Page 1

4

SERVICE

4 SERVICE

Page 2

Main Precautions for Maintenance

1. Points to be confirmed before maintenance

Before starting maintenance, ask a user

and collect information about troubles occurred on the machine before the maintenance and the conditions of the machine to

grasp key points for the maintenance.

2. Copy sample

Be sure to make copy samples at the start

and the end of maintenance for checking

images.

3. Drum

1) Never expose the drum to the sunlight.

4 SERVICE

2) When replacing a drum or a cleaning

Be also careful not to expose a drum to

indoor light as far as possible.

When a drum unit or a drum is out of the

machine, never fail to cover it with a

drum cover.

blade, refer to item of mounting/dismounting of a cleaning blade for doing a

replacement work.

4. After replacing a drum, be sure to reset a

drum counter before image adjustment. After replacing developer, L detection adjustment must be conducted also.

5. When maintenance is completed, be sure

to reset the PM counter. Incidentally, a development counter is reset automatically in

the course of L detection adjustment.

6. When replacing a toner bottle, wait until the

toner supply LED on the operation panel

flashes before the replacement.

Caution: Turn the main switch off and

pull out the power plug without fail before the work of

maintenance.

Page 3

SERVICE SCHEDULE

SERVICE SCHEDULE

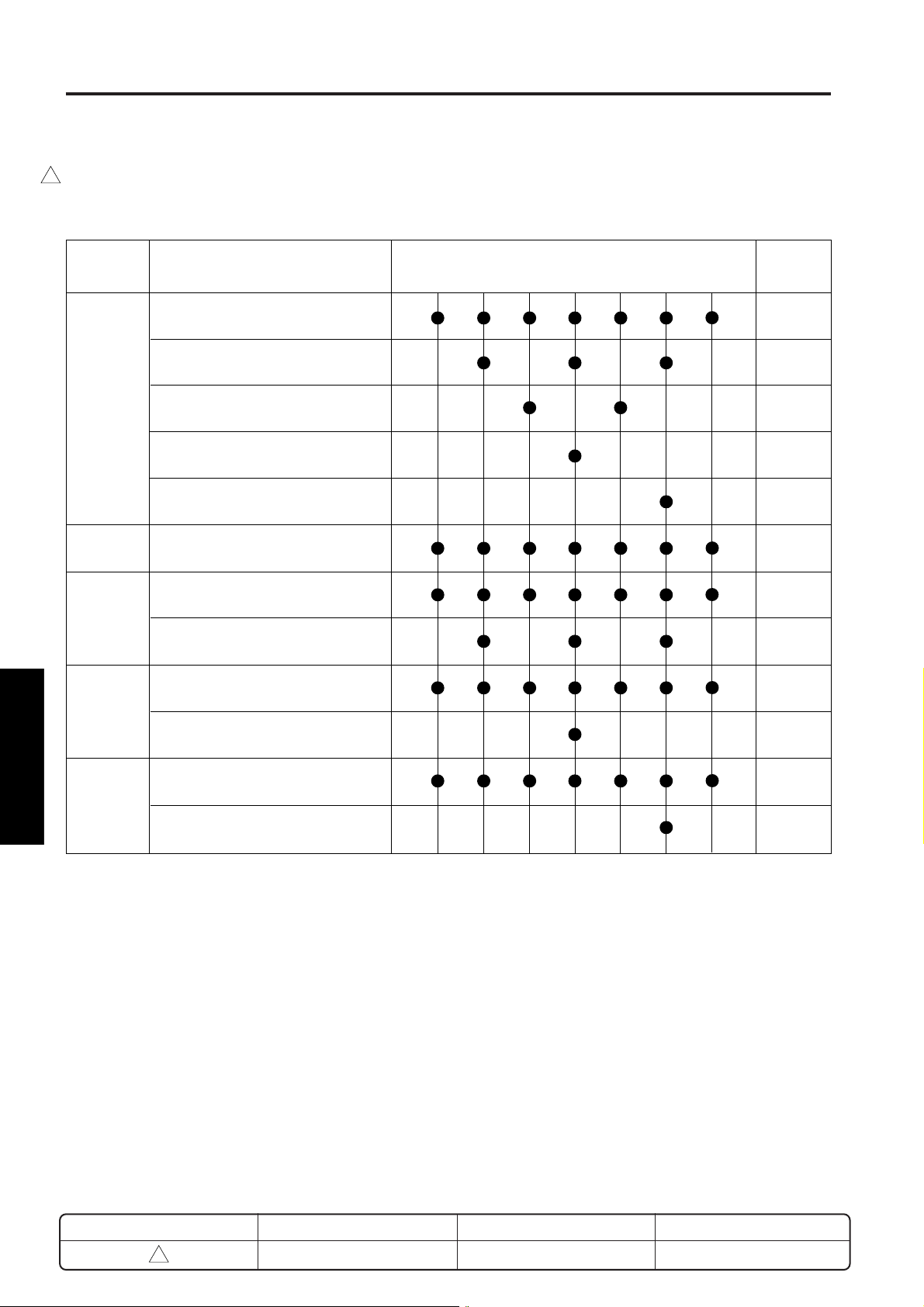

[1] Service schedule

1. 7020/7025/7030/7035

3

Service item (cycles)

(Every 100,000 copies or prints)

(Every 200,000 copies or prints)

Main body

(Every 300,000 copies or prints)

Periodic check (III)

(Every 400,000 copies or prints)

Periodic check (IV)

