komatsu PC600LC-8 SPECIFICATIONS

HORSEPOWER

Gross:323 kW 433 HP @ 1800 rpm

Net:320 kW 429 HP @ 1800 rpm

OPERATING WEIGHT

Backhoe:57300–60000 kg

126,320–132,280 lb

Loading shovel:61300–62300 kg

135,140–137,350 lb

Photo may include optional equipment.

PC600

/

600LC-8 BACKHOE

PC600

/

600LC-8 LOADING SHOVEL

PC

600

HYDRAULIC EXCAVATOR

2 3

WALK-AROUND

H YDRAULIC E XCAVATOR

HYDRAULIC EXCAVATOR

PC600-8

PC600-80

HORSEPOWER

Gross:323 kW 433 HP @ 1800 rpm

Net:320 kW 429 HP @ 1800 rpm

OPERATING WEIGHT

Backhoe

57300 – 60000 kg

126,320 – 132,280 lb

Loading shovel

61300– 62300 kg

135,140 – 137,350 lb

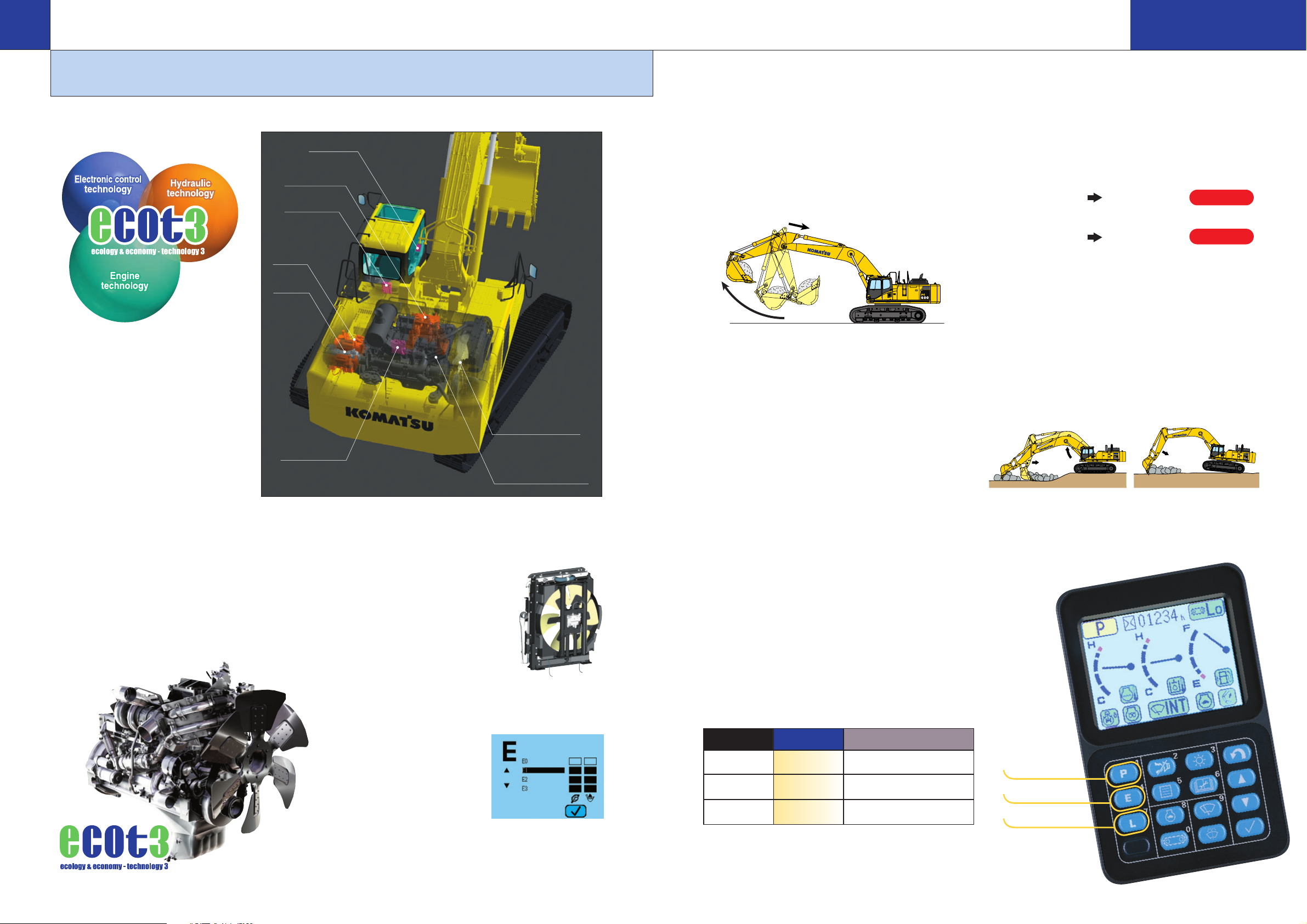

Ecology and Economy Features

● Komatsu SAA6D140E-5 Engine Meets Tier 3 Emissions Regulations.

• World’s first cooled EGR system with bypass-assist type electronically

controlled venturi

• Offers high power and low fuel consumption, while conforming to

Tier 3 emission regulations.

• Reduces NOx emissions approximately 40%.

• Equipped with an electronically controlled variable speed fan.

●

Economy mode Four-level Setting

Enables operator to select the appropriate Economy mode level to match production

requirement with lowest fuel consumption.

● Reduction of Ambient Noise

Meets the EU Stage 2 noise regulations.

• Electronically controlled variable speed fan drive

• Large hybrid fan

• Glasswool-furnished low-noise muffler and noise reducing cover around the muffler

See page 4.

Working Environment

● Large Comfortable Cab

• Low noise and vibration with cab damper mounting

• Large-capacity air conditioner (optional)

• Pressurized cab prevents external dust from entering

• OPG top guard level 2 (by ISO 10262 standard)

capable with optional bolt-on top guard.

See page 8.

Advanced Monitor Features

• Machine condition can be checked with

Equipment Management Monitoring System

