Konica 7115-18 Service Manual 7115fv30e

TROUBLESHOOTING

1. INTRODUCTION

1-1. Reading the Text

1. The paper transport failure troubleshooting procedures are given according to the

symptom. First identify the location where the paper is present and start the procedure

for that particular location. For malfunction troubleshooting, start with step 1 and

onward.

2. Make checks in the numerical order of steps and, if an item is checked okay, go to the

next step.

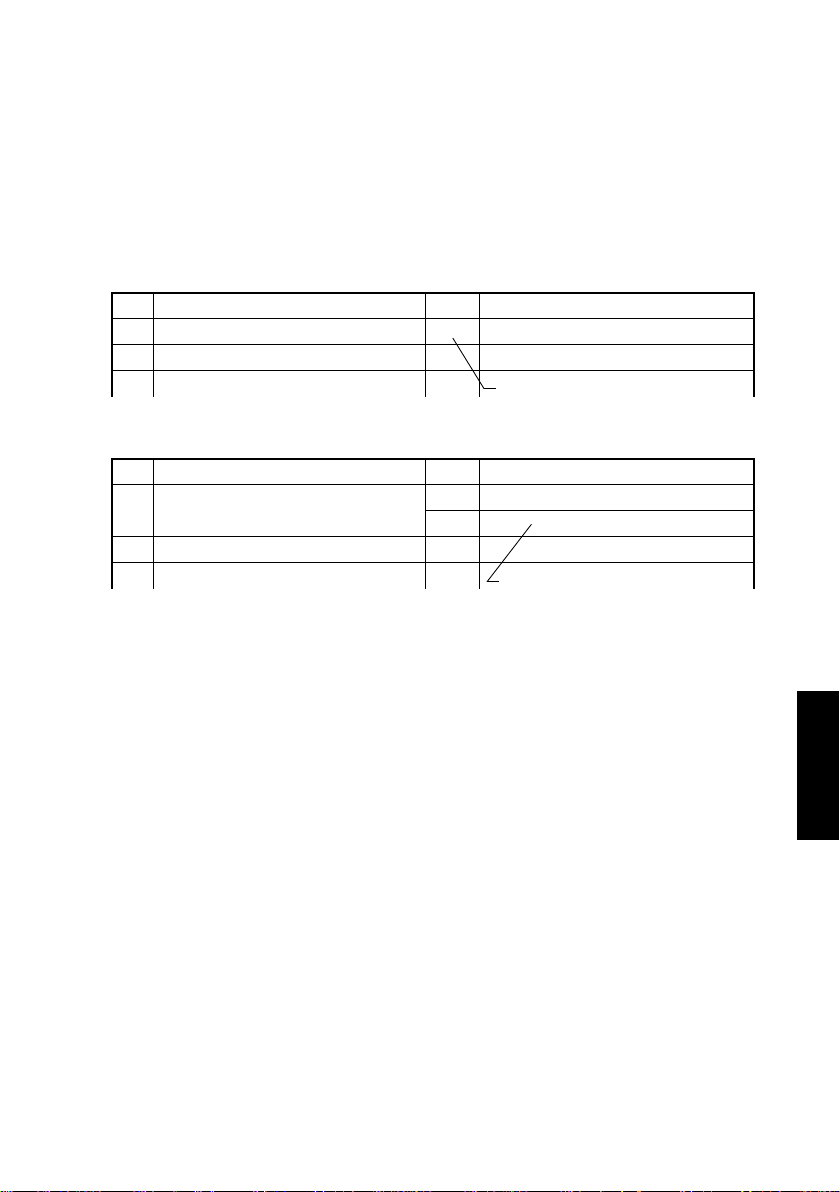

<E.g.: Pattern 1>

Step Check Result Action

1—NO—

2

Go to the next step if y ou answered

YES.

<E.g.: Pattern 2>

Step Check Result Action

1—

2

YES —

NO —

Go to the next step if it checks okay.

T-1

2. PAPER TRANSPORT FAILURE

2-1. Paper Misfeed Detection

(1) Outline

• A paper misfeed is detected by detecting different states of signals (H, L) of several sen-

sors located near the paper take-up section and the Exit Paper Sensor.

• The timings of the rising and falling edges of the paper take-up-related sensors and the

Exit Paper Sensor are monitored to detect a misfeed of paper being fed through the

copier.

• The states (H, L) of the paper take-up-related sensors and the Exit Paper Sensor are

monitored to detect a sheet of paper left in the copier.

• All drives are brought to an immediate stop when a sheet of paper misfeed or left in the

copier is detected.

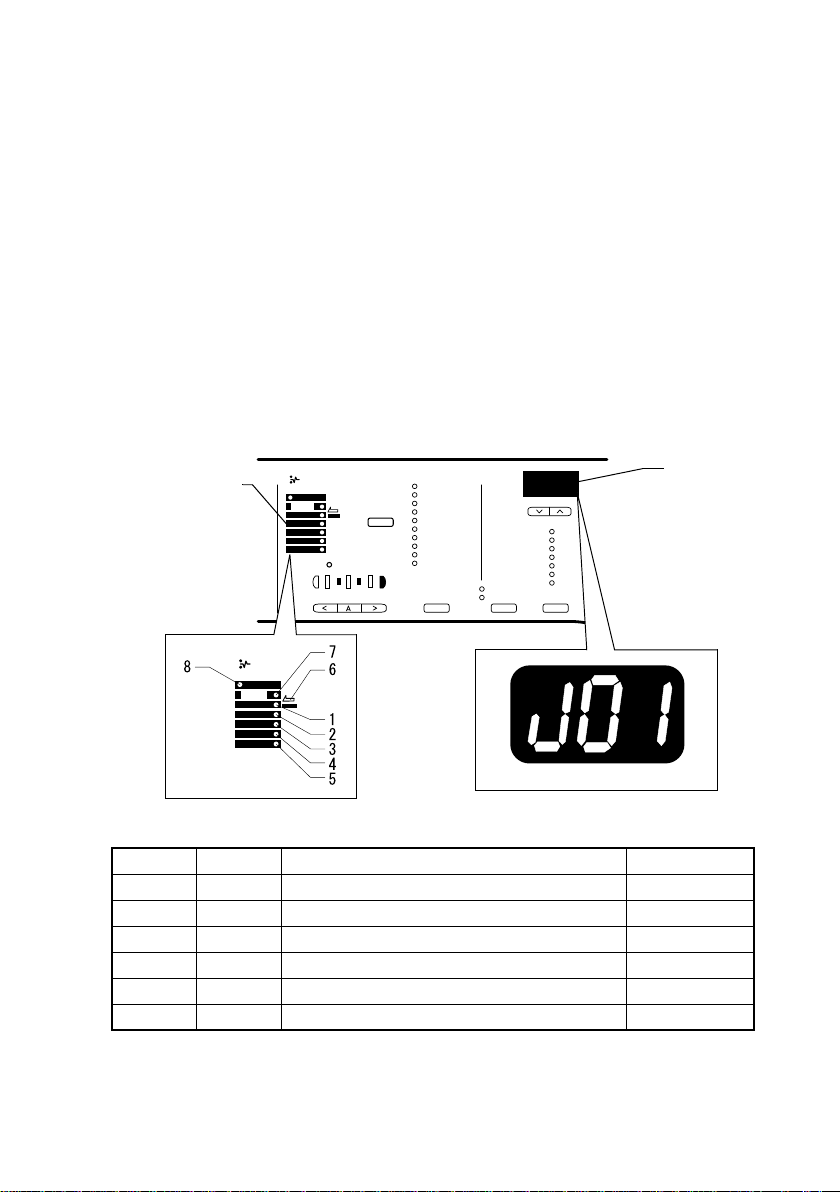

2-2. Paper Misfeed

When a paper misfeed occurs, the control panel shows the misfeed location and paper

location.

