Konica 7155-65 Service Manual 7155fv1e

1

ADJUSTMENT

1 ADJUSTMENT

HOW TO USE THIS SECTION

HOW TO USE THIS

SECTION

[1] Scope and Precautions

This section provides detailed information about

adjustment items and procedures. Before addressing

customer complaints, perform the following checks.

1. Check whether the power supply voltage meets

the specifications.

2. Check whether the power supply is properly

grounded.

3. Check whether this machine shares the power

supply with any other machine that draws large

current intermittently (e.g., elevator and air conditioner that produce electrical noise).

4. Check whether the installation environment is

good.

a. High temperature / High humidity, direct sun-

light, ventilation, etc.

b. Level of installed location

5. Check whether original has a problem that may

cause defective images.

6. Check whether the selected density value is correct.

7. Check whether the platen glass, slit glass, etc. is

soiled.

8. Check whether correct paper is used for copying.

9. Check whether copying materials and parts

(e.g., developer, drum, and cleaning blade) are

replenished and replaced when they reach the

end of their useful life.

10. Check whether toner remains.

When servicing the machine, observe the following

precautions:

ADJUSTMENTS MADE WHEN REPLACING PARTS

Adjustments (including checks) and settings are not

only required when a customer complaint about the

copy image quality is received, but also after replacing

or reassembling parts.

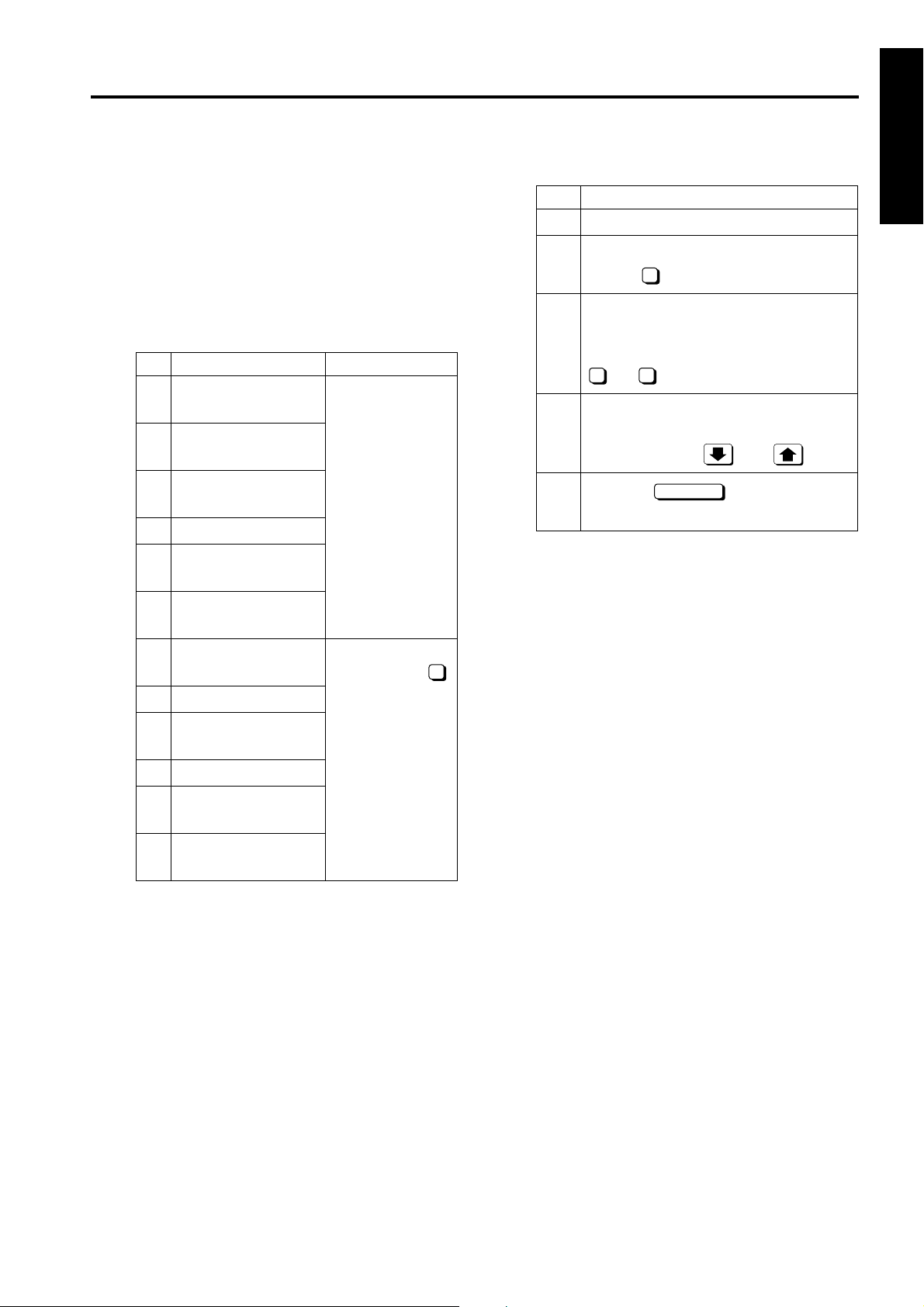

[How to Read Tables]

Components of the tables used in this section are as

follows:

1. Mode

Adjustment mode to be selected.

[P]: P mode

[25]: 25 mode

[36]: 36 mode

[47]: 47 mode

2. Code

Code and copy quantity setting button used in

each mode.

3. Page

Page in the "ADJUSTMENT" section.

4. Circled numbers

2

1

Indicate that adjustments (including

checks) must be made in order of precedence.

(Circle without numeric character):

Indicates that adjustments (including

checks) can be made independently.

1 ADJUSTMENT

11. Only either side of the AC line is shut off when the

SW1 (main power) of this machine is turned off.

Always unplug the power cord before starting

service work. If it is necessary to service the

machine with the power on, take care not to be

caught in the scanning gear of the exposure unit.

12. Special care should be taken when handling the

fixing unit because it operates at extremely high

temperatures.

13. The developing unit has a strong magnetic field.

Keep watches and measuring equipment away

from it.

14. Take care not to damage the drum with tools and

so on.

