Komatsu PC16R-2 Maintenance Manual

WEAM007800

Operation & Maintenance

Manual

PC16R-2

HYDRAULIC EXCAVATOR

SERIAL NUMBER

PC16R-2 F00003

WARNING

Unsafe use of this machine may cause serious injury

or death. Operators and maintenance personnel

must read this manual before operating or

maintaining this machine.

This manual should be kept inside the cab for

reference and periodically reviewed by all personnel

who will come into contact with the machine.

and up

FOREWORD

1.1 FOREWORD

q This manual has been compiled by Komatsu Utility S.p.A. in order to supply customers with all the necessary

information on the machine and on safety regulations, as well as the use and maintenance instructions that

enable the operator to exploit the capacity of the machine with optimal results and to keep the machine efficient

over time.

q The operation manual, together with the spare parts catalogue, is an integral part of the machine and must

accompany it, even when it is resold, until its final disposal.

q The manual must be handled with the greatest care and always kept on board the machine, so that it can be

consulted at any moment; it must be placed in the appropriate compartment inside the seat support, where the

registration documents and the logbook are usually kept.

q This manual must be given to the staff who have to use the machine and carry out the routine maintenance

operations; they must read the contents carefully more than once, in such a way as to clearly understand what

are the correct operating conditions and the dangerous conditions that must be avoided.

In case of loss or damage, request a new copy to Komatsu or your Komatsu Dealer.

q The illustrations contained in this manual may represent machine configurations available on request.

Komatsu machines are constantly improved in order to increase their efficiency and reliability; this manual sums

up all the information regarding the most recent technology applied at the moment in which the machine is

launched.

For any further and/or updated information, contact your Komatsu Dealer.

q Punctual periodic annotations regarding the maintenance operations that have been carried out are important,

since they provide a clear report on the situation and say exactly what has been done and what has to be done

after the next maintenance interval. Therefore, it is advisable to consult both the hour meter and the

maintenance plan frequently.

q Over the years Komatsu Dealers have gathered considerable experience in customer service.

If more information is needed, do not hesitate to contact your Komatsu Dealer: he always knows how to get the

best performance from the machine, he can recommend the equipment that is most suitable for specific needs

and can provide the technical assistance necessary for any change that may be required to conform the

machine to the safety standards and traffic rules.

Furthermore, Komatsu Dealers also offer assistance for the supply of Komatsu genuine spare parts, which

guarantee safety and interchangeability.

q The table included in this manual must be filled in with the machine data, which are also the data that must be

communicated to the Dealer when requiring assistance and ordering spare parts.

CAUTION

q The incorrect use of the machine and inappropriate maintenance operations may cause serious injury

and even death.

q Operators and maintenance personnel must carefully read this manual before using the machine or

performing maintenance operations.

q Any serious accident that may occur during the use of the machine or during maintenance operations is

due to failure to comply with the instructions given herein.

q The application of the procedures and precautions described in this manual will ensure safety only

provided that the machine is used correctly.

If the machine is used for any purpose or in any way other than those described herein, the operator

shall be responsible for his own safety and for the safety of any other person involved.

1

INFORMATION ON SAFETY

1.2 INFORMATION ON SAFETY

Many accidents are caused by insufficient knowledge of and failure to comply with the safety regulations

prescribed for the maintenance operations that must be performed on the machine.

In order to avoid accidents, before starting work and before carrying out any maintenance operation, carefully read

and be sure to understand all the information and warnings contained in this manual and given on the plates

applied onto the machine. To enable the operator to use this machine safely, safety precautions are explained in

this manual and labels and warning plates are affixed to the machine to highlight situations involving potential

hazards and suggest how to avoid them.

Terminology used in the signs

The following words are used in the signs to inform the user that there is a potential hazard that may lead to

personal injury or damage to property.

In this manual, on the labels and on the plates, the following words are used to express the potential level of the

hazard.

DANGER

q Indicates a situation of imminent danger that, if not avoided, may cause serious injury and even death.

The use of this term must be limited to situations of extreme danger.

WARNING

q Indicates a situation of potential danger that, if not avoided, may cause serious injury and even death.

CAUTION

q Indicates a situation of potential danger that, if not avoided, may cause moderate injury. This term can

also be used as a warning against dangerous interventions.

Other terms used in the signs

In addition to those indicated above, the following warning terms are used to recommend the precautions to be

taken to protect the machine or to supply useful information.

IMPORTANT

q This term is used to indicate precautions that must be taken in order to avoid actions that may shorten

the life of the machine.

NOTE

q This word is used to indicate a useful piece of information.

Komatsu cannot reasonably predict every circumstance that might involve a potential hazard during the operation

or maintenance of the machine; for this reason, the safety warnings included in this manual and applied onto the

machine may not include all possible safety precautions.

If all the instructions given in relation to this machine are kept to, the operators and anyone in the vicinity can work

in total safety, and do not run the risk of damaging the machine. In case of doubt regarding the safety measures

necessary for some procedures, contact Komatsu or your local Komatsu Dealer.

2

INFORMATION ON SAFETY

DANGER

q Before starting any maintenance operation, position the machine on a firm and level surface, lower the

equipment to the ground, engage the safety locks of the equipment and the controls, and stop the

engine.

DANGER

q To make the information clearer, some illustrations in this manual represent the machine without safety

guards. Do not use the machine without guards and do not start the engine when the hood is open,

unless this is expressly prescribed for certain maintenance operations.

WARNING

q It is strictly forbidden to modify the setting of the hydraulic system safety valves; Komatsu cannot be

held liable for any damage to persons, property or the machine, if this has been tampered with by

modifying the standard settings of the hydraulic system.

WARNING

q Before carrying out any electric welding, disconnect the battery and the alternator. (See "2.8.13

PRECAUTIONS TO BE TAKEN WHEN HANDLING THE BATTERY AND THE ALTERNATOR").

WARNING

q Install only authorized optional equipment (see "6.1 AUTHORIZED OPTIONAL EQUIPMENT".

DANGER

q It is absolutely forbidden to operate the machine while standing on the ground.

Every single manoeuvre must be carried out by the operator, correctly seated in driving position.

3

INTRODUCTION

1.3 INTRODUCTION

1.3.1 INTENDED USE OF THE MACHINE

The Komatsu machines described in this manual have been designed and constructed to be used mainly for

EXCAVATION and EARTH-MOVING OPERATIONS.

If provided with suitable safety devices, they can be used with authorized optional equipment having the

characteristics illustrated in paragraph "6.1 AUTHORIZED OPTIONAL EQUIPMENT".

1.3.2 IMPROPER OR UNAUTHORIZED USES

CAUTION

q This paragraph describes some of the improper or unauthorized uses of the machine; since it is

impossible to predict all the possible improper uses, if it is necessary to use the machine for particular

applications, contact your Komatsu Dealer before carrying out the work.

IMPORTANT

q The instructions regarding the authorized optional equipment are given in the relevant operation and

maintenance manuals; if the equipment is supplied by Komatsu, these publications are enclosed to this

manual.

q The instructions regarding the assembly of the authorized equipment, the controls requiring special

arrangements on the machine and the hydraulic couplings necessary for the operation of such

equipment are grouped in the final section of this manual.

Komatsu machines are constructed exclusively for the handling, excavation and treatment of inert materials;

therefore, the following uses are absolutely forbidden:

q USE OF THE MACHINE BY MINORS OR INEXPERIENCED PERSONS.

q USE OF THE MACHINE FOR LIFTING PERSONS OR OBJECTS.

q TRANSPORT OF CONTAINERS WITH FLAMMABLE OR DANGEROUS FLUIDS.

q USE OF THE BUCKET FOR DRIVING OR EXTRACTING PILES.

q USE OF THE MACHINE FOR TOWING DAMAGED VEHICLES.

1.3.3 MAIN CHARACTERISTICS

q Simple and easy operation.

q Hydrostatic transmission obtained through two axial piston motors that operate epicyclic reduction gears.

q Rotation of the turret achieved by means of an axial piston hydraulic motor acting on an epicyclic reduction gear.

q Main equipment controlled through servo levers ensuring also combined movements that can be modulated

proportionally and continually.

q Boom swing and optional equipment operated through foot pedal controls.

q Travel and blade operated through levers.

q Travel speed selection push button.

q Hydraulic track gauge adjustment (optional).

q Complete series of instruments visible from the operating position.

q Lever accelerator.

q Easy maintenance with simplified intervals.

4

INTRODUCTION

1.3.4 RUNNING-IN

Every machine is scrupulously adjusted and tested before delivery.

A new machine, however, must be used carefully for the first 100 hours, in order to ensure proper running-in of the

various components.

If the machine is subjected to excessive work load at the beginning of operation, its potential productivity and its

functionality will be shortly and untimely reduced.

Every new machine must be used carefully, paying special attention to the following instructions:

q After the start, let the engine idle for 5 minutes, in such a way as to warm it up gradually before actual operation.

q Avoid operating the machine with the limit loads allowed or at high speed.

q Avoid abrupt starts or accelerations, useless sudden decelerations and abrupt reversals.

SYNTHETIC BIODEGRADABLE OIL TYPE HEES

For machines in which synthetic biodegradable oil type HEES is used, perform the following operations in addition

to the standard maintenance operations:

q After the first 50 hours of operation, change the hydraulic circuit drain filter.

q After the first 500 hours of operation, change the hydraulic circuit oil.

IMPORTANT

q When changing the oil filters (cartridges), check their inner part to make sure that there are no deposits.

If considerable deposits are observed, find out what may have caused them before starting the machine.

q The number of operating hours is indicated by the hour meter.

