Konica 7155-65 Service Manual 7155fv4e

4

SERVICE

4 SERVICE

Main Precautions for Maintenance

4 SERVICE

1. Points to be confirmed before maintenance

Before starting maintenance, ask a

user and collect information about troubles that occurred on the machine

before the maintenance and the conditions of the machine to grasp key points

for the maintenance.

2. Copy sample

Be sure to make copy samples at the

start and the end of maintenance for

checking images.

3. Drum

a) Never expose the drum to the sunlight.

Be also careful not to expose a drum to

indoor light as far as possible.

When a drum unit or a drum is out of the

machine, never fail to cover it with a

drum cover.

b) When replacing a drum, toner guide

roller or cleaning blade, refer to the Item

removing and installing a cleaning

blade.

4. When replacing the drum and developer, must perform neccessary adjustment by refering to the List of

Adjustment Items.

5. After having completed maintenance

work, must reset the PM counter (using

the 25 mode).

6. When replacing the fixing unit cleaning

web, developer, and drum must reset

the fixing unit cleaning web counter(

using the 36 mode).

7. When replacing a toner cartridge, wait

until the toner supply LED on the operation panel flashes before the replacement.

Caution:Turn the main power switch

(SW1) off and pull out the power

pulg without fail before the

work of maintenance.

