Page 1

DF-216

SERVICE HANDBOOK

KONICA CORPORATION

TECHNOLOGY SUPPORT CENTER

TOKYO JAPAN

Page 2

DF-216

SERVICE MANUAL

11563

Page 3

CONTENTS

GENERAL, MECHANICAL/ELECTRICAL

1. SPECIFICATIONS ........................................................................................... M-1

2. COMPONENTS IDENTIFICATION .................................................................M-2

3. CROSS-SECTIONAL VIEW ............................................................................M-2

4. DRIVE SYSTEM ..............................................................................................M-3

5. ELECTRICAL COMPONENT LAYOUT ...........................................................M-4

6. DESCRIPTION OF MODES ............................................ .............. ..................M-4

7. DOCUMENT TAKE-UP/FEEDING MECHANISM ............................................M-5

7-1. Document Take-Up Mechanism ..............................................................M-5

7-2. Document Separating Mechanism ...........................................................M-6

8. DOCUMENT TRANSPORT/EXIT MECHANISM .............................................M-7

8-1. Document Transport Mechanism .............................................................M-7

8-2. Document Exit Mechanism ......................................................................M-7

8-3. Raised/Lowered Position Detection Mechanism .....................................M-8

9. WIRING DIAGRAM ..........................................................................................M-9

TECH. REP. MODE

1. OUTLINE OF USER’S CHOICE MODE ..........................................................S-1

1-1. User’s Choice Function Setting Procedure ..............................................S-1

1-2. Functions Available from the User’s Choice Mode ..................................S-1

2. OUTLINE OF THE TECH. REP. MODE ..........................................................S-2

2-1. Tech. Rep. Mode Setting Procedure .......................................................S-2

(1) Function “F” .....................................................................................S-2

(2) Adjust “A” ................................................ ............... ..........................S-3

DIS/REASSEMBLY, ADJUSTMENT

1. MAINTENANCE SCHEDULE ..........................................................................D-1

2. DISASSEMBLY ...............................................................................................D-2

2-1. Removal of the Document Cover .............................................................D-2

2-2. Removal of the ADF Cover ......................................................................D-2

2-3. Removal of the ADF Assembly ................................................................D-3

2-4. Removal of the Sprit Roller Assembly .....................................................D-4

3. ADJUSTMENT .................................................................................................D-5

3-1. Print of Test Patte rn .................................... ......................... ....................D-5

(1) Entering the Tech. Rep. Mode .........................................................D-5

(2) Entering the Adjust Mode ................................................................D-5

(3) Producing a Test Pattern .................................................................D-5

3-2. Adjustment of the Skewed Feed ..............................................................D-6

(1) Check of the Skewed Feed .............................................................D-6

(2) Adjustment of the Skewed Feed ......................................................D-6

3-3. Adjustment of the Zo o m ............... ..................................................... .......D-7

(1) Check of the Zoom ..........................................................................D-7

(2) Adjustment of the Zoom ............... ............... ....................................D-7

3-4. Adjustment of the Registration ..................................... ............... .............D-8

(1) Check of the Registration ...............................................................D-8

(2) Adjustment of the Registration .................................. ......................D-9

i

Page 4

TROUBLESHOOTING

1. INTRODUCTION .............................................................................................T-1

1-1. Reading the Text .....................................................................................T-1

2. PAPER TRANSPORT FAILURE .....................................................................T-1

2-1. Paper Misfeed ..........................................................................................T-1

3. MALFUNCTION DETECTION ............................................. ............................T-3

3-1. Display “oA” .............................................................................................T-3

ii

Page 5

GENERAL,

MECHANICAL/ELECTRICAL

Page 6

1. SPECIFICATIONS

Name : Automatic Document Feeder

Installation : Screwed to the copier

Type of Document :

Detectable Document

Sizes

Capacity :

Alignment : Rear Document Adjust Plate

Document Loading : Face up

Document Exchange

Speed

Modes : 1-Sided Original

Power Source : DC24V, DC5V (supplied from the copier)

Power Consumption : 30W

Dimensions : Width: 552 mm (21.7 in)

Weight : 4.3 Kg (9.47 lb)