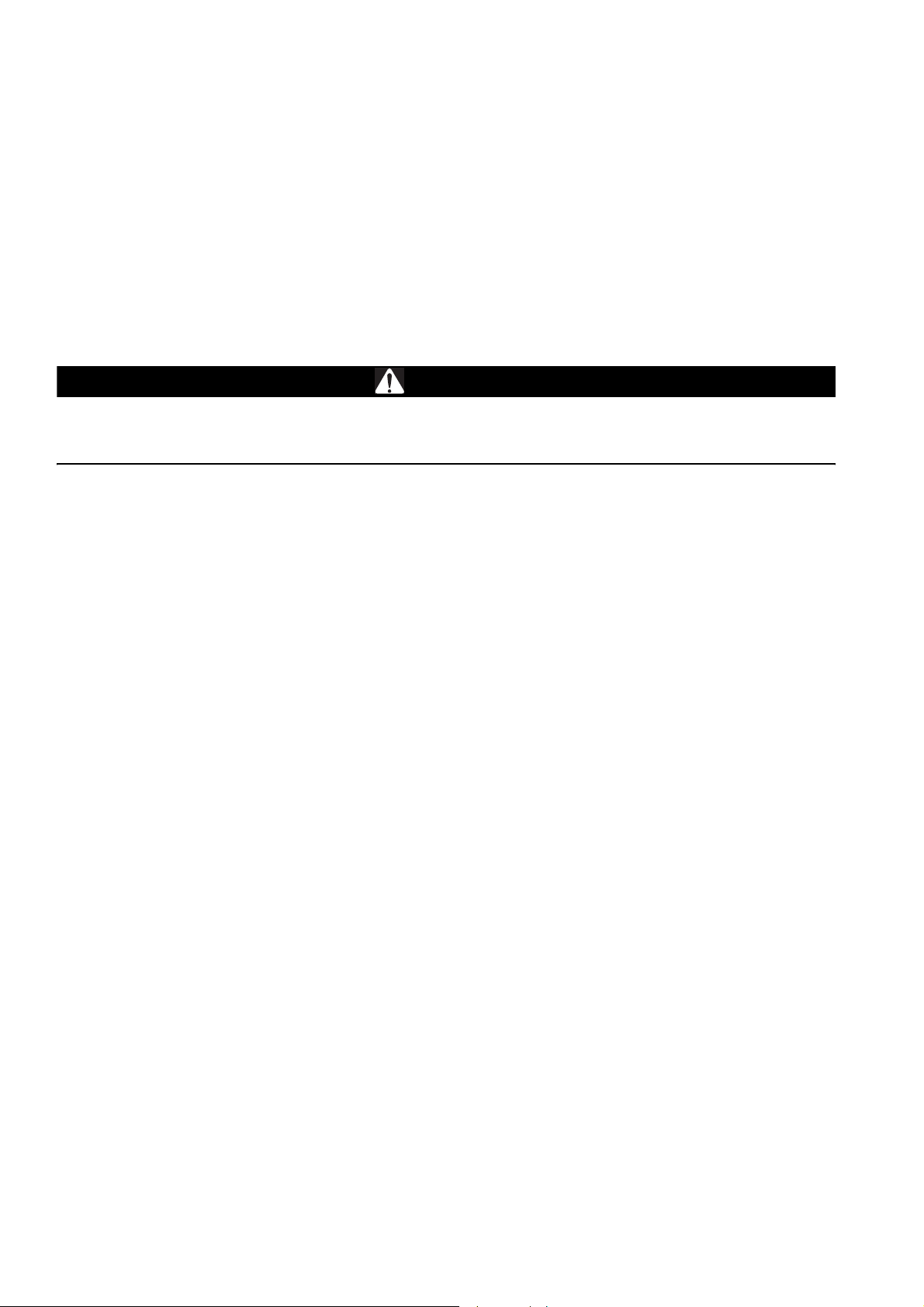

1.3.5 POSITIONS AND DIRECTIONS OF THE MACHINE

Front

Operator's seat

Left

Right

Sprocket

Rear

RYA00050

In this manual, the terms front/forward, rear/backward, left, and right refer to the travel direction as seen from the

operator seat when it is facing the front and the sprocket is at the rear of the machine.

5

PRODUCT IDENTIFICATION

1.4 PRODUCT IDENTIFICATION

The Komatsu excavator and its main components are identified by serial numbers stamped on the identification

plates.

The serial number and the identification numbers of the components are the only numbers that must be

communicated to the Dealer when requiring assistance and ordering spare parts.

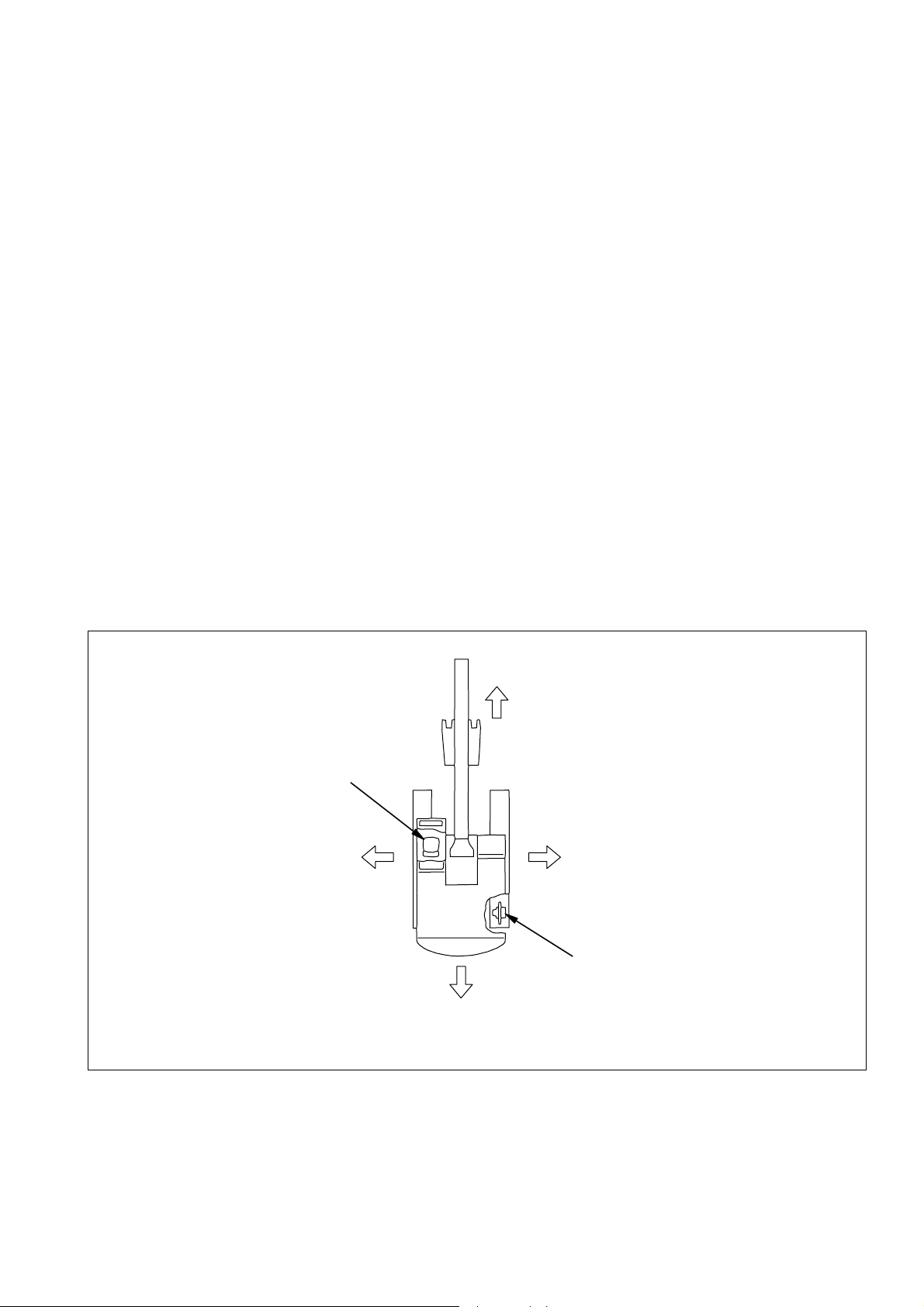

1.4.1 MACHINE SERIAL NUMBER

The machine serial number is stamped on the front upper part of

the main frame, on the left side.

RKAB5040

1.4.2 MACHINE IDENTIFICATION PLATE AND PRODUCT IDENTIFICATION NUMBER (PIN)

The Komatsu excavators described in this manual are CE

marked, in fact they are in compliance with the EU harmonised

standards.

The plate with the CE marking is applied to the front wall of the

main frame, on the right side.

RKAB5050

MODEL

SERIAL No.

MANUFACT.YEAR

MASS

Product Identification Number

MANUFACTURER

KOMATSU UTILITY EUROPE S.p.A 36025 NOVENTA VICENTINA (VI) - I

UNDER LICENSE OF KOMATSU LTD., TOKYO, JAPAN

MODEL

Product Identification Number

ENGINE POWER

22L-09-R1370

SERIAL No.

MANUFACT.YEAR

MASS

ENGINE POWER

kg

kw

RWA39210

kg

kw

MANUFACTURER

KOMATSU UTILITY EUROPE S.p.A 36025 NOVENTA VICENTINA (VI) - I

UNDER LICENSE OF KOMATSU LTD., TOKYO, JAPAN

6

PRODUCT IDENTIFICATION

1.4.3 ENGINE SERIAL NUMBER AND EXHAUST GAS EMISSION PLATE

The engine serial number is stamped on the plate positioned on

the engine itself.

The exhaust gas emission plate is applied to the counterweight.

RKA16540

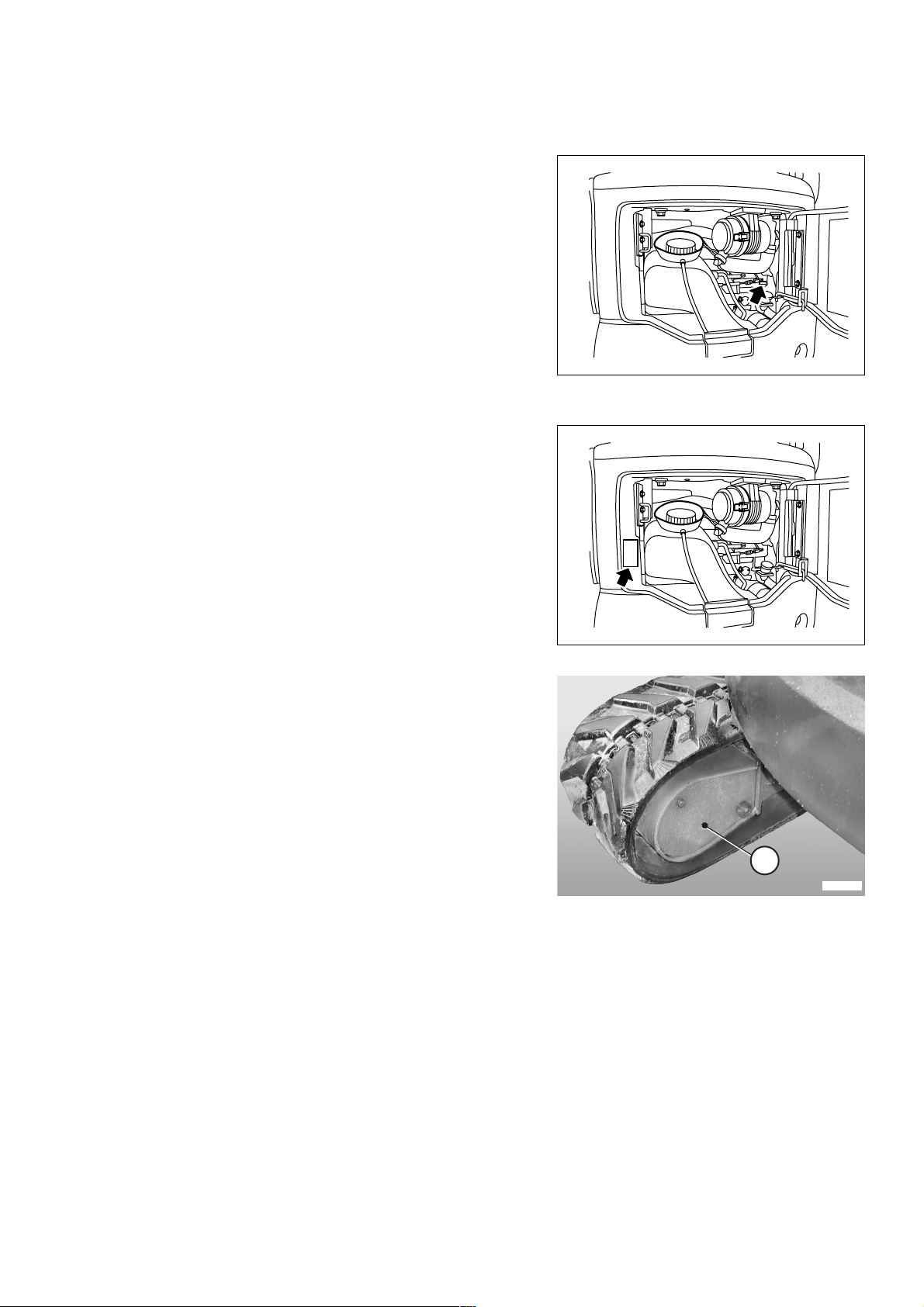

1.4.4 TRAVEL REDUCTION GEAR SERIAL NUMBER

The serial number is stamped on the plate positioned inside the

travel reduction gear and can be seen after removing the cover

(1).

RKA16550

1

RKAB5060

7

PRODUCT IDENTIFICATION

1.4.5 SWING REDUCTION GEAR SERIAL NUMBER

The serial number is stamped on the plate positioned on the

upper side of the swing motor.