(Every 600,000 copies or prints)

DF-314

DB-409*/410

(LCT)

DB-209*/210

(2 Tray)

FS-107

(Every 100,000 copies or prints)

(Every 1,000,000 copies or prints)

(Every 100,000 copies or prints)

(Every 200,000 copies or prints)

(Every 100,000 copies or prints)

(Every 400,000 copies or prints)

(Every 100,000 copies or prints)

(Every 600,000 copies or prints)

Maintenance

Periodic check (I)

Periodic check (II)

Maintenance

Periodic check

Maintenance

Periodic check

Maintenance

Periodic check

Maintenance

Periodic check

Guarantee period (5 years or 1,200,000 copies)

10 20 30 40 50 60 90 100 110

70 80

×10,000 copies

1 OUTLINE

Service

times

11 times

5 times

2 ISW

3 times

2 times

1 time

11 times

1 time

3 SERVICE

11 times

5 times

11 times

2 times

4 SERVICE

11 times

1 time

* DB-209/DB-409 do not yet support 7035.

REVISED EDITION

3

DATE

Jan. 2002

4-1

PAGE

4-1

METHOD

REPLACEMENT

Page 4

SERVICE SCHEDULE

3

1 OUTLINE

2. 7022/7130

2 ISW

Main body

DF-314

3 SERVICE

DB-410

(LCT)

DB-210

(2 Tray)

4 SERVICE

FS-107

Service item (cycles)

Maintenance

(Every 100,000 copies or prints)

Periodic check (I)

(Every 200,000 copies or prints)

Periodic check (II)

(Every 300,000 copies or prints)

Periodic check (III)

(Every 400,000 copies or prints)

Periodic check (IV)

(Every 600,000 copies or prints)

Maintenance

(Every 100,000 copies or prints)

Maintenance

(Every 100,000 copies or prints)

Periodic check

(Every 200,000 copies or prints)

Maintenance

(Every 100,000 copies or prints)

Periodic check

(Every 400,000 copies or prints)

Maintenance

(Every 100,000 copies or prints)

Periodic check

(Every 600,000 copies or prints)

Guarantee period (5 years or 800,000 copies)