4022T501AA

4022T503AA

Display

☞

T-7

☞

T-1 1

☞

T-1 1

☞

T-1 1

☞

T-1 1

☞

T-7

Misfeed Location

Indicator LED

4022T502AA

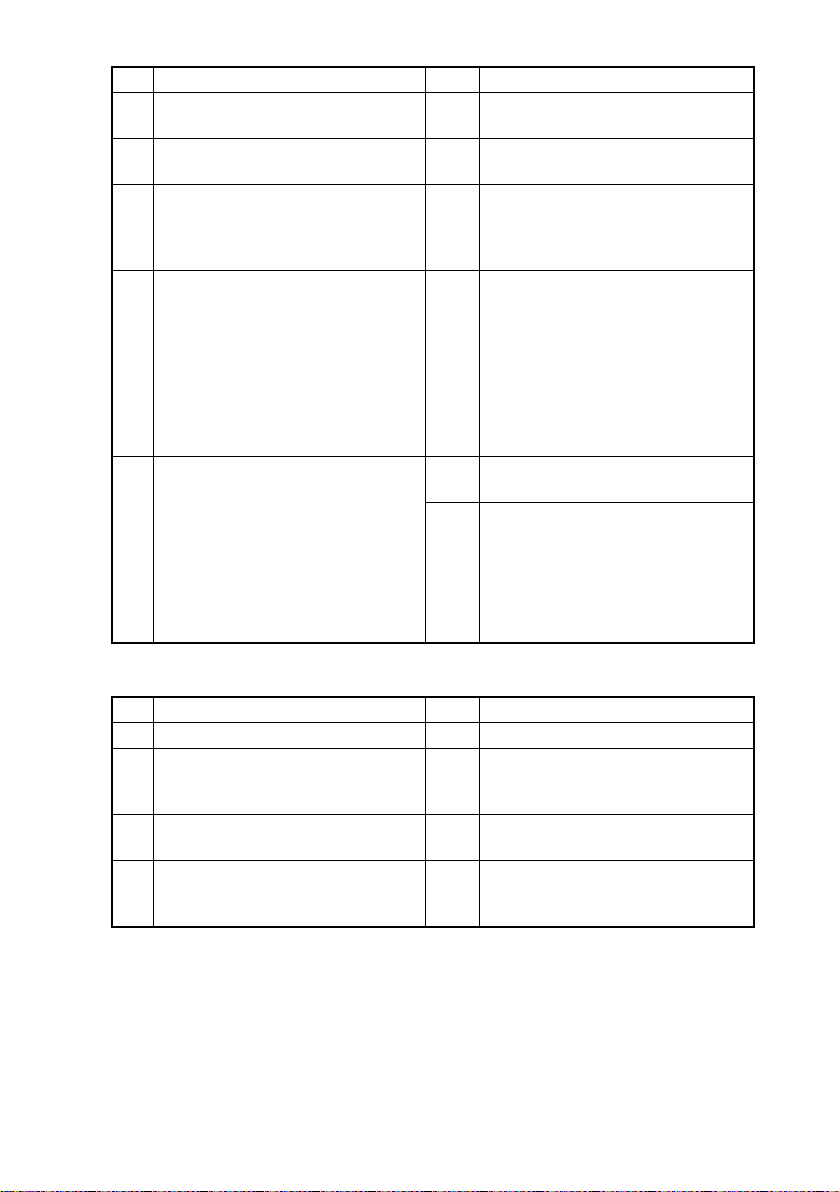

LED No. Code Misfeed/Paper Location Action Ref. Page

1 J01 Misfeed at the 1st Tray

2 J02 Misfeed at the 2nd Tray

3 J03 Misfeed at the 3rd Tray

4 J04 Misfeed at the 4th Tray

5 J05 Misfeed at the 5th Tray

6 J06 Misfeed at the Bypass Tray

T-2

LED No. Code Misfeed/Paper Location Action Ref. Page

2/3 J1 Misfeed on paper transport path between PC1

and PC12 (3rd Tray)

3/4 Misfeed on paper transport path between PC12

(3rd Tray) and PC12 (4th Tray)

4/5 Misfeed on paper transport path between PC12

(4th Tray) and PC12 (5th Tray)

7 J2 Misfeed at the PC Drum

7 J3 Misfeed at the Fusing Unit

8 J80 Original misfeed: ADF Separator See option

J81 Original misfeed: ADF registration

J83 Original misfeed: ADF exit

1/7 J – – Paper left: PC1

7 Paper left: PC3

2 Paper left: 2nd Tray Paper Take-Up Sensor

3 Paper left: 3rd Tray Paper Take-Up Sensor

4 Paper left: 4th Tray Paper Take-Up Sensor

5 Paper left: 5th Tray Paper Take-Up Sensor

8 Paper left: ADF See option

6 byp Paper left: Manual Bypass Tray

☞

T-1 1

☞

T-1 1

☞

T-1 1

☞

T-1 3

☞

T-1 6

service manual.

☞

T-7

☞

T-1 6

☞

T-1 1

☞

T-1 1

☞

T-1 1

☞

T-1 1

service manual.