RKAB5920

8

1.4.6 SERIAL NUMBERS AND DEALER’S ADDRESS

Machine no.° Model

Product identification number (PIN)

Engine no.°

Travel reduction gear no.°

Swing reduction gear no.°

Dealer:

PRODUCT IDENTIFICATION

Address:

Contact person:

NOTES:

Te l.

9

TABLE OF CONTENTS

TABLE OF CONTENTS

FOREWORD

1.1 FOREWORD.......................................................................................................................................... 1

1.2 INFORMATION ON SAFETY ................................................................................................................ 2

1.3 INTRODUCTION ................................................................................................................................... 4

1.3.1 INTENDED USE OF THE MACHINE ....................................................................................... 4

1.3.2 IMPROPER OR UNAUTHORIZED USES ................................................................................ 4

1.3.3 MAIN CHARACTERISTICS ...................................................................................................... 4

1.3.4 RUNNING-IN ............................................................................................................................ 5

1.3.5 POSITIONS AND DIRECTIONS OF THE MACHINE............................................................... 5

1.4 PRODUCT IDENTIFICATION ............................................................................................................... 6

1.4.1 MACHINE SERIAL NUMBER .................................................................................................. 6

1.4.2 MACHINE IDENTIFICATION PLATE AND PRODUCT IDENTIFICATION NUMBER (PIN) ... 6

1.4.3 ENGINE SERIAL NUMBER AND EXHAUST GAS EMISSION PLATE ................................... 7

1.4.4 TRAVEL REDUCTION GEAR SERIAL NUMBER ................................................................... 7

1.4.5 SWING REDUCTION GEAR SERIAL NUMBER ..................................................................... 8

1.4.6 SERIAL NUMBERS AND DEALER’S ADDRESS .................................................................... 9

SAFETY AND ACCIDENT PREVENTION

2.1 SAFETY, NOISE AND VIBRATION PLATES....................................................................................... 18

2.1.1 POSITION OF THE SAFETY PLATES..................................................................................... 18

2.1.2 PICTOGRAMS AND RELEVANT MEANINGS ......................................................................... 19

2.1.3 POSITION OF THE NOISE PLATES ...................................................................................... 24

2.1.4 VIBRATIONS TO WHICH THE OPERATOR IS SUBJECTED................................................. 24

2.2 GENERAL PRECAUTIONS .................................................................................................................. 25

2.2.1 GENERAL SAFETY RULES..................................................................................................... 25

2.2.2 SAFETY DEVICES AND GUARDS .......................................................................................... 25

2.2.3 CLOTHING AND PERSONAL PROTECTION ITEMS ............................................................ 25

2.2.4 UNAUTHORIZED MODIFICATIONS........................................................................................ 26

2.2.5 LEAVING THE OPERATOR SEAT ......................................................................................... 26

2.2.6 GETTING ON AND OFF THE MACHINE ................................................................................. 27

2.2.7 PREVENTING FIRES DUE TO FUEL AND OIL ...................................................................... 28

2.2.8 PREVENTING BURNS ............................................................................................................ 28

2.2.9 PREVENTING DAMAGE DUE TO ASBESTOS POWDER ..................................................... 29

2.2.10 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT ........................................ 29

2.2.11 FIRE EXTINGUISHERS AND FIRST AID KIT ......................................................................... 30

2.2.12 PRECAUTIONS CONCERNING THE ROPS STRUCTURE.................................................... 30

2.2.13 PRECAUTIONS CONCERNING THE EQUIPMENT................................................................ 30

2.3 PRECAUTIONS TO BE TAKEN BEFORE STARTING THE ENGINE ................................................. 31

2.3.1 SAFETY AT THE WORK SITE ................................................................................................. 31

2.3.2 FIRE PREVENTION ................................................................................................................ 31

2.3.3 PRECAUTIONS CONCERNING THE OPERATOR SEAT ...................................................... 31

2.3.4 ROOM VENTILATION ............................................................................................................. 32

2.3.5 PRECAUTIONS TO BE TAKEN FOR THE LIGHTS ................................................................ 32

2.4 PRECAUTIONS TO BE TAKEN WHEN WORKING............................................................................. 33

2.4.1 STARTING THE ENGINE ........................................................................................................ 33

2.4.2 CHECK THE DIRECTION BEFORE STARTING THE MACHINE .......................................... 33

10

TABLE OF CONTENTS

2.4.3 HAND SIGNALS ....................................................................................................................... 34

2.4.4 CHECKS FOR TRAVELLING IN REVERSE ........................................................................... 39

2.4.5 MOVING THE MACHINE ........................................................................................................39

2.4.6 MOVING ON SLOPES ............................................................................................................ 40

2.4.7 WORKING ON SLOPES .........................................................................................................41

2.4.8 UNAUTHORIZED OPERATIONS ........................................................................................... 41

2.4.9 PREVENTING ELECTROCUTION .......................................................................................... 43

2.4.10 VISIBILITY................................................................................................................................ 43

2.4.11 WORKING ON ICY OR SNOW-COVERED SURFACES ........................................................ 43

2.4.12 PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT ......................................... 44

2.4.13 WORKING ON LOOSE GROUND ........................................................................................... 44

2.4.14 PARKING THE MACHINE........................................................................................................ 44

2.5 TRANSPORTING THE MACHINE ON MOTOR VEHICLES ................................................................ 45

2.5.1 LOADING AND UNLOADING THE MACHINE ........................................................................ 45

2.5.2 TRANSPORTING THE MACHINE ........................................................................................... 45

2.6 BATTERY .............................................................................................................................................. 46

2.6.1 PREVENTING RISKS THAT MAY BE DUE TO THE BATTERY ............................................ 46

2.6.2 STARTING WITH BOOSTER CABLES .................................................................................. 46

2.7 PRECAUTIONS FOR THE REMOVAL OF THE MACHINE ................................................................. 47

2.8 PRECAUTIONS FOR MAINTENANCE................................................................................................. 48

2.8.1 WARNING PLATES ................................................................................................................ 48

2.8.2 TOOLS .................................................................................................................................... 48

2.8.3 MAINTENANCE STAFF ........................................................................................................... 48

2.8.4 EQUIPMENT ........................................................................................................................... 49

2.8.5 WORKING UNDER THE MACHINE ....................................................................................... 49

2.8.6 CLEANING THE MACHINE .................................................................................................... 49

2.8.7 USE OF THE ENGINE DURING MAINTENANCE................................................................... 50

2.8.8 PERIODICAL CHANGE OF THE PARTS THAT ARE CRITICAL FOR SAFETY..................... 50

2.8.9 STOP THE ENGINE BEFORE CARRYING OUT ANY MAINTENANCE OPERATION

OR INSPECTION .................................................................................................................... 50

2.8.10 RULES TO BE FOLLOWED WHEN REFUELLING OR ADDING OIL..................................... 51

2.8.11 CHECKING THE COOLANT LEVEL IN THE RADIATOR ...................................................... 51

2.8.12 USING LAMPS ........................................................................................................................ 51

2.8.13 PRECAUTIONS TO BE TAKEN WHEN HANDLING THE BATTERY

AND THE ALTERNATOR......................................................................................................... 52

2.8.14 PRECAUTIONS CONCERNING THE STARTER .................................................................... 52

2.8.15 HANDLING HIGH-PRESSURE HOSES .................................................................................. 52

2.8.16 PRECAUTIONS TO BE TAKEN WHEN HANDLING HIGH-PRESSURE OIL ......................... 53

2.8.17 PRECAUTIONS FOR MAINTENANCE OPERATIONS AT HIGH

TEMPERATURES AND HIGH PRESSURE............................................................................. 53

2.8.18 PRECAUTIONS TO BE TAKEN WHEN USING HIGH-PRESSURE

GREASE TO ADJUST THE TRACK TENSION ...................................................................... 54

2.8.19 DO NOT REMOVE THE SHOCK ABSORBING SPRING FROM THE

SHOCK ABSORBER UNIT ...................................................................................................... 54

2.8.20 HYDRAULIC ACCUMULATOR ............................................................................................... 54

2.8.21 COOLING FAN AND BELT .....................................................................................................55

2.8.22 WASTE MATERIALS .............................................................................................................. 55

2.8.23 COMPRESSED AIR ................................................................................................................. 55

2.8.24 PRECAUTIONS TO BE TAKEN WHEN HANDLING TECHNOPOLYMERS

AND ELASTOMERS ................................................................................................................ 56

2.8.25 PRECAUTIONS TO BE TAKEN WHEN USING SYNTHETIC BIODEGRADABLE

OIL TYPE HEES....................................................................................................................... 56

11

TABLE OF CONTENTS

THE MACHINE AND ITS OPERATIONS

3.1 MACHINE ILLUSTRATIONS ................................................................................................................ 58

3.1.1 OVERALL VIEW OF THE MACHINE ....................................................................................... 58

3.1.2 CONTROLS AND GAUGES ..................................................................................................... 59

3.2 INSTRUMENTS AND CONTROLS ....................................................................................................... 60

3.2.1 WARNING LIGHTS AND GAUGES ......................................................................................... 60

3.2.1.1 EMERGENCY WARNING LIGHTS ......................................................................... 61

3.2.1.2 GAUGES ................................................................................................................. 62

3.2.1.3 WARNING LIGHTS ................................................................................................. 63

3.2.2 SWITCHES AND PUSH BUTTONS ......................................................................................... 65

3.2.3 CONTROL LEVERS AND PEDALS ......................................................................................... 68

3.2.4 COVERSWITH LOCK............................................................................................................... 75

3.2.5 ENGINE HOOD ........................................................................................................................ 76

3.2.6 RADIATOR COVER ................................................................................................................. 77

3.2.7 BATTERY COVER ................................................................................................................... 78

3.2.8 TILTING THE CAB FLOOR ......................................................................................................79

3.2.9 FUSES...................................................................................................................................... 82

3.2.10 MAIN FUSE .............................................................................................................................. 83

3.2.11 TECHNICAL DOCUMENTATION COMPARTMENT ............................................................... 83

3.2.12 TOOL BOX ............................................................................................................................... 83

3.3 USE OF THE MACHINE AND RELATED CONTROLS........................................................................ 84

3.3.1 BEFORE STARTING THE ENGINE ......................................................................................... 84

3.3.1.1 VISUAL CHECKS.................................................................................................... 84

3.3.1.2 CHECKS TO BE CARRIED OUT BEFORE STARTING THE ENGINE .................. 85

3.3.1.3 ADJUSTMENTS...................................................................................................... 92

3.3.1.4 OPERATIONS TO BE CARRIED OUT BEFORE STARTING THE ENGINE ......... 94

3.3.2 STARTING THE ENGINE......................................................................................................... 96

3.3.2.1 STARTING WITH WARM ENGINE OR IN WARM CLIMATES............................... 96

3.3.2.2 STARTING WITH COLD ENGINE OR IN COLD CLIMATES ................................. 98

3.3.3 AFTER STARTING THE ENGINE ............................................................................................ 100

3.3.3.1 RUNNING IN A NEW MACHINE............................................................................. 100

3.3.3.2 WARMING-UP OPERATIONS ................................................................................ 101

3.3.4 STOPPING THE ENGINE ........................................................................................................103

3.3.5 HOW TO MOVE THE MACHINE.............................................................................................. 104

3.3.5.1 PRELIMINARY OPERATIONS TO BE CARRIED OUT BEFORE

MOVING THE MACHINE ........................................................................................ 104

3.3.5.2 MOVING THE MACHINE FORWARD .................................................................... 104

3.3.5.3 MOVING THE MACHINE IN REVERSE ................................................................. 106

3.3.5.4 STOPPING THE MACHINE .................................................................................... 107

3.3.6 STEERING THE MACHINE...................................................................................................... 108

3.3.6.1 STEERING (CHANGING DIRECTION) .................................................................. 108

3.3.7 SWINGING THE TURRET ....................................................................................................... 110

