KOMATSU PW95-1 SHOP MANUAL

SHOP MANUAL

WEBMPW9500

PW95-1

HYDRAULIC EXCAVATOR

SERIAL NUMBER

0000007 and up

CONTENTS

No. of page

10 STRUCTURE AND FUNCTION ............................................. 10-1

20 TESTING AND ADJUSTING ................................................ 20-1

30 DISASSEMBLY AND ASSEMBLY ........................................... 30-1

40 MAINTENANCE STANDARD ............................................... 40-1

00-1

00-2

The affected pages are indicated by the use of the

following marks. It is requested that necessary actions be taken to these pages according to table

below.

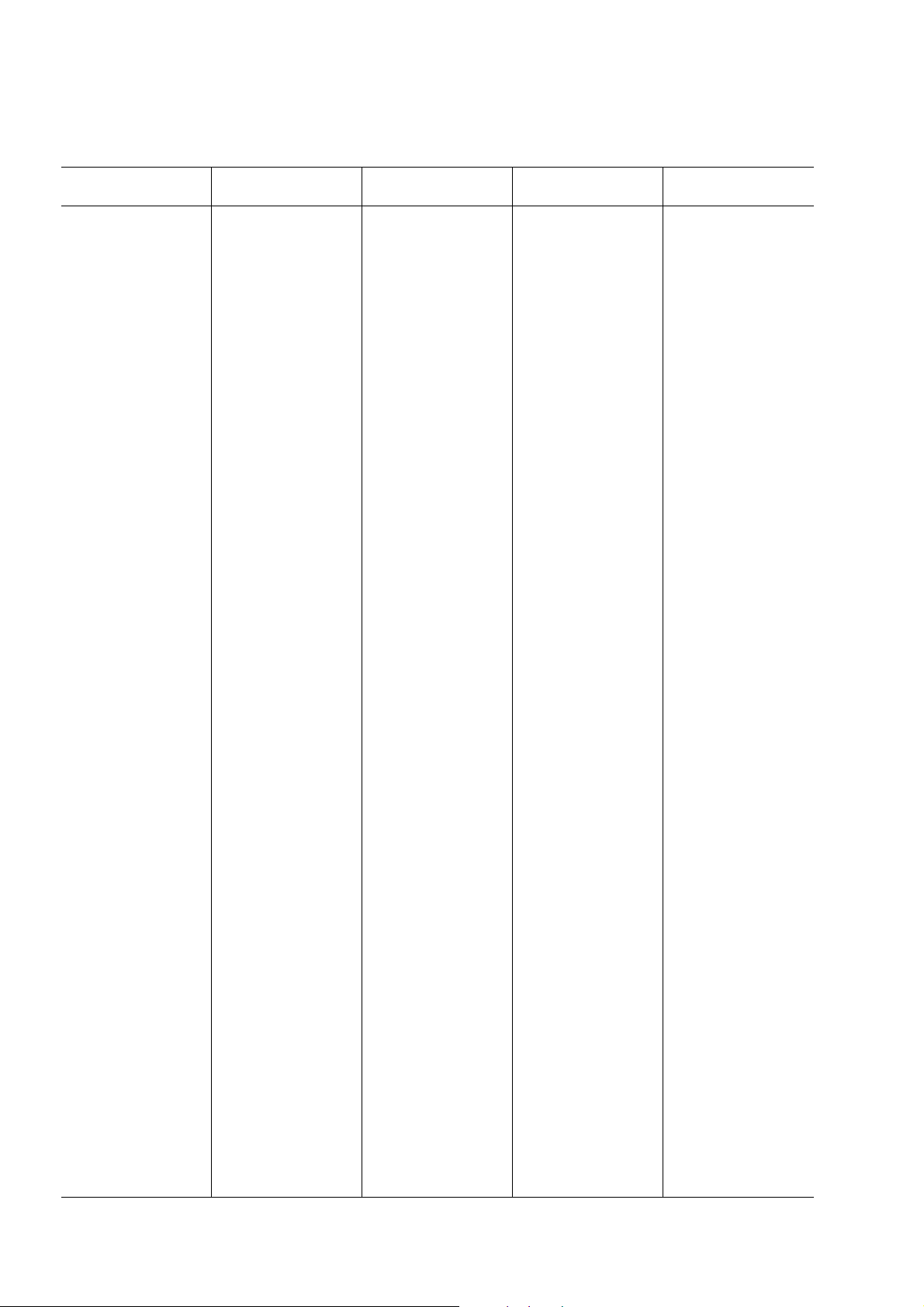

Mark Indication Action required

C Page to be newly

Add

Mark Page

00-1

00-2

00-2-1

00-2-2

00-3

00-4

00-5

00-6

00-7

00-8

00-9

00-10

00-11

00-12

10-1

10-2

10-3

10-4

10-5

10-6

10-7

10-8

10-9

10-10

10-11

10-12

10-13

10-14

10-15

10-16

10-17

10-18

10-19

10-20

10-21

10-22

10-23

10-24

10-25

Time of

revision

Mark Page

10-26

10-27

10-28

10-29

10-30

10-31

10-32

10-33

10-34

10-35

10-36

10-37

10-38

10-39

10-40

10-41

10-42

10-43

10-44

10-45

10-46

10-47

10-48

10-49

10-50

10-51

10-52

10-53

10-54

10-55

10-56

10-57

10-59

10-61

10-63

10-65

10-67

10-69

10-71

Pages having no marks are those previously revised

or made additions.

LIST OF REVISED PAGES

Time of

revision

Mark Page

20-1

20-2

20-3

20-4

20-5

20-6

20-7

20-8

20-9

20-10

20-11

20-12

20-13

20-14

20-15

20-16

20-17

20-18

20-19

20-20

20-21

20-22

20-23

20-24

20-25

20-26

20-27

20-28

20-29

20-30

20-31

20-32

20-33

20-34

20-35

20-36

20-37

20-38

20-39

20-40

c Page to be replaced

( ) Page to be delete

Time of

revision

Mark Page

Time of

revision

20-41

20-42

20-43

20-44

20-45

20-46

20-47

20-48

20-49

20-50

20-51

20-52

20-53

20-54

20-55

20-56

20-57

20-58

20-59

20-60

20-61

20-62

20-63

20-64

20-65

20-66

20-67

20-68

20-69

20-70

20-71

20-72

20-73

20-74

20-75

20-76

20-77

20-78

20-79

20-80

Replace

Discard

Mark Page

20-81

20-82

20-83

20-84

20-85

20-86

20-87

20-88

20-89

20-90

20-91

20-92

20-93

20-94

20-95

20-96

20-97

20-98

20-99

20-100

20-101

20-102

20-103

20-104

20-105

20-106

20-107

20-108

20-109

20-110

20-111

20-112

20-113

20-114

20-115

20-116

20-117

20-118

20-119

20-120

Time of

revision

00-2-1

Mark Page

Time of

revision

Mark Page

Time of

revision

Mark Page

Time of

revision

Mark Page

Time of

revision

Mark Page

Time of

revision

20-121

20-122

20-123

20-124

20-125

20-126

20-127

20-128

20-129

30-1

30-2

30-3

30-4

30-5

30-6

30-7

30-8

30-9

30-10

30-11

30-12

30-13

30-14

30-15

30-16

30-17

30-18

30-19

30-20

30-21

30-22

30-23

30-24

30-25

30-26

30-27

30-28

30-29

30-30

30-31

30-32

30-33

30-34

30-35

30-36

30-37

30-38

30-39

30-40

30-41

30-42

30-43

30-44

30-45

30-46

30-47

30-48

30-49

30-50

30-51

30-52

30-53

30-54

30-55

30-56

30-57

30-58

30-59

30-60

30-61

30-62

30-63

30-64

30-65

30-66

30-67

30-68

30-69

30-70

30-71

30-72

30-73

30-74

30-75

30-76

30-77

30-78

30-79

30-80

30-81

30-82

30-83

30-84

30-85

30-86

30-87

30-88

30-89

30-90

30-91

30-92

30-93

30-94

30-95

30-96

30-97

30-98

30-99

30-100

30-101

30-102

30-103

30-104

30-105

30-106

30-107

30-108

30-109

30-110

30-111

30-112

30-113

30-114

30-115

30-116

30-117

30-118

30-119

30-120

30-121

30-122

30-123

30-124

30-125

30-126

30-127

30-128

30-129

30-130

30-131

30-132

30-133

30-134

30-135

30-136

30-137

30-138

30-139

30-140

30-141

30-142

30-143

30-144

30-145

30-146

30-147

30-148

30-149

30-150

30-151

30-152

30-153

30-154

30-155

30-156

30-157

30-158

30-159

30-160

30-161

30-162

30-163

30-164

30-165

30-166

30-167

30-168

30-169

30-170

30-171

30-172

30-173

30-174

30-175

30-176

30-177

30-178

30-179

40-1

40-3

40-4

40-5

40-6

40-7

40-8

40-9

40-10

40-11

40-12

40-13

40-14

40-15

40-16

40-17

40-18

40-19

40-20

40-21

40-22

40-23

40-24

40-25

40-26

40-27

40-28

40-29

40-30

40-31

40-32

40-33

00-2-2

IMPORTANT SAFETY NOTICE

Proper service and repair is extremely important for the safe operation of your machine.

The service and repair techniques recommended by FKI and describe in this manual are both effective

and safe methods of operation. Some of these operations require the use of tools specially designed by

FKI for the purpose.

To prevent injury to workers, the symbols

ual. The cautions accompanying these symbols should always be carefully followed. If any danger arises

or may possibly arise, first consider safety, and take necessary steps to face.

and are used to mark safety precautions in this man-

SAFETY

GENERAL PRECAUTIONS

Mistakes in operation extremely dangerous.

Read all the Operation and Maintenance Manual carefully BEFORE operating the machine.

1. Before carrying out any greasing or repairs, read

all the precautions written on the decals which

are suck on the machine.

2. When carrying out any operation, always wear

safety shoes and helmet. Do not wear loose work

clothes, or clothes with buttons missing.

. Always wear safety glasses when hitting parts

with a hammer.

. Always wear safety glasses when grinding

parts with a grinder, etc.

3. If welding repairs are needed, always have a

trained, experienced welder carry out the work.

When carrying out welding work, always wear

welding gloves, apron, glasses, cap and other

clothes suited for welding work.

4. When carrying out any operation with two or more

workers, always agree on the operating procedure

before starting. Always inform your fellow workers

before starting any step of the operation. Before

starting work, hang UNDER REPAIR signs on

the controls in the operator's compartment.

5. Keep all tools in good condition and learn the correct way to use them.

6. Decide a place in the repair workshop to keep

tools and removed parts. Always keep the tools

and parts in their correct places. Always keep

the work area clean and make sure that there is

no dirt or oil on the floor.

Smoke only in the areas provided for smoking.

Never smoke while working.

PREPARATIONS FOR WORK

7. Before adding or making any repairs, park the machine on hard, level ground, and block the wheels

to prevent the machine from moving.

8. Before starting work, lower ourigger, bucket or

any other work equipment to the ground. If this

is not possible, use blocks to prevent the work

equipment from falling down. In addition, be sure

to lock all the control levers and hang warning

sign on them.

9. When disassembling or assembling, support the

machine with blocks, jacks or stands before starting work.

10. Remove all mud and oil from the steps or other

places used to get on and off the machine. Always

use the handrails, ladders or steps when getting

on or off the machine.

Never jump on or off the machine.

If it is impossible to use the handrails, ladders or

steps, use a stand to provide safe footing.

PRECAUTIONS DURING WORK

11. When removing the oil filler cap, drain plug or hydraulic pressure measuring plugs, loosen them

slowly to prevent the oil from spurting out.

Before disconnecting or removing components of

the hydraulic circuit and engine cooling circuit,

first remove the pressure completely from the circuit.

12. The water and oil in the circuits are not hot when

the engine in stopped, so be careful not to get

burned.

