Page 1

2

UNIT EXPLANATION

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Page 2

1 OUTLINE

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Blank page

Page 3

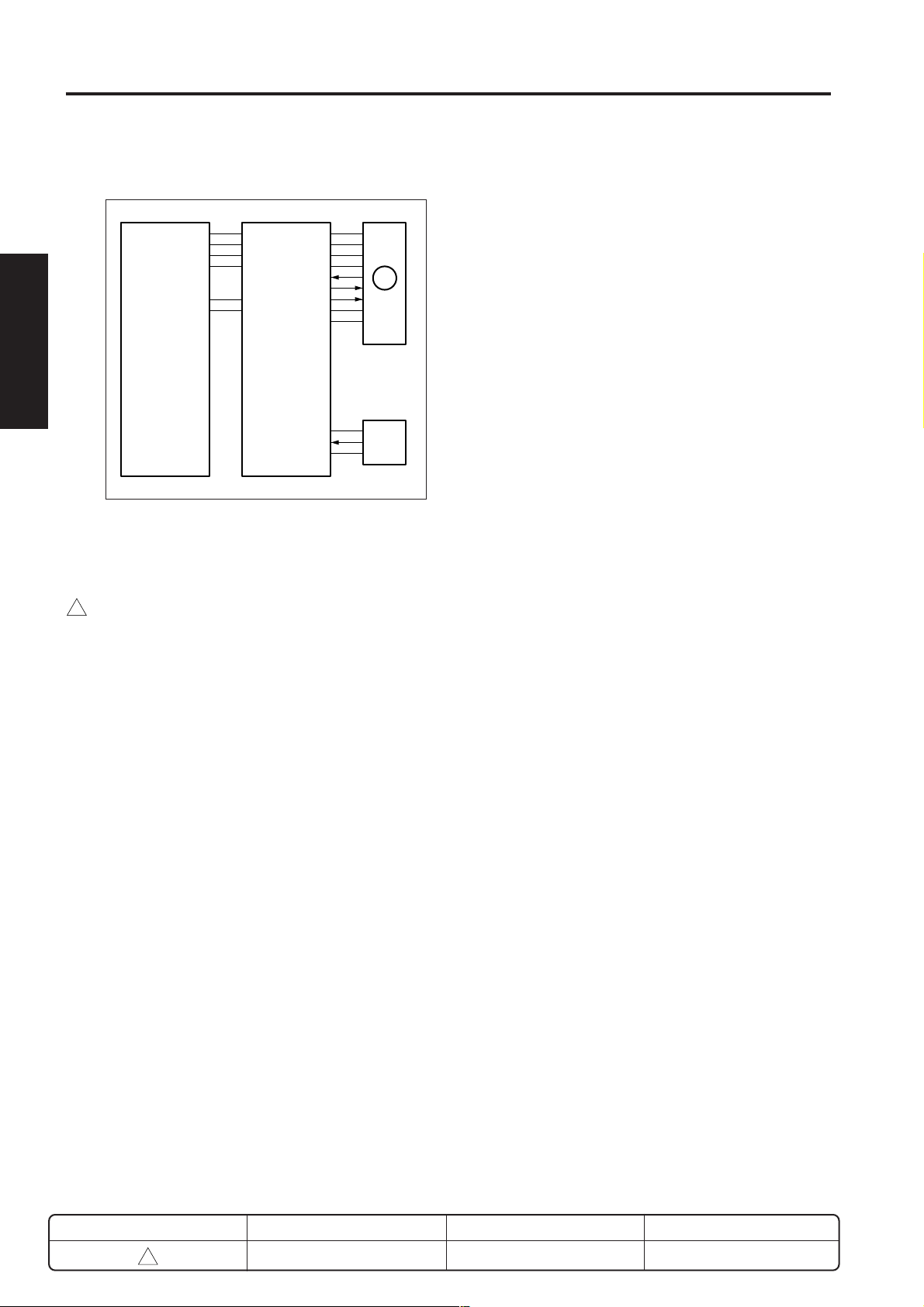

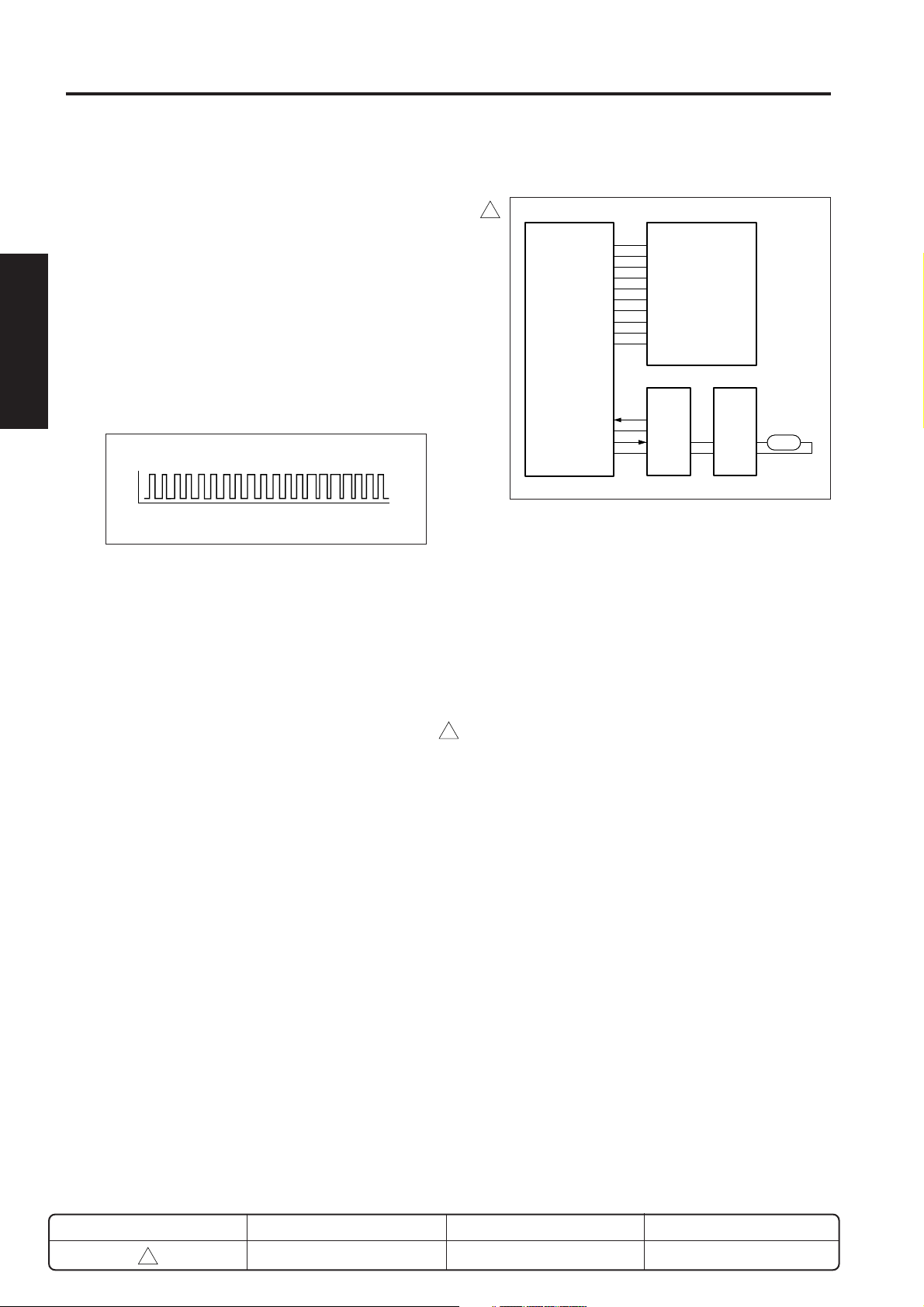

EXTERNAL SECTION

EXTERNAL SECTION

[1] Composition

1

Sub power switch

(SW2)

Main power switch

(SW1)

1 OUTLINE

Platen cover (Option)

Operation panel

Exit tray

2 UNIT EXPLANATION

Front door

Upper tray

Lower tray

3 DIS./ASSEMBLY

By-pass tray

KRDS interface (serial)

ISW interface (parallel)