3.3.8 WORK EQUIPMENT CONTROLS AND FUNCTIONS............................................................. 111

3.3.9 UNAUTHORIZED OPERATIONS............................................................................................. 114

3.3.10 PRECAUTIONS FOR USE.......................................................................................................116

3.3.11 PRECAUTIONS TO BE TAKEN WHEN TRAVELLING ON SLOPES ...................................... 118

3.3.12 GETTING THE MACHINE OUT OF MUD ................................................................................ 120

3.3.13 OPERATIONS THAT CAN BE PERFORMED WITH THE HYDRAULIC EXCAVATOR .......... 121

3.3.14 CHANGING THE BUCKET.......................................................................................................123

3.3.15 PARKING THE MACHINE........................................................................................................ 124

3.3.16 CHECKING THE MACHINE EVERY DAY AFTER WORK ...................................................... 126

3.3.16.1 BEFORE STOPPING THE ENGINE ....................................................................... 126

3.3.16.2 AFTER STOPPING THE ENGINE .......................................................................... 126

12

TABLE OF CONTENTS

3.3.17 LOCKING THE MACHINE........................................................................................................ 126

3.3.18 RUBBER TRACKS (Machines equipped with rubber tracks only) ........................................... 127

3.3.18.1 OPTIMAL USE OF THE RUBBER TRACKS .......................................................... 127

3.3.18.2 WARRANTY ON RUBBER TRACKS ...................................................................... 127

3.3.18.3 USE OF THE RUBBER TRACKS ........................................................................... 128

3.3.18.4 HOW TO PRESERVE THE RUBBER TRACKS OVER TIME ................................ 128

3.4 TRANSPORTING THE MACHINE ........................................................................................................ 132

3.4.1 TRANSPORT PROCEDURE ................................................................................................... 132

3.4.2 LOADING AND UNLOADING THE MACHINE......................................................................... 132

3.4.3 LIFTING THE MACHINE .......................................................................................................... 138

3.5 USING THE MACHINE IN THE COLD SEASON ................................................................................. 140

3.5.1 PRECAUTIONS TO BE TAKEN WHEN USING THE MACHINE IN THE COLD SEASON ..... 140

3.5.1.1 FUEL AND LUBRICANTS....................................................................................... 140

3.5.1.2 COOLANT............................................................................................................... 140

3.5.1.3 BATTERY................................................................................................................ 141

3.5.2 PRECAUTIONS TO BE TAKEN EVERY DAY AT THE END OF WORK................................. 142

3.5.3 HOW TO PROCEED AT THE END OF THE COLD SEASON ................................................ 142

3.6 LONG PERIODS OF INACTIVITY ........................................................................................................ 143

3.6.1 BEFORE A PERIOD OF INACTIVITY...................................................................................... 143

3.6.2 DURING A PERIOD OF INACTIVITY ...................................................................................... 143

3.6.3 AFTER A PERIOD OF INACTIVITY ......................................................................................... 143

3.7 TROUBLESHOOTING .......................................................................................................................... 144

3.7.1 IF FUEL RUNS OUT COMPLETELY ....................................................................................... 144

3.7.2 OCCURRENCES THAT ARE NOT FAILURES ....................................................................... 144

3.7.3 REMOVING THE MACHINE .................................................................................................... 144

3.7.4 PRECAUTIONS TO BE TAKEN WHEN WORKING IN PARTICULAR CONDITIONS ............ 145

3.7.5 IF THE BATTERY IS DOWN .................................................................................................... 145

3.7.5.1 REMOVING AND INSTALLING THE BATTERY .................................................... 146

3.7.5.2 CHARGING THE BATTERY ................................................................................... 146

3.7.5.3 STARTING WITH BOOSTER CABLES .................................................................. 147

3.7.6 OTHER TROUBLES................................................................................................................. 149

3.7.6.1 ELECTRICAL CIRCUIT........................................................................................... 149

3.7.6.2 FRAME.................................................................................................................... 150

3.7.6.3 ENGINE .................................................................................................................. 150

MAINTENANCE

4.1 GUIDE TO MAINTENANCE .................................................................................................................. 154

4.2 MAINTENANCE NOTES ....................................................................................................................... 156

4.2.1 OIL, FUEL AND COOLANT...................................................................................................... 156

4.2.1.1 OIL .......................................................................................................................... 156

4.2.1.2 FUEL ....................................................................................................................... 157

4.2.1.3 COOLANT............................................................................................................... 157

4.2.1.4 KOWA (KOMATSU OIL WEAR ANALYSIS) ........................................................... 158

4.2.1.5 STORING OIL AND FUEL ...................................................................................... 159

4.2.1.6 FILTERS ................................................................................................................. 159

4.2.2 NOTES ON THE MAINTENANCE OF THE ELECTRICAL SYSTEM ...................................... 160

4.2.3 NOTES ON THE MAINTENANCE OF THE HYDRAULIC SYSTEM........................................ 160

4.2.4 MAINTENANCE NOTES REGARDING LUBRICATION .......................................................... 160

4.3 PARTS SUBJECT TO WEAR ............................................................................................................... 161

4.3.1 LIST OF THE PARTS SUBJECT TO WEAR............................................................................ 161

13

TABLE OF CONTENTS

4.4 FUEL, COOLANT AND LUBRICANTS.................................................................................................162

4.4.1 APPROVED SYNTHETIC BIODEGRADABLE LUBRICANTS TYPE HEES............................ 164

4.5 TIGHTENING TORQUES ...................................................................................................................... 165

4.5.1 STANDARD TIGHTENING TORQUES FOR SCREWS AND NUTS ....................................... 165

4.5.2 STANDARD TIGHTENING TORQUES FOR HOSES WITH ORFS......................................... 166

4.6 LUBRICATION ...................................................................................................................................... 167

4.6.1 LUBRICATION DIAGRAM........................................................................................................167

4.7 PERIODICAL CHANGE OF SAFETY-RELATED COMPONENTS ...................................................... 168

4.7.1 SAFETY-RELATED PARTS ..................................................................................................... 169

4.8 MAINTENANCE PLAN.......................................................................................................................... 170

4.8.1 MAINTENANCE PLAN ............................................................................................................. 170

4.8.2 MAINTENANCE INTERVALS IN CASE OF USE OF THE HYDRAULIC BREAKER............... 171

4.8.2.a CHANGING THE HYDRAULIC OIL FILTER ........................................................... 171

4.8.2.b CHANGING THE HYDRAULIC OIL ........................................................................ 171

4.9 MAINTENANCE PROCEDURES .......................................................................................................... 172

4.9.1 WHEN REQUIRED ................................................................................................................... 172

4.9.1.a CHECKING, CLEANING OR CHANGING THE AIR FILTER CARTRIDGE............ 172

4.9.1.b CHECKING THE BATTERY CHARGE LEVEL ....................................................... 174

4.9.1.c CLEANING THE WATER SEPARATOR FILTER .................................................. 175

4.9.1.d DRAINING THE FUEL TANK .................................................................................. 176

4.9.1.e CHECKING AND ADJUSTING THE STEEL TRACK TENSION............................. 176

4.9.1.f CHECKING THE RUBBER TRACKS...................................................................... 178

4.9.1.g CHECKING AND ADJUSTING THE RUBBER TRACK TENSION ......................... 180

4.9.1.h CHANGING THE RUBBER TRACKS ..................................................................... 182

4.9.1.i BLEEDING THE HYDRAULIC SYSTEM ................................................................ 185

4.9.2 CHECKS TO BE CARRIED OUT BEFORE STARTING THE ENGINE ................................... 186

4.9.3 MAINTENANCE AFTER THE FIRST 50 HOURS OF OPERATION

(Only for machines in which synthetic biodegradable oil type HEES is used) .......................... 186

4.9.4 MAINTENANCE AFTER THE FIRST 500 HOURS OF OPERATION

(Only for machines in which synthetic biodegradable oil type HEES is used) .......................... 186

4.9.5 MAINTENANCE EVERY 500 HOURS OF OPERATION ......................................................... 187

4.9.5.a LUBRICATION ........................................................................................................ 187

4.9.5.b CHANGING THE ENGINE OIL AND THE ENGINE OIL FILTER CARTRIDGE ..... 189

4.9.5.c CHANGING THE FUEL FILTER CARTRIDGE ....................................................... 190

4.9.5.d CHECKING THE OIL LEVEL IN THE FINAL REDUCTION GEARS ...................... 191

4.9.5.e CHECKING AND CLEANING THE FINS OF THE RADIATOR AND

OF THE EXCHANGER ........................................................................................... 191

4.9.5.f CHECKING AND ADJUSTING THE FAN BELT TENSION .................................... 192

4.9.5.g DRAINING THE HYDRAULIC OIL TANK

(Only for machines in which synthetic biodegradable oil type HEES is used) ........ 193

4.9.6 MAINTENANCE EVERY 1000 HOURS OF OPERATION ....................................................... 194

4.9.6.a CHANGING THE HYDRAULIC OIL FILTER ........................................................... 194

4.9.6.b CHANGING THE OIL IN THE FINAL REDUCTION GEARS .................................. 196

4.9.6.c CHECKING AND ADJUSTING THE ENGINE VALVE CLEARANCE ..................... 196

4.9.7 MAINTENANCE EVERY 2000 HOURS OF OPERATION ....................................................... 197

4.9.7.a CHANGING THE OIL IN THE HYDRAULIC TANK AND CLEANING THE FILTER 197

4.9.7.b CHANGING THE COOLANT .................................................................................. 199

4.9.7.c CHECKING THE ALTERNATOR AND THE STARTER ......................................... 200

14

TABLE OF CONTENTS

TECHNICAL SPECIFICATIONS

5.1 TECHNICAL DATA ............................................................................................................................... 202

5.2 LIFTING CAPACITIES .......................................................................................................................... 204

5.2.1 LIFTING CAPACITIES ............................................................................................................. 204

AUTHORIZED OPTIONAL EQUIPMENT

6.1 AUTHORIZED OPTIONAL EQUIPMENT ............................................................................................. 208

6.1.1 PRECAUTIONS REGARDING SAFETY .................................................................................. 208

6.1.2 PRECAUTIONS REGARDING THE INSTALLATION OF EQUIPMENT.................................. 209

6.1.3 CHARACTERISTICS OF THE OPTIONAL EQUIPMENT ........................................................ 210

6.1.3.1 CHARACTERISTICS OF THE OPTIONAL EQUIPMENT....................................... 210

6.2 MACHINE CONFIGURATION FOR THE INSTALLATION OF ATTACHMENTS ................................ 211

6.2.1 POSITION OF THE DEVICES ................................................................................................. 211

6.2.2 HYDRAULIC CIRCUIT ............................................................................................................. 213

6.2.2.1 INSTALLING AND CONNECTING THE EQUIPMENT ........................................... 213

6.2.2.2 MAINTENANCE ...................................................................................................... 213

6.2.2.3 BLEEDING .............................................................................................................. 214

6.3 OPERATING THE EQUIPMENT ........................................................................................................... 215

6.3.1 LONG PERIODS OF INACTIVITY ........................................................................................... 216

6.4 PRECAUTIONS TO BE TAKEN WHEN USING OPTIONAL EQUIPMENT ......................................... 217

6.4.1 HYDRAULIC BREAKER........................................................................................................... 217

