed, running this function will complete all the necessary adjustments and there is

no need of running “After PC Drum has been changed.”

1. Open the Front Door.

2. Press the Stop key, 0, Stop key, and 2, in that

order, to set the copier into the Developer

Change mode.

3. Close the Front Door.

4. Select “After Dev. (C/M/Y/Bk) has been changed”

and set the copier into the ATDC Sensor Adjust

1154D099CA

(Auto) mode.

5. Touch “On” for the color to be adjusted and press

the Start key.

1154D100CA

1179P463CA

1154D101CA

6. After the adjustment has been made, the results

are displayed on the Touch Panel. If the results

are acceptable, select “On” to enter the reference

value.

7. After ATDC Sensor Adjust (Auto) has been completed, touch “Ex.” to set the copier into the AIDC

Sensor Adjust (Auto) mode.

8. With the AIDC Sensor Adjust (Auto) screen on

the Touch Panel, press the Start key. This lets

the copier start an automatic adjustment

sequence.

D-133

Page 41

1154D102CA

”

9. After AIDC Sensor Adjust (Auto) has been completed, the results are displayed. If they are okay,

touch “Ex.” to set the copier into the AIDC Offset

mode.

10. With the AIDC Offset screen on the Touch Panel,

press the Start key to let the copier start an automatic adjustment sequence.

11. After the adjustment sequence has been completed, the results are displayed on the Touch

Panel. Make sure that the value shown for each

color falls within the specified range.

1154D102CA

Specifications Range

Cyan, Magenta, Yellow: 60 to 304

Black: 0 to 28

12. If the value is outside the range, return to the Service Mode Menu, select “Test Print”

and “Solid Pattern,” and press the Start key to produce a test print.

13. Check to see if the solid pattern on the test print produced is faulty (particularly if the

image density is too low). If the solid pattern looks good, replace the AIDC Sensor and

make the check again.

14. After AIDC Offset has been completed, touch

“Ex.” to set the copier into the Black ATDC Adjust

mode.

15. With the Black ATDC Adjust screen on the Touch

Panel, press the Start key to let the copier start

the automatic adjustment sequence.

16. After the sequence has been completed, touch

1154D103CA

“Ex.” to return to the Developer Change Mode.

17. Turn OFF, then ON, the Power Switch to return to

the initial screen.

18. Check the Bk Developing Unit for adjustment for

unit-to-unit variations.

Unit-to-Unit Variations Check Procedure

1. Select “State Confirm” from the Service mode

menu.

2. Select “Bk. Toner Sup. Status” and check that the

values for “Dev. Constant” are one other than “0.

1179P464CA

3. After the check, touch “Ex.”

D-134

Page 42

(3) Gradation Adjust

-

Gradation Adjust is to be performed three times to improve correction accuracy after the

copier has been set up and each time a service job has been performed.

1. Press the Utility key and then open the Meter Count screen.

2. Press the following keys in this order to set the copier into the Service mode: Stop → 0

→

0 → Stop → 0 → 1.

3. Select “Gradation Adjust” from the Service Mode Menu.

1144U074AA

1179P465CA

1179P465CA

1179P466CA

4. Press the Start key.

5. Place the test copy fed out of the copier on the

Original Glass.

NOTE

Examine the display on the Touch Panel for the direc

tion in which the copy is to be placed on the glass.

6. Place ten blank sheets of A3 or 11 × 17 paper on

that test copy and lower the Original Cover.

7. Press the Start key again.

✽

The copier scans the original, but does not feed

out a test copy.

8. When the Service Mode Menu reappears on the

Touch Panel, select “Gradation Adjust” again.

9. Press the Start key.

✽

The copier feeds out a test copy at this time.

10. Perform steps 5 through 9 a total of three times.

D-135

Page 43

11. After the copier has completed scanning the original a third time, select “Gradation Adjust” again

and check the values for “Conv. Value.”

Specified Ranges (cyan, magenta, yellow, and

black)

Max.: 0 ±100

1179P466CA

13. If the values fall outside the range, perform “Gradation Adjust” a fourth time and make a

check again.

14. If the values fall within the specified range this time, touch “Ex.”

15. If the values still fall outside the range, make an image sample from the Test Chart and:

• If the sample is not faulty, end the procedure.