15. Do not touch IC pins with bare hands.

1-1

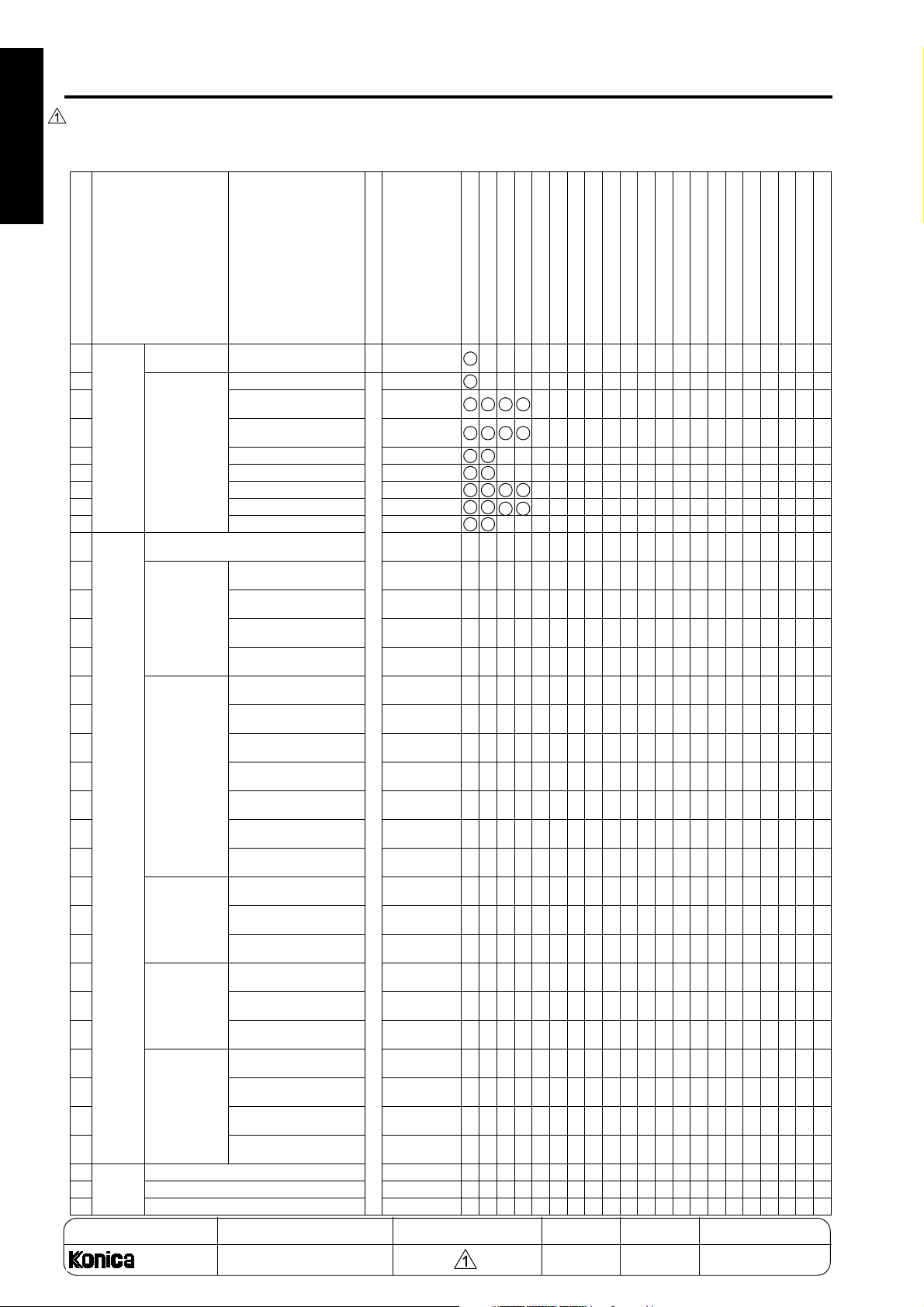

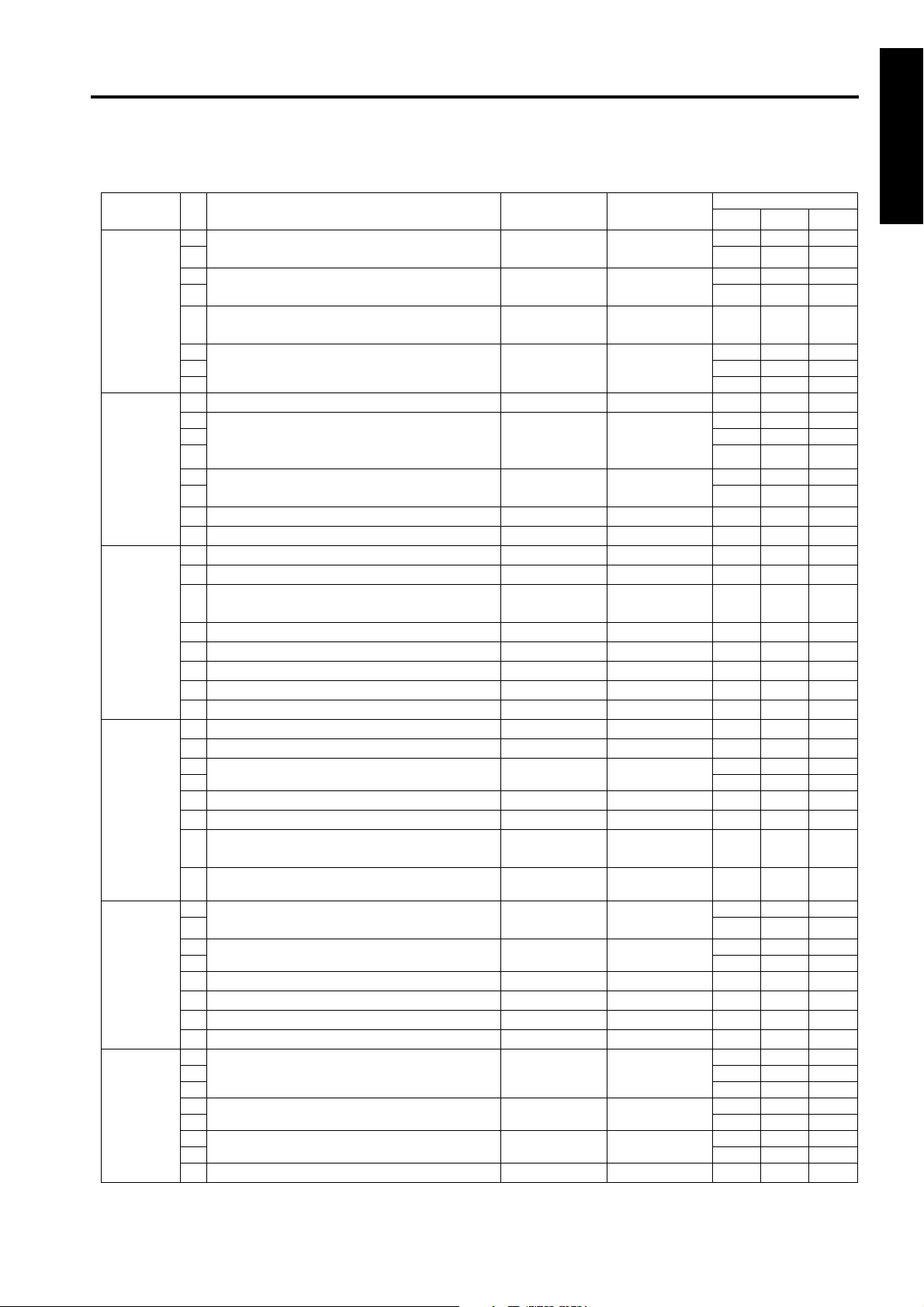

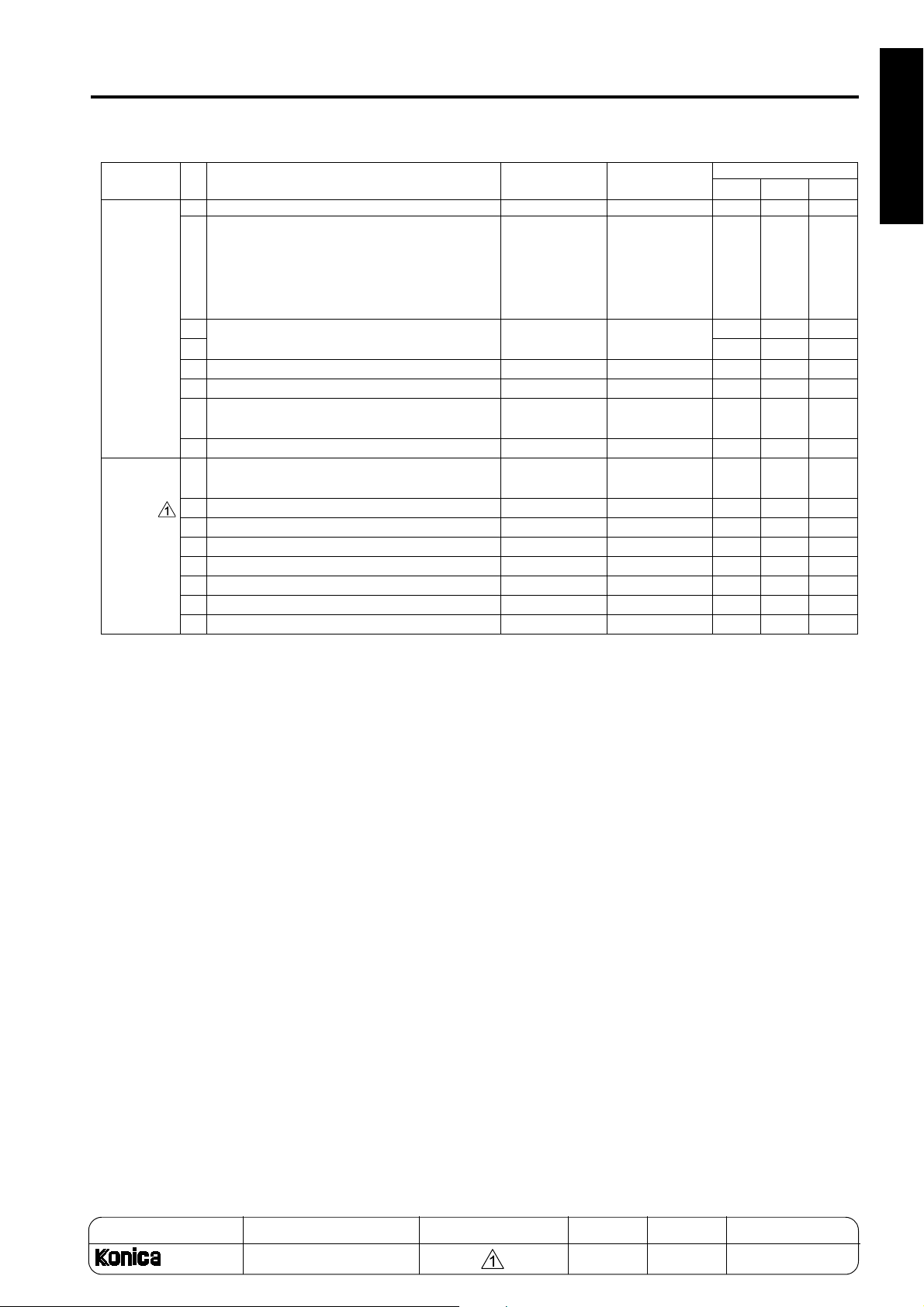

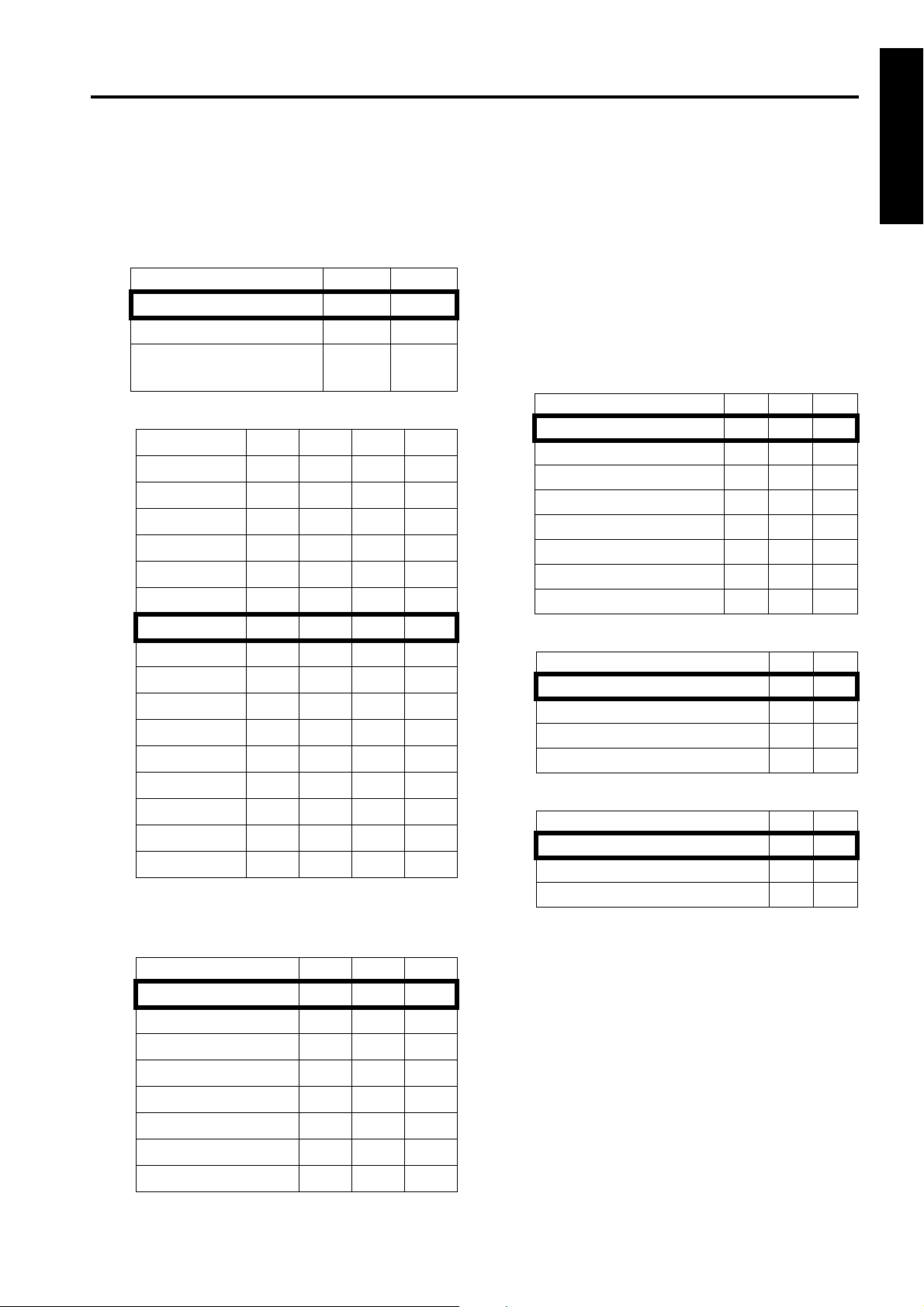

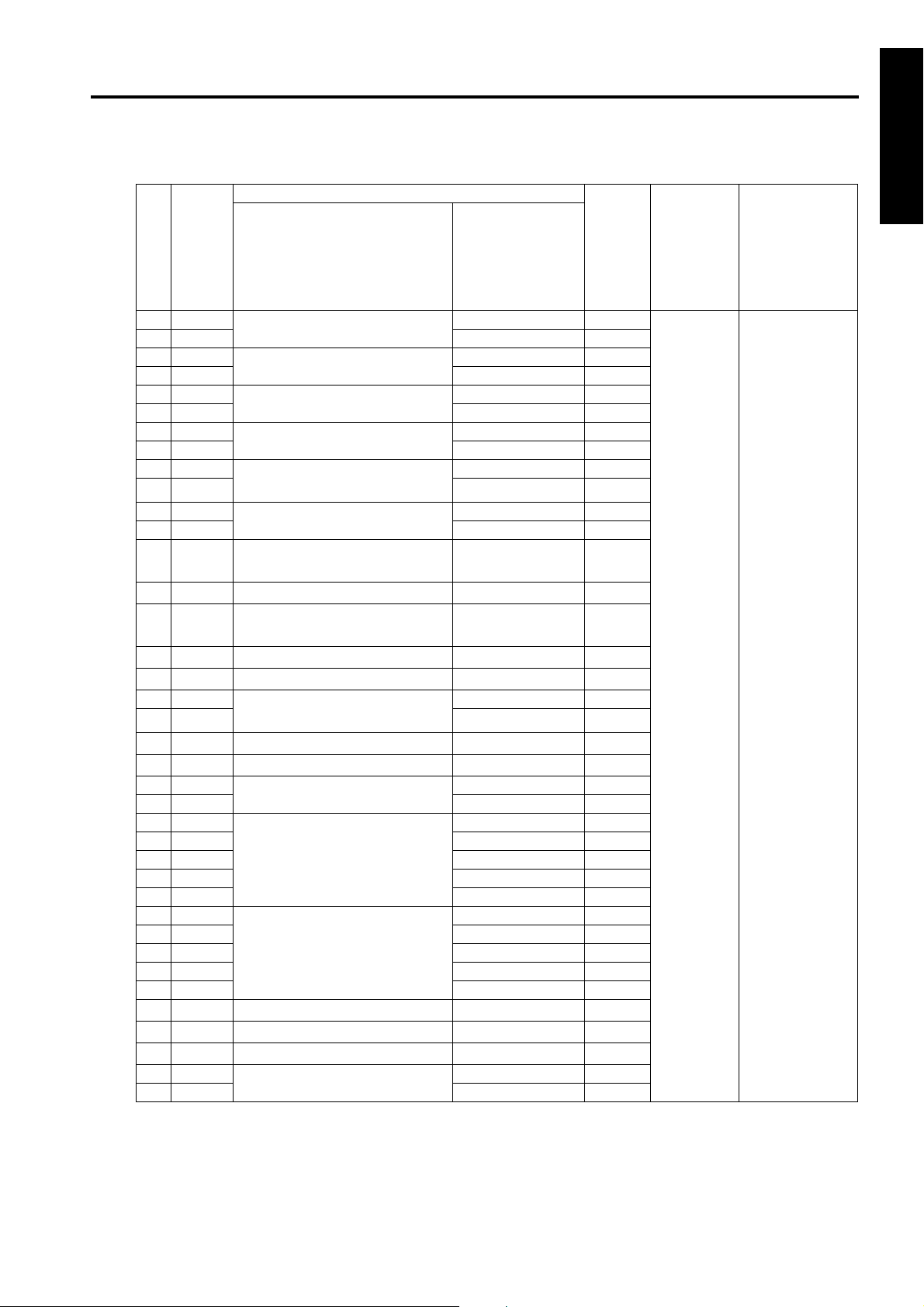

LIST OF ADJUSTMENT ITEMS ON 7155/7165

LIST OF ADJUSTMENT ITEMS ON 7155/7165

1 ADJUSTMENT

Item No.

Process

1

Adjustment

2Drum Pecu-

3

4

5 LD1 offset adjustment 1-51

6 LD2 offset adjustment 1-52

7

8

9

Image

10

Adjustment

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32 Finisher

Adjust-

33 Folding stopper adjustment 1-79

ment

34 Cover sheet tray size adjustment 1-80

Classification by Adjustment

High voltage

adjustment

liarity Adjustment

Tray Adjustment

Magnification

Adjustment

Timing Adjustment

RADF Adjustment

Centering

Adjustment

Warp Adjustment (Copier)

Stitch and fold stopper adjustment 1-79

Charging grid manual

adjustment

Blade setting mode

Auto maximum density

adjustment

Auto dot diameter

adjustment

Auto gamma adjustment (1dot)

Auto gamma adjustment (2dot)

Cartridge set mode

Printer vertical magnification adjustment

Printer horizontal magnification adjustment

Scanner (platen) vertical

adjustment

Scanner (RADF) vertical

adjustment

Printer leading edge timing adjustment

Printer registration loop

adjustment

Printer pre-registration

adjustment

Printer leading edge timing adjustment

Scanner (platen) leading

edge timing adjustment

Scanner (RADF) leading

edge timing adjustment

Scanner (RADF) registration loop adjustment

RADF density adjustment

RADF original size

adjustment

RADF incline offset

adjustment

Printer centering adjustment

Scanner (platen) centering adjustment

Scanner (RADF) centering adjustment

Scanner (platen) warp

(main scan)

Scanner (platen) warp

(sub-scan)

Scanner (RADF) warp

(main scan)

Scanner (RADF) warp

(sub-scan)

Adjustment Item

36

Mode

1-48

1-49

1-49

1-50

1-53

1-54

1-54

1-56

1-57

1-58

1-58

1-59

1-61

1-61

1-62

1-62

1-63

1-63

1-64

1-65

1-65

1-66

1-67

1-67

1-68

1-68

1-68

1-68

1-68

Page

Drum

Developer

Write unit

Dust-proof glass

Each tray unit

By-pass paper feed unit

Tray up/down wire

Registration roller

Registration unit

Registration clutch

Mis-centering detection sensor

ADU unit

CCD unit

Fixing unit

1

3

4 2 2 2

5 3 1 1

6 4

7 5

8 6 3 3

9 7

4 4

2 1

OO O

OO O

OO

OO

O OOO O

OO

(O)

OOO

OO

(O)