15

PAGE INTENTIONALLY LEFT BLANK

16

SAFETY AND

ACCIDENT PREVENTION

17

SAFETY, NOISE AND VIBRATION PLATES

2.1 SAFETY, NOISE AND VIBRATION PLATES

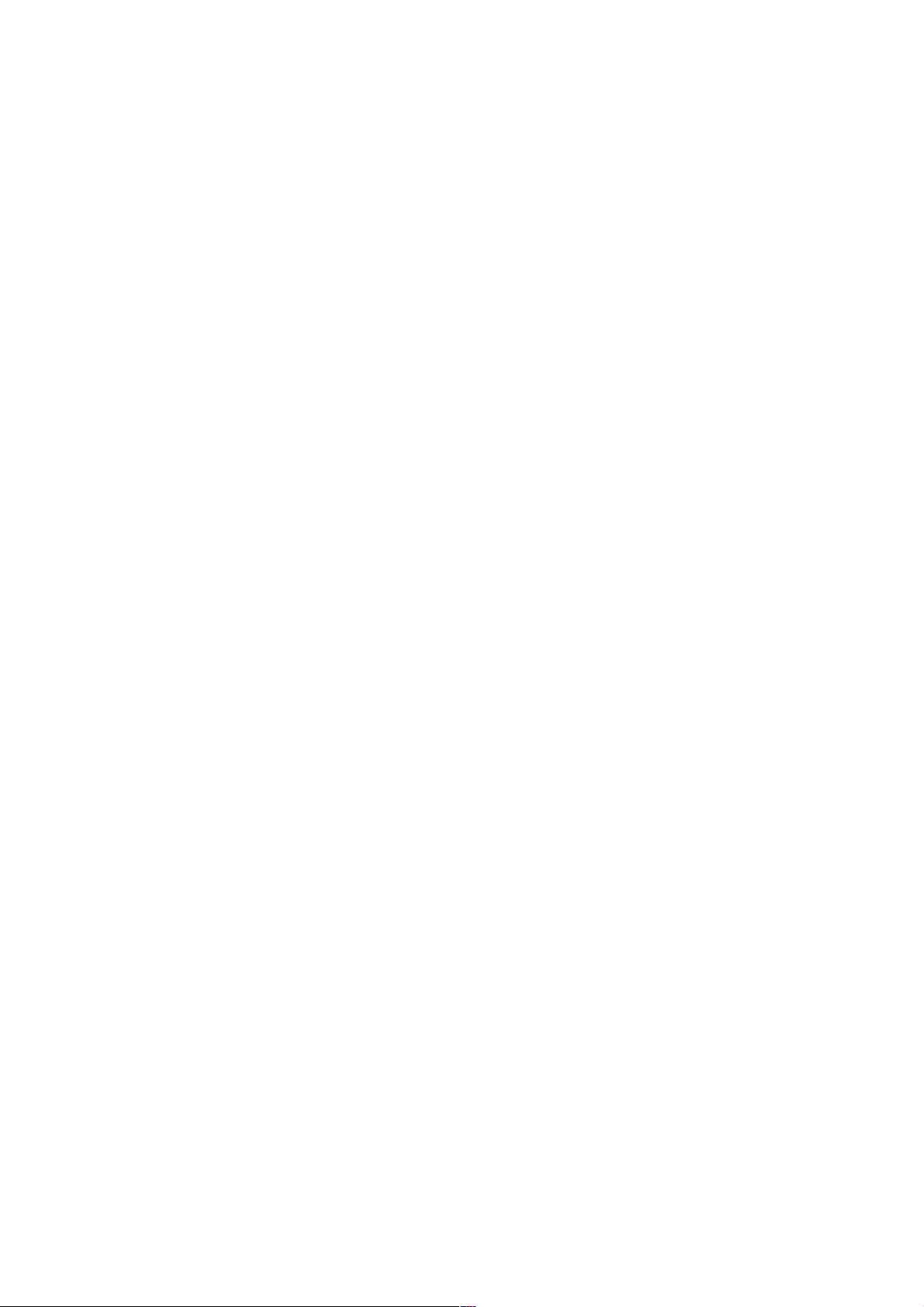

2.1.1 POSITION OF THE SAFETY PLATES

q The safety plates must always be legible and in good conditions; for this reason, if they are dirty with dust, oil or

grease, it is necessary to clean them with a solution made of water and detergent.

Do not use fuel, petrol or solvents.

q If the plates are damaged, ask for new ones to Komatsu or to your Komatsu Dealer.

q In case of replacement of a component provided with a safety plate, make sure that such a plate is applied also

to the new part.

q The machine can be provided with other plates in addition to those indicated below; keep also to the instructions

given in the additional plates, in any case.

18

RKA16560

SAFETY, NOISE AND VIBRATION PLATES

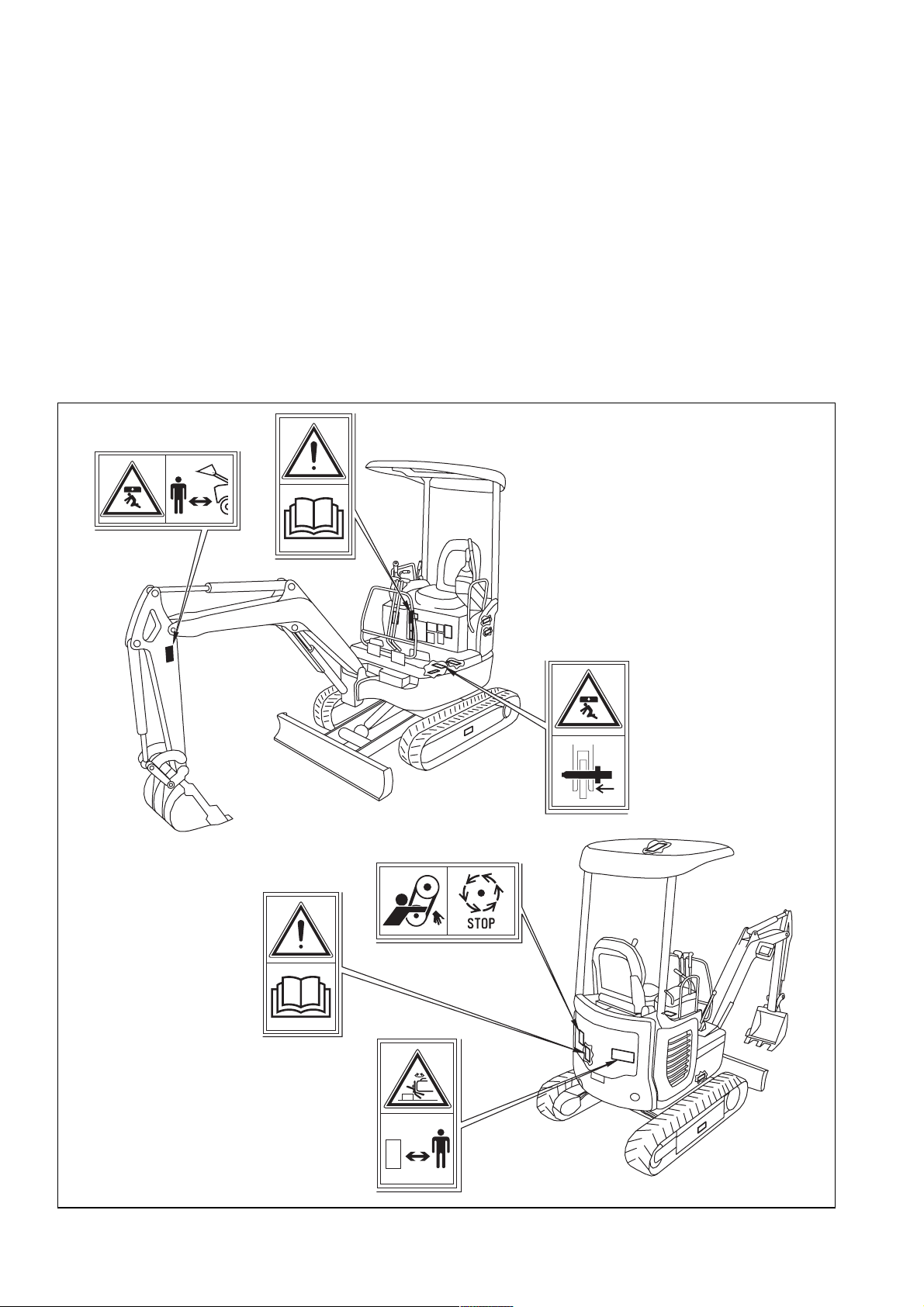

2.1.2 PICTOGRAMS AND RELEVANT MEANINGS

The warning and danger plates applied onto the machine include or are accompanied by pictograms.

The staff in charge with the operation and maintenance of the machine must be perfectly familiar with the symbols

contained in the pictograms; the following list illustrates what they look like and their respective meanings.

WORK IN PROGRESS

q Do not approach or stand within the equipment operating range

when the boom and the bucket are raised.

DO NOT OPEN THE ENGINE HOOD

q Do not open or remove the hood when the engine is running.

CONSULT THE MANUAL

q Carefully read the contents of the manual before using the

machine or performing maintenance operations.

3F05B2612

3F30B2612

RWA00020

RWA00010

SAFETY DISTANCE

q Do not get too near the machine and do not stand within its

operating range.

09651-A0481

RWA00030

22L-98-22270

19

SAFETY, NOISE AND VIBRATION PLATES

PLATFORM LIFTING SAFETY PLATE

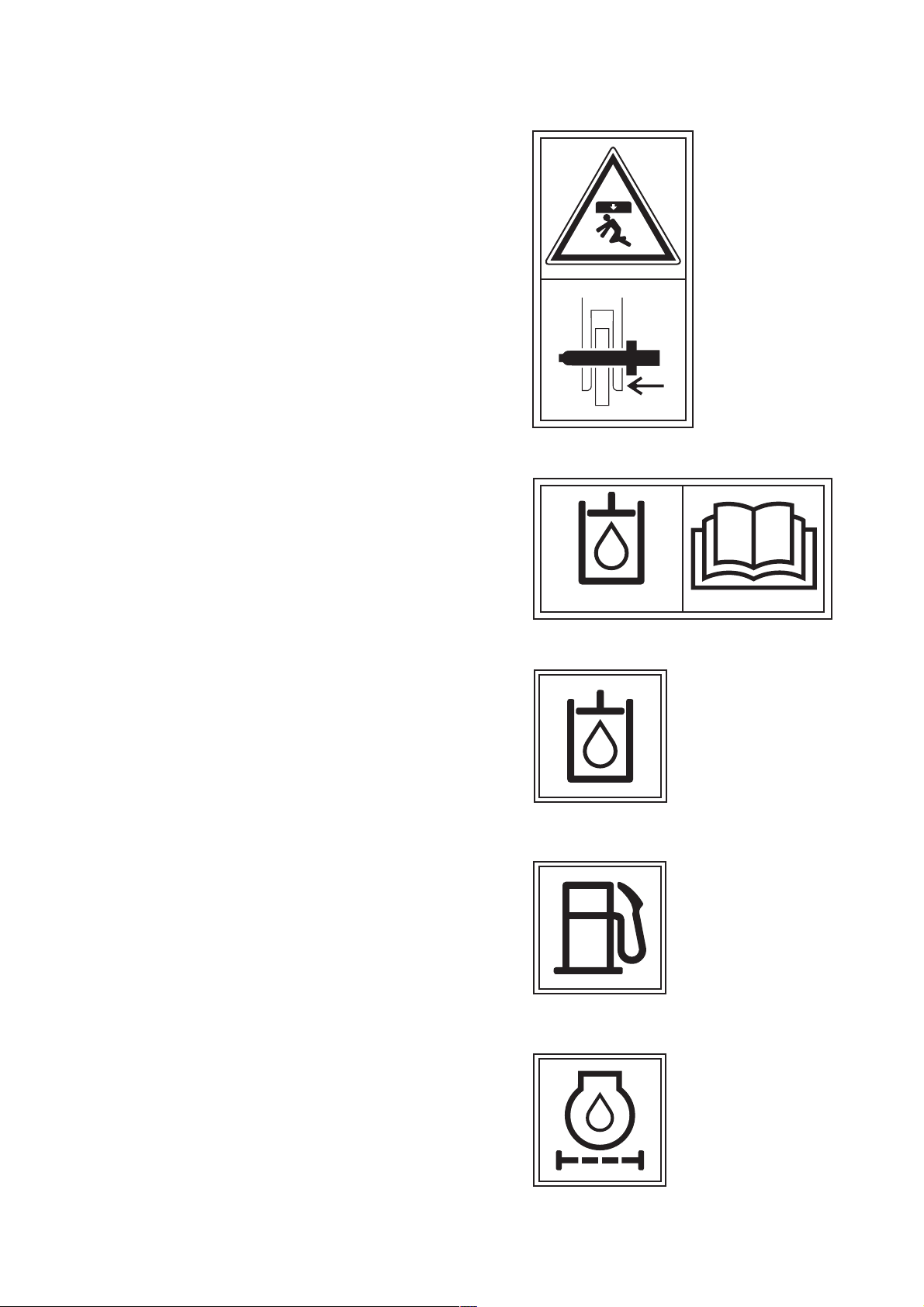

HYDRAULIC OIL TOPPING UP

q (Only for machines in which synthetic biodegradable oil type

HEES is used)