10 20 30 40 50 60

×10,000 copies

70

Service

times

7 times

3 times

2 times

1 time

1 time

7 times

7 times

3 times

7 times

1 time

7 times

1 time

REVISED EDITION

3

DATE

Jan. 2002

4-2

PAGE

4-1-1

METHOD

ADDITION

Page 5

SERVICE SCHEDULE

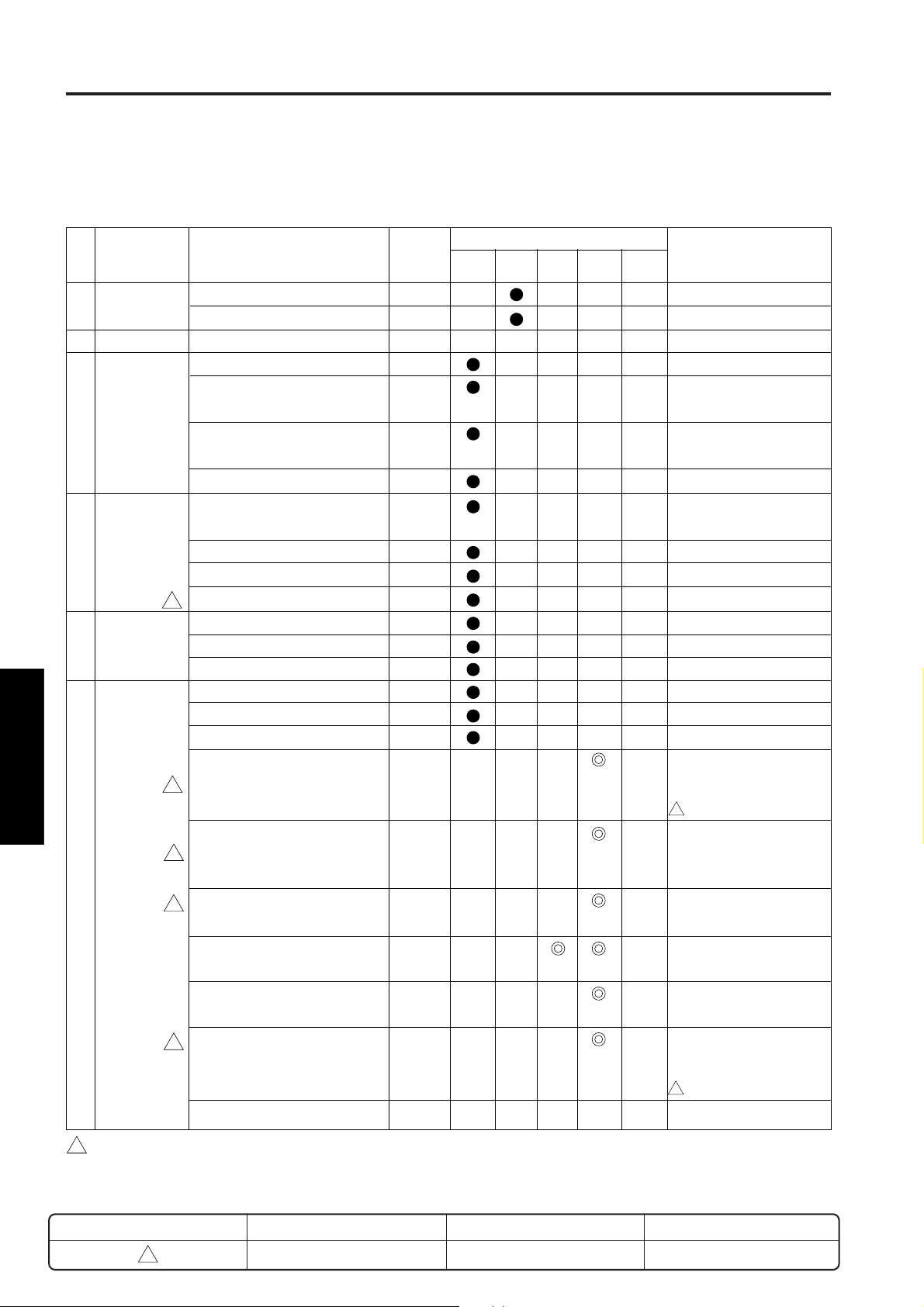

[2] Maintenance items

1 OUTLINE

1. Main body (Every 100,000 copies or prints)

ClassificationNo.