Operating Environment : Same as copier

Originals Which Should Not be Used

Type of Original Possible Trouble

Sheets stapled or clipped together Take-up failure, damaged sheet,

Sheets glued together Take-up failure, damaged sheet

Sheets folded, torn, or wrinkled Take-up failure, damaged sheet

Sheets severely curled Sheets misfeed due to being dog-eared or fed in

Thin Paper, Thick Paper,

Carbon paper, Thermal paper,

Coating paper, Uneven paper,

Post-it paper, CF paper

Plain paper (50 ~ 110 g/m

: Width: 139.5 ~ 220 mm (5.5 ~ 8.7 in)

Length:139.5 ~ 355.6 mm (5.5 ~ 14 in)

139.5 ~ 1000 mm (Copier with FK-116)

50 sheets max. (A4: 80 g/m

: 12 sheets/min

Depth: 397.3 mm (15.6 in)

Height: 158 mm (6.3 in)

defective drive mechanism due to jammed clips.

askew

Take-up failure, damaged sheet

2

)

2

, LTR & Legal: 75 g/m2)

M-1

Page 7

2. COMPONENTS IDENTIFICATION

21

3

4

5

6

1. Document Guide Extender

2. Document Guide

3. Adjust Plate

4. SDH Cover

5. Cover 2

6. ADF Cover

3. CROSS-SECTIONAL VIEW

1. Pick-Up Roller

2. Main Feed Roller

3. Sprit Roller

4. Turning Roller

5. White Roller

6. Exit Roller

4647G001AA

1

6

2

3

4

5

4647G002AA

M-2

Page 8

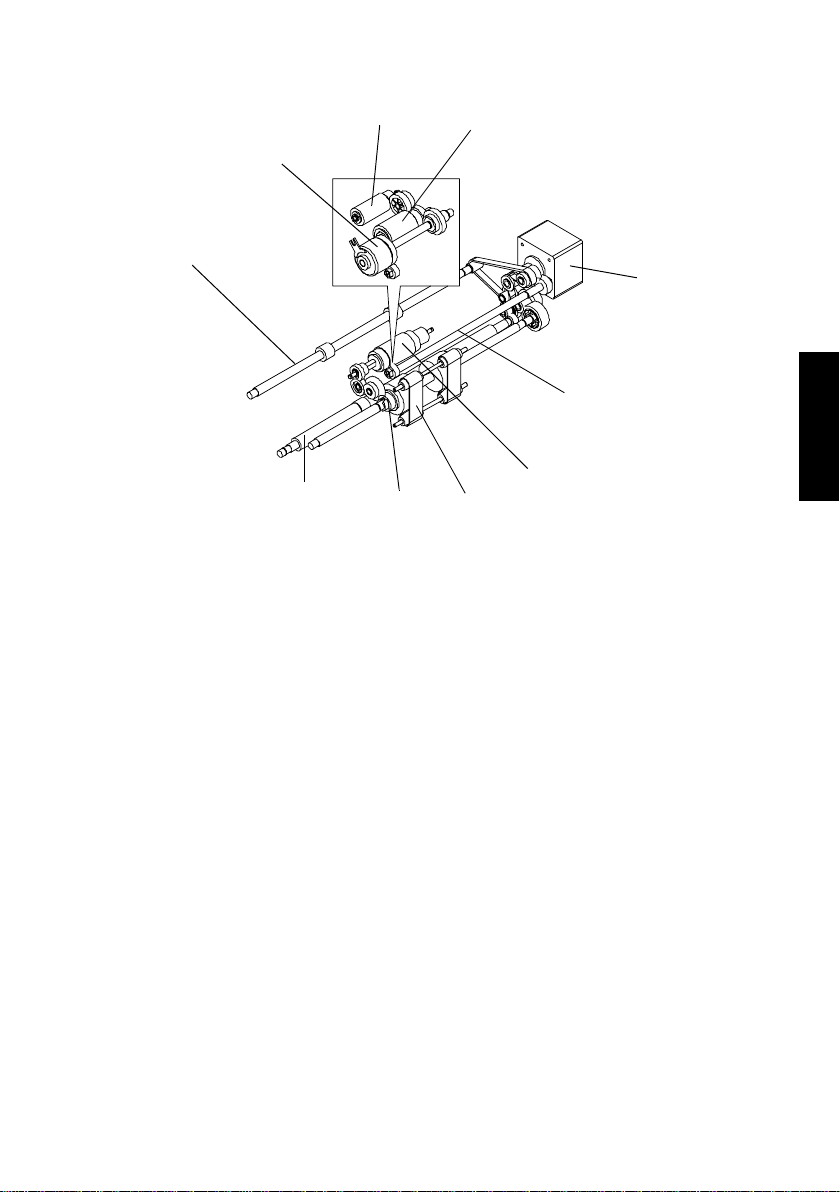

4. DRIVE SYSTEM

1

1. Exit Roller

2. Magnetic Clutch

3. Pick-Up Roller

4. Main Feed Roller

5. Main Mot or

3

2

10

9

4

7

8

6. Transfer Roller

7. Sprit Roller

8. Rubber Belt

9. Turning Roller

10. White Roller

5

6

4647G003AA

M-3

Page 9

5. ELECTRICAL COMPONENT LAYOUT

1

7

1. Document Empty Sensor (S1)

2. SDH PCB ASSY

3. Cover Sensor A (S3)

4. Main Mot or

2

3

5

6

5. Registration Sensor (S2)

6. Magnetic Clutch

7. Cover Sensor B (S4)

4

4647G004AA

6. DESCRIPTION OF MODES

✽

1-Sided Original Mode

• When a multi-page document is being used, the copier detects the size of only the first

page of the document and runs for the subsequent pages based on that size detection.

• The mode is used when making copies of a document set consisting of pages of the

same size.

M-4

Page 10

7. DOCUMENT TAKE-UP/FEEDING MECHANISM

7-1. Document Take-Up Mechanism

Pick-Up Roller

Main Motor

Main Feed Roller

Document Empty Sensor

• The document is taken up as the Pick-Up Roller and Main Feed Roller turn.

• The Pick-Up Roller transports the document up to the Main Feed Roller, moving up and

down at all times during a document take-up sequence.