• If the sample is faulty, take necessary steps by referring to “IMAGE QUALITY PROB-

LEMS” of TROUBLESHOOTING.

Highlight: 0 ±60

These ranges should be regarded only for reference,

as they are subject to fluctuations with varying environmental conditions.

12. If the values fall within the specified range, touch

“Ex.”

D-136

Page 44

3-10. OTHER ADJUSTMENTS

(1) Adjustment of the AIDC Sensor Position

2. Cover

1. Tape

NOTE

After the sensor has been

adjusted for its correct position,

secure the harness with tape to

prevent it from lifting off.

Fig. 1 Adjusting Procedure

AIDC Sensor

Fig. 1

Developing Unit

1179D062AA

AIDC Sensor Positioning Jig

Adjusting screws

1. Loosen the AIDC Sensor adjusting screws.

2. Install the AIDC Sensor Positioning Jig.

3. Press the AIDC Sensor tightly up against the jig

and, at the same time, tighten the adjusting screws.

D-137

AIDC Sensor

1179D063AA

Page 45

(2) Focus-Positioning of the Scanner and 2nd/3rd Mirrors Carriage

Scanner/Mirrors Carriage

Positioning Jigs

2nd/3rd Mirrors Carriage

Adjusting Procedure

Scanner positioning screw ×2

Scanner

Cable fixing screw

Scanner/Mirrors Carriage Positioning Jigs

Adjusting

screw

1179D219AC

Scanner

2nd/3rd Mirrors Carriage

1144D220AA

1. Loosen the Scanner positioning screws.

2. Install the Scanner/Mirrors Carriage Positioning Jigs.

3. Press the Scanner and 2nd/3rd Mirrors Carriage up against the jigs as shown

above.

4. If there is a clearance between the jigs and 2nd/3rd Mirrors Carriage, loosen the

cable fixing screw on the front frame and turn the adjusting screw in the adjustable

anchor to eliminate the clearance.

5. Tighten the Scanner positioning screws.

D-138

Page 46

(3) Adjustment of the Gap between the Doctor Blade and Sleeve Roller (Db Adjust-

ment)

Toner Scattering

Prevention Plate

Fig. 1 Adjusting Procedure

Doctor Blade

Doctor Blade

Fig. 1

Developer Supply Roller

1144D222AA

Front

Adjusting screw

Db Adjusting Jig ×2

Rear

Developer Supply Roller

1. Remove the Toner Scattering Prevention Plate.

2. Remove the Doctor Blade.

3. Clean the Developer Supply Roller.

4. Refit the Doctor Blade and temporarily secure it.

5. Fit the Db Adjusting Jigs and, with the Doctor Blade pushed down, tighten the adjusting screw.

NOTE

Make sure that there are no foreign objects wedged between the Db Adjusting Jigs and

Developer Supply Roller.

1144D221AA

D-139

Page 47

(4) Adjustment of the Amount of Transfer Drum Retraction

Retracting Cam

Paper Take-Up Board/

Engine Power Supply

Board

Retracting

Lever

Fig. 1

Paper Take-Up

Motor

Fig. 1 Adjusting Procedure

Retracting Lever

Transfer Adjusting Jig

1154D263AD

Adjusting

screw

Retracting Cam

1154D264AA

1. Remove the Paper Take-Up Board/Engine Power Supply Board.

2. Manually turn the Paper Take-Up Motor in the direction of the arrow until the retracting

cam stops.

3. Insert the Transfer Adjusting Jig into the space between the retracting cam and

retracting lever. Press the retracting lever against the retracting cam and, at the same

time, tighten the adjusting screw.

D-140

Page 48

(5) Adjustment of the Paper Separator Finger Roll Position

Roll (front)

Fig. 1

Adjusting screws

Fig. 1 Adjusting Procedure

Position at which to secure the roll

Loosen the adjusting screws of the roll (front) and, after positioning the roll as shown

below, tighten the screws.