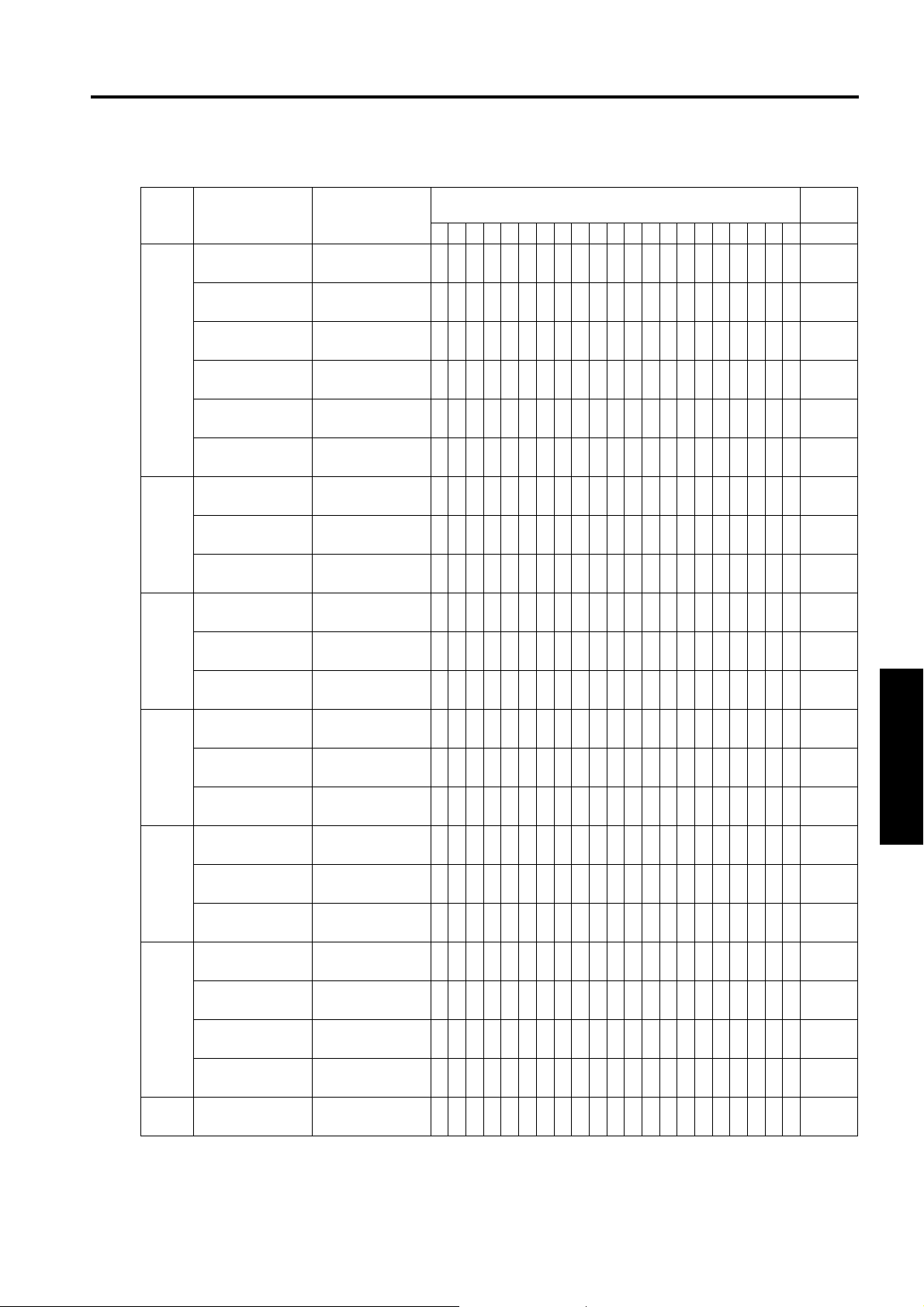

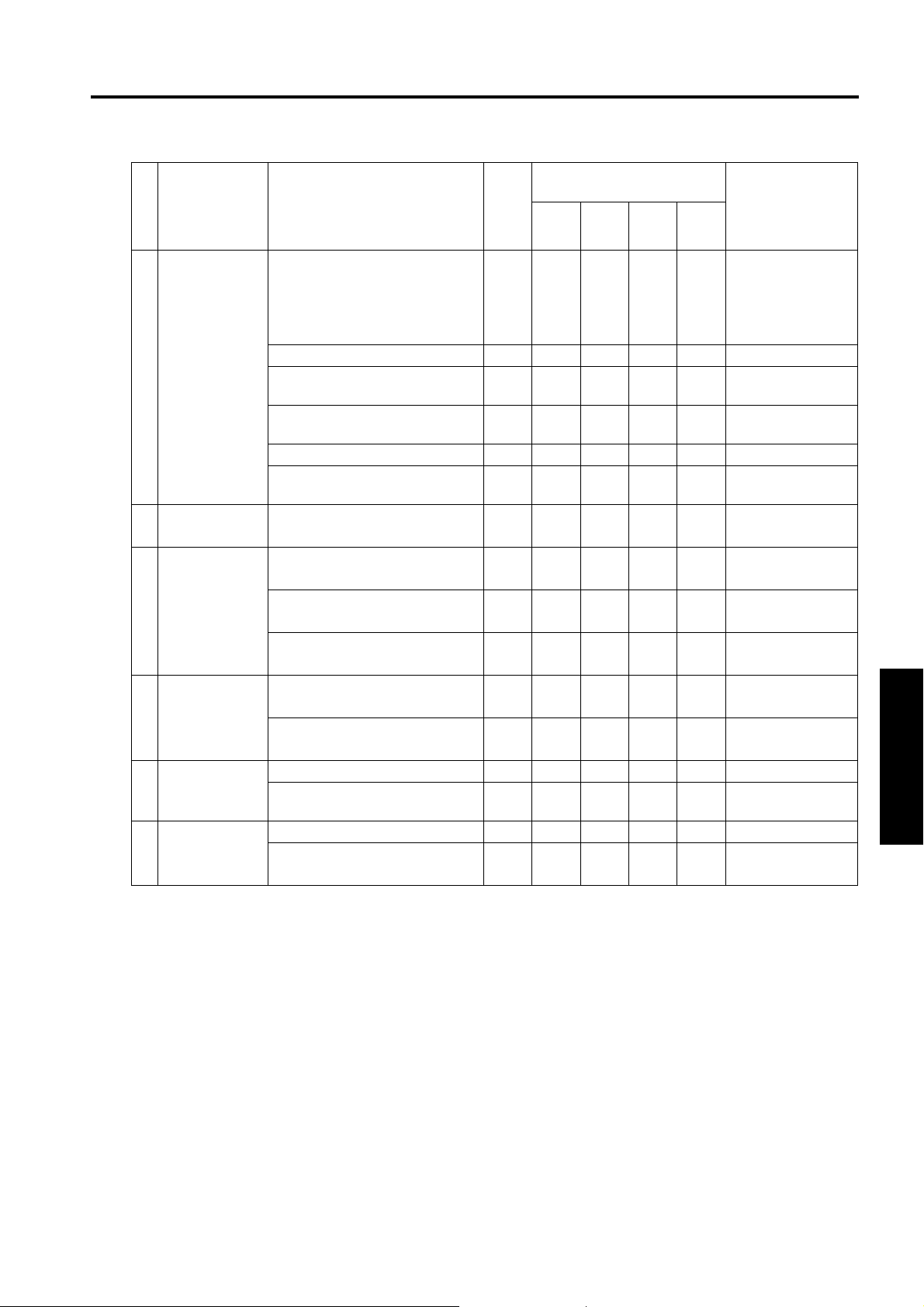

SERVICE SCHEDULE

[1] Service Schedule

Service item Numbe of copies

Main

body

RADF

DF-316

FNS

FS-110

FNS

FS-210

LCT

LT-402/412

PI

PI-110

PK

PK-110

Maintenance Every 250,000 cop-

ies

Periodic check (I) Every 500,000 cop-

ies

Periodic check (II) Every 1,000,000

copies

Periodic check (III) Every 2,000,0000

copies

Periodic check (IV) Every 2,500,000

copies

Periodic check (V) Every 4,000,000

copies

Maintenance Every 250,000 cop-

ies

Periodic check (I) Every 500,000 cop-

ies

Periodic check (II) Every 1,500,000

copies

Maintenance Every 250,000 cop-

ies

Periodic check (I) Every 1,000,000

copies

Periodic check (II) Every 2,500,000

copies

Maintenance Every 250,000 cop-

ies

Periodic check (I) Every 1,000,000

copies

Periodic check (II) Every 2,500,000

copies

Maintenance Every 250,000 cop-

ies

Periodic check (I) Every 1,000,000

copies

Periodic check (II) Every 4,000,000

copies

Maintenance Every 250,000 cop-

ies

Periodic check (I) Every 500,000 cop-

ies

Periodic check (II) Every 1,000,000

copies

Periodic check (III) Every 3,000,000

copies

Maintenance Every 250,000 cop-

ies

SERVICE SCHEDULE

Guarantee period (5 years or 5,000,000 copies)