22L-98-R2390

RKA01380

HYDRAULIC OIL TOPPING UP

REFUELLING

BIO-OIL

RWA00050

D

RWA00040

RWA34380

ENGINE OIL FILTER

20

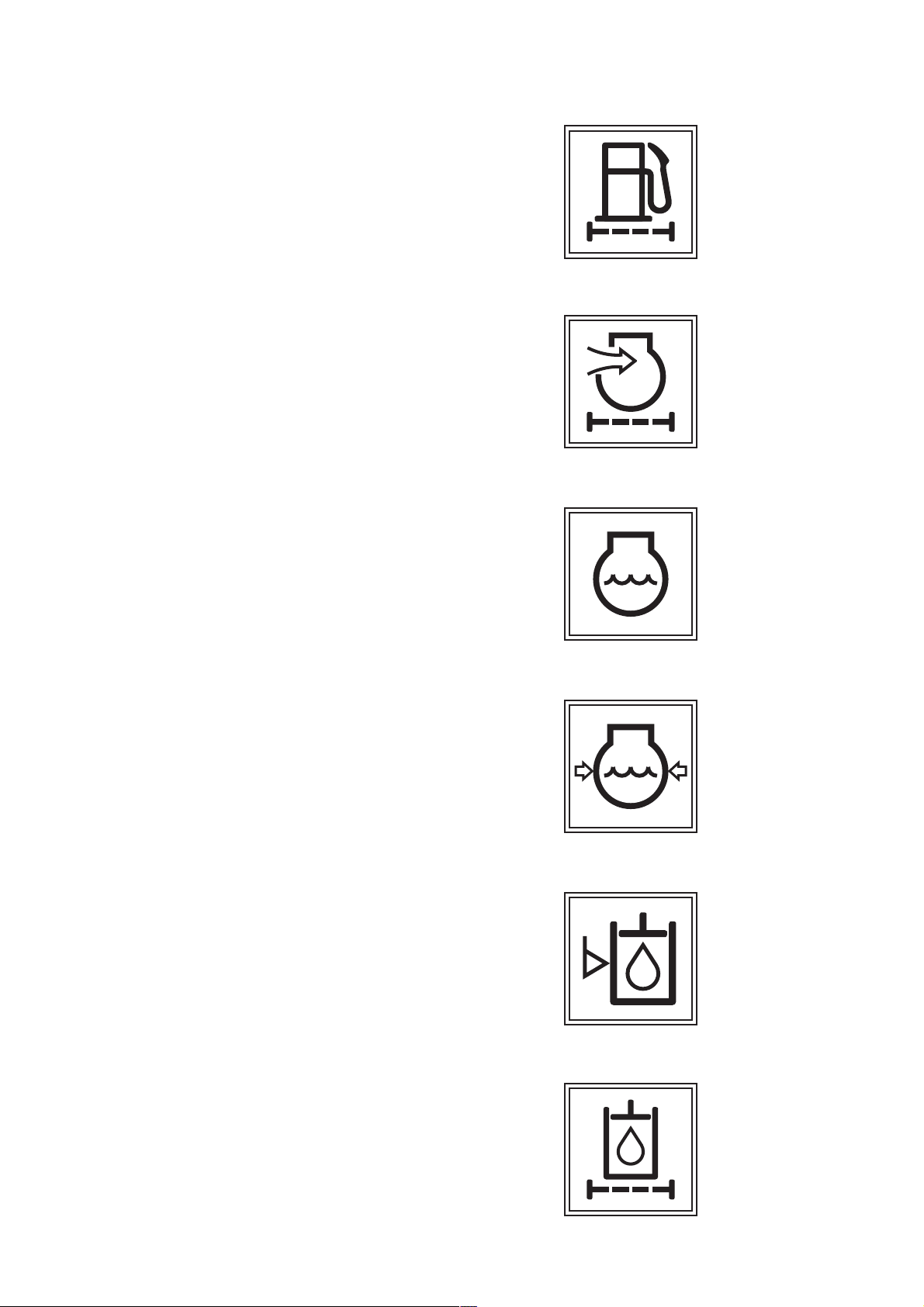

RWA00080

FUEL FILTER

ENGINE AIR INTAKE FILTER

ENGINE COOLANT

SAFETY, NOISE AND VIBRATION PLATES

D

RWA00060

RWA00090

ENGINE COOLANT PRESSURE

HYDRAULIC OIL LEVEL

RWA00130

RWA00110

RWA00100

HYDRAULIC OIL FILTER

RWA00070

21

SAFETY, NOISE AND VIBRATION PLATES

POWER OUTLET

ANCHORAGE POINT

LIFTING POINT

RWA00120

12 V

RWA00200

RWA04920

22

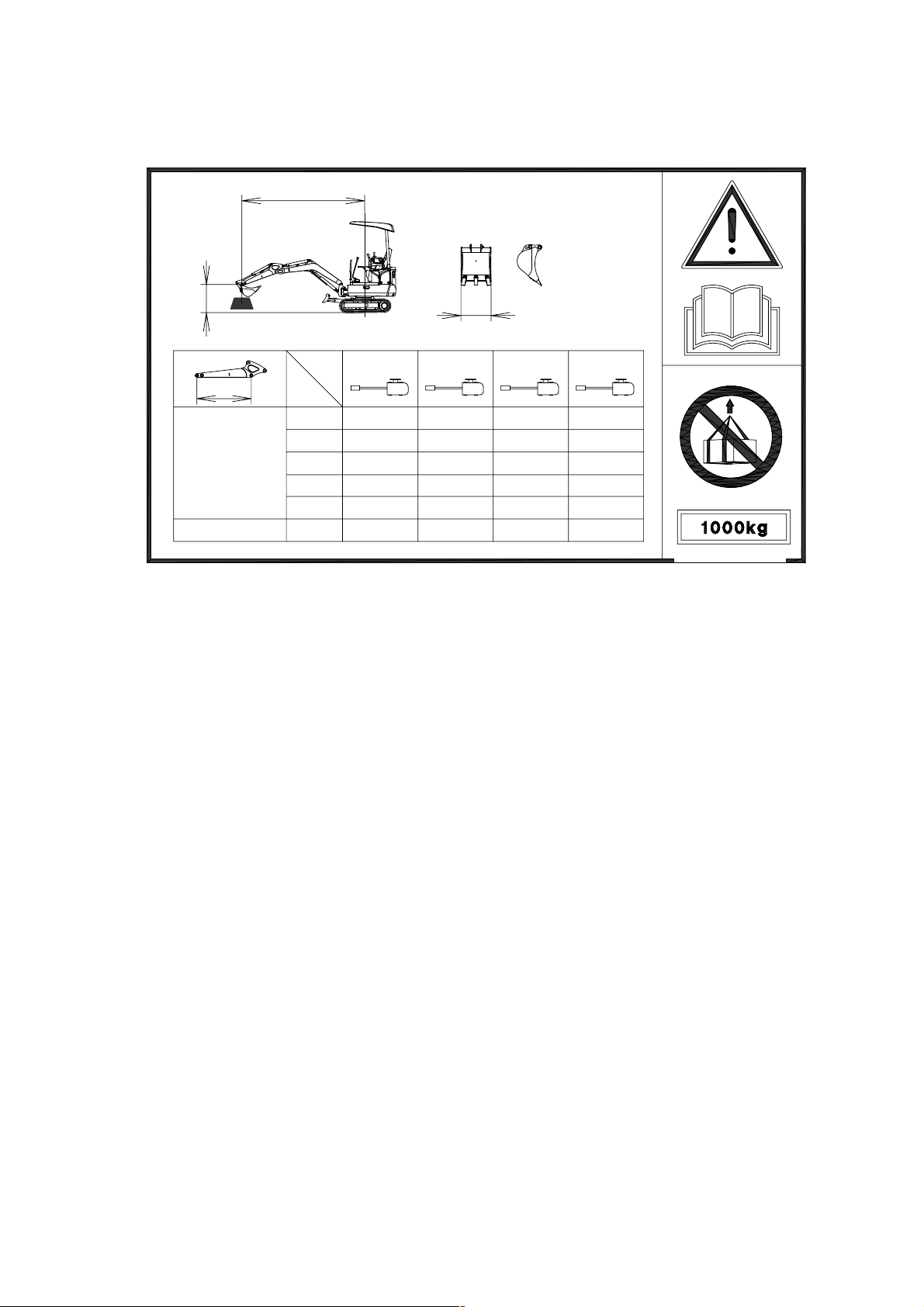

LIFTING CAPACITIES

B

SAFETY, NOISE AND VIBRATION PLATES

A

W=400mm

kg 23

W

RKA16650

L

L=965mm

L=1210mm

B

3m

2m

1m

-1m

0

0

A

1m

825kg

2m 3m MAX

310kg

285kg

300kg

280kg

280kg

275kg

165kg

155kg

150kg

310kg

170kg

140kg

145kg

195kg

125kg

>

20W-98-91510

23

SAFETY, NOISE AND VIBRATION PLATES

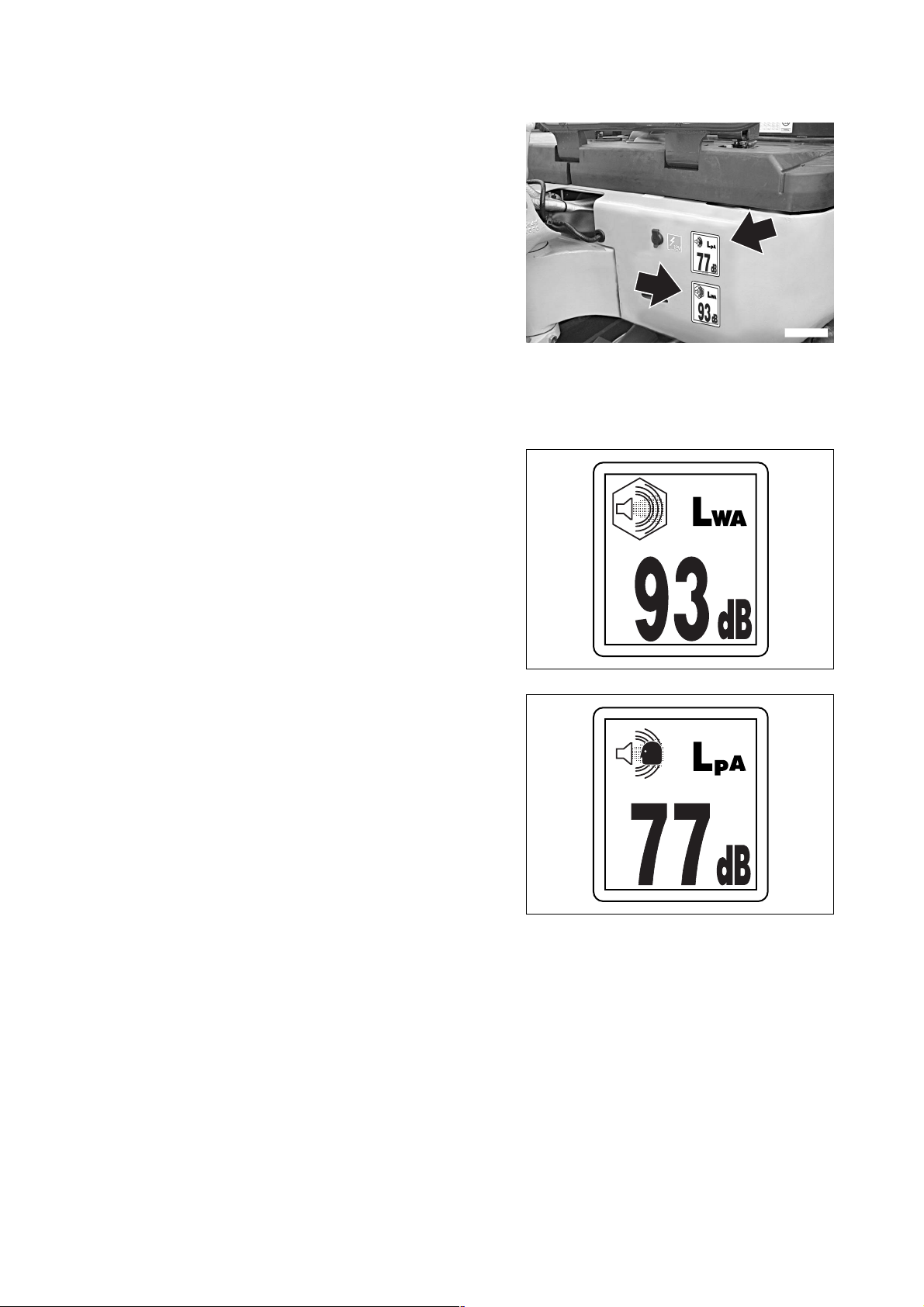

2.1.3 POSITION OF THE NOISE PLATES

q The noise plates must always be legible and in good conditions;

for this reason, if they are dirty with dust, oil or grease, it is

necessary to clean them with a solution made of water and

detergent.

Do not use fuel, petrol or solvents.

q If the plates are damaged, ask for new ones to Komatsu or to

your Komatsu Dealer.

q In case of replacement of a component provided with a noise

plate, make sure that such a plate is applied also to the new

part.

EXTERNAL NOISE

q This value indicates the noise level outside the machine and

refers to the noise perceived by persons in the vicinity of the

work area.

RKAB5950

2000/14/EC

NOISE PERCEIVED BY THE OPERATOR

q This value indicates the noise level perceived by the operator

when seated in driving position.

ISO 6396

2.1.4 VIBRATIONS TO WHICH THE OPERATOR IS SUBJECTED

q According to the results of the tests carried out to determine the vibrations transmitted to the operator by the

machine, the upper limbs are subjected to vibrations lower than 2.5 m/sq.sec., while the seated part of the body

is subjected to vibrations lower than 0.5 m/sq.sec.

24

GENERAL PRECAUTIONS

2.2 GENERAL PRECAUTIONS

2.2.1 GENERAL SAFETY RULES

q Only trained and authorized staff can use the machine and perform maintenance operations.

q Follow all the safety rules, precautions and instructions when using the machine or performing maintenance

operations.

q When working with other operators or when the work site is often occupied by other operators, make sure that