• The Pick-Up Roller and Main Feed Roller are turned through the Magnetic Clutch and by

gears driven by the Main Motor.

• The Document Empty Sensor is used to detect a document loaded on the Document

Guide.

• The leading edge of the document is determined by the Sprit Roller. when the document

gets over the Sprit Roller, it stops between Main feed Roller and Sprit Roller.

Magnetic Clutch

Document stop position

4647G005AA

Main Feed Roller

Sprit Roller

4647G011AA

M-5

Page 11

7-2. Document Separating Mechanism

Pick-Up Roller

• The Sprit Roller is turned in the direction opposite to that of the Main Feed Roller, which

effectively separates the top page of the document from the rest.

• The Sprit Roller is turned by gears driven by the Main Motor.

Main Feed Roller

Sprit Roller

Main Motor

4647G006AA

M-6

Page 12

8. DOCUMENT TRANSPORT/EXIT MECHANISM

8-1. Document Transport Mechanism

Main Motor

Rubber Belt

Roller

Turning Roller

• The document taken up is transported to the document scanning position of the copier by

the Turning Roller and Rubber Belt.

• The Turning Roller and Rubber Belt are driven by gears which are driven by the Main

Motor.

8-2. Document Exit Mechanism

4647G007AA

Main Motor

Exit Roller

• The document is fed out of the ADF by the Exit Roller.

• The Exit Roller is driven by gears and a belt which are driven by the Main Motor.

4647G008AA

M-7

Page 13

8-3. Raised/Lowered Position Detection Mechanism

Magnet

ADF Set Switch

4647G009AB

• There is a magnet installed in the ADF body to allow the copier to know that the ADF is

raised or lowered.

• This magnet actuates and deactuates the ADF Set Switch on the copier.

M-8

Page 14

9. WIRING DIAGRAM

4647G010AB

JP2

TUBE

CORE

Main Motor

M

Y

R

BL

4

321

JP1

1413121110

15

BK

BR

1413121110

15

Magnetic Clutch

CL

BK

W

R

BK

2

1

JP6

8

7

9

654

Y

W

BL

PL

BK

OR

GR

BR

GY

8

7

9

654

Document Empty Sensor (S1)

PC

1

2

4

3

PJ1

R

BK

BR

OR

4

3

2

1

JP5

321

R

Y

OR

321

Registration Sensor (S2)

PC

321

PJ2

R

BL

BK

2

3

1

JP4

SDH PCB

Assy

Cover Sensor A (S3)

S

R

BK

2

1

JP7

JP3

Cover Sensor B (S4)

S

R

BK

2

1

From The

Copier

M-9

Page 15

TECH. REP. MODE

Page 16

1. OUTLINE OF USER’S CHOICE MODE

Highlighted

• User’s Choice Mode is used to make various settings according to the user’s needs.