1 Preparations

2 Fixing unit

3 Reading

2 ISW

section

4 Paper feed

unit

3 SERVICE

5 Bypass feed

unit

6 Fixing unit

4 SERVICE

Service item

(1) Image check

(2) Exterior check

(1) Removal of fixing unit

(1) Original glass

(2) Original glass/1 (slit glass)

(3) Optics mirror/1 (lamp unit

mirror)

(4) Optics mirror/2 (V-mirror)

(1) Double feed prevention

roller (upper)

(2) Feed roller

Double feed prevention roller (lower)

(3)

(4) Paper dust removing brush

3

(1) By-pass reverse roller

(2) By-pass pickup roller

(3) By-pass conveyance roller

(1) Fixing claw

(2) Fixing sensor

(3) Fixing thermostat

(4) Fixing heat roller

3

3

3

3

26NA5303* (Other than 7035)

26TA5303* (7035)

(5) Fixing press roller

26NA5304* (Other than 7035)

26TA5304* (7035)

(6) Fixing web (Note:1)

26NA5343*(7020/25/30/35)

(7) Heat insulating sleeve/A

26NA5372

(8) Heat insulating sleeve/B

26NA5373

(9)

Fixing cleaning roller (Note:1)

26NA5383*(7020/25/30/35)

Number

of parts

replaced

*

*

1

1

1

2

1

1

Implementation classification

Lubri-

Cleaning

Check

cation

Replacement

Supply

Material used

Tools used, etc.

Drum cleaner/cleaning pad

Drum cleaner/cleaning pad

Drum cleaner/cleaning pad

Drum cleaner/cleaning pad

Drum cleaner/cleaning pad

Drum cleaner/cleaning pad

Drum cleaner/cleaning pad

Blower brush/cleaning pad

Drum cleaner/cleaning pad

Drum cleaner/cleaning pad

Drum cleaner/cleaning pad

Drum cleaner/cleaning pad

Drum cleaner/cleaning pad

Drum cleaner/cleaning pad

Actual durable count :

(7020/25/30/35)

100,000

200,000 (7022/7130)

3

Actual durable count :100,000

Actual durable count :100,000

Actual durable count :100,000

Solvest 240

Actual durable count :100,000

Actual durable count :

100,000

(7020/25/30/35)

200,000 (7022/7130)

3

(10) Install of fixing unit

Note 1: It is recommended that you replace the entire cleaner assembly (26NA-540*) as a unit instead of replacing

3

REVISED EDITION

individual parts.

DATE

PAGE

METHOD

4-4

3

Jan. 2002

4-2

REPLACEMENT

Page 6

SERVICE SCHEDULE

Number

Classification

No.

7 Final check

3

3

Note2: For the 7022/7130, the counter is reset at 200,000 copies.

Remarks:

and in the maintenance category denote the following.

Maintenance items with

decide whether or not replacement is necessary be checking the actual durable count.

Service item

(1) Loading of toner cartridge

Check of W.U.T measurement

(2)

(3) Check of image adjustment

(4) Check of copy samples

(5) Fixing counter reset (Note:2)

(7020/25/30/35)

(6) Reset of PM counter

(7) Check of leakage breaker

(8) Peripheral and exterior of

the machine

marking are compulsory. And, as for those with , maintenance personnel is to

of parts

replaced

Cleaning

Implementation classification

Lubri-

Replace-

Check

cation

ment

Supply

Material used

Tools used, etc.

Drum cleaner/cleaning pad

1 OUTLINE

2 ISW

3 SERVICE

REVISED EDITION

3

DATE

Jan. 2002

4-5

PAGE

4-3

4 SERVICE

METHOD

REPLACEMENT

Page 7

SERVICE SCHEDULE

2. DF-314 (Every 100,000 copies or prints)

1 OUTLINE

Number

Classification

No.

1 Inside the

machine

2 ISW

2

3. DB (DB-209/210/409/410) (Every 100,000 copies or prints)

2

Classification

No.