0 ±0.5 mm

Adjusting

screws

1154D273AB

1179D064AA

Roll (front)

D-141

Page 49

(6) Adjustment of Clearance between the Transfer Drum Joint and Paper Separator

Guide

Adjusting screw

Guide roll

Direction of Transfer Drum rotation

Transfer Adjusting Jig

measurement point

Guide

Flat surface in joint

1179D065AA

Paper Separator Finger Solenoid

Adjusting Procedure

1. Turn the Transfer Drum so that the center (flat surface) of the joint is located under

the guide.

2. Loosen the adjusting screw and move the guide roll as far as it will go in the direction toward the Transfer Drum (in which case there is the widest clearance between

the Transfer Film and guide). With the guide roll at this position, tighten the adjusting screw.

3. Push the Paper Separator Finger Solenoid in the direction of the arrow and, using

the Transfer Adjusting Jig, check the clearance at the measurement point shown

above. Details:

Go No-go

1144D329AA

Transfer Adjusting Jig

Clearance between Joint and Guide Tip

Measurement point

Guide

Transfer Film

Joint

0.5 ±0.3 mm

1179D066AB

4. If the jig goes, loosen the adjusting screw and move the guide roll in the direction

away from the Transfer Film (which results in a narrower clearance). Then, check

the clearance using the same procedure as in step 3.

D-142

Page 50

(7) Adjustment of the Amount of Projection of Backup Blade 2 and 1

Adjusting screw

(Backup Blade 1)

Adjusting screw

(Backup Blade 1)

Scale

Adjusting screw

(Backup Blade 2)

Adjusting screw

1144D264YA

(Backup Blade 2)

Adjusting Procedure

1. Remove the Transfer Film kit.

2. Loosen the adjusting screws.

3. Hold the scale at a right angle to the end face of the mounting bracket. Move the

blade bracket to obtain the specified length between the end face of the mounting

bracket and the blade tip, then tighten the adjusting screws.

Backup Blade 2 Projection Standard

Mounting

bracket

Blade

bracket

19.5 ±0.3 mm

Adjusting

screw

Film

1144D266AA

Backup Blade 1 Projection Standard

Mounting

bracket

Blade

bracket

Adjusting

screw

D-143

22.5 ±0.3 mm

Film

1144D265AA

Page 51

(8) Adjustment of Sprocket Unit Position

Fig 1

1154D284AA

Fig. 1 Adjusting Procedure Press the scale against the position shown and adjust the

Adjusting screw

Adjustment Instructions:

If the clearance between the sprocket unit and copier frame is wider than the specifications, turn the adjusting screw counterclockwise.

If the clearance is narrower, turn the adjusting screw clockwise.

clearance between the sprocket unit and the copier frame

using the adjusting screw.

27.0 ~ 27.5 mm

1154D279AA

D-144

Page 52

4. MISCELLANEOUS

4-1. INSTALLATION OF THE PLUG-IN COUNTER MOUNTING

BRACKET (OPTION)

1144D267YB

1. Remove the covers.

1154D242AA

2. Unplug the short-circuit

connector.

1154D243AB

3. Plug in the connector of the

Plug-In Counter mounting

bracket.

4. Install the Plug-In Counter

mounting bracket using one

screw, and one screw and nut.

D-145

Page 53

4-2. INSTALLATION OF THE ORIGINAL SIZE DETECTING SEN-

SORS (OPTION)

NOTE

When the optional Original Size Detecting Sensors have been added, set “Set” for “Option

Sensor” of “Orig. Detect Sensor” available from “Setting 2” of the Service Mode Menu and

run “Orig. Detect Sensor” of “Machine Adjust 2.”

1. Remove the Original Glass.

2. Mount the Original Size Detecting Sensors.

SE3

SE6

SE5

Sensor Mounting Position

SE3 E

SE5 G

SE6 H

1179D076AB

D-146

Page 54

4-3. RAM PACK REPLACEMENT PROCEDURE

Step before Replacement

Select “List Output” from the Service Mode Menu and produce the following lists: “Image

Processing” and “Counter.”

NOTE

Check the settings of the following functions and make a note of them before replacement,

as no lists will be produced for them.

Setting 1: CH Cleaning, A6 Card Margin (4 × 6 Paper Margin)

Setting 2: Paper Kind, Admin. Mode, RD Mode, Orig. Detect Sensor

Machine Adjust 1: Fuser Temp.

In addition, the settings in the User’s Choice of Utility are not printed. Check and make a

note of these settings, too, as may be necessary.