(EMMS). See page 11.

• Two working modes combine with lifting mode

for maximum productivity. See page 5.

Photo may include optional equipment.

Productivity Features

● High Work Equipment Speed

Increased arm dumping and bucket

dumping speed realize efficient loading

operation.

● Lifting Mode

The lifting mode increases the lifting force

and capacity 14%.

● Large Digging Force

Pressing the Power Max function button

temporarily increases the digging force

8%.

● Two-mode Setting for Boom

Switch selection allows either powerful

digging or smooth boom operation.

● Excellent Swing Performance is achieved by

twin-swing motor system even on slope.

● Large Drawbar Pull and Steering Force

provide excellent mobility.

See page 5.

Excellent Reliability and Durability

● Strengthened Boom and Arm

● KMAX Bucket offers superior wear-resistance for

specific use in quarry. (optional)

● Fuel Pre-filter with water separator equipped as standard

● O-ring Face Seals, which have excellent sealing

performance, are used for the hydraulic hoses.

● High-pressure In-line Filtration

The cool-running hydraulic system is protected with the most

extensive filtration system available, including a high pressure

in-line filter for each main pump.

● Highly Reliable Electronic Devices

Exclusively designed electronic devices have passed severe testing.

• Controller • Sensors • Connectors

• Heat resistant wiring

See page 6, 7.

Easy Maintenance

● Easy Cleaning of Cooling unit

Fan reverse-rotation function facilitates

clogged radiator cleaning.

● Radiator and oil cooler are easily

detachable from full open type

engine hood.

● Centralized Arrangement of Engine

Checkpoints

● Work on Machine Anti-slip Plates for

Safe

● Large Handrail, Step and Catwalk

provide easy access to the engine

and hydraulic equipment.

See page 10.