Wait for the oil water to cool before carrying out

any work on the cooling water circuits.

00-3

13. Before starting work, remove the leads from the

battery. Always remove the lead from the negative

( ± ) terminal first.

14. When raising heavy components, use a hoist or

crane. Check that the wire rope, chains and hooks

are free from damage.

Always use lifting equipment which has ample capacity. Install the lifting equipment at the correct

places.

Use a hoist or crane and operate slowly to prevent

the component from hitting any other part.

Do not work with any part still raised by the hoist

or crane.

15. When removing covers which are under internal

pressure or under pressure from a spring, always

leave two bolts in position on opposite sides.

Slowly release the pressure, then slowly loosen

the bolts to remove.

16. When removing components, be careful not to

break or damage the wiring.

Damage wiring may cause electrical fires.

17. When removing piping, stop the fuel or oil from

spilling out. If any fuel or oil drips on to the floor,

wipe it up immediately.

Fuel or oil on the floor can cause you to slip, or

can even start fires.

24. Take sure when removing or installing tracks of in

particular rubber tracks. When removing the

track, the track separates suddenly, so never let

anyone stand at either end of the wheel.

18. As a general rule, do not use gasoline to wash

parts. In particular, use only the minimum of gasoline when washing electrical parts.

19. Be sure to assemble all parts again in their original places. Replace any damage parts with new

parts.

. When installing hoses and wires, be sure that

they will not be damaged by conctat with other

parts when the machine is being operated.

20. When installing high pressure hoses, make sure

that they are not twisted. Damaged tubes are dangerous, so be extremely careful when installing

tubes for high pressure circuits. Also, check that

connecting parts are correctly tightened.

21. When assembling or installing parts, always use

specified tightening torques.

When installing the parts which vibrate violently or

rotate at high speed, be particulary careful to

check that they are correctly installed.

22. When aligning two holes, never insert your fingers

or hand.

23. When measuring hydraulic pressure, check that

the measuring tool is correctly assembled before

taking any measurement.

00-4

FOREWORD

This shop manual has been prepared as an aid to improve the quality of repairs by giving the operator an accurate understanding of the product and by showing him the correct way to perform repairs and make judgements.

Make sure you understand the contents of this manual and use it to full effect at every opportunity.

This shop manual mainly contains the necessary technical information for operations performed in a service

workshop.

The manual is divided into chapters on each main group of components; these chapters are further divided into

the following sections.

STRUCTURE AND FUNCTION

This section explains the structure and function of each component. It serves not only to give an understanding of the structure, but also serves as reference material for troubleshooting.

TESTING AND ADJUSTING

This sections explains checks to be made before and after performing repairs, as well as adjustments to be

made at completion of the checks and repairs.

Troubleshooting charts correlating «Problems» to «Causes» are also included in this section.

DISASSEMBLY AND ASSEMBLY

This section explains the order to be followed when removing, installing, dissassembling or assembling

each component, as well as precautions to be taken for these operations.

MAINTENANCE STANDARD

This section gives the judgement standards when inspecting disassembled parts.

NOTICE

The specifications contained in this shop manual are subject to change at any time and without any

notice.

Contact your FKI distributor for the latest information.

00-5

HOW TO READ THE SHOP MANUAL

e

HOW TO READ THE SHOP MANUAL

VOLUMES

Shop manual are issued as a guide to carry out repairs. These various volumes are designed to avoid

duplicating the same information.

DISTRIBUTION AND UPDATING

Any additions, amendments or other changes will

be sent to FKI distributors.

Get the most up-to-date information before you start

any work.

FILING METHOD

1. See the page number on the bottom of the page.

File the pages in correct order.

2. Following examples show you how to read the

page number.

Example

10 - 3

Numero dell'articolo (10. Struttura

funzionamento)

Numero di pagina progressivo per

ogni articolo

3. Additional pages: additional pages are indicated

by a hyphen (-) and number after the page number.

Fle as in the example.

Example:

10-4

10-4-1

10-4-2

] Added pages

10-5

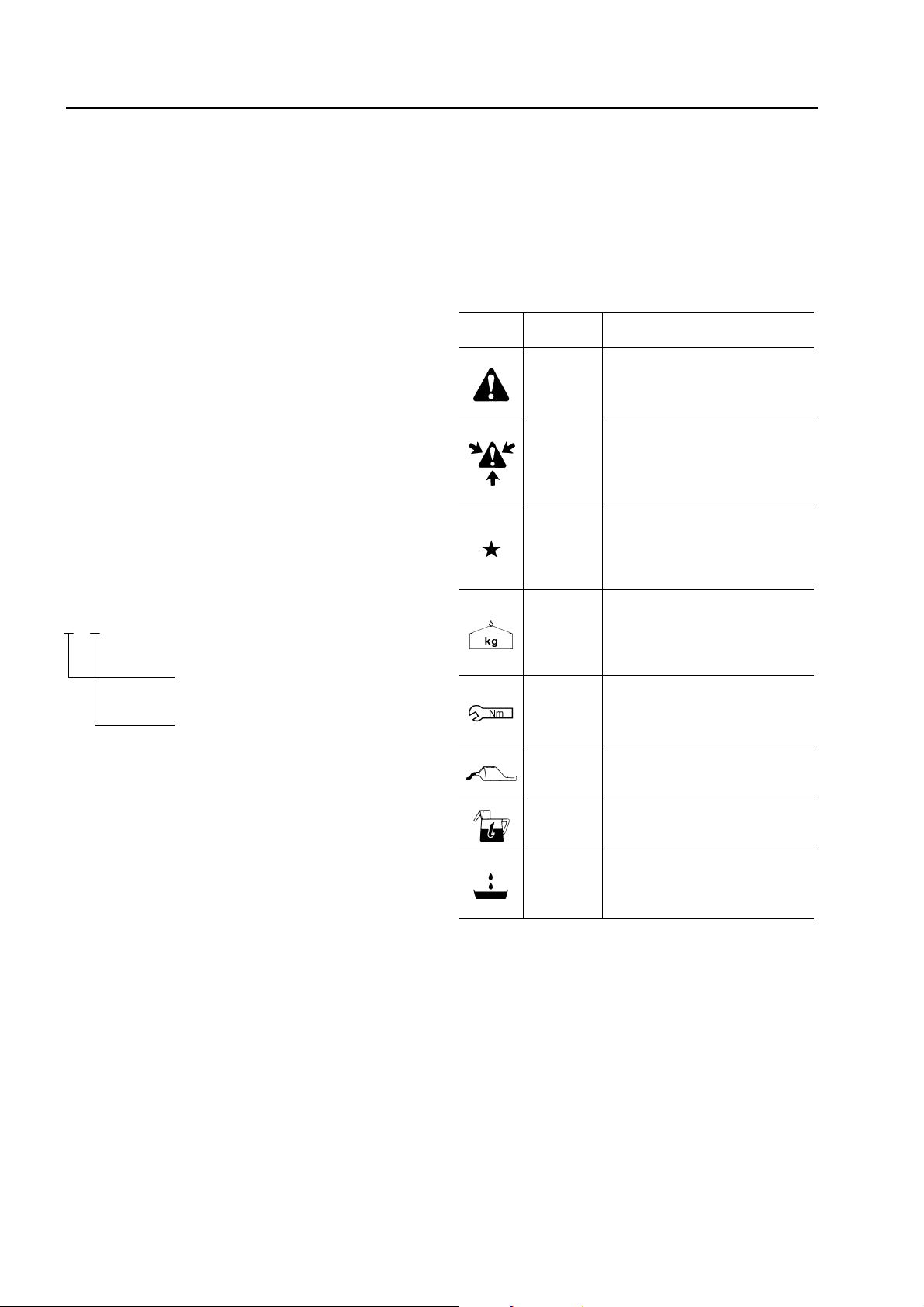

SYMBOLS

In order to make the shop manual greatly chelpful,

important points about safety and quality are marked

with the following symbols.

Symbol Item Remarks

Special safety precautions are necessary when performing the

work.

Safety

Caution

Weight

Tightening

torque

Coat

Oil, water

Drain

Extra special safety precautions

are necessary when performing

the work because it is under internal pressure.

Special technical precautions or

other precautions for preserving

standards are necessary when

performing the work.

Weight of parts or systems.

Caution necessary when selecting

hoisting wire, or when working

posture is important, etc.

Parts that require special attention

for the tightening torque during assembly.

Parts to be coated with adhesives

and lubricants etc.

Places where oil, water or fuel

must be added, and their quantity.

Places where oil or water must be

drained, and quantity to be

drained.

REVISED EDITION MARK

(123....)

When a manual is revised, an edition mark is re-

corded on the bottom outside corner of the pages.

REVISIONS

Revised pages are shown on the LIST OF REVISED PAGES between the title page and SAFETY

page.

00-6

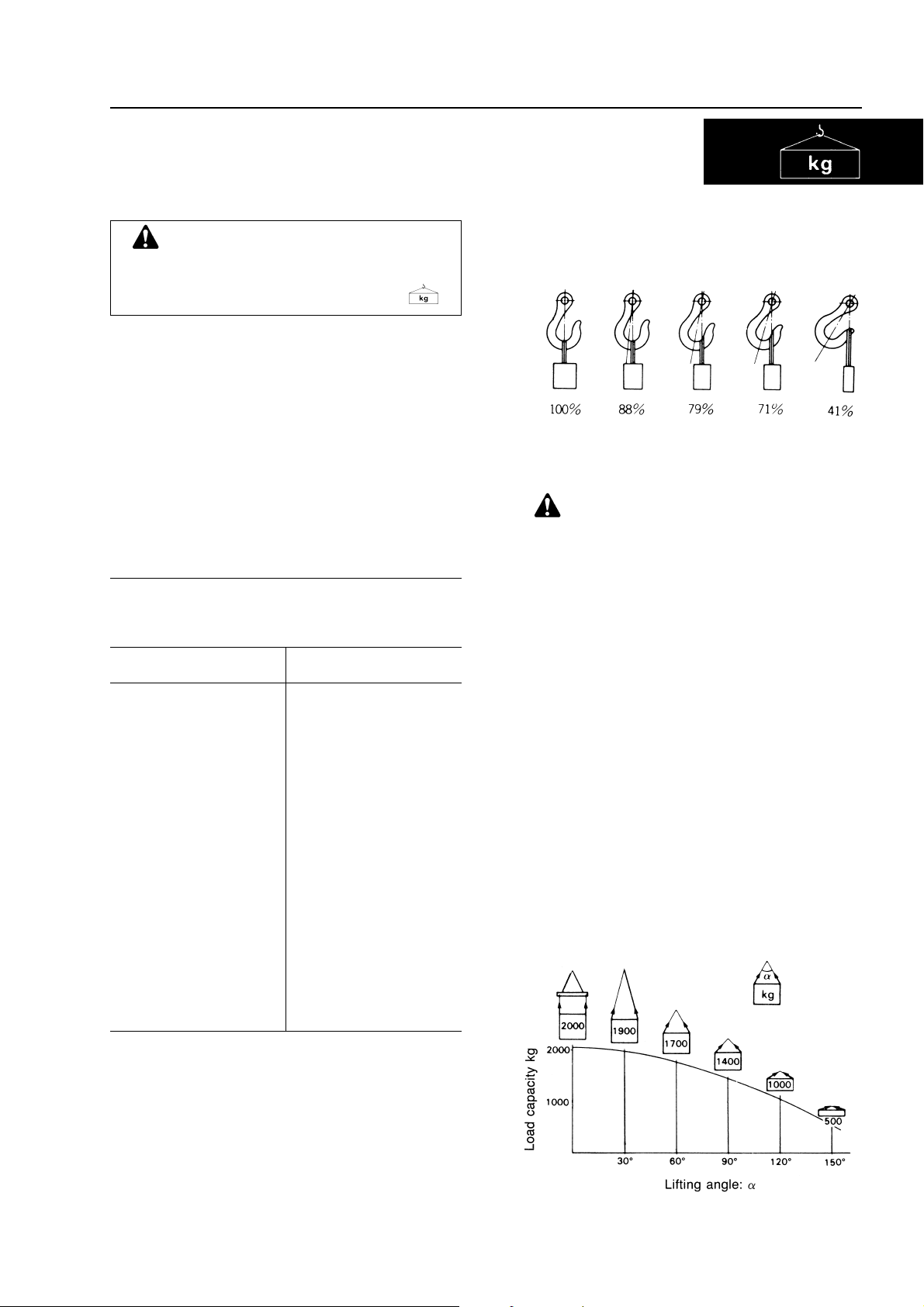

HOISTING INSTRUCTIONS

HOISTING INSTRUCTIONS

Heavy parts (25 kg or more) must be lifted

with a hoist etc. In the Disassembly and As-

sembly section, every part weighing 25 kg or

more is clearly indicated with the symbol

1. If a part cannot be smoothly removed from the

machine by hoisting, the following checks should

be made:

. Check for removal of all bolts fastening the part

to the relative parts.