1-1. User’s Choice Function Setting Procedure

<Setting Procedure>

1. On the copying mode screen, hold down the Exposure Control Lighter < key f or about 3

second or more.

2. Using the 1Key and 10Key, select the appropriate choice code.

3. Press the Start key to show the current setting.

4. Using the 1Key and 10Key, select the appropriate choice data.

5. Press the Start key to validate the choice data entered.

<Exiting the Mode>

• Press the Clear/Stop key.

1-2. Functions Available from the User’s Choice Mode

✽

Function available on the display only when the copier is equipped with the ADF option.

Choice Code.

U9

Setting (The default is ).

<Density (Automatic Document Feeder)>

Select the copy image density level when the copier is equipped with

an Automatic Document Feeder.

Data Description

When the standard original (text original) is used.

1

2 For sharper reproduction of a faint original.

S-1

Page 17

2. OUTLINE OF THE TECH. REP. MODE

• This mode is used by the Tech. Rep. to set, adjust, and/or program vari ous service functions.

2-1. Tech. Rep. Mode Setting Procedure

<Setting Procedure>

1. Press the following keys in this order:

Clear/Stop → Exposure Control Lighter (<) → Clear/Stop → Exposure Control Darker (>)

2. Press the 1Key until the desired Tech. Rep. sub-mode is reached. Sub-modes cycle as

follows:

Display “d” Tech. Rep. Choice “C” Function “F” Adjust “A”

3. When the code that represents the desired sub-mode is displayed, press the Start key.

4. Press the 1Key as necessary until the desired code appears on the display.

5. Press the Start key to let the copier start the sequence.

<Exiting the Mode>

• Press the Clear/Stop key.

(1) Function “F”

• Only the function which relates to ADF is described.

Code Description

<Original Passage Test>

<Test Pattern 1>

F3

F5

FE

Checks the Automatic Document Feeder for corr ect docum ent passage.

<Procedure>

1. Place paper on the Document Guide.

2. Press the Start key to let the Automatic Document Feeder start

the document take-up and feeding sequence.

Produces a test pattern for adjusting the Paper Tray for correct alignment and registration in the main scanning and sub-scanning directions.

<Original Scanning Position Contamination Test>

Checks the Automatic Document Feeder original scanning position

(Original Glass) for contamination.

<Procedure>

1. Place A4 blank paper on the original scanning part.

2. Press the Start key to let the copier produce a copy.

3. Check the copy for poss ible contamination.

S-2

Page 18

(2) Adjust “A”

Highlighted

• Only the function which relates to ADF is described.

Adjust Code

A5

Adjust the zoom ratio in the CD direction on the IR side (when the

Automatic Document Feeder is used).

Data

Description Reduced Enlarged

Setting (The default is ).

<Zoom Adjustment in CD Direction>

45................................. ................................55

50

A6

A7

A8

Adjust the zoom ratio in the FD direction on the IR side (when the

Automatic Document Feeder is used).

Data

Description Reduced Enlarged

Adjust registration in the CD direction on the IR side (when the Automatic Document Feeder is used).

Data

Description

Adjust registration in the FD direction on the IR side (when the Automatic Document Feeder is used).

Data

Description

<Zoom Adjustment in FD Direction>

45................................. ................................55

<Registration Adjustment in CD Direction>

40................................. ................................60

-5.0mm ±0 +5.0mm

<Registration Adjustment in FD Direction>

40................................. ................................60

-5.0mm ±0 +5.0mm

50

50

50

S-3

Page 19

DIS/REASSEMBLY,

ADJUSTMENT

Page 20

1. MAINTENANCE SCHEDULE

• To ensure that the copier produces good copies and to extend its service life, it is recom-

mended that the maintenance jobs described in this schedule be carried out as

instructed.