Steps after Replacement

1. Clean the optical parts (PH Assy, Original Glass, lens, mirrors, Lamp).

2. Add fuser oil up to the required level.

3. Replace the Toner Collecting Box with an empty one, or dump toner from the Toner Collecting Box.

4. Remove the Rear Cover to prevent predrive from being initiated.

NOTE

Since the new Backup Memory RAM has no old developer data, the copier may detect a

malfunction as it relates to the Developing Unit if predrive is initiated.

5. Using Touch Panel Correct, correct the position of the keys on the Touch Panel.

6. On the list of “Life 3 (Others)” available from “Counter” of the Service Mode Menu,

select “Toner Collect” and press the Clear key.

7. Since the Touch Panel language is English, select “Language” of “User’s Choice” available from Utility and change the setting as necessary.

8. Select “Marketing Area” of “Setting 2” available from Service Mode Menu and select the

same marketing area as that before the replacement.

D-147

Page 55

9. Carry out the following tasks in the Developer Change Mode in the order given below.

Task Procedure Function Order

Developer Discharge 1

Developer Filling 2

Developer Agitating 3

Developer

AIDC Sensor

AIDC

AIDC Offset Automatic adjustment 5

ATDC Sensor

: Adjustment : Check

10. Select “Bk Toner Sup. Status” of “State Confirm” available from Service Mode Menu

and check that “Dev. Constant” is not “0.”

11. Enter the data on the list produced before the replacement and that recorded in

advance for the following Service Mode items.

NOTE

It is not possible to reenter the counter values. It is therefore necessary that the copier be

maintained according to the Counter list produced before the replacement.

Setting 1 Setting 2 Machine Adjust 1 Machine Adjust 2

CH Cleaning Paper Size Fuser Speed Left Image

OHP Speed Paper Kind Fuser Temp. Top Image

Transfer Table Admin. Mode Transfer Output CD-Mag

PC Action RD Mode Feed Motor Speed FD-Mag

Fuser Action Orig. Detect Sensor Top Margin ADF Check

PC PAT Serial # Input Left Margin

A6 Card Margin

(4 × 6 Paper Margin)

Check that the value falls within 4.0 ±0.3 V

as a result of an automatic adjustment performed.

Check that the value falls within 5.0

C,M,Y

±0.2% as a result of an automatic

adjustment performed.

Bk Automatic adjustment 7

Fuser Oil Choice Dup. Left Margin

Fuser Oil Supply Transfer Timing

Paper Loop

4

6

D-148

Page 56

12. Carry out the following tasks in the Service Mode Menu in the order given below.

Task Procedure Function Order

PRT Max Density

PRT Highlight

Background Voltage

ATDC Level Setting

Image Adjust

VB Shift

AE Adjust

Setting 1

Manual Paper Width Automatic adjustment 7

Machine Adjust 1

Jam Sensor Automatic adjustment 8

Machine Adjust 2

Orig. Detect Sensor Automatic adjustment 9

Date/Time Input

: Adjustment : Check

13. Reinstall the Rear Cover.

14. Select “Gradation Adjust” from the Service Mode Menu and run Gradation Adjust.

15. Turn OFF, then ON, the Power Switch to return to the Basic screen.

Check that “0” has been set. Set to “0” if

set otherwise.

Check that “0” has been set. Set to “0” if

set otherwise.

Check that “0” has been set. Set to “0” if

set otherwise.

Check that “5%” has been set. Set to “5%”

if set otherwise.

Check that “0” has been set. Set to “0” if

set otherwise.

Check that “2” has been set. Set to “2” if

set otherwise.

Check that the current time-of-day and

date are set. Set them if otherwise set.

1

2

3

4

5

6

10

D-149

Page 57

4-4. FLASH MEMORY

Software has conventionally been upgraded by replacing ROM on each board. This copier

employs flash memory for the system control IC mounted on the IR Control Board (on the

IR side) and Master Board (on the engine side). Its contents are reprogrammed easily by

performing the following steps using the IC card (memory card), in which data has been

previously downloaded.

NOTE

NEVER remove or insert the memory card with the copier power turned ON.