OO

OO

OO

OO

MODEL MANUAL REVISED EDITION DATE PAGE METHOD

Memory board

RADF unit

LCT

Finisher

Stapler unit

Cover sheet feeder

Puncher

O

O

O

O

O

O

O

O

O

OO

O

O

O

OO

O

O

O

OO

OO

OO

OO

OO

SERVICE HANDBOOK Nov. 20017155/7165

1-2

REPLACEMENT

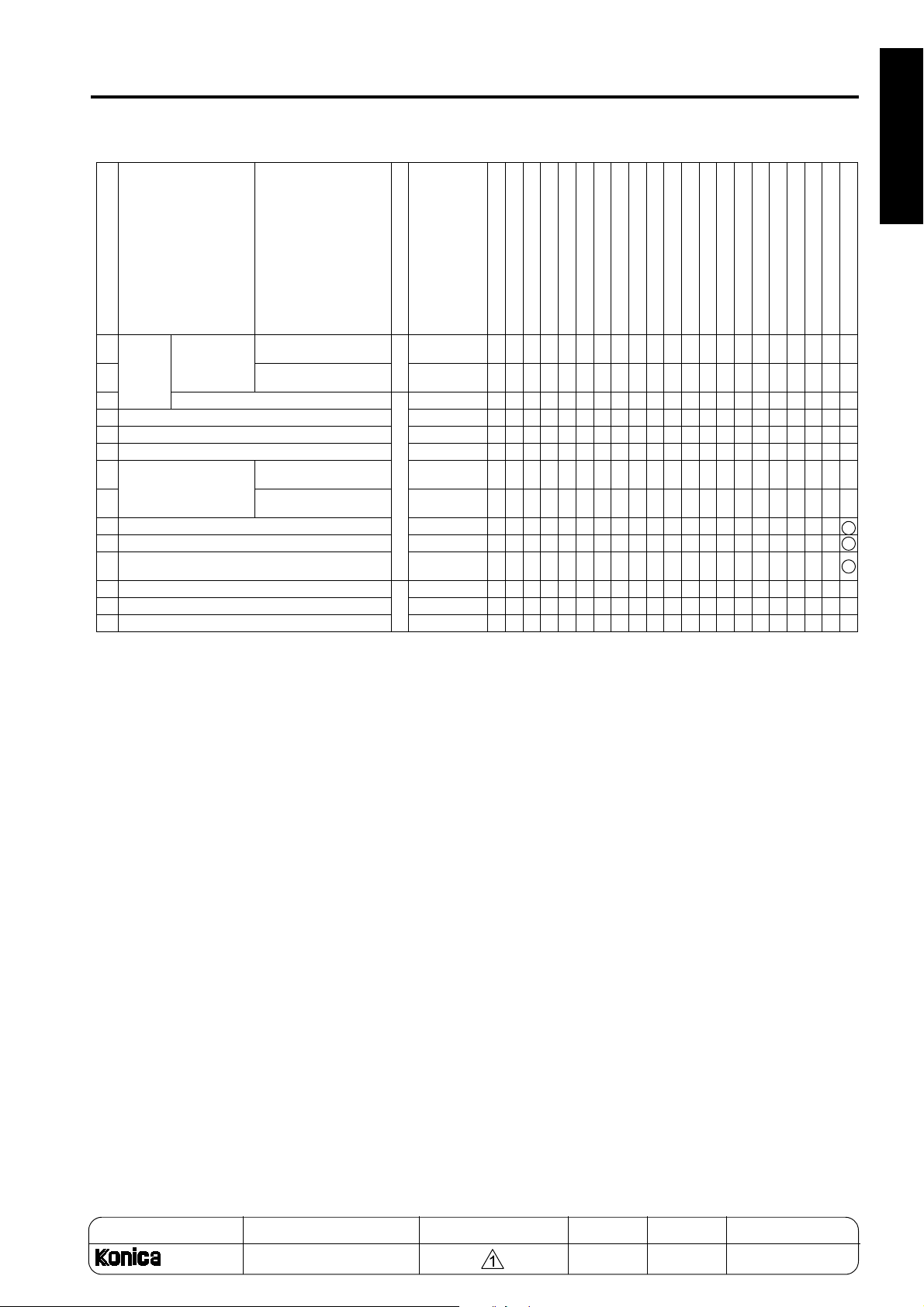

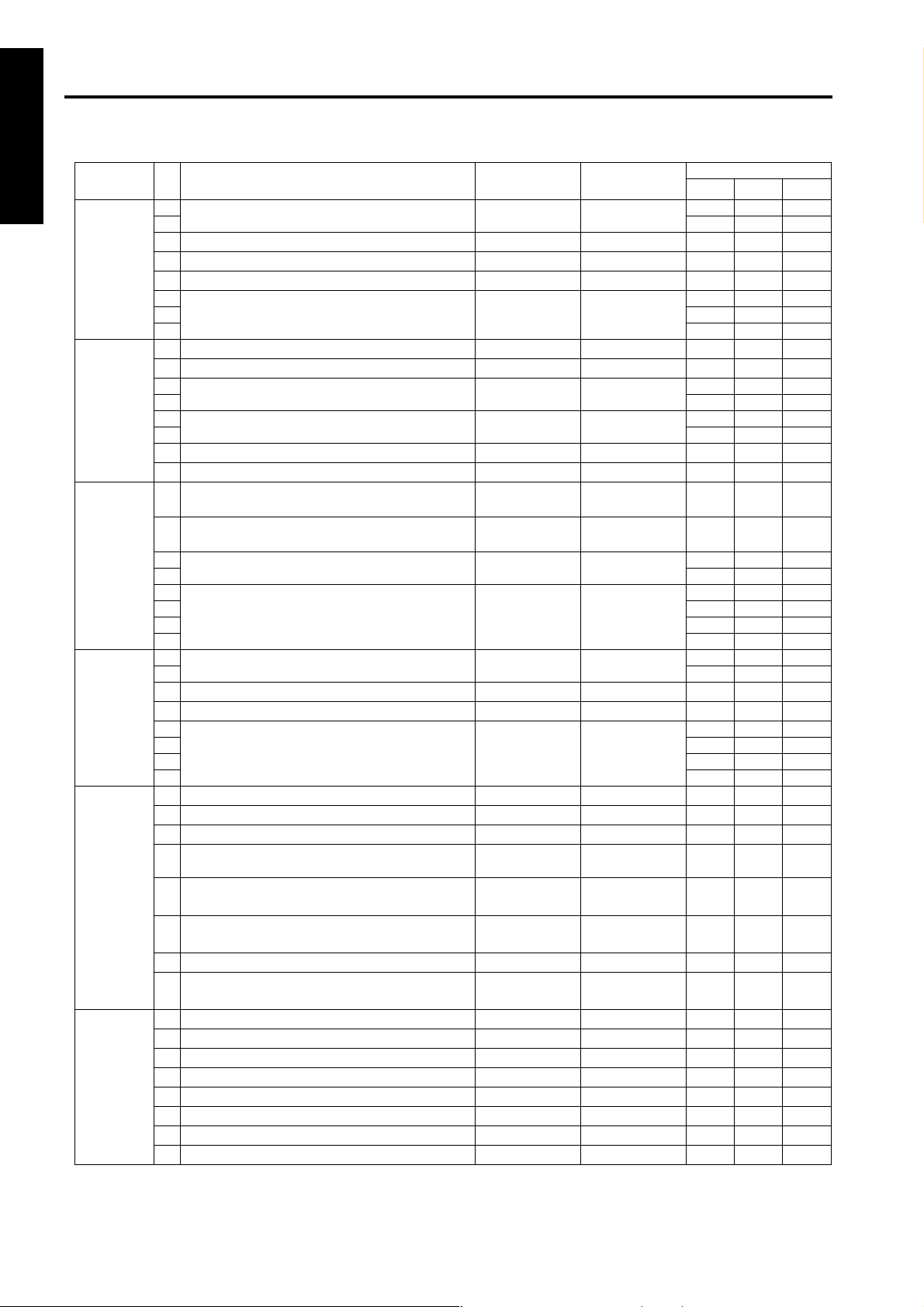

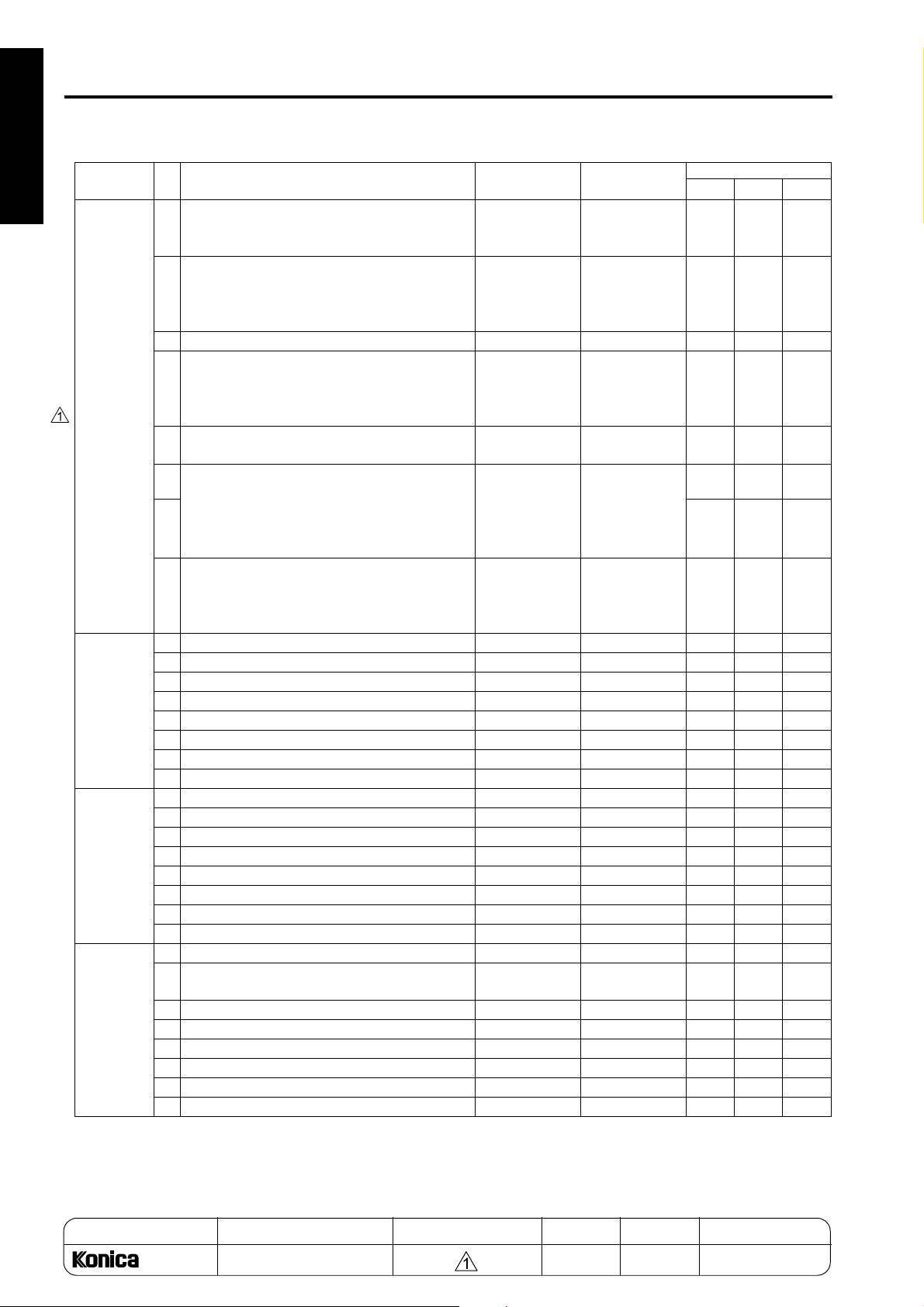

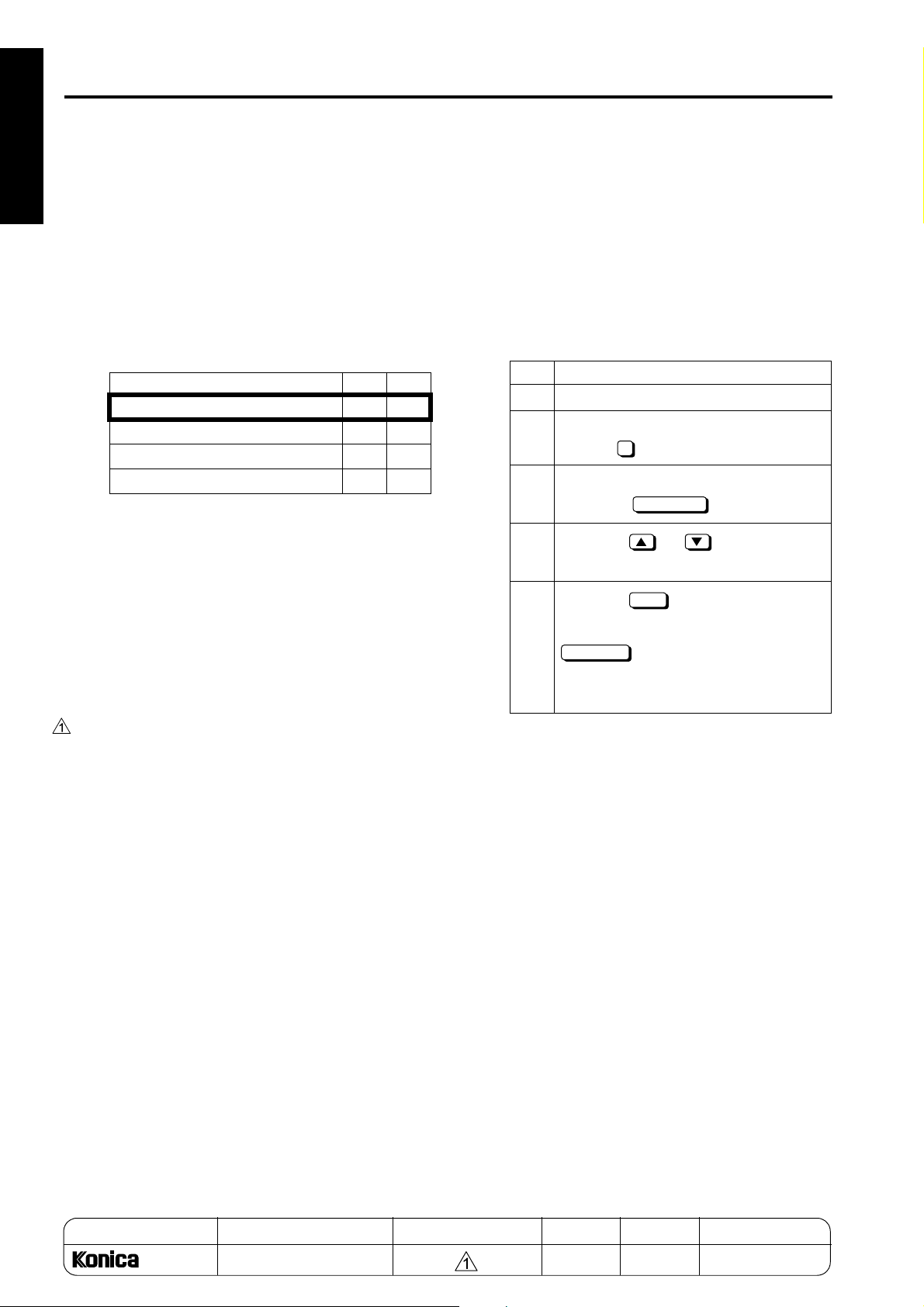

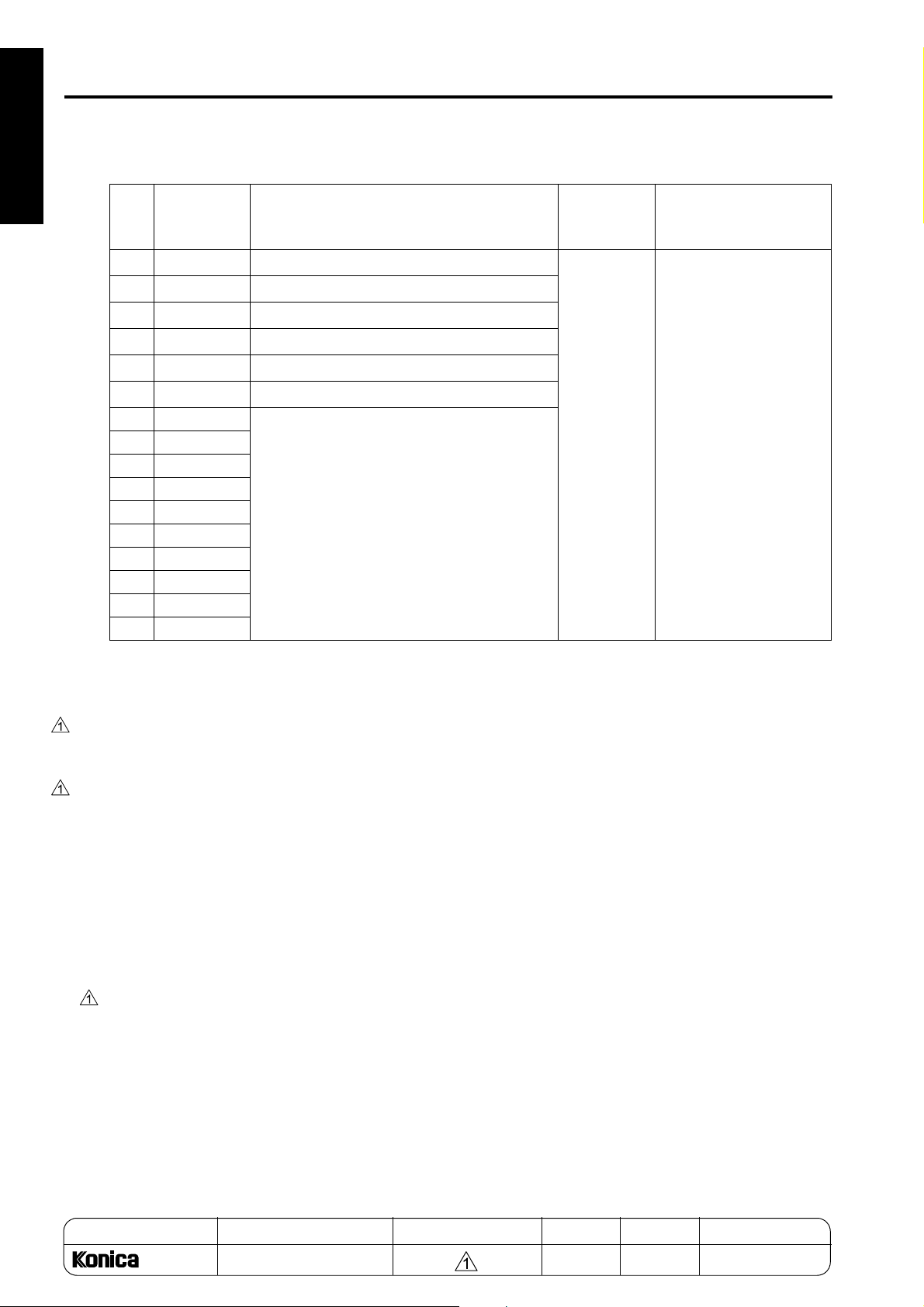

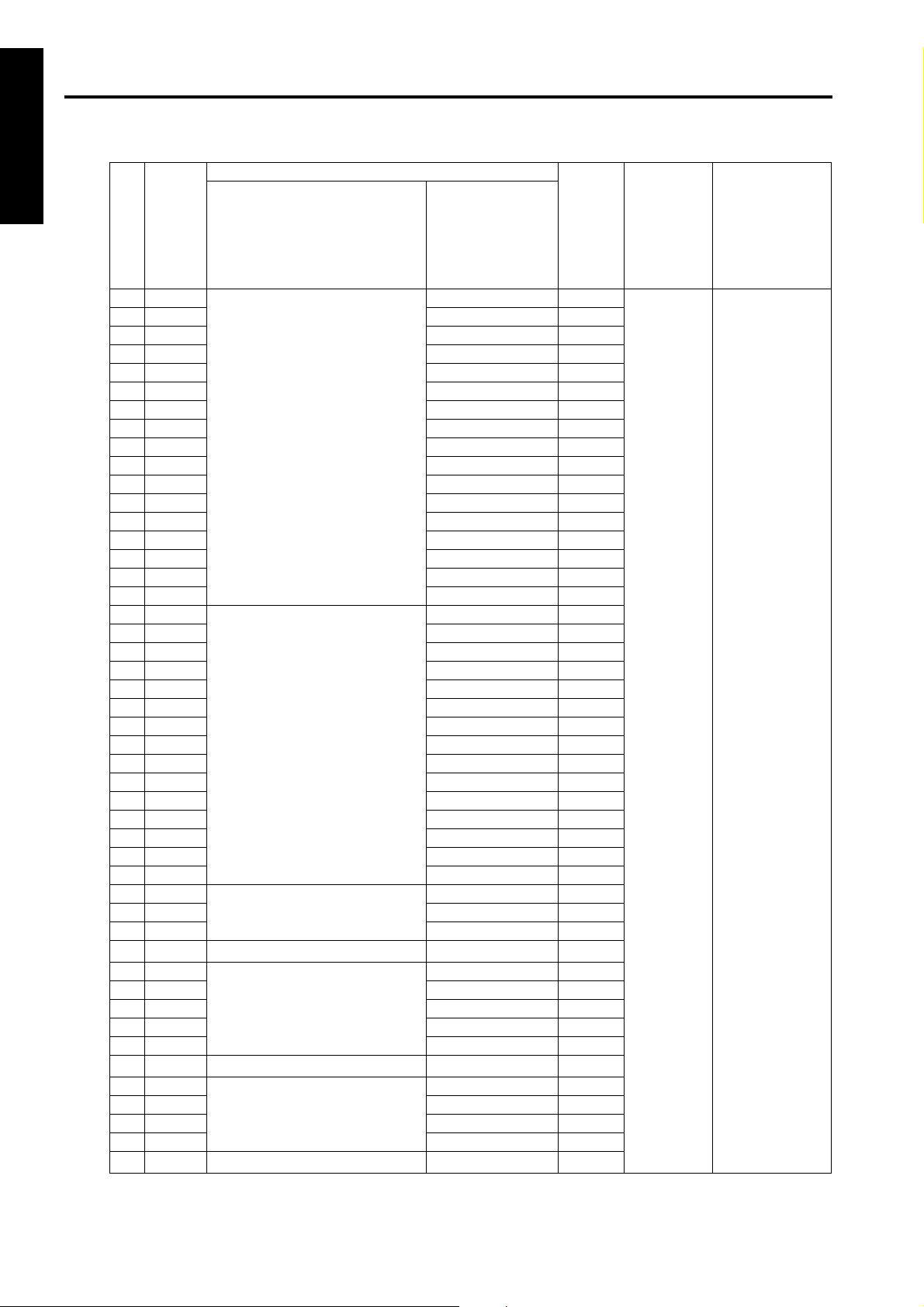

LIST OF ADJUSTMENT ITEMS ON 7155/7165

1 ADJUSTMENT

Item No.

