SEBM036301

MACHINE MODEL SERIAL NUMBER

PC130-7 70001 and up

• This shop manual may co ntain attachiments and optio nal equipment that are not availabl e in your

area. Please consult your local Komatsu distributor for those items you may require.

Materials and specifications are subject to change without notice.

• PC130-7 mounts the SAA4D95LE-3 engine.

For details of the engine, see the 95-3 Series Engine Shop Manual.

© 2004

All Rights Reserved

Printed in Japan 04-04(02)

00-1

(1)

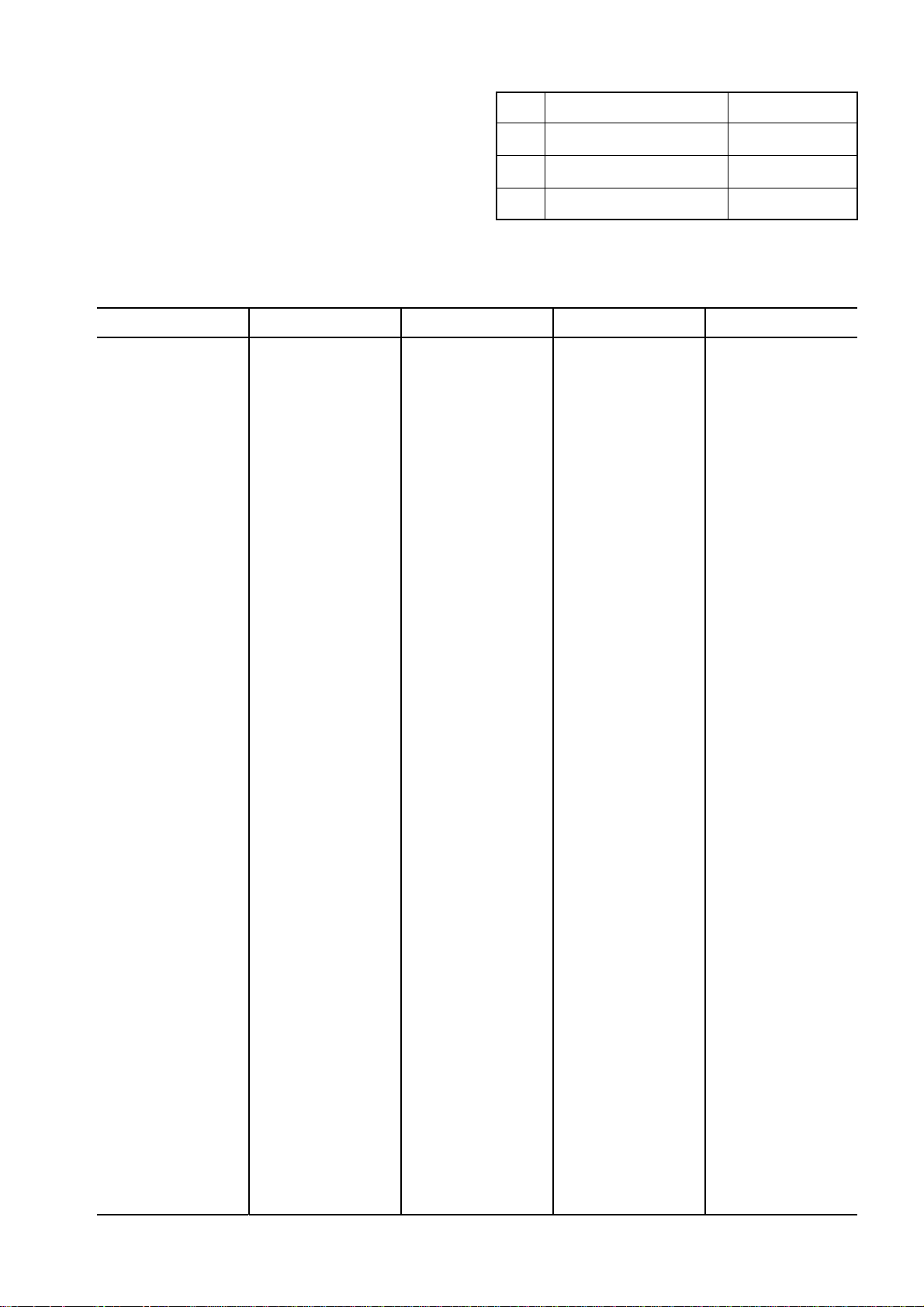

CONTENTS

No. of page

01 GENERAL ................................................................................................................01-1

10 STRUCTURE AND FUNCTION.................................................................10-1

20 TESTING AND ADJUSTING .......................................................................20-1

30 DISASSEMBLY AND ASSEMBLY.............................To be issued next time

40 MAINTENANCE STANDARD......................................................................40-1

90 OTHERS ....................................................................................................................90-1

00-2 PC130-7

(1)

The affected pages are indicated by the use of the

following marks . It is requested that necessary

actions be taken to these pages according to the

table below.

LIST OF REVISED PAGES

Mark Page

00-1

q

00-2 (1)

q

00-2-1 (1)

Q

00-2-2 (1)

Q

00-2-3 (1)

Q

00-3

00-4

00-5

00-6

00-7

00-8

00-9

00-10

00-11

00-12

00-13

00-14

00-15

00-16

00-17

00-18

00-19

00-20

00-21

00-22

01-1

01-2

01-3

01-4

01-5

01-6

01-7

01-8

01-9

10-1

10-2

10-3

10-4

10-5

Revision

number

(1)

Mark Page

10-6

10-7

10-8

10-9

10-10

10-11

10-12

10-13

10-14

10-15

10-16

10-17

10-18

10-19

10-20

10-21

10-22

10-23

10-24

10-25

10-26

10-27

10-28

10-29

10-30

10-31

10-32

10-33

10-34

10-35

10-36

10-37

10-38

10-39

10-40

10-41

10-42

10-43

10-44

10-45

10-46

Revision

number

Mark Page

10-47

10-48

10-49

10-50

10-51

10-52

10-53

10-54

10-55

10-56

10-57

10-58

10-59

10-60

10-61

10-62

10-64

10-65

10-66

10-67

10-68

10-69

10-70

10-71

10-72

10-73

10-74

10-75

10-76

10-77

10-78

10-79

10-80

10-81

10-82

10-83

10-84

10-85

10-86

10-87

10-88

Mark Indication Action required

Page to be newly added Add

Q

Page to be replaced Replace

q

( ) Page to be deleted Discard

Pages having no mark s a r e tho se pr ev io us ly r evi s ed

or made aditions.

Revision

number

Mark Page

10-89

10-90

10-91

10-92

10-93

10-94

10-95

10-96

10-97

10-98

10-99

10-100

10-101

10-102

10-103

10-104

10-105

10-106

10-107

10-108

10-109

10-110

10-111

10-112

10-113

Revision

number

Mark Page

10-131

10-132

10-133

10-134

10-135

10-136

10-137

10-138

10-139

10-140

10-141

10-142

10-143

10-144

10-145

10-146

10-147

10-148

10-149

10-150

10-151

10-152

10-153

10-154

10-155

Revision

number

10-114

10-115

10-116

10-117

10-118

10-119

10-120

10-121

10-122

10-124

10-125

10-126

10-127

10-128

10-129

10-130

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

Q

20-1

20-2

20-3

20-4

20-5

20-6

20-7

20-8

20-9

20-10

20-11

20-101

20-102

20-103

20-104

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

PC130-7 00-2-1

(1)

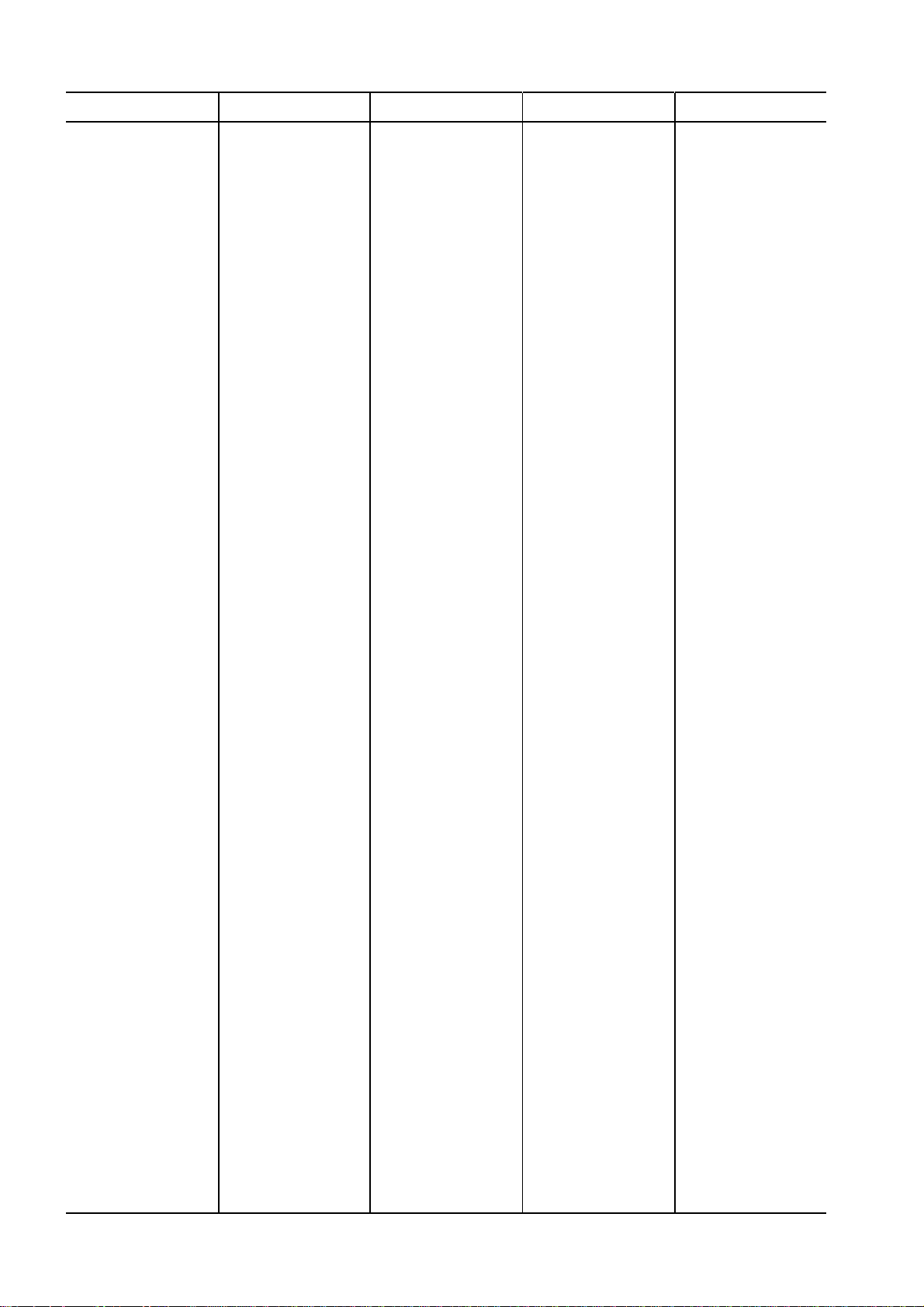

Mark Page

20-105

Q

20-106

Q

20-107

Q

20-108

Q

20-109

Q

20-110

Q

20-111

Q

20-112

Q

20-113

Q

20-114

Q

20-115

Q

20-116

Q

20-117

Q

20-118

Q

20-119

Q

20-120

Q

20-121

Q

20-122

Q

20-123

Q

20-124

Q

20-125

Q

20-126

Q

20-127

Q

20-128

Q

20-129

Q

20-130

Q

20-131

Q

20-132

Q

20-133

Q

20-134

Q

20-135

Q

20-136

Q

20-137

Q

20-138

Q

20-139

Q

20-140

Q

20-141

Q

20-142

Q

20-143

Q

20-144

Q

20-145

Q

20-146

Q

20-147

Q

20-148

Q

20-149

Q

20-150

Q

20-151

Q

20-152

Q

20-153

Q

20-154

Q

20-155

Q

Revision

number

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

Mark Page

20-156

Q

20-157

Q

20-158

Q

20-159

Q

20-160

Q

20-161

Q

20-162

Q

20-163

Q

20-164

Q

20-165

Q

20-166

Q

20-167

Q

20-168

Q

20-169

Q

20-170

Q

20-171

Q

20-201

Q

20-202

Q

20-203

Q

20-204

Q

20-205

Q

20-206

Q

20-207

Q

20-208

Q

20-209

Q

20-210

Q

20-211

Q

20-212

Q

20-213

Q

20-214

Q

20-215

Q

20-216

Q

20-217

Q

20-218

Q

20-219

Q

20-220

Q

20-222

Q

20-223

Q

20-224

Q

20-225

Q

20-226

Q

20-228

Q

20-229

Q

20-230

Q

20-231

Q

20-232

Q

20-233

Q

20-234

Q

20-235

Q

20-236

Q

20-237

Q

Revision

number

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

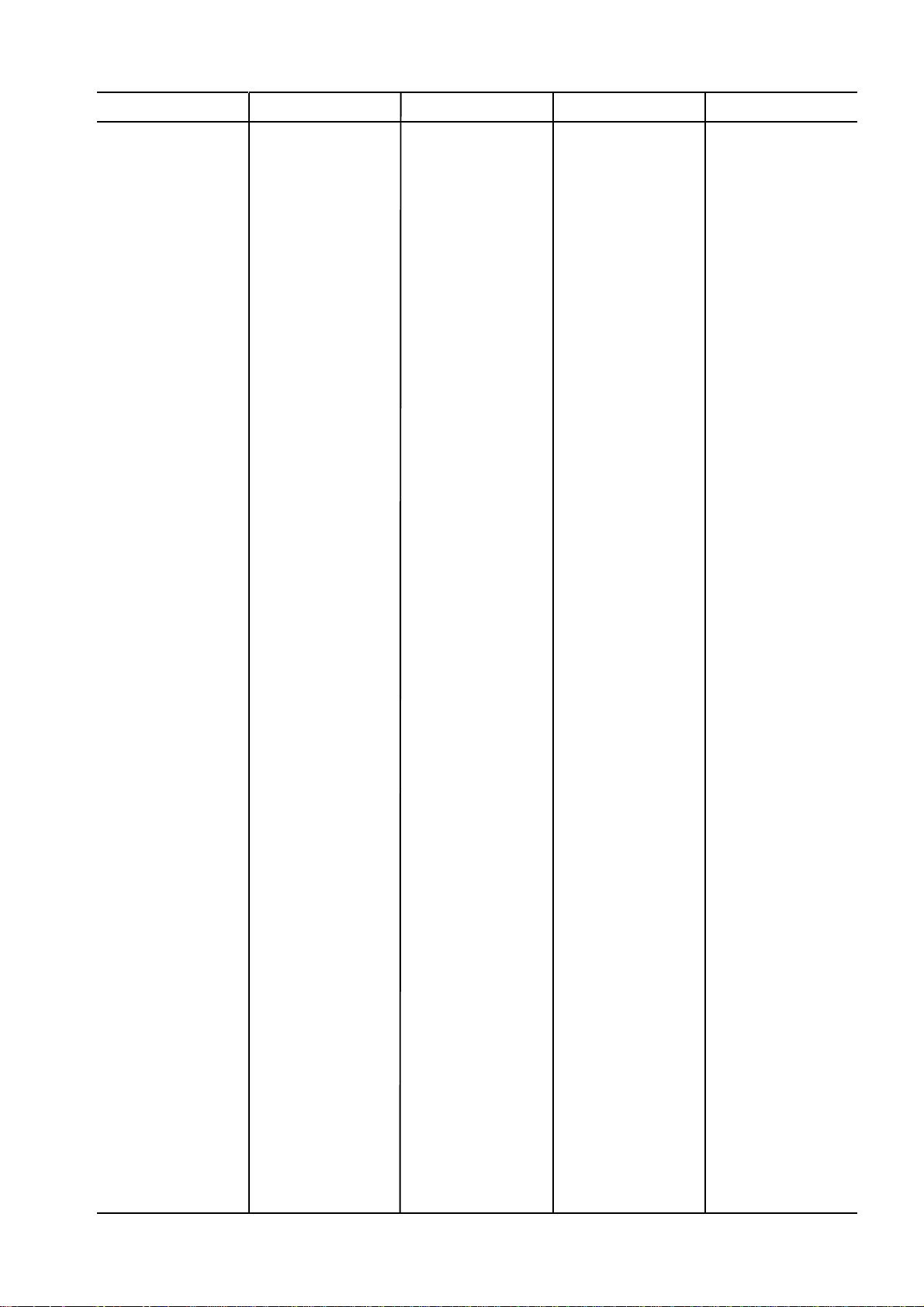

Mark Page

20-238

Q

20-239

Q

20-240

Q

20-241

Q

20-242

Q

20-243

Q

20-244

Q

20-245

Q

20-246

Q

20-247

Q

20-248

Q

20-249

Q

20-250

Q

20-251

Q

20-252

Q

20-253

Q

20-254

Q

20-255

Q

20-256

Q

20-257

Q

20-258

Q

20-301 (1)