REVISED EDITION

1

DC5V jack

ADU door

DATE

May 2000

2-A-1

PA GE

2-A-1

Rear cover

METHOD

REPLACEMENT

Page 4

1 OUTLINE

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Blank page

Page 5

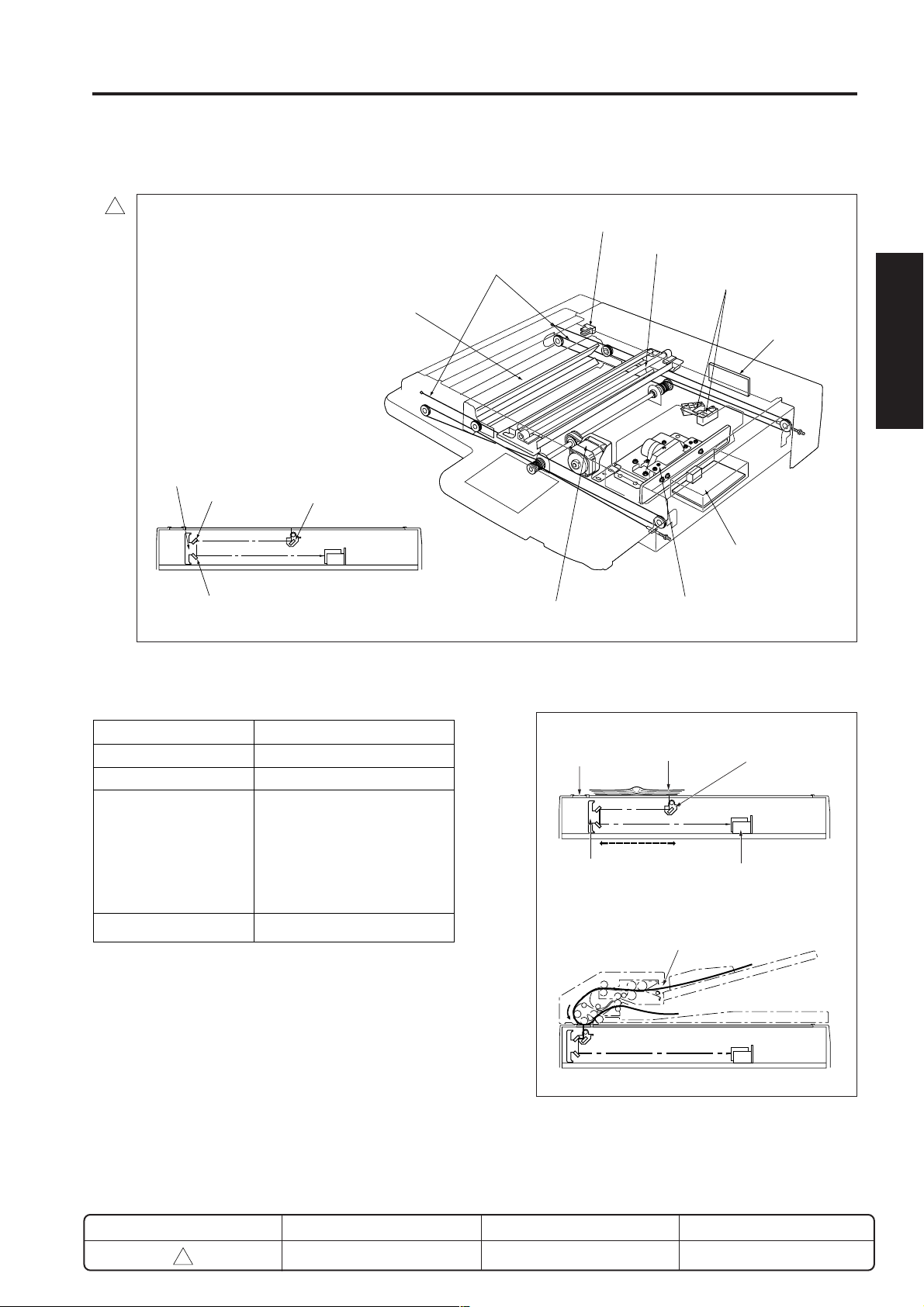

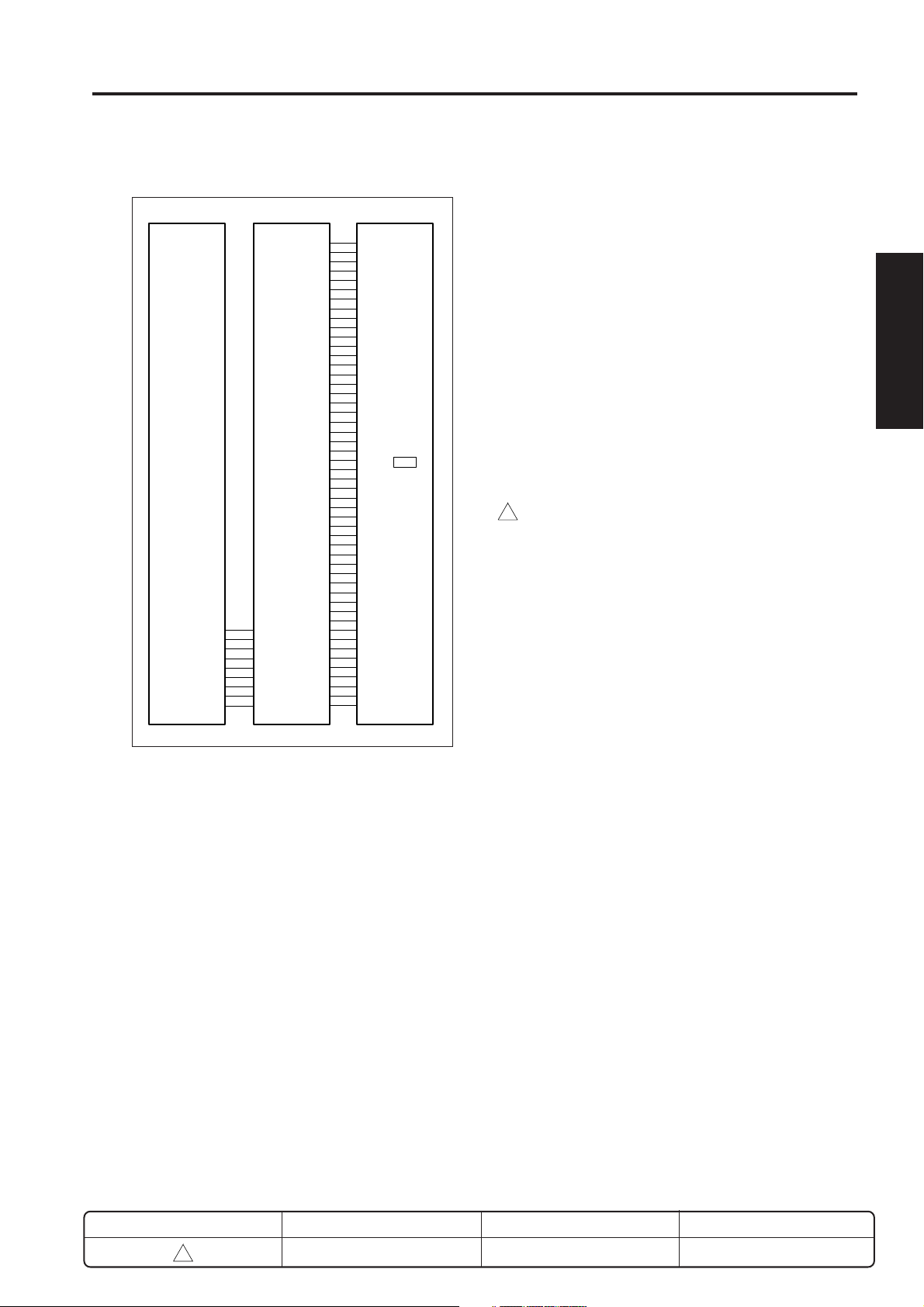

DRIVE SECTION

DRIVE SECTION

[1] Composition

2

Main motor (M1)

Paper feed drive

motor (M9)

1 OUTLINE

2 UNIT EXPLANATION

Toner supply motor 1 (M4)

Toner supply motor 2 (M10)

* 7035 only

3 DIS./ASSEMBLY

Developing motor (M3)

[2] Mechanisms

Mechanism Method

2

Drum, Conveyance, Gear drive (M1)

Developer agitation,

Fixing, and exit drive,

ADU conveyance drive,

IT conveyance/exit

drive (when installing IT)

Developing sleeve drive Gear drive (M3)

Paper feed drive, ADU Gear drive (M9)

conveyance drive

Toner supply drive Gear drive (M4)

Toner bottle rotation drive Gear drive (M10)

(7035 only)

ADU drive Gear drive (M6)

ADU motor (M6)

REVISED EDITION

2

DATE

Feb. 2001

2-B-1

PAG E

2-B-1

METHOD

REPLACEMENT

Page 6

DRIVE SECTION

1 OUTLINE

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

[3] M1 (main motor) control

24VDC

24VDC

PGND

PGND

SGND

5VDC

DCPS

M1 (main motor) is controlled by the PRDB (printer drive

board).

1. Operation

M1 is a brushless motor running on 24 VDC. It drives

2

the 2nd paper feed, fixing, drum, toner conveyance

screw and toner recycle screw, and also drives part

of the developer agitation screw, IT drive coupling

and the ADU conveyance section.

PRDB

24VDC

24VDC

PGND

PGND

LOCK SIG

M1 CLK

M1 CONT

5VDC

SGND

SGND

PS3

5VDC

M1

PS3

2. Signals

a. Input signals

(1) LOCK SIG (M1 → PRDB)

A monitoring signal for the rotation of M1.

Goes [L] when M1 rotation reaches the rated speed.

[H]: Stopped, or rotating at other than rated speed.

[L]: Rotating at rated speed. (PLL: stable)

(2) PS3 (PS3 → PRDB)

Paper exit passage detect signal.

[H] when paper is detected.

b. Output signals

(1) M1 CONT (PRDB → M1)

M1 drive control signal.

[L]: M1 ON

[H]: M1 OFF

(2) M1 CLK (PRDB → M1)

Reference clock for M1 rotation control.

When IT is installed, M1 drives IT conveyance section and also drives the paper exit section via the IT

drive coupling.

M1 includes an internal speed PS, and utilizes PLL

control to maintain constant speed. Rotational speed

is controlled by a reference clock signal output by

PRDB.

M1 comes ON when the START button is pressed, and

goes OFF at a predetermined time interval after PS3

(exit sensor) goes OFF for the final copy.

At warm-up start, M1 comes ON. only during initial

drum charging.

REVISED EDITION

2

DATE

Feb. 2001

2-B-2

PA GE

2-B-2

METHOD

REPLACEMENT

Page 7

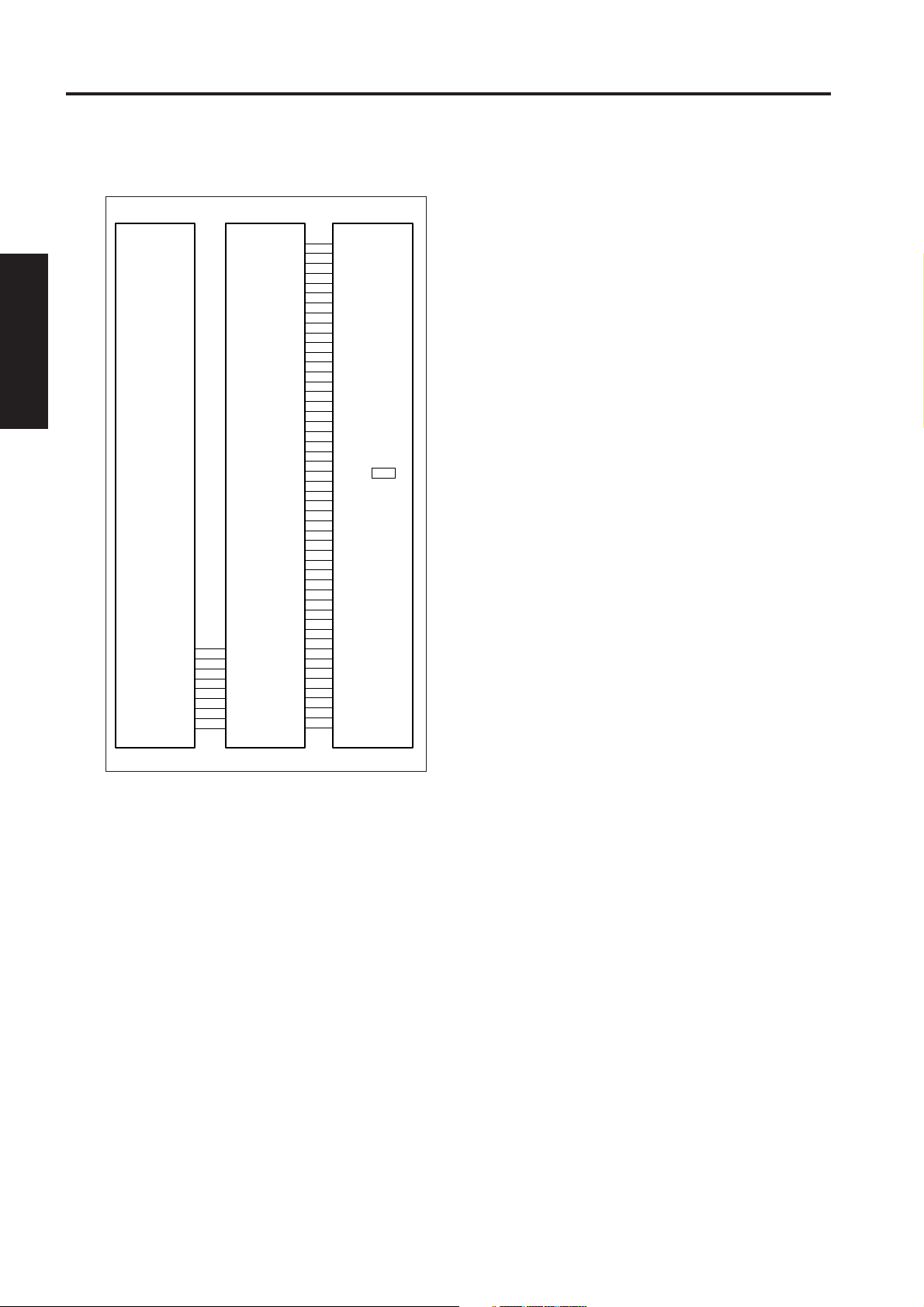

READ SECTION

READ SECTION

[1] Composition

2

V mirror unit

2nd mirror

3rd mirror

1st mirror

V mirror unit

Optics wires

Optical motor (M2)

Home-position

sensor (PS14)

Exposure unit

APS sensors 1 and 2

(PS17, PS18)

Exposure-lamp

inverter (INV1)

Scanner drive

board (SCDB)

CCD unit (AD converter

board (ADB))

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

[2] Mechanisms

Mechanism Method

Light source Xenon lamp

Exposure Light source slit exposure

Scanning * Platen original scanning:

Movement of 1st, 2nd,

and 3rd mirrors.

RADF original scanning:

Original is moved with light

source held stationary.

Lamp power supply Lamp cord

* Platen and RADF scans operate as follows.

a. Platen original: The original is placed on the platen

glass, and reading is accomplished by movement

of the exposure unit and V mirror unit.

b. RADF original: The exposure unit and V mirror unit

are shifted under slit glass, and the original is

scanned as it passes over the exposure unit.