. Check for any part causing interference with

the part to be removed.

2. Wire ropes

1) Use adequate ropes depending on the weight

of parts to be hoisted, referring to the table below:

WIRE ROPES

(Standard «S» or «Z» twist ropes

without galvanizing)

Rope diameter (mm) Allowable load (tons)

10

11.2

12.5

14

16

18

20

22.4

1.0

1.4

1.6

2.2

2.8

3.6

4.4

5.6

ing, and a serious accident can result.

Hooks have maximum strenght at the middle

portion.

3) Do not sling a heavy load with one rope alone,

but sling with two or more ropes symmetrically

wound on to the load.

Slinging with one rope may cause turning of

the load during hoisting, untwisting of the

rope, or slipping of the rope from its original

winding position on the load, which can

cause dangerous accidents.

4) Do not sling a heavy load with ropes forming a

wide hanging angle from the hook.

When hoisting a load with two or more ropes,

the force subjected to each rope will increase

with the hanging angles.

The table below shows the variation of allowable load (kg) when hoisting is made with two

ropes, each of which is allowed to sling up to

1000 kg vertically, at various handing angles.

When two ropes sling a load vertically, up to

2000 kg of total weight can be suspended.

This weight becomes 1000 kg when two ropes

make a 120ë hanging angle.

On the other hand, two ropes are subjected to

an excessive force as large as 4000 kg if they

sling a 2000 kg load at a lifting angle of 150ë.

30

40

50

60

The allowable load value is estimated to be

one-sixth or one-seventh of the breaking

strength of the rope used.

2) Sling wire ropes from the middle portion of the

hook. Slinging near the edge of the hook may

cause the rope to slip off the hook during hoist-

10.0

18.0

28.0

40.0

00-7

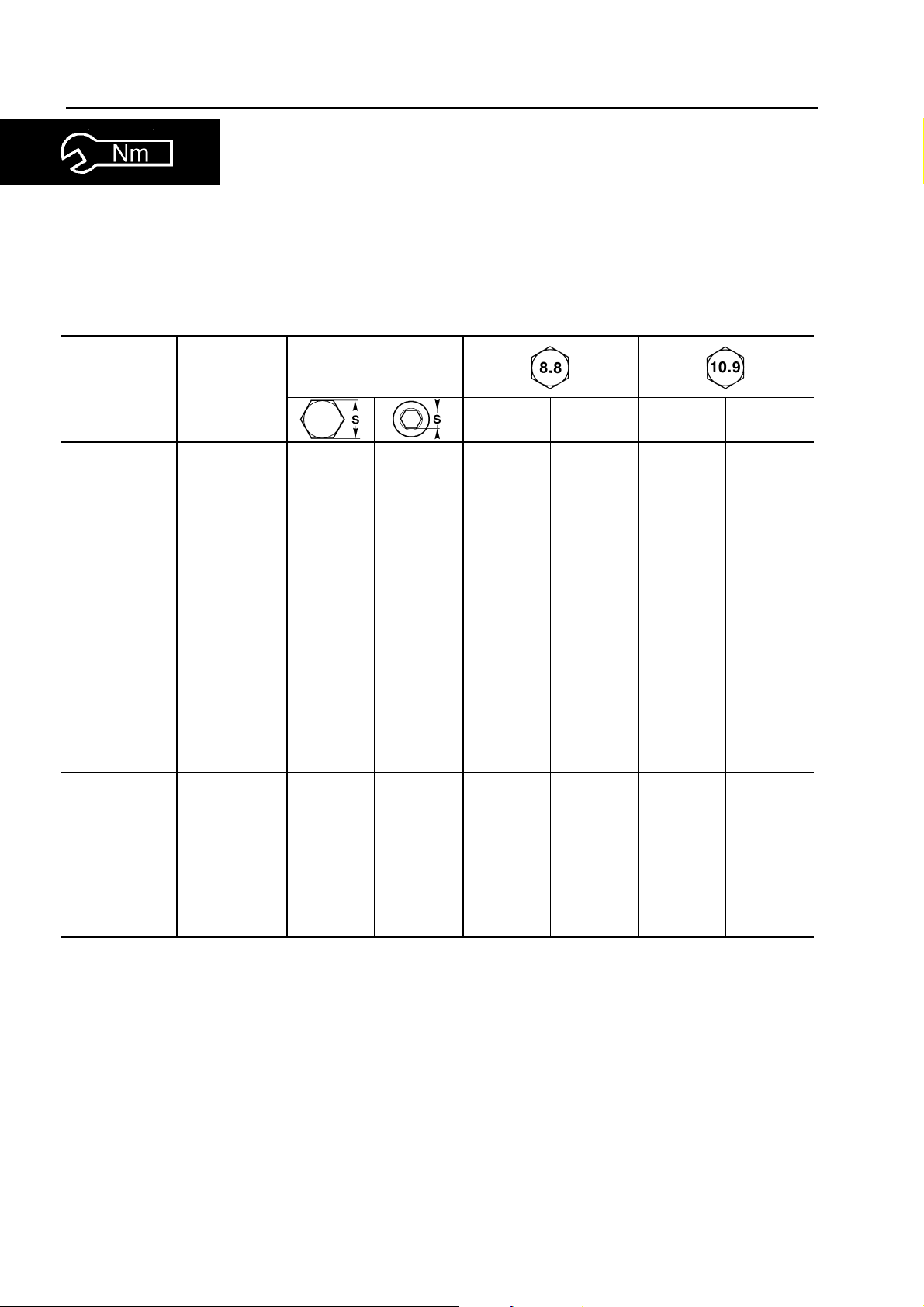

STANDARD TIGHTENING TORQUE

STANDARD TIGHTENING TORQUE

The following charts give the stardard tightening torques of bolts and nuts. Exceptions are given in sections of «Disassembly and Assembly».

1. STANDARD TIGHTENING TORQUE OF BOLTS AND NUT

Thread diameter

of bolts

(mm)

6

8

10

12

14

16

18

20

22

24

27

Pitch of

bolts

(mm)

1

1.25

1.5

1.75

2

2

2.5

2.5

2.5

3

3

Width across flat

(mm)

10

13

17

19

22

24

27

30

32

36

41

5

6

8

10

12

14

14

17

17

19

19

kgm Nm kgm Nm

0.96w0.1

2.3w0.2

4.6w0.5

7.8w0.8

12.5w1

19.5w2

27w3

38w4

52w6

66w7

96w10

9.5w1

23w2

45w4.9

77w8

122w13

191w21

262w28

372w40

511w57

644w70

945w100

1.3w0.15

3.2w0.3

6.5w0.6

11w1

17.5w2

27w3

37w4

53w6

73w8

92w10

135w15

1329w140

13.5w1.5

32.2w3.5

63w6.5

108w11

172w18

268w29

366w36

524w57

719w80

905w98

30

33

36

39

This torque table does not apply to bolts or nuts which have to fasten nylon or other parts non-ferrous metal washer.

. Nm (Newton meter): 1 Nm = 0.102 kgm

3.5

3.5

4

4

46

50

55

60

22

24

27

Ð

131w14

177w20

230w25

295w33

1287w140

1740w200

2250w250

2900w330

184w20

250w27

320w35

410w45

1810w190

2455w270

3150w350

4050w450

00-8

STANDARD TIGHTENING TORQUE

2. TIGHTENING TORQUE FOR NUTS OF FLARED

Use these torques for nut part of flared.

Thread diameter

of nut part

(mm)

1/2" - 20

9/16" - 18

3/4" - 16

7/8" - 14

1

1.

/16"-12

5

1.

/16"-12

5/8"

1.

-12

22

33

Width across flats

of nut part

(mm)

17

17

22

27

32

38

50

27

41

TIGHTENING TORQUE

kgm Nm

2.6w0.5

4w0.5

6.7w2

8w2

9.7w3

17w3

20w5

8w2

20w5

COATING MATERIALS

The recommended coating materials prescribed in FKI Shop Manuals are listed below:

Nomenclature Code Applications

Used to apply rubber pads, rubber gaskets and cork plugs.

Used to apply resin, rubber, metallic and non-mettalic parts when a fast, strong

seal is needed.

Used for low resistance locking of screws, check nuts and adjustment nuts.

To prevent the loosening of bolts, nuts and plugs and the leakage of oil. Used for

medium resistance locking of screws and nuts of every type, and for locking keys

and bearings.

Used for high resistant of threaded parts that can be removed with normal tools.

Used for high resistant locking and for sealing threaded parts, bolts and stud

bolts.

Used for sealing the union threads for hydraulic tubes.

Used for sealing rather exact plane surfaces when the option of possible future

dismantling is required.

Used for high resistant locking of mechanical components that can be removed

only after heating

Used to lock cylindrical couplings and for the permanent locking of threaded parts,

and also to lock shafts to bearings, gears, pulleys, pins, bushings, etc.

Used by itself to seal grease fittings, tapered screw fittings and tapered screw fit-

tings in hydraulic circuits of less than 50 mm in diameter.

Used by itself on mounting suface on the final drive and transmission cases.

(Thickness after tightening :0.07-0.08 mm).

Applied to bearings and taper shaft to facilitate press-fitting and to prevent sticking, burning or rusting.

Applied to bearings, sliding parts and oil seals for lubrication, rust prevention and

facilitation of assembling work.

Used for protecting battery electrode terminals from corrosion.

Adhesives

Gasket sealant

Antifriction compound

(Lubricant inclunding

Molybdenum disulfide)

Grease

(Lithium grease)

Vaseline

ASL800010

ASL800020

Loctite 222

Loctite 242

Loctite 262

Loctite 270

Loctite 542

Loctite 573

Loctite 601

Loctite 675

ASL800060

ASL800070

ASL800040

ASL800050

±

25.5w4.9

39.2w4.9

65.7w19.6

78.5w19.6

95.15w29.4

166.7w29.4

196.2w49

78.5w19.6

196.2w49

00-9

ELECTRIC WIRE CODE

ELECTRIC

ELECTRIC WIRE CODE

In the wiring diagrams. various colors and symbols are employed to indicate the thickness of wires.

This wire code table will help you understand WIRING DIAGRAMS.

Example: R -N 1.5 indicates a cable having a nominal number 1.5 and red coating with black stripe.

CLASSIFICATION BY THICKNESS

Nominal

number

0.35 11 0.20 0.35 1.55 3.5 Proximity sensor

0.5 16 0.20 0.50 2.40 6 Instrument

0.8 11 0.30 0.78 2.80 8 Instrument - transmitter

1 14 0.30 0.99 2.80 11 Lighting - signal etc.

1.5 21 0.30 1.48 3.35 14 Working light - solenoid valve etc.

2.5 35 0.30 2.47 3.80 20

4 56 0.30 3.95 4.60 28 Alternator - preheating etc.

6 84 0.30 5.93 5.20 37 Starter motor fuses

50 399 0.40 50.11 14 160 Ground - starter motor

Number

strands

Copper wire

ù of strands

(mm)

Cross section

(mm

2

)

Cable O.D.