Q

20-302 (1)

Q

20-303 (1)

Q

20-304 (1)

Q

20-305 (1)

Q

20-306 (1)

Q

20-307 (1)

Q

20-308 (1)

Q

20-310 (1)

Q

20-311 (1)

Q

20-312 (1)

Q

20-313 (1)

Q

20-314 (1)

Q

20-315 (1)

Q

20-316 (1)

Q

20-317 (1)

Q

20-318 (1)

Q

20-319 (1)

Q

20-320 (1)

Q

20-321 (1)

Q

20-322 (1)

Q

20-323 (1)

Q

20-324 (1)

Q

20-325 (1)

Q

20-326 (1)

Q

20-327 (1)

Q

20-328 (1)

Q

20-329 (1)

Q

20-330 (1)

Q

20-331 (1)

Q

Revision

number

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

Mark Page

20-332 (1)

Q

20-333 (1)

Q

20-334 (1)

Q

20-335 (1)

Q

20-336 (1)

Q

20-337 (1)

Q

20-338 (1)

Q

20-339 (1)

Q

20-340 (1)

Q

20-341 (1)

Q

20-342 (1)

Q

20-343 (1)

Q

20-344 (1)

Q

20-345 (1)

Q

20-346 (1)

Q

20-347 (1)

Q

20-348 (1)

Q

20-349 (1)

Q

20-350 (1)

Q

20-351 (1)

Q

20-352 (1)

Q

20-354 (1)

Q

20-355 (1)

Q

20-356 (1)

Q

20-357 (1)

Q

20-358 (1)

Q

20-359 (1)

Q

20-360 (1)

Q

20-362 (1)

Q

20-363 (1)

Q

20-364 (1)

Q

20-365 (1)

Q

20-401 (1)

Q

20-402 (1)

Q

20-403 (1)

Q

20-404 (1)

Q

20-405 (1)

Q

20-406 (1)

Q

20-408 (1)

Q

20-409 (1)

Q

20-410 (1)

Q

20-411 (1)

Q

20-412 (1)

Q

20-413 (1)

Q

20-414 (1)

Q

20-415 (1)

Q

20-416 (1)

Q

20-417 (1)

Q

20-418 (1)

Q

20-419 (1)

Q

20-420 (1)

Q

Revision

number

Mark Page

20-421 (1)

Q

20-422 (1)

Q

20-423 (1)

Q

20-424 (1)

Q

20-425 (1)

Q

20-426 (1)

Q

20-427 (1)

Q

20-428 (1)

Q

20-429 (1)

Q

20-430 (1)

Q

20-431 (1)

Q

20-432 (1)

Q

20-433 (1)

Q

20-434 (1)

Q

20-436 (1)

Q

20-437 (1)

Q

20-438 (1)

Q

20-439 (1)

Q

20-440 (1)

Q

20-441 (1)

Q

20-442 (1)

Q

20-443 (1)

Q

20-444 (1)

Q

20-445 (1)

Q

20-446 (1)

Q

20-447 (1)

Q

20-448 (1)

Q

20-449 (1)

Q

20-450 (1)

Q

20-451 (1)

Q

20-452 (1)

Q

20-453 (1)

Q

20-454 (1)

Q

20-455 (1)

Q

20-456 (1)

Q

20-457 (1)

Q

20-458 (1)

Q

20-459 (1)

Q

20-460 (1)

Q

20-461 (1)

Q

20-462 (1)

Q

20-463 (1)

Q

20-464 (1)

Q

20-465 (1)

Q

20-466 (1)

Q

20-467 (1)

Q

20-468 (1)

Q

20-469 (1)

Q

20-470 (1)

Q

20-471 (1)

Q

20-472 (1)

Q

Revision

number

00-2-2 PC130-7

(1)

Mark Page

20-473 (1)

Q

20-474 (1)

Q

20-475 (1)

Q

20-476 (1)

Q

20-501

Q

20-502

Q

20-504

Q

20-505

Q

20-506

Q

20-507

Q

20-508

Q

20-509

Q

20-510

Q

20-511

Q

20-512

Q

20-513

Q

20-514

Q

20-515

Q

20-516

Q

20-517

Q

20-518

Q

20-519

Q

20-520

Q

20-521

Q

20-522

Q

20-523

Q

20-524

Q

20-525

Q

20-601

Q

20-602

Q

20-603

Q

20-604

Q

20-605

Q

20-606

Q

20-607

Q

20-608

Q

20-609

Q

20-610

Q

20-611

Q

20-612

Q

20-613

Q

20-614

Q

20-615

Q

20-616

Q

20-617

Q

20-618

Q

20-619

Q

20-620

Q

20-621

Q

20-622

Q

20-623

Q

Revision

number

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

(1)

Mark Page

20-624

Q

40-1

40-2

40-3

40-4

40-5

40-6

40-7

40-8

40-9

40-10

40-11

40-12

40-13

40-14

40-15

40-16

40-17

40-18

40-19

40-20

40-21

40-22

40-23

40-24

40-25

40-26

40-27

40-28

40-29

40-30

40-31

40-32

40-34

40-35

40-36

40-37

40-38

40-39

40-40

40-41

90-1 (1)

q

90-3

90-5 (1)

q

90-7 (1)

q

90-9 (1)

q

90-11 (1)

q

90-13 (1)

Q

90-15 (1)

Q

Revision

number

(1)

Mark Page

90-17 (1)

Q

90-19 (1)

Q

Revision

number

Mark Page

Revision

number

Mark Page

Revision

number

PC130-7 00-2-3

(1)

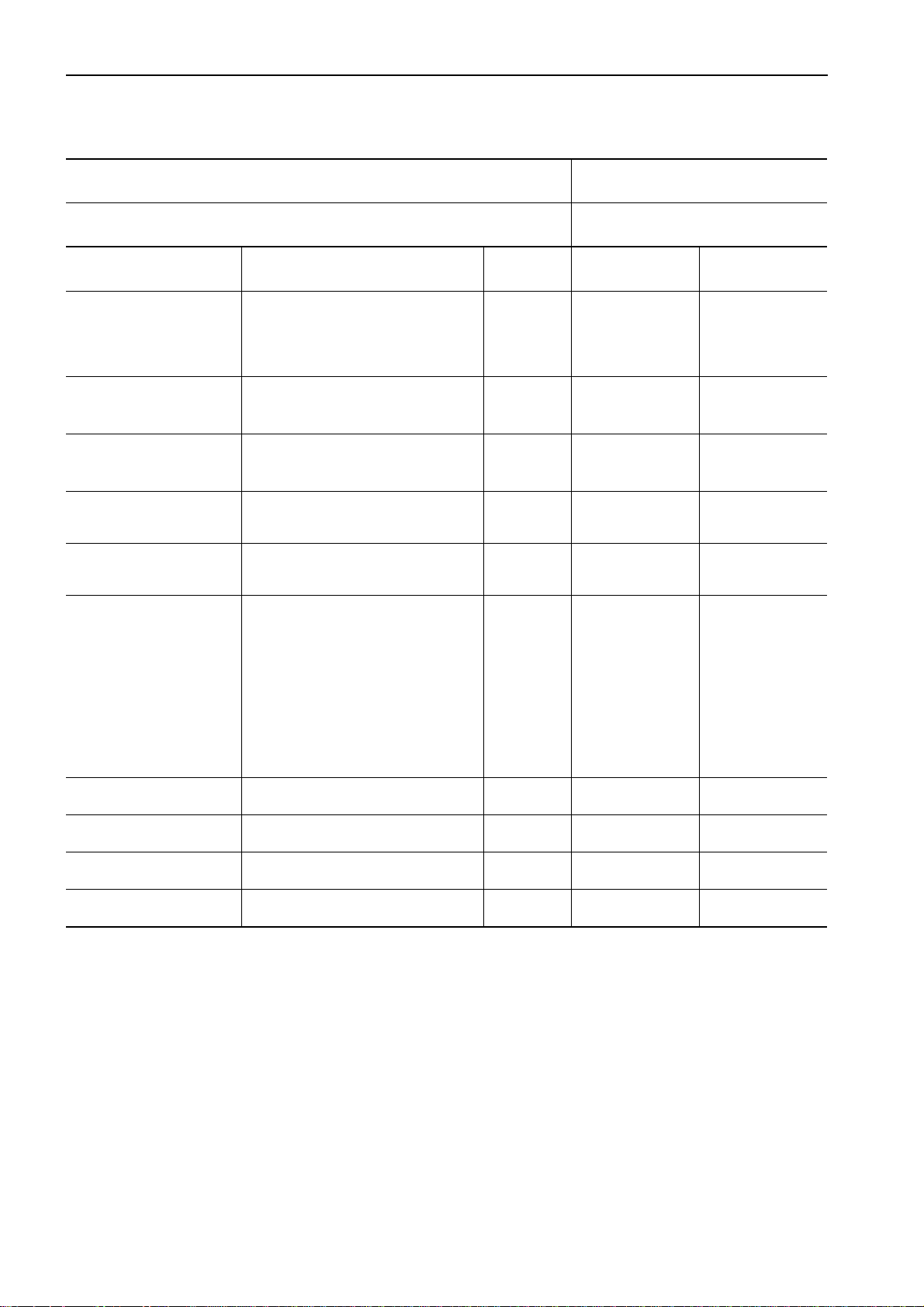

20 TESTING AND ADJUSTING

STANDARD VALUE TABLE FOR ENGINE.......... 20- 2

STANDARD VALUE TABLE FOR CHASSIS........20- 3

TESTING AND ADJUSTING............ ...... ....... ...... . 20-101

TROUBLESHOOTING ......................................... 20-201

Note the following when makin g judgements using the standard value tables for testi ng, adjusting , or troubleshooting.

1. The standard value for a new machine given in the table is the value used when shipping the machine from

the factory and is given for reference. It is used as a guideline for judging the progress of wear after the

machine has been operated, and as a reference value when carrying out repairs.

2. The servic e limit value given in the tables is the estimate d value for the shipped machine based on the

results of various tests. It is used for r efer en ce together with the state of repair and the histo ry of op erati on

to judge if there is a failure.

3. These standard values are not the standards used in dealing with claims.

When carrying out testing, adjusting, or troubleshooting, park the machine on level ground, inset the safety

pins, and use blocks to prevent the machine from moving.

When carrying out work together with other workers, always use signals and do not let unauthorized people

near the machine.

When checking the water level, always wait for the water to cool down. If the radiator cap is removed when

the water is still hot, the water will spurt out and cause burns.

Be careful not to get caught in the fan, fan belt or other rotating parts.

PC130-7 20-1

(1)

TESTING AND ADJUSTING

STANDARD VALUE TABLE FOR ENGINE

Model name PC130-7

Engine SAA4D95LE-3

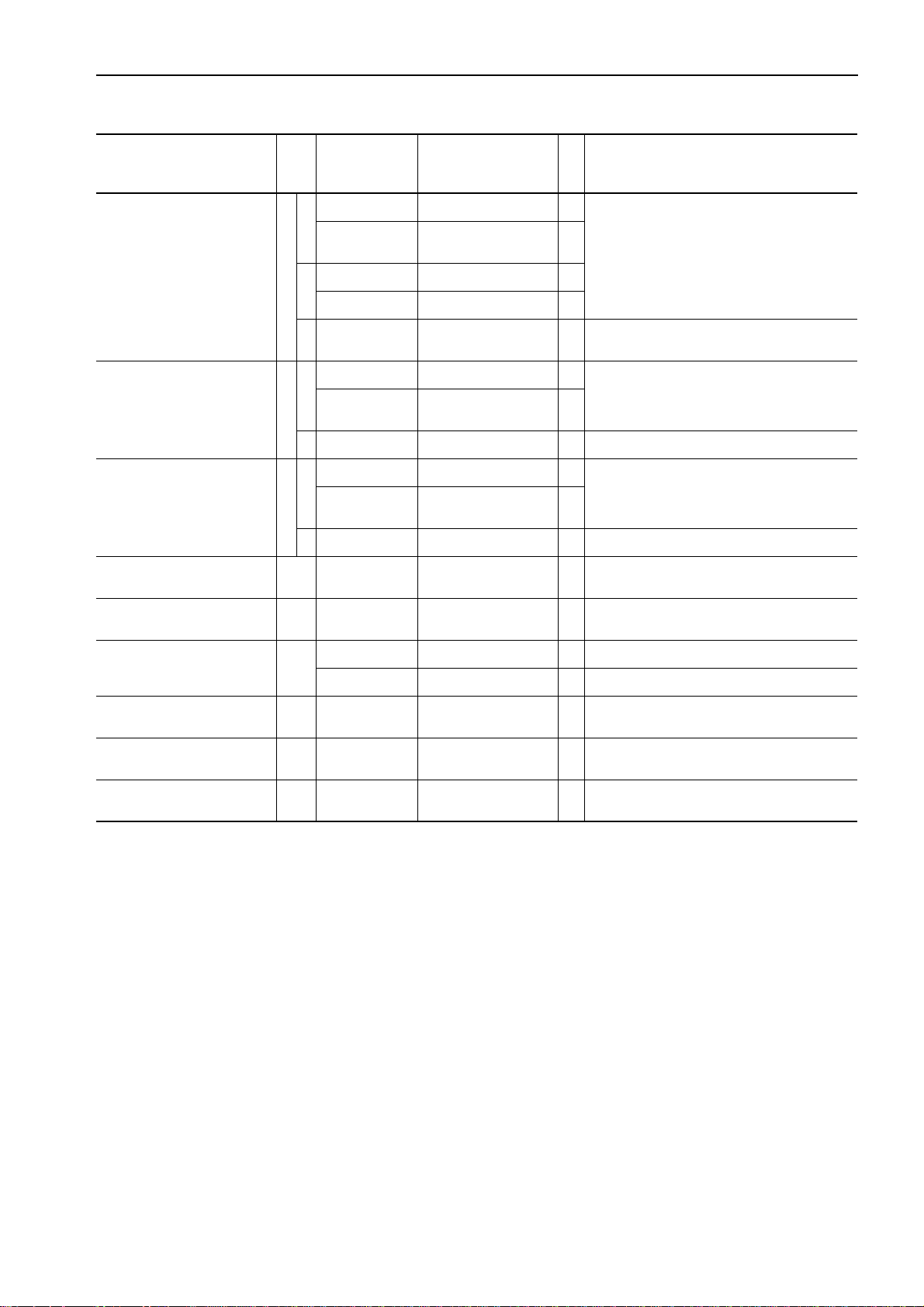

Item Measurement condition Unit Standard value Permissible value

STANDARD VALUE TABLE FOR ENGINE

High idling

Engine speed Low idling 1,100 ± 50 1,100 ± 50

Rated speed 2,200 —

Exhaust gas color

Valve clearance

(Cooled)

Compression pressure

Blow-by pressure

Oil pressure

During sharp acceleration

During high idling Max. 1.0 Max. 2.0

Intake valve

Exhaust valve 0.50 —

Oil temperature: 40 – 60 °C

(Engine speed)

Coolant temperature:

Within operating range

At rated output

Coolant temperature:

Within operating range

At high idling (SAE30)

At high idling (SAE10W)

At low idling (SAE30)

At high idling (SAE10W)

rpm

Bosch

index

mm

MPa

{kg/cm

(rpm)

kPa

{mmH

MPa

{kg/cm

2

}

O}

2

2

}

2,350 ± 100 2,350 ± 100

Max. 4.5 Max. 6.5

0.35 —

Min. 2.9

{Min. 30}

(320 – 360)