Maintenance Schedule

PM Parts

Cleaning Replacement

Sprit Roller Assembly 10 1

Pick-Up Roller 10 1

Main Feed Roller 10 1

Turning Roller 10 2

White Roller 10 1

NOTE

1. During regular maintenance visit, clean or replace parts as necessary.

2. K=1,000 originals

(K)

Qty

D-1

Page 21

2. DISASSEMBLY

2-1. Removal of the Document Cover

1. Open the ADF Cover.

4647D001AA

2

1

4647D002AA

2. Remove the Document Guide.

NOTE

Bring the Document Guide into the upright position (1)

and then pull it straight upward. (2)

2-2. Removal of the ADF Cover

1. Remove Cover 2.

NOTE

Turn Cover 2 clockwise until it stops, then remove it

together with the spring.

4647D003AA

2. Remove the two screws and ADF Cover.

4647D004AA

D-2

Page 22

2-3. Removal of the ADF Assembly

1. Remove the three screws and PCB Cover.

2. Remove the three screws and Cover 1.

Cover 1

PCB Cover

4647D005AA

1

2

3. Unplug the seven connectors from the SDH PCB

Assy.

3

7

6

4

5

4647D006AB

4. Remove the three screws and Hinge.

NOTE

Whenever the Hinge have been removed, be sure to

make the following adjustments:

• Checking and adjustment for skewed feed.

• Checking and adjustment for zoom adjust.

• Checking and adjustment for registration.

4647D018AA

NOTE

When reinstalling the Hinge, Secure it in Position with

the center .

5. Remove the five screws and ADF Assembly.

A. Front screw part is removed.

B. Rear screw part is removed.

B

C. Remove the front end first.

A

C

4647D007AB

D-3

Page 23

2-4. Removal of the Sprit Roller Assembly

1. Open the ADF Cover.

4647D008AA

2. Remove the two screws and Roller Cover.

4647D009AA

3. Unhook the spring.

4647D010AA

4647D011AA

4. Snap off the E-rings and remove the bushings.

5. Remove the Sprit Roller Assembly.

D-4

Page 24

3. ADJUSTMENT

3-1. Print of Test Pattern

(1) Entering the Tech. Rep. Mode

Procedure:

Press the following keys in this order:

Clear/Stop → Exposure Control Lighter (<) → Clear/Stop → Exposure Control Darker (>)

(2) Entering the Adjust Mode

Procedure:

1. Enter the Tech. Rep. mode.

2. Press the following keys in this order:

1Key → 1Key → 1Key → Start key → Press the 1Key until the specific function is displayed.

(3) Producing a Test Pattern

NOTE

A test pattern is used when making the following adjustments:

• Skewed Feed adjustment

• Zoom adjustment

• Registration adjustment

Procedure

1. Enter the Tech. Rep. mode.

2. Press the following key s in this order to enter the function of “F5 Test Pattern 1”:

1Key → 1Key → Start key → 1Key → 1Key → 1Key → 1Key

3. Press the Start key.

NOTE

To exit the test pattern function, press the Clear/Stop key to go back to the Basic screen.

✽

Direction where test pattern is copied

Test pattern

4647D019AA

The test pattern should be copier in one specified

direction only.

Do not copy it in the opposite direction.

D-5

Page 25

3-2. Adjustment of the Skewed Feed

(1) Check of the Skewed Feed

A

Copy

B

4647D019AA

(2) Adjustment of the Skewed Feed

✽

If A is too long and B is too short

4647D020AA

1. Set test pattern 1 in the Automatic Document

Feeder , and press the Start Key.

2. Check to see if the dimensions A and B meet the

following equation.

Requirement: A B = 1.6 mm

3. If the requirement is not met, adjust the tilt.

1. Loosen the two screws in the Hinge section and

slide the Hinge in the direction of the arrow.

2. Loosen the screw securing the reading scale, and

slide it in the direction of the arrow.

3. Make another copy and check the dimensions

again.

4647D021AA

✽

If A is too short and B is too long

4647D022AA

4647D023AA

1. Loosen the two screws in the Hinge section and

slide the Hinge in the direction of the arrow.

2. Loosen the screw securing the reading scale, and

slide it in the direction of the arrow.

3. Make another copy and check the dimensions

again.

D-6

Page 26

3-3. Adjustment of the Zoom

(1) Check of the Zoom

C

Copy

(2) Adjustment of the Zoom

d A

D

4647D019AA

2

3

1. Set test pattern 1 in the Automatic Document

Feeder , and press the Start Key.

2. Check to see if dimensions by C (main scan) and D

(sub scan) falls within the specified range.