Slit glass

V mirror unit

Platen original

RADF original

Exposure unit

CCD unit

REVISED EDITION

2

DATE

Feb. 2001

2-C-1

PA GE

2-C-1

METHOD

REPLACEMENT

Page 8

READ SECTION

222

1 OUTLINE

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

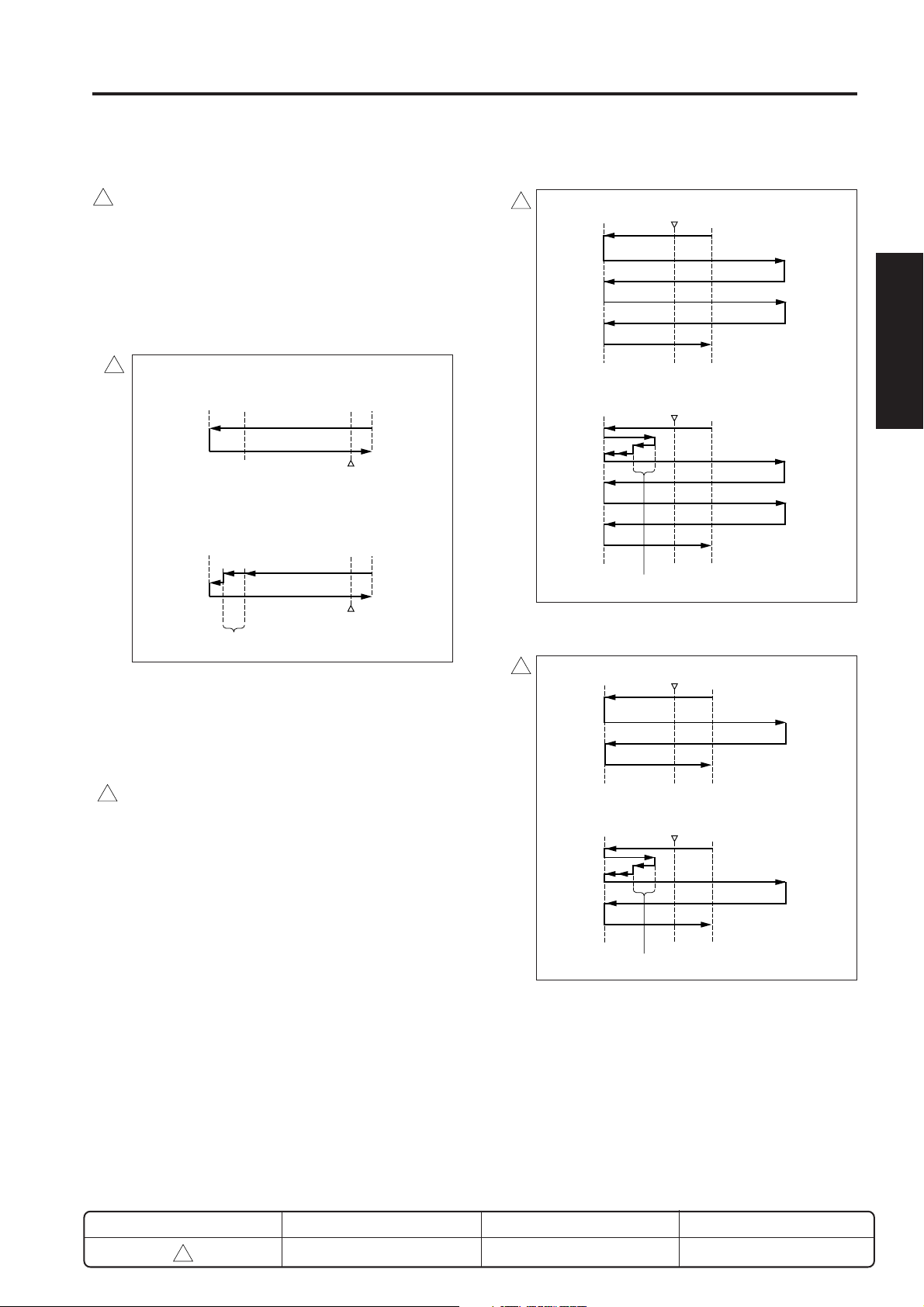

[3] M2 (optical motor) control

24VDC

24VDC

24VDC

PGND

PGND

PGND

5VDC

5VDC

SGND

SGND

DCPS

SCDB

M2 (optical motor) is controlled by the SCDB (scanner

drive board). A related signal is provided by PS14 (optics

home position PS).

1. Operation

a. Operation of M2

M2 is a 3 phase stepping motor running on 24VDC.

This motor drives the exposure unit so as to

implement scanning. Forward rotation, reverse

rotation, and rotation speed are switched as

necessary to carry out each scan cycle.

The exposure unit's home position is detected by

PS14. M2 operation (drive time span and drive

direction) is controlled by time count after PS14 ON

or PS14 OFF.

b. Exposure unit’s scan speed

Scan Speed

2

Scan Speed

Forward <7020/25/30>

140mm/sec

(1:1 magnification)

<7035>

80mm/sec

(1:1 magnification)

Reverse <7020/25/30>

241mm/sec (max)

<7035>

310mm/sec (max)

c. Initial operation when power is turned ON

When SW2 (sub power switch) comes ON, the

exposure unit starts a home position search. The

search procedure differs according to whether PS14

is ON or OFF. Upon completing the search, the

exposure unit stands by at the platen mode's APS

reading position.

SGND

OPT_HOME

5VDC

U

V

W

M2

PS14

(1) When PS14 is turned ON

<7020/25/30>

Shading correction

Reference point

<7035>

Reference point

reading

PS14

Shading correction

reading

PS14

Platen APS

reading position

Platen APS

reading position

(2) When PS14 is goes OFF

<7020/25/30>

Shading correction

Reference point

<7035>

Reference point

reading

PS14

Shading correction

reading

PS14

Platen APS

reading position

Platen APS

reading position

d. Shading correction reading

Shading correction read out is implemented using the

white reference plate attached beneath the glass

stopper plate. Shading correction is executed when

SW2 comes ON.

In the case of the 7035, shading correction is

performed when SW2 is turned ON, and also during

each scanning job.

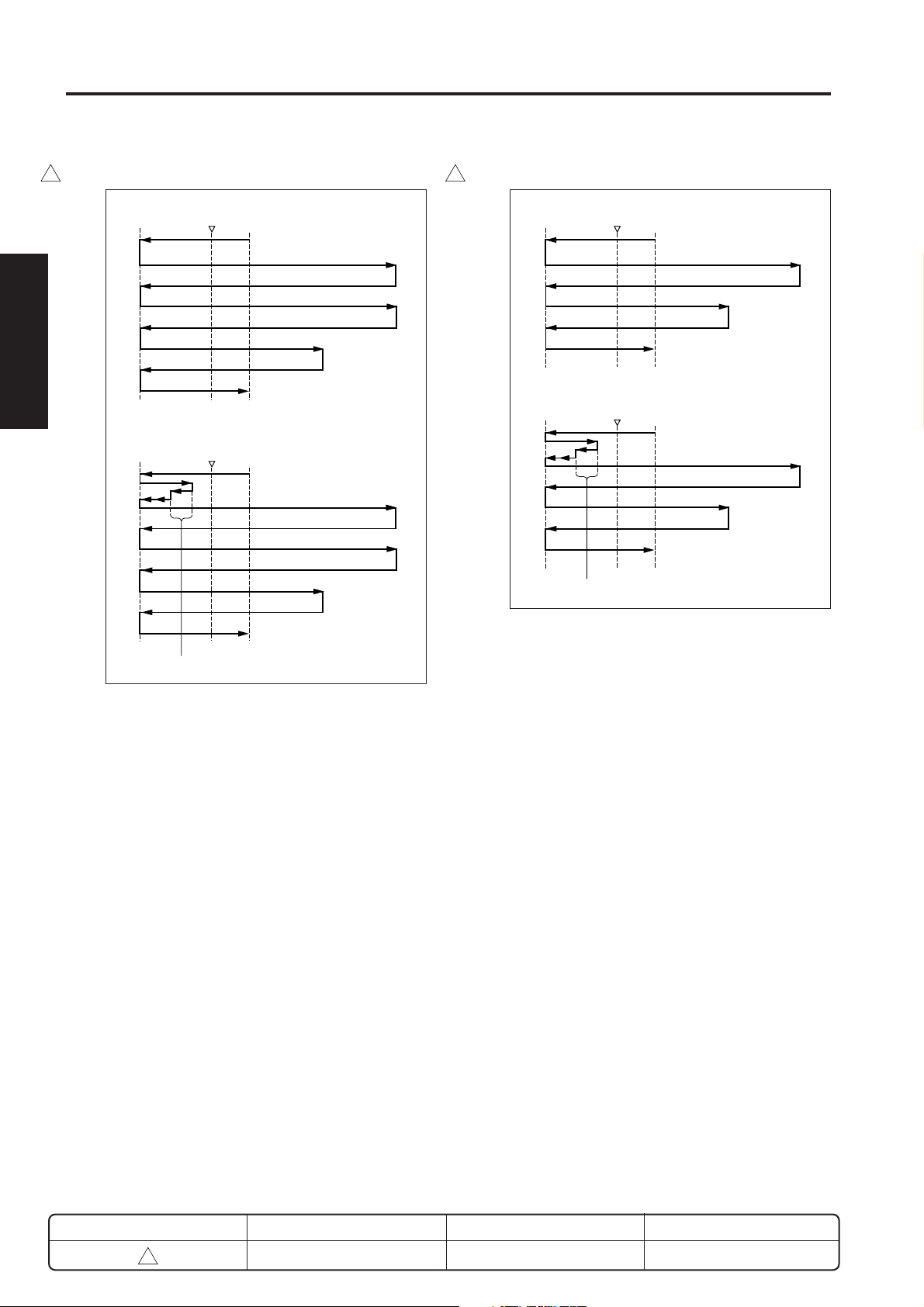

e. Exposure scanning modes

Two modes are implemented: platen mode and DF mode.

In platen mode, the exposure unit moves as necessary

to scan the original. In DF mode, the RADF side

moves the original while the exposure unit stays fixed

in a specified position (the DF reading position).

REVISED EDITION

DATE

PA GE

METHOD

2-C-2

2

Feb. 2001

2-C-2

REPLACEMENT

Page 9

READ SECTION

f. Operation in DF mode

The read position in the DF mode is on the paper exit side

2

of PS14, and the exposure unit moves from the standby

position (platen APS read position) to the DF read

position (in the case of the 7020/25/30). In the case of

the 7035, shading correction takes place while the

exposure unit is moving to the DF read position.

It then returns to the platen APS reading position after

completing the original scan and again enters standby.

2

<7020/25/30>

DF reading

position

Reference point

<7035>

DF reading

position

Shading correction reading

Reference point

Platen APS

reading position

PS14

Platen APS

reading position

PS14

(1) AE mode

<7020/25/30>

2

Reference point

<7035>

Reference

point

Shading correction reading

(2) Manual copy mode

PS14

PS14

1 OUTLINE

AE scan

Exposure scan

Platen APS

reading position

2 UNIT EXPLANATION

AE scan

Exposure scan

Platen APS

reading position

3 DIS./ASSEMBLY

g. Operation in platen mode

In this mode, the scan sequence depends on the

copy density selection (either AE or manual).

When the start button is pressed

When the AE mode is selected, the AE scan takes

2

place. When the AE mode is not selected, an

exposure scan takes place immediately (in the case

of the 7020/25/30). In the case of the 7035, shading

correction is performed before the commencement of

scanning, for all operations.

After completing the scan, exposure unit turns to the

platen APS reading position.

2

<7020/25/30>

<7020/25/30>

Reference point

Reference

point

Shading correction reading

PS14

Exposure scan

Platen APS

reading position

PS14

Exposure scan

Platen APS

reading position

REVISED EDITION

2

DATE

Feb. 2001

2-C-3

PA GE

2-C-3

METHOD

REPLACEMENT

Page 10

READ SECTION

1 OUTLINE

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

2

<7020/25/30>

PS14

AE scan

Exposure scan (Latter half)

Exposure scan (First half)

Platen APS

Reference point

<7035>

Reference

point

Shading correction reading

PS14

reading position

AE scan

Exposure scan (Latter half)

Exposure scan (First half)

Platen APS

reading position

(4) Dual page (Manual mode, Left binding) mode(3) Dual page (AE mode, Left binding) mode

2

<7020/25/30>

PS14

Exposure scan (Latter half)

Exposure scan (First half)

Platen APS

reading position

Reference point

<7035>

Reference

point

PS14

Exposure scan (Latter half)

Exposure scan (First half)

Platen APS

reading position

Shading correction reading

REVISED EDITION

2

DATE

Feb. 2001

2-C-4

PA GE

2-C-3-1

METHOD

ADDITION

Page 11

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Blank page

REVISED EDITION

2

DATE

Feb. 2001

PAG E

–

METHOD

ADDITION

Page 12

1 OUTLINE

2

2 UNIT EXPLANATION

READ SECTION

2. Signals

a. Input signal

(1) OPT_HOME (PS14 → SCDB)

Exposure unit's home position detect signal.

[L]: Exposure unit is in home position.

[H]: Exposure unit out of home position.

b. Output signal

(1) M2 U, V, W (SCDB → M2)

M2 (Optical motor) ON/OFF drive signals.

24V

0V

[4] Exposure control

2

24VDC

24VDC

24VDC

PGND

PGND

PGND

5VDC

5VDC

SGND

SGND

L1 EM

PGND

LAMP_ON/OFF

24VDC

SCDB

DCPS

LV

HV

INV1 L1INVB

L1

Power for L1 (exposure lamp) is supplied by INV1

(exposure lamp inverter). This action is controlled by the

SCDB (scanner drive board).