Max. 0.49

{Max. 50}

0.34 – 0.59

{3.5 – 6.0}

0.29 – 0.54

{3.0 – 5.5}

Min. 0.1

{Min. 1.0}

Min. 0.08

{Min. 0.8}

2.0

{20}

(320 – 360)

0.98

{100}

0.25

{2.5}

0.21

{2.1}

0.07

{0.7}

0.07

{0.7}

Oil temperature Through speed range (In oil pan) °C 90 – 110 120

Fuel injection timing Before top dead center (BTDC) ° 6 ± 0.75 6 ± 0.75

Fan belt tension

Air conditioner compres-

sor belt tension

Deflection under finger pressure of

58.8 N {6 kg}

Deflection under finger pressure of

58.8 N {6 kg}

mm 6 – 10 6 – 10

mm 6 – 10 6 – 10

20-2 PC130-7

(1)

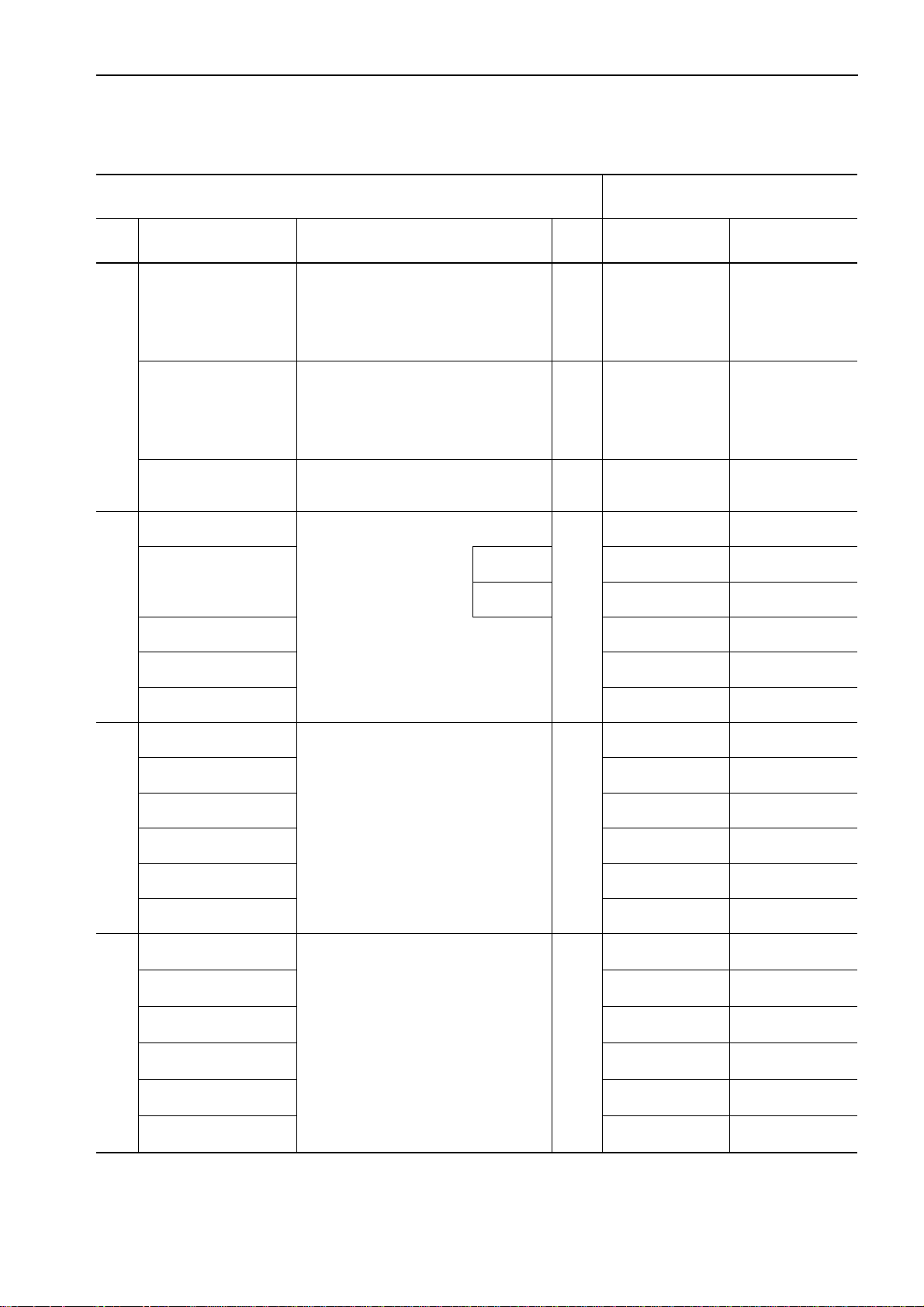

TESTING AND ADJUSTING

STANDARD VALUE TABLE FOR CHASSIS

STANDARD VALUE TABLE FOR CHASSIS

Model name PC130-7

Cate-

gory

Engine speed

Control val v e spool stroke

Item Measurement condition Unit Standard value Permissible value

• Engine coolant temperature:

Pump relief

Pump relief + Onetouch power maximizing

During auto-deceleration

Boom control valve • Engine: Stopped

Arm control valve

Bucket control valve 8.0 ± 0.5 8.0 ± 0.5

Swing control valve 8.0 ± 0.5 8.0 ± 0.5

Travel control valve 8.0 ± 0.5 8.0 ± 0.5

• Hydraulic oil temperature: 45 – 55 °C

• Engine speed: High idling

• Working mode: A

• Arm OUT relief

• Engine coolant temperature:

• Hydraulic oil temperature: 45 – 55 °C

• Engine speed: High idling

• Arm OUT relief + One-touch power

maximizing switch ON

• Engine speed: High idling

• Auto-decelerator switch: ON

• All control levers in neutral

Within operating range

rpm 2,120 ± 100 2,120 ± 100

Within operating range

rpm 2,180 ± 100 2,180 ± 100

rpm 1,400 ± 100 1,400 ± 100

8.0 ± 0.5 8.0 ± 0.5

IN 9.5 ± 0.5 9.5 ± 0.5

OUT 8.0 ± 0.5 8.0 ± 0.5

mm

Boom control lever

Arm control lever 85 ± 10 85 ± 10

Bucket control lever 85 ± 10 85 ± 10

Swing control lever 85 ± 10 85 ± 10

Travel control lever 112 ± 15 112 ± 15

Control lever stroke

Play of control lever 10 ± 15 10 ± 15

Boom control lever

Arm control lever

Bucket control lever

Swing control lever

Travel control lever

Travel control pedal

Operating effort of control lever

• Engine: Stopped

• Center of lever grip

• Read max. value to stroke end

(Exclude play in neutral position).

• Hydraulic oil temperature:

Within operating range

• Engine speed: High idling

• Center of lever grip

• Tip of pedal

• Read max. value to stroke end

mm

N

{kg}

85 ± 10 85 ± 10

15.7 ± 3.9

{1.6 ± 0.4}

15.7 ± 3.9

{1.6 ± 0.4}

12.7 ± 2.9

{1.3 ± 0.3}

12.7 ± 2.9

{1.3 ± 0.3}

24.5 ± 5.9

{2.5 ± 0.6}

80.4 ± 20.1

{8.2 ± 2.0}

Max. 24.5

{Max. 2.5}

Max. 24.5

{Max. 2.5}

Max. 21.6

{Max. 2.2}

Max. 21.6

{Max. 2.2}

Max. 39.2

{Max. 4.0}

Max. 107.9

{Max. 11}

PC130-7 20-3

(1)

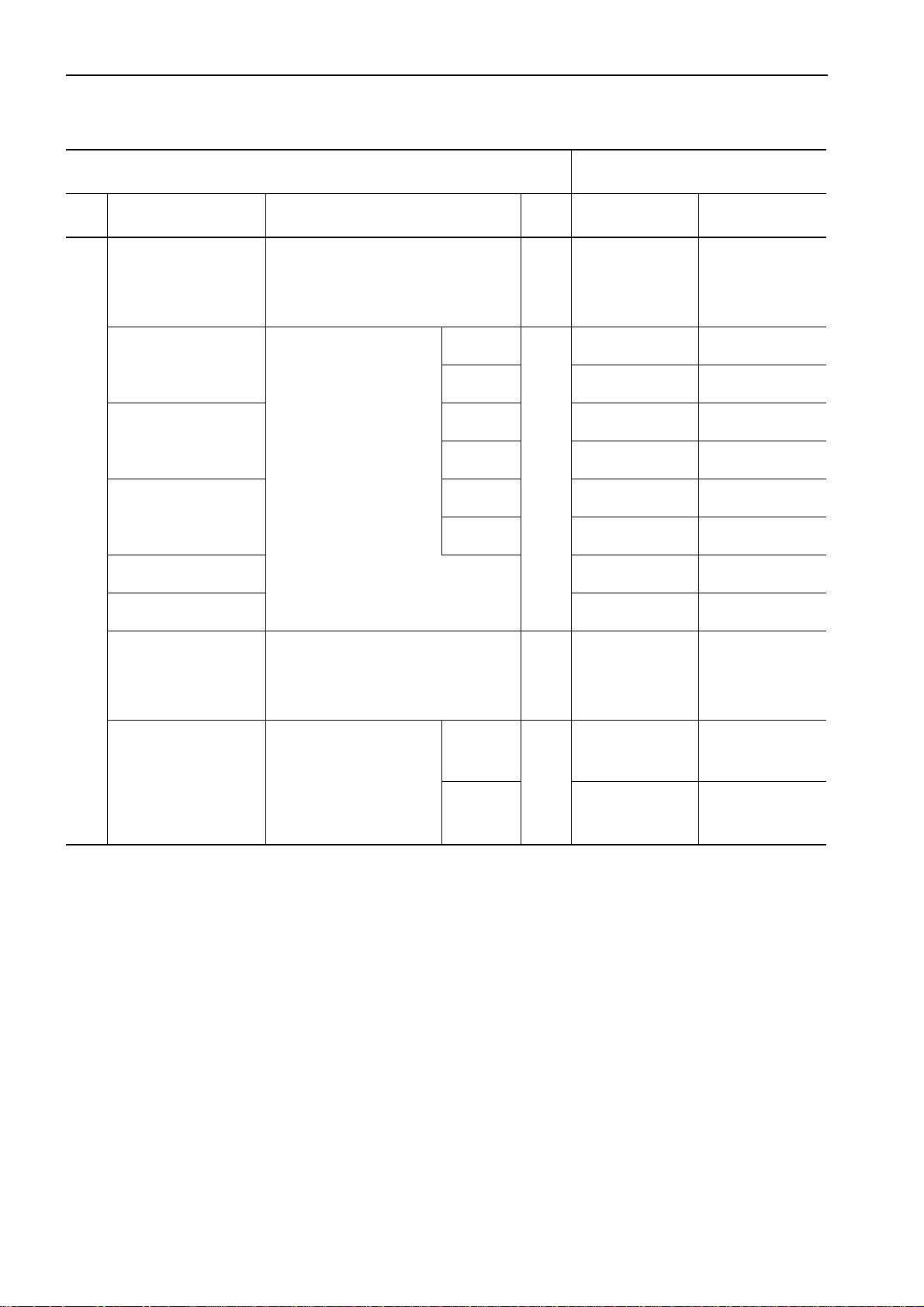

TESTING AND ADJUSTING

+2.00+20

0

+2.00+200+2.00+20

0

+1.0

–0.7

+10

– 7

+1.0

–0.7

+10

– 7

STANDARD VALUE TABLE FOR CHASSIS

Model name PC130-7

Cate-

gory

Oil pressure

Item Measurement condition Unit Standard value Permissible value

Unload pressure

Boom relief pressure

Arm relief pressure

Bucket relief pressure

Swing relief pressure

Travel relief pr essure

Control circuit basic

pressure

LS differential pressure

• Hydraulic oil temperature: 45 – 55 °C

• Engine speed: High idling

• Working mode: A

• Pump outlet pressure when all levers

are in neutral

• Hydraulic oil temperature: 45 – 55 °C

• Engine speed:

High idling

• Working mode: A

• Pump outlet pressure

when measured c ircuit is

relieved

At normal

relief

At power

max.

At normal

relief

At power

max.

At normal

relief

At power

max.

• Hydraulic oil temperature: 45 – 55 °C

• Engine speed: High idling

• Outlet pressure of self-reducing pressure valve when all levers are in neutral

• Hydraulic oil temper atur e:

45 – 55 °C

• Engine speed: High idling

• Working mode: A

• Pump pressure - LS pressure

When all

levers are

in neutral

When

travel system runs

idle at Hi

MPa

{kg/cm2}

MPa

{kg/cm2}

MPa

{kg/cm2}

MPa

{kg/cm2}

2.9 ± 0.5

{30 ± 5}

31.9

{325 }

34.8 ± 1.0

{355 ± 10}

31.9

{325 }

34.8 ± 1.0

{355 ± 10}

31.9

{325 }

34.8 ± 1.0

{355 ± 10}

28.9 ± 1.5

{295 ± 15}

34.8 ± 1.0

{355 ± 10}

3.23 ± 0.2

{33 ± 2}

2.7

{28 }

2.2 ± 0.1

{22.5 ± 1}

2.9 ± 0.5

{30 ± 5}

33.3 – 36.8

{340 – 375}

36.3 – 39.2

{370 – 400}

33.3 – 36.8

{340 – 375}

36.3 – 39.2

{370 – 400}

33.3 – 36.8

{340 – 375}

36.3 – 39.2

{370 – 400}

28.9 – 32.9

{295– 335}

36.3 – 39.2

{370 – 400}

2.84 – 3.43

{29 – 35}

2.7

{28 }

2.2 ± 0.1

{22.5 ± 1}

20-4 PC130-7

(1)

TESTING AND ADJUSTING

STANDARD VALUE TABLE FOR CHASSIS

Model name PC130-7

Cate-

gory

Item Measurement condition Unit Standard value Permissible value

Overrun of swing

Time taken to start

swinging

• Hydraulic oil temperature: 45 – 55 °C

• Engine speed: High idling

• Working mode: A

• Quantity of overrun of swing circle

when it stops after 1 turn

• ( ): Qty of overrun of periphery of

swing circle

90°

• Hydraulic oil temperature:

• Engine speed: High idling

• Working mode: A

• Time taken to swing 90° and

180° after starting

45 – 55 °C

180° 4.0 ± 0.4 Max. 8.5

deg

(mm)

sec

75 ± 10

{730 ± 100}

2.9 ± 0.3 Max. 3.5

Max. 90

(Max. 870)