Finisher

35

Adjustment

36

37 Three-holding adjustment

38 Tray Centering Adjustment 1-97

39 RADF Mounting Position Adjustment 1-108

40 RADF Skew Adjustment 1-109

RADF Paper Skew

41

Adjustment

42

43 PI Centering adjustment 1-129

44 PK Adjusting the Skew of Punched Holes Position 1-127

PK Adjusting the Vertical Positioning of Punched

45

Holes

46 Drum Count Reset 1-38

47 Developer Count Reset 25 1-38

48 Web Counter Reset 1-38

Classification by Adjustment

Punch Adjustment

Punch side-position

adjustment

Punch registration loop

adjustment

Face side of original

paper skew

Back side of original

paper skew

Adjustment Item

Mode

1-81

36

1-81

1-82

1-110

1-111

Other Adjustments

1-128

Caution: Replacing the image control board

• When a damaged image control board is replaced, the memory board on this board must be used on the

new image control board.

Only when the memory board is damaged, use a new memory board on a new control board.

Since the new memory board does not have adjustment data, the all adjustments are required. Before making the all adjustments, make the

47mode-92(output) " setting to make the new memory board effective.

"

• After making any adjustment, make the “47mode -96 (output) setting”. After made the “47mode-96 (output)”

setting, the adjustment data is saved.

• However, the “47mode-92” and -96” settings are protected to prevent them from careless operation. In order

to make “47mode -92” and -96” settings using the saved adjustment data, the protection must be disabled.

For the unprotection method, contact the service manager ot the authorized distributor.

Page

Drum

O

O

Developer

Write unit

Dust-proof glass

Each tray unit

By-pass paper feed unit

Tray up/down wire

Registration roller

Registration unit

Registration clutch

Mis-centering detection sensor

ADU unit

CCD unit

Fixing unit

Memory board

RADF unit

LCT

Finisher

Stapler unit

Cover sheet feeder

Puncher

OO

OO

OO

OO

O

O

O

O

3

1

2

O

MODEL MANUAL REVISED EDITION DATE PAGE METHOD

SERVICE HANDBOOK Nov. 20017155/7165

1-3 REPLACEMENT

LCD ADJUSTMENT

LCD ADJUSTMENT

1 ADJUSTMENT

[1] LCD Control Panel Adjustment

Enter the key operator mode and select " Touch

panel adjustment" to adjust the LCD touch panel.

*If you cannot select the touch panel adjustment

mode pressing any numeric key after entering

key operator mode will take you directly to "

Touch panel adjustment".

[2] LCD Panel Contrast/Key Sound

Adjustment

Enter the key operation mode and select " LCD

Panel contrast/Key sound adjustment" to adjust the

contrast, backlight, and/or buzzer as desired.

10

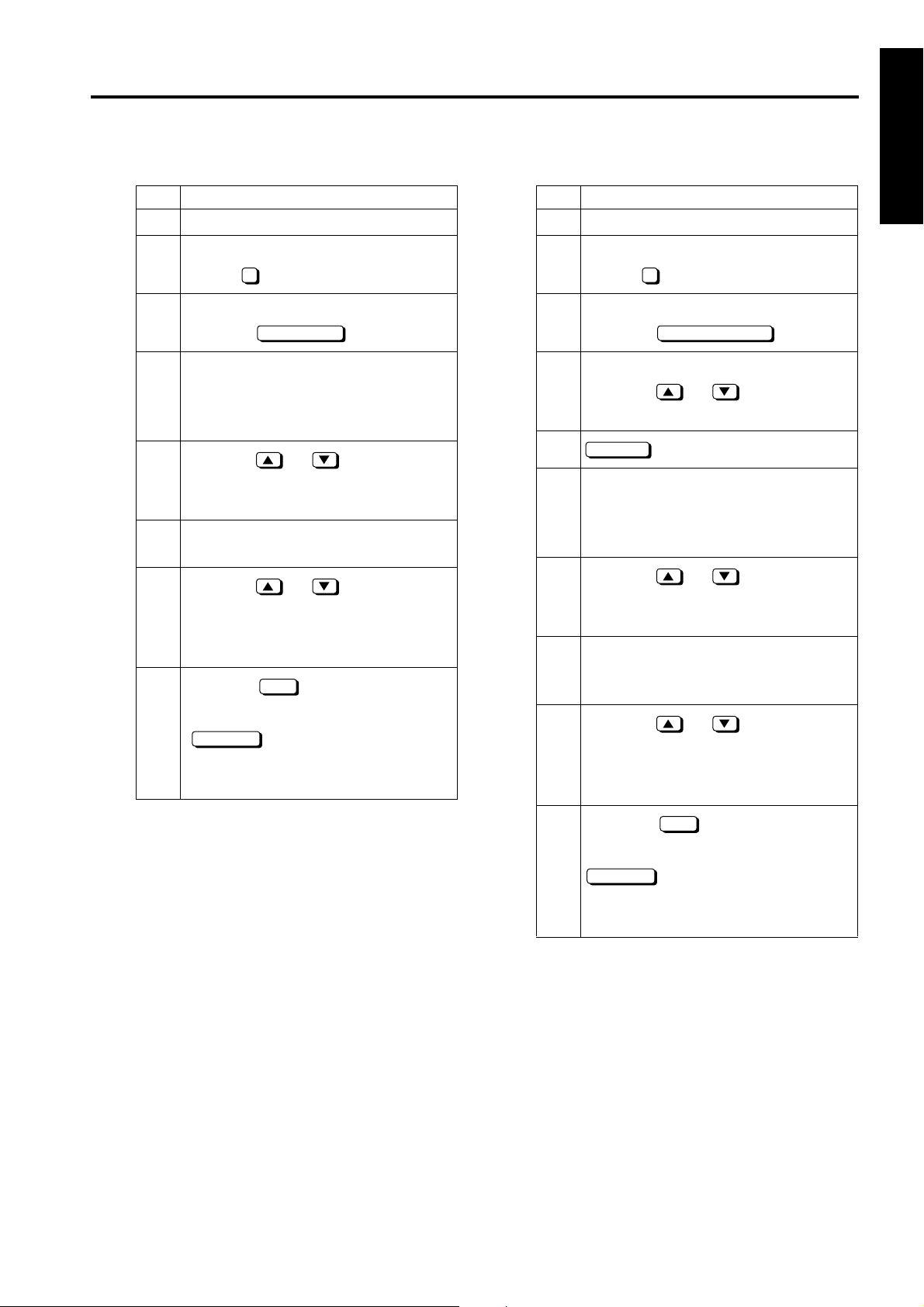

SETTINGS AND ADJUSTMENTS MADE WITH THE P FUNCTION

The P function allows you to perform following numerical value checks using the P button:

10

7

1. Total counter

2. Copier counter

3. Printer counter

4. * PM counter

5. Density Shift (Auto <Text/Photo>)

6. Density Shift (Inclease Contrust)

7. Density Shift (Photo)

8. Density Shift (Text)

* PM counter is only displayed when Check

key is pressed on the operation panel.

!

[1] Checking and Printing the P Function

1. Turn ON the SW2 (sub power).

2. Press the P button.

3. Counter list is displayed.

4. Press the key.

5. Press the START button to print out the counter

list. The P function is cancelled automatically.

6. If the counter list need not be displayed, press

the key.

COUNTER MENU

EXIT

[2] Setting up the P Function

1. Turn ON the SW2 (sub power).

2. Press the key.

3. Select the required image quality, text, photo etc.

Then press the P button to set the desired density shift.

4. Enter a value (0-5) with a numeric key, then

press the key. The smaller the value, the

darker the density.

5. Press the key to return to the Basic

screen.

SPECIAL

ORIGINAL

OK

OK

1-4

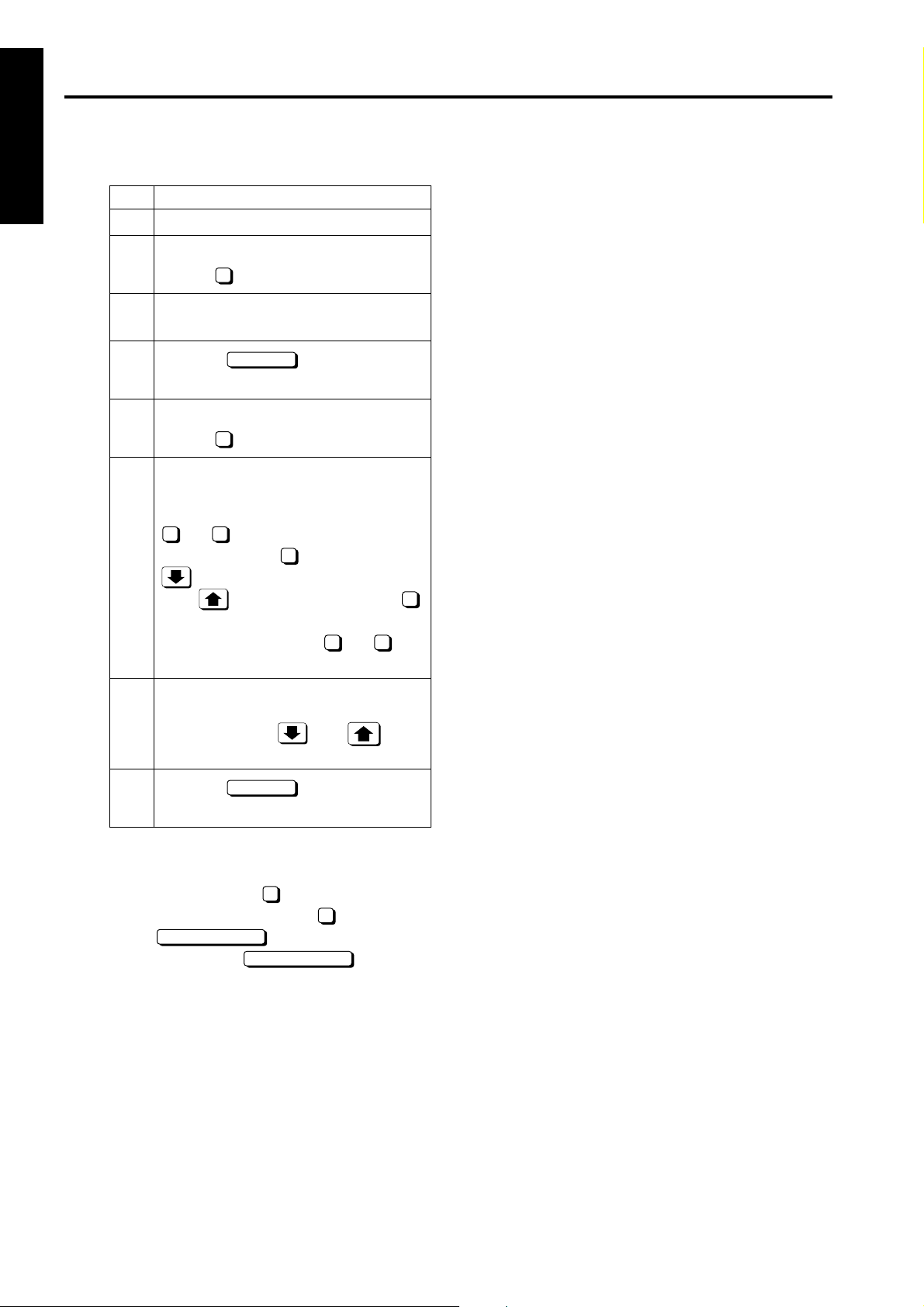

MODE CHANGING MENU

[1] Mode Selection

MODE CHANGING MENU

You can select a mode from the following [Mode changing menu: [Select mode] without turning OFF and ON

the power switch.

1

Basic screen

2

3-6 mode

3

2-5 mode

4

Key operation mode

5

4-7 mode

Step Operation

Turn on the SW2 (sub power).

1

Press P button and wait until [Enter pass-

word for mode selection] message

2

appears.

1 ADJUSTMENT

Enter the password 9272 and press the

Start button.(Note that this password is

3

fixed and cannot be changed.)The [Mode

changing menu] appears.

Enter the number to select the desired

4

mode.

To return to the [Mode changing menu],

press P button and wait until the menu

5

appears again.

Upon completion of the adjustment, press

6

EXIT

key to return to the Basic screen.

1-5

25 MODE

25 MODE

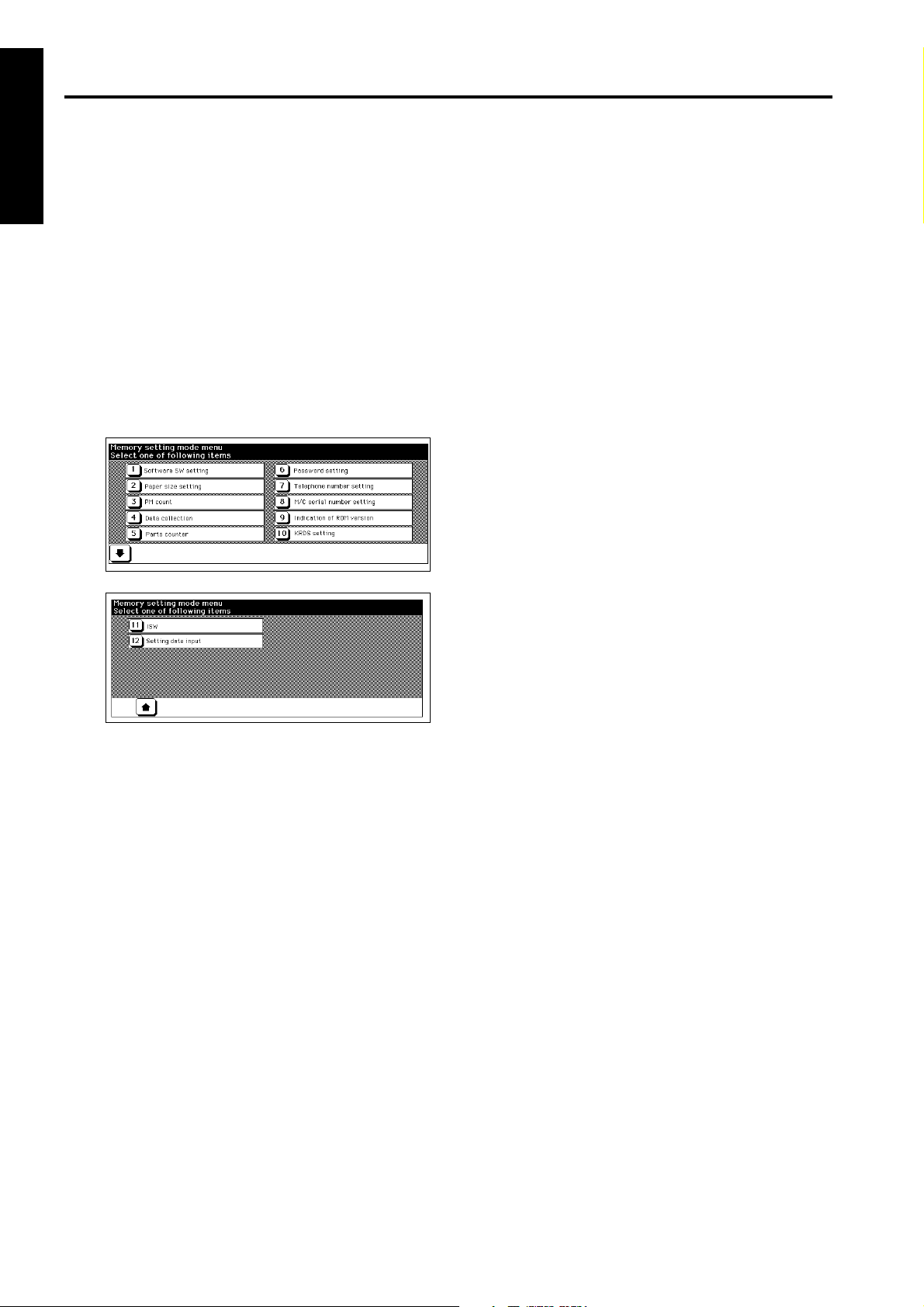

[1] Setting the 25 Mode

This machine has an adjustment mode called the "25

1 ADJUSTMENT

Mode". Select this mode to rewrite data in the non-volatile memory or make various settings.

1. Turn OFF the SW2 (sub power).

2. While pressing the copy quantity setting button 2

and 5, turn ON the SW2 (sub power).

The Memory setting mode menu Screen will

appear.

Now the machine is in the 25 mode, disabling

normal copy operations.