(1) Using a Single Memory Card

Memory Card Cover

IR Control Board

Master Board

Hopper Unit

1154D274AB

1179D069AA

1. With the Power Switch in the OFF position,

unplug the power cord from the power outlet.

2. Remove the Hopper Unit.

3. Remove two screws and the memory card cover.

4. Mount the memory card in the IR Control Board

(upper one) or Master Board (lower one).

5. Plug the power cord into the power outlet.

6. Turn ON the Power Switch.

✽

This lets the copier start rewriting the data.

✽

The Touch Panel shows “Downloading.”

7. On the Touch Panel, check that the data has been

properly rewritten (in which case the message

“Downloading Completed” appears) and check

the checksum (“Check Sum: OOOO” on the

panel).

✽

The illustration represents the Touch Panel display

when the Master Board has been rewritten.

1179D532AA

D-150

Page 58

8. Unplug the power cord from the power outlet.

NOTE

Do not turn OFF the Power Switch at this time.

9. Remove the memory card and turn OFF the Power Switch.

10. Using the same procedure, rewrite the data on the other board.

11. Check that “ROM Version” of “State Confirm” available from the Service Mode Menu

shows the version indicated on the memory card.

(2) Using Two Memory Cards

Memory Card Cover

IR Control Board

Master Board

Hopper Unit

1154D274AB

1179D039AA

1. With the Power Switch in the OFF position, unplug

the power cord from the power outlet.

2. Remove the Hopper Unit.

3. Remove two screws and the memory card cover.

4. Mount the memory cards in the IR Control Board

(upper one) and the Master Board (lower one).

5. Plug the power cord into the power outlet.

6. Turn ON the Power Switch.

✽

This lets the copier start rewriting the data.

✽

The Touch Panel shows “Downloading.”

7. On the Touch Panel, check that the data has been

properly rewritten (in which case the message

“Downloading Completed” appears) and check the

checksum (“Check Sum: OOOO” on the panel).

1179D522AA

D-151

Page 59

8. Unplug the power cord from the power outlet.

NOTE

Do not turn OFF the Power Switch at this time.

9. Remove the memory cards and turn OFF the Power Switch.

10. Check that “ROM Version” of “State Confirm” available from the Service Mode Menu

shows the version indicated on the memory card.

(3) Writing upon Replacement of IR Control Board/Master Board

• If the IR Control Board or the Master Board is replaced individually, load the memory

card in the board that has been replaced for data writing.

• If both the IR Control Board and the Master Board are replaced at the same time and if a

single memory card is to be used, start writing the data with the Master Board side.

The copier does not rewrite data if an attempt is made to write data first for the IR Control

Board.

(4) Action to be Taken When Data Transfer Fails

When the message “Engine: N.G” or “IR: N.G” appears on the Touch Panel, it indicates that

data has not been properly rewritten. In this case, perform the following steps.

If two memory cards have been used, only the specific board with which data transfer failed

is displayed.

1. Perform the data rewriting procedures again according to the above steps.

2. If the sequence is not normally terminated, change the memory card for a new one and

try another rewriting sequence.

3. If the sequence still fails, replace the Master Board or IR Control Board and then try

another rewriting sequence.

If the message “Engine: N.G” appears, replace the Master Board.

If the message “IR: N.G” appears, replace the IR Control Board.

D-152

Page 60

SWITCHES ON PWBs,

TECH. REP. SETTINGS

17196

Page 61

Blank page

Page 62

CONTENTS

1. CONTROL PANEL KEYS AND TOUCH PANEL .............................................S-1

1-1. Control Panel Keys .................................................................................. S-1

1-2. Explanation of the Touch Panel ...............................................................S-3

(1) Basis Screen ................................................................................... S-3

(2) Warning Screens .............................................................................S-4

2. FUNCTION OF SWITCHES AND OTHER PARTS ON PWBs ........................S-6

2-1. PWB Location ..........................................................................................S-6

2-2. PWB-S (Tech. Rep. Setting Switches Board) ..........................................S-6

(1) Clearing Procedures ........................................................................S-7

(2) Data/Conditions Cleared by Reset Switches/Pins ........................... S-7

3. UTILITY MODE ................................................................................................S-8

3-1. Utility Mode Selection Screen ..................................................................S-8