3 DIS./ASSEMBLY

1. Operation

L1 is a xenon lamp, and is driven by an inverter

circuit. Since the xenon lamp provides a stable light

intensity with low heat generation, it does not require

light intensity control circuit or overheat protection

circuit.

2. Signals

2

a. Input signal

(1) L1 EM (INV1 → SCDB)

1NV1 error detect signal

Enabled only when LAMP_ON/OFF is ON [L].

[L]: L1 ON

[H]: L1 OFF

* L1 EM is always High when LAMP_ON/OFF is OFF [H].

b. Output signal

(1) LAMP_ON/OFF (SCDB → INV1)

L1 ON/OFF control signal.

REVISED EDITION

2

DATE

Feb. 2001

2-C-6

[L]: L1 ON

[H]: L1 OFF

PA GE

2-C-4

METHOD

REPLACEMENT

Page 13

READ SECTION

[5] Original reading control

5VDC

5VDC

SGND

SGND

12VDC

SGND

-12VDC

SGND

DCPS

12VDC

CB

SGND

YCK 1

SGND

RCK

SGND

YG

SGND

CLAMP

SGND

SCK

SIN

SLD

MD0

MD1

MD2

SGND

OD0

OD1

OD2

OD3

SGND

OD4

OD5

OD6

OD7

SGND

ED0

ED1

ED2

ED3

SGND

ED4

ED5

ED6

ED7

APR

12VDC

12VDC

12VDC

12VDC

SGND

5VDC

5VDC

5VDC

5VDC

SGND

-5VDC

-5VDC

-5VDC

-5VDC

ADB

CCD

1. Operation

The light from the exposure lamp reflects back from

the original, passes through a lens, and hits the CCD

sensor. The CCD sensor generates an analog

electrical signal corresponding to the light intensity.

The ADB (A/D conversion board) then converts this

signal into a digital signal.

a. Original reading

The reading timing is as follows.

(1) Platen mode

Reading starts at a predetermined time interval after

the START button is pressed and when the exposure

unit has moved 6mm in the paper feed direction after

PS14 (optics home position) goes OFF.

(2) DF mode

When the leading edge of the original turns ON

1

PS311 (original registration PS) then moves a further

24.1 mm.

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Original reading is carried out by the CCD sensor on the

ADB (A/D conversion board).

REVISED EDITION

1

DATE

May 2000

2-C-7

PA GE

2-C-5

METHOD

REPLACEMENT

Page 14

READ SECTION

1 OUTLINE

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

[6] APS control

1

5VDC

5VDC

SGND

SGND

12VDC

SGND

-12VDC

SGND

DCPS

12VDC

5VDC

5VDC

SGND

SGND

CB

OPT_HOME

TIMING 1

APS_DATA 1

APS_DATA 2

SCDB

SGND

5VDC

SGND

5VDC

SGND

5VDC

SGND

5VDC

APS detection is carried out at opening or closing of the

RADF cover or original cover, and is controlled by the

SCDB (scanner drive board) based on signals from the

APS sensors and CCD sensor. Related signals are

provided by PS14 (optics home position PS), PS15 (APS

timing PS) and by PS304 (DF open/close PS) on the

RADF.

CCD

ADB

PS14

PS15

PS17

PS18

L1 is ON during APS detection, so that the illumination level (light or dark level) in the main scanning differs according to whether the original is present or

absent. To detect line width (main scanning width),

the CCD sensor detects the difference from sky shot

black level to paper edge white level at each side. If

the RADF is installed, original size detection in the

main scanning is reexecuted when PS304 (DF open/

close PS) comes ON, so as to confirm the original

size.

The two APS sensors (PS17 and PS18) each consist

of a photosensor and a LED. If the original is present

at the sensor position, the light generated by the LED

reflects from the original and is detected by the

photosensor.

Exit

side

PS17 PS18

: Photosensor

: LED

1. Operation

a. APS detect operation

APS detection operation differs according to whether

operation is in platen mode or DF mode.

(1) Platen mode

Size is detected by the combination of the ON/OFF

action of PS17 (APS sensor 1) and PS18 (APS

sensor 2) and the detect signal from the CCD sensor

on the ADB (A/D conversion board).

PS17 and PS18 detect the original size in the sub

scanning direction, while the CCD sensor detects the

size in the main scanning direction.

(2) DF mode

Original size detection is carried out by ON/OFF

action of PS306 (original size detect PS 1), and

PS307 (original size detect PS 2), and by the

resistance level of VR301 (original size detect VR)

located in the RADF paper feed tray.

REVISED EDITION

1

DATE

May 2000

2-C-8

PAG E

2-C-6

METHOD

REPLACEMENT

Page 15

READ SECTION

1

Original Size

The following table shows the relation between the

PS sensors and detected original sizes.

Sensor

A3

11 × 17

B4

8.5 × 14

F4(8.5 × 13R)

8.5 × 11R

A4R

A4

8.5 × 11

B5

A5

B5R

A5R

B6R

PS17

PS306

ON

ON

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

PS18

PS307

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON : Original detected

OFF : Original not detected

2. Signals

a. Input signals

(1) TIMING1 (PS15 → SCDB)

RADF cover or platen cover open/close detect signal.

[L]: ON (Execute APS)

[H]: OFF (Cancel APS)

(2) APS_DATA1 (PS17 → SCDB)

Original size detect signal.

[L]: Original detected.

[H]: Original not detected.

(3) ASP_DATA2 (PS18 → SCDB)

Original size detect signal.

[L]: Original detected.

[H]: Original not detected.

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

b. APS detection timing

APS detection timing differs according to whether

operation is in platen mode or DF mode.

(1) Platen mode

Detection is carried out when PS15 (APS timing PS)

comes ON.

• If the RADF is installed, detection is carried out

again when PS304 (DF open/close PS) comes

ON.

• If the platen cover or RADF is open, detection is

carried out when the START button comes ON.

(2) DF mode

If DF mode has been selected or if an original is set in

the RADF paper feed tray, detection is carried out

using PS306 (original size detect PS 1), PS307

(original size detect PS 2), and VR301 (original size

detect VR).

REVISED EDITION

1

DATE

May 2000

2-C-9

PA GE

2-C-7

METHOD

REPLACEMENT

Page 16

READ SECTION

1 OUTLINE

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

[7] AE control

SGND

YCK 1

SGND

RCK

SGND

YG

SGND

CLAMP

SGND

SCK

SIN

SLD

MD0

MD1

MD2

SGND

OD0

OD1

OD2

OD3

SGND

OD4

OD5

OD6

CCD

OD7

SGND

ED0

ED1

ED2

ED3

SGND

ED4

ED5

ED6

ED7

APR

12VDC

12VDC

12VDC

12VDC

SGND

5VDC

5VDC

SGND

SGND

12VDC

SGND

-12VDC

SGND

DCPS

12VDC

CB

During AE scan, the CCD sensor on the ADB (A/D

conversion board) reads the density level of the original.

The CPU on the CB (overall control board) processes the

data and, based on the results, selects the gamma

correction curve that will best reproduce the original.

5VDC

5VDC

5VDC

5VDC

SGND

-5VDC

-5VDC

-5VDC

-5VDC

ADB

1. Operation

a. AE detect operation

(1) Platen copy

AE scanning is carried out when the START button is

pressed. The operation measures density over the

range described below.

<AE sampling range>

1) If the platen cover or RADF cover is open,

sampling is carried out to the boundaries of the

non image area erase or within the area detected

by APS.

2) If the platen cover or RADF cover is closed,

scanning is carried out over the range from the

center to 20mm away from each edge of the

original, as detected by APS.

• If APS is unable to detect the size, sampling is

carried out up to 20mm short of the minimum

supported original size in each direction.

(2) DF mode (1-1)

Pressing the START button causes the original to

feed. The leading area of the original is read, and

density is measured based on the read data. The

sampling range is as follows.

<AE sampling range>

1) In the main scanning direction

Sampling is carried out to the boundaries of the

non image area erase or within the area detected

by APS.

• Sampling is carried out over the range from the

center to 20mm away from each edge of the

original, as detected by APS.

• If APS is unable to detect the size, scanning is

carried out up to 20mm short of the minimum

suppoted original size in each direction.

2) In the sub scanning direction

Sampling starts 1.5mm from the leading edge and

ends 2.9mm from the leading edge.

2-C-8

Page 17

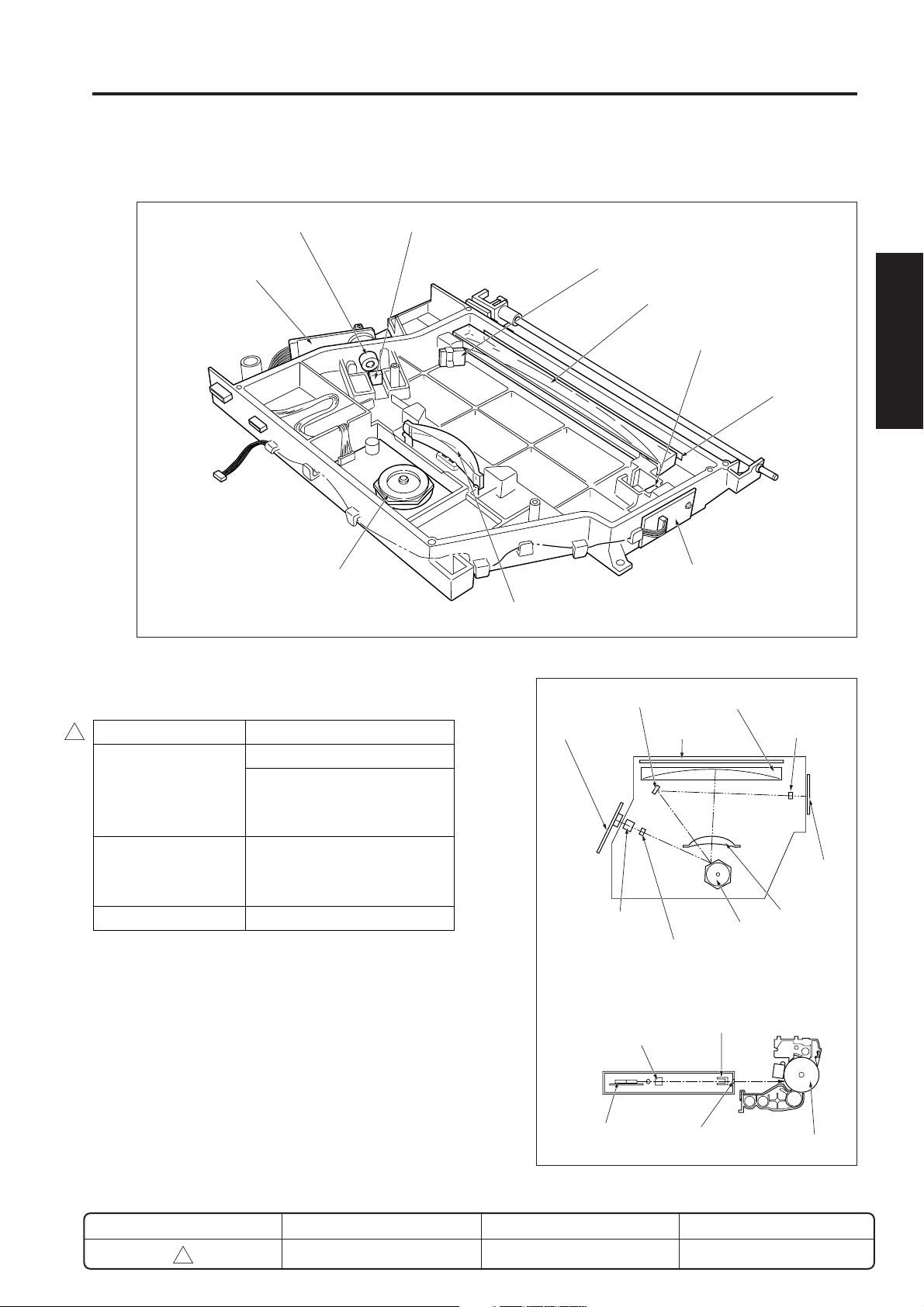

WRITE UNIT

[1] Composition

WRITE UNIT

1 OUTLINE

1 OUTLINE

Collimater lens unit

LD drive board (LDB)

Polygon motor

Cylindrical lens 1

fθ lens

Index mirror

Cylindrical lens 2

Index lens

Index sensor board (INDEX)

Dust-proof

glass

2 UNIT EXPLANATION

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

3 DIS./ASSEMBLY

[2] Mechanisms

Mechanism Method

2

Scan *

Light source Laser diode

• Output: Max. 5mW

• Wavelength: 780nm

Positioning Index sensor

* : Path of laser light

The light output from semiconductor laser is radiated

onto the opc drum via the collimater lens, cylindrical

lens 1, polygon mirror, fθ lens, cylindrical lens 2.