Swing

Time taken to swing

Hydraulic drift of swing

sec 28.6 ± 4.8 28.6 ± 5.8

• Hydraulic oil temperature: 45 – 55 °C

• Engine speed: High idling

• Working mode: A

• Time taken to swing 5 turns after

swinging 1 turn

mm 0 0

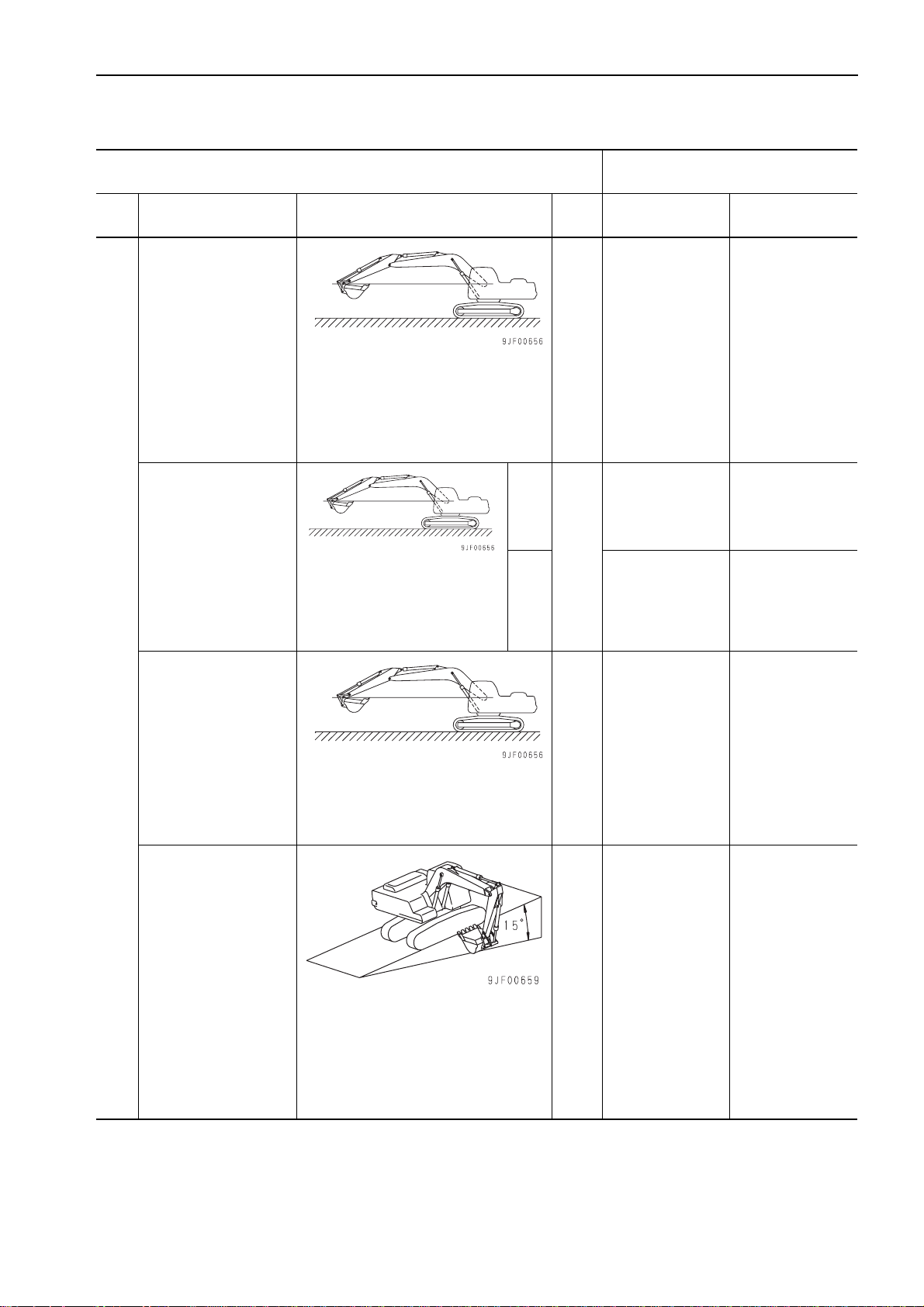

• Hydraulic oil temperature: 45 – 55 °C

• Engine: Stopped

• Set upper structure at 90° to machine

body on slope of 15°.

• Make match marks on inner race and

outer race of swing circle.

• Measure deviation of match marks in

15 minutes.

PC130-7 20-5

(1)

TESTING AND ADJUSTING

STANDARD VALUE TABLE FOR CHASSIS

Model name PC130-7

Cate-

gory

Swing

Travel

Item Measurement condition Unit Standard value Permissible value

Leakage from swing

motor

Travel speed (Idle run)

Travel speed

(Actual travel)

• Hydraulic oil temperature: 45 – 55 °C

• Engine speed: High idling

• Swing lock switch: LOCK

• Measure leakage for 1 minutes while

swing circuit is relieved.

Lo

• Hydraulic oil temperature:

• Engine speed: High idling

• Working mode: A

• Measure time taken to rotate

track shoe 5 turns after 1 turn.

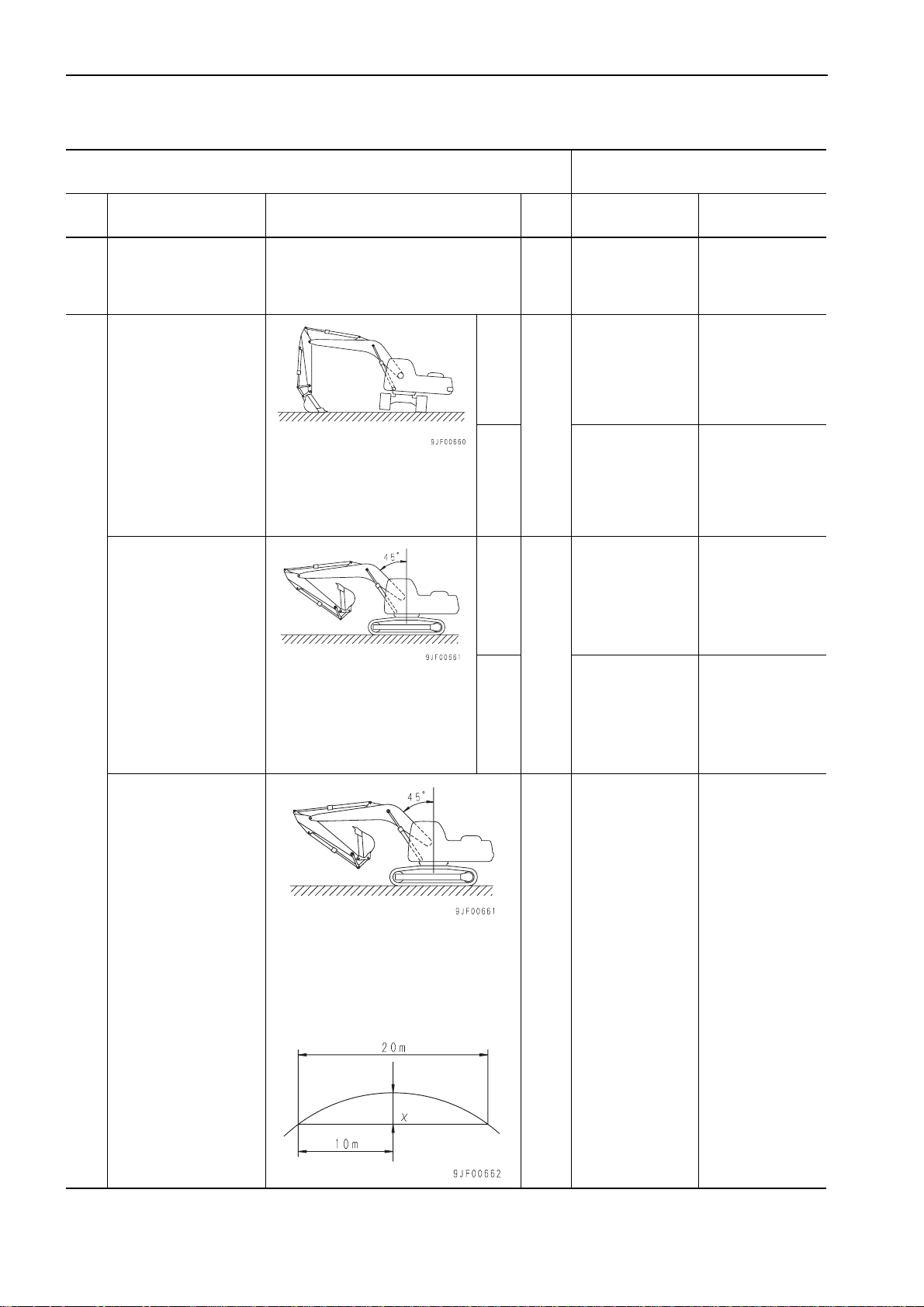

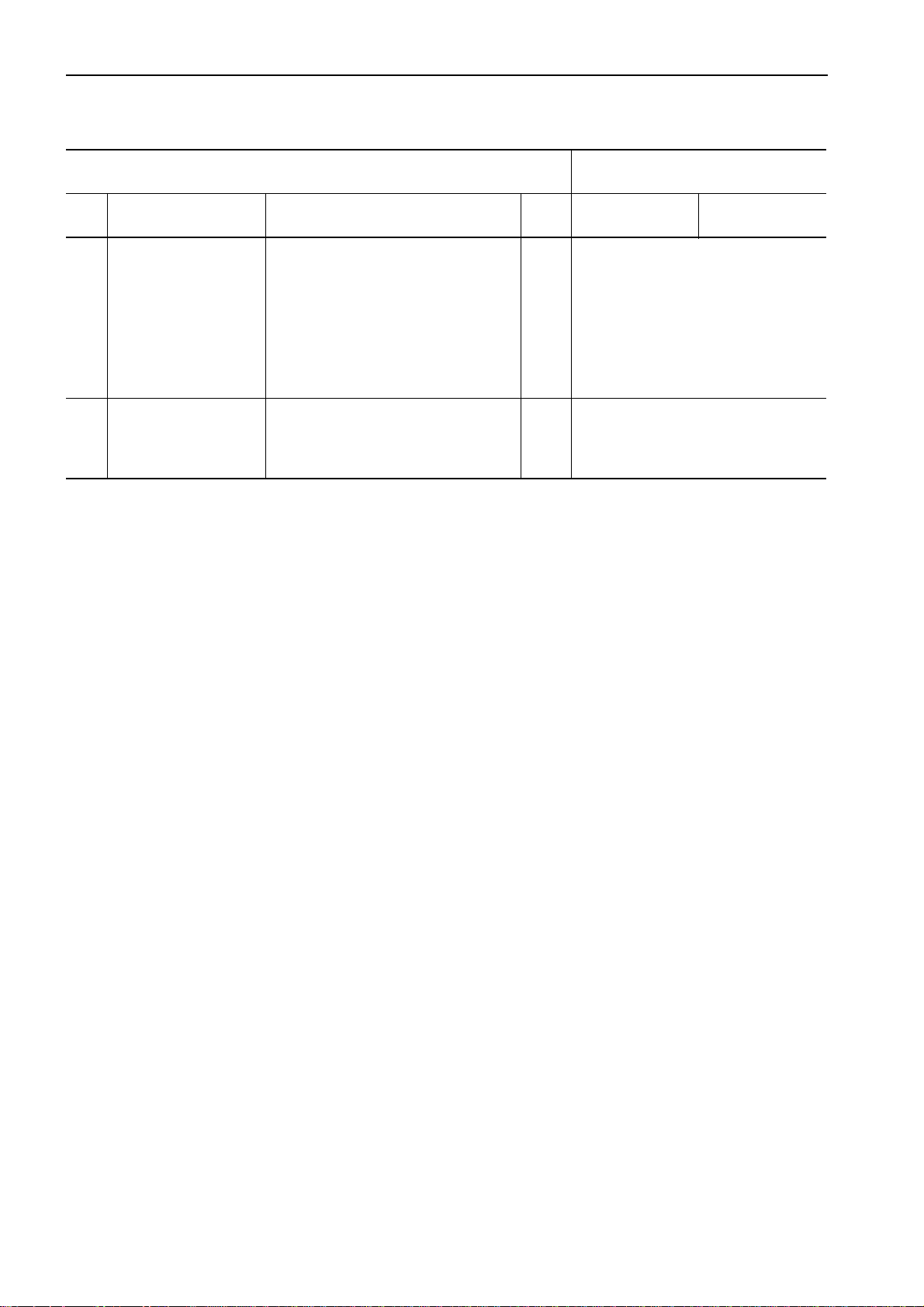

• Hydraulic oil temperature:

• Engine speed: High idling

• Working mode: A

• Hard and level place

• Measure time taken to travel 20

m after running up 10 m.

45 – 55 °C

45 – 55 °C

Hi 21.9 ± 2.2 23.1 ± 3.0

Lo 27.6 ± 5.1 27.6 ± 7.1

Hi 13.2 ± 1.2 13.2 ± 1.7

l/min Max. 3 Max. 6

46.1 ± 9.2 46.1 ± 9.2

sec

• Hydraulic oil temperature: 45 – 55 °C

• Engine speed: High idling

Travel deviation

• Working mode: A

• Travel speed: Lo

• Hard and level place

• Measure travel deviation in travel of

20 m after running up 10 m.

mm Max. 200 Max. 220

20-6 PC130-7

(1)

TESTING AND ADJUSTING

STANDARD VALUE TABLE FOR CHASSIS

Model name PC130-7

Cate-

gory

Travel

Item Measurement condition Unit Standard value Permissible value

Hydrauli c drift of travel

Leakage from travel

motor

Whole work

equipment

(Hydraulic drift of tooth tip)

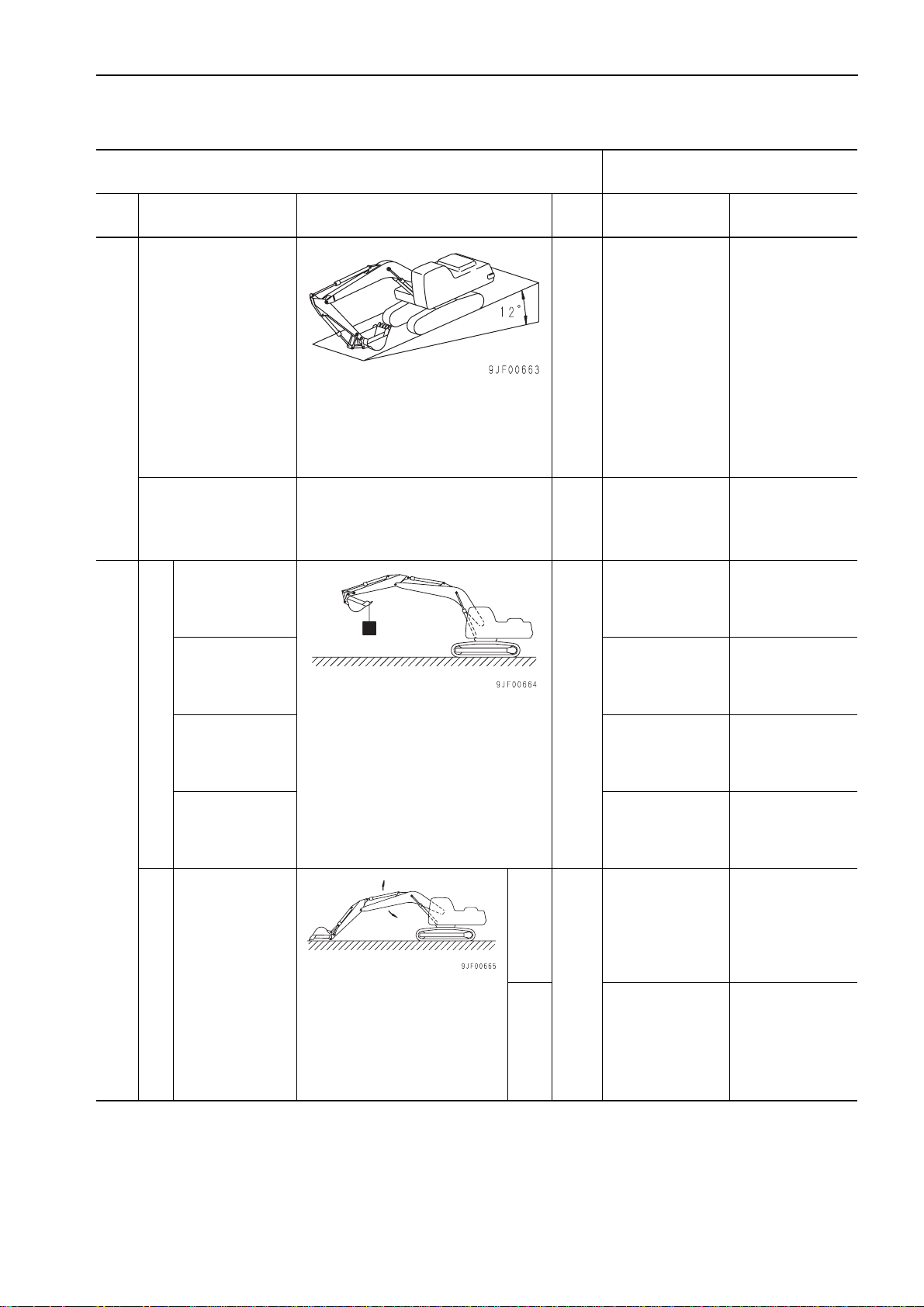

• Hydraulic oil temperature: 45 – 55 °C

• Engine: Stopped

• Stop mac hi ne on slope of 12 degrees

with sprocket on upper side.

• Measure hydraulic drift of travel in 5

minutes.