(mm)

Current rating

(A)

Applcable circuit

Control panel - Ignition switch etc.

CLASSIFICATION BY COLOUR AND CODE

Primary Auxiliary

Code A A-B A/B A-G A/G A-N A/N A-R A/R A-V A/V

Colour Light blue Light blue-White Light blue-Yellow Light blue-Black Light blue-Red Light blue-Green

Code B B-G B/G B-L B/L B-N B/N B-R B/R

Colour White White-Yellow White-Blue White-Black White-Red ÐÐ

Code C C-B C/B C-N C/N C-V C/V

Colour Orange Orange-White Orange-Black Orange-Green ÐÐ ÐÐ

Code G G-N G/N G-R G/R G-V G/V ÐÐ ÐÐ ÐÐ ÐÐ

Colour Yellow Yellow-Black Yellow-Red Yellow-Green ÐÐ ÐÐ

Code H H-G H/G H-N H/N H-R H/R ÐÐ ÐÐ ÐÐ ÐÐ

Colour Gray Gray-Yellow Gray-Black Gray-Red ÐÐ ÐÐ

Code L L-G L/G L-N L/N L-R L/R ÐÐ ÐÐ ÐÐ ÐÐ

Colour Blue Blue-Yellow Blue-Black Blue-Red ÐÐ ÐÐ

Code M M-B M/B M-N M/N ÐÐ ÐÐ ÐÐ ÐÐ ÐÐ ÐÐ

Colour Brown Brown-White Brown-Black ÐÐ ÐÐ ÐÐ

Code N ÐÐ ÐÐ ÐÐ ÐÐ ÐÐ ÐÐ ÐÐ ÐÐ ÐÐ ÐÐ

Colour Black ÐÐ ÐÐ ÐÐ ÐÐ ÐÐ

Code R R-N R/N R-V R/V ÐÐ ÐÐ ÐÐ ÐÐ ÐÐ ÐÐ

Colour Red Red-Black Red-Green ÐÐ ÐÐ ÐÐ

Code S S-G S/G S-N S/N ÐÐ ÐÐ ÐÐ ÐÐ ÐÐ ÐÐ

Colour Pink Pink-Yellow Pink-Black ÐÐ ÐÐ ÐÐ

Code V V-B V/B V-N V/N V-R V/R ÐÐ ÐÐ ÐÐ ÐÐ

Colour Green Green-White Green-Black Green-Red ÐÐ ÐÐ

Code Z Z-B Z/B Z-G Z/G Z-N Z/N ÐÐ ÐÐ ÐÐ ÐÐ

Colour Violet Violet-White Violet-Yellow Violet-Black ÐÐ ÐÐ

ÐÐ ÐÐ ÐÐ ÐÐ

ÐÐ ÐÐ

COMPOSITION OF THE COLOURS

The coloration of two-colour wires is indicated by the composition of the symbols listed.

Example: G-V = Yellow-Green with longitudinal colouring.

G/V = Yellow-Green with transversal colouring.

00-10

WEIGHT TABLE

This weight table is a guide for use when transporting or handling components.

Machine model PW95-1

From serial no. 0000007

Engine assembly 492

Radiator - exchanger 41

Hydraulic tank (without hydraulic oil) 76

Fuel tank (without fuel) 104

Revolving frame 1092

Counter weight 1150

Swing circle 130

Swing machinery assembly 65

Main hydraulic pump 60

Auxiliary pump 16.5

Operator's cab 250

Operator's seat 32

Operator's seat support 9

Unit: kg

Platform 55

Control valve 60

Track frame assembly 860

Front axle 403

Rear axle 410

Transmission assembly 72

Wheel assembly 79

Center swivel joint 97

Axle locking cylinder cylinder 30.5

Swing bracket 36

Engine hood (movable) 60

Engine hood (fixed) 83

Control valve hood 16

Boom 358

st

1

boom 272

nd

2

boom 195

Arm (L=1850) 156

Arm (L=1600) 134

Outrigger 76

Bracket 29

Outrigger support 140

Blade 192

00-11

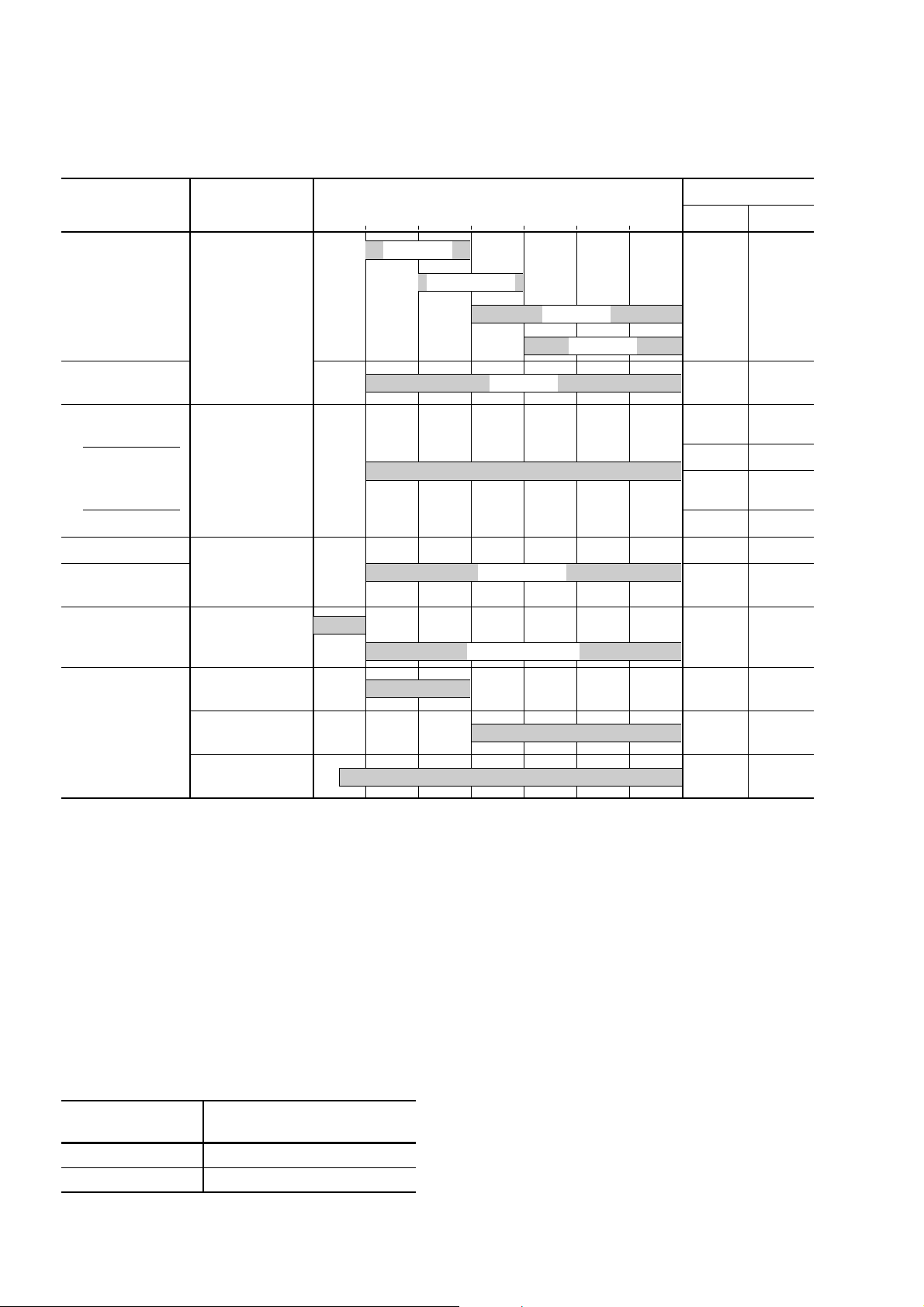

TABLE OF OIL AND COOLANT QUANTITIES

RESERVOIR

Lubricating oil

sump

Engine oil filter

Hydraulic system 148 82

Front axle:

.

differential

. planetary (each)

Rear axle:

.

differential

. planetary (each)

Transmission

Swing

machinery

Fuel

tank

KIND OF

FLUID

OIL

. API CD-SG

. MIL-L-2104 E

. CCMC D4-G4

OIL

. UTTO FLUID

OIL

. API GL5

. MIL-L-2105 D

DIESEL FUEL 140 ÐÐ

±20 ±10 0 10 20 30ëC

*

AMBIENT TEMPERATURE CAPACITY (

Specified Refill

SAE 10W

SAE 20W-20

SAE 30

SAE 40

SAE 10W

SAE 80W/90

ASTM D975 N. 2

11.5

1

7.8 7.8

0.9 0.9

7.8 7.8

0.9 0.9

1.9 1.9

44

11.5

< )

1

WATER+

ANTI-FREEZE

Cooling system

ASTM: America Society of Testing and Materials

SAE: Society of Automotive Engineers

API: American Petroleum Institute

MIL: USA Military Specification

CCMC: Common Market Constructors Committe

Specified capacity: Total amount of oil including oil for components and oil in piping.

Refill capacity: Amount of oil needed to refill system during normal inspection and maintenance.

WATER 20 ÐÐ

PERMANENT

LIQUID

ASTM D975 N. 1

*

NOTE:

(1) When fuel sulphur content is less than 0.5%,

change oil in the oil pan ebery periodic maintenance hours described in operation and maintenance manual.

Change oil according to the following table if fuel

sulphur content is above 0.5%.

Fuel sulphur content

0.5 to 1.0% 1/2 of regular interval

Above 1.0% 1/4 of regular interval

Oil change interval in engine oil

pan

(2) When starting the engine is weathers temperature

below 0ëC, be sure to use engine oil SAE 10W,

SAE 20W-20, even if weather temperature goes

up to 10ëC day time.

(3) Use classification CD as engine oil, if use classifi-

cation CC, reduce the engine oil change interval to

half.

(4) Use original products, which have characteristics

specifically formulated and approved for the engine, the hydraulic circuit of equipment and for reductions.

20 ÐÐ

20 ÐÐ

00-12

GROUP

10

STRUCTURE AND FUNCTION

P.T.O. .............................................. 10- 2

Power train ........................................ 10- 3

Transmission ...................................... 10- 4

Front axle - differential. .. ......................... 10- 6

Rear axle - differential .. .......................... 10- 7

Planetary........................................... 10- 8

Axles ............................................... 10- 9

Parking brake and cylinder. .. .................... 10-10

Steering system ................................... 10-12

Steering unit .. ..................................... 10-16

Swing circle........................................ 10-17

Swing machinery ... ............................... 10-18

Check valve and oil cooler safety by-pass . .. . .. 10-19

Hydraulic circuit diagram......................... 10-20

Main hydraulic pump ............................. 10-21

Pump drive ........................................ 10-22

Summation horsepower control.................. 10-23

3 circuit control valve ............................. 10-26

Mode-System ...................................... 10-28

Auxiliary pump .................................... 10-29

Priority valve. . ..................................... 10-30

Control valve (valve) .............................. 10-31

Control valve (ports) .............................. 10-32

Swing motor ... .................................... 10-34

Swing motor relief valve .......................... 10-35

Center swivel joint . ............................... 10-36

Travel motor .. ..................................... 10-37

Displacement automatic control high

pressure related ................................... 10-38

Travel motor brake valves........................ 10-39

Servocontrol feed unit ............................ 10-40

R.H. PPC valve.. .................................. 10-42

L.H. PPC valve .. .................................. 10-43

Accumulators ...................................... 10-44

Swing motor braking circuit selector valve...... 10-45

Travel PPC valve . ................................. 10-46

nd

2

boom PPC valve .. ............................ 10-47

Boom swing PPC valve ........................... 10-48

Outrigger and blade PPC valve. ................. 10-49

Outrigger and blade safety valve ................ 10-50

Brake pump . ....................................... 10-51

Axle locking valve ................................. 10-52

Solenoid valves. ................................... 10-53

Electrical circuit diagrams:

1 - Starting and engine line ...................... 10-59

2 - Beams, direction indicator horn and

fan line .. ....................................... 10-61

3 - Column steering switch, R.H. dashboard

switch, mechanical travel speed change

relay and rotary and cutting shovel switch

line ............................................. 10-63

4 - Mode System, relief servocontrol and L.H.

dashboard switch line . ....................... 10-65

5 - Steering emergency switch steering

selection switch and upper slip ring

collector line .. ................................. 10-67

6 - Track frame solenoid valve and steering

relay box line .................................. 10-69

7 - Main box and track frame relay box

disposition ..................................... 10-71

10-1

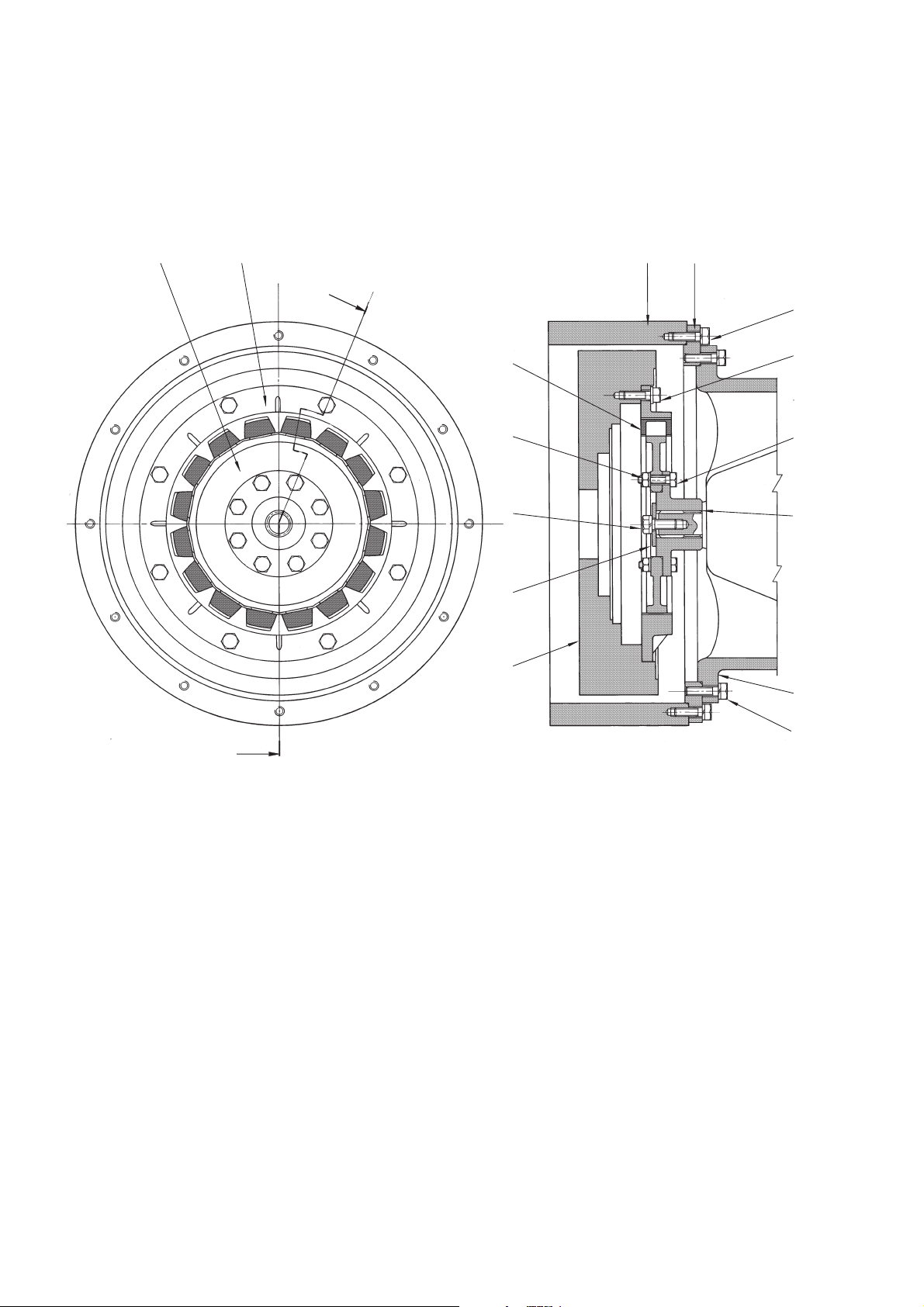

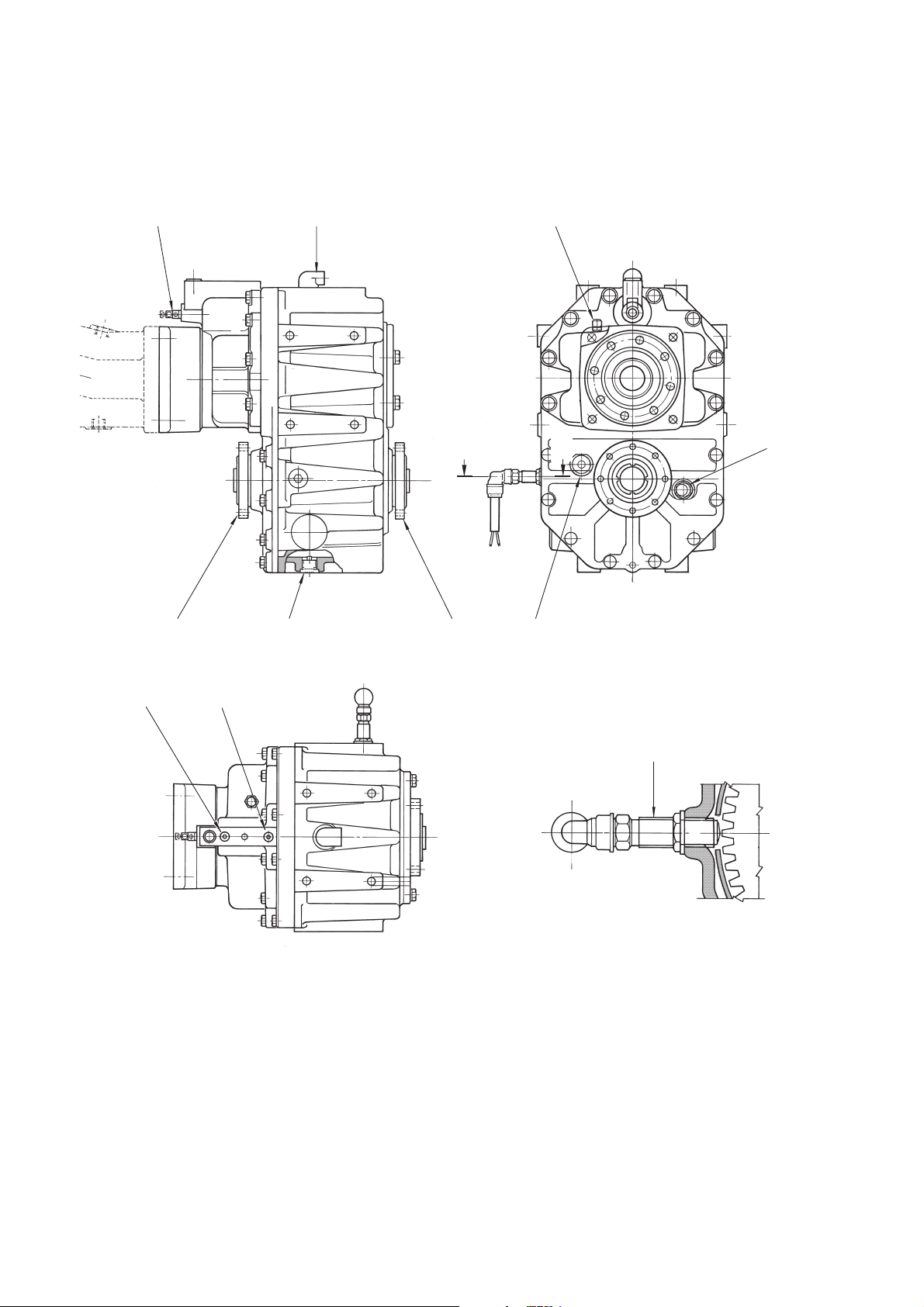

P.T.O.