×10,000 copies

0 25 50 75 100 125 150 175 200 225 250 275 300 325 350 375 400 425 450 475 500

zzzzzzzzzzzzzzzzzzz

zzzzzzzzzz

zzzz

zz

z

z

zzzzzzzzzzzzzzzzzzz

zzzzzzzzz

zzz

zzzzzzzzzzzzzzzzzzz

zzzz

z

zzzzzzzzzzzzzzzzzzz

zzzz

z

zzzzzzzzzzzzzzzzzzz

zzzz

z

zzzzzzzzzzzzzzzzzzz

zzzzzzzzz

zzzz

z

zzzzzzzzzzzzzzzzzzz

Service

count

19 times

9 times

4 times

2 times

1 times

1 times

19 times

9 times

3 times

19 times

4 times

1 times

19 times

4 times

4 SERVICE

1 times

19 times

4 times

1 times

19 times

9 times

4 times

1 times

19 times

4-1

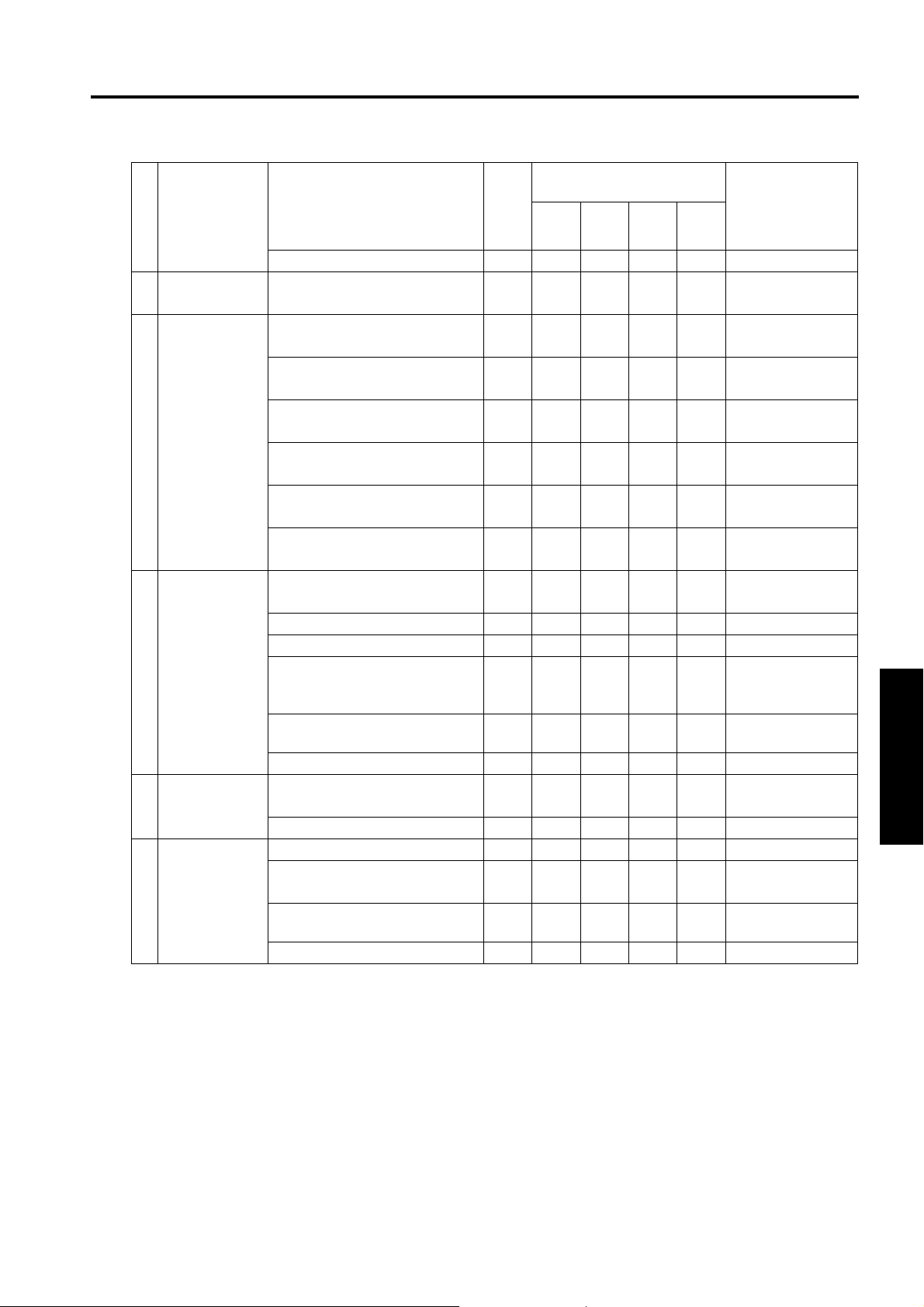

SERVICE SCHEDULE

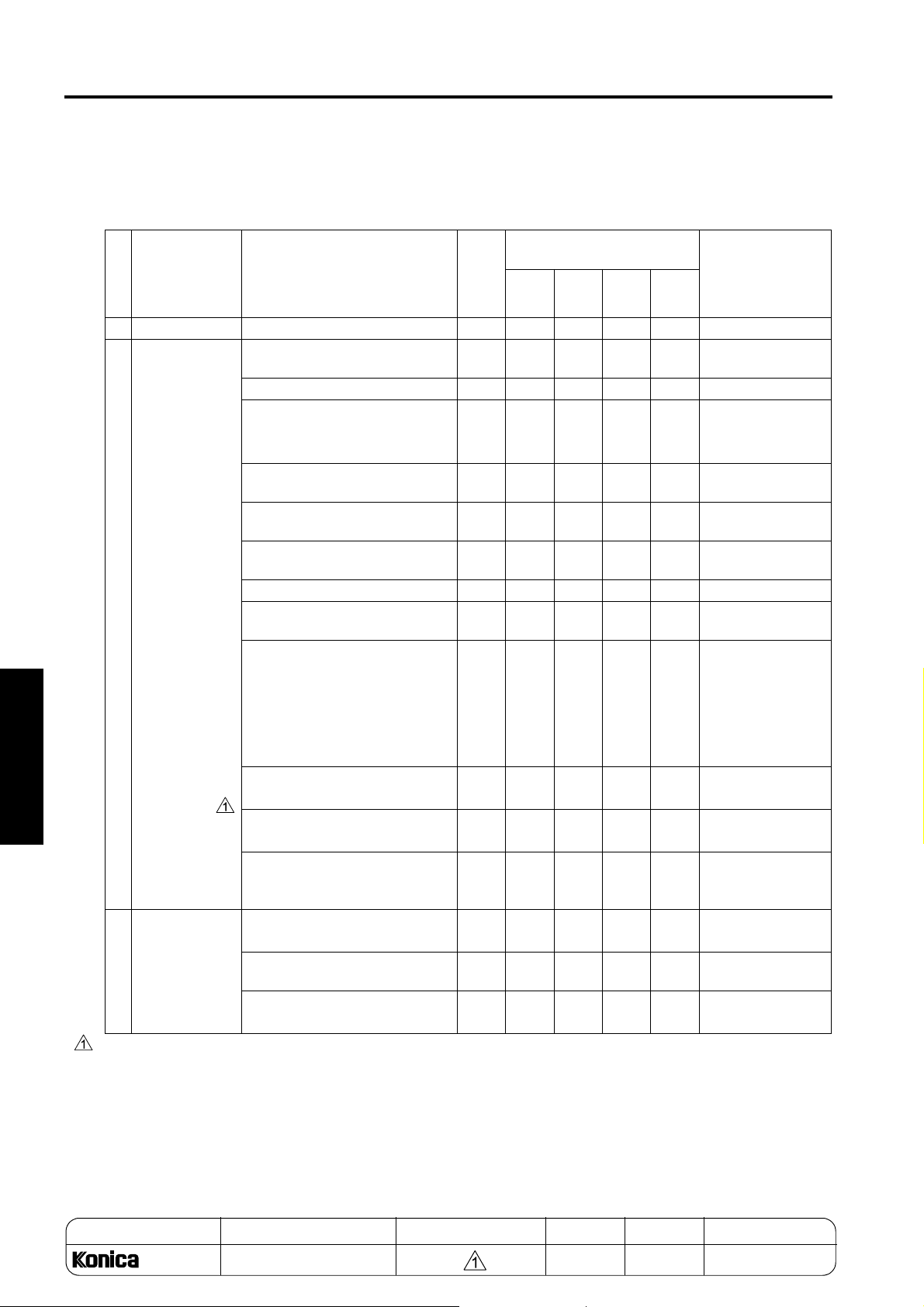

[2] Maintenance Items

1. Main body (Every 250,000 copies)

N

Classification Service item

O

1 Preparation

2Drum unit

4 SERVICE

3 Developing

unit

Note:

*1 After replacing the toner guide roller, be sure to apply an electricity lubricant on the edge of the guide

roller shaft (on power supply pin side).

(1) Image check

(1) Charging control plate

56AA2503*

(2) Charging wire 56AA2509*

(3) Charging corona unit (back

plate and peripheral section,

PCL)

(4) Charger cleaning base

56AA2540*

(5) Charger slide block

56AA2538*

(6) Charger cleaning block /U

56AA-253*

(7) Resin ring (φ 2) 45AA2040*

(8) Charger cleaning block /L

56AA-254*

(9) Drum cartridge, bottom plate of

the developing unit, toner control sensor, separation claw

(10) Toner collection screw A

(11) Toner guide roller *1

56AA-213*

(12) Cleaning blade (36 mode

blade setting mode)

56AA2010*

(1) Developing bias armature

(2) Developer (25 mode counter

resetting)

(3) Developing unit

Number of

parts

replace

d

1

1

1

1

1

1

1

1

1

1

Implementation classifica-

tion

Clea-

ning

Inspe-

ction

Lubric

-ation

Repla

ce-

ment

z

z

z

z

z

z

z

z

z

z

z

zz

z

z

z

z

Materials/tools

used

Drum cleaner/

waste/blower

brush

Blower brush/

cleaning pad/A

drum cleaner is

used only when

cleaning a toner

control sensor.