Work Equipment Speed Increased

An arm quick return circuit is provided for arm dumping. This

returns a portion of oil flow directly to the hydraulic tank at

arm dumping to reduce the hydraulic pressure loss.

Combined with increased bucket dumping speed, faster

loading work is realized.

Large Drawbar Pull and Steering Force

Since the machine has a large drawbar pull and a high

steering force, it demonstrates excellent mobility even when

it is being used on inclined sites.

Large Digging Force

With the addition of one-touch Power Max. function digging

force has been further increased. (8.5 seconds of operation)

Maximum arm crowd force (ISO):

228 kN (23.3t) 246 kN (25.1t)

(with Power Max.)

Maximum bucket digging force (ISO):

294 kN (30.0t) 317 kN (32.3t)

(with Power Max.)

Lifting Mode

When lifting mode is selected, lifting capacity increases 17%

by raising hydraulic pressure. The work equipment and

swing speeds are lowered at the same time to provide

additional control.

Two-mode Setting for Boom

Smooth mode provides easy operation for gathering

blasted rock and scraping operations. When maximum

digging force is needed, switch to power mode for more

effective excavating.

54

PRODUCTIVITY & ECOLOGY FEATURES

H YDRAULIC E XCAVATOR

HYDRAULIC EXCAVATOR

PC600-8

PC600-80

Power Mode

Lifting Mode

Working Mode Application Advantage

Power

● Maximum production/power

P

Mode ● Fast cycle time

E Economy

● Good cycle time

Mode ● Good fuel economy

Lifting

● Hydraulic pressure is

L

Mode increased 17%.

Hydraulics

Unique two-pump system assures smooth compound movement of the

work equipment. OLSS (Open Center Load Sensing System) controls all

pumps for efficient engine power use. This system also reduces hydraulic

loss during operation.

Power and Economy Mode

The PC600-8 excavator is equipped with two working modes. Each mode

is designed to match engine speed, pump speed, and system pressure to

the current application, giving the operator flexibility to match equipment

performance to the job at hand.

Multi-Function Color

Monitor

Working Mode Selection

Environment-friendly Clean Engine Mounted

The PC600-8, which is equipped with the Komatsu

SAA6D140E-5 engine, meets the Tier 3 emission

regulations in the North America (EPA) and EU stage 3A.

The SAA6D140E-5 engine adopts the world’s first cooled

EGR system with electronically controlled bypass-assist type

venturi to reduce NOx emission 40% , while maintaining the

high power and low fuel consumption.

Electronically Controlled Variable Speed Fan

contributes to Low Fuel

Consumption and Low Noise

The electronic control system sets the

rotational speed of the cooling fan

according to the coolant, hydraulic oil,

and ambient temperature; effectively

uses the engine output to prevent

wasteful fuel consumption; and

reduces noise during low-speed fan

rotation.

Lower and Economical Fuel Consumption Using

Economy Mode

Enables operator to set the Eco

mode to up to four levels

according to working conditions

so that production requirement is

achieved at lowest possible fuel

consumption.

Reduction of Ambient Noise

Reduced noise by adoption of an electronically controlled

variable speed fan drive, large hybrid fan, low-noise muffler

and cover with glasswool, to meet EU Stage 2 noise

regulations.

8%

UP

8%

UP

(E0,E1,E2,E3)

Komatsu Technology

Komatsu develops and produces all major

components, such as engines, electronics

and hydraulic components, in house.

With this “Komatsu Technology,” and adding

customer feedback, Komatsu is achieving

great advancements in technology.

To achieve both high levels of productivity and

economical performance, Komatsu has

developed the main components with a total

control system.

The result is a new generation of high

performance and environment friendly

excavators.

Economy Mode

This is an image photo: may

differ from the actual engine.