3

1

4

2

A

5

15

14

13

12

11

A

Section A - A

6

7

8

9

10

D0400002

1. Connecting plate

2. Crown wheel

3. Flywheel housing

4. Centering ring

5. Screw

6. Screw

7. Screw

8. Hub

9. Pump plate

10-2

10. Screw

11. Flywheel

12. Washer

13. Screw

14. Nut

15. Loose piece

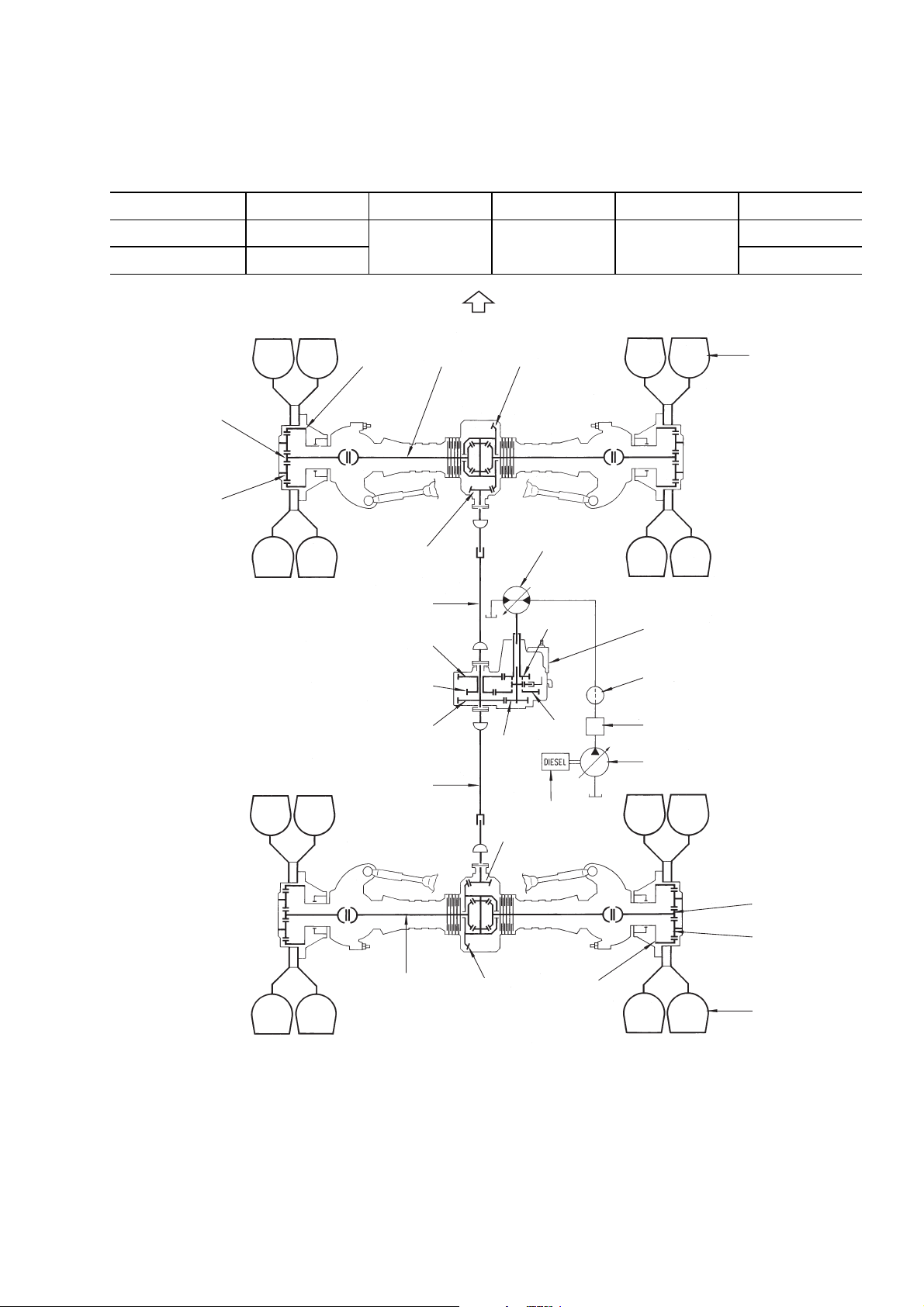

POWER TRAIN

REDUCTION RATIO

Transmission Differential Planetary Axle Total

High speed

Low speed

1.96

3.22 4.25 13.68

6.062 82.92

Front of machine

26.82

Z=12

Z=13

Z=39

Z=9

Z=51

Z=29

Z=49

8

Z=29

10

5

7

Z=29

6

4

Z=51

Z=25

3

2

7

1. Engine

2. Pump

3. Control valve

4. Swivel joint

5. Travel motor

6. Transmission

1

Z=9

Z=12

Z=13

9

Z=29

Z=39

11

D0400003

7. Propeller shaft

8. Front axle

9. Rear axle

10. Front wheel

11. Rear wheel

10-3

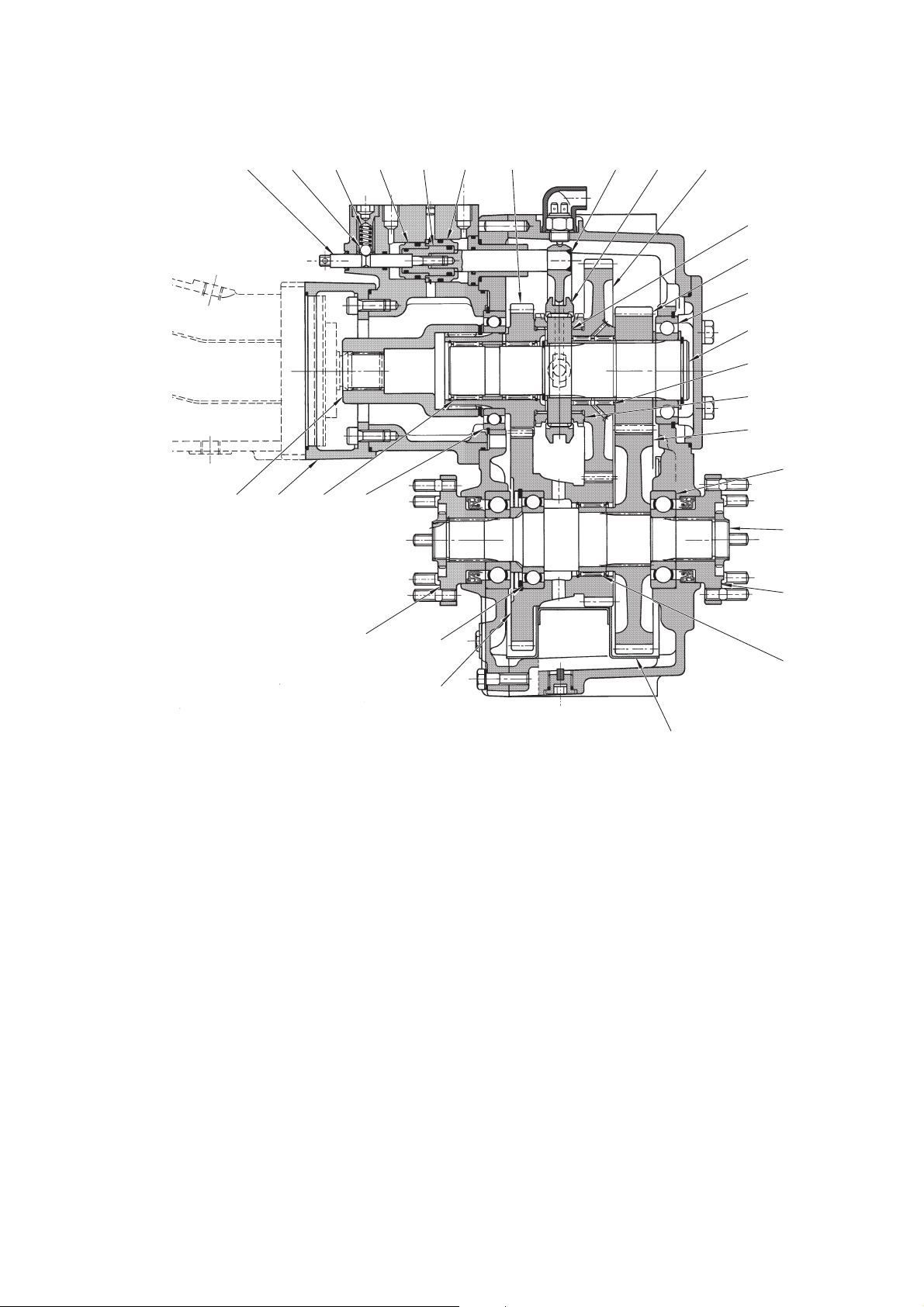

TRANSMISSION

6

7

9

A

1

a

3

2

b

A

4

5

8

1. Front coupling

2. Rear coupling

3. Oil drain plug

4. Refilling plug

5. Oil level

6. Safety switch

7. Neutral manual control

8. Speed surveyor

9. Vent plug

10-4

Section A - A

D0400004

a. A port (From EV3 - A2 port)

b. B port (From EV3 - A3 port)