Blower brush/

cleaning pad

Electricity lubricant

Blower brush/

cleaning pad

Blower brush/

cleaning pad

MODEL MANUAL REVISED EDITION DATE PAGE METHOD

7155/7165

SERVICE HANDBOOK Nov. 2001

4-2 REPLACEMENT

SERVICE SCHEDULE

N

Classification Service item

O

4 Transfer / sep-

aration corona

5 Toner supply

6 Conveyance

unit

7 Registration

8 Drive section

and filter

9 Paper exit unit

(1) Transfer separation corona unit

(front and rear block), guide

rail, separation bridge,

entrance guide plate, lightning

protection sheet, back plate

( 2) Di s ch ar g e w ir e 56AA 26 09 *

(3) Transfer cleaning assembly

(4) Separation cleaning assem-

b ly 5 6A A -2 67 *

(5) Resin ring (φ2 ) 4 5A A2 04 0*

(6) Transfer presser rubber

(1) Cartridge holder member

(1) Conveyance section upper sur-

face

(2) Conveyance belt

(3) TSL cover member

(1) Paper dust removing brush

(2) 2nd paper feed roller

( 1) Oz o ne fi l te r K 55 FA 73 01 *

(2) Developing suction filter

(1) Sensor (one section)

(2) Roller (two sections)