3-2. Utility Mode Function Tree .......................................................................S-8

3-3. Settings in the Utility Mode ......................................................................S-9

(1) Admin. Mode ...................................................................................S-10

(2) User’s choice mode .........................................................................S-12

4. SERVICE MODE .............................................................................................S-14

4-1. Service Mode Menu Screen ....................................................................S-14

4-2. Service Mode Function Setting Procedure ..............................................S-14

4-3. Service Mode Menu Function Tree ..........................................................S-15

4-4. Setting in the Service Mode .....................................................................S-17

(1) Setting .............................................................................................S-17

(2) Machine Adjust ................................................................................S-22

(3) Image Adjust .................................................................................... S-24

(4) State Confirm ...................................................................................S-25

(5) Counter ............................................................................................S-28

(6) List Output .......................................................................................S-32

(7) Test Print .........................................................................................S-33

(8) Gradation Adjust .............................................................................. S-33

5. SECURITY MODE ...........................................................................................S-34

5-1. Security Mode Menu Screen ...................................................................S-34

5-2. Security Mode Setting Procedure ............................................................S-34

5-3. Settings in the Security Mode ..................................................................S-35

6. DEVELOPER CHANGE MODE .......................................................................S-37

6-1. Developing Change Mode Menu Screen .................................................S-37

6-2. Developing Change Mode Setting Procedure .........................................S-37

6-3. Developer Change Mode Function Tree ..................................................S-38

6-4. Setting in the Developer Change Mode ...................................................S-39

7. TOUCH PANEL CORRECTION MODE ..........................................................S-41

7-1. Touch Panel Correction Mode Screen .....................................................S-41

7-2. Touch Panel Correction Mode Setting Procedures .................................S-41

8. DATE/TIME INPUT MODE .............................................................................. S-42

8-1. Date/Time Input mode Screen .................................................................S-42

8-2. Date/Time Input Mode Setting Procedure ...............................................S-42

i

Page 63

Blank page

Page 64

1. CONTROL PANEL KEYS AND TOUCH PANEL

1-1. Control Panel Keys

123 4

14

5

13

6

7

8

12

9

10

11

1179O007CC

S-1

Page 65

1. Access Mode Key

• Press to enter the access number when

Copy Track of the Administrator mode

available. Press the access Key.

2. Energy Saver Key

• Press to set machine into the Energy

saver mode.

3. Interrupt Key

• Press to select the Interrupt mode.

4. Panel Reset Key

• Press to set the machine into the initial

mode, clearing all settings made on the

control panel.

5. Clear Key

• Clear the various numeric values.

6. Stop Key

• Stop a scanning cycle.

7. Start Key

• Start a print cycle.

8. Auto Color/Full Color/Black Keys

• Auto Color Key: Press to make copies

according to the type of the original being

used.

• Full Color Key: Press to make full color

copies.

• Black Key: Press to make black-andwhite copies.

9. Touch Panel

• Shows various screens and message.

10. Job Recall Key

• Press to display the Job Recall screen.

11. Utility Key

• Press to show the Utility Mode menu.

12. Display Contrast Control Knob

• Use to adjust the brightness of the Touch

Panel.

13. 10-Key Pad

• The number of copies to be made.

• The various numeric values.

14. Copy Key/Scan Key

• Press to select the Scanner mode and

the Copy mode.

✽

The Scan mode is enabled when a printer

controller is mounted on the copier.

S-2

Page 66

1-2. Explanation of the Touch Panel

(1) Basis Screen

The Basic screen is the initial screen that appears when the copier is turned ON.

1

2

3

4

1. Supplementary Function Keys

• Digital Art, Color Adjust, Input Output, and Basics keys are displayed.

2. Message Display

• Shows the current machine status, operating instructions and precautions, and other

data including the number of copies selected.

3. Basic Display

• Shows the basic function keys and the corresponding functions currently selected for

use.

4. Set Function Display

• Shows graphic representations of function set other than the initial ones, including the

Input Output and Digital Art types.

1179P165CA

S-3

Page 67

(2) Warning Screens

The Warning screen may be a malfunction display, error display, warning display, or a caution display.

Given when a malfunction occurs.

<Malfunction Display>

E.g.: Malfunctions that can be identified

with a specific code.