Boom raised

Smooth

mode

Power

mode

Hydraulic control valve

Hydraulic system

controller

Main pump

Pump for fan

Electronic control

unit for engine

LCD color monitor

Electronically controlled

variable speed fan

Engine

Heavy duty HPCR

Common Rail)

Electronically controlled cooled

EGR system

(High Pressure

system

7

6

RELIABILITY FEATURES

H YDRAULIC E XCAVATOR

HYDRAULIC EXCAVATOR

PC600-8

PC600-80

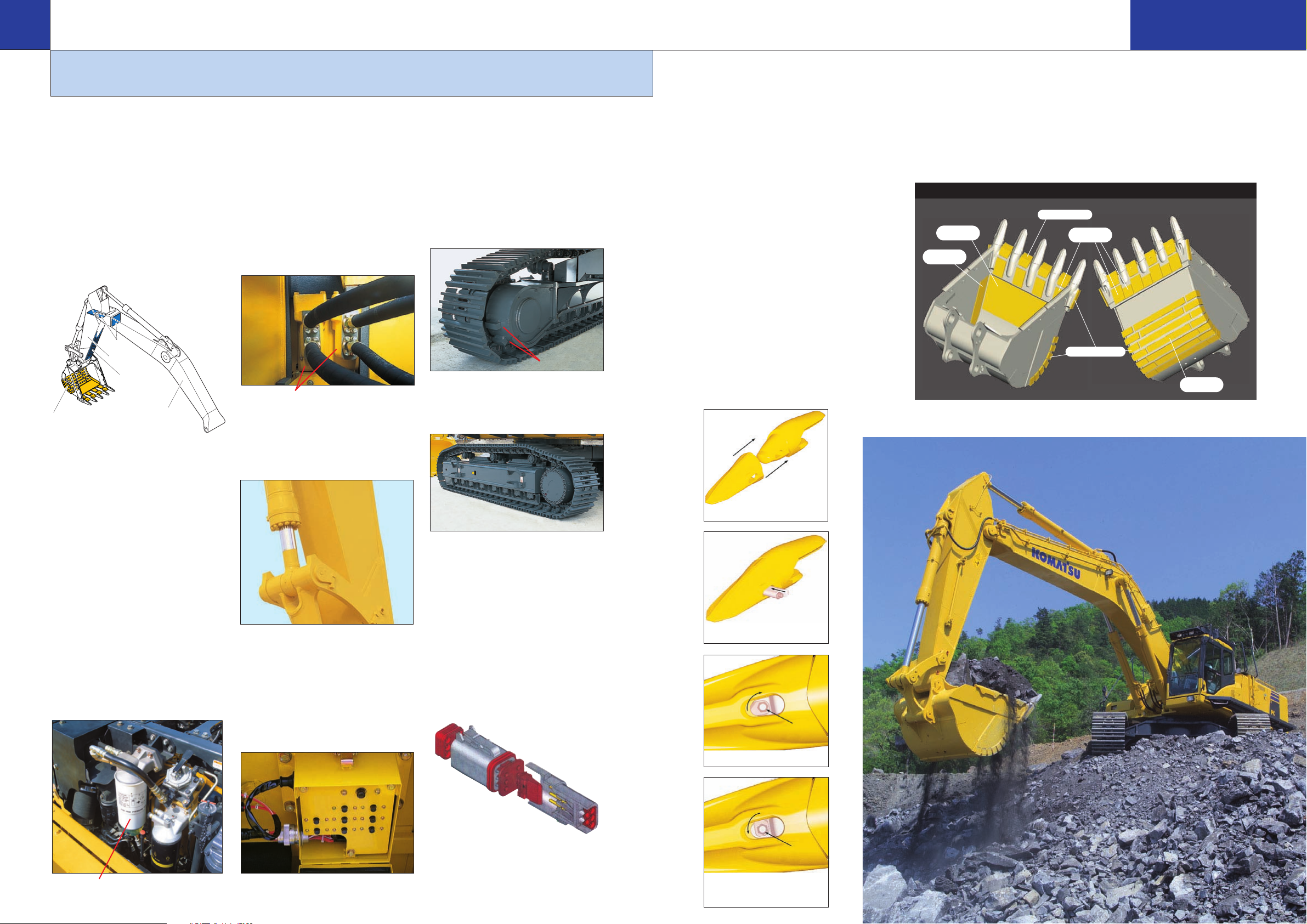

Strengthened Quarry Bucket for Provides Outstanding Wear-resistance (optional)

The bucket for specific use in quarry is impact and wear resistant, providing high performance and long life.