56AA-264*

55VA2615*

56AA-735*

Number of

parts

replace

d

3

1

1

2

3

1

1

Implementation classifica-

tion

Clea-

ning

Inspe-

ction

Lubric

-ation

Repla

ce-

ment

z

z

z

z

z

z

z

z

z

z

z

z

z

z

z

z

Materials/tools

used

Blower brush/

cleaning pad/cotton swab/drum

cleaner

Cleaning pad

Drum cleaner/

cleaning pad

Drum cleaner/

cleaning pad

Drum cleaner/

cleaning pad

Cleaning pad/

blower brush

Drum cleaner/

cleaning pad

4 SERVICE

Blower brush

Drum cleaner/

cleaning pad

4-3

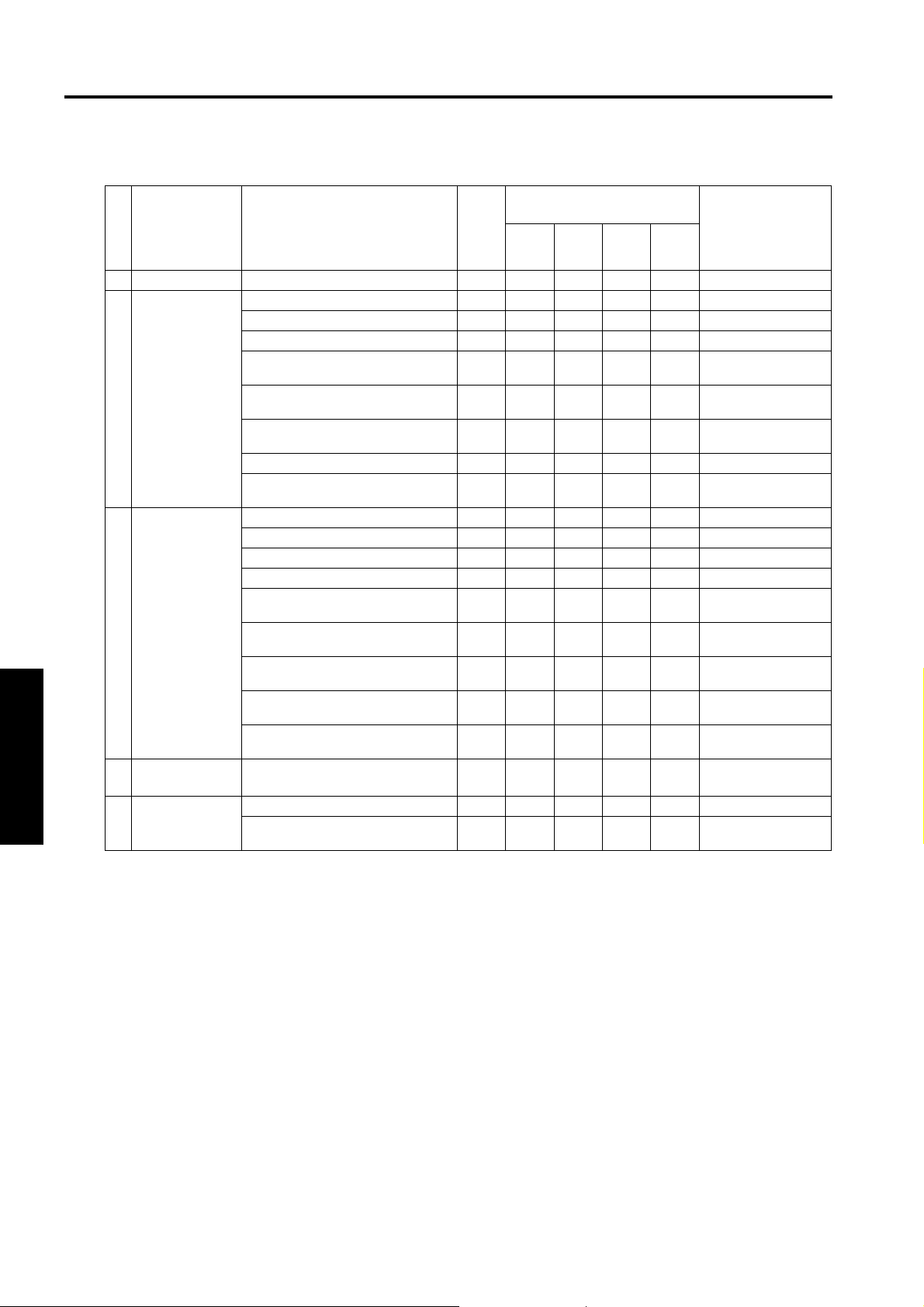

SERVICE SCHEDULE

4 SERVICE

N

Classification Service item

O

10 ADU

10 ADU (10) Gears

11 Paper feed

section

12 By-pass feed

section

13 Scanner

section

(1) Roller cleaning

(2) Reverse/exit roller

(3) ADU reverse roller

(4) ADU conveyance roller /1-4

(5) ADU registration roller

(6) Sensors

(7) Gate sensor (two points)

(8) ADU horizontal conveyance

sections (four points)

(9) ADU reverse section (one

point)

(1) Sensor (three points/tray)

(2) Gears (double feed preven-

tion section)

(3) Conveyance/driven roller

(paper feed)

(4) Feed roller/paper feed con-

veyance roller

(5) Double feed prevention

roller

(1) Sensor (four points)

(2) Gears

(3) Section peripheral of the by-

pass feed unit

(4) Feed roller/paper convey-

ance roller

(5) Double feed prevention

roller

(1) Original glass (including slit

glass)