☞

T-7

T-3

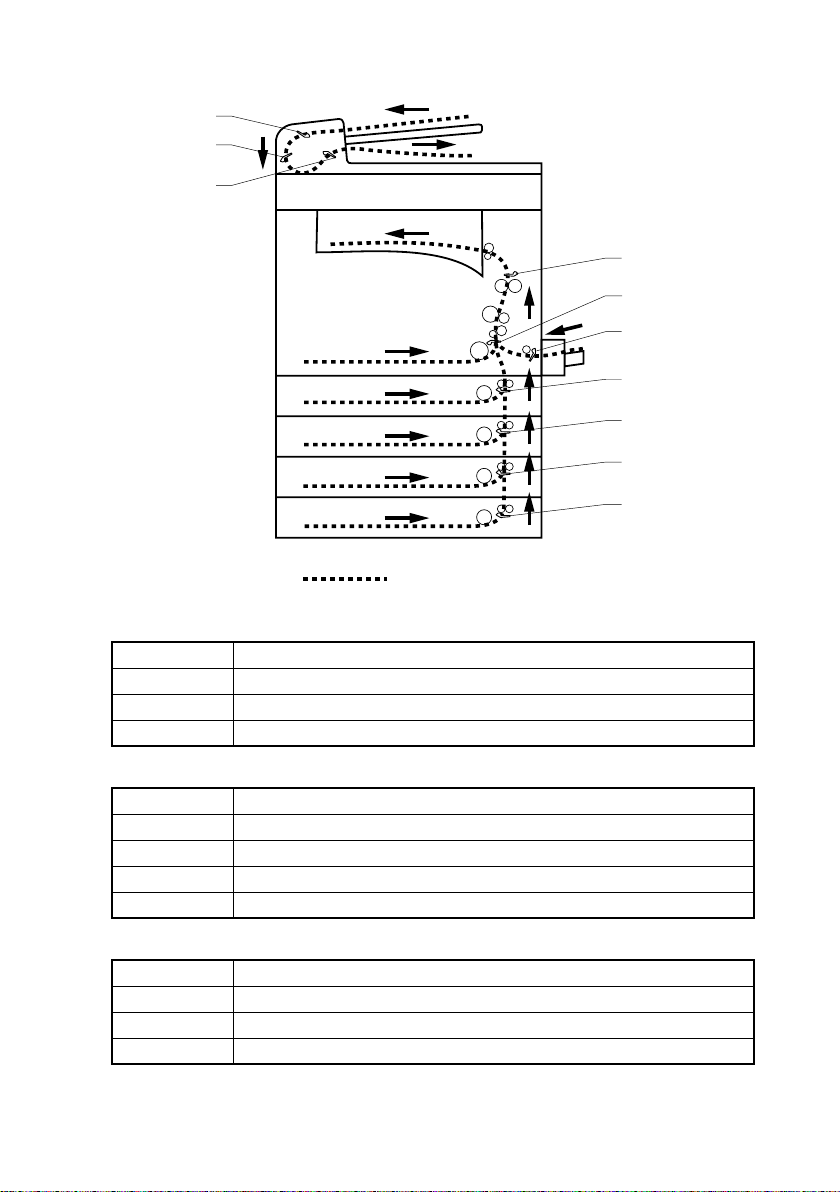

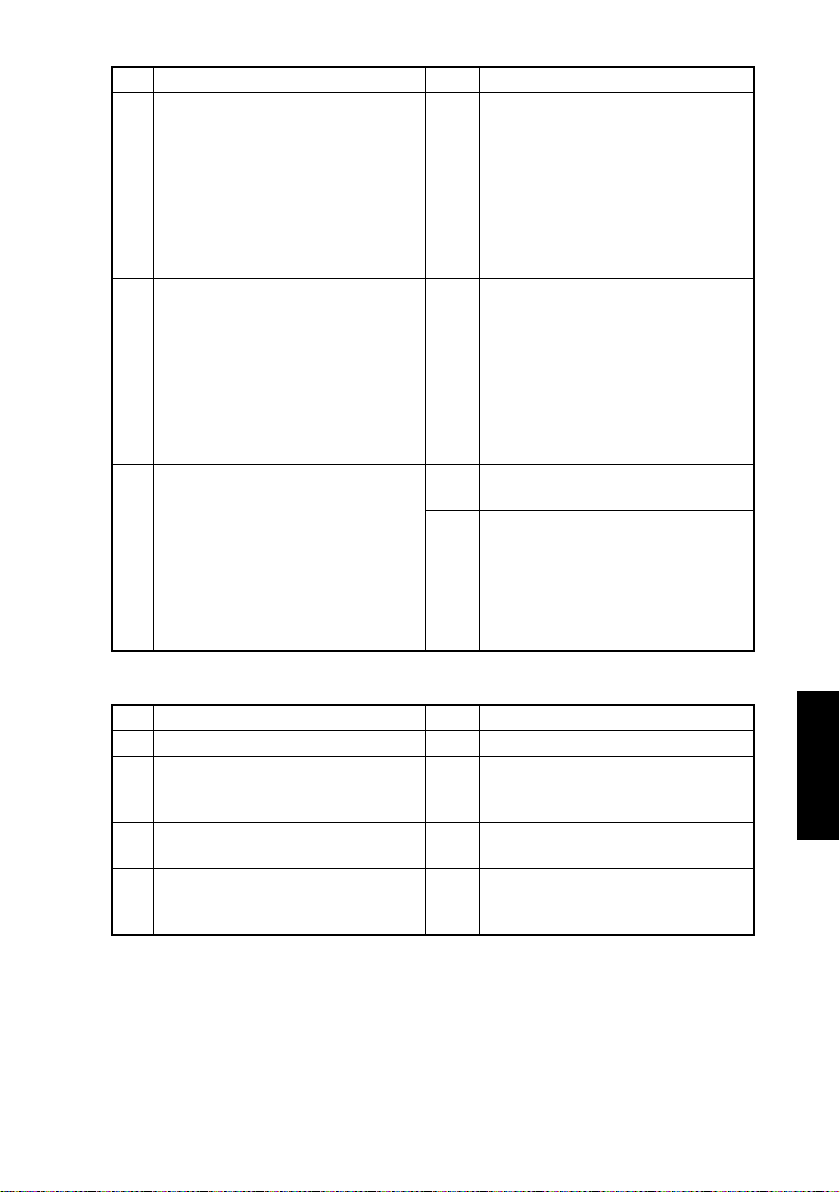

2-3. Misfeed Detection Sensor Layout

PC4*

PC3*

PC5*

PC3

PC1

PC2

PC12*

PC12*

PC12*

PC12*

Paper Pat h

Copier

Symbol Name

PC1 Synchronizing Roller Sensor

PC2 Manual Feed Paper Sensor

PC3 Exit Paper Sensor

Paper Feed Cabinet (option)

Symbol Name

PC12* 2nd Tray Paper Take-Up Sensor

PC12* 3rd Tray Paper Take-Up Sensor

PC12* 4th Tray Paper Take-Up Sensor

PC12* 5th Tray Paper Take-Up Sensor

ADF (option)

Symbol Name

PC3* Registration Sensor

PC4* Separator Sensor

PC5* Paper Exit Sensor

T-4

4022T504AA

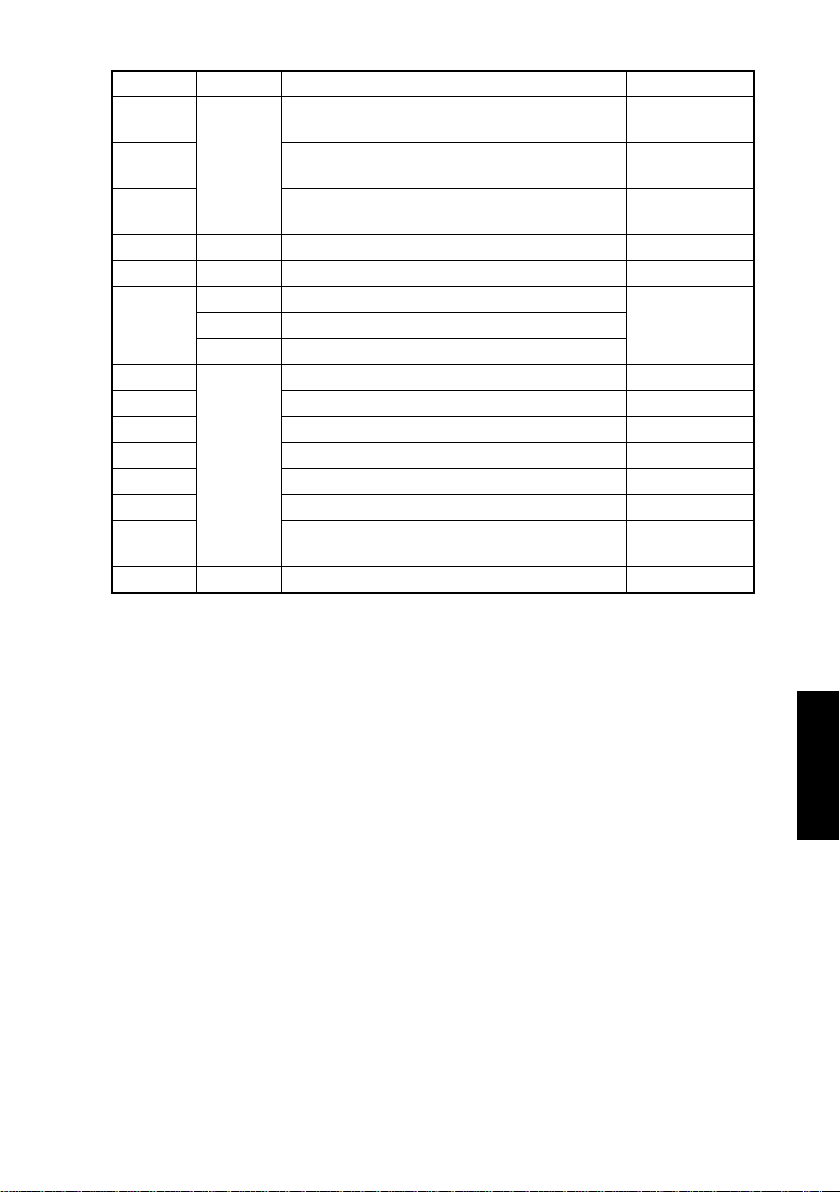

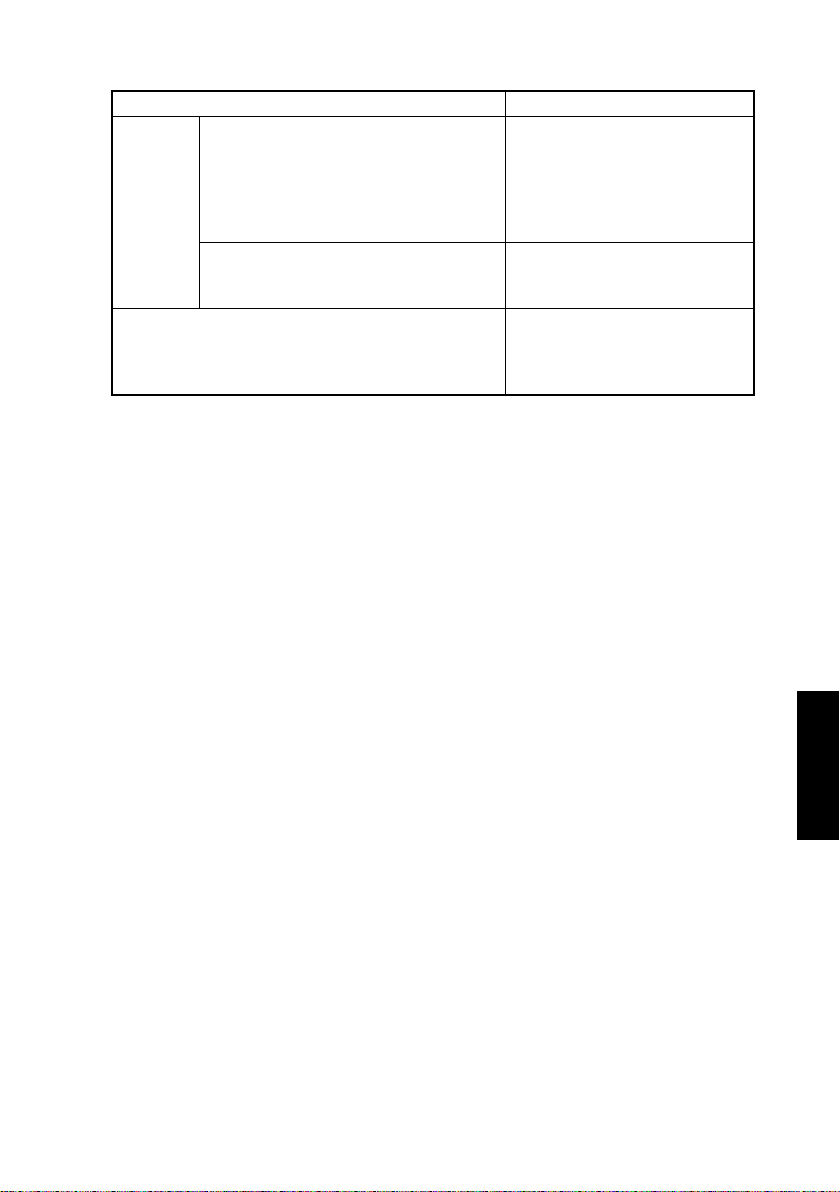

<Resetting the Misfeed Display>

Misfeed Location Resetting Procedure

Misfeed in

the copier

Misfeed in the option:

J02, J03, J04, J05, J1, J80, J81, and J83

Misfeed at 1st Tray J01,

misfeed at Multiple Bypass Tray J06,

misfeed at Manual Bypass Tray J06,

misfeed at PC Drum J2,

misfeed at Fusing Unit J3,

paper left J - -

Paper wedged at Manual Bypass Tray byp Pull the paper wedged out of the

Open the Right Door or slide out

the 1st Tray, remove all sheets of

paper misfeed and left inside, and

close the Right Door.

tray. (Removing the paper will

reset the misfeed display.)

Remove all sheets of paper misfeed and left inside and then raise

and lower or disconnect and

reconnect the option.

T-5

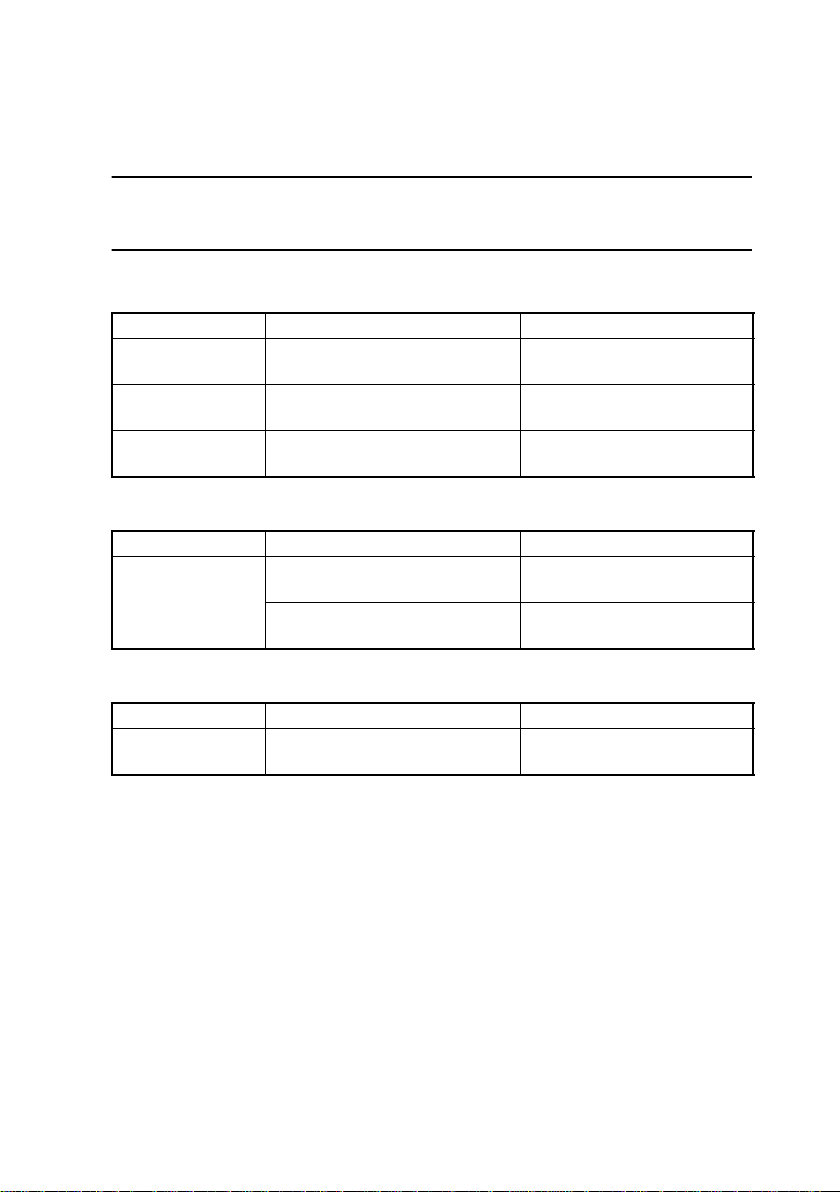

2-4. Types of Misfeed Detection and Detection Timings

• The following list the types of misfeed detection and detection timings for different misfeed locations.

• The symbol “L” (for the leading edge) and “T” (for the trailing edge) given in ( ) indicate

the particular edge of the paper detected by the sensor.

NOTE

• For the types of misfeed detection and detection timings of options, see the relevant

option service manual.

<Misfeed at the Paper Take-Up Section>

Type Detection Start Paper Detection

Misfeed at 1st Tray

J01

Misfeed at Manual

Bypass Tray J06

Misfeed at Multiple

Bypass Tray J06

<Misfeed at the PC Drum>

Type Detection Start Paper Detection

Misfeed at PC Drum J2Synchronizing Roller Sensor (PC1)

Paper Take-Up Solenoid (SL1)

energized

Manual Bypass Solenoid (SL2)

energized

Multiple Bypass Solenoid (SL21)

energized

(L)

Synchronizing Roller Sensor (PC1)

(L)

Synchronizing Roller Sensor

(PC1) (L)

Synchronizing Roller Sensor

(PC1) (L)

Synchronizing Roller Sensor

(PC1) (L)

Exit Paper Sensor (PC3) (L)

Synchronizing Roller Sensor

(PC1) (T)

<Misfeed at the Fusing Unit>

Type Detection Start Paper Detection

Misfeed at Fusing

Unit J3

Synchronizing Roller Sensor (PC1)

(T)

Exit Paper Sensor (PC3) (T)

T-6

3. MISFEED TROUBLESHOOTING PROCEDURES

3-1. Misfeed at Copier Paper T ake-Up J01 and Misfeed at Bypass

Tray J06

Relevant Electrical Parts

Synchronizing Roller Sensor (PC1)

Manual Feed Paper Sensor (PC2)

Paper Take-Up Solenoid (SL1)

MANUAL BYPASS SECTION

Manual Feed

Paper Senser

Multiple Bypass

Multiple

Bypass Solenoid

Manual Bypass Solenoid (SL2)

Multiple Bypass Solenoid (SL21)

Master Board (PWB-A)

PWB-A

Master Board

Manual Feed

Bypass Solenoid

CN26

DRAWER SECTION

Paper Take-Up

Solenoid

TRANSPORT SECTION

Synchronizing

Roller Senser

Misfeed at 1st Tray J01 Trou bleshooting Procedures

Step Check Result Action

1 Paper meets product specifications. NO • Change paper.

2 Paper is curled, wavy, or damp. YES • Change paper.

3 Edge Guide and Trailing Edge Stop

are at correct position to accommodate paper.

• Instruct user to load paper that

meets product specifications.

NO • Adjust as necessary.

PC1 ANODE

4022T522AA

T-7

Step Check Result Action

4 Paper Take-Up Roll (1st Tray) is dirty,

scratchy, deformed, or worn.

5 Paper Separator Roll (1st Tray) is

dirty, scratchy, deformed, or worn.

6 Paper Take-Up Roll drive shaft turns

when the Start key is pressed.

7 Paper Take-Up Solenoid (SL1) is

operational when the Start key is

pressed.

<Check Procedure>

Check voltage across a Master Board

(copier: PWB-A) pin and GND.

• Voltage across PJ5A-2 and GND

In standby: DC24 V

When pressed: DC0 V

8 Synchronizing Roller Sensor (PC1) is

operational.

<Check Procedure>

Check voltage across a Master Board

(copier: PWB-A) pin and GND when

the sensor is blocked.

• Voltage across PJ6A-3 and GND

When blocked: DC5 V

When unblocked: DC0 V

YES • Clean or change.