Polygon mirror

Rotational speed

7020/25/30 : 33070.9 rpm

7035 : 42519.6 rpm

Index mirror

LD drive board

(LDB)

Collimater lens unit

fθ lens

Dust-proof glass

Polygon mirror

Cylindrical lens 1

Cylindrical lens 2

Dust-proof glassPolygon mirror

Cylindrical

lens 2

Index lens

Index sensor

board

fθ lens

OPC drum

REVISED EDITION

2

DATE

Feb. 2001

2-D-1

PA GE

2-D-1

METHOD

REPLACEMENT

Page 18

WRITE UNIT

1 OUTLINE

1 OUTLINE

2

2

2 UNIT EXPLANATION

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

3 DIS./ASSEMBLY

[3] M5 (polygon motor) control

POLY LOCK

POLY CLK

POLY CONT

PGND

PGND

24VDC

DCPS

M5 (polygon motor) is controlled by the PRDB (printer

drive board).

24VDC

PRDB

1. Operation

a. M5 is a brushless motor running on 24V DC

power. The motor turns the polygon mirror,

causing the laser beam from the LDB (LD drive

board) to scan along the drum shaft direction.

M5 includes an internal speed sensor, and utilizes PLL control to maintain a constant speed.

M5

2. Signals

a. Input signal

(1) POLY LOCK (M5 → PRDB)

M5 status detect signal.

[L] when M5 rotation reaches the rated speed.

b. Output signals

(1) POLY CONT (PRDB → M5)

M5 drive control signal.

[L]: M5 ON

[H]: M5 OFF

(2) POLY CLK (PRDB → M5)

Reference clock for M5 rotation control.

b. M5 rotation speed is as follows.

2

Machine State Rotation Speed

Copying 33070.9 rpm (7020/25/30)

42519.6 rpm (7035)

Idling Any of the following three

speeds can be selected by

using "25" mode.

7020/25/30

33070.9 rpm

16000 rpm*

* If one of these speeds has been selected, M5

rotation speed will change at a specified time

upon completion of warm up or completion of

copy processing. You can select this time period,

using "25" mode, to any of the following: 15 sec,

30 sec. 60 sec, 120 sec.

42519.6 rpm

25000 rpm*

Stop*

7035

REVISED EDITION

2

DATE

Feb. 2001

2-D-PB

PA GE

2-D-2

METHOD

REPLACEMENT

Page 19

WRITE UNIT

[4] Image write control

5VDC

CCD

ADB

5VDC

5VDC

SGND

SGND

12VDC

SGND

SGND

12VDC

DCPS

The CCD sensor outputs analog image data. The ADB (A/

D conversion board) converts this data to digital form. The

CB (overall control board) processes this data within

memory, generating a laser recording signal. This signal is

transmitted, by means of a CB control signal, to the LDB

(LD drive board), and is output as an optical signal by the

LDB's laser emitting element. The write start position for

the laser recording signal is detected by the index sensor

on the index sensor board.

1. Operation

a. Image processing

2

The CB carries out the following processing.

SGND

/S/H

/ENB

/VIDEO

SGND

/ALM

DACLK

LDPR+5VDC

5VDC

SGND

/IND

SGND

INDPR+5VDC

CB

NC

DI

LD

LDB

INDEX

(7) Magnification change processing

(8) Error diffusion processing

(9) Data compression processing

(10) Write density correction

b. Write

CB transmits image data one pixel by one pixel to the

LDB. The LDB emits the laser onto the drum in

certain time for each pixel determined by the image

data received from the CB.

(1) MPC (Maximum Power Control)

The CB informs LDB of the maximum laser output

value. The LDB keeps and uses this value in APC

(automatic power control) to maintain the laser

intensity.

<MPC Timing>

(1) After SW2 (sub power switch) is set at ON when

2

L detection adjustment has been completed or

the drum counter has been reset.

(2) When SW is turn ON first thing in the morning.

(3) Every 20th copy during a continuous copy

operation.

(2) APC (Automatic Power Control)

After the CB has set the MPC, it outputs an APC start

command to the LDB in accordance with the following

timing.

<APC Timing>

1 OUTLINE

1 OUTLINE

2 UNIT EXPLANATION

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

3 DIS./ASSEMBLY

(1) AGC (automatic gain correction)

When SW2 comes ON, the level from the white

reference board is read by turning ON the L1

(exposure lamp), and the analog amplification for the

CCD sensor output is automatically adjusted such

that this level becomes the upper limit for the A/D

converter.

(2) Shading correction

<Execution timing>

White correction / Black correct

• At SW2 (sub power switch) ON

(3) Brightness/density conversion

(4) AE processing

(5) Text/dot pattern judgment

(6) Filtering

REVISED EDITION

2

DATE

Feb. 2001

(3) Write timing

2-D-3

At detection of M5 (polygon motor) PLL lock.

Thereafter, LDB automatically monitors the laser

drive current for each line, and controls the laser such

that the light intensity is always at MPC.

The index board's /IND signal determines the start

time for laser writing of each scan in the drum shaft

direction.

PA GE

2-D-3

METHOD

REPLACEMENT

Page 20

1 OUTLINE

1 OUTLINE

2

2

2 UNIT EXPLANATION

2 UNIT EXPLANATION

WRITE UNIT

2. Signals

2

a. Input signals

(1) /IND (INDEX → CB)

Index signal for write system.

(2) INDPR + 5VDC (INDEX → CB)

INDEX board detect connection monitor signal.

[H]: Not present

[L]: Present

(3) /ALM (LDB → CB)

Indicates abnormality in laser drive current (APC

operation).

[H]: Normal

[L]: Abnormal

(4) LDPR + 5VDC (LDB → CB)

LDB connection monitoring signal.

[H]: Not present

3 DIS./ASSEMBLY

3 DIS./ASSEMBLY

[L]: Present

b. Output signals

(1) /VIDEO (CB → LDB)

Image signal for / VIDEO laser.

(2) DACLK (CB → LDB)

Clock signal used for transfer of MPC data.

(3) DI (CB → LDB)

MPC data signal.

(4) LD (CB → LDB)

MPC data memorize command signal.

(5) /S/H (CB → LDB)

APC sampling signal (for one line).

(6) /ENB (CB → LDB)

ON/OFF control signal for laser APC function. If OFF,

laser output is stopped.

REVISED EDITION

2

DATE

Feb. 2001

2-D-PB

PA GE

2-D-4

METHOD

REPLACEMENT

Page 21

DRUM UNIT

DRUM UNIT

[1] Composition

1

Drum

Cleaning section

Separation

claws

Charging

corona unit

Cleaning/Toner-recycle section

PCL

Charging

corona unit

Developing unit

Transfer

corona unit

Paper entrance

guide plate

Separation

claws

Drum

Separation

corona unit

TSL

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

[2] Mechanisms

Mechanism Method

Pedestal hold Fixed rail

PCL LED

Auxiliary separation Separation claws *

The drum unit is a single unit consisting of the drum, the

charging corona unit, the cleaning, toner recycle section,

and the PCL.

REVISED EDITION

1

DATE

May 2000

2-E-1

* : Operation of the separation claws

When SD7 (separation claw SD) is activated, the rod

connected to it moves such that the cutouts on the

rod allow the claws to fall into contact with the drum

under their own weight. The contact of the claws aids

in paper separation.

1

Rod

Separation

claw SD (SD7)

PA GE

2-E-1

Separation

claws

METHOD

REPLACEMENT

Page 22

DRUM UNIT

1 OUTLINE

[3] PCL/TSL control

[4] Separation claws control

2

24VDC

PCL CONT

24VDC

TSL DRIVE

5VDC

MC1 DRIVE

PRDB

SGND

PS1

5VDC

SGND

PS3

5VDC

2 UNIT EXPLANATION

DCPS

24VDC

24VDC

PGND

PGND

SGND

5VDC

The PCL (pre-charging lamp) and TSL (transfer synchronization lamp) are LED type lamps, and are controlled by

the PRDB.

3 DIS./ASSEMBLY

1. Operation

PCL lights up when the START button is pressed,

and goes OFF at a predetermined time interval after

PS3 (paper exit PS) goes OFF on exit of the final

copy. TSL comes ON at a predetermined time interval after MC1 (registration clutch) comes ON, and

goes OFF at a predetermined time interval after PS1

(registration PS) goes OFF.

PCL

TSL

MC1

PS1

PS3

DCPS

24VDC

24VDC

PGND

PGND

SGND

5VDC

SD7 DRIVE

MC1 DRIVE

PRDB

24VDC

5VDC

SD7

MC1

The separation claws are driven by SD7 (separation claw

SD), which is controlled by the PRDB (printer drive board).

1. Operation

SD7 comes ON at a predetermined interval after MC1

(registration clutch) comes ON, causing the separation claws to make contact with the drum so as to assist in separating the paper from the drum.

2. Signals

a. Output signal

(1) SD7 DRIVE (PRDB → SD7)

SD7 drive control signal.

2. Signals

a. Input signal

(1) PS1 (PS1 → PRDB)

Detection of paper at paper feed temporary stop

position.

[H] when paper is detected.

b. Output signals

(1) PCL DRIVE (PRDB → PCL)

PCL ON/OFF control signal.

[L]: PCL ON

[H]: PCL OFF

(2) TSL DRIVE (PRDB → TSL)

TSL ON/OFF control signal.

[L]: TSL ON

[H]: TSL OFF

[L]: SD7 ON

[H]: SD7 OFF

2-E-2

Page 23

DRUM UNIT

[5] Paper entrance guide plate control

24VDC

24VDC

PGND

PGND

SGND

5VDC

DCPS

A fixed voltage is applied to the paper entrance guide plate

so as to prevent toner from sticking to the plate.

1. Operation

24VDC

24VDC

M1 LOCK SIG

M1 CLK

M1 CONT

GP CONT

PRDB

PGND

PGND

5VDC

SGND

PGND

24VDC

M1

GP

HV

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

a. ON/OFF timing

ON/OFF in sync with M1 (main motor).

b. Applied voltage

–500V DC (constant voltage)

2. Signals

a. Output signal

(1) GP CONT (PRDB → HV)

Controls application of fixed voltage to the paper

entrance guide plate.

[L]: Voltage applied

[H]: No voltage

2-E-3

Page 24

1 OUTLINE

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Blank page

Page 25

CORONA UNIT

CORONA UNIT

[1] Composition

<Charging-corona unit>

PCL

Charging control

plate

Charging wire

[2] Mechanisms

Mechanism Method

Charging

Transfer DC positive corona discharge

Separation AC/DC corona discharge

Scorotron (DC negative corona discharge)

Discharge wire:

Tungsten, φ0.06mm

(gold-plated skin path)

Grid control: Stainless-steel plate

with manual wire cleaning

feature

Discharge wire:

Oxide-coated tungsten, φ0.06mm

with manual wire cleaning

feature

Discharge wire:

Oxide-coated tungsten, φ0.06mm

with manual wire cleaning

feature

Charging-wire cleaning

material

Spark arrester

plate (front)

<Transfer/Separation corona unit>

Paper entrance guide plate

Separation wire

Transfer wire

Spark arrester

plate (rear)

Plunging

prevention plate

Power supply to the Transfer/Separation corona

unit

Caution: Do not carry out copying with the

ADU door open by forcibly setting

the interlock ON, as doing so will

generate high-voltage output at the

contacts (springs) on the main-body

board.

Closing of the ADU door establishes the connection to the

power supply.

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

2-F-1

ADU door

Contact point

Page 26

CORONA UNIT

1 OUTLINE

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

[3] Charging control

1

24VDC

24VDC

PGND

PGND

M1 LOCK SIG

M1 CLK

M1 CONT

5VDC

SGND

PGND

24VDC

C CONT

C SHIFT

G SHIFT

F(C) SIG GRID

PRDB

DCPS

24VDC

24VDC

PGND

PGND

SGND

5VDC

The HV (high voltage unit) carries out charging by

outputting a high voltage onto the charging wire.

The HV is controlled by analog control signals output from

the PRDB (printer drive board).