• Hydraulic oil temperature: 45 – 55 °C

• Engine speed: High idling

• Lock sprocket.

• Measure leakage for 1 minutes while

travel circuit is relieved.

mm 0 0

l/min Max. 5 Max. 10

Max. 460 Max. 700

Boom cylinder

(Retraction of cylinder)

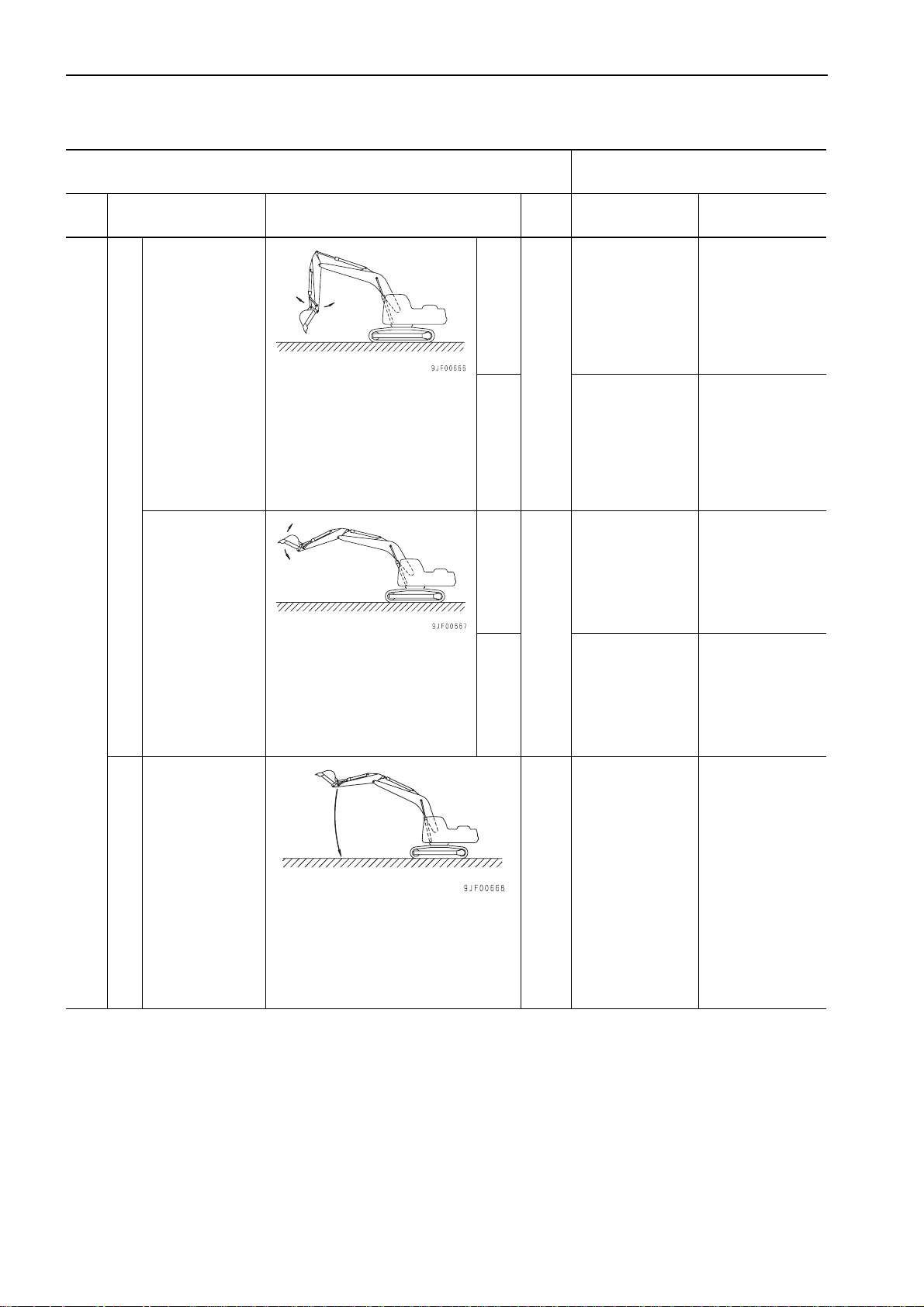

• Hydraulic oil temperature: 45 – 55 °C

• Level and flat place

Arm cylinder

(Extension of cylinder)

Hydraulic drift of work equipment

Bucket cylinder

(Retraction of cylinder)

Work equipment

Boom speed

Work equipment speed

• Bucket: Full of dirt and sand or filled

with rated load (1,080 kg)

• Level boom top, retract arm cylinder

fully, and extract bucket cylinder fully.

• Engine: Stopped

• Work equipment con trol lev er: Ne utra l

• Start measuring hy draulic drift just

after setting machine and measure

every 5 minutes for 15 minutes.

RAISE

• Hydraulic oil temperature:

• Engine speed: High idling

• Working mode: A

• Measure time taken to move

bucket between RAISE stroke

end and ground touch point of

bucket.

45 – 55 °C

LOWER

mm

sec

Max. 10 Max. 12

Max. 80 Max. 90

Max. 22 Max. 40

3.7 ± 0.4 Max. 4.3

2.6 ± 0.5 Max. 3.2

PC130-7 20-7

(1)

TESTING AND ADJUSTING

STANDARD VALUE TABLE FOR CHASSIS

Model name PC130-7

Cate-

gory

Work equipment

Item Measurement condition Unit Standard value Permissible value

Arm speed

Work equipment speed

Bucket speed

• Hydraulic oil temperature:

45 – 55 °C

• Engine speed: High idling

• Working mode: A

• Measure time taken to move

arm between OUT stroke end

and IN stroke end (between

starting points of cushion).

• Hydraulic oil temperature:

45 – 55 °C

• Engine speed: High idling

• Working mode: A

• Measure time taken to move

bucket between DUMP stroke

end and CURL stroke end

CURL

sec

DUMP

CURL

sec

DUMP

3.2 ± 0.4 Max. 4.4

3.1 ± 0.3 Max. 3.7

2.9 ± 0.3 Max. 3.7

2.3 ± 0.2 Max. 2.9

Boom time lag

Time lag

• Hydraulic oil temperature: 45 – 55 °C

• Engine speed: Low idling

• Working mode: A

• Lower boom from RAISE stroke end

and measure time taken to start raising front of machine after bucket

touches ground.

sec Max. 3.0 Max. 4.0

20-8 PC130-7

(1)

TESTING AND ADJUSTING

STANDARD VALUE TABLE FOR CHASSIS

Model name PC130-7

Cate-

gory

Work equipment

Item Measurement condition Unit Standard value Permissible value

Arm time lag

Time lag

Bucket time lag

Cylinder

Center swivel joint Max. 10 Max. 50

Oil leakage

Travel deviation in

compound operation

of work equipment and

travel

• Hydraulic oil temperature: 45 – 55 °C

• Engine speed: Low idling

• Working mode: A

• Move IN ar m from OUT stroke end

and measure time taken to start moving arm again after it is stopped.

• For measuring posture, see WORK

EQUIPMENT 6.

• Hydraulic oil temperature: 45 – 55 °C

• Engine speed: Low idling

• Working mode: A

• Curl bucket from DUMP stroke end

and measure time taken to start moving bucket again after it is stopped.

• For measuring posture, see WORK

EQUIPMENT 7.

• Hydraulic oil temperature: 45 – 55 °C

• Engine speed: High idling

• Relieve cylinder to be measured or

travel circuit and measure leakage in

1 minute.

• Hydraulic oil temperature: 45 – 55 °C

• Engine speed: High idling

• Working mode: A

• Travel speed: Lo

• Hard and level place

• Measure travel deviation in travel of

20 m after running up 10 m.

sec Max. 2.0 Max. 3.0

sec Max. 2.0 Max. 3.0

Max. 3.5 Max. 15

cc/min

mm Max. 500 Max. 500

Compound operation performanc e

PC130-7 20-9

(1)

TESTING AND ADJUSTING

STANDARD VALUE TABLE FOR CHASSIS

Model name PC130-7

Cate-

gory

PC flow control

Pump

Item Measurement condition Unit Standard value Permissible value

Time taken to swing

90° in compound op eration of raising boom

and starting swinging

characteristics

Hydraulic pump

capacity

performance

• Hydraulic oil temperature: 45 – 55 °C

• Engine: High idling

• Working mode: A

• Bucket: Filled with rated load

• Hard and level place

• Set arm vertically and lower back of

bucket to ground.

• Raise boom and start swinging simultaneously from above posture and

measure time taken to pass 90° point.

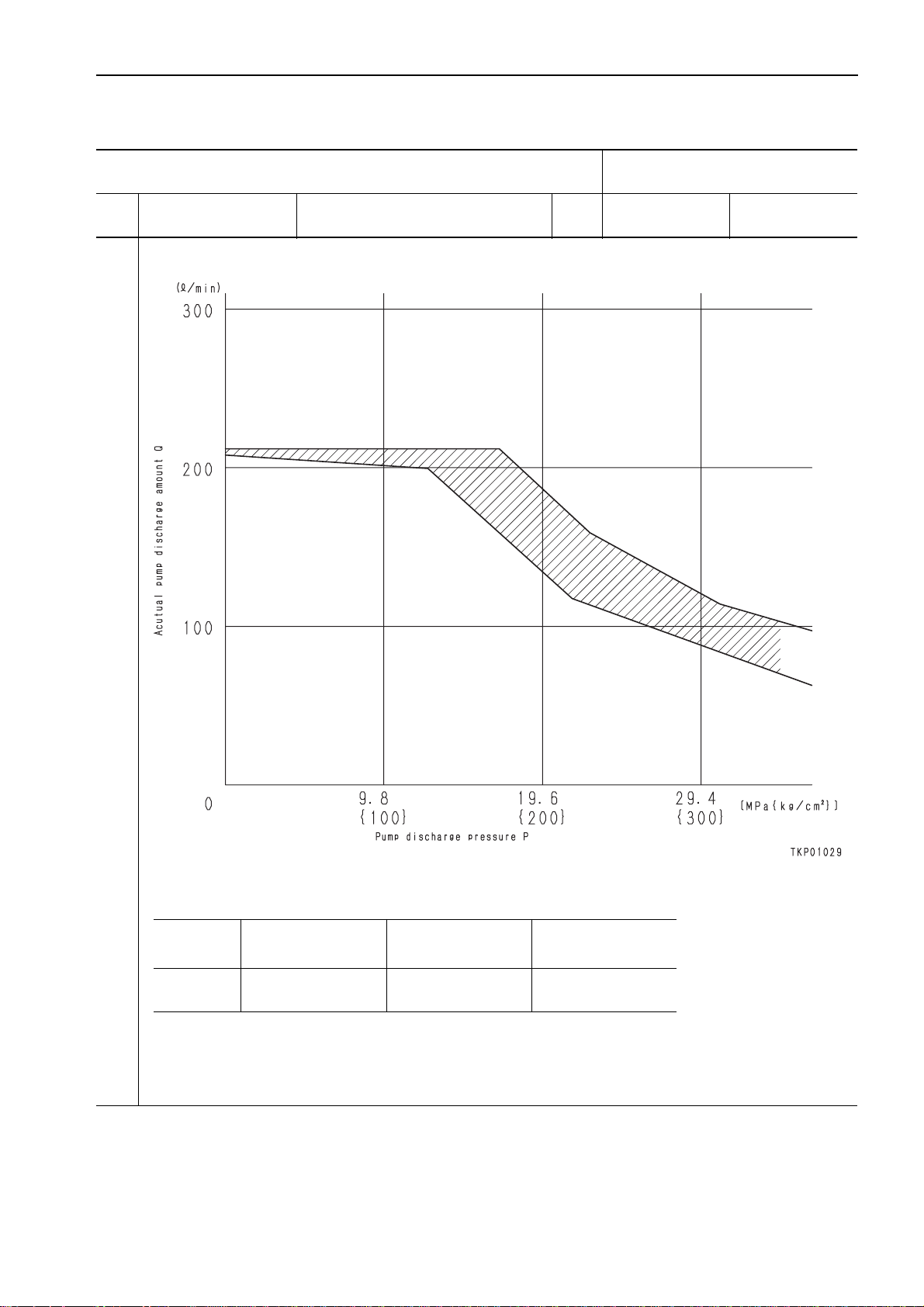

• See graph. l/min See graph.

sec

4.0

(Reference value)

20-10 PC130-7

(1)

TESTING AND ADJUSTING

STANDARD VALUE TABLE FOR CHASSIS

Model name PC130-7

Cate-

gory

Item Measurement condition Unit Standard value Permissible value

Hydraulic pump performance

Pump performance

• PC-EPC current: 400 mA

• Pump speed: 2,000 rpm

Check point

Any point P

a Avoid measuring near a broken point of the graph, since the error becomes large at that point.

a When measuring without removing the pump from the machine, if the engine speed cannot be set to the speci-

fied speed with the fuel control dial, calc ulate the pump discharge pressure at the specified speed from the

engine speed and pump discharge at the time of measurement.

Test pump discharge

pressure

(MPa{kg/cm2})

Standard discharge

(l/min)

Q

(See graph)

Lower limit of

discharge

(l/min)

Q

(See graph)

PC130-7 20-11

(1)

TESTING AND ADJUSTING

TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING ......................................................... 20-102

TESTING AND ADJUSTING ENGINE SPEED ..........................................................................................20-104

MEASURING EXHAUST GAS COLOR ....................................................................................... ....... .......20-105

ADJUSTING VALVE CLEARANCE ......... ....... ...... ....... ...... ....... ...... ...... ....... ....................................... ....... 20-107

MEASURING COMPRESSION PRESSURE ............................................................................................. 20-109

MEASURING BLOW-BY PRESSURE ....................................................................................................... 20-110

MEASURING ENGINE OIL PRESSURE ................................................................................................... 20-111

TESTING AND ADJUSTING FOR FUEL INJECTION TIMING ................................................................ 20-112

ADJUSTING ENGINE SPEED SENSOR ....................................... ...... ....... ...... ....... ................................. 20-116

TESTING AND ADJUSTING FAN BELT TENSION .................................................................................. 20-117

TESTING AND ADJUSTING AIR CONDITIONER COMPRESSOR BELT TENSION .............................. 20-118

MEASURING CLEARANCE OF SWING CIRCLE BEARING .................................................................... 20-119

TESTING AND ADJUSTING TRACK SHOE TENSION ............................................................................ 20-120

TESTING AND ADJUSTING OIL PRESSURE IN WORK EQUIPMENT, SWING, AND TRAVEL CIRCUITS

MEASURING CONTROL CIRCUIT BASIC PRESSURE ........................................................................... 20-125

TESTING AND ADJUSTING OIL PRESSURE IN PUMP PC CONTROL CIRCUIT .................................. 20-126

TESTING AND ADJUSTING OIL PRESSURE IN PUMP LS CONTROL CIRCUIT .................................. 20-129

MEASURING SOLENOID VALVE OUTPUT PRESSURE .........................................................................20-133

MEASURING PPC VALVE OUTPUT PRESSURE .................................................................................... 20-135

ADJUSTING PLAY OF WORK EQUIPMENT AND SWING PPC VALVES ............................................... 20-136

TESTING PARTS WHICH CAUSE HYDRAULIC DRIFT OF WORK EQUIPMENT .................................. 20-137

MEASURING OIL LEAKAGE ..................................................................................................................... 20-139

RELEASING RESIDUAL PRESSURE IN HYDRAULIC CIRCUIT ............................................................. 20-142

BLEEDING AIR FROM EACH PART ......................................................................................................... 20-143

TESTING PROCEDURE FOR DIODE ......................................................................................................20-146

SPECIAL FUNCTIONS OF MONITOR PANEL ......................................................................................... 20-147

PREPARATION WORK FOR TROUBLESHOOTING FOR ELECTRIC SYSTEM .................................... 20-166

PM-CLINIC SERVICE................................................................................................................................. 20-167

....... 20-122

PC130-7 20-101

(1)