214365 7 8910

11

12

13

14

15

16

17

18

272829

26

19

20

25

24

23

1. Neutral manual control shaft

2. Ball

3. Spring

4. Piston (slow drive control)

5. Piston

6. Piston (high drive control)

7. Input gear

8. Shifting fork

9. Shifting (dog) gear

10. Low speed driven gear

11. Gear (coupling internal gear)

12. Output drive gear

13. Bearing

14. Input shaft

15. Roller bearing

16. Ring gear

17. Output driven gear

18. Bearing

19. Output shaft

20. Rear coupling

21. Roller bearing

22. Protection

23. Low speed idle gear

24. Bearing

25. Front coupling

26. Bearing

27. Roller bearing

28. Flange

29. Coupling

Low speed

Reduction ratio: 1 : 6.0617

High speed

Reduction ratio: 1 : 1.96

Amount of oil: 1.9

22

21

D0400153

,

10-5

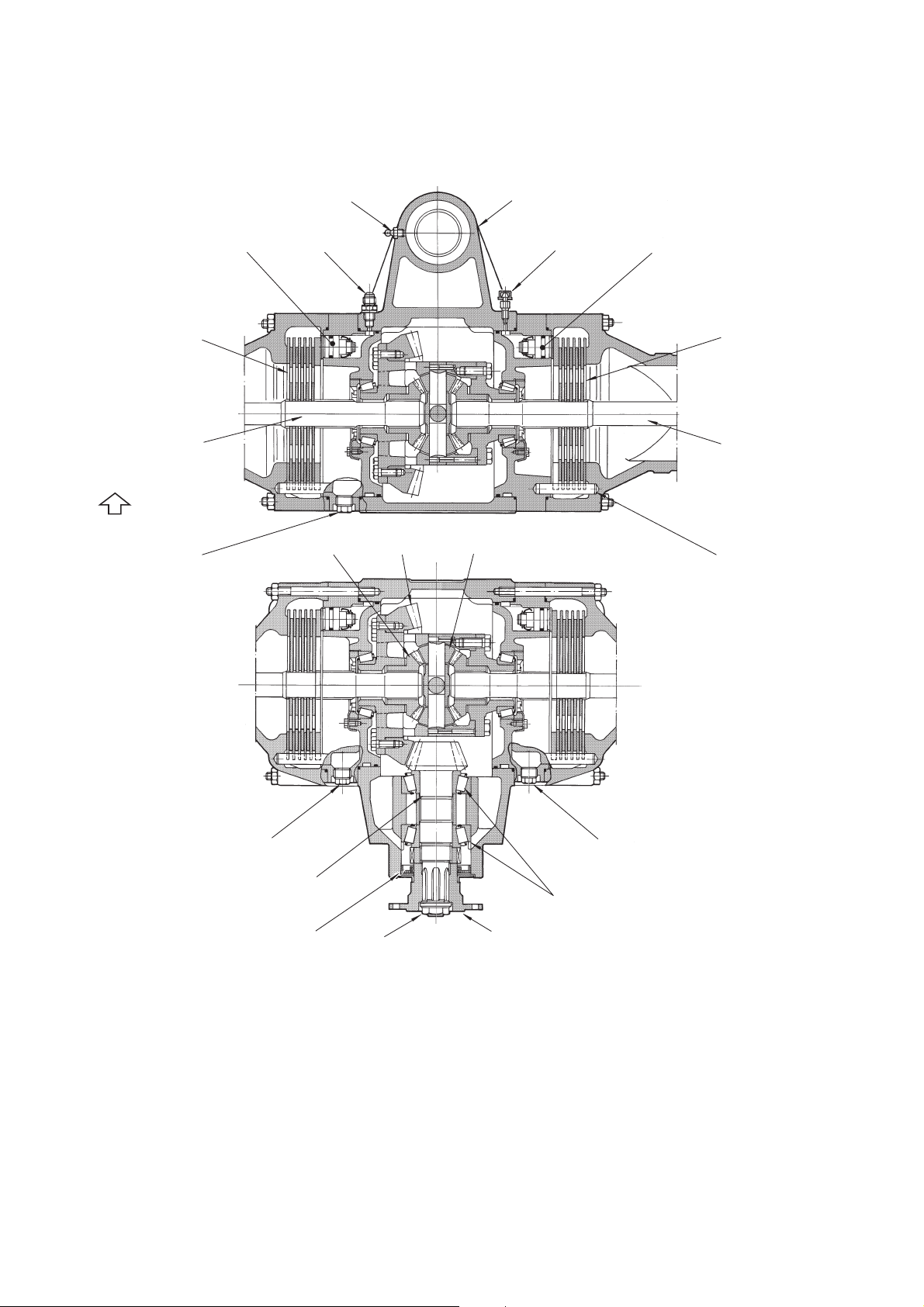

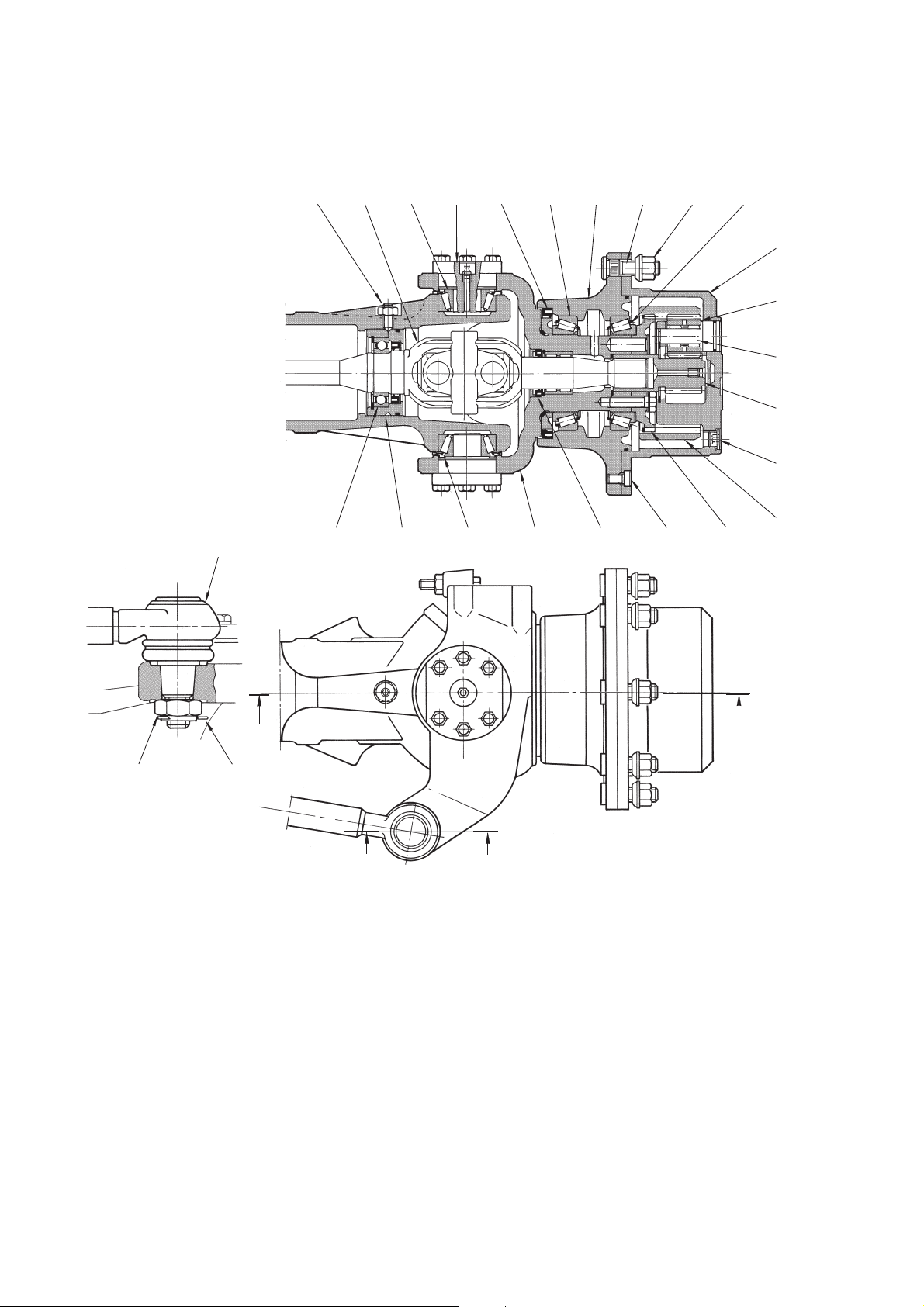

FRONT AXLE - DIFFERENTIAL

1

10

Front of machine

3

12

4

5

7

89

11

2

3

4

5

6

1. Central housing

2. Brake bleading screw

3. Service brake piston

4. Braking group

5. Drive shaft

6. Pin

7. Drain plug

8. Differential gear

9 Bevel gear

10. Grease nipple

11. Ring bevel gear

10-6

19

18

17

16

19

14

15

12. Union brake pump

13. Differential bearing

14. Pinion bearing

15. Coupling

16. Nut

17. Seal ring

18. Bevel pinion

19. Refilling plug

Amount of oil: 7.8

D0400006

,

REAR AXLE - DIFFERENTIAL

21

3

6

89

13

10

11

12

4

5

1415 16

24

10

11

7

Front of machine

1. Adjustment screw

2. Cylinder fulcrum lever

3. Parking brake cylinder

4. Differential brake

5. Bevel gear

6. Brake bleading screw

7. Right lever

8. Adjustment screw

9. Push rod

10. Braking group

11. Drive shaft

12. Drain plug

13. Union brake pump

23

22

18

19

2021

14. Central housing

15. Ring bevel gear

16. Service brake piston

17. Pin

18. Pinion bearing

19. Seal ring

20. Nut

21. Coupling

22. Bevel pinion

23. Refilling plug

24. Left lever

Amount of oil: 7.8

17

D0400007

,

10-7

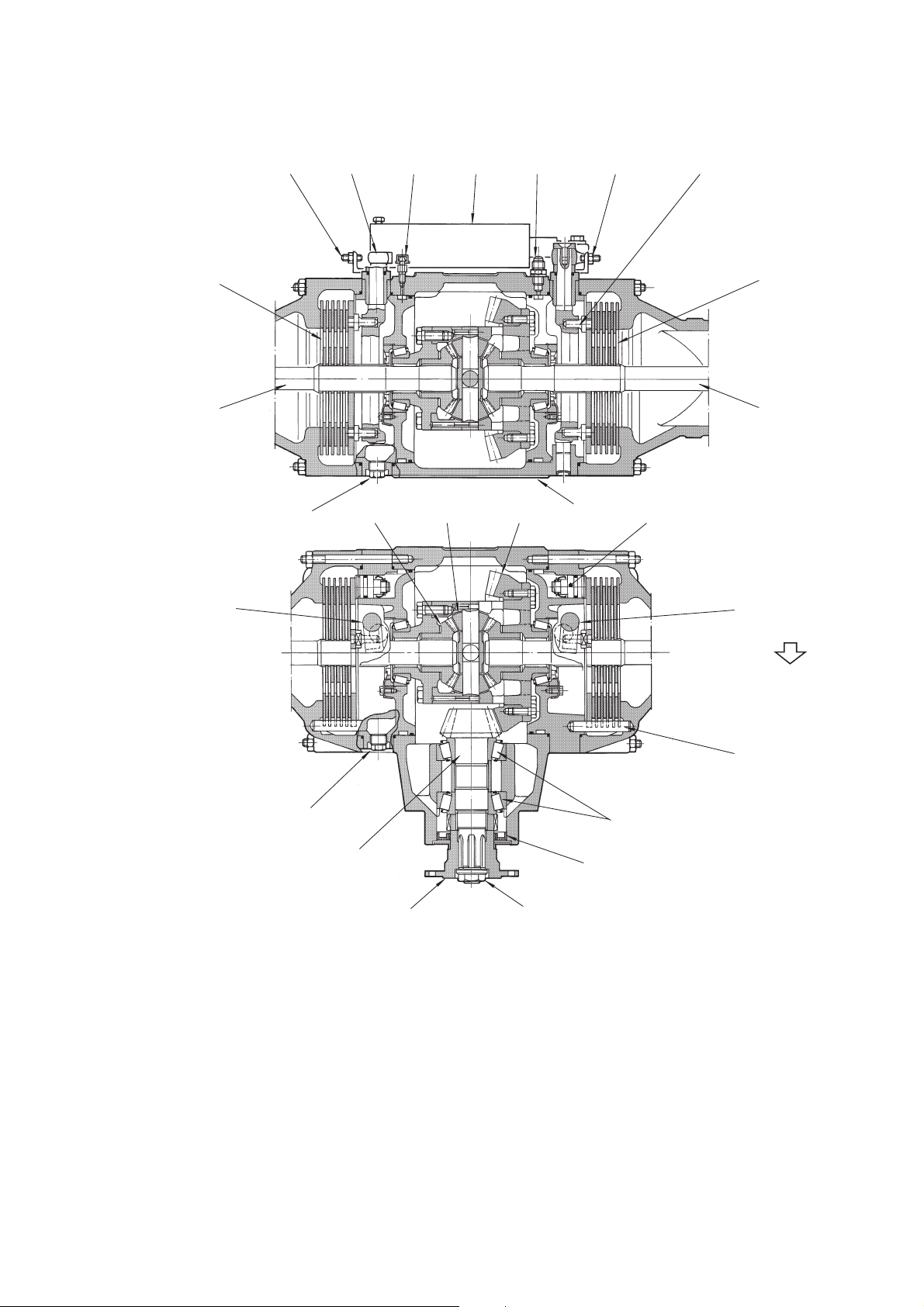

PLANETARY

214365789

22

10

11

Section A - A

23

Section B - B

25

24

A

2

18192021

1617

A

12

13

14

15

1. Drive shaft

2. Bearing

3. Knuckle pin

4. Seal ring

5. Bearing

6. Wheel hub

7. Stud bolt

8. Nut

9. Bearing

10. Planetary carrier

11. Bevel gear

12. Bevel gear pin

13. Pinion

14. Plug

10-8

B

B

15. Ring gear

16. Ring gear support

17. Screw

18. Seal ring

19. Steering knuckle

20. Bushing

21. Bearing

22. Screw

23. Nut

24. Cotter pin

25. Ball-and-socket joint

Amount of oil: 0.9

D0400008

,

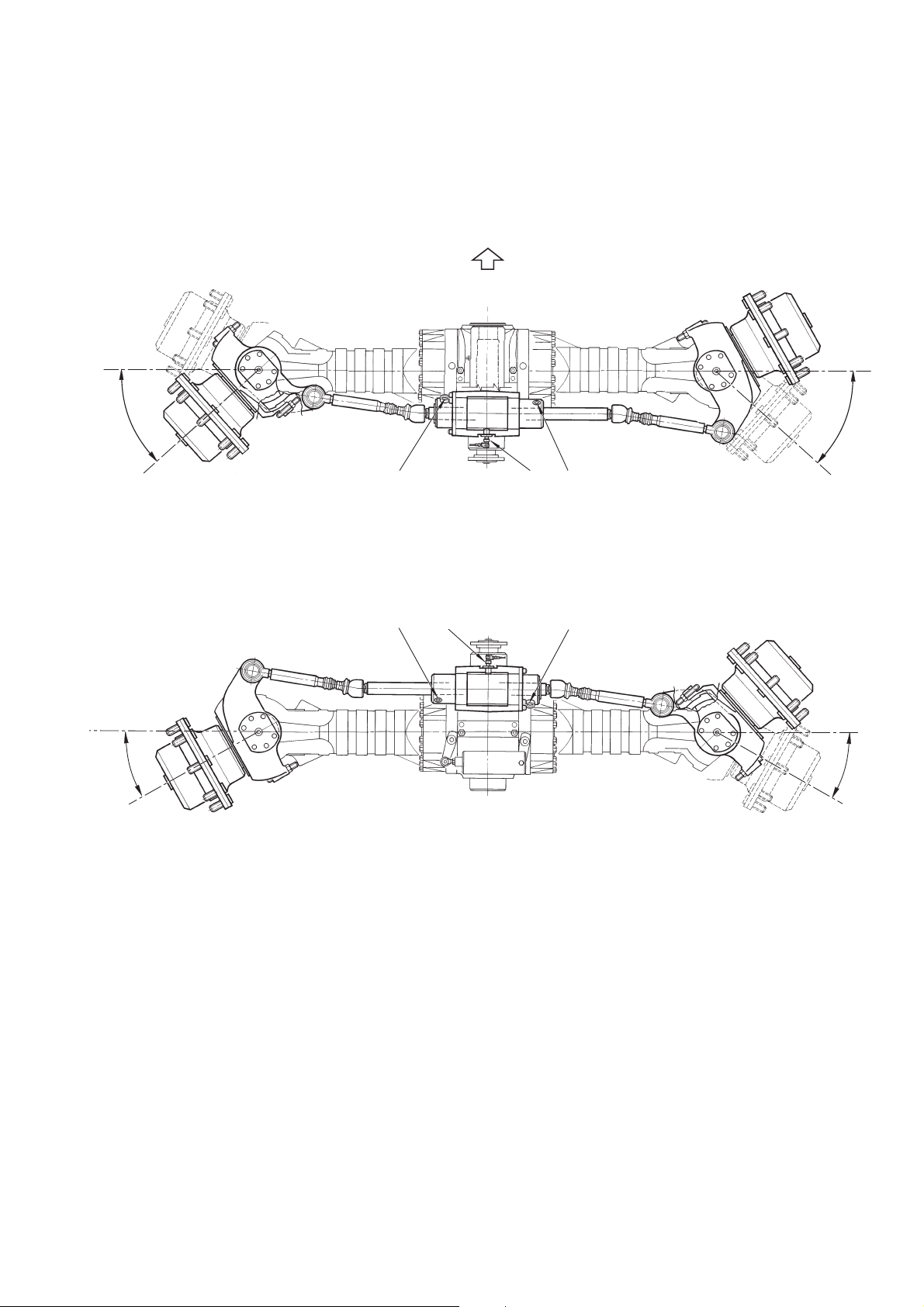

AXLES

Front of machine

28°

ba

Front axle

c d

28°

3

Rear axle

3

D0400009

28°

28°

1. Adjustment screw

2. Nut

3. Sensor

FRONT AXLE

a. A Port - From EV9-EV10 group (T Port)

b. B Port - From swivel joint (9a Port)