1 Paper feed

3 SERVICE

section

Service item

(1) Registration sensor

(2) Read sensor

(3) Size detection sensors

(at two locations)

(4) Feeding roller

Duble feed prevention roller

(5)

(6) Read roller

(7) Paper dust removing brush

Service item

(1) Double feed prevention

roller (upper)

(2) Feed roller

Duble feed prevention roller (lower)

(3)

of parts

replaced

Number

of parts

replaced

Implementation classification

Lubri-

Cleaning

Cleaning

Check

Implementation classification

Check

cation

Lubrication

Replacement

Replacement

Supply

Supply

Material used

Tools used, etc.

Blower brush

Blower brush

Blower brush

Drum cleaner/cleaning pad

Drum cleaner/cleaning pad

Water/cleaning pad

Caution: Do not use alcohol.

Blower brush

Material used

Tools used, etc.

Drum cleaner/cleaning pad

Drum cleaner/cleaning pad

Drum cleaner/cleaning pad

4. FS-107 (Every 100,000 copies or prints)

No.

Classification

1 Conveyance

section

Service item

(1) Conveyance drive roller/A

(2) Papaer exit drive roller

4 SERVICE

Number

of parts

replaced

Implementation classification

Lubri-

Cleaning

Check

cation

Replacement

Supply

Material used

Tools used, etc.

Drum cleaner/cleaning pad

Drum cleaner/cleaning pad

REVISED EDITION

2

DATE

Feb. 2001

4-6

PAGE

4-4

METHOD

REPLACEMENT

Page 8

SERVICE SCHEDULE

[3] Periodic check items (main body)

1. Periodic check (I) (Every 200,000 copies or prints)

Number

No.

Classification

1 Drum unit

2 Charging

corona unit

Transfer/separation

3

corona unit

4 Developing

section

5

Main body

6

Fixing unit

7

3

Final check

Service item

(1) Drum

(2) Cleaning blade assembly

26NA-209

3

3

3

3

26TA-209* (Other than 7020/25/35)

(3) Drum counter reset

(1) Charging wire

(2) Charging control plate

(1) Corona wire

(1) Developer

include the developing unit installing

(

(2) L-detection adjustment

(1) Ozone filter

26NA1017

20WA1017

26TA1017

(2) Suction filter/A

26TA3111*(Other than 7020/25/35)

(1) Separation claw

(2) Fixing roller holder/Upper

(3) Fixing roller holder/Lower

(4) Fixing Web (Note:1)

26NA5343

Fixing cleaning roller (Note:1)

(5)

26NA5383* (7022/7130)

(1) Fixing counter reset

(2) Check of image adjustment

*

*

*

*

*

(7020/25/30)

(7020/25/30)

(7022/7130)

(7035)

26NA5427

26NA5371

26NA5359

(7022/7130)

(7022/7130)

of parts

replaced

1

1

1

)

1

1

6

*

2

*

2

*

1

1

Implementation classification

Replace-

Cleaning

Check

Lubrication

ment

Material used

Supply

Tools used, etc.

Setting powder

Actual durable count :

200,000

Actual durable count :

200,000

Cotton swab

Cleaning pad

Cotton swab

(Transfer/separation)

Actual durable count :

200,000

Actual durable count :

200,000

Actual durable count :

200,000

Actual durable count :

200,000

Actual durable count :

200,000

Actual durable count :

200,000

Actual durable count :

200,000

Actual durable count :

200,000

Actual durable count :

200,000

1 OUTLINE

2 ISW

3 SERVICE

4 SERVICE

Note 1: It is recommended that you replace the entire cleaner assembly (26NA-540*) as a unit instead of replacing

3

individual parts.

REVISED EDITION

DATE

PAGE

METHOD

4-7

3

Jan. 2002

4-5

REPLACEMENT

Page 9

SERVICE SCHEDULE

2. Periodic check (II) (Every 300,000 copies or prints)

1 OUTLINE

No.

Classification

1 Bypass feed

2 ISW

Service item

(1) By pass reverse roller

40AA-406

(2) By pass pickup roller

26NA-428

(3) By pass conveyance roller

40AA-425

*

*

*

3. Periodic check (III) (Every 400,000 copies or prints)

Number

of parts

replaced

1

1

1

Implementation classification

Lubri-

Cleaning

Check

cation

Replacement

Material used

Supply

Tools used, etc.