TESTING AND ADJUSTING

TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

Testing and adjusting item

Measuring exhaust gas

color

Adjusting valve clearance

Measuring compression

pressure

Measuring blow-by pressure

Measuring engine oil pressure

Part No. Part name

Symbol

1 799-203-9000

A

Commercially

2

available

Commercially

B

available

795-502-1205 Compres sion gauge 1 0 – 6.9MPa {0 – 70kg/cm2}

C

795-502-1370 Adapter 1

6204-11-3880 Gasket 1

D

799-201-1504 Blow-by checker 1 —

799-101-5002 Hydraulic tester 1

1

790-261-1203

E

2 799-401-2320 Hydraulic tester 1 Pressure gauge: 0.98MPa {10kg/cm

3

799-401-3500 Adapter 1 Size: 06

799-101-5220 Nipple 1

4

07002-11023 O-ring 1

Handy smoke

checker

Smoke meter 1

Feeler gauge 1

Digital hydraulic

tester

Q'ty

1

Pollution level: 0 – 70% (With standard

color)

(Pollution level x 1/10 C Bosch index)

(Air intake side: 0.35 mm, Exhaust side:

0.50 mm)

For 95E-3 engine

Pressure gauge: 2.5,5.9,39.2,58.8MPa

1 Pressure gauge: 58.8MPa {600kg/cm

Size: 10 x 1.25mm

Remarks

{25,60,400,600kg/cm

2

}

2

}

2

}

Measuring fuel injection

timing

Measuring clearanc e of

swing circle bearing

Testing and adjusting oil

pressure in work equipment, swing, and travel circuits

Measuring control circuit

basic pressure

Testing and adjusting oil

pressure in pump PC control circuit

1

795-102-2103 Spring pusher 1

F

Commercially

2

available

Commercially

G

available Dial gauge 1 —

799-101-5002 Hydraulic tester 1

1

790-261-1203

H

799-101-5220 Nipple 1

2

07002-11023 O-ring 1

799-101-5002 Hydraulic tester 1

1

790-261-1203

J

799-101-5230 Nipple 1

2

07002-11423 O-ring 1

799-101-5002 Hydraulic tester 1

1

790-261-1203

K

799-101-5230 Nipple 2

2

07002-11423 O-ring 2

Dial gauge 1

Digital hydraulic

tester

Digital hydraulic

tester

Digital hydraulic

tester

For deliver y valve method

* Same as E1

1

* Same as E4

* Same as E1

1

Size: 14 x 1.5mm

1

* Same as H ( Only quantity is different)

20-102 PC130-7

(1)

TESTING AND ADJUSTING

TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

Testing and adjusting item

Testing and adjusting oil

pressure in pump LS control circuit

Measuring s olenoid valv e

output pressure

Measuring PPC valve output pressur e

Measuring oil leakage

Measuring water temperature and oil temperature

Part No. Part name

Symbol

799-101-5002 Hydraulic tester 1

1

790-261-1203

L

799-101-5230 Nipple 2

2

07002-11423 O-ring 2

3

799-401-2701

799-101-5002 Hydraulic tester 1

1

M

790-261-1203

2

799-401-3100 Adapter 1 Size: 03

799-101-5002 Hydraulic tester 1

1

N

790-261-1203

2

799-401-3100 Adapter 1 * Same as M2

Commercially

P

available

—

799-101-1502 Digital thermometer 1 -99.9 – 1,299°C

Digital hydraulic

tester

Differential pressure

gauge

Digital hydraulic

tester

Digital hydraulic

tester

Measuring cylinder 1

Q'ty

1

* Same as H (Only quantity is different)

1—

* Same as E1

1

* Same as E1

1

Remarks

Measuring operating effort

and pressing force

Measuring stroke and

hydraulic drift

Measuring work equipment

speed

Measuring voltage and

resistance

79A-264-0021 Push-pull scale 1 0 – 294N {0 – 30kg}

—

79A-264-0091 Push-pull scale 1 0 – 490N {0 – 50kg}

Commercially

—

available

Commercially

—

available

Commercially

—

available

Scale 1 —

Stopwatch 1 —

Circuit tester 1 —

a For the model names and part Nos. of the T-adapters and boxes u sed for troubleshooting for the monitor

panel, controllers, se nso r s, act uators, and wiring h ar nes se s, se e T RO UB LE SHO O TING, Layout of connectors and electric circuit diagram of each system.

PC130-7 20-103

(1)

TESTING AND ADJUSTING

TESTING AND ADJUSTING ENGINE SPEED

TESTING AND ADJUSTING

ENGINE SPEED

MEASURING

1. Preparation work

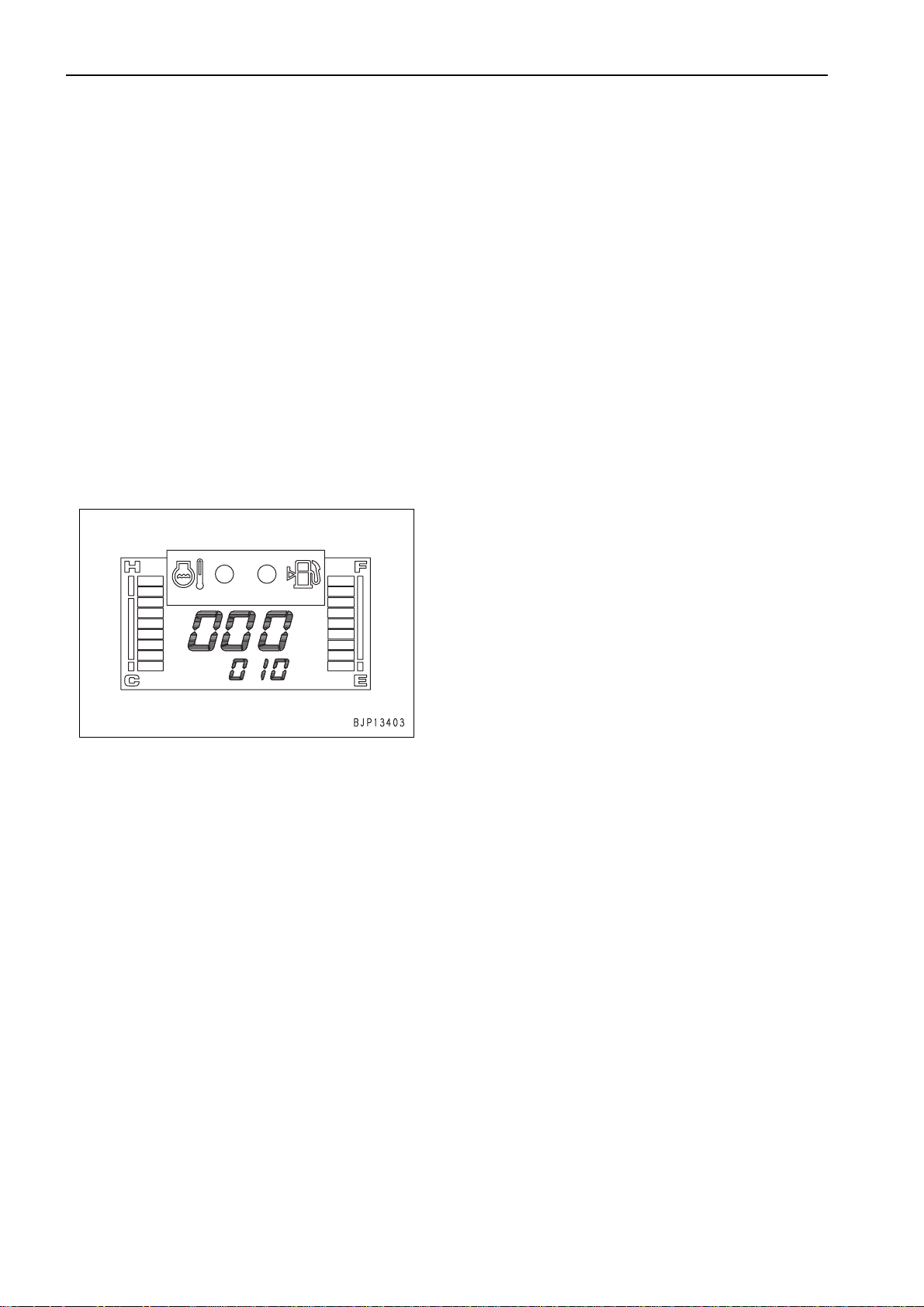

1) Turn the starting switch ON and set the monitor panel in the "Monitoring func tion [02]" to

prepare for measurement of the engine

speed.

a For the operating method, see "Special

functions of monitor panel".

• Monitoring code: 010 (Engine speed)

a The engine speed is displayed in rpm.

2) Warm up the engine to the following o perating condition.

• Engine coolant temperature: Within oper-

ating range

• Hydraulic oil temperature: 45 – 55°C

a Measure the engine speed with the work-

ing mode switch in the A-mode position.

4. Measuring pump relief and one-touch power

maximizing speed

1) Set the fuel control dial in the high idling

(MAX) position.

2) Relieve the arm circuit by moving the arm IN,

keeping pressing the one-touc h power max imizing switch, and measure the engine

speed.

a The one-touch power maximizing func-

tion is reset automatically in about 8.5

seconds even if the switch is kept held.

Accordingly, measure the engine speed

in that period.

5. Measuring auto-deceleration speed

1) Start the engine and set the fuel contr ol dial

in the high idling position (MAX).

2) Set the work equip ment control, swing con-

trol, and travel levers in n eutr a l an d me as ure

the engine speed.

a The engine speed lowers to a certain

level about 5 seconds after all the levers

are set in neutral. This level is the autodeceleration speed.

1. Measuring low idling speed

1) Set the fuel contr ol dial in t he low idli ng (M IN)

position.

2) Set the work equipment control, swing control, and travel levers in neu tr al a nd m eas ure

the engine speed.

2. Measuring high idling speed

1) Turn the auto-decelerator switch OFF.

2) Set the fuel control dial in the high idling

(MAX) position.

3) Set the wo rk equipment control, swing control, and travel levers in neu tr al a nd m eas ure

the engine speed.

ADJUSTING

Adjusting governor spring

a If the high idling speed is out of the standard

range or the engine speed is unstable (the

engine hunts), adjust the governor spring with

"Governor adjustment function [03]" of the monitor panel.

a For the adjustment procedure, see SPECIAL

FUNCTIONS OF MONITOR PANEL.

3. Measuring pump relief speed

1) Set the fuel control dial in the high idling

(MAX) position.

2) Relieve the arm circui t by mo ving the a rm IN

and measure the engine speed.

20-104 PC130-7

(1)

TESTING AND ADJUSTING

MEASURING EXHAUST GAS COLOR

MEASURING EXHAUST GAS

COLOR

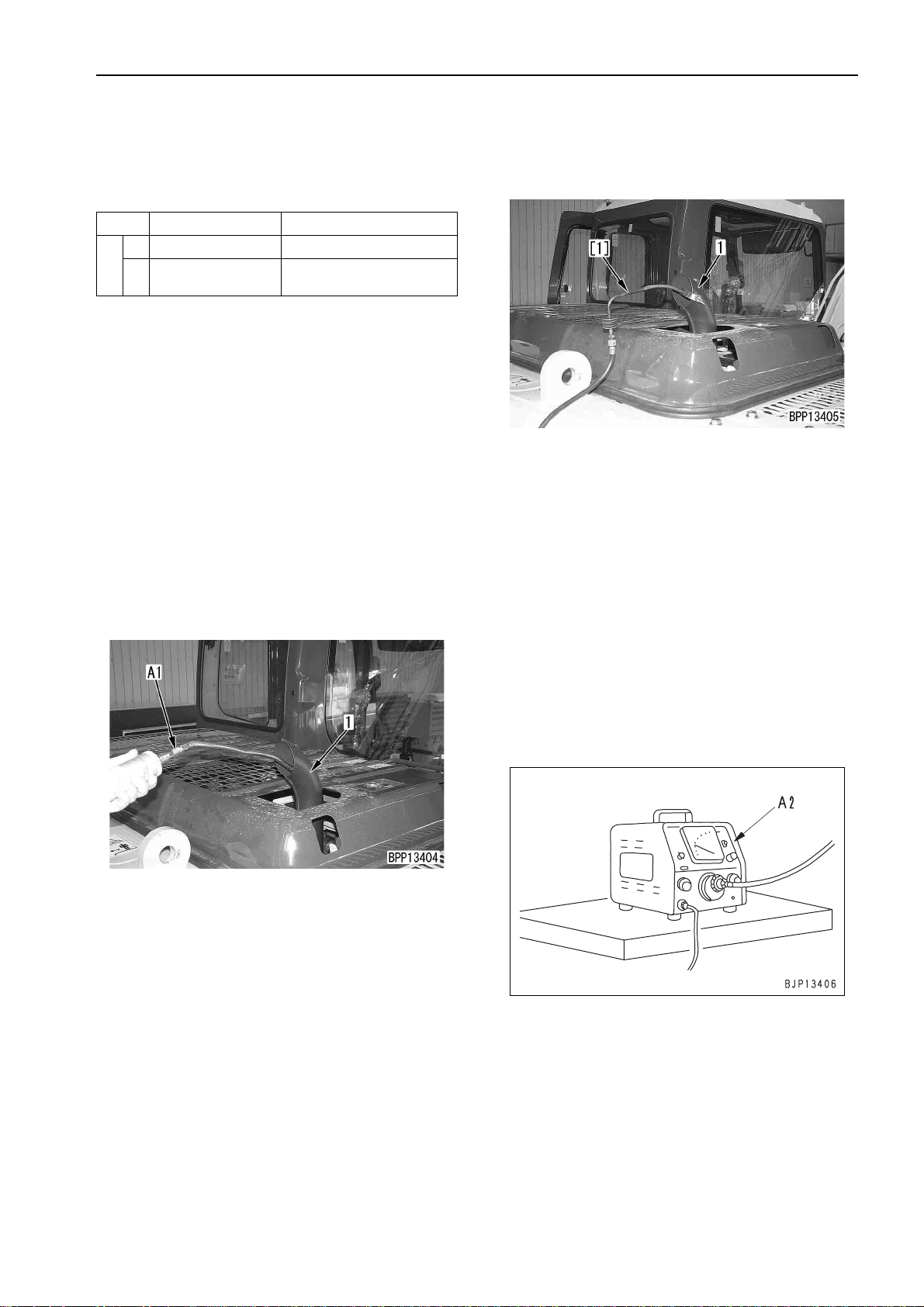

a Measuring instruments for exhaust gas color

Symbol Part No. Part name

1 799-201-9000 Handy Smoke Checker

A

k When installing and removing the measuring

a If an air source and an el ec tric p ower source are

not available in the field, use handy smo ke

checker A1. When recording official data, use

smoke meter A2.

1. Measuring with handy smoke checker A1

1) Stick a sheet of filter paper to smoke checker

2) Insert the exhaust gas intake pipe in exhaust

3) Run the engine.

4) Accelerate the engine suddenly or run it at

Commercially

2

instruments, take care not to touch a hot part.

available

A1.

pipe (1).

high idling and operate the han dle of smoke

checker A1 so that the filter paper will absorb

the exhaust gas.