[Memory setting mode menu Screen]

3. Press the numeric button of the desired setting

item.

The associated setting screen will appear.

4. Enter data in the setting screen.

5. Turning OFF the SW2 (sub power) cancels the

25 mode.

6. New data will take effect after restart.

1-6

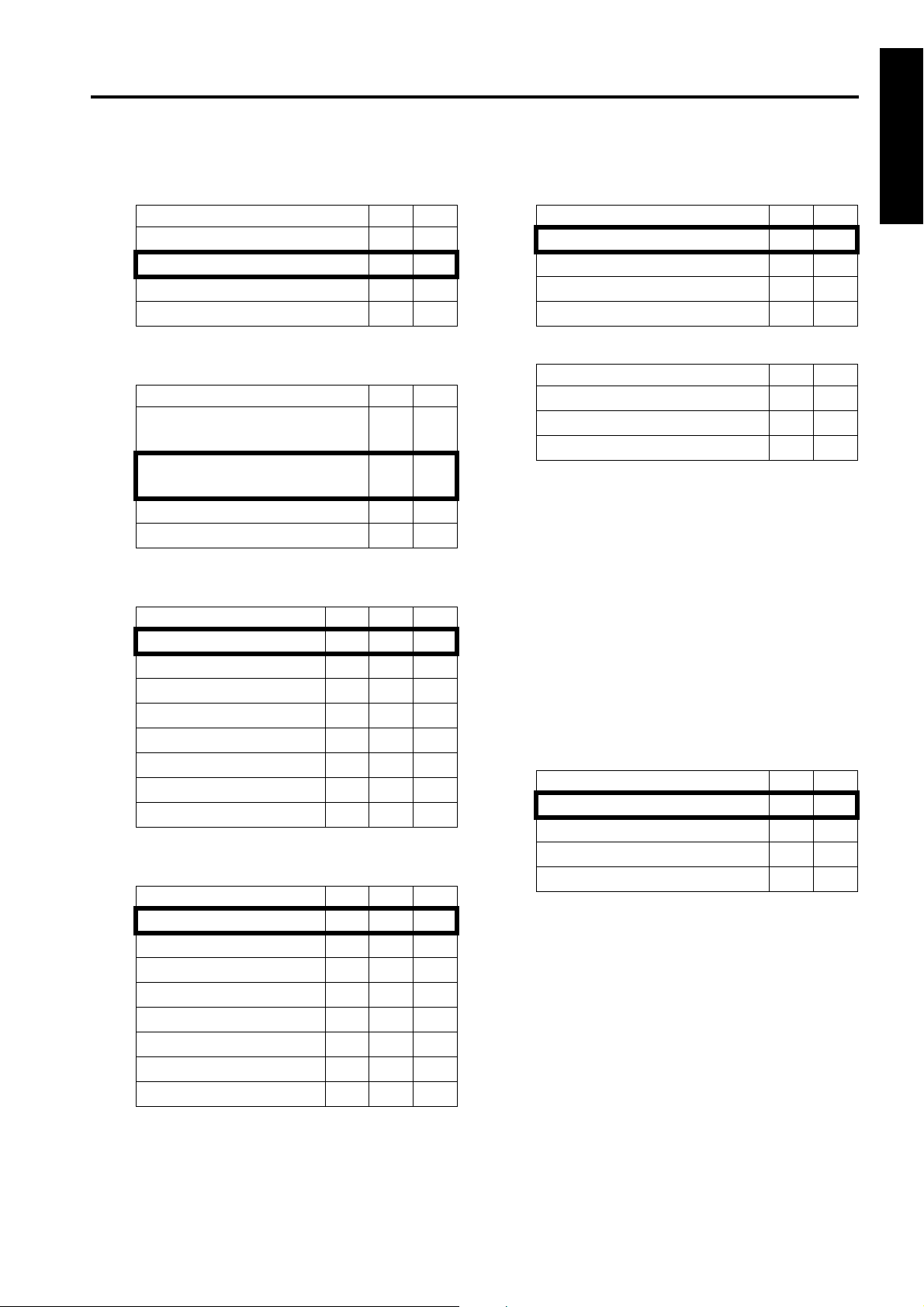

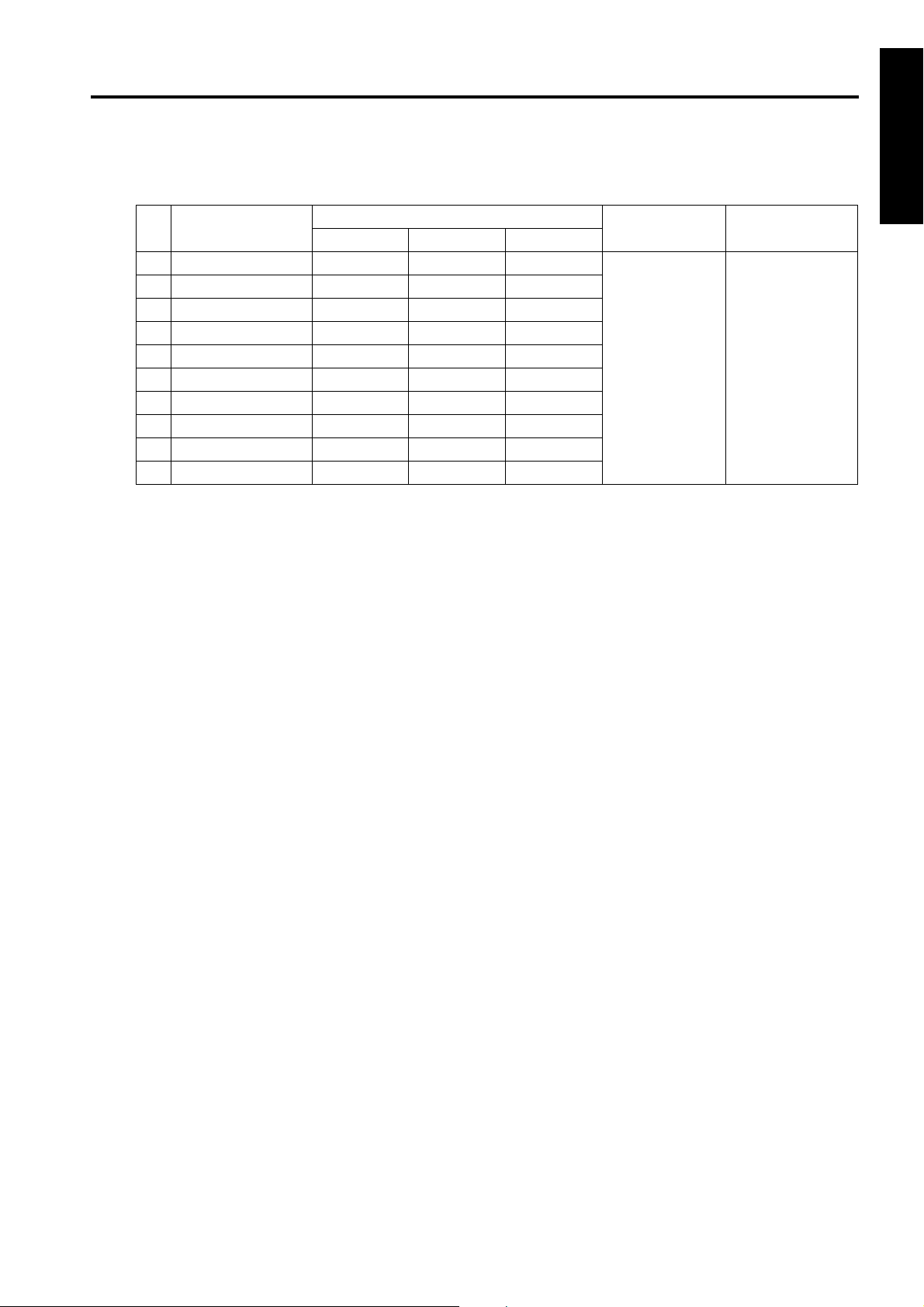

[2] List of Adjustment Items for 25 Mode

Adjustment Item Menu Remarks

Software DIP SW setting See "list of Software DIP

1

Paper size setting

2

PM count Resetting PM Count

3

Setting PM cycle

Data collection Total count of each paper size

4 1

Copy count of each paper size

2

Print count of each paper size

3

RADF count

4

Black ratio of each section

5

Black ratio ranking list

6

JAM data of time series

7

JAM count

8

Count of each copy mode

9

SC count

10

JAM count of each section

11

SC count of each section

12

Parts counter Count of special parts COUNT RESET

5 1

Count of each part COUNT RESET

2

Password setting Key Operator password 4 digits

6

EKC master key code 8 digits

Weekly timer password 4 digits

HDD management password 4 digits

Telephone/Fax number set-

7

ting

M/C serial number setting Main body

8

Indication of ROM version Indication of versions of

9

KRDS setting Setting Host Call See Chapter 3.

10 1

ISW updating

11

Setting date input

12

Customer support telephone number 16 digits

Customer support FAX number 16 digits

Optional tray

Finisher

Setting Host Password

2

Setting KRDS Phone Number

3

Setting KRDS Software SW

4

Setting KRDS Setup

5

25 MODE

1 ADJUSTMENT

Switches".

Part name setting

P/N setting

Limit Setting

ROMs installed in the image

control, printer control, finisher, and Z-fold.

1-7

25 MODE

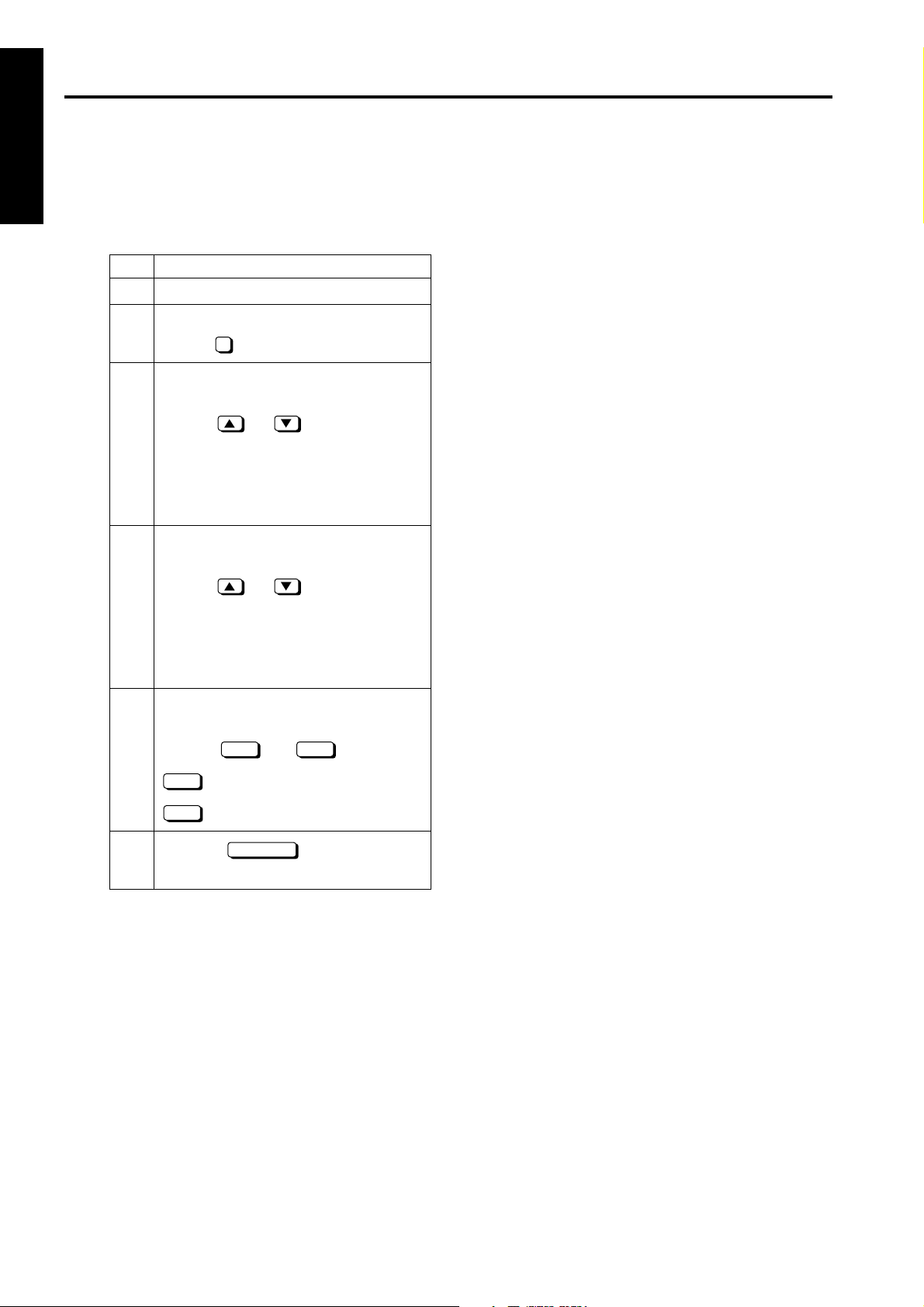

[3] Setting Software DIP Switches

1 ADJUSTMENT

1. Procedure

Bring up the Software DIP SW Setting screen

and set software DIP switches.

Step Operation

Enter the 25 mode.

1

[Memory setting mode menu Screen]

2

Select " Software DIP SW setting".

[Software DIP SW setting screen]

Select a DIP switch number.

Use the or key or numeric

3

keys.

To use numeric keys, press the DIP

switch number key at the left before

entering a DIP switch number.

Select a bit number of the selected DIP

switch.

1

Use the or key or numeric

4

keys.

To use numeric keys, press the bit number key at the upper center before entering a DIP switch number.

Select ON (=1), or OFF (=0) of the

switch.

Use the or key.

5

ON

OFF

Press the key to return to the

6

ON OFF

: Sets 1.

: Sets 0.

RETURN

Memory setting mode menu Screen.

For the function of each switch, refer to “list of

Software DIP Switches”.