(2) Exposure lamp

(3) Reflector

(4) Lens

(5) 1st to 3rd mirrors

(6) APS sensor

(7) Photo interrupter

Number of

parts

replace

d

Implementation classifica-

tion

Clea-

ning

Inspe-

ction

Lubric

-ation

Repla

ce-

ment

z

z

z

z

z

z

z

z

z

z

z

z

z

z

z

z

z

z

z

z

z

z

z

z

z

z

z

Materials/tools

used

Drum cleaner/

cleaning pad

Drum cleaner/

cleaning pad

Drum cleaner/

cleaning pad

Drum cleaner/

cleaning pad

Drum cleaner/

cleaning pad

Blower brush

Blower brush

Blower brush

Blower brush

Plus guard No. 2

Blower brush

Plus guard No.2

Drum cleaner/

cleaning pad

Drum cleaner/

cleaning pad

Drum cleaner/

cleaning pad

Blower brush

Plas guard No.2

Drum cleaner/

cleaning pad

Drum cleaner/

cleaning pad

Drum cleaner/

cleaning pad

Drum cleaner/

cleaning pad

Blower brush

Cleaning pad

Blower brush/

cleaning pad

Blower brush/

cleaning pad

Blower brush

Blower brush

4-4

SERVICE SCHEDULE

N

Classification Service item

O

(8) Optical guide rail

14 Writing section (1) Dust-proof glass (external)

15 Fixing unit (1) Fixing upper roller

(2) Fixing lower roller

(3) Fixing claw (L)

(4) Paper exit roller

(5) Paper exit conveyance

roller (right) and guide rib

(6) Fixing unit entrance and exit

guide plate

15 Fixing unit

16 Vertical con-

veyance

17 Final check

(7) Fixing temperature sensor /2

(8) Decurler

(9) Fixing gear

(10) Fixing web unit (25 mode

counter resetting)

56AA-543*

(11) Fixing claw (U)

56AA5427*

(12) Heat insulating sleeve

(1) Horizontal conveyance roller

(2) Sensor

(1) W.U.T. check

(2) Peripheral and exterior clean-

ing

(3) Image and paper through

check

(4) PM counter resetting (25 mode)

Number of

parts

replace

d

1

6

2

5

Implementation classifica-

tion

Clea-

ning

Inspe-

ction

Lubric

-ation

Repla

ce-

ment

z

z

z

z

z

z

z

z

z

z

z

z

z

z

z

z

z

z

z

z

Materials/tools

used

Cleaning pad

Blower brush/

cleaning pad

Roller cleaner/

cleaning pad

Roller cleaner/

cleaning pad

Drum cleaner/

cleaning pad

Drum cleaner/

cleaning pad

Drum cleaner/

cleaning pad

Drum cleaner/

cleaning pad

Blower brush/

paper

Cleaning pad

Moly therm grease

Tri-flow

Drum cleaner/

cleaning pad

Blower brush

Drum cleaner/

cleaning pad

4 SERVICE

4-5

SERVICE SCHEDULE

2. RADF [DF-316](Every 250,000 copies)

N

O

1

2

3

4

4 SERVICE

5 Final check

Classification Service item

Preparation (1) Paper through check

Paper feed sec-

tion

Conveyance

section

Paper exit section

(1) Size detection sensor/1

(2) Size detection sensor/2

(3) Registration sensor

(4) Feed roller

(5) Paper feed roller rubber

(6) Double feed prevention roller

rubber

(7) Cleaning pad

(8) Registration roller

(1) Read sensor

(2) Skew sensor (F)

(3) Skew sensor (R)

(4) Double side registration sensor

(5) Read roller (F)

(6) Read roller (R)

(7) Platen guide

(8) Reverse conveyance roller/1

(9) Reverse conveyance roller/2

(1) Paper exit roller

(1) Paper through check

(2) Exterior cleaning

Number of

parts

replace

d

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Implementation classifica-

tion

Clea-

ning

Inspe-

ction

Lubric

-ation

Repla

ce-

ment

z

z

z

z

z

z

z

z

z

z

z

z

z

z

z

z

z

z

z

z

z

Materials/tools

used

Blower brush

Blower brush

Blower brush

Drum cleaner/clean-

ing pad

Drum cleaner/clean-

ing pad

Drum cleaner/clean-

ing pad

Blower brush

Drum cleaner/clean-

ing pad

Blower brush

Blower brush

Blower brush

Blower brush

Drum cleaner/clean-

ing pad

Drum cleaner/clean-

ing pad

Drum cleaner/clean-

ing pad

Drum cleaner/clean-

ing pad

Drum cleaner/clean-

ing pad

Drum cleaner/clean-

ing pad

Drum cleaner/cleaning pad

4-6

Loading...

Loading...