Smoke Meter

2. Measuring with smoke meter A2

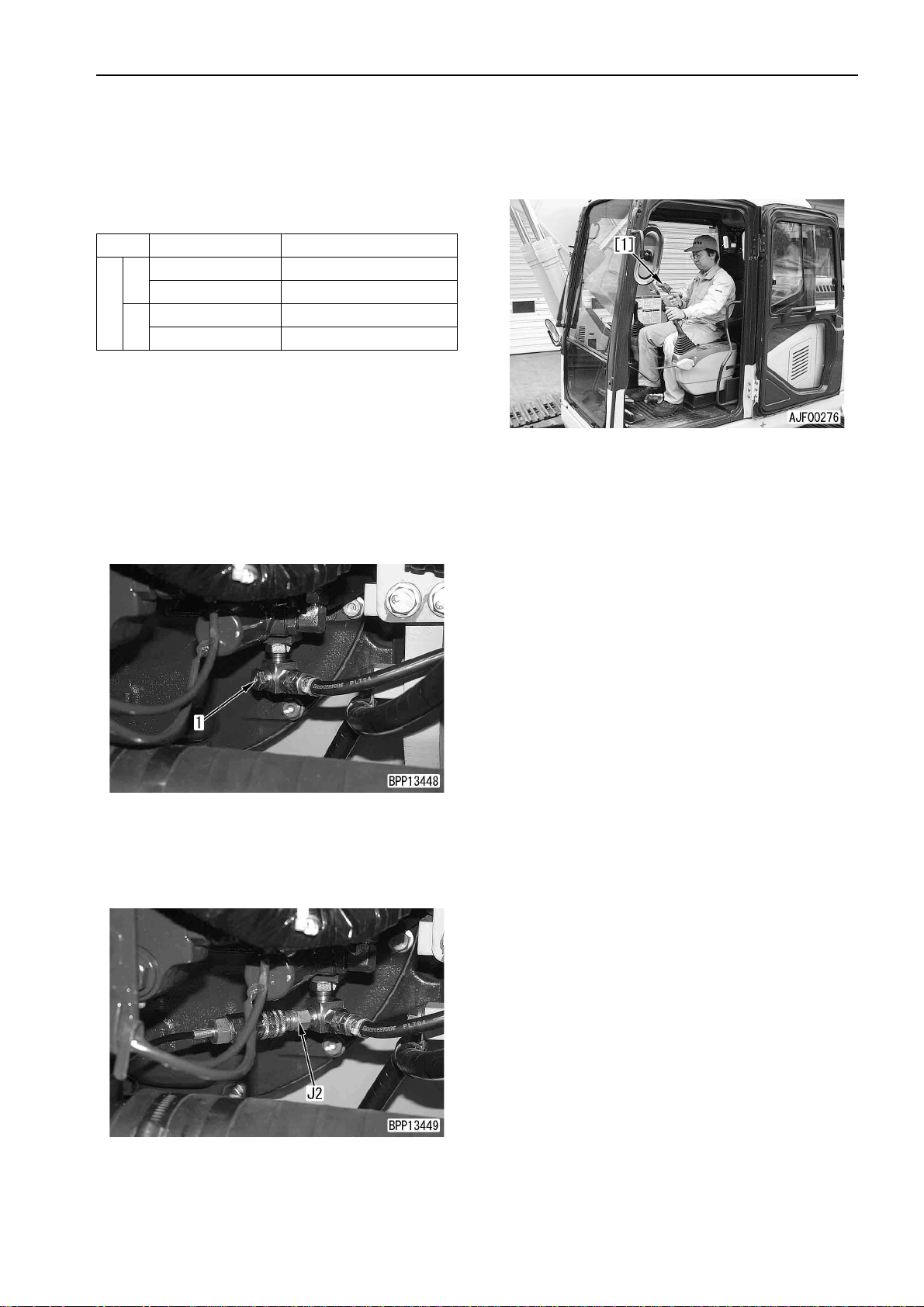

1) Insert probe [1] of smoke meter A2 in the

outlet of exhaust pipe (1) and fix it to the

exhaust pipe with a clip.

2) Connect the probe hose, receptacle of the

accelerator switch, and air hose to smoke

meter A2.

a Limit the supplied air pressure to 1.5

MPa {15 kg/cm

3) Connect the p ower cable to a receptacle of

AC 100 V.

a Before connecting the cable, chec k that

the power switch of the smoke meter is

turned OFF.

4) Loosen the cap nut of the sucti on pump and

fit the filter paper.

a Fit the filter paper securely so that the

exhaust gas will not leak.

5) Turn on the power switch of smoke meter

A2.

2

}.

5) Remove the filter paper and compare it with

the attached scale.

6) After finishing measurement, remove the

measuring instrument and return the

removed parts.

6) Start the engine and heighten the engine

coolant temperature to the operating range.

PC130-7 20-105

(1)

TESTING AND ADJUSTING

7) Accelerate the engine suddenly or run it at

high idling and press the accelerator pedal of

smoke meter A2 and co llect the exhau st ga s

into the filter paper.

8) Place the contaminated filter paper on the

clean filter paper (at least 10 sheets) in the

filter paper holder and read the indicated

value.

9) After finishing measurement, remove the

measuring instrument and return the

removed parts.

MEASURING EXHAUST GAS COLOR

20-106 PC130-7

(1)

TESTING AND ADJUSTING

ADJUSTING VALVE CLEARANCE

ADJUSTING VALVE

CLEARANCE

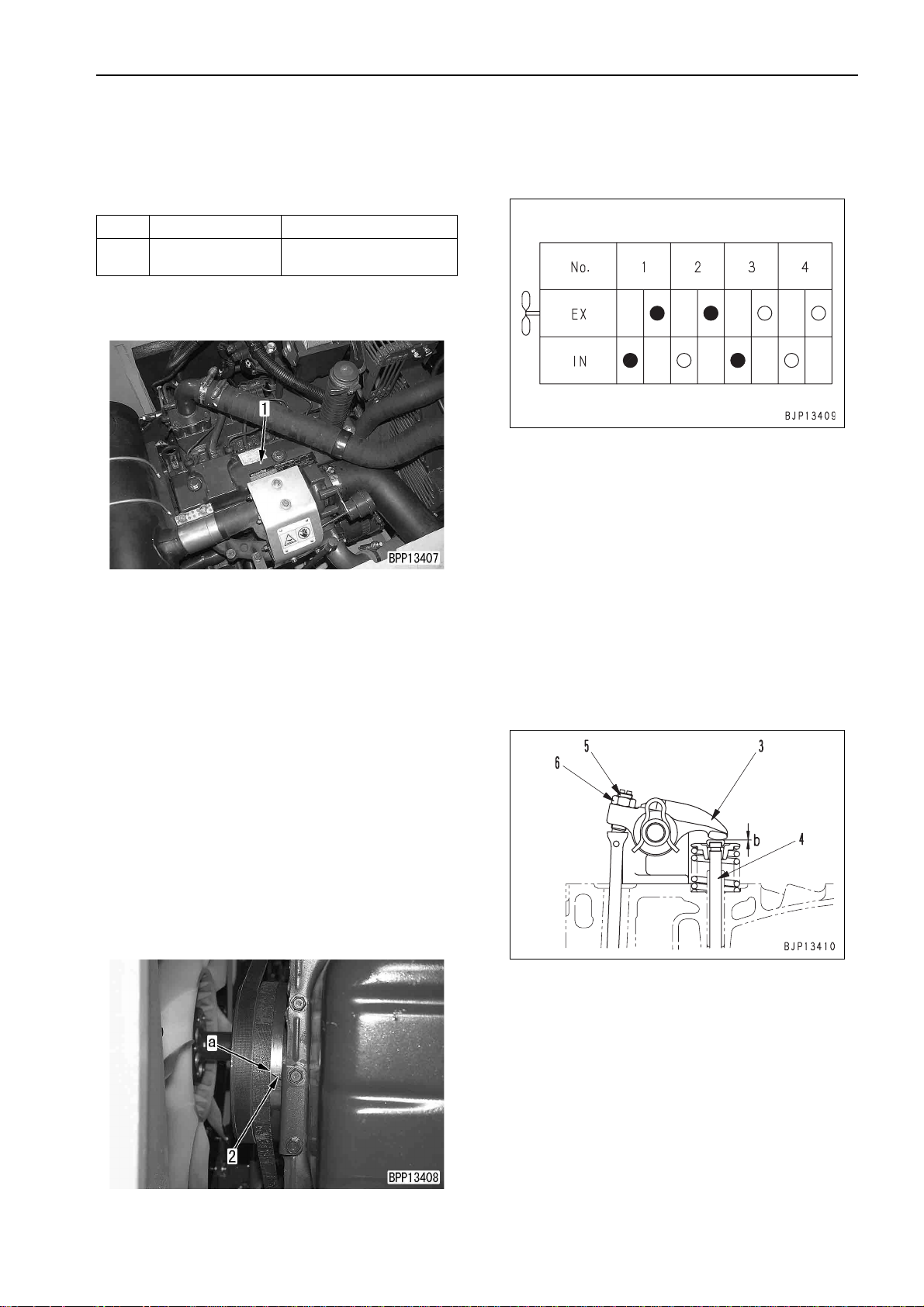

a Adjusting instrument for valve clearance

Symbol Part No. Part name

B

1. Open the engine hood and remove all cylinder

head covers (1).

2. Remove the engine unde rcover (on the radiator

side).

3. Rotate the crankshaft forward to bring the

stamped "1.4TOP" line (a) of the crank p ulley to

pointer (2) and set the N o. 1 c yli nde r to the compression top dead center.

a Crank the crankshaft with the crank pulley

a There are 2 stamped "1.4TOP" lines on the

a When the No. 1 cylinder is at the c ompres-

Commercially

available

mounting bolt.

crank pulley. Use the one at the diagonal

position of "2.3TOP".

sion top dead center, the rocker arm of the

No. 1 cylinder can be moved by the valve

clearance with the hand. If the rocker arm

cannot be moved, the No. 1 cyl in der is not at

the compression top dead center. In th is

case, rotate the crankshaft one more turn.

Feeler gauger

4. While the No. 1 cylinder is at the compression

top dead center, adjust the valve clearances

marked with q in the valve arran gem ent dr awi ng

according to the following procedure.

1) Insert feeler gauge B in clearance (b)

between rocker arm (3) and valve stem (4)

and adjust the clearance with adjustment

screw (5).

a With the feeler gauge inserted, turn the

adjustment screw to a degree that you

can move the filler gauge lightly.

2) Secure adjustment screw (5) and tighten

locknut (6).

3 Locknut: 39.2 – 49 Nm {4 – 5 kgm}

a After tightening the locknut, check the

valve clearance again.

a After adjusting all of the valves marked

with q, go to the next procedure.

5. Rotate the crankshaft forward to bring the

stamped "1.4TOP" line (a) of t he crank pulley to

pointer (2) and set the No . 4 c ylin der to t he c ompression top dead center.

PC130-7 20-107

(1)

TESTING AND ADJUSTING

6. While the No. 4 cylinder is at the compression

top dead center, adjust the valve clearances

marked with Q in the valve arrangement drawing.

a Adjust the valve clearance acc ording to st ep

4 above.

7. After finishing adjustment, return the removed

parts.

3 Cylinder head cover mounting bolt:

7.84 – 9.8 Nm {0.8 – 1.0 kgm}

ADJUSTING VALVE CLEARANCE

20-108 PC130-7

(1)

TESTING AND ADJUSTING

MEASURING COMPRESSION

PRESSURE

a Measuring instruments for compression pressure

Symbol Part No. Part name

795-502-1205 Compression gauge

C

a When measuring the compression pressure,

take care not to burn yourself on the exhaust

manifold, muffler, etc. or get caught in a rota ting

part.

1. Adjust the valve clearance.

a See Adjusting valve clearance.

2. Warm up the engine until the engine oil temperature is 40 – 60°C.

795-502-1370 Adapter

6204-11-3880 Gasket

MEASURING COMPRESSION PRESSURE

6. Remove governor spring (2).

7. Put governor l ever (3) of the fuel injection pump

to the STOP side stopper and fix it.

3. Prepare for measuring the engine speed.

a See Testing and adjusting engine speed.

4. Open the engine hood and remove nozzle holder

(1) of the cylinder to measure the compression

pressure.

5. Install adapter [1] of compression gauge C to the

mounting part of the nozzle ho lder and connect

gauge [2].

a Install the gasket to the end of the adapter.

a Secure the adapter with the clamping holder

and mounting bolt for the nozzle holder.

3 Mounting bolt: 39.2 – 49 Nm {4 – 5 kgm}

8. Crank the engine with the starting motor and

measure the compression pressure.

a Read the compression gauge when its

pointer is stabilized.

a When measuring the compression pr essure,

measure the engine speed, too, and check

that it is in the measurement condition range.

9. After finishing measurement, remove the measuring instruments and return the removed parts.

a Check that the fulcrum of the clamping

holder for the nozzle holder is seated on the

cylinder head, and then ti ghten th e mounti ng

bolt.

3 Mounting bolt: 39.2 – 49 Nm {4 – 5 kgm}

PC130-7 20-109

(1)

TESTING AND ADJUSTING

MEASURING BLOW-BY PRESSURE

MEASURING BLOW-BY

PRESSURE

a Measuring instruments for blow-by pressure

Symbol Part No. Part name

D 799-201-1504 Blow-by checker

1. Remove the engine und ercover (on the flywhee l

side).

2. Install nozzle [1] of blow- by che ck er C to the end

of blow-by hose (1) and connect it to gauge [2].

5. Run the engine at high idling and measure the

blow-by pressure .

• Working mode: A

• Work equipment, swing, and travel circuit:

Relieve the travel circuit.

6. After finishing measurement, remove the measuring instruments and return the removed parts.

3. Start the engine and lock the travel mechanism.

k Put pin [3] between the sprocket and track

frame to lock the travel mechanism

securely.

4. Start the engine and warm it up to t he operating

range.

• Engine coolant temperature: Within operat-

ing range

• Hydraulic oil temperature: 45 – 55°C

20-110 PC130-7

(1)

TESTING AND ADJUSTING

MEASURING ENGINE OIL PRESSURE

MEASURING ENGINE OIL

PRESSURE

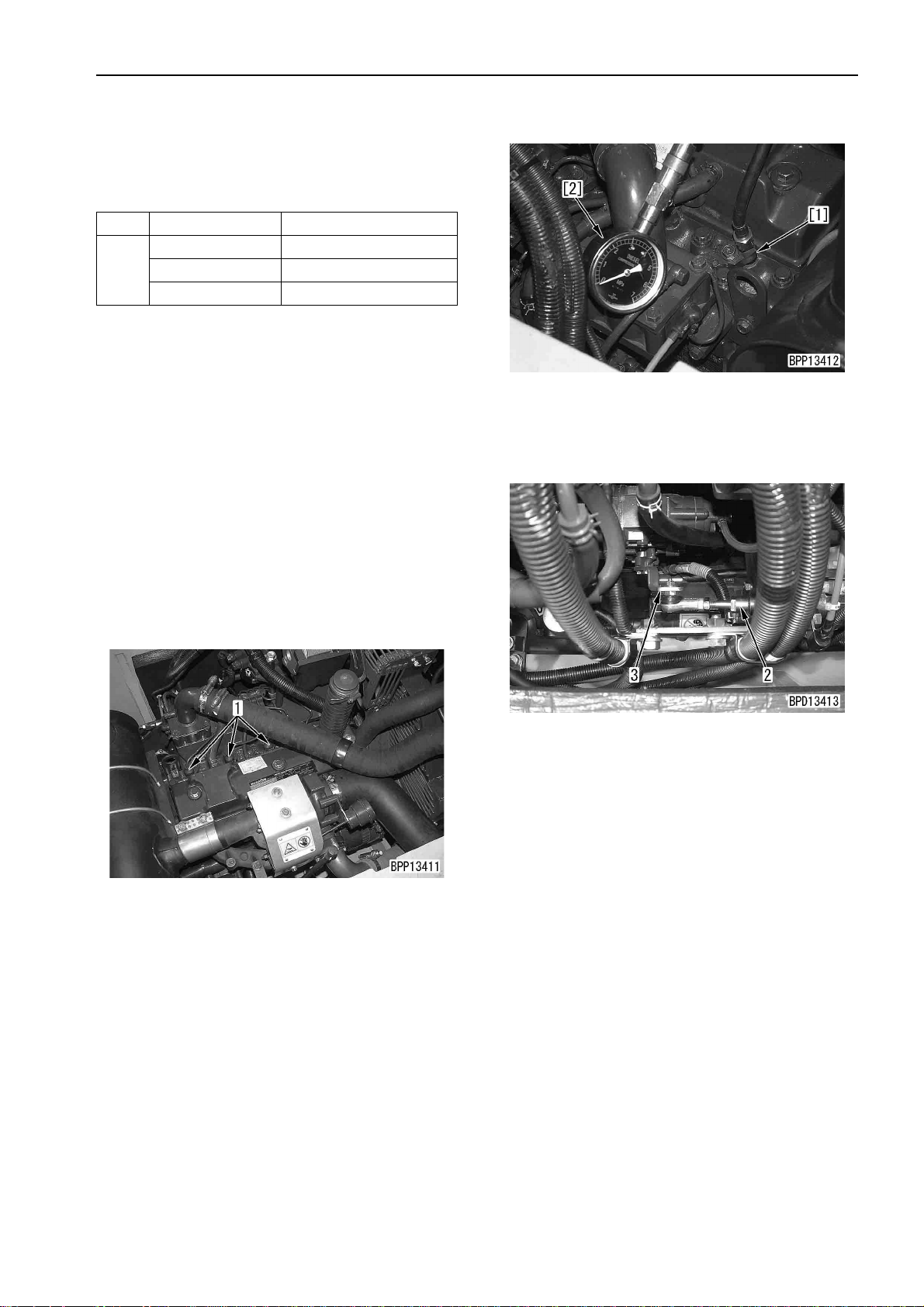

a Measuring instruments for engine oil pressure

Symbol Part No. Part name

799-101-5002 Hydraulic tester

1

790-261-1203 Digital hydraulic tester

2 799-401-2320 Hydraulic tester

E

3 799-401-3500 Adapter (Size: 06)

799-101-5220 Nipple (10 x 1.25 mm)

4

07002-11023 O-ring

1. Open the pump room cover and disconnect outlet hose (1) of the engine oil filter.

5. Measure the oil pressure during low idling and

high idling.