YES • Clean or change.

NO • Reinstall the Paper Take-Up Roll

drive shaft.

• Reinstall the Paper Take-Up Roll

drive gear and spring.

NO • Change Paper Take-Up Solenoid

(SL1).

NO • Change Synchronizing Roller Sen-

sor (PC1).

YES • Change Master Board (copier:

PWB-A).

Misfeed at Manual Bypass Tray J06 Troubleshooting Procedures

Step Check Result Action

1 Paper meets product specifications. NO • Change paper.

2 Paper is curled, wavy, or damp. YES • Change paper.

3 Paper Guides are at correct position

to accommodate paper.

4 Transpor t Roller (Manual Bypass

Tray) is dirty, scratchy, deformed, or

worn.

• Instruct user to load paper that

meets product specifications.

NO • Adjust as necessary.

YES • Clean or change.

T-8

Step Check Result Action

5 Manual Bypass Solenoid (SL2) is

operational when the Start key is

pressed.

<Check Procedure>

Check voltage across a Master Board

(copier: PWB-A) pin and GND.

• Voltage across PJ4A-2 and GND

In standby: DC24 V

When pressed: DC0 V

6 Manual Feed Paper Sensor (PC2) is

operational.

<Check Procedure>

Check voltage across a Master Board

(copier: PWB-A) pin and GND when

the sensor is blocked.

• Voltage across PJ4A-5 and GND

When unblocked: DC5 V

When blocked: DC0 V

7 Synchronizing Roller Sensor (PC1) is

operational.

<Check Procedure>

Check voltage across a Master Board

(copier: PWB-A) pin and GND when

the sensor is blocked.

• Voltage across PJ6A-3 and GND

When blocked: DC5 V

When unblocked: DC0 V

NO • Change Manual Bypass Solenoid

(SL2).

NO • Change Manual Feed Paper Sen-

sor (PC2).

NO • Change Synchronizing Roller Sen-

sor (PC1).

YES • Change Master Board (copier:

PWB-A).

Misfeed at Multiple Bypass Tray J06 Troubleshooting Procedures

Step Check Result Action

1 Paper meets product specifications. NO • Change paper.

2 Paper is curled, wavy, or damp. YES • Change paper.

3 Paper Guides are at correct position

to accommodate paper.

4 • Paper Take-Up Roll drive shaft

(Multiple Bypass Tray) turns when

the Start key is pressed.

• Instruct user to load paper that

meets product specifications.

NO • Adjust as necessary.

NO • Reinstall.

T-9

Step Check Result Action

5 Multiple Bypass Solenoid (SL21) is

operational when the Start key is

pressed.

<Check Procedure>

Check voltage across a Master Board

(copier: PWB-A) pin and GND.

• Voltage across PJ4A-2 and GND

In standby: DC24 V

When pressed: DC0 V

6 Paper Take-Up Roll (Multiple Bypass

Tray) is dirty, scratchy, deformed, or

worn.

7 Separator Roll (Multiple Bypass T r a y)

is dirty, scratch y, deformed, or worn.

8 Synchronizing Roller Sensor (PC1) is

operational.

<Check Procedure>

Check voltage across a Master Board

(copier: PWB-A) pin and GND when

the sensor is blocked.

• Voltage across PJ6A-3 and GND

When unblocked: DC5 V

When blocked: DC0 V

NO • Change Multiple Bypass Solenoid

(SL21).

YES • Clean or change.

YES • Clean or change.

NO • Change Synchronizing Roller Sen-

sor (PC1).

YES • Change Master Board (copier:

PWB-A).