1-8

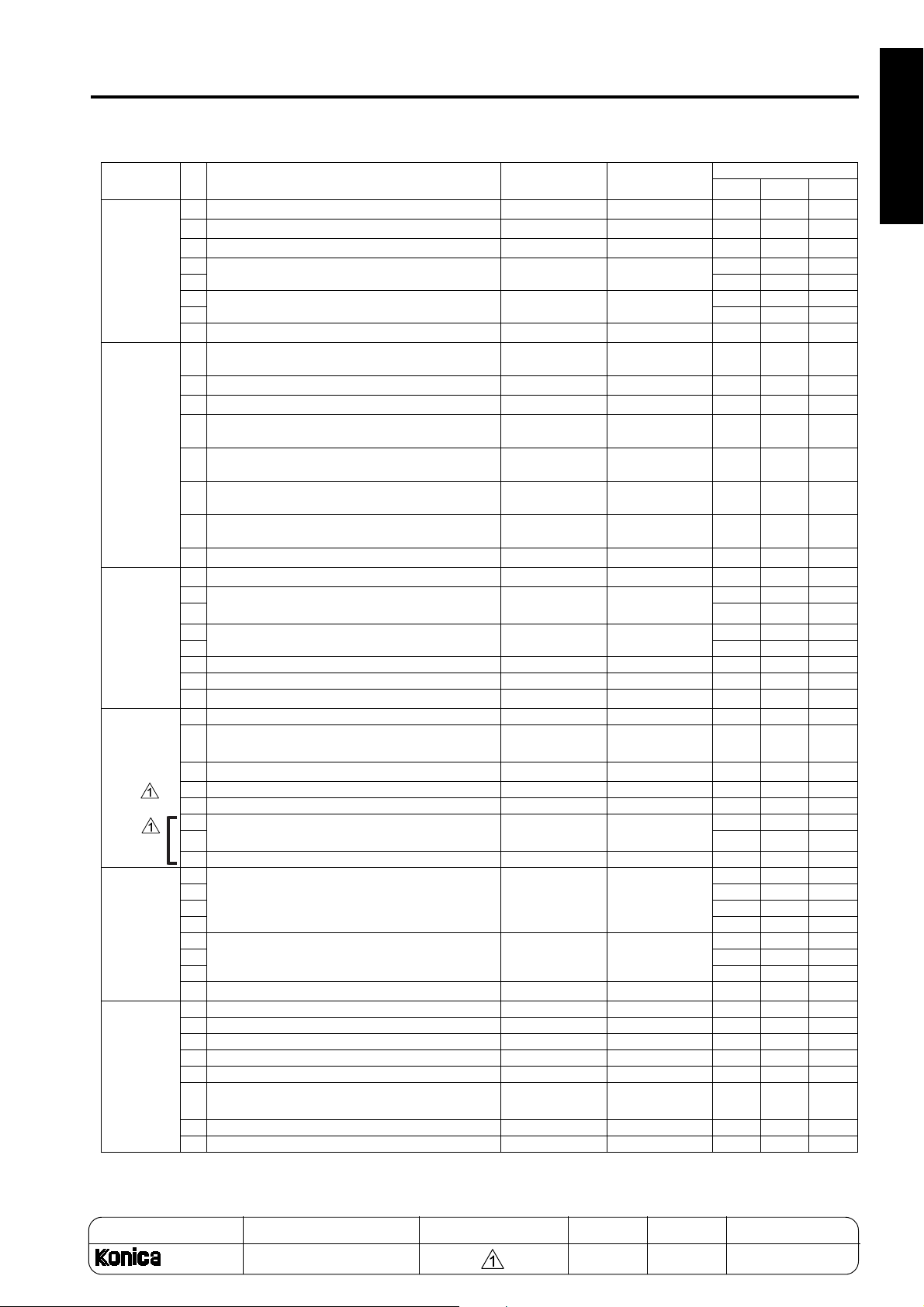

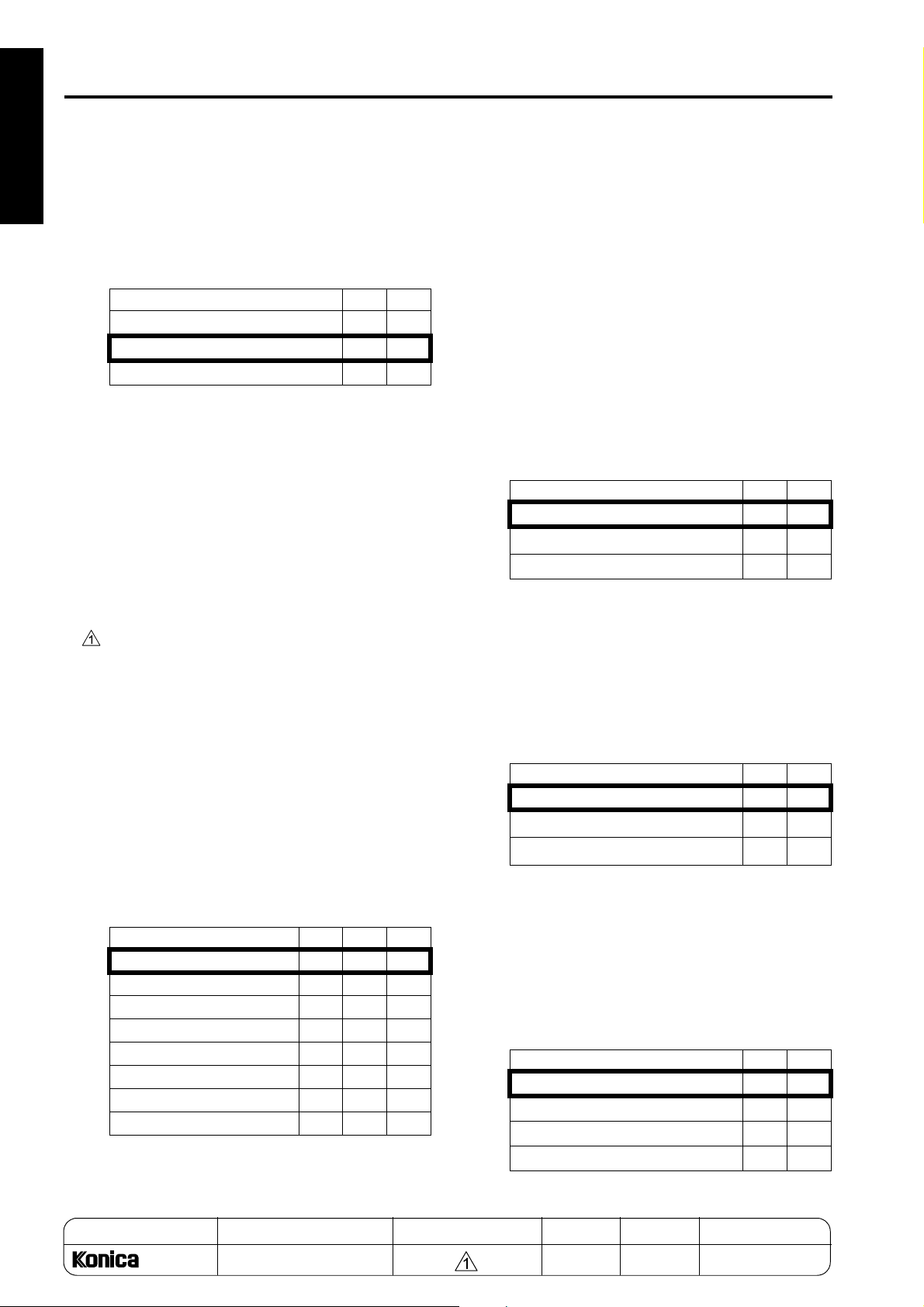

< List of Software Switches >

DIPSW

No.

Bit Function 0 1

0 Condition for stopping copying after indica-

tion of toner supply

1 000

2 Method for stopping copying after indica-

tion of toner supply

3 000

DIPSW 1

Inhibition of copying when PM count is

4

reached

5

Number of copies made before inhibition of

6 000

copying when PM count is reached

7 000

Hard disk connection

0

1 Electrode cleaning cycle (when power is

2 000

turned ON, fixing temperature is 50ºC or

3 000

DIPSW2

DIPSW3

DIPSW4

less)

4 Electrode cleaning cycle (after power is

turned ON)

5 000

-

6

-

7

-

0

SC latch

1

25, 36, 47 mode password request (pass-

2

word: 9272)

Charger cleaning function

3

Transfer/separation cleaning function

4

-

5

47 mode 15-01 data collection clearing

6

JobEditor connection

7

ADF automatic skew adjustment

0

Inhibition of postcard double sided copy

1

2

Destination selection

3 001

Key counter removal recovery

4

Inhibition of magnified APS

5

Fixed magnification rate setting change in

6

key operator mode

A3 (11x17) counting method

7

0 Image density selection (Toner concentra-

tion threshold)

1 000

2

Image density selection (laser PWM)

DIPSW5

3 000

-

4

- - -

5

-

6

-

7

0

Transfer/separation output for plain paper

1 000

2 000

3

DIPSW 6

Transfer/separation output for thick paper

4 000

5

Transfer/separation output for thin paper

6 000

-

7

25 MODE

Initial Value

Japan Inch Metric

* 1 * 1

* 2 * 2

111

111

Disabled Inhibited 0 0 0

000

* 3 * 3

Disconnected Connected 0 0 0

000

* 4 * 4

* 5 * 5

000

- - 000

- - 000

- - 000

Unlatched Latched 0 0 0

Not requested Requested 0 0 0

ON OFF 0 0 0

ON OFF 0 0 0

- - 000

Disabled Enabled 0 0 0

Disconnected Connected 0 0 0

Enabled Disabled 0 0 0

Disabled Enabled 0 0 0

* 6 * 6

010

Disabled Enabled 0 0 0

Enabled Disabled 0 1 0

Enabled Disabled 1 0 0

Incremented by 1Incremented by

2

* 7 * 7

* 8 * 8

000

000

111

- - 000

000

- - 000

- - 000

000

* 9 * 9

* 10 * 10

* 11 * 11

000

000

- - 000

1 ADJUSTMENT

1-9

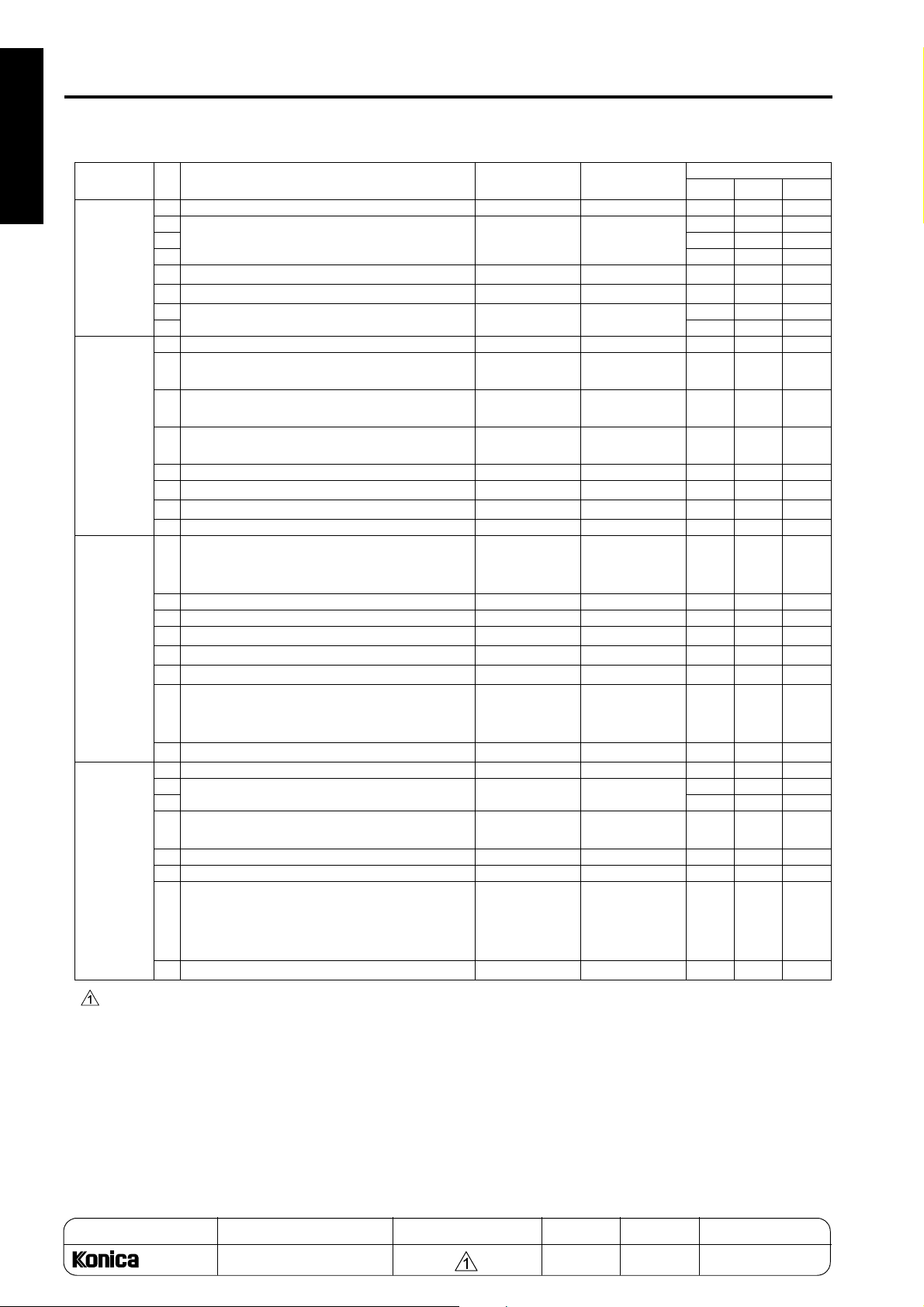

25 MODE

1 ADJUSTMENT

DIPSW

No.

DIPSW 7

DIPSW8

DIPSW 9

DIPSW10

DIPSW11

DIPSW 12

Bit Function 0 1

0

Toner guide roller current correction

1 000

-

2

-

3

-

4

5

Transfer/separation output for recycled

6 000

paper

7 000

-

0

- - -

1

2

Fixing roller initial rotation

3 111

4

Fixing roller initial rotation time setting

5 000

A3(11 × 17) PM counter switch

6

Store on hard disk

7

Operation at key counter removal (copy)

0

Operation at key counter removal (IP-511)

1

2

Message switching

3 000

* 12 * 12

- - 000

- - 000

- - 000

* 13 * 13

- - 000

* 14 * 14

* 15 * 15

1 count 2 count 0 0 0

Enable Disable 0 0 0

Same as stop

key

Ignored

Immediate

stop (JAM)

Same as

DIPSW9-0

* 16 * 16

4

5 000

Copy count limit

6 000

* 17 * 17

Initial Value

Japan Inch Metric

000

000

000

000

011

0 0 0

000

000

000

7 000

0

Page memory allocation when powered.

1 000

Page memory allocation when job starts

2

-

3

* 18 * 18

* 19 * 19 0 0 0

- - 000

4

Transfer/separation output for high-quality

5 000

paper

6 000

* 20 * 20

000

000

7 000

-

0

-

1

-

2

SC/E code screen switchover

3

Selection of filter for jagged edges on slant-

4

ing lines

Tone switchover in photo mode

5

-

6

JAM indication screen type

7

Black stripe creation interval

0

-

1

-

2

Printer automatic centering correction

3

High voltage output in 36/47 mode

4

-

5

-

6

-

7

- - 000

- - 000

- - 000

Switched

Not switched (All

are F codes)

000

Not selected Selected 0 0 0

2bitED-2dot

PWM

1bitED-2dot

PWM

000

- - 000

Without Jam

code

Every 10 copies Every 50 copies

With Jam code 0 0 0

000

- - 000

- - 000

Enable Disable 0 0 0

Not output Output 1 1 1

- - 000

- - 000

- - 000

1-10

25 MODE

DIPSW

No.

DIPSW 13

DIPSW14

DIPSW15

DIPSW16

DIPSW17

DIPSW18

Bit Function 0 1

Size detection 1

0

Size detection 2

1

Size detection 3

2

3

Size detection 4

4 010

5

F4 size detection

6 000

-

7

0 Size detection 5 (main body)

-

1

-

2

3 Size detection 5 (by-pass feed)

4 Size detection 5 (platen)

5 Size detection 5 (ADF)

6 Size detection 5 (PI)

-

7

-

0

1 Maximum number of sheets to an be sta2 000

pled

3

FNS alarm stop SW * 24 * 24

4 000

A5 5.5 x 8.5 0 1 0

A4R 8.5 x 11R 0 1 0

8.5 x 14 F4 0 0 1

* 21 * 21

* 22 * 22

- - 000

B4 : 11 x 17/

B5 : 8.5 x 11/B5R

8K/16K/16KR 0 0 0

- - 000

- - 000

B4 : 11 x 17/

B5 : 8.5 x 11/B5R

B4 : 11 x 17/

B5 : 8.5 x 11/B5R

B4 : 11 x 17/

B5 : 8.5 x 11/B5R

B4 : 11 x 17/

B5 : 8.5 x 11/B5R

8K/16K/16KR 0 0 0

8K/16K/16KR 0 0 0

8K/16K/16KR 0 0 0

8K/16K/16KR 0 0 0

- - 000

- - 000

* 23 * 23

Initial Value

Japan Inch Metric

000

000

000

000

5 KRDS modem connection recognition Disconnect Connect 0 0 0

6 Dmax. value in printer mode 1.43 1.35 0 0 0

-

7

- - 000

0 - - - 000

1Multi-job

-

2

Reservation

enabled

- - 000

Reservation

disabled

000

3 C(K) counting in printer mode Not counted Counted 0 0 0

4 TC start date indication (P mode) Indicated Not indicated 0 0 0

5 Non-original area automatic erasure mode

6 000

judgement level

* 25 * 25

000

7 - - - 000

0

1 111

Weekly timer summer time setting * 26 * 26

2 111

000

3 000

4

Density selection for scanning tab paper * 27 * 27

5 000

000

6 000

-

7

- - 000

0 Tray 1's faulty part isolation Normal Unavailable 0 0 0

1 Tray 2's faulty part isolation Normal Unavailable 0 0 0

2 Tray 3's faulty part isolation Normal Unavailable 0 0 0

3 LCT faulty part isolation Normal Unavailable 0 0 0

4 ADF faulty part isolation Normal Unavailable 0 0 0

Folding, stapling and three-holding faulty

5

part isolation

Normal Unavailable 0 0 0

6 PI faulty part isolation Normal Unavailable 0 0 0

7 HDD faulty part isolation Normal Unavailable 0 0 0

1 ADJUSTMENT

MODEL MANUAL REVISED EDITION DATE PAGE METHOD

SERVICE HANDBOOK Nov. 20017155/7165

REPLACEMENT1-11

25 MODE

1 ADJUSTMENT

DIPSW

No.