6. After finishing measurement, remove the measuring instruments and return the removed parts.

2. Install adapter E3 and conne ct the di sconnec ted

hose again.

3. Install nipple E4 and connect it to hydraulic tester

E2.

4. Start the engine and heighten the engine coolant

temperature to the operating range.

PC130-7 20-111

(1)

TESTING AND ADJUSTING

TESTING AND ADJUSTING FOR FUEL INJECTION TIMING

TESTING AND ADJUSTING

FOR FUEL INJECTION TIMING

a Testing and adju sting instruments for fuel injec-

tion timing (for delivery valve method)

Symbol Part No. Part name

1 795-102-2103 Spring pusher

F

TESTING AND ADJUSTING BY MATCH MARK

METHOD

a After removing and installing the fuel injection

pump without repairing it or when only checking

the injection timing, test and adjust the injection

timing according to the following procedure.

2

Commercially

available

Dial gauge

4. Remove cover (3) of the fuel injection pump

drive shaft.

TESTING

1. Open the engine hood and remove all cylinder

head covers (1).

2. Remove the engine under cover (on the radiator

side).

3. Rotate the crankshaft forward to bring the

stamped "1.4TOP" line (a) of the crank pulley to

pointer (2) and set the No. 1 cyl inder to th e c ompression top dead center.

a Crank the crankshaft with the crank pulley

mounting bolt.

a There are 2 stamped "1.4TOP" lines on t he

crank pulley. Use the one at the diagonal

position of "2.3TOP".

a When the No. 1 cylinder is at the compres-

sion top dead center, the rocker arm of the

No. 1 cylinder can be moved by the valve

clearance with the han d. If the rocker arm

cannot be moved, the No. 1 cy li nde r is no t at

the compression top dead center. In this

case, rotate the crankshaft one more turn.

5. Insert pin [1] in the mounting bolt hole of the front

cover (on the outside of the engi ne) to chec k the

fuel injection timing.

a Use a pin 4.0 – 4.5 mm in diameter and

about 80 mm in length.

a If the pin enters smoothly to inside of the

drive gear of the fuel injection pump, the fuel

injection timing is normal. In this case, return

the removed parts.

a If the pin touches the drive gear of the fuel

pump, the fuel injection timing is abnormal.

In this case, adjust the fuel injection timing.

ADJUSTING

a If the fuel injection timing is abnormal, adjust it

according to the following procedure.

1. Remove the fuel pump, holder, and drive gear

together.

a See DISASSEMBLY AND ASSEMBLY,

Removal, installation of fuel pump assembly.

20-112 PC130-7

(1)

TESTING AND ADJUSTING

TESTING AND ADJUSTING FOR FUEL INJECTION TIMING

2. Remove bolt (3) and fix drive gear (4) to holder

(5) with fixing bolt [2].

a As fixing bolt [2], use a bolt 6 mm in t hread

diameter and 35 mm in length.

a Pass the fixing bolt through the screw hole of

bolt (3) and tighten it into the screw hole of

the drive gear, and the fuel injec tion pump is

fixed in the fuel injection timing.

3. Install the fuel inje ction pump, holder, and drive

gear together.

a See DISASSEMBLY AND ASSEMBLY,

Removal, installation of fuel pu mp assembly.

a Af te r i ns talling the fuel injection pump tempo-

rarily, check the fuel injection timing according to the above described procedure.

4. After finishing adjustment, remove the measuring tools and return the removed parts.

k Be sure to remove pin [1] and fixing bolt [2].

3 Cylinder head cover mounting bolt:

7.84 – 9.8 Nm {0.8 – 1.0 kgm}

ADJUSTING BY DELIVERY VALVE METHOD

a After repairing or replacing the fuel injection

pump or timing gear, adjust the injection timing

according to the following procedure.

ADJUSTING

a Apply the delivery valv e method to only adjust-

ment of the injection timing.

1. Open the engine hood and remove all cylinder

head covers (1).

2. Remove the engine under cover (on the radiator

side).

3. Rotate the crankshaft forward to bring the

stamped "1.4TOP" line (a) of t he crank pulley to

pointer (2) and set the No . 1 c ylin der to t he c ompression top dead center.

a Crank the crankshaft with the crank pulley

mounting bolt.

a There are 2 stamped "1.4TOP" lines on t he

crank pulley. Use the one at the diagonal

position of "2.3TOP".

a When the No. 1 cylinder is at the compres-

sion top dead center, the rocker arm of the

No. 1 cylinder can be moved by the valve

clearance with the hand. If the rocker arm

cannot be moved, the No. 1 cy lind er is n ot at

the compression top dead center. In this

case, rotate the crankshaft one more turn.

PC130-7 20-113

(1)

TESTING AND ADJUSTING

TESTING AND ADJUSTING FOR FUEL INJECTION TIMING

4. Remove snap ring (6 ) of the rocker arm shaft on

the No. 1 cylinder side , and then remove rocker

arm (7) of the No. 1 air intake valve.

a Remove the valve stem cap, too.

5. Using spring pusher F1, remove v alve cotter (8)

of the No. 1 air intake valve.

6. Loosen spring pusher F1 and remove seat (9)

and spring (10).

8. Install dial gauge F2 on the valve stem of No. 1

air intake valve (11) and set it to the 0 point.

a Since the No. 1 cylinder is at the compres-

sion top dead center, set this point as th e 0

point.

9. Rotate the crankshaft about 45° in reverse.

10. Rotate the crankshaft forward slowly so tha t dial

gauge F2 will indicate fuel injection timing dimension (a).

a When adjusting the crankshaft to fuel injec-

tion timing dimen sion ( a), be sure to rotat e it

forward so that the adjustme nt will not be

affected by the backlash of the drive gear. (If

the crankshaft passes the adjustment dimension, return it sufficiently, and then adjust it

again forward.)

a Fuel injection timing dimension (a) and fuel

injection timing

Fuel injection timing

dimension (a)

Fuel injection timing

(Reference)

mm 0.42 ± 0.08

°6 ± 0.75

7. While No. 1 air intake valve (11) is in contact with

the top of piston (12), turn the valve stem with

the hand to press No. 1 air intake valve (11)

against the piston.

a Since the piston stroke will be meas ured at

11. Disconnect all of co nnected fuel injection tubes

(12), if there are any.

the valve stem top, check that the valve bottom is in contact with the piston top securely.

20-114 PC130-7

(1)

TESTING AND ADJUSTING

TESTING AND ADJUSTING FOR FUEL INJECTION TIMING

12. Remove delivery valve holder (14) for the No. 1

cylinder of fuel pump (13), delivery valve (15),

and spring (16), and then install delivery valve

holder (14) again.

13. Remove governor spring (1 7), and then put the

governor lever ( 18) of the fuel inj ection pump to

the stopper on the FULL side and fix it.

14. Remove the fixing bracket and lubrication tube of

fuel injection pump ( 13), loosen 4 mounting nuts

(19), and lean the fuel injection pump outward

fully.

a Loosen the mounting nuts to a degree that

the fuel injection pump can be moved in and

out within the range of the oblong hole (Do

not loosen them so much that the fuel injection pump will have play).

16. Tighten 4 mounting nuts (19) of fuel injection

pump (13) securely and alternately.

17. After finishing a djustment, remove the adjusting

tools and return the removed parts.

a Replace the O-ring and copper gasket of the

delivery valve with new ones.

k Tighten the delivery valve securely in 3

times. (If it is not tightened sufficient ly, the

gasket may be broken.)

3 Delivery valve holder:

39.2 – 44.1 Nm {4 – 4.5 kgm}

3 Fuel injection tube sleeve nut:

19.6 – 24.5 Nm {2 – 2.5 kgm}

3 Cylinder head cover mounting bolt:

7.84 – 9.8 Nm {0.8 – 1.0 kgm}

a After finishing adjustment, if the stamped

lines of the fuel injection pump and holder

are not at the same position or there is not a

stamped line on the fuel injection pump,

stamp a new line to show that the fuel injection timing has been adjusted.

15. Operating priming pump (20) of fuel injection

pump 13, move the injection pump gradually

toward the cylinder block and stop when the fuel

stops flowing out of No. 1 del ivery valve holder

(14), and then tighten the mounting nuts tempo rarily.

a The position where fuel stops flowing out of

the No. 1 delivery valve holder is the position

to start fuel injection in the No. 1 c ylinder

(fuel injection timing).

PC130-7 20-115

(1)

TESTING AND ADJUSTING

ADJUSTING ENGINE SPEED SENSOR

ADJUSTING ENGINE SPEED

SENSOR

a If the engine speed sensor has been removed

and installed or its signal contains an error,

adjust it according to the following procedure.

a Remove engine speed sensor ( 1) before adju st-

ing it and check that its tip is free from steel chips

(The engine speed sensor is installed to the right

side of the flywheel housing).

4. After finishing adjustment, check that the monitor

panel displays the en gine speed normally in the

"Monitoring mode".

a For the operating method, see "Special func-

tions of monitor panel".

• Monitoring code: 010 (Engine speed)

1. Screw in senso r (1) until its tip touches the too th

tip of flywheel ring gear (2).

2 Threads: Gasket sealant (LG-6)

2. Return sensor (1) by the specified angle.

a Returning angle of sensor: 1 ± 1/6 turn

a After this adjustment, clearance (a) b etween

the sensor tip and gear tooth tip is 1.25 –

1.75 mm.

3. Fixing sensor (1), tighten nut (3).

2 Nut: 49 – 68.6 Nm {5 – 7 kgm}

20-116 PC130-7

(1)

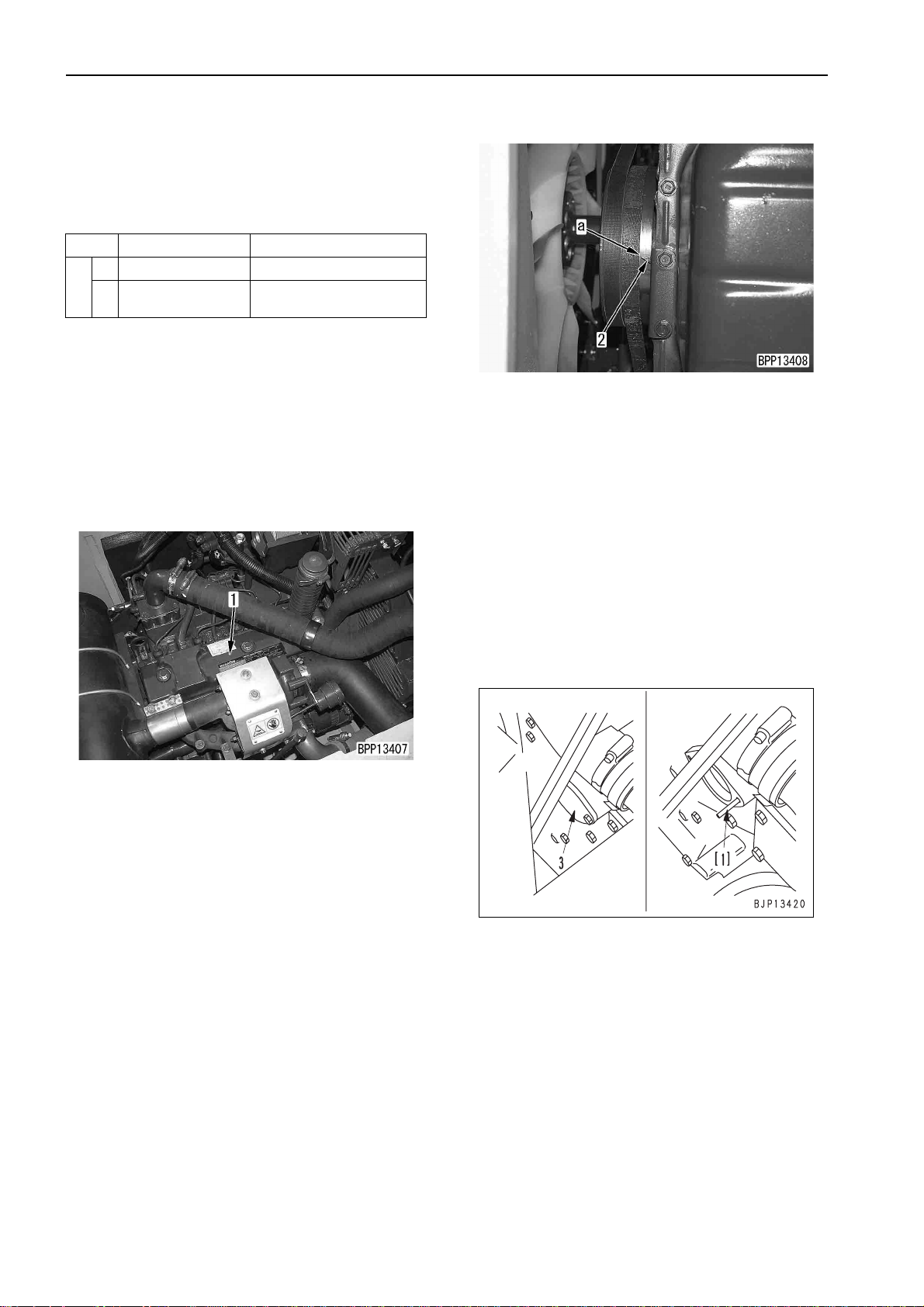

TESTING AND ADJUSTING

TESTING AND ADJUSTING FAN BELT TENSION

TESTING AND ADJUSTING

FAN BELT TENSION

TESTING

1. Open the engine hood and remove the belt cover

from above the alternator.

2. Press the inter mediate point of the belt between

the fan pulley and alternator pull ey with a finger

and measure deflection (a) of the belt.

• Force to press belt: Approx. 58.8 N {6 kg}

• Deflection (a): 6 – 10 mm

ADJUSTING

a If the deflection of the belt is abnormal, adjust it

according to the following procedure.

1. Loosen alternator mounting bolts (1) and (2).

2. Adjust the b elt tension by moving al ternator (5)

with adjustment bolt (4).

a Turn the adjusting belt to left, the belt tension

tight.

3. Tighten locknut (3) and mounting bolts (2) and

(1).

a Check breakage of the pulleys, wear of the

V-grooves, and contact of the belts and Vgrooves.

a If a belt is lengthened to the adjustment limit,

cut, or cracked, replace it with new one.

4. After finishing adjustment, return the covers.

a If a V-belt is replaced, adjust its tension again

after 1 operating hour.

PC130-7 20-117

(1)

TESTING AND ADJUSTING

TESTING AND ADJUSTING AIR CONDITIONER

COMPRESSOR BELT TENSION

TESTING AND ADJUSTING

AIR CONDITIONER

COMPRESSOR BELT

TENSION

TESTING

1. Open the engine hood and remove the belt cover

from above the air conditioner compres s or.

2. Press the intermed iate point of the belt between

the fan pulley an d alternator pulley with a finger

and measure deflection "a" of the belt.

• Force to press belt: Approx. 58.8 N {6 kg}

• Deflection (a): 6 – 10 mm

ADJUSTING

a If the deflection of the belt is abnorm al, adjust it

according to the following procedure.

1. Loosen compressor bracket mounting bolts (1)

and (2).

2. Adjust the belt tension by moving compressor (3)

and bracket (4) together.

a Use a bar, etc. to mov e the bracket (Do not

push the compressor directly with a bar, etc.)

3. Tighten mounting bolts (2) and (1).

a Check breakage of the pulleys, wear of the

V-grooves, and contact of the belts