T-10

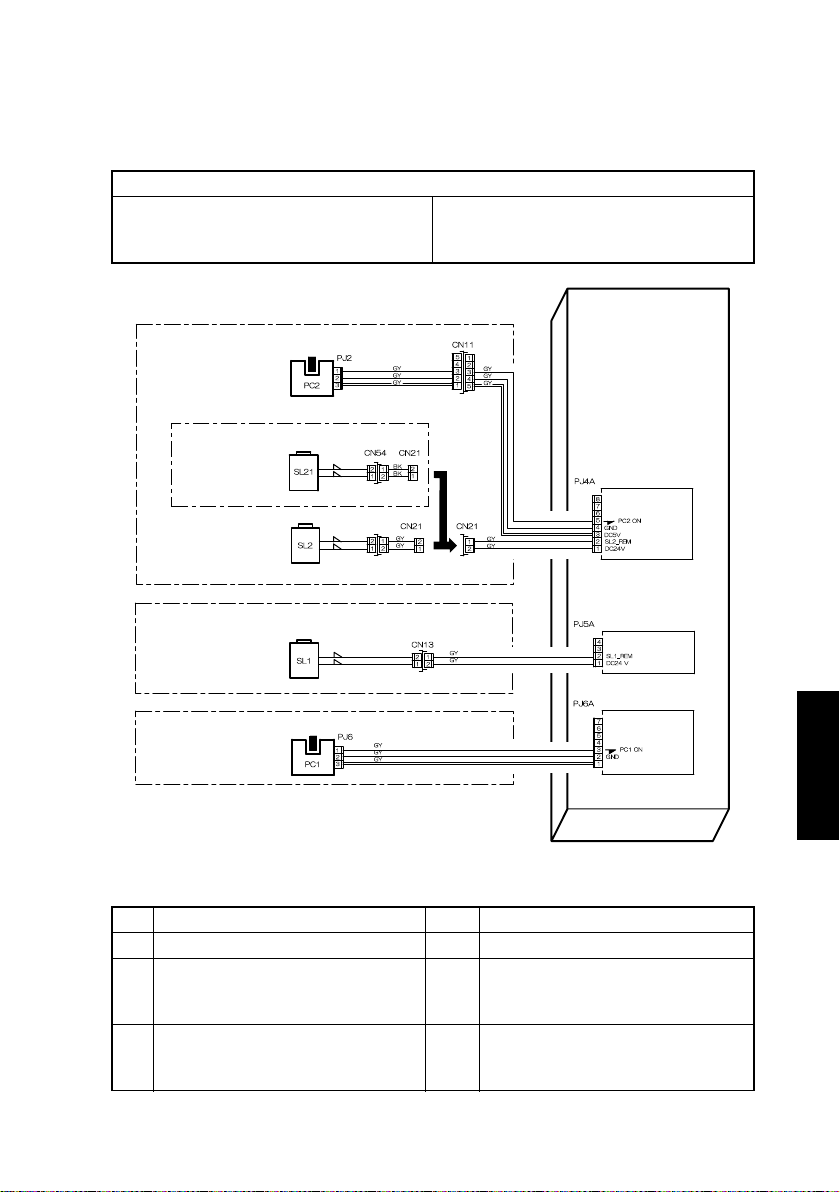

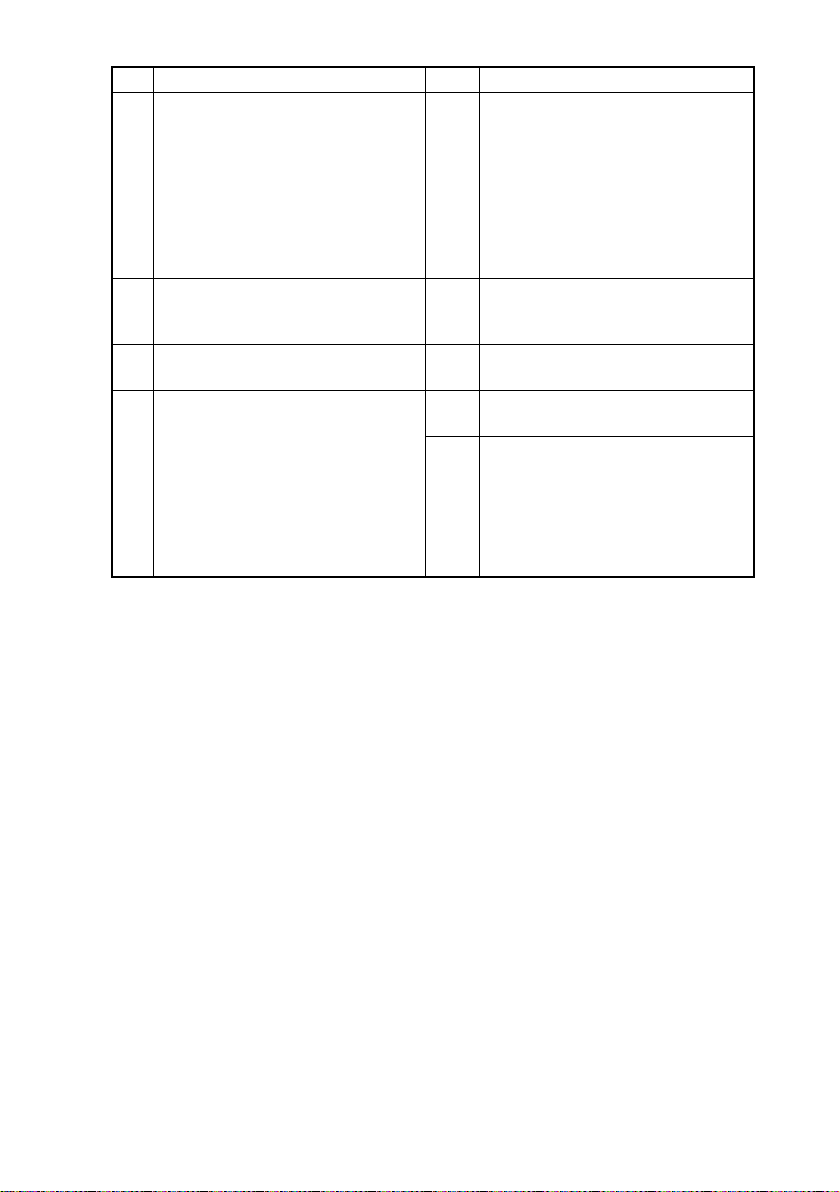

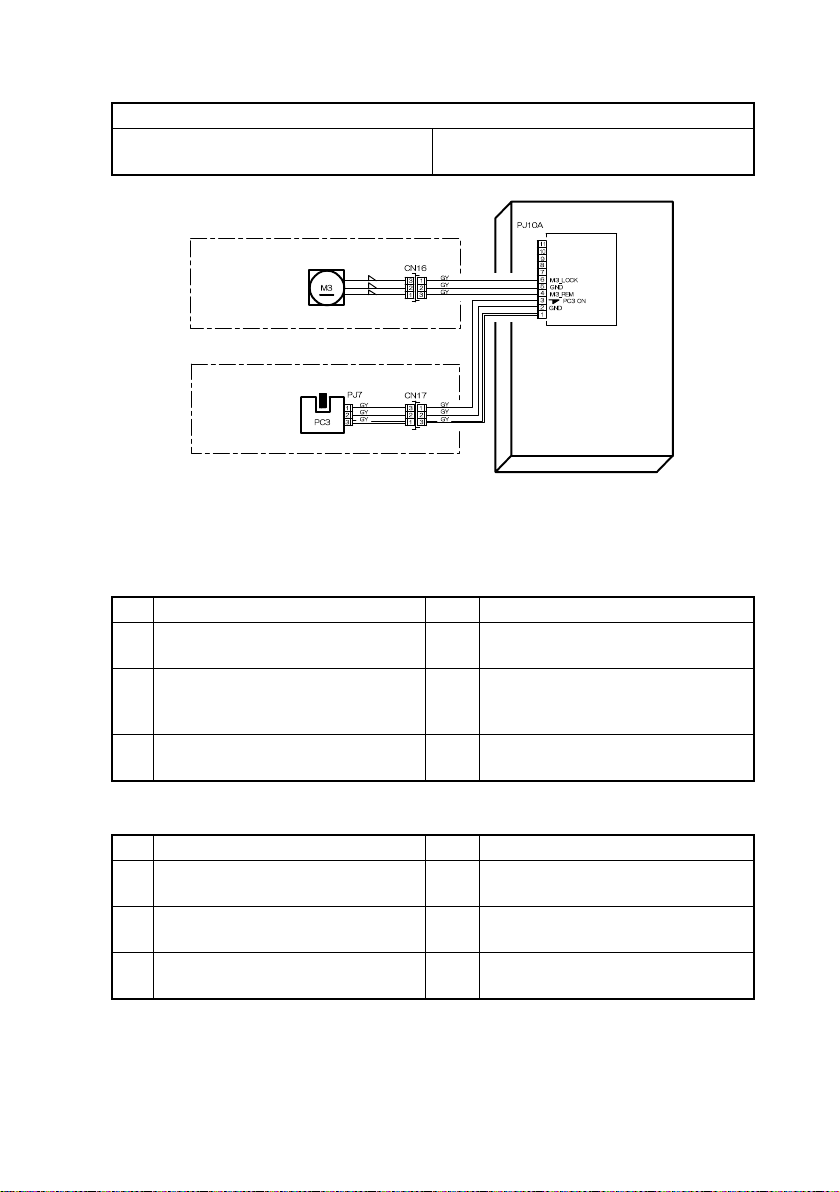

3-2. Misfeed at P aper Feed Cabinet Paper T ake-Up and Transport

Section J02, J03, J04, J05, J1 (PF-121)

Relevant Electrical Parts

Paper Take-Up Solenoid (SL11)

Synchronizing Roller Sensor (PC1)

Paper Take-Up Sensor (PC12)

Master Board (PWB-A)

Control Board (PWB-A): PF-121

PJ6A-1(PC1 ANODE)

PJ18A

Master Board

SL11

SL11

SL11

PJ6A-2(GND)

PJ6A-3(PC1 ON)

PWB-A

CN53

CN53

CN53

CN25

2nd T ra y

PJ3A-1A(SL11 ON)

PJ3A-2A(GND)

3rd Tray

PJ3A-1A(SL11 ON)

PJ3A-2A(GND)

4th Tray

PJ3A-1A(SL11 ON)

PJ3A-2A(GND)

PJ1A

PJ3A-3B(DC5 V)

PJ3A-2B( PC12ON)

PJ3A-1B(GND)

PWB-A

PJ2APJ1A

PJ1A

PJ3A-3B(DC5 V)

PJ3A-2B( PC12ON)

PJ3A-1B(GND)

PWB-A

PJ2APJ1A

PJ1A

PJ3A-3B(DC5 V)

PJ3A-2B( PC12ON)

PJ3A-1B(GND)

PWB-A

PJ2APJ1A

PJ6

13

(PF-121)

13

(PF-121)

13

(PF-121)

PC1

Synchronizing

Roller Sensor

PJ53

PJ53

PJ53

PC12

PC12

PC12

Paper

Take-Up

Sensor

Paper

Take-Up

Sensor

Paper

Take-Up

Sensor

SL11

CN53

5th Tray

PJ3A-1A(SL11 ON)

PJ3A-2A(GND)

T-11

PJ1A

PJ3A-3B(DC5 V)

PJ3A-2B( PC12ON)

PJ3A-1B(GND)

PWB-A

13

(PF-121)

PJ53

PC12

Paper

Take-Up

Sensor

4022T543AA

Misfeed at Paper Feed Cabinet P aper Take-Up and Transport Section J02, J03, J04, J05,

J1 (PF-121) Troubleshooting Procedures

• Paper is not taken up at all.

Step Check Result Action

1 Paper meets product specifications. NO • Change paper.

2 Paper is curled, wavy, or damp. YES • Change paper.

3 Edge Guides and Trailing Edge Stop

are at correct position to accommodate paper.

4 Paper Take-Up Roll is dirty, scratchy,

deformed, or worn.

5 Mylar is dirty, scratch y, or deformed. YES • Clean or change.

6 Separator Fingers are dirty or

deformed.

7 Paper guide plate is dirty or

deformed.

8 Paper Take-Up Solenoid (SL11)

operation check:

The voltage across PJ3A-1A on Con-

trol Board (PF-121: PWB-A) and

GND changes from DC0 V to DC24 V

when the Start key is pressed.

9 Paper Take-Up Sensor (PC12) oper-

ation check:

The voltage across PJ3A-2 on Con-

trol Board (PF-121: PWB-A) and

GND is DC 5 V when the sensor is

unblocked and DC 0 V when the sen-

sor is blocked.

• Instruct user to load paper that

meets product specifications.

NO • Adjust position as necessary.

YES • Clean or change.

YES • Clean or change.

YES • Clean or change.

YES • Change Paper Take-Up Solenoid

(SL11).

NO • Change Control Board (PF-121:

PWB-A).

YES • Change Control Board (PF-121:

PWB-A) and/or Master Board

(copier: PWB-A).

NO • Correct actuator and/or change

Paper Take-Up Sensor (PC12).

• Paper is at a stop near the vertical transport section or Synchronizing Roller.

Step Check Result Action

1 Vertical T ransport Roller/Rolls are

dirty, deformed, or worn.