Requirements: C 100 1.0 mm

3. If dimensions C and D fall outside the specified

range, adjust enlargement/reduction.

1. Show “d” (TEC. REP. MODE) on the display.

2. Press the 1Key as necessary until “A” appears on

the display.

3. Press the Start key.

A1

display

D 200 3.0 mm

<C (main scan) Adjust>

A1 A5

4

display

<D (sub scan) Adjust>

display

Set Value Enlargement/reduction Set Value Enlargement/reduction

6

A5 A6

8

10

45 - 2.0 % 51 0.4 %

46 - 1.6 % 52 0.8 %

47 - 1.2 % 53 1.2 %

48 - 0.8 % 54 1.6 %

49 - 0.4 % 55 2.0 %

50 0

5

5052

9

5047

4. Press the 1Key as necessary until “A5” appears on

the display.

5. Press the Start key.

6. Press the 1key or 10key to adjust the enlargement/

reduction.

• If dimension C on the copy is longer than the speci-

fied range, adjust the reduction amount.

• If dimension C on the copy is shorter than the speci-

fied range, adjust the enlargement amount.

7. Press the Start key to validate the setting value.

8. Press the 1Key as necessary until “A6” appears on

the display.

9. Press the Start key.

10. Press the 1key or 10key to adjust the enlargement/

reduction.

• If dimension D on the copy is longer than the speci-

fied range, adjust the reduction amount.

• If dimension D on the copy is shorter than the speci-

fied range, adjust the enlargement amount.

11. Press the Start key to validate the setting value.

D-7

Page 27

3-4. Adjustment of the Registration

(1) Check of the Registration

4647D025AA

1. Set test pattern 1 in the Automatic Document

Feeder , and press the Start Key.

2. Fold the copy in half, correctly aligning both edges

as shown.

E (center line)

crease

Copy

F

Copy

G

H

4647D026AA

4647D026AA

3. Check the crease and E (center line) on the copy.

• If E on the copy deviates on the G side, increase the

setting value.

• If E on the copy de viates on the H side , decrease the

setting value.

✽

Repeat these steps until the center line and crease

are aligned properly with each other.

4. Check to make sure that dimension F falls within

the range specified below.

Requirement: F 20 2.0 mm

✽

If dimension F falls outside the specified range,

adjust as necessary.

D-8

Page 28

(2) Adjustment of the Registration

d A

2

3

1. Show “d” (TEC. REP. MODE) on the display.

2. Press the 1Key as necessary until “A” appears on

3. Press the Start key.

A1

display

the display.

<E (center line) Adjust>

A1 A7

4

display

<F (left edge) Adjust>

display

Set Value Enlargement/reduction Set Value Enlargement/reduction

6

A7 A8

8

10

40 - 5.0 mm 51 0.5 mm

41 - 4.5 mm 52 1.0 mm

42 - 4.0 mm 53 1.5 mm

43 - 3.5 mm 54 2.0 mm

44 - 3.0 mm 55 2.5 mm

45 - 2.5 mm 56 3.0 mm

46 - 2.0 mm 57 3.5 mm

47 - 1.5 mm 58 4.0 mm

48 - 1.0 mm 59 4.5 mm

49 - 0.5 mm 60 5.0 mm

50 0

5

5052

9

5047

4. Press the 1Key as necessary until “A7” appears on

the display.

5. Press the Start key.

6. Press the 1key or 10key to adjust the enlargement/

reduction.

• If E on the copy deviates on the H side, change the

value to a negative (-) value.

• If E on the copy deviates on the G side, change the

value to a positive (+) value.

7. Press the Start key to validate the setting value.

8. Press the 1Key as necessary until “A8” appears on

the display.

9. Press the Start key.

10. Press the 1key or 10key to adjust the enlargement/

reduction.

• If dimension F is longer that the specified range,

change the value to a negative (-) value.

• If dimension F is shorter that the specified range,

change the value to a Positive (+) value.

11. Press the Start key to validate the setting value.

D-9

Page 29

TROUBLESHOOTING

Page 30

1. INTRODUCTION

1-1. Reading the Text

1. The paper transport failure troubleshooting procedures are given according to the

symptom. First, identify the location where the paper is present and start the procedure

for that particular location. For malfunction troubleshooting, start with step 1 and

onward.

2. Make checks in the numerical order of steps and, if an item is checked okay, go to the

next step.