1179P435CA 1179P421CA

Given when an error occurs.

E.g.: Paper misfeed, door open, etc.

<Error Display>

<Warning Display>

Given when only a defective copy will be

produced because of erroneous or illegal

panel settings.

E.g.: Unmatched paper size in Auto Paper.

<Caution Display>

Given when, though further copier operation will be possible, it could eventually

result in a malfunction.

E.g.: Toner near empty, etc.

1179P391CA4004P035CA

S-4

Page 68

<Image Stabilization Fault>

When an image stabilization fault occurs, a mark appears at the lower left corner of

the screen. Touch this mark, and the display shows the details of the fault.

NOTE

• For details, see TROUBLE SHOOTING.

1179P393CA 1179P394CA

S-5

Page 69

2. FUNCTION OF SWITCHES AND OTHER PARTS ON

PWBs

2-1. PWB Location

PWB-S2

1154S011AA

2-2. PWB-S (Tech. Rep. Setting Switches Board)

1179S001AA

Symbol Name Description

S25 Trouble Reset Switch Resets the malfunction display.

S26 Disabled

PJ2 Initialize Switch Resets a misfeed, malfunction, and erratic display.

Clears all data.

TP1 Memory Clear Test Point

TP3 COM Test Point Ground used for memory clear.

NOTE

• It does not, however, clear data of Electronic

counters, Administrator and RD mode functions.

S-6

Page 70

(1) Clearing Procedures

Initialize

1. Turn ON the Power Switch.

2. With the circuit across pins of PJ2 closed, turn OFF then ON the Power Switch.

3. Open the circuit in about 5 seconds.

4. Check that the message “Initialize Completed” is displayed on the Touch Panel and then

touch the “Enter” key.

Memory Clear

1. Turn ON the Power Switch.

2. With the circuit across TP1 and TP3 closed, turn OFF then ON the Power Switch.

3. Open the circuit in about 5 seconds.

4. Check that the message “Memory Clear Completed” is displayed on the Touch Panel

and then touch the “Enter” key.

NOTES

• If the copier exhibits an erratic display or operation, reset and clear in the following order:

Initialize

• If Memory Clear has been performed, make settings of various functions once again.

(2) Data/Conditions Cleared by Reset Switches/Pins

→

Memory Clear.

Clearing Method

Data Cleared

Misfeed display

Malfunction

display

Erratic operation/display –

Job/Image –––

User’s Choice –––

Tech. Rep. Mode –––

Security Mode –––

❍

: Cleared –: Not cleared

Fusing/

Optical

Others

Front Door

Open/Close

❍

–

❍❍❍

Trouble Reset

Switch

S25

–

❍❍

❍❍❍

Initialize

PJ2

❍

Memory

Clear

TP1

–

–

–

❍

❍

❍

❍

S-7

Page 71

3. UTILITY MODE

• Utility Mode is used to make various settings according to the user’s need.

3-1. Utility Mode Selection Screen

• Press the Utility key on the control panel.

3-2. Utility Mode Function Tree

Default Setings

1179P437CA

Meter Count

Admin. Mode

Utility

✽

✽

✽

✽

1: Displayed when “Mode 1 or 2” is selected for “Peripheral Mode” available from the

Job Memory Input

User’s Choice

Image Centering

Scanner Addr. Input

1

2

Data Send

3

Fuser Oil Refill

Copy Track Functions.

Gradation Adjust

Thick 2 Duplex

Dummy Rotation

Gammacurve limitation

Language

Energy Saver

Auto Reset

Confirmation Beep

Key Counter

Intelligent Sort

Custom 2in1

ACS Judgement Level

Adjust

Service mode.

✽

2: Displayed when a Data Terminal is connected to the copier.

✽

3: Displayed when “User Set” is selected for “Fuser Oil Supply” available from the

Service mode and, at the same time, when the fuser oil is a near-empty condition.

S-8

Page 72

3-3. Settings in the Utility Mode

Touch Panel

Display

Default Settings Select the copying function settings established when the Power

Switch is turned ON or the Panel Reset key is pressed.

NOTE

• To designate the “Current Settings,” make the necessary settings

before using this function and then designate them using this function.

Current Settings