2 Paper is curled, wavy, or damp. YES • Change paper.

3 Synchronizing Roller Sensor (PC1)

operation check:

The voltage across PJ6A-3 on Master Board (copier: PWB-A) and GND

is DC5 V when the sensor is blocked

and DC0 V when the sensor is

unblocked.

YES • Clean or change.

• Instruct user to load paper that

meets product specifications.

YES • Change Master Board (copier:

PWB-A).

NO • Correct actuator and/or change

Synchronizing Roller Sensor

(PC1).

T-12

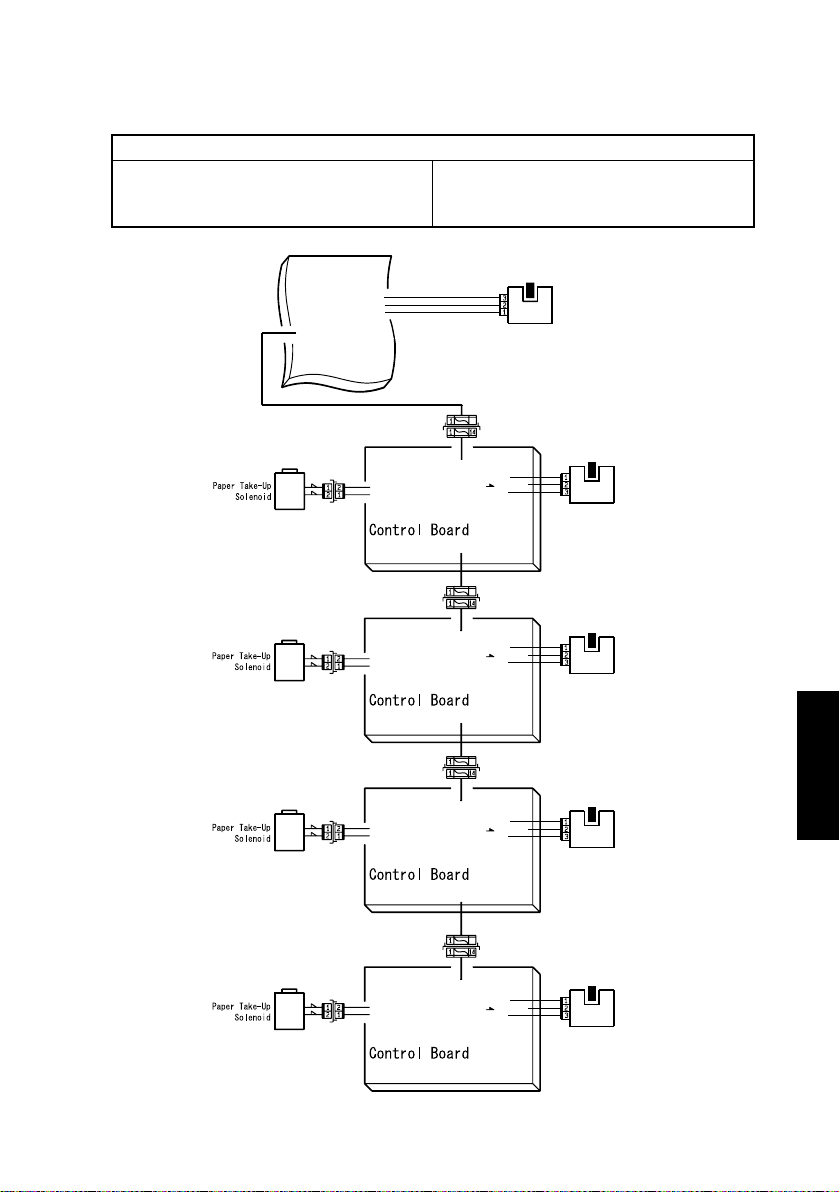

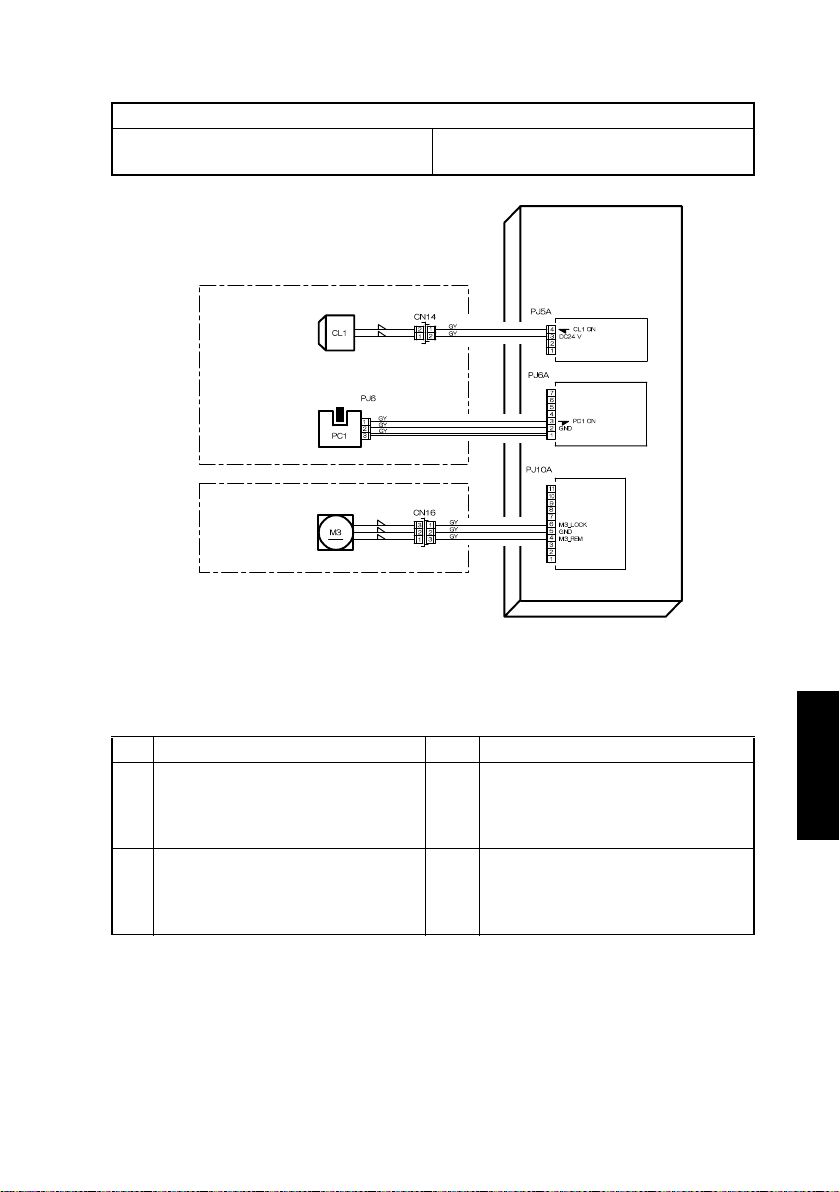

3-3. Misfeed at PC Drum J2

Relevant Electrical Parts

Synchronizing Roller Sensor (PC1)

Fusing Cooling Fan Motor (M3)

TRANSPORT SECTION

Synchronizing

Roller Clutch

Synchronizing Roller Clutch (CL1)

Master Board (PWB-A)

PWB-A

Master Board

Synchronizing

Roller Senser

PC1 ANODE

FUSING SECTION

Fusing Cooling

Fan Motor

4022T523AA

Misfeed at PC Drum J2 Troubleshooting Procedures

• Paper is at a stop at the Synchronizing Roller.

Step Check Result Action

1 Synchronizing Rollers are dirty,

scratchy, deformed, or worn.

2 Loop length is set to an appropriate

value.

YES • Clean or change the Synchronizing

Rollers.

• Clean or change the Paper Dust

Remover.

NO • Adjust loop length using Tech. Rep.

Choice.

• For details, see DIS/REASSEMBLY , ADJUSTMENT.

T-13

Step Check Result Action

3 Synchronizing Roller Sensor (PC1) is

operational.

<Check Procedure>

Check voltage across a Master Board

(copier: PWB-A) pin and GND when

the sensor is blocked.

• Voltage across PJ6A-3 and GND

When blocked: DC5 V

When unblocked: DC0 V

4 The following voltage is supplied to

the Synchronizing Roller Clutch

(CL1).

<Check Procedure>

Check voltage across a Master Board

(copier: PWB-A) pin and GND when

the Start key is pressed.

• Voltage across PJ5A-4 and GND

In standby: DC24 V

When pressed: DC0 V

• Paper is at a stop at the PC Drum.