Pattern 1

Step Check Result Action

1~ YES~

2

Go to step 2 if you answered No.

Pattern 2

Step Check Result Action

1~ YES ~

2

Go to step 2 if it checks okay.

2. PAPER TRANSPORT FAILURE

2-1. Paper Misfeed

When a document misfeed occurs, the display shows “J8.”

<Resetting misfeed display>

Open the relevant cover, remove the misfeed, and close the cover.

Symptom

• The document

is not properly

detected when

it is loaded.

• The document

is not taken up

at all.

Step

No.

1 Is the Document Empty

1 Does the Pick-Up Roller

2 Is the Main Motor ener-

3 After exchanging the SDH

Check Item Result Action

YES Check cables and conSensor operational, as

checked through a sensor

check?

NO Check the actuator for

NO Check the drive transmit-

press the document?

YES Check the drive transmitgized?

NO Check Main Motor cables

NO Change the Main Motor.

PCB Assy: Is the Main

Motor energized?

NO ~

nectors for connection.

Change the SDH PCB

Assy.

operation and, if it is

intact, change the sensor.

ting gears.

Check the Pick-Up Roller

Spring.

ting gears up to the Main

Feed Roller.

and connectors (JP2) for

connection.

T-1

Page 31

Symptom

• Multiple feed of

document

pages occurs.

• The document

stops midway.

Step

No.

1 Does the document being

used fall outside the category of reliable feeding?

2 Has the capacity of the Doc-

ument Guide been

exceeded?

3 Is any of the Pick-Up Roller,

Main Feed Roller, and Sprit

Roller deformed, worn, or

dirty with paper dust?

4 Is the Sprit Roller pressed

against the Main Feed

Roller?

1 Is a foreign object present

along the document path?

2 Is the ADF Cover closed in

position?

3 Is the Registration Sensor

operational, as checked

through a sensor check?

4 Is any of the Turning Roller,

Rubber Belts, and Exit

Roller deformed, worn, or

dirty with paper dust?

5 Does the Turning Roller or

Exit Roller turn?

Check Item Result Action

YES Instruct the user to use

the document that meets

the specifications for reliable feeding.

YES Instruct the user not to

exceed the capacity.

YES Clean or change the

defective roller.

NO Check the spring.

YES Change the Sprit Roller

Assy.

YES Remove the foreign

object.

NO Close the cover in posi-

tion.

YES Change the SDH PCB

Assy.

NO Check the actuator for

operation and, if it is

intact, change the sensor.

YES Clean or change the

defective part.

NO Check the drive transmit-

ting gears and belt.

T-2

Page 32

Symptom

• The document

is fed in askew.

• The document

wrinkles or

breaks.

Step

No.

1 Is a foreign object present

2 Is the ADF Cover closed in

3 Does the document consist

4 Is any of the rollers

1 Does the document being

2 Has the capacity of the Doc-

3 Is a foreign object present

4 Is any of the rollers

Check Item Result Action

along the document path?

position?

of pages of different sizes?

deformed, worn, or dirty with

paper dust?

used fall outside the category of reliable feeding?

ument Loading Tray been

exceeded?

along the document path?

deformed, worn, or dirty with

paper dust?

YES Remove the foreign

object.

NO Close the cover in posi-

tion.

YES Align one edges properly

when loading the document.

YES Clean or change the

defective roller.

YES Instruct the user to use

the document that meets

the specifications for reliable feeding.

YES Instruct the user not to

exceed the capacity.

YES Remove the foreign

object.

YES Clean or change the

defective roller.

3. MALFUNCTION DETECTION

Any of the following operation faults can be detected and the corresponding malfunction

code is shown on the Copier Display.

3-1. Display “oA”

It is displayed when the ADF Cover is not in correct position.

Symptom

•“oA” display

does not disappear.

Step

No.

1 Is the ADF Cover closed in

2 Is the Cover Sensor A and B

3 Check Sensor cables and

4 After exchanging the SDH

Check Item Result Action

position?

deformed or dirty with paper

dust?

connectors (JP3, 7)

PCB Assy: Is the Main

Motor energized?

NO Close the cover in posi-

NO Clean or change the

NO Reconnect the cables and

NO Change the Cover Sensor

T-3

tion.

defective Sensor.

connectors.

A and B.

Loading...

Loading...