Actual durable count :

100,000

Actual durable count :

100,000

Actual durable count :

100,000

3

3

3

Classification

No.

1 Main body

paper feed

unit

3 SERVICE

Transfer/separation

2

corona unit

3 Fixing unit

4 SERVICE

Service item

(1) Feed rubber

26NA4009

(2) Double feed prevention

rubber/Upper

26NA4011

(3) Double feed prevention

rubber/Lower 26NA4012

(1) Transfer/separation corona

unit 26NA-260

(1) Fixing sensor

26NA8801

(2) Fuse mounting plate

assembly 26NA-535

(3) Fixing heater /1

26NA8302

(4) Fixing heater /2

26NA8303

*

*

*

*

*

*

*

*

Number

of parts

replaced

2

2

2

1

1

1

1

1

Implementation classification

Lubri-

Cleaning

Check

cation

Replacement

Supply

Material used

Tools used, etc.

Actual durable count :

200,000

Actual durable count :

200,000

Actual durable count :

200,000

Actual durable count :

400,000

Actual durable count :

400,000

Actual durable count :

400,000

Actual durable count :

400,000

Actual durable count :

400,000

4. Periodic check (IV) (Every 600,000 copies or prints)

Number

No.

Classification

Developing

1

unit

Drum unit

2

Main unit

3

REVISED EDITION

Service item

(1) Developing unit

(Unit without developer)

26NA-300

3

3

3

26TA-300

*

(2)

Drum unit (Unit without drum)

26NA-990* (7020/25/30)

26WA-990

(3) Filter cover assembly

26TA-314* (Other than 7020/25/30)

*

(7020/25/30)

*

(Other than 7020/25/30)

(Other than 7020/25/30)

DATE

of parts

replaced

1

1

1

Cleaning

4-8

3

Jan. 2002

Implementation classification

Replace-

Check

Lubrication

PAGE

4-6

ment

Supply

Material used

Tools used, etc.

Actual durable count :

600,000

Actual durable count :

600,000

Actual durable count :

600,000

METHOD

REPLACEMENT

Page 10

SERVICE SCHEDULE

[4] Periodic check items (options)

1. RADF (DF-314) (Every 1,000,000 copies or prints) (Note 1)

Number

No.

Classification

1 Paper feed

section

Above replacement standard estimating DF usage ratio is 25%.

•

Note 1: The 7022/7130 are not covered.

3

Service item

(1) Paper feed roller/A

13GL4011

(2)

Double feed prevention roller/A

assembly

13GL-405

of parts

replaced

1

*

1

*

2. DB (DB-409/410) (Every 200,000 copies or prints)

Number

No.

Classification

1 Paper feed

section

Service item

(1) Feed rubber

26NA4009

(2) Double feed prevention

rubber/Upper 26NA4011

(3) Double feed prevention

rubber/Lower 26NA4012

of parts

replaced

1

*

1

*

1

*

Implementation classification

Cleaning

Cleaning

Check

Implementation classification

Check

Lubrication

Lubrication

Replacement

Replacement

Supply

Supply

Material used

Tools used, etc.

Actual durable count :

250,000

Actual durable count :

250,000

Material used

Tools used, etc.

Actual durable count :

200,000

Actual durable count :

200,000

Actual durable count :

200,000

1 OUTLINE

2 ISW

3 SERVICE

3. DB (DB-209/210) (Every 400,000 copies or prints)

Number

No.

Classification

1 Paper feed

section

Service item

(1) Feed rubber

26NA4009

(2) Double feed prevention

rubber/Upper 26NA4011

(3) Double feed prevention

rubber/Lower 26NA4012

of parts

replaced

2

*

2

*

2

*

4. FNS (FS-107) (Every 600,000 copies or prints)

Number

Classification

No.

1 Paper exit

section

Service item

(1) Exit roller/A

13GQ4519

of parts

replaced

1

*

Implementation classification

Replace-

Cleaning

Implementation classification

Cleaning

Check

Check

Lubrication

Lubrication

ment

Replacement

Supply

Supply

Material used

Tools used, etc.