Step Check Result Action

1 Image Transfer Roller is dirty. YES • Clean or change.

2 PC Drum Paper Separator Fingers

are dirty, scratchy, deformed, worn, or

damaged.

3 Charge Neutralizing Plate is dirty,

scratched, broken, or bent.

NO • Change Synchronizing Roller Sen-

sor (PC1).

YES • Change Synchronizing Roller

Clutch (CL1).

NO • Change Master Board (copier:

PWB-A).

YES • Clean or change.

YES • Clean, correct, or change.

T-14

• Paper is at a stop at the transport section.

Step Check Result Action

1 Transport guide plate is dirty,

scratchy, deformed, worn, or damaged.

2 The following voltage is supplied to

the Fusing Cooling Fan Motor (M3).

<Check Procedure>

Check voltage across a Master Board

(copier: PWB-A) pin and GND when

the Start key is pressed.

• Voltage across PJ10A-4 and GND

During decelerated rotation: DC8 V

During full speed rotation: DC24 V

YES • Clean or change.

YES • Change Fusing Cooling Fan Motor

(M3).

NO • Change Master Board (copier:

PWB-A).

T-15

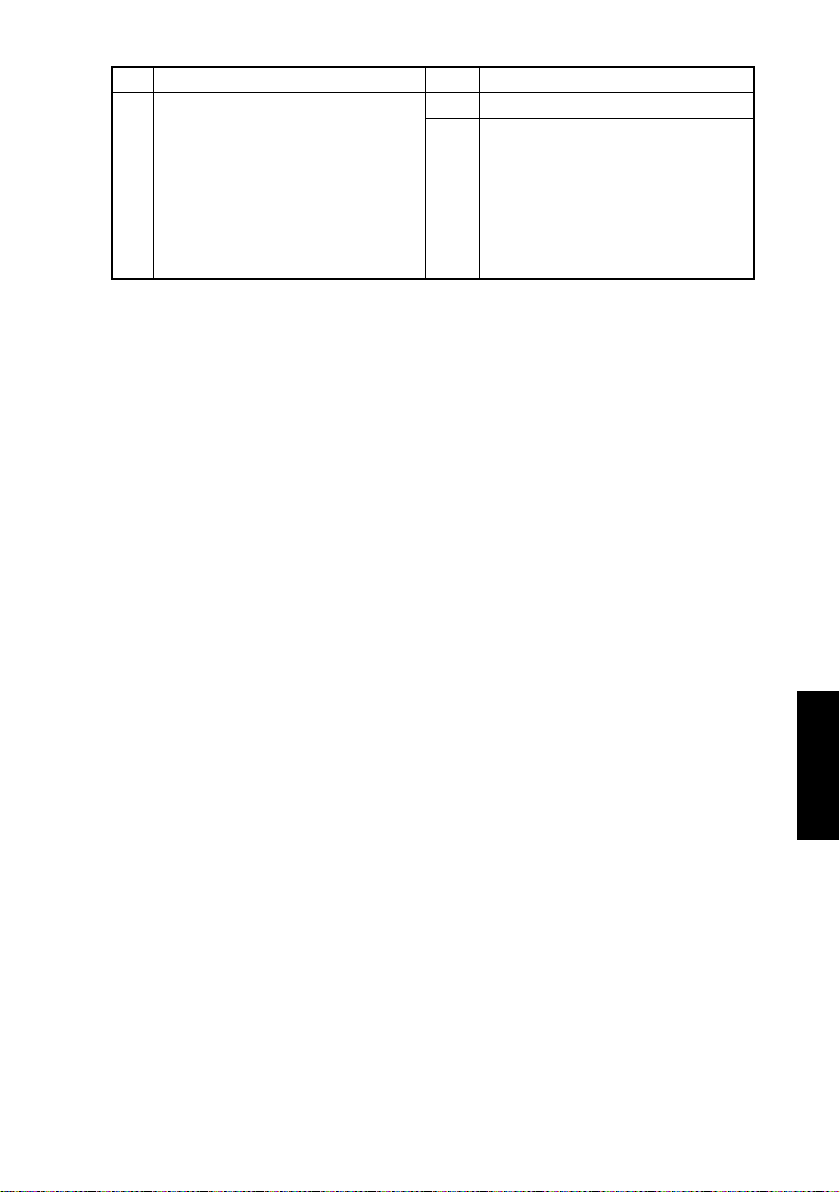

3-4. Misfeed at Fusing Unit J3

Relevant Electrical Parts

Exit Paper Sensor (PC3)

Fusing Cooling Fan Motor (M3)

FUSING SECTION

Fusing Cooling

Fan Motor

Master Board (PWB-A)

PC3 ANODE

PAPER EXIT SECTION

Exit Paper

Sensor

Misfeed at Fusing Unit J3 Troubleshooting Procedures

• Paper is at a stop at the Fusing Unit.

Step Check Result Action

1 Fusing guide plate is dirty, sc ratchy,

deformed, worn, or damaged.

2 Fusing Paper Separator Fingers are

dirty, scratchy, deformed, or worn.

3 Fusing Rollers are dirty, scratchy,

deformed, or worn.

• Paper is at a stop at the paper exit section.

Step Check Result Action

1 Exit guide plate is dirty, scratchy,

deformed, worn, or damaged.

2 Transpor t Roller is dirty, scratchy,

deformed, or worn.

3 Exit Roller/Rolls are dirty, scratchy,

deformed, or worn.

YES • Clean or change.

YES • Clean or change the Fusing Paper

YES • Clean or change.

YES • Clean or change.

YES • Clean or change.

YES • Clean or change.

PWB-A

Master Board

4022T511AA

Separator Fingers, or change

spring.

T-16

Step Check Result Action

4 Exit Paper Sensor (PC3) is opera-

tional.

<Check Procedure>

Check voltage across a Master Board

(copier: PWB-A) pin and GND when

the sensor is blocked.

• Voltage across PJ10A-3 and GND

When blocked: DC5 V

When unblocked: DC0 V

NO • Change Exit Paper Sensor (PC3).

YES • Change Master Board (copier:

PWB-A).

T-17

4. MALFUNCTION

The copier’s CPU is equipped with a self-diagnostics function that, on detecting a malfunction, gives the corresponding malfunction code on the Display.

4-1. Detection Timing by Malfunction Code

Code Description Detection Timing

C0000 Main Motor malfunc-

tion

C0045 Fusing Cooling Fan

Motor malfunction

C004E Power Supply Cool-

ing Fan Motor malfunction

C0070 Toner Replenishing

Motor malfunction

C0210 Abnormal image

transfer voltage

C03FF Improper l y set Adjus t

Mode 11

C0500 Warm-up failure • It takes the surface temperature of the Left Fusing

C0510 Abnormally low fus-

ing temperature

C0520 Abnormally high fus-

ing temperature

• The Main Motor (M1) Lock signal remains HIGH for a

continuous 1-sec. period at any time 1 sec. after the

Main Motor has started turning.

• The Fusing Cooling Fan Motor (M3) Lock signal

remains HIGH for a continuous 1-sec. period while the

Fusing Cooling Fan Motor is turning at full speed or

decelerated speed.

• The Power Supply Cooling Fan Motor (M4) Lock signal remains HIGH for a continuous 1-sec. period while

the Pow er Supply Cooling Fan Motor Remote signal

remains ON (for full-speed rotation) or OFF (for decelerated-speed rotation).

• The Toner Bottle Home P osition Sensor (PC7) outputs

a HIGH signal for a continuous 3.5-sec. period while

the Toner Bottle is turning.

• The Toner Bottle Home P osition Sensor (PC7) outputs

a LOW signal f or a continuous 2-sec. period while the

Toner Bottle is turning.

• The image transfer voltage remains more than 100 V

for a continuous given per iod of time while the PC

Drum remains stationary.

• An incorrect setting is made of Adjust 11.

Roller more than 35 sec. to reach 100 °C since the

start of a warm-up cycle.

• It takes the surface temperature of the Left Fusing

Roller more than 25 sec. to reach 140 °C after it has

reached 100 °C.

• It takes more than 20 sec. for the warm-up cycle to be

completed after the surface temperature of the Left

Fusing Roller has reached 140 °C.

• The surface temperature of the Left Fusing Roller

remains lower than 120 °C for a given period of time

while the copier is in a standby state.

• The surface temperature of the Left Fusing Roller

remains lower than 120 °C for a given period of time

during a print cycle.

The surface temperature of the Left Fusing Roller

remains higher than 240 °C for a given period of time.

T-18

Loading...

Loading...