1. Operation

The HV comes ON together with M1 (main motor),

and goes OFF at a predetermined time interval after

transfer output for the final sheet goes OFF.

a. Charging

An inverter boosts the 24VDC power from the DCPS,

generating a high negative DC voltage that is

discharged from the charging wire.

M1

CHARGING

HV

2. Signal

a. Input signal

(1) F (C) SIG (HV → PRDB)

[L] if charge output has been forcibly switched OFF

owing to detection of spark or occurrence of output

short.

b. Output signals

(1) C CONT (PRDB → HV)

Charge voltage and grid voltage ON/OFF control

signal.

[L]: Charge and grid voltages ON

[H]: Charge and grid voltages OFF

(2) C SHIFT (PRDB → HV)

Analog signal from PRDB; controls the output level of

the charging corona unit.

C SHIFT output range 4 to 10V

Charging output range –100 to –650µA

(3) G SHIFT (PRDB → HV)

Analog signal from PRDB; controls the output level of

the grid voltage.

1

G SHIFT output range 4 to 10V

Grid voltage output –450 to –1090V

range

b. Grid voltage

The HV applies grid voltage to the charging control

plate.

REVISED EDITION

1

DATE

May 2000

2-F-2

PA GE

2-F-2

METHOD

REPLACEMENT

Page 27

CORONA UNIT

[4] Transfer/Separation control

1

24VDC

MC1 DRIVE

SGND

PS1

5VDC

PGND

S SHIFT(AC)

S SHIFT(DC)

PRDB

24VDC

T CONT

T SHIFT

S CONT

F(T) SIG

F(S) SIG

DCPS

24VDC

24VDC

PGND

PGND

SGND

5VDC

The transfer/separation corona units are controlled by the

PRDB (printer drive board) and the HV (high voltage unit).

1. Operation

Transfer and separation come ON at predetermined

intervals after M1 (main motor) comes ON, and go

OFF at predetermined intervals after PS1 (registration

PS) goes OFF.

MC1

PS1

SEPARATION

TRANSFER

HV

2. Signals

a. Input signals

(1) F (T) SIG (HV → PRDB)

[L] if transfer output has been forcibly switched OFF

owing to detection of spark or occurrence of output

short.

(2) F (S) SIG (HV → PRDB)

[L] if separation output has been forcibly switched

OFF owing to detection of spark or occurrence of

output short.

b. Output signals

(1) T CONT (PRDB → HV)

Transfer corona unit ON/OFF control signal.

[L]: Transfer corona unit ON

(2) T SHIFT (PRDB → HV)

Transfer corona unit output control signal.

Analog signal from PRDB; controls the output level of

the transfer corona unit.

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

a. Transfer

Constant current is applied so as to produce a high

voltage DC discharge.

b. Separation

Constant voltage is applied to produce a high voltage

AC discharge, and constant current is applied to

produce high voltage DC discharge.

T SHIFT output range 4 to 10V

Transfer output range 0 to 350µA

(3) S CONT (PRDB → HV)

Separation corona unit ON/OFF control signal.

[L]: Separation corona unit ON

(4) S SHIFT (AC) (PRDB → HV)

Separation corona unit output control signal.

Analog signal from PRDB; controls the level of the

AC component of the separation corona unit.

S SHIFT (AC) output range 3 to 10V

Separation AC output range 1.5 to 5.0kV

(5) S SHIFT (DC) (PRDB → HV)

Separation corona unit output control signal.

Analog signal from PRDB; controls the level of the

DC component of the separation corona unit.

S SHIFT (DC) output range 4 to 10V

Separation DC output range 0 to –300µA

REVISED EDITION

1

DATE

May 2000

2-F-3

PA GE

2-F-3

METHOD

REPLACEMENT

Page 28

1 OUTLINE

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Blank page

Page 29

DEVELOPING UNIT

DEVELOPING UNIT

[1] Composition

1

Developing

sleeve

Developing

unit cover

Agitator screws

Developing

regulator plate

Agitator wheel

Developing

sleeve

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

[2] Mechanisms

Mechanism Method

Developing 2-component developing

Developing bias DC bias

Developer agitation Main and supplemental

agitation

Developing unit drive

The developing unit is driven by two different motors.

The developing motor (M3) drives the developing

sleeve, while the main motor (M1) drives the agitator

section.

REVISED EDITION

1

DATE

May 2000

2-G-1

PA GE

2-G-1

METHOD

REPLACEMENT

Page 30

DEVELOPING UNIT

1 OUTLINE

[3] M3 (developing motor) control

[4] Developing bias control

1

2

2 UNIT EXPLANATION

DCPS

24VDC

24VDC

PGND

PGND

SGND

5VDC

PRDB

24VDC

24VDC

PGND

PGND

SGND

M3 LD

M3 CLK

M3 CONT

SGND

5VDC

M3 (developing motor) is controlled by the PRDB (printer

drive board).

1. Operation

M3 runs on 24V DC power, and drives the developing

3 DIS./ASSEMBLY

sleeve. M1 drives the agitator wheel and agitator

screws. (For information about M1, refer to “M1 (Main

motor) control.”) M3 includes an internal speed sensor, and utilizes PLL control to maintain a constant

speed, using a reference clock signal output by

PRDB.

M3

DCPS

24VDC

24VDC

PGND

PGND

SGND

5VDC

24VDC

PGND

M3 CW/CCW

M3 CONT

B CONT

B SHIFT

PRDB

24VDC

24VDC

PGND

PGND

SGND

M3 LD

M3 CLK

SGND

5VDC

SGND

PS1

5VDC

M3

PS1

BIAS

HV

Developing bias is controlled by the PRDB (printer drive

board) and the HV (high voltage unit).

1. Operation

Application of developing bias to the developing

sleeve starts a predetermined time interval after M3

(developing motor) comes ON, and ends a

predetermined time interval after charging goes OFF.

M3 goes ON and OFF in sync with M1.

2. Signals

a. Input signal

(1) M3 LD (M3 → PRDB)

M3 status detect signal.

Goes [L] when M3 rotation reaches the rated speed.

[H]: Stopped, or rotating at other than rated speed.

[L]: Rotating at rated speed. (PLL: stable)

b. Output signals

(1) M3 CONT (PRDB → M3)

M3 drive control signal.

[L]: M3 ON

[H]: M3 OFF

(2) M3 CLK (PRDB → M3)

Reference clock for M3 rotation control.

2. Signals

a. Output signals

(1) B CONT (PRDB → HV)

Developing bias ON/OFF control signal.

[L] sets developing bias ON and outputs high voltage.

(2) B SHIFT (PRDB → HV)

Developing bias level control signal.

Analog signal from PRDB; controls the developing

bias output level.

B SHIFT output range 2 to 8V

Bias-Voltage output range –350 to –830V

REVISED EDITION

1

DATE

May 2000

2-G-2

PA GE

2-G-2

METHOD

REPLACEMENT

Page 31

DEVELOPING UNIT

[5] Toner density control

2

24VDC

24VDC

PGND

PGND

SGND

DCPS

5VDC

12VDC

SGND

M3 CW/CCW

M3 CONT

TDS CONT

TONER ANG

PRDB

24VDC

24VDC

PGND

PGND

SGND

M3 LD

M3 CLK

SGND

5VDC

24VDC

24VDC

24VDC

24VDC

12VDC

SGND

SGND

PS1

5VDC

(2) During a copy operation

1 OUTLINE

The following table shows the relation between TDS

output voltage and toner supply time.

2

TDS output voltage Replenishment Time

M3

≤ 2.00 (2.01)V 0 sec.

2.01 to 2.05 (2.04)V 0.24 (0.10)sec.

2.06 (2.04) to 2.09 (2.08)V 0.48 (0.20)sec.

2.10 (2.08) to 2.13 (2.12)V 0.72 (0.30)sec.

A

A

B

B

A

A

B

B

M4

M10

7035

TDS

2.14 (2.12) to 2.17 (2.19)V 0.96 (0.40)sec.

2.18 (2.19) to 2.21 (2.35)V 1.20 (0.50)sec.

≥ 2.22 (2.35)V 1.80 (0.70)sec.

Parenthesized values are for the 7035

2. Signals

a. Input signal

(1) TONER ANG (TDS → PRDB)

2 UNIT EXPLANATION

Outputs an analog voltage corresponding to the toner

density.

PS1

3 DIS./ASSEMBLY

b. Output signals

Toner density is controlled by the TDS (toner density

2

sensor), M4 (toner supply motor 1), M10 (toner supply

motor 2: 7035 only) and the PRDB (printer driver board).

1. Operation

a. Toner density control

The TDS uses L detection to detect the toner density

in the developing unit, and outputs to the PRDB an

analog signal corresponding to the detected density.

The PRDB determines whether toner supply is

necessary by comparing the detected value against

the developer's initial density.

b. Supply of toner to the developing unit

M4 and M10 (7035 only) are stepping motor running

2

on 24VDC. Drive time is controlled by the PRDB.

(1) When the power switched ON

Following power on, M1 (main motor) turns the

2

agitator screws, and after a predetermined time

interval the TDS reads the toner density. The PRDB

compares the density detected by TDS with the

developer's initial density. If the detected density is

low, M4 and M10 (7035 only) comes on and supplies

toner until the proper density level is restored.

(1) TDS CONT (PRDB → TDS)

TDS output voltage adjustment signal.

Output range: 3 to 8 V

(2)

M4 A, A, B, B (PRDB → M4)

M4 drive control signals.

(3)

2

M10 A, A, B, B (PRDB → M10)

M10 drive control signals. (7035 only)

REVISED EDITION

2

DATE

Feb. 2001

2-G-3

PA GE

2-G-3

METHOD

REPLACEMENT

Page 32

1 OUTLINE

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Blank page

Page 33

TONER SUPPLY UNIT

TONER SUPPLY UNIT

[1] Composition

Toner supply unit

Toner bottle

Toner supply paddle

Toner-cavity

prevention plate

Toner conveyance screw

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

[2] Mechanisms

Mechanism Method

Toner supply Screw conveyance

Toner level detection Piezoelectric method:

Approx. 30g

Toner agitation *1 Toner agitator plate + screw

Toner bottle *2 Rotation cartridge

Toner leak prevention Toner supply shutter

*1: Toner agitation

2

The toner agitator plate is powered by the toner

supply motor 1 (M4) via gears.

*2: Toner bottle

2

<Operation in the case of the 7020/25/30>

The toner bottle rotates while the toner bottle SD

(SD6) is ON. This rotation is driven by the toner

supply motor 1 (M4). Rotation causes the toner to

move toward the bottle outlet along the spiral

groove cut into the bottle surface.

<Operation in the case of the 7035>

When toner supply motor 2 (M10) goes ON, the

toner bottle rotates, causing the toner to move

along the spiral groove cut in the surface of the

toner bottle to the outlet of the toner bottle.

<Common Operation>

At the outlet of the toner bottle is a toner supply

paddle which pushes the toner to the agitation/

conveyance section of the toner supply unit along

with the rotation of the toner bottle.

Toner cavity

prevention plate

Toner conveyance screw

Toner supply paddle

REVISED EDITION

2

DATE

Feb. 2001

2-H-1

PA GE

2-H-1

METHOD

REPLACEMENT

Page 34

1 OUTLINE

2

2 UNIT EXPLANATION

TONER SUPPLY UNIT

[3] Toner level detection control

2

24VDC

24VDC

24VDC

24VDC

5VDC

TLD

SGND

A

A

B

B

A

A

B

B

DCPS

24VDC

24VDC

PGND

PGND

SGND

5VDC

PRDB

M4

M10

TLD

7035

[4] Toner bottle detection control

24VDC

24VDC

PGND

PGND

SGND

5VDC

DCPS

PS5 (toner bottle PS) detects the presence or absence of

the toner bottle.

PRDB

SGND

PS5 SIG

5VDC

PS5

Control of toner level detection is carried out by the TLD

(toner level detecter) and the PRDB (printer control board).

1. Operation

a. Toner level detection

3 DIS./ASSEMBLY

The TLD uses a piezo element. When TLD detects

that toner in the cartridge has run low, it outputs a

toner supply signal to the PRDB, generating a

message on the LCD (display board).

b. Detection timing

Detection is carried out at the following times.

• During copying

c. Toner supply operation to toner supply unit

2

<Operation in the case of the 7020/25/30>

When TLD detects that toner is empty, SD6 (toner-

bottle SD) goes ON and engages the gear. When M4

(toner supply motor 1) goes ON, the bottle turns,

sending new toner to the toner supply unit.

1. Operation

PS5 detects mounting of the toner bottle, and the

machine enters copy standby.