REAR AXLE

c. C Port - From EV9 - EV10 Port (A Port)

d. D Port - From EV9 - EV10 Port (B Port)

10-9

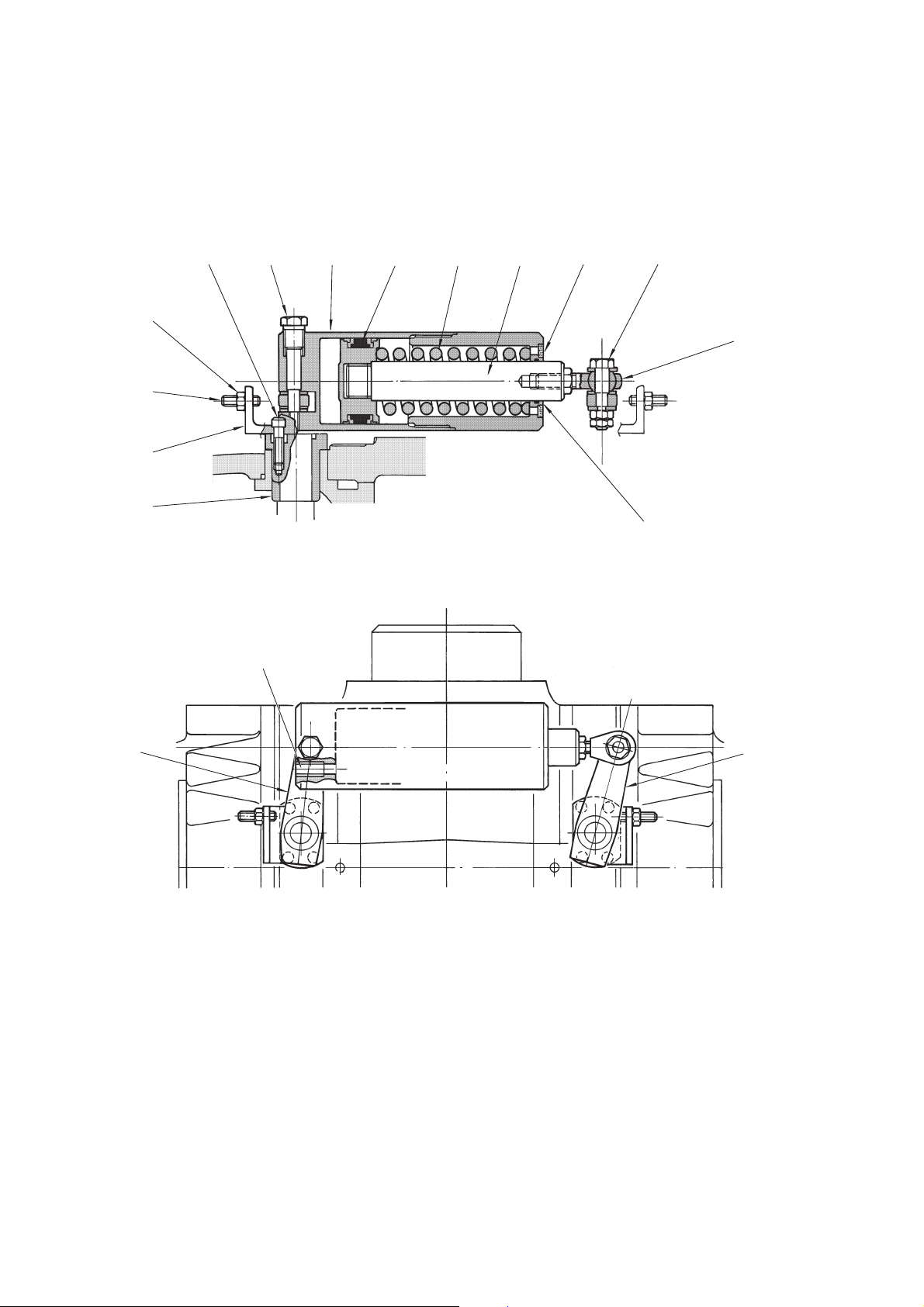

PARKING BRAKE AND CYLINDER

4365789

13

2

1

14

12

10

11

15

1. Screw

2. Nut

3. Cylinder fulcrum pin

4. Cylinder

5. Gasket

6. Spring

7. Piston

8. Filter

9. Piston fulcrum pin

10. Ball joint

11. Scraper ring

a

12. Bushing

13. Screw

14. Bracket

15. Cylinder fulcrum lever

16. Piston fulcrum lever

a. From EV1 - A Port

SPECIFICATIONS

. Minimum unlocking pressure: 20 bar

. Required oil volume: 47 cm

16

D0400010

3

10-10

110

16

18 19

417

20

D0400011

17. Lever

18. Push rod

19. Push disk

20. Brake disks

B

15

20

EV2

Servocontrol

feed unit

Brake

pump

SYSTEM DESCRIPTION

The parking brake is of the «negative» type, e.i. it provides full mechanical braking in the absence of pressure in the circuits that make the machine safe to

drive.

b

A

19

467

17

D

18

19

18

P3

Engine

C

20

D0400155

16

OPERATION

When the engine is started up the auxiliary pump (P3)

connected to it sends oil to the brake pump and the

servocontrol circuit and pressurizes the system to

which the solenoid valve EV2 is connected when the

machine is idle.

When push-button is pushed EV2 is energized and allows oil to flow into chamber b of the cylinder (4); when

the pressure exceeds the loading on the spring (6) it is

compressed and the piston (7) moves, thus lengthening side B-C of the parallelogram A-B-C-D formed by

the swing centers of the levers (15) and (16), the cylinder fulcrum B (4) and the fulcrum C of the lever (16)

connected to the piston (7).

The swing of levers (15) and (16), coupled directly to

lever (17), cancels out the action on the push rods

(18) joined to the push disks (19).

The limit of the swing and the distribution of the load

generated by the pressure in the cylinder (4) are governed by adjustable screws (1) that act directly on levers (15) and (16).

When the engine stops, EV2 is de-energized, and releases pressure in the circuit. As pressure drops the

spring (6) commences the thrusting action that rotates

the levers (15) and (16). The force of the spring is

transferred to the push rods of the push disks (19)

which act on the brake disks (20) on the rear axle.

10-11

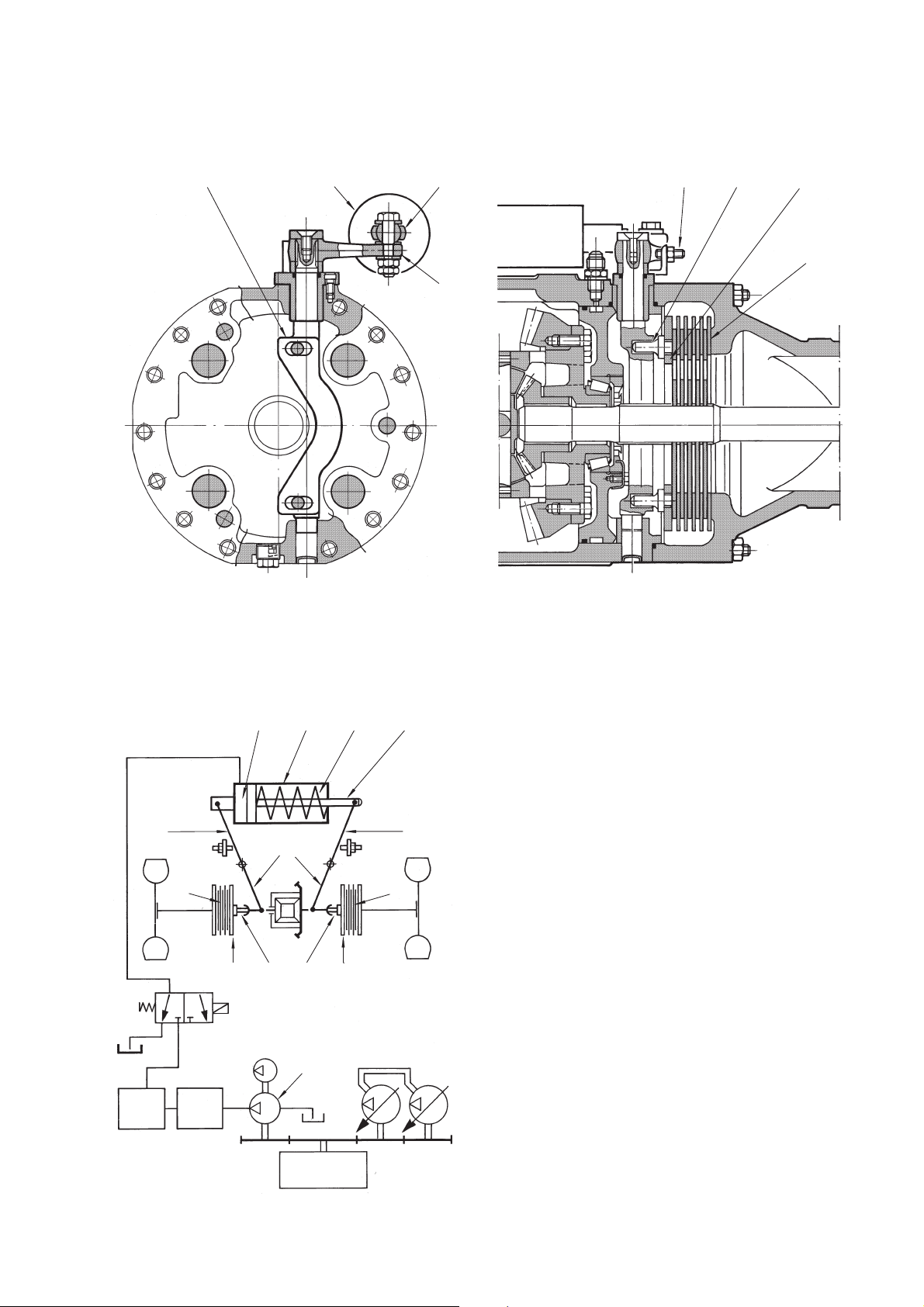

STEERING SYSTEM

12

4

1

3

10

a

T

P

11

d

5

A

2

(P4)

6

B

b

LR

7

(EV9)

(EV10)

8

9

D

13

C

c

D0400013

1. Engine

2. Pump (P4)

3. Tank

4 Priority valve

5. Steering unit

6. Steering wheel

7. Swivel joint

8. Elettrovalvola EV9 esclusione sterzatura ponte

posteriore

9. Elettrovalvola EV10 inversione senso sterzatura

ponte posteriore

10. Cilindro di sterzatura ponte anteriore

11. Cilindro di sterzatura ponte posteriore

12. Pistone cilindro ponte anteriore

13. Pistone cilindro ponte posteriore

DESCRIPTION

. The steering system is completely hydraulic. The

oil required, supplied by the pump (2) driven by

the motor (1), is sent to the priority valve (4) which

functions by Load Sensing, and sends the necessary quantity of oil to the steering system (5), even

when other oleodynamic components supplied by

the same circuit are in operation. The oil passes

from this group (5) into the swivel joint (7) and from

there into the steering cylinders (10) and (11).

Two solenoid valves (8) and (9) can switch the oil

flow to provide three types of steering:

1 - 2 wheels steering

Steering condition in which the rear axle is excluded.

2 - 2 wheels steering and 2 wheels countersteer-

ing. Steering condition in which rear steering is

activated and the direction of the rear wheels is

contrary to that of the front wheels.

3 - 4 wheels steering in the same direction.

Steering condition in which rear axle steering is

activated and the direction of the rear wheels

agrees with that of the front wheels.

. The hydraulic power supplied by the pump (2) is

transferred to cylinders (10) and (11) and transformed into mechanical steering power.

10-12

Loading...

Loading...