Actual durable count :

200,000

Actual durable count :

200,000

Actual durable count :

200,000

Material used

Tools used, etc.

Actual durable count :

600,000

4 SERVICE

REVISED EDITION

3

DATE

Jan. 2002

4-9

PAGE

4-7

METHOD

REPLACEMENT

Page 11

SERVICE SCHEDULE

[5] List of actual durable counters for replacement parts

3

1 OUTLINE

Other than

7020

7020/25/30

/25/30

1

1

2

2

3

3

4

4

5

2 ISW

4 SERVICE

5

6

6

7

7

8

–

9

–

10

8

11

9

12

10

13

11

14

12

15

13

16

14

3 SERVICE

17

15

18

16

19

17

20

18

21

19

22

20

23

21

24

22

25

23

26

24

27

25

28

26

29

27

30

28

31

29

32

30

33

31

34

32

35

33

36

34

37

35

38

36

39

37

40

38

41

39

Note 1:* Parts varies depending on the spec. (destination), and the 9th digit will be changed in accordance with the

Note 2: Becomes 200,000 for machines other than 7020/25/30/35.

3

Note 3:It is recommended that you replace the "cleaner assembly" instead of the "fixing web" and the "fixing cleaning roller".

Unit

DC

(including changing

corona unit)

Transfer separation

corona unit

Developing unit

Main body

Main body

paper feed unit

DB (Tray3 or LCT)

paper feed unit

DB (Tray4)

paper feed unit

By-pass feed unit

Fixing unit

DF-314

FS-107

design chang of the parts.

Transfer separation corona unit

Filter cover assembly (7035 only)

(Tray1) Double feed prevention rubber/Upper

(Tray1) Double feed prevention rubber/Lower

(Tray2) Double feed prevention rubber/Upper

(Tray2) Double feed prevention rubber/Lower

(Tray3 or LCT) DB feed rubber

(Tray3 or LCT) DB double feed prevention rubber/Upper

(Tray3 or LCT) DB double feed prevention rubber/Lower

(Tray4) DB double feed prevention rubber/Upper

(Tray4) DB double feed prevention rubber/Lower

Fuse mounting plate assembly

Double feed prevention roller/A assembly

Parts name

Drum

Cleaning blade assembly

Drum unit

Developer

Developing unit

Ozone filter

Suction filter/A (7035 only)

(Tray1) Feed rubber

(Tray2) Feed rubber

(Tray4) DB feed rubber

By-pass reverse roller

By-pass pick up roller

By-pass conveyance roller

Fixing heat roller

Fixing pressure roller

Fixing web

Heat insulating sleeve/A

Heat insulating sleeve/B

Fixing cleaning roller

(Cleaner assembly

Fixing claw

Fixing roller holder/Upper

Fixing roller holder/Lower

Fixing sensor

Fixing heater/1

Fixing heater/2

Paper feed roller/A

Paper exit roller/A

)

Parts No.

7020/25/30 7035

—

26NA-209

26NA-990

26NA-260

—

26NA-300

26NA1017

—

—

26NA4009

26NA4011

26NA4012

26NA4009

26NA4011

26NA4012

26NA4009

26NA4011

26NA4012

26NA4009

26NA4011

26NA4012

40AA-406

26NA-428

40AA-425

26NA5303

26NA5304

26NA5343

26NA5372

26NA5373

26NA5383

(26NA-540*)

26AA5427

26NA5371

26NA5359

26NA8801

26NA-535

26**8302

26**8303

13GL4011

13GL-405

13GQ4519

26TA-209

*

26WA-990

*

*

26TA-300

*

26TA1017

*

26TA3111

26TA-314

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

26TA5303

*

26TA5304

*

*

*

*

*

(26TA-540*)

*

*

*

*

*

*

*

*

*

*

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

—

—

Other than7020/25/30/35

—

*

*

←

←

←

—

*

*

*

*

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

26NA5303

*

26NA5304

*

*

*

←

←

←

←

(

26NA-540*)