Koma-hard materials* provide excellent wear resistance. Combined with adoption of long-life KMAX tooth, durability of bucket

is drastically enhanced.

* Koma-hard materials (KVX materials):

Komatsu developed, wear-resistant, reinforced materials.

Brinell hardness: 500 or more (180kgf/mm

2

class).

Features high wear-resistance and little quality change by

the heat generated during rock loading, maintaining the

hardness for a long term.

Excellent Reliability and Durability

Strengthened Boom and Arm

Thanks to the large cross-sectional

structure employing a high tensile

strength steel with a thick plate,

partition wall, etc., the boom and arm

exhibit excellent durability and are

highly resistant to bending and

torsional stress.

Metal Guard Rings

Metal guard rings protect all the

hydraulic cylinders and improve

reliability.

Sturdy guards shield the travel motors

and piping against damage from rocks.

(Rock protectors are optional.)

Strengthened Revolving Frame

Underguard

Guards the machine body against

being hit by rocks from below and

prevents hydraulic components and

the engine from being damaged.

High-pressure In-line Filtration

The PC600-8 has the most extensive

filtration system available, providing inline filters as standard equipment. An

in-line filter in the outlet port of each

main hydraulic pump reduces failures

caused by contamination.

Track roller guard (full length)

(optional)

Partition

wall

O-ring Face Seal

The hydraulic hose seal method has

been changed from a conventional

taper seal to an O-ring seal. This

provides improved sealing performance

during operation.

Frame Structure

The revolving frame mount and center

frame mount on the swing circle are no

welding structure so that force is

transmitted directly to the thick plate of

the frame without passing through any

welding.

Fuel Pre-filter

(with Water Separator)

Removes water and contaminants from

in the fuel to enhance the fuel system

reliability.

Sturdy Undercarriage

The undercarriage is strengthened to

provide excellent reliability and

durability when working on rocky

ground or blasted rock.

Rock protectors

KMAX Tooth for Quarry Bucket

• Unique bucket tooth shape superior digging

performance

• Long-term high sharpness

• Great penetration performance

• Hammerless, safe, and easy tooth

replacement

(Tooth replacement time: Halves the

conventional machine.)

STEP 1

Observing proper safety procedures,

place tooth onto adapter (as shown).

STEP 2

Insert fastener, making sure it is in the

unlocked position (as shown).

STEP 3

Using the correct size socket, rotate the

pin locking shaft 90˚ clockwise (as

shown) to finish the installation.

STEP 4

To remove fastener, use the correct size

socket to rotate the pin locking shaft 90˚

counter-clockwise (as shown). Remove

fastener and tooth. Repeat steps 1-3 for

a new installation.

pin locking shaft

pin locking shaft

Photo may include optional equipment.

Fuel pre-filter

In-line filter

Heat-resistant Wiring

Heat-resistant wiring is utilized for the

engine electric circuit and other major

component circuit.

Circuit Breaker

With circuit breaker, the machine can

be easily restarted after repair.

DT-type connectors

DT-type connectors seal tight and

have higher reliability.

Partition

wall

Wide width arm

Arm dent

preventive plate

(optional)

Large cross-sectional

Wear plates

(optional)

structure boom

High-tensile

strength steel

High-tensile

strength steel

Quarry Bucket with KMAX Tooth

Shroud: Enlarged

High-tensile

strength steel

Koma-hard materials

High-tensile

strength steel

Loading...

Loading...