everyone knows and understands all the agreed signals and, in any case, that everyone works in such a way as

to be able to see the machine and to be visible to the operator.

2.2.2 SAFETY DEVICES AND GUARDS

q Make sure that all the guards and covers are in the correct position. Have guards and covers changed or

repaired if damaged. Neither use the machine without guards, nor remove the guards when the engine is

running.

q Always use the proper safety devices to lock the machine when parking; always fasten the seat belt.

q Do not remove the safety devices and always keep them in good operating conditions.

q Any improper use of the safety devices may result in serious injury or even death.

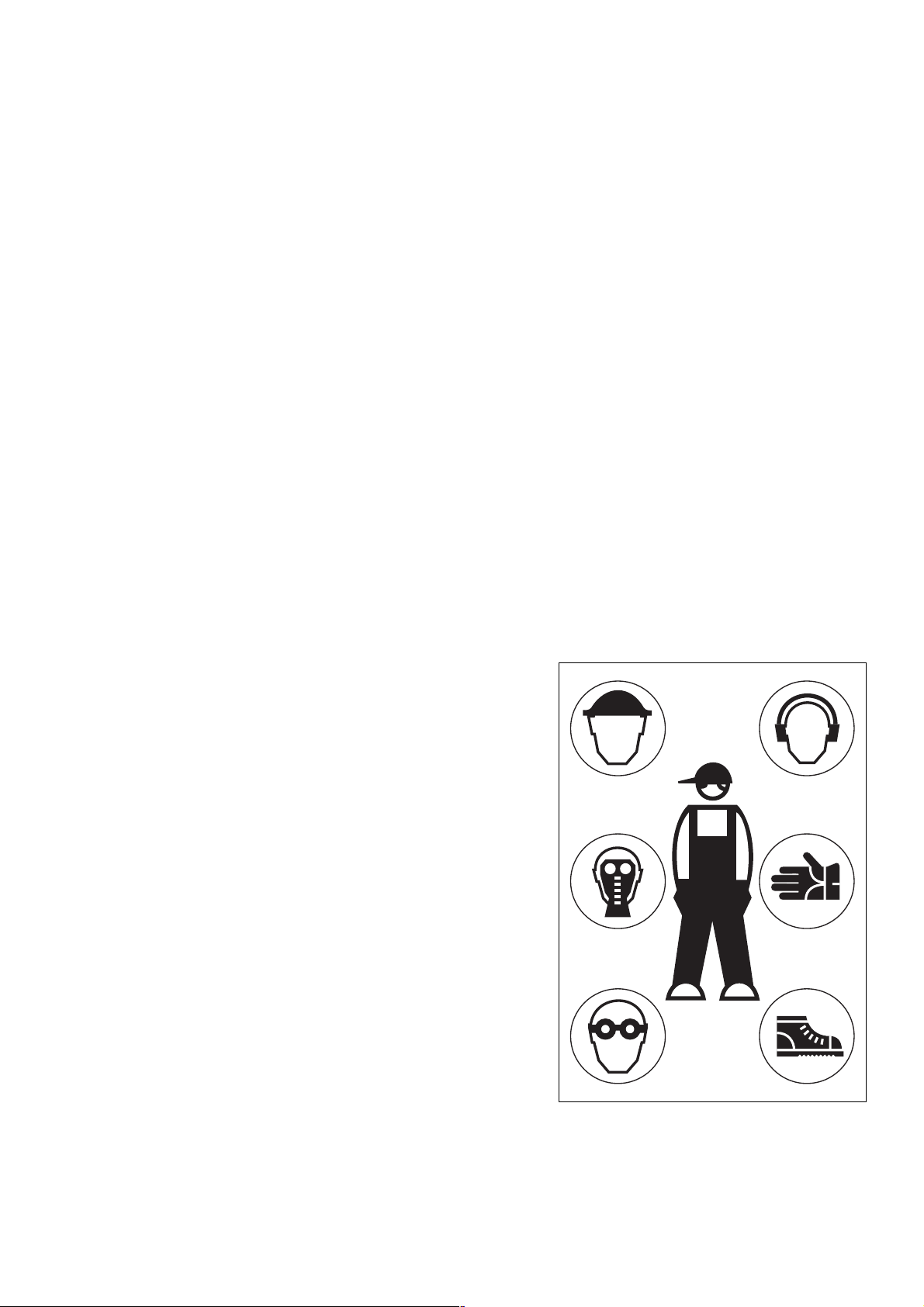

2.2.3 CLOTHING AND PERSONAL PROTECTION ITEMS

q Do not wear large or loose clothes, rings and watches, and do

not approach the machine with loose long hair, since they can

get entagled in the moving parts of the machine and cause

serious injury or damage.

Avoid also wearing clothes dirty with oil or fuel, since they are

flammable.

q Wear a hard hat, goggles, safety shoes, mask, gloves and ear

muffs when operating the machine or performing maintenance

operations.

q Always wear safety goggles, a hard hat and heavy gloves if

your job involves scattering metal chips or minute materials;

these precautions are particularly useful when hammering the

equipment connection pins and when blowing compressed air

into the air filter and the radiator.

During these operations, make also sure that no one is standing

or working near the machine without the necessary protection

items.

q When working for 8 hours with a noise level exceeding 90 dBA,

it is necessary to use headphones or ear plugs and be

particularly careful, especially at the end of the work shift.

RKA00510

25

GENERAL PRECAUTIONS

2.2.4 UNAUTHORIZED MODIFICATIONS

q Any modification made without the authorization of Komatsu can involve hazards.

q Before making a modification, consult your Komatsu Dealer. Komatsu declines any responsibility for injury or

damage caused by unauthorized modifications.

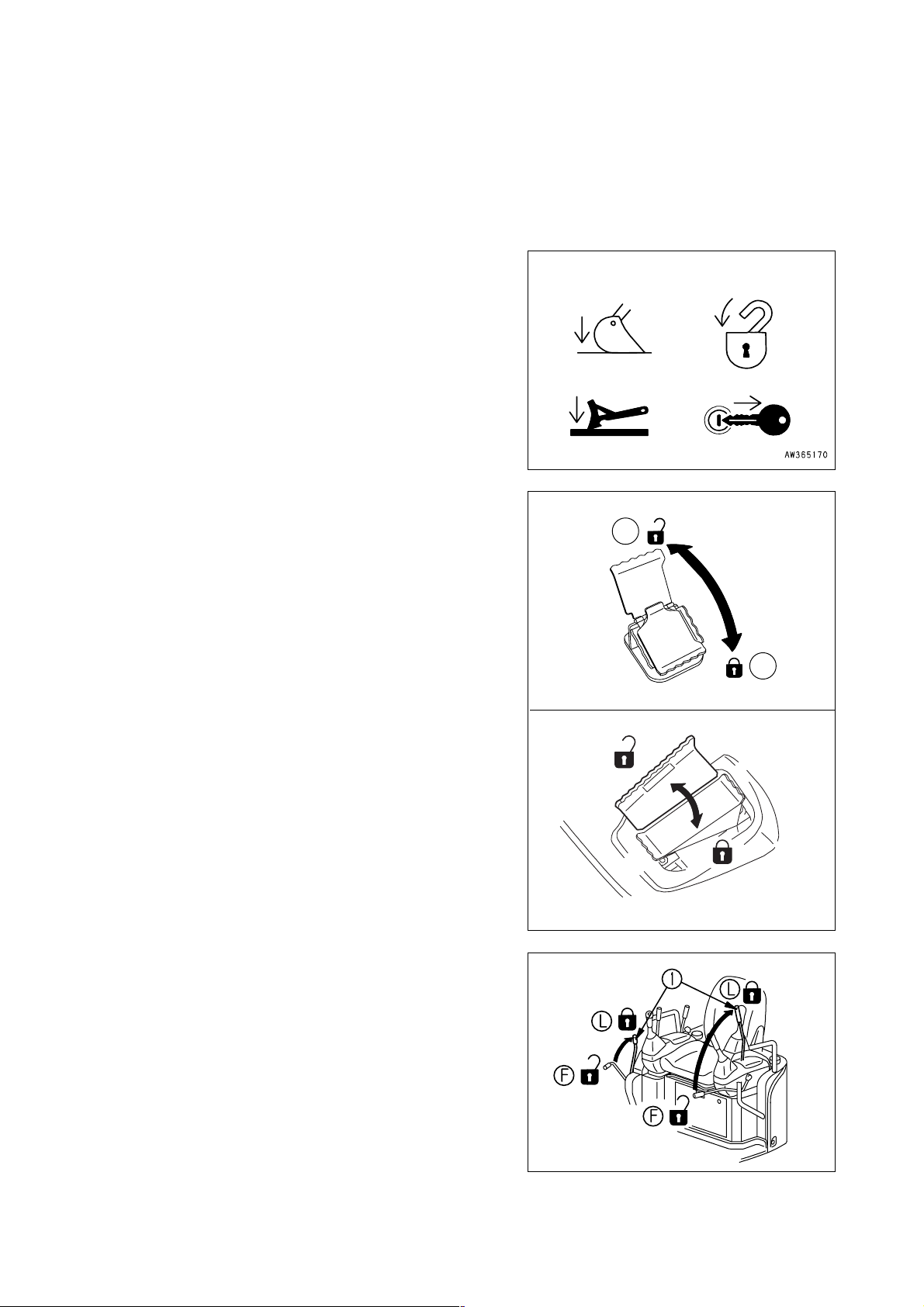

2.2.5 LEAVING THE OPERATOR SEAT

q When leaving the operator seat, even if temporarily, make sure

that the machine is in a safe position. (See "2.4.14 PARKING

THE MACHINE").

q Before leaving the operator seat, carry out the following

operations in the sequence indicated below:

1 - Lower the equipment to the ground.