←

←

←

←

←

←

←

←

←

←

Actual durable

count

200,000

200,000

600,000

400,000

200,000

600,000

200,000

200,000

600,000

200,000

200,000

200,000

200,000

200,000

200,000

200,000

200,000

200,000

200,000

200,000

200,000

100,000

100,000

100,000

100,000

100,000

100,000

100,000

100,000

100,000

100,000

200,000

200,000

200,000

400,000

400,000

400,000

400,000

250,000

250,000

600,000

REVISED EDITION

3

DATE

Jan. 2002

4-10

PAGE

4-8

METHOD

REPLACEMENT

Page 12

[6] Important maintenance parts

3

• The important parts specified by Konica in order to

maintain safety of the products are referred to as

“important maintenance parts”.

The important maintenance parts for this machine

are as described below:

SERVICE SCHEDULE

1 OUTLINE

No.

1 Fixing unit Fuse mounting SP00-0110 1

•“SP” is indicated in front of the parts number of the

Unit

classification

important maintenance part. Exercise care when

installing the parts according to “3. Directions for

disassembly and assembly” in this manual.

Parts name Parts No Qty

plate assembly

2 ISW

3 SERVICE

REVISED EDITION

3

DATE

Jan. 2002

4-11

PAGE

4-8-1

4 SERVICE

METHOD

ADDITION

Page 13

COPY MATERIALS

COPY MATERIALS

[1] PM parts kit

1. 7020/25/30/35 (100,000 copies/kit)

3

Name

Fixing heat roller

Fixing pressure roller

Fixing web

Quantity

1

1

1

Name

Fixing cleaning roller

Cotton swabs (4 pcs.)

Cleaning pad (10 pcs.)

1 OUTLINE

Quantity

1

2 ISW

1

1

3 SERVICE

Heat insulating sleeve/A

Heat insulating sleeve/B

2

1

Dust bag

1

4 SERVICE

REVISED EDITION

3

DATE

Jan. 2002

4-13

PAGE

4-9

METHOD

REPLACEMENT

Page 14

COPY MATERIALS

1 OUTLINE

2. 7022/7130 (100,000 copies/kit)

3

Fixing heat roller

2 ISW

Fixing pressure roller

Heat insulating sleeve/A

3 SERVICE

Heat insulating sleeve/B

Name

Quantity

1

1

2

1

Name

Cotton swabs (4 pcs.)

Cleaning pad (10 pcs.)

Dust bag

Quantity

1

1

1

[2] Consumables (Single unit supply)

4 SERVICE

1. 7020/25/30/35

3

Name Durability/copies

Toner bottle

Developer

Drum

2. 7022/7130

3

Toner bottle

Developer

Drum

Fixing cleaner ass’y

REVISED EDITION

Name Durability/copies

3

26,000

200,000

200,000

29,391

200,000

200,000

200,000

Jan. 2002

DATE

4-14

PAGE

4-9-1

METHOD

ADDITION

Page 15

COPY MATERIALS

SERVICE MATERIALS LIST

[1] Maintenance kit composition

1 OUTLINE

Material No. Description

000V-16-0

000V-19-0

2 ISW

000V-18-1

1

00GR00210

3 SERVICE

Shape Remark

Drum cleaner

200 ml

Setting powder

25 g

Cleaning pad

10 pcs

1 pack

Solvest 240

4 SERVICE

REVISED EDITION

DATE

PAGE

METHOD

4-16

1

May 2000

4-10

REPLACEMENT

Page 16

SPECIAL TOOLS LIST

SPECIAL TOOLS LIST

3

3

Tool No. Description Shape Quantity Remark

26NA21340

26NAJG011

00VD-5000

120A97110

Drum rotation material

Mirror positioning jig

New pyramid chart

ADJ chart

1

2

1

1

Mounted on the drum

unit.

1 OUTLINE

2 ISW

3 SERVICE

120A97120

00VC-2-00

00VD-1000

00VE-1004

White chart

Drum cover

Blower brush

Tester

1

1

1

1

4 SERVICE

REVISED EDITION

3

DATE

Jan. 2002

4-11

4-17

PAGE

4-11

METHOD

REPLACEMENT

Loading...

Loading...