2. Signal

a. Input signal

2

(1) PS5 SIG (PS5 → PRDB)

Toner bottle detect signal.

[H]: Toner bottle not present.

[L]: Toner bottle is present.

<Operation in the case of the 7035>

When the TLD detects that the toner is empty up,

M10 (toner supply motor 2) goes ON and rotates the

toner bottle, causing new toner to be supplied to the

toner supply unit.

2. Signals

a. Input signal

(1) TLD (TLD → PRDB)

Goes [L] when the quantity of toner in the toner

cartridge runs low. If [L] state continues for a

predetermined period, a corresponding message is

displayed in the LCD.

REVISED EDITION

2

DATE

Feb. 2001

2-H-2

PA GE

2-H-2

METHOD

REPLACEMENT

Page 35

CLEANING/TONER RECYCLE UNIT

CLEANING/TONER RECYCLE UNIT

[1] Composition

1

Cleaning blade

Collected toner conveyance screw

Collected toner

conveyance screw

Cleaning

blade

Toner

collection

sheet

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

[2] Mechanisms

Mechanism Method

Drum cleaning Cleaning blade

(spring load type)

Toner recycle* Toner conveyance by screw

Toner collection Toner collection sheet

*Toner recycle

Toner collected by the cleaning blade is conveyed

to the collected toner exit (and returned to the

toner supply unit) by the action of the collected

toner conveyance screw.

1

Collected toner

conveyance screw

REVISED EDITION

1

DATE

May 2000

2-I-1

PA GE

2-I-1

METHOD

REPLACEMENT

Page 36

1 OUTLINE

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Blank page

Page 37

PAPER FEED UNIT

PAPER FEED UNIT

[1] Composition

1

Upper tray

Lower tray

Paper feed roller

Paper lift-up plate

Paper feed roller

Paper lift-up plate

Double feed

prevention roller

/upper

Registration rollers

Double feed

prevention

roller

Loop rollers

By-pass conveyance roller

By-pass pick-up roller

By-pass reverse roller

Loop roller

Double feed prevention roller

/upper

Double feed prevention roller

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

[2] Mechanisms

Mechanism Method

Paper stacking Two trays

Paper lift-up Paper lift-up plate

Double feed prevention Torque limiter

Tray loading Front loading

First paper feed Paper feed SD

Paper feed roller

Loop clutch

Loop roller

Second paper feed Registration clutch

Registration rollers

By-pass feed By-pass feed SD

1

By-pass conveyance

rollers

Loop roller

Paper size detection Paper size setting unit

1

REVISED EDITION

1

DATE

May 2000

2-J-1

PA GE

2-J-1

METHOD

REPLACEMENT

Page 38

PAPER FEED UNIT

1 OUTLINE

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

[3] Paper feed control

24VDC

24VDC

PGND

PGND

M9 CLK

M9 CONT

5VDC

SGND

SGND

PS1

5VDC

MC1 DRIVE

MC2 DRIVE

SD1 DRIVE

SD2 DRIVE

SD3 DRIVE

PRDB

24VDC

24VDC

24VDC

24VDC

24VDC

DCPS

24VDC

24VDC

PGND

PGND

SGND

5VDC

M9 (paper feed motor) drive power is transmitted to the

various rollers by means of SD1 (first paper feed SD (upper

tray)), SD2 (first paper feed SD (lower tray)), and SD3 (bypass SD). When M9 first comes ON, no rollers are in

contact with paper; accordingly, SD1, SD2, or SD3 operate

to raise or lower the feed rollers or by-pass plate so as to

make contact with paper and initiate feeding.

M9

PS1

MC1

MC2

SD1

SD2

SD3

1. Operation

a. Timing for first paper feed (by-pass)

(1) Start for first sheet

At a predetermined time interval after START button

ON.

(2) Start for second sheet

At a predetermined time interval after first sheet SD3

ON.

(3) OFF timing

At a predetermined time interval after SD3 ON.

b. Timing for first paper feed (upper tray)

(1) Start for first sheet

At a predetermined time interval after START button

ON.

(2) Start for second sheet

At a predetermined time interval after first sheet SD1

ON.

(3) OFF timing

At a predetermined time interval after SD1 ON.

c. Timing for first paper feed (lower tray)

(1) Start for first sheet

At a predetermined time interval after START button

ON.

When SD1 (first paper feed SD) comes ON, MC2 (loop

clutch) also comes ON at the same time, conveying the

paper up to the registration rollers. PS1 (registration PS)

detects the leading edge of the paper, MC2 goes OFF,

and the paper is formed into a loop. When the drum

charge stabilizes, MC1 (registration) and MC2 both come

ON to drive the second paper feed.

Paper feed operations are controlled by the PRDB (printer

drive board).

(2) Start for second sheet

At a predetermined time interval after first sheet SD2

ON.

(3) OFF timing

At a predetermined time interval after SD2 ON.

d. Control for second paper feed (MC1)

(1) ON timing

At a predetermined time interval after PS1 ON.

(2) OFF timing

At a predetermined time interval after PS1 OFF.

2-J-2

Page 39

PAPER FEED UNIT

e. Control of paper feed loop formation (MC2)

(1) ON timing

At the same time as SD1 ON, SD2 ON or SD3 ON.

(2) OFF timing

At a predetermined time interval after PS1 ON.

2. Signals

a. Output signals

(1) M9 CONT (PRDB → M9)

M9 drive control signal.

[L]: M9 ON

[H]: M9 OFF

(2) M9 CLK (PRDB → M9)

Reference clock for M9 rotation control.

(3) SD1 DRIVE (PRDB → SD1)

[L]: SD1 ON

[H]: SD1 OFF

(4) SD2 DRIVE (PRDB → SD2)

[L]: SD2 ON

[H]: SD2 OFF

[4] Paper up down control

M7 UP M DRIVE

24VDC

SGND

PS9

5VDC

SGND

PS7

5VDC

M8 LOW M DRIVE

24VDC

SGND

PS12

5VDC

SGND

PS10

5VDC

PRDB

DCPS

24VDC

24VDC

PGND

PGND

SGND

5VDC

When a tray is set into the machine, its presence is

detected by PS9 (tray detect PS (upper)) or PS12 (tray

detect PS (lower)), which in turn causes M7 (tray motor

(upper)) or M8 (tray motor (lower)) to come ON for a fixed

interval so as to raise the tray's bottom plate. Signals

related to this operation are PS7 (upper limit detect PS

(upper)) and PS10 (upper limit detect PS (lower))

M7

PS9

PS7

M8

PS12

PS10

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

(5) SD3 DRIVE (PRDB → SD3)

[L]: SD3 ON

[H]: SD3 OFF

(6) MC1 DRIVE (PRDB → MC1)

MC1 drive control signal.

[L]: MC1 ON

[H]: MC1 OFF

(7) MC2 DRIVE (PRDB → MC2)

MC2 drive control signal.

[L]: MC2 ON

[H]: MC2 OFF

1. Operation

a. ON timing

PS9 ON causes M7 ON. PS12 ON causes M8 ON.

b. OFF timing

PS7 ON causes M7 OFF. PS10 ON causes M8 OFF.

2-J-3

Page 40

PAPER FEED UNIT

2. Signals

1 OUTLINE

a. Input signals

[5] Paper size detection control

2

(1) PS9 (PS9 → PRDB)

Upper tray detect signal.

[L]: tray is present;

[H]: tray is not present.

Detection of the tray causes M7 to raise the paper in

the upper tray.

(2) PS12 (PS12 → PRDB)

2 UNIT EXPLANATION

Lower tray detect signal.

[L]: tray is present;

[H]: tray is not present.

Detection of tray causes M8 to raise the paper in the

lower tray.

(3) PS7 (PS7 → PRDB)

Upper limit detect signal for upper tray.

Goes [H] when paper in the upper tray has been

3 DIS./ASSEMBLY

raised to the upper limit, causing M7 to go OFF.

(4) PS10 (PS10 → PRDB)

Upper limit detect signal for lower tray.

SGND

DCPS

24VDC

24VDC

PGND

PGND

SGND

5VDC

PS20

5VDC

5VDC

VR1 ANG

SGND

U SIZE D

U SIZE C

U SIZE B

U SIZE A

U SIZE SELECT

L SIZE D

L SIZE C

L SIZE B

L SIZE A

L SIZE SELECT

PRDB

PS20

VR1

SW1

PFDB(UPPER)

SW2

PFDB(LOWER)

Tray paper size is detected by the PRDB (printer driver

board) based on detection signals issued from the PFDBs

(paper feed detection boards). Detection of paper size in

the by-pass tray is carried out by PS20 (by-pass tray

paper size detect PS) and VR1 (by-pass tray paper size

VR).

Goes [H] when paper in the lower tray has been

raised to the upper limit, causing M8 to go OFF.

b. Output signals

(1) M7 DRIVE (PRDB → M7)

M7 drive control signal.

[L]: M7 ON

[H]: M7 OFF

(2) M8 DRIVE (PRDB → M8)

M8 drive control signal.

[L]: M8 ON

[H]: M8 OFF

2-J-4

Page 41

PAPER FEED UNIT

1. Operation

a. Paper size detection for upper and lower

trays

Paper size for the upper tray is set by SW1 on PFDB

(UPPER), and paper size for the lower tray is set by

SW2 on PFDB (LOWER). The PRDB detects the

switch signals output in accordance with position of

each of these switches. The following table shows

the relation between switch signals and paper size.

For U.S.A.

Paper size

Tray1

8.5 x 14

B5R

B4

A5R

A4

A4R

F4

5.5 x 8.5

8.5 x 11

8.5 x 11R

Tray2

11 x 17

A5R

A4

A4R

A3

F4

5.5 x 8.5

8.5 x 11

8.5 x 11R

8.5 x 14

SIZE A SIZE B SIZE C SIZE D

Switching

b. Paper size detection for by-pass tray

Paper length in the by-pass tray is detected by PS20

ON/OFF. Paper width in the by-pass tray is detected

by VR1, whose resistance value changes in

accordance with the tray's guide position.

2. Signals

a. Input signals

(1) PS20 (PS20 → PRDB)

Paper length detection signal for by-pass tray.

[L]: B4 size or more

[H]:A4R size or less

(2) VR1 ANG (VR1→ PRDB)

Paper width detection signal for by-pass tray.

(3) U SIZE A, B, C, D (PFDB (UPPER) → PRDB)

Paper size ON/OFF detect signals for upper tray.

(4) L SIZE A, B, C, D (PFDB (LOWER) → PRDB)

Paper size ON/OFF detect signals for lower tray.

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

For Europe

Paper size

Tray1

8.5 x 14

B5

B4

A5R

A4

A4R

F4

5.5 x 8.5

8.5 x 11

8.5 x 11R

Tray2

11 x 17

B5

B4

A5R

A4

A4R

A3

F4

8.5 x 11

8.5 x

11R

Switching

SIZE A SIZE B SIZE C SIZE D

2-J-5

Page 42

1 OUTLINE

2

PAPER FEED UNIT

[6] No paper detection control

SGND

PS13 SIG

5VDC

SGND

5VDC

SGND

PS8 SIG

5VDC

PS13

PS8

[7] Control of paper-level detection

2

SGND

5VDC

SGND

PS9 SIG

5VDC

PS9

SGND

PS11 SIG

5VDC

2 UNIT EXPLANATION

DCPS

PRDB

No paper detection is carried out by PS8 (no paper detect

PS (upper)), PS11 (no paper detect PS (lower)), and PS13

(by-pass no paper detect). Detection is controlled by the

PRDB (printer drive board).

1. Operation

3 DIS./ASSEMBLY

a. No paper detection control

When the upper, lower, or by-pass tray runs out of

paper, the corresponding PS comes ON (PS8, PS11,

or PS13), causing the LCD (display board) to display

a paper out message.

2. Signals

a. Input signals

2

(1) PS8 SIG (PS8 → PRDB)

No paper detection signal for upper tray.

PS11

SGND

DCPS

PRDB

PS12 SIG

5VDC

PS12

After the trays have been set in the machine, paper level is

detected by PS9 (tray detect sensor (upper)) and PS12

(tray detect sensor (lower)).

As the paper level in tray runs low, the actuator at the rear

part of the tray gradually rotates as illustrated below. The

level is detected by the number of times the sensor goes

ON/OFF (the number of slits detected).

View looking from rear

Direction of rotation

when the paper lifting

plate rises.

Tray detect

sensor

Slit 1

Slit 2

Actuator

[H]: Paper does not exist

[L]: Paper exist

(2) PS11 SIG (PS11 → PRDB)

No paper detection signal for lower tray.