DIPSW 19

DIPSW20

DIPSW21

DIPSW22

Bit Function 0 1

Initial Value

Japan Inch Metric

0 - - - 000

1

Fixing temperature setting switch over

2 000

* 28 * 28

000

3 000

-

4

PK faulty part isolation

5

6

IP scanner default resolution * 29 * 29

7 000

- - 000

Normal Unavailable 0 0 0

000

0 Group stapling Disabled Enabled 0 0 0

Original size scanning with shift function

1

(Note1)

2 Stamp page number switching

Normal

Based on original

3 Keyboard layout ABC layout

Original priority

Based on

transfer paper

QWERTY layout

000

000

000

4 - - - 000

-

5

-

6

- - 000

- - 000

7 Tandem connection Disconnected Connected 0 0 0

Mixed sized print stapling inhibition

0

(IP-511)

Enabled (realtime output)

Disabled

(batch processing)

000

1 LCT size setting in key operator mode Disabled Enabled 0 0 0

2 Original count display Displayed Not displayed 0 0 0

-

3

-

4

-

5

- - 000

- - 000

- - 000

Enabled

Special paper APS response

6

Disabled

(except thick

000

paper)

-

7

- - 000

0 IP address setting Inhibited Allowed 1 1 1

1

Number of punched holes * 30 * 30

2 001

Image reference position of unspecified

3

size of paper

- - 000

010

4 Power save button function Enabled Disabled 0 0 0

5 - - - 000

Request for

6 FNS no staple operation

Staple supply

requested

staple supply

and stapling

000

canceled

-

7

- - 000

Note1:When "Normal" is selected, the original size is compared with the copy paper size and the smaller one

is assumed to be the image area size. When "Original priority" is selected, the original size is com-

pared assumed to be the image area size only when the image shift mode is selected.

MODEL MANUAL REVISED EDITION DATE PAGE METHOD

SERVICE HANDBOOK Nov. 20017155/7165

1-12

REPLACEMENT

25 MODE

DIPSW

No.

DIPSW23

DIPSW24

Bit Function 0 1

Initial Value

Japan Inch Metric

0 - - - 000

Operation when printer EKC password is

not matched

1

Counted and

output to EKC

or other user

domain

Not output

(display it on

the JOB list

that is not pro-

000

duced)

Image density selection (toner density

2

selection of developer)

3

- - - 000

4

- - - 000

5

Registration of by-pass special paper set-

6

ting for JOB memory

- - - 000

7

Method of accessing Hard disk JOB Password Password +

0

Job Editor scan data transfer method Pull type Push type 0 0 0

1

- - - 000

2

- - - 000

3

- - - 000

4

- - - 000

5

- - - 000

6

- - - 000

7

* 31 * 31 0 0 0

000

Prohibited Allowed 0 0 0

000

file name

1 ADJUSTMENT

MODEL MANUAL REVISED EDITION DATE PAGE METHOD

SERVICE HANDBOOK Nov. 20017155/7165

REPLACEMENT1-13

25 MODE

1 ADJUSTMENT

DIPSW

No.

DIPSW27

DIPSW28

DIPSW29

DIPSW30

Bit Function 0 1

Image's gray background control at power

ON

0

Not performed Performed

Initial Value

Japan Inch Metric

000

(toner density reduction control) *32

's gray background control at power

Image

ON

1

(toner recycle MC control during printing)

Not performed Performed

000

*32

Toner supply operation (use prohibited) Performed Not performed

2

Image

s gray background control at power

'

ON

3

(drum/developer rotation control at power

Not performed Performed

000

000

ON after γ correction) *32

Image density optimization control (use

4

prohibited)

Image

s gray background control at power

5

'

ON

Performed Not performed

Not performed Performed

000

000

(toner recycle MC ON control during drum/

developer rotation performed when the

6 000

power is turned ON) *32

Image

s gray background control at power

'

ON

7

(toner recycle MC ON control during Dmax

Not performed Performed

000

and γ correction) *32

- - -

0

- - -

1

- - -

2

Limitation of punch function Selected Not selected

3

- - -

4

- - -

5

- - -

6

- - -

7

- - -

0

- - -

1

- - -

2

- - -

3

- - -

4

- - -

5

- - -

6

- - -

7

- - -

0

25 mode collection data 7-12 for checking Display

1

- - -

2

- - -

3

- - -

4

- - -

5

- - -

6

Passwords to save/access hard disk JOB Not displayed Displayed

7

restriction

No display

restriction

000

000

000

000

000

000

000

000

000

000

000

000

000

000

000

000

000

000

000

000

000

000

000

000

MODEL MANUAL REVISED EDITION DATE PAGE METHOD

SERVICE HANDBOOK Nov. 20017155/7165

1-14

REPLACEMENT

25 MODE

*1 Condition for stopping copying after indication of

toner supply request

Mode 1-1 1-0

Stops after printing 1,500 copies

Stops after printing 3,000 copies

Stops after printing 4,000 copies

Stops after printing 5,000 copies

*2 Method for stopping copying after indication of

toner supply request

Mode 1-3 1-2

Stops after ejecting the paper

remaining in the machine

Stops after printing specified number of copies

Stops at the end of the current job

Does not stop

*3 Number of copies made before inhibition of

copying when PM count is reached

Mode 1-7 1-6 1-5

1,000 copies

2,000 copies

3,000 copies

4,000 copies

5,000 copies

1,000 copies

1,000 copies

1,000 copies

*4 Electrode cleaning cycle (fixing temperature is

50°C or lower when power is turned ON)

Mode 2-3 2-2 2-1

When power is tured ON

5,000 copies

10,000 copies

15,000 copies

20,000 copies

25,000 copies

30,000 copies

Not cleaned

00

01

10

11

00

01

10

11

000

001

010

011

100

101

110

111

000

001

010

011

100

101

110

111

*5 Electrode cleaning cycle (after power is turned

ON)

Mode 2-5 2-4

10,000 copies

20,000 copies

30,000 copies

40,000 copies

*6 Destination switchover

Mode 4-3 4-2

Japan

Inch area

Metric area

*7 Image density selection

(toner concentration threshold)

These bits set the read level of the toner concentration patch formed on the drum to determine

the toner concentration. Against image excessive density, image blur, and toner scattering in

all tone areas, the setting should be made by

shifting the threshold of black color to the positive

side.

Against insufficient density in all tone areas, shift

to the negative side.

• Standard -10:The image becomes darker.

• Standard +10:The image becomes lighter.

• Standard +20:The image becomes far lighter.

Mode 5-1 5-0

Standard

Standard -10

Standard +10

Standard +20

Note: There are three DIP switches to change

the image density : 5-0/1 (toner concentration threshold, 5- 2/3 (laser PWM), and

23-2/3 (toner density of developer).

The priority of order of these adjustments

are as follows :

(1) Laser PWM

(2) Toner density of developer

(3) Toner concentration threshold

00

01

10

11

00

01

10

00

01

10

11

1 ADJUSTMENT

1-15

25 MODE

1 ADJUSTMENT

*8 Image density selection

These bits set image write laser PWM. Against

exessive density of 100% black color, thick letters and lines, and excessive toner consumption,

the setting should be made by selecting “light.”

In the opposite case, select “dark.”

Mode 5-3 5-2

Darker (255)

Normal (235)

Lighter (215)

00

01

10

Note: There are three DIP switches to change

the image density :

5-0/1(toner concentration threshold),

5-2/3 (laser PWM), and 23-2/3 (toner

density of developer). The priority of

order of these adjustments are as follows:

(1) Laser PWM

(2) Toner density of developer

(3) Toner concentration threshold

*9 Transfer/separation output for plain paper

These bits are used when "- - - -", "Normal",

"Color", "Special" or "Seal" is selected for "Paper

type/special size setting" in the key operator

mode.

When "User paper" is selected with this bit, the

transfer/separation output for the "user paper

setting" made in the 36 mode is applied.

When "No specification" is selected, the output

data by destination and paper size (metric or inch

system) (Japan/metric: 64g/m

2

plain paper,

Inch: 20 lb plain paper, Inch area / Inch: 20 lb

plain paper, metric: 80g/m

area/metric: 80g/m

2

2

plain paper, Metric

plain paper, Inch: 20 lb plain

paper) is used.

Mode 6-2 6-1 6-0

No specification

Not used

Not used

Not used

Recycled paper 1 (Japan)

Recycled paper 2 (Inch area)

Recycled paper 3 (Metric area)

User paper

000

001

010

011

100

101

110

111

*10 Transfer/separation output for thick paper

This bit is used when "Thick" is selected for

"Paper type/special size setting" in the key operator mode to change transfer/separation output,

linear speed, and fixing temperature.

When "No specification" is selected, standard

data for 170g/m

• 170g/m

2

or heavier paper is used.

2

or heavier (TSL OFF) : When toner is

scattered around the image.

• Plain paper : Transfer / separation data for

plain paper of each destination is used to set

only the line speed and fixing temperature for

thick paper. This setting is applied when the

fixing condition is insufficient even though

paper is not so thick.

Mode 6-4 6-3

No specification

170 g/m

2

or more (TSL OFF)

Plain paper

00

01

10

*11 Transfer/separation output for thin paper

This bit is used when "Thin" is selected for "Paper

type/special size setting" in the key operator

mode.

When "No specification" is selected, the output

data by destination (Japan: 52.4 g/m

2

Inch area: 16lb, paper, Metric area: 48g/m

paper) is used.

Mode 6-6 6-5

No specification

52.4 g/m

64 g/m

2

paper

2

paper

00

01

10

*12 Toner guide roller current correction

When the room temperature causes defect

cleaning, the bias value of the toner guide roller

should be changed to +10 µA or +20 µA. If the

original setting value is changed without any

defective cleaning observed, the drum can be

damaged, or the toner may be spilled. In this

case, the use of copier is never recommended.

Mode 7-1 7-0

Standard

Approx. +10 µA

Approx. +20 µA

No correction

00

01

10

11

paper,

2

MODEL MANUAL REVISED EDITION DATE PAGE METHOD

SERVICE HANDBOOK Nov. 20017155/7165

1-16 REPLACEMENT

25 MODE

*13 Transfer/separation output for recycled paper

These bits are used when "Recycle" is selected

for "Paper type/special size setting" in the key

operator mode.

When "User paper" is selected with these bits,

the transfer/separation output for the user paper

setting made in the 36 mode is applied. When

"No specification" is selected, output data by

destination and paper size (metric or inch series)

(Japan/metric: 64 g/m

2

recycled paper, Inch: 20

lb recycled paper, Inch area/inch: 20 lb recycled

paper, metric: 80g/m

area/metric: 80g/m

2

recycled paper, Metric

2

recycled paper, inch: 20 lb

recycled paper) is used.

When humid paper causes uneven image, select

“humid paper 1/2/3”.

Mode 7-7 7-6 7-5

No specification

64 g/m2 standard paper

(Japan)

20 lb standard paper (USA)

80g/m2 standard paper

(Europe)

Humid paper 1 (Japan)

Humid paper 2 (USA)

Humid paper 3 (Europe)

User paper

000

001

010

011

100

101

110

111

Mode 8-3 8-2

Low temperature

Low and normal temperature

Low, normal, and high temperatures

No initial rotation

00

01

10

11

*15 Fixing roller initial rotation time setting

This bit sets the maximum time of initial rotation

of the fixing roller.

Mode 8-5 8-4

2 minutes (Japan)

3 minutes (Inch and Metric series)

4 minutes

10 minutes

*16 Message switching

Mode 9-3 9-2

Please insert key counter.

Please insert copy card.

Please insert coin.

Please insert key counter.

1 ADJUSTMENT

00

01

10

11

00

01

10

11

*14 Fixing roller initial rotation

Fixing may be insufficient if the temperature of

the place where the machine is installed is low.

To prevent this, increase the warm-up time (fixing roller initial rotation time) to allow the fixing

roller to be evenly warmed up. This bit specifies

the condition(s) under which initial rotation of the

fixing roller is required.

• Low temperature: Initial rotation of the fixing

roller is carried out only under the low temperature condition.

• Low and normal temperatures: Initial rotation

of the fixing roller is carried out under low and

normal temperature conditions.

• Low, normal, and high temperatures: Initial

rotation of the fixing roller is carried out under

low, normal, and high temperature conditions.

MODEL MANUAL REVISED EDITION DATE PAGE METHOD

SERVICE HANDBOOK Nov. 20017155/7165

1-17 REPLACEMENT

25 MODE

1 ADJUSTMENT

*17 Copy count limit

Mode 9-7 9-6 9-5 9-4

No limit 0 0 0 0

1 copy 0 0 0 1

3 copies 0 0 1 0

5 copies 0 0 1 1

9 copies 0 1 0 0

10 copies 0 1 0 1

20 copies 0 1 1 0

30 copies 0 1 1 1

50 copies 1 0 0 0

99 copies 1 0 0 1

No limit 1 0 1 0

No limit 1 0 1 1

No limit 1 1 0 0

No limit 1 1 0 1

No limit 1 1 1 0

No limit 1 1 1 1

*18 Page memory allocation when powered

Mode 10-1 10-0

No allocation

32 MB

64 MB

00

01

10

*19 Page memory allocation when starts

When memory overflow occurs in a mode where

page memory is used, this bit allocates page

memory at the start of job to print out copied

paper, the data of which was already read in the

memory.

Page memory quantity differs as in the following

table, according to the number of gradation.

1 bit ED

2 bit ED

Mode

No allocation

Allocated

18 MB (A3 x 2)

36 MB (A3 x 2)

10-2

0

1

When “Allocated” is selected by DIP switch 10-0

or 10-1 with power supply ON, this setting has

priority.

*20 Transfer/separation out put for high-quality

paper

These bits are used when “High-quality” is

selected for “Paper type/special size setting” in

the key operator mode.

When “No specification” is selected, output data

by paper size (metric or inch system) (metric:

2

64g/m

standard paper, Inch: 20 lb standard

paper) is used.

Mode 10-7 10-6 10-5 10-4

No specification

64 g/m

2

paper for

printing press

2

80g/m

paper for

printing press

0000

0001

0010

*21 Size detection 4

Destination Mode 13-4 13-3

Metric series

A5R 0 0

B6R 0 1

Inch series

5.5 x 8.5R 1 0

*22 F4 size detection

Mode 13-6 13-5

8 x 13

8.25 x 13

8.125 x 13.25

8.5 x 13

00

01

10

11

*23 Maximum number of sheets that can be stapled

Mode 15-2 15-1

50 sheets

45 sheets

40 sheets

35 sheets

00

01

10

11

*24 FNS alarm stop SW

Mode 15-4 15-3

Stop immediately after detection

Stop at end of copy after detection

No alarm stop

No alarm stop

00

01

10

11

MODEL MANUAL REVISED EDITION DATE PAGE METHOD

SERVICE HANDBOOK Nov. 20017155/7165

1-18 REPLACEMENT

25 MODE

*25 Selection of area to be erased in non-original

area automatic erasure

These bits are used to make a setting associated

with the non-original automatic erasure mode

(application function).

Mode 16-6 16-5

Standard

Dark original

Coping with light interference

*26 Weekly timer summer time setting

Mode

0 minute

10 minutes

20 minutes

30 minutes

40 minutes

50 minutes

60 minutes

70 minutes

80 minutes

90 minutes

100 minutes

110 minutes

120 minutes

130 minutes

140 minutes

150 minutes

*27 Density selection for scanning tab paper

The higher the brightness level, the higher the

density.

17-3 17-2 17-1 17-0

0000

0001

0010

0011

0100

0101

0110

0111

1000

1001

1010

1011

1100

1101

1110

1111

00

01

10

*28 Fixing temperature setting switch over

This setting is performed to change fixing temperature when fixing is insufficient or paper curl

is excessive.

This setting is effective only when standard

paper is used. Therefore, it is not applied when

thick or thin paper is used or temperature is specified in power mode.

• Standard Standard setting value

• Standard+α Set when fixing is insufficient

• Standard-α Set when paper curl is excessive

Mode 19-3 19-2 19-1

Standard

Standard+5°C

Standard+10°C

Standard+15°C

Standard-5°C

Standard-10°C

Standard-15°C

Standard-20°C

*29 IP scanner default resolution

Mode 19-7 19-6

400dpi

600dpi

200dpi

300dpi

*30 Number of punched holes

Mode 22-2 22-1

2 holes (Japan)

3 holes (Inch area)

4 holes (Metric area)

000

001

010

011

100

101

110

111

1 ADJUSTMENT

00

01

10

11

00

01

10

Mode 17-6 17-5 17-4

80 (brightness level)

40

60

100

120

160

200

255(not clipped)

000

001

010

011

100

101

110

111

1-19

25 MODE

1 ADJUSTMENT

*31 Image density selection (toner density selection

of developer)

These bits set the toner density of developer by

changing toner supply threshold and developing

sleeve rotation speed with image density

unchanged.

Decrease toner density when the image is gray

background or toner is scattered. Increase toner

density when the image is unevenly transferred

or white spots occur.