2 - Engage the safety locks of the boom swing, optional

equipment and turret swing controls.

F

3 - Lock the equipment control by shifting the safety lever (1) to

the “locked” position (L).

4 - Stop the engine. (See "3.3.4 STOPPING THE ENGINE").

5 - If you have to go so far away that you will not be able to see

the machine, extract the ignition key.

L

9JA05440

RKA10550

CAB

26

RKA16340

GENERAL PRECAUTIONS

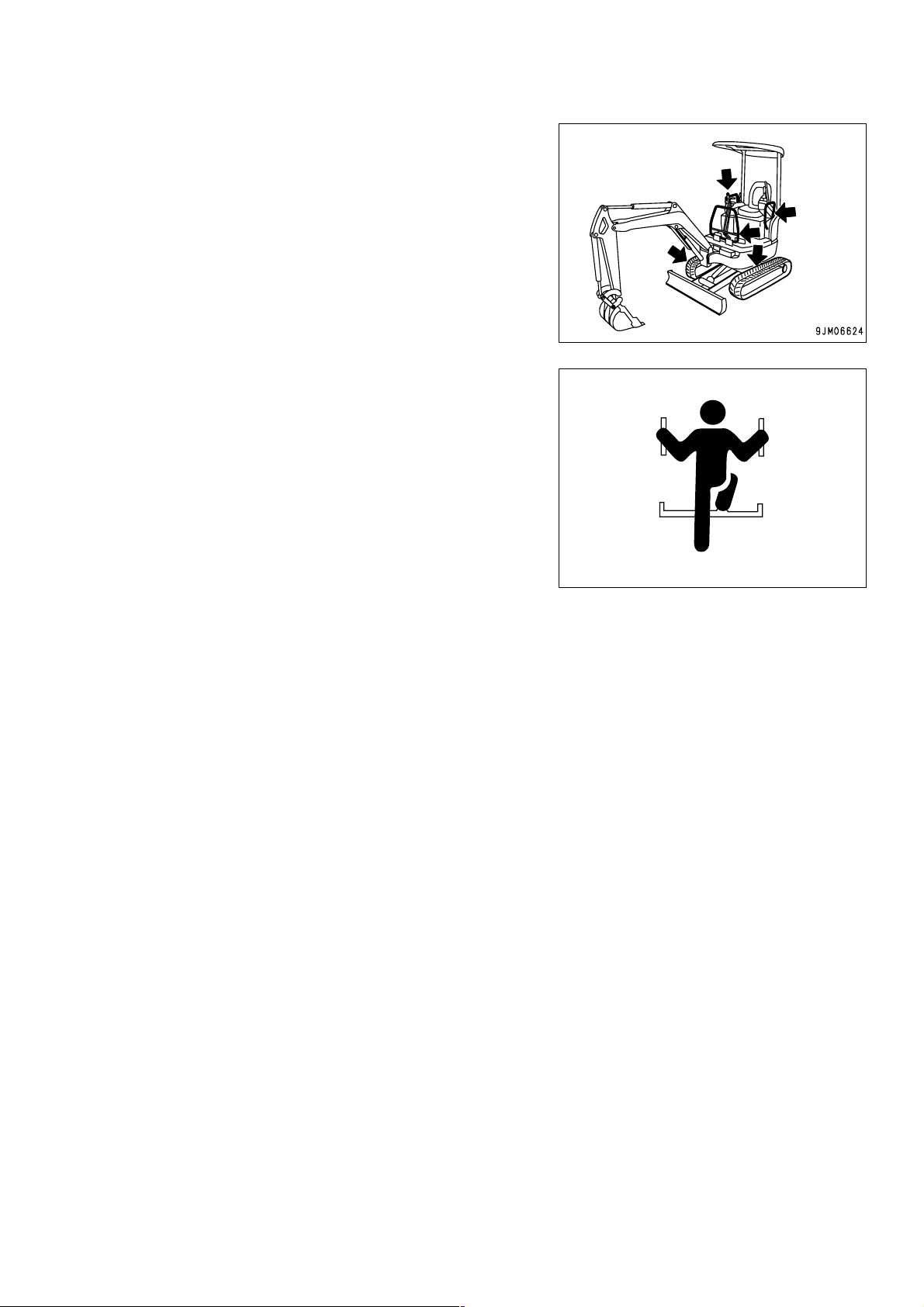

2.2.6 GETTING ON AND OFF THE MACHINE

q Do not jump on or off the machine, neither when it is at rest nor

when it is moving.

q When getting on or off the machine, always use the handles

and the tracks; get on and off the machine very carefully.

q Do not hold or rest on the control levers.

q Both when getting on and when getting off the machine, always

maintain three points of contact (holding or resting points), in

order to avoid losing your balance and falling down.

q Tighten the handle screws if they are loose, and clean the

handles and tracks if they are dirty with oil or grease.

Carefully clean the cab floor if it is dirty with oil, grease, mud or

rubble.

CANOPY

RWA18670

27

GENERAL PRECAUTIONS

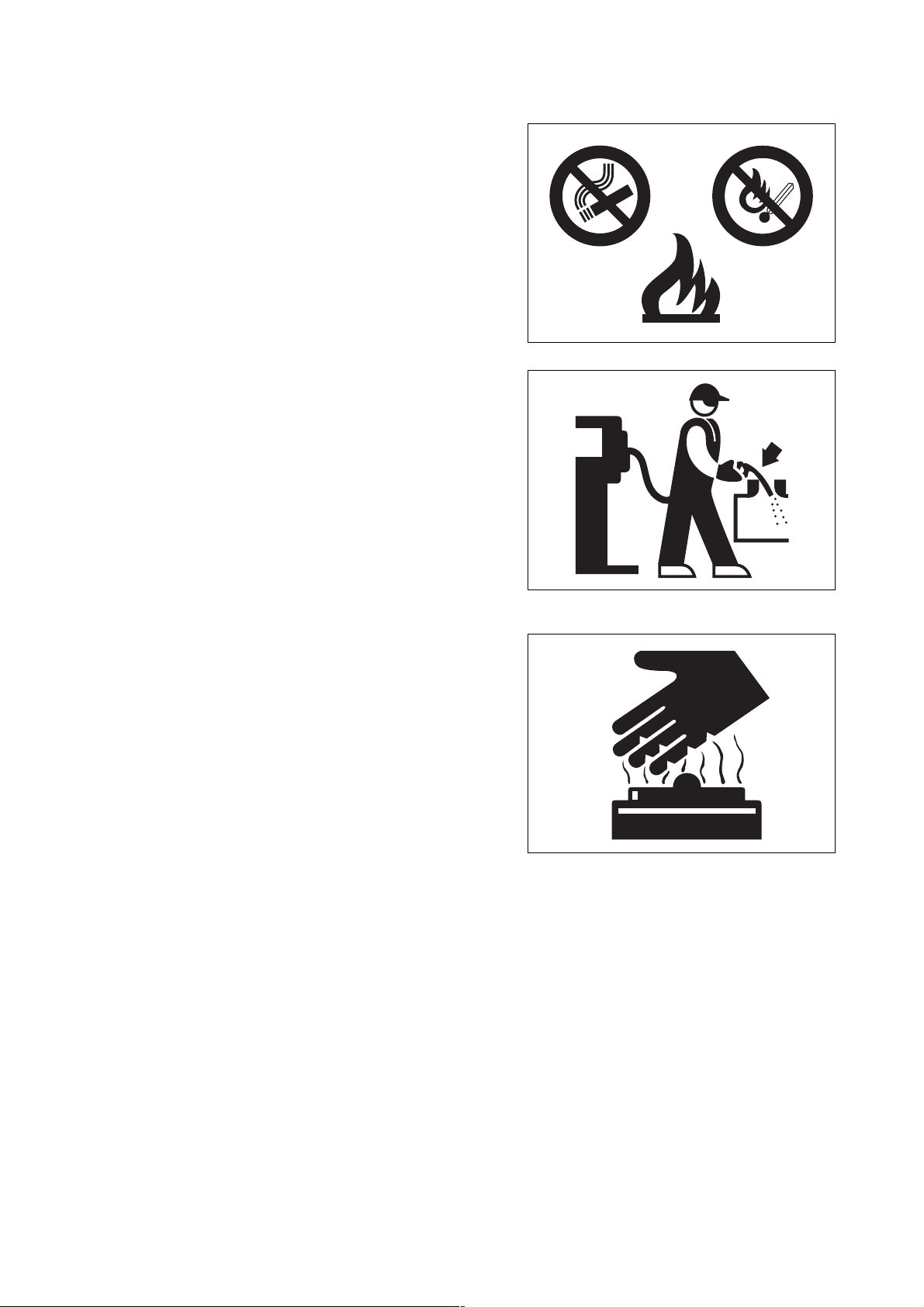

2.2.7 PREVENTING FIRES DUE TO FUEL AND OIL

Fuel, oil and some types of antifreeze can easily ignite if they get

in contact with a flame. Fuel is flammable and therefore very

dangerous.

q Keep any naked flame away from flammable fluids.

q Stop the engine and do not smoke when refuelling.

q Refuel and add oil only after stopping the engine and in well

ventilated places.

q Refuel and add oil in a well delimited area and do not allow

unauthorized persons to approach.

q When refuelling, hold the fuel gun firmly and keep it constantly

in contact with the filler until you have finished, in order to avoid

sparks due to static electricity.

q After refuelling or adding oil, tighten the fuel or oil cap securely.

q Do not fill the tank completely, in order to leave room for the fuel

to expand.

q In case some fuel is spilled, wipe it up immediately.

RKA00480

2.2.8 PREVENTING BURNS

q If the engine coolant, the engine oil and the hydraulic oil are hot,

use heavy cloths and wear gloves, heavy clothing and safety

goggles before carrying out any check or touching the hot parts.

q Before checking the coolant level, stop the engine and let the

fluid cool down.

If a check is necessary due to the overheating of the engine,

slowly loosen the radiator cap to release any residual pressure

before removing it. The hot fluid that spurts out may cause

serious burns.

q Before checking the engine oil and hydraulic circuit oil levels,

stop the engine and let the oil cool down. The hot oil that can be

sprayed out of the tank may cause serious burns.

RKA00490

RKA00500

28

Loading...

Loading...