[H]: Paper does not exist

[L]: Paper exist

(3) PS13 SIG (PS13 → PRDB)

No paper detection signal for by-pass tray.

[H]: Paper exist

[L]: Paper does not exist

REVISED EDITION

2

DATE

Feb. 2001

Operation

a. Detection of paper level in tray

The following shows the relation between the paper

level and the number of slit detections by the sensor

(PS9 or PS12).

0 slits : Full

1 slit : Medium

2 slits : Low

PAG E

2-J-6

2-J-6

METHOD

REPLACEMENT

Page 43

PAPER FEED UNIT

[8] Intermediate conveyance control

2

(7030/35 only)

PRDB

SGND

PS21 SIG

SGND

PS22 SIG

5V

5V

PS21

PS22

SGND

5VDC

DCPS

PS21 (intermediate conveyance sensor/upper) and PS22

(intermediate conveyance sensor/lower) are installed in

proximity of the loop rollers of tray 1 and tray 2

respectively. As the paper feeding intervals of the 7030

and 7035 are decreased during continual copying, there is

a chance that a slight increase in the timing of paper

feeding may cause jams. To prevent this, the condition of

the paper is monitored by PS21 and PS22 immediately

after the start of paper feeding.

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

1. Operation

If PS21 or PS22 detect paper within a predetermined

period of time after the start of feeding the second and

subsequent sheets of paper, the MC2 (loop clutch) will be

stopped momentarily to ensure a constant interval

between paper feeding.

2. Signal

a. Input signals

(1) PS21 SIG (PS21 → PRDB)

PS21 paper detect signal

[H]: Paper does not exist

[L]: Paper exist

(2) PS22 SIG (PS22 → PRDB)

PS22 paper detect signal

[H]: Paper does not exist

[L]: Paper exist

REVISED EDITION

2

DATE

Feb. 2001

2-J-7

PA GE

2-J-7

METHOD

ADDITION

Page 44

1 OUTLINE

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

Blank page

REVISED EDITION

2

DATE

Feb. 2001

PAG E

2-J-8

METHOD

ADDITION

Page 45

FIXING UNIT

FIXING UNIT

[1] Composition

Fixing guide

Cleaner cover

Fixing exit

plate

Fixing cleaning

roller

Fixing web

Fixing heaters

(Main) (Sub)

Neutralizing

brush

Fixing claws

Fixing heat

roller

1 OUTLINE

Fixing guide

2 UNIT EXPLANATION

Fixing

pressure

roller

Pressure roller

neutralizing brush

3 DIS./ASSEMBLY

[2] Mechanisms

Mechanism Method

Fixing Pressure + heat roller

Heat source Heater lamps (2 lamps)

Cleaning Fixing web

Fixing cleaning roller

Heat roller Aluminum + PFA coating

Pressure roller Silicone rubber + PFA tube

Separation Fixing claws (6 claws)

Temperature Heat roller

detection contact thermistor

Overheating Heat roller

prevention Contact thermostat

Neutralizing Neutralizing brush

1

(paper, fixing pressure roller)

Fixing roller presure/release

The pressure on the fixing roller is released by

opening of the fixing guide.

Fixing guide

REVISED EDITION

1

DATE

May 2000

2-K-1

PAG E

2-K-1

METHOD

REPLACEMENT

Page 46

FIXING UNIT

2

1 OUTLINE

2

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

[3] Fixing temperature control

L2 CONT

L3 CONT

RL CONT

L2 DRIVE

L3 DRIVE

RL

AC

DCPS

The fixing heat roller is heated by lamps L2 (fixing heater

lamp 1) and L3 (fixing heater lamp 2). The PRDB (printer

drive board) detects the temperature on the roller by

means of TH1 and TH2 (fixing temperature sensor 1 and

2), and controls L2 and L3 accordingly via the DCPS (DC

power source).

1. Operation

a. Temperature control

(1) Warm-up

The PRDB turns on the fixing heater lamp circuit

within the DCPS immediately when power comes on,

and holds L2 and L3 on until the fixing heat roller

reaches the specified temperature. L2 and L3 have

different light (heat) distribution characteristics (see

illustration below), and control temperature through

TH1 and TH2.

L2

L3

TS

PRDB

TH1 ANG

SGND

TH2 ANG

SGND

TH1

TH2

L2 light distribution characteristics

Bright

Dark

L3 light distribution characteristics

Bright

Dark

Once warm-up has completed, the PRDB switches

L2 and L3 ON and OFF as necessary to maintain the

set temperature.

Heat roller

Front

TH2 TH1 L3

REVISED EDITION

2

L2

DATE

Feb. 2001

Rear

2-K-2

(Warm up time)

7020/25/30: Within 30 seconds (from room temperature

of 20˚C).

7035: Within 45 seconds (from room temperature of

20˚C).

(2) Idling

L2 and L3 go ON/OFF repeatedly so as to maintain

the temperature between 191˚C and 187˚C (U.S.A.)/

202˚C and 187˚C (Europe).

PAG E

2-K-2

METHOD

REPLACEMENT

Page 47

FIXING UNIT

(3) Copying

(When feeding from any trays other than the by-pass

tray)

Temperature control during copying differs according

2

to the paper size. If the selected size is small (B5R,

B6R, A5R, or 5.5x8.5R), then although L2 and L3

both go ON/OFF repeatedly control is for the most

part implemented by L2 only (so as to prevent

overheating at the ends of the fixing roller). Other

than small sizes, these lamps go ON/OFF so as to

hold temperature at about 194°C (about 199°C in the

case of the 7030/35).

(When feeding from the by-pass tray)

The temperature is held approximately 10°C higher

than the temperature indicated above. Where OHP

has been selected using the application function,

control is the same as for normal copying.

(Doble sided copying)

Temperature is held about 5°C lower that the

temperature used when feeding from any tray other

than the by-pass tray.

(4) Low-power mode

L2 and L3 go ON/OFF repeatedly so as to maintain

2

the temperature at about 85°C (about 170°C in the

case of the 7035).

The temperature for low power mode can by 25 mode

DIPSW.

2. Signals

a. Input signals

(1) TH1 ANG (TH1 → PRDB)

TH1 output signal.

Outputs a voltage that varies according to the surface

temperature at the center of the fixing heat roller. This

signal is used both for normal temperature control

and for detection of heating error (overheating, etc.).

(2) TH2 ANG (TH2 → PRDB)

TH2 output signal.

Outputs a voltage that varies according to the surface

temperature at the ends of the fixing heat roller. This

signal is used both for normal temperature control

and for detecting of heating error (overheating, etc.).

b. Output signals

(1) L2 DRIVE (DCPS → L2)

AC (N) power line for L2.

Sets AC power on and off in accordance with the L2

CONT signal.

(2) L3 DRIVE (DCPS → L3)

AC (N) power line for L3.

Sets AC power on and off in accordance with the L3

CONT signal.

(3) L2 CONT (PRDB → DCPS)

L2 ON/OFF control signal.

1 OUTLINE

2 UNIT EXPLANATION

3 DIS./ASSEMBLY

b. Protection against abnormality

A thermostat (TS) in contact with the fixing heat roller

protects against overheating of the roller. The

operating temperature of TS is shown below.

TS: Approximately 220˚C

REVISED EDITION

2

DATE

Feb. 2001

[L]: L2 ON

[H]: L2 OFF

(4) L3 CONT (PRDB → DCPS)

L3 ON/OFF control signal.

[L]: L3 ON

[H]: L3 OFF

PAG E

2-K-3

2-K-3

METHOD

REPLACEMENT

Page 48

FIXING UNIT

1 OUTLINE

[4] SD4 (cleaning web SD) control

2

DCPS

24VDC

24VDC

PGND

PGND

PRDB

24VDC

24VDC

PGND

PGND

LOCK SIG

M1 CLK

M1 CONT

5VDC

SGND

24VDC

SD4 DRIVE

2 UNIT EXPLANATION

SD4 (cleaning web SD) is controlled by the PRDB (printer

drive board).

1. Operation

SD4 (cleaning web SD) is set ON by PS2 (fixing exit

PS), stays ON for 100msec, and then goes OFF.

3 DIS./ASSEMBLY

However, that SD4 does not come at all for certain

copy counts.

2. Signals

M1

SD4

a. Output signal

(1) SD4 DRIVE (PRDB → SD4)

[L]: SD4 ON

[H]: SD4 OFF

2-K-4

Page 49

ADU/PAPER EXIT SECTION

ADU/PAPER EXIT SECTION

[1] Composition

1

1 OUTLINE

Exit rollers

Switching gate

ADU unit (ADU door)

2 UNIT EXPLANATION

ADU conveyance rollers

3 DIS./ASSEMBLY

Without DB

If a DB is installed.

Switching PET

ADU rollers

Switching guide plate

Note: The switching guide plate

must be removed when the

DB is installed.

REVISED EDITION

1

DATE

May 2000

2-L-1

PA GE

2-L-1

METHOD

REPLACEMENT

Page 50

ADU/PAPER EXIT SECTION

1 OUTLINE

[2] Mechanisms

[3] Paper exit/ADU conveyance

2

Mechanism Method

Paper path Switching guide,

switching (*1) Switching PET

Paper conveyance Roller conveyance

*1:Switching of the paper path

The switching guide directs the paper that exits

from the fixing unit to either to the exit area or to

the ADU unit.

• Switching operation

2 UNIT EXPLANATION

For double sided copies, the switching guide

directs the paper to the rear side of the ADU door.

The trailing edge of the sheet reaches the point

just in front of the ADU rollers, at which point the

switching mylar returns the sheet to the feed path,

the ADU rollers reverse direction, and the sheet is

conveyed back to the drum unit.

3 DIS./ASSEMBLY

switching control

2

24VDC

24VDC

PGND

PGND

LOCK SIG

M1 CLK

M1 CONT

5VDC

SGND

MC1 DRIVE

24VDC

24VDC

SD5 DRIVE

DCPS

24VDC

24VDC

PGND

PGND

SGND

5VDC

PRDB

SGND

PS1 SIG

5VDC

SGND

EXIT PS

5VDC

SGND

FULL PS

5VDC

The paper exit unit's SD5 (ADU gate SD) switches the

conveyance path toward either the exit or the ADU unit.

M1

MC1

SD5

PS1

PS3

PS19

Switching

guide

Switching

PET

ADU roller

The paper is conveyed by M1 (main motor) and M9 (paper

feed motor), and M1 and SD5 are controlled by PRDB

(printer drive board). M1 and SD5 are controlled by the

PRDB (printer drive board). Related signals are MC1

(registration clutch), PS19 (exit limit detect PS), PS2

(fixing exit PS) and PS3 (paper exit PS).

1. Operation

a. Control of paper exit/ADU conveyance

switching

In single sided copy mode, SD5 remains OFF and

paper exits straight to the exit unit. In double sided

copy mode, SD5 comes ON during copying of the

front side, so that the paper is conveyed into the ADU

unit. The ADU unit inverts the paper so that the back

side of the paper is copied. When PS2 goes OFF by

the last paper, SD5 goes OFF, so that paper is

directed to the exit.

REVISED EDITION

2

DATE

Feb. 2001

2-L-2

PAG E

2-L-2

METHOD

REPLACEMENT

Page 51

ADU/PAPER EXIT SECTION

2. Signals

a. Input signal

(1) FULL PS (PS19 → PRDB)

Paper exit limit detect signal.

Goes [H] when the exit section is full, causing display

of message indicating that paper should be removed.

It is selectable to stop the machine when PS19 is ON

according to a setting in 25 mode.

b. Output signal

(1) SD5 DRIVE (PRDB → SD5)

SD5 drive control signal.

[L]: SD5 ON (Convey to ADU)

[H]: SD5 OFF (Straight to exit only)

[4] ADU conveyance control

2

A

A

B

B

24VDC

24VDC

MC1 DRIVE

24VDC

24VDC

MC2 DRIVE

PRDB

SGND

PS1 SIG

5VDC

SGND

PS2 SIG

5VDC

SGND

PS4 SIG

5VDC

DCPS

24VDC

24VDC

PGND

PGND

SGND

5VDC

M6 (ADU motor), a 24V DC step motor, drives the ADU

rollers that drive the conveyance. When paper directed to

the ADU side by SD5 reaches PS4 (ADU PS), M6

operates as necessary (forward, stop, reverse) to direct

the paper to the drum unit so that copy can be made to the

back side. M6 and PS4 are controlled by the PRDB