Mode 23-3 23-2

Standard toner density

Approx. 0.75% up

Approx. 0.75% down

Approx. 1.5% down

00

01

10

11

Note: There are three DIP switches to change

the image density : 5-0/1 (toner concentration threshold), 5-2/3 (lase PWM), and

23-2/3 (toner density of developer). The

priority of order of these adjustment are

as follows:

(1) Laser PWM

(2) Toner density of developer

(3) Toner concentration threshold

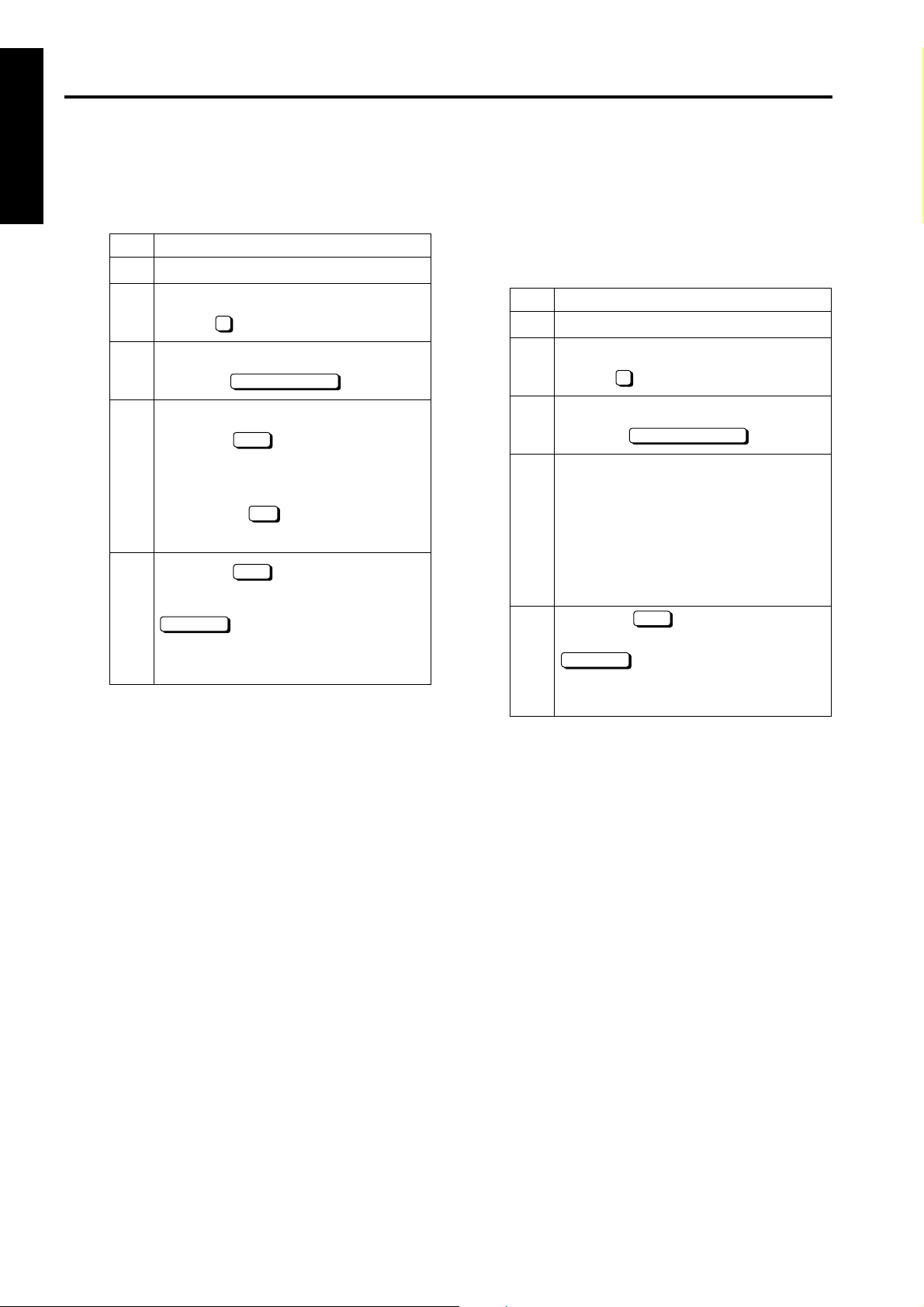

[4] Setting the Paper Size

When the LCT paper type is changed, it must be stored

in the main body. This setting is effective when an

optional LCT is added.

Select a paper size among standard, non-standard

paper sizes. After selecting a tray size, specify a paper

size.

1. Setting the standard size

Step Operation

1 Enter the 25 mode.

2 [Memory setting mode menu Screen]

Select " Paper size setting".

3 [Paper size setting mode Screen]

Press the key.

4

Press the or button to select

a paper size.

5

Press the key to finish setting.To

cancel the new setting, press the

CANCEL

display the Memory setting mode menu

Screen again.

2

STD SIZE

OK

key, Pressing either key will

*32 Image's gray background control at power ON

If an image

's gray background problem occurs

while making about 100 copies after power ON

(the fixing temperature is 50°C or lower), set bits

0, 1, 3, 5, 6, and 7 of DIPSW27 to 1.

Note: When this setting is used, be sure to set

six bits to 1 all together. And never set bits

2 and 4 of DIPSW27 to 1.

MODEL MANUAL REVISED EDITION DATE PAGE METHOD

SERVICE HANDBOOK Nov. 20017155/7165

1-20 REPLACEMENT

2. Setting the non-standard size 3. Setting the wide paper

Step Operation

1 Enter the 25 mode.

2 [Memory setting mode menu Screen]

Step Operation

1 Enter the 25 mode.

2 [Memory setting mode menu Screen]

25 MODE

1 ADJUSTMENT

Select " Tray Size Setting."

2

3 [Paper size setting mode Screen]

Press the key.

Non STD size

4 [Paper size input Screen]

Press the key for specifying the main

(vertical) scanning direction to highlight

it.

5

Press the or key or numeric

keys to enter the size in the main (vertical)scanning direction. Max. 314 mm

6 Press the key for specifying the sub (hor-

izontal) scanning direction to highlight it.

7

Press the or key or numeric

keys to enter the size in the sub (horizontal) scanning direction. Max. 223

mm(LT-402), 459mm(LT-412)

8

Press the key to finish setting.

OK

To cancel the new setting, press the

CANCEL

key.

Pressing either key will display the Memory setting mode menu Screen again.

Select " Paper size setting."

2

3 [Paper size setting mode Screen]

Press the key.

Wide size paper

4 [Paper size selecting Screen]

Press the or key to select a

wide paper size.

5

Input size

key.

6 [Paper size input Screen]

Press the key for specifying the main

(vertical) scanning direction to highlight

it.

7

Press the or key or numeric

keys to enter the size in the main (vertical) scanning direction. Max. 314 mm

8 Press the button for specifying the sub

(horizontal) scanning direction to highlight it.

9

Press the or key or numeric

keys to enter the size in the sub (horizontal) scanning direction. Max.

223mm(LT-402), 459mm(LT-412)

10

Press the key to finish setting.

OK

To cancel the new setting, press the

1-21

CANCEL

key.

Pressing either key will display the Memory setting mode menu Screen again.

Reference 1:

Each time the current tray size is changed on this

screen, the new setting will be written into the

non-volatile memory.

25 MODE

[5] PM Count Resetting

1 ADJUSTMENT

Care should be taken not to reset the PM count by mistake.

Step Operation

1 Enter the 25 mode.

2 [Memory setting mode menu Screen]

Select " PM count".

3 [PM count/cycle Screen]

Press the key.

4 [Reset Confirmation Screen]

Press the key.The PM count is

reset and the start date is input automatically.

Pressing the key closes the Reset

Confirmation screen at once.

5

Press the key to finish setting.

To cancel the new setting, press the

CANCEL

Pressing either key will display the Memory setting mode menu Screen again.

3

COUNT RESET

YES

NO

OK

key.

[6] Setting the PM Cycle

This function allows you to change the PM cycle.

Caution: The PM cycle is factory-set. Use this

function to change the factory-set PM

cycle.

Step Operation

1 Enter the 25 mode.

2 [Memory setting mode menu Screen]

Select " PM count".

3 [PM count/cycle Screen]

Press the key.

4 After making sure that three digits of the

cycle value are displayed in reverse

video, enter a desired cycle value using

numeric keys.

Only the three digits of the cycle value

can be entered. The entered digits will

be shifted to the left one after another.

5 Press the key to finish setting.

To cancel the new setting, press the

CANCEL

Pressing either key will display the Memory setting mode menu Screen again.

3

PM Cycle Setting

OK

key.

1-22

25 MODE

[7] Collecting Data

This function allows you to view various data retained

by the machine.

Reference: The above data can also be viewed

using the data collection function of

the KRDS.

1. Data that can be Viewed

No. Data Type Pre-operation

Total count of

1

each paper size

Copy count of

2

each paper size

Print count of

3

each paper size

RADF count

4

Black ratio of each

5

section

Black ratio of ranking

6

list

JAM data of time

7

series

JAM count

8

Count of each copy

9

mode

SC count

10

JAM count of each

11

section

Enter the 25

mode, select "

Software DIPSW

Setting", and set

bit 1 of address

30-1 to 1. (Note 1)

1

2. Viewing Collecting Data No.1 to No.6

Step Operation

1 Enter the 25 mode.

2 [Memory setting mode menu Screen]

Select " Data collection".

3 [Collecting data menu Screen]

Select the collecting data you want to

view by pressing one of numeric keys

1 6

4 [Individual data view Screen]

View the selected data by scrolling the

screen using the and keys.

5

Press the key to return to the

Memory setting mode menu Screen.

4

to .

RETURN

1 ADJUSTMENT

SC count of each sec-

12

tion

Note: When bit 1 of DIP switch 30-1 is set to 0,

only collected data 1 to collected data 6

can be viewed.

1-23

1 ADJUSTMENT

25 MODE

3. Viewing Collecting Data No.7 to No.12

Step Operation

1 Enter the 25 mode.

2 [Memory setting mode menu Screen]

Select " Software DIP SW setting".

1

3 [Software DIP SW Setting Screen]

Set bit 1 of DIP switch 30-1 to 1.

4

Press the key to return to the

RETURN

Memory setting mode menu Screen.

5 [Memory setting mode menu Screen]

Select " Data Collection".

4

6 [Collecting data menu Screen]

Select the collected data you want to

view by pressing one of numeric keys

to .

7 12

To select the key or later press the

11

key.

If the key is pressed with key

11

displayed, the Collected Data Selection

screen containing keys to

1 12

appears again.

7 [Individual data view Screen]

View the selected data by scrolling the

screen using the and keys.

(Note)

8

Press the key to return to the

RETURN

Memory setting mode menu Screen.

Note: On the Individual Data View screen

showing the JAM count of each section

(collected data ) or SC count of each

section (collected data ), the

COUNT RESET

Pressing the key resets

11

12

key appears.

COUNT RESET

the selected data count.

1-24

4. Details on Display Data

(1) Collecting data No.1 to No.3: Total/copy/print counts of each paper size

KRDS parameter

NO

1 00 A2 17x22 A2

2 01 A3 11x17 A3

302 B48.5x14B4 (8K)

4 03 A4 8.5x11 A4

5 04 B5 5.5x8.5 B5 (16K)

605 A5 - A5

706 B6 - F4

807 8.5x14- -

908 8.5x11A4 -

10 09 Special Special Special

1. Each time a printed copy is ejected, the counter is incremented by 1 regardless of the paper size.

2. Any size other than paper sizes 1-9 is counted as Special size. (SEL/LEF are counted as the same size.)

(B1, B6, B8)

Japan Inch area Metric area

Destination

Maximum count Remarks

99999999

All counters are

8-digit counters.

25 MODE

1 ADJUSTMENT

1-25

1 ADJUSTMENT

25 MODE

(2) Collecting data No.4: RADF mode

KRDS

NO

parameter

(F0)

100

201

302

403

504

605

706

807

908

10 09

11 0A

12 0B

13 0C

14 0D

15 0E

16 0F

Number of originals fed in ADF mode

Number of originals fed in RADF mode

Number of 1-sided mixed original fed

Number of 2-sided mixed original fed

Number of 1-sided Z-folded mode original fed

Number of 2-sided Z-folded mode original fed

Undefined

Items

Maximum

count

99999999

Remarks

All counters are 8-digit

counters.

1. The counter is incremented each time one original side has been scanned in each mode.

2. Counters 1 and 2 count original sides independently of counters 3-7.

(3) Collecting data No.5: Black ratio of each section *1

This allows checking the average black ratio of 5000 prints for the latest 30 data.

(4) Collecting data No.6: Black ratio of ranking list *1

This allows checking black ratio data, number of prints, transfer paper size, mode, and date for the top 15

job data ranked from highest rates of black ratio.

The black ratio rank list is allowed to contain only those jobs which have five or more copies, so that jobs that

have made erroneous copies will be excluded from the list.

(5) Collecting data No. 7: JAM data of time series

A jam code, total count, date and time of occurrence, tray type, paper size, and magnification can be displayed for the latest 100 jams.

*1 This black ratio is the theoretical value obtained by converting the black dot area on the image data and

the area of the transfer paper, therefore it is different from the black ratio obtained by the actual printing.

MODEL MANUAL REVISED EDITION DATE PAGE METHOD

SERVICE HANDBOOK Nov. 20017155/7165

1-26 REPLACEMENT

25 MODE

(6) Collecting data No.8: JAM count / Collecting data No.11: JAM count of each section (can be reset)

Description of JAM Jam

KRDS

param-

NO

eter

(J0)

100

201 10-2 6

302

403 11-2 1

504

605 12-2 2

706

807 13-2 3

9 08 Tray 4 paper feed

10 09 14-2 4

11 0A

12 0B 15-2 5

13 0C

14 0D

15 0E

16 0F

17 10

18 11 Paper feed conveyance (tray 4)

19 12 17-7 7

20 13

21 14

22 15

23 16 31-2 10

24 17

25 18 32-2 11

26 19 32-3 11

27 1A 32-4 11

28 1B 32-5 11

29 1C

30 1D 92-2 12

31 1E 93-1 13

32 1F 94-1 13

33 20 94-2 13

34 21

35 22

36 23

37 24

38 25 71-2 -

By-pass paper feed

Tray 1 paper feed

Tray 2 paper feed

Tray 3 paper feed

(Japan only)

LCT paper feed

Paper feed conveyance (common to all trays)

Paper feed conveyance (tray 1)

Paper feed conveyance

(tray 2/3/4)(Japan only)

Paper feed conveyance (tray 2)

Paper feed conveyance (tray 3)

(Japan only)

LCT

Drum

Second paper feed conveyance

Fixing / Exit

ADU

Vertical conveyance door

LCT

Front door

FNS

Location of jam

Code displayed

when display of

jam code is

selected by

25DIPSW

10-1 6

11-1 1

12-1 2

13-1 3

14-1 4

15-1 5

17-1 9

17-2 7

17-3 7

17-4 7

17-5 7

17-6 7

17-8 8

21-1 10

31-1 9

32-1 11

92-1 12

19-1 19-2 51-1 71-1 -

position

display

on operation

panel

Maximum

count

999999

Counting

condition

All counts are

6-digit counters.

1 ADJUSTMENT

1-27

1 ADJUSTMENT

25 MODE

NO

39 26

40 27 61-2 41 28 62-1 14

42 29 62-2 14

43 2A 62-3 14

44 2B 62-4 14

45 2C 62-5 14

46 2D 62-6 14

47 2E 62-7 14

48 2F 62-8 14

49 30 62-9 14

50 31 62-10 14

51 32 63-1 15

52 33 63-2 15

53 34 63-3 15

54 35 63-4 15

55 36 63-5 15

56 37

57 38 72-17 16

58 39 72-18 16

59 3A 72-19 16

60 3B 72-20 16

61 3C 72-21 16

62 3D 72-22 17

63 3E 72-23 17

64 3F 72-24 18

65 40 72-25 18

66 41 72-26 18

67 42 72-27 16

68 43 72-28 16

69 44 72-29 16

70 45 72-30 16

71 46

72 47 72-33 19

73 48 72-34 19

74 49

75 4A

76 4B 72-39 20

77 4C 72-40 20

78 4D 72-41 20

79 4E 72-42 20

80 4F

81 50

82 51 72-45 20

83 52 72-46 20

84 53 72-47 20

85 54

KRDS

param-

eter

(J0)

ADF

FNS

-

PI

-

PK

-

FNS

Description of JAM Jam

Location of jam

Code displayed

when display of

jam code is

selected by

25DIPSW

61-1 -

72-16 16

72-32 19

72-35 17

72-38 20

72-43 16

72-44 20

72-48 18

position

display

on operation

panel

Maximum

count

999999

Counting

condition

All counts are

6-digit counters.

1-28

Description of JAM Jam

KRDS

param-

NO

1. When a jam occurs, the associated counter is incremented by 1 (Static jams are not counted.)

eter

(J0)

86 55

87 56 72-50 17

88 57 72-51 17

89 58

90 59 72-82 16

91 5A 72-83 16

92 5B 72-90 16

PI

FNS

Location of jam

Code displayed

when display of

jam code is

selected by

25DIPSW

72-49 17

72-81 16

position

display

on operation

panel

Maximum

count

999999

Counting

condition

All counts are

6-digit counters.

25 MODE

1 ADJUSTMENT

1-29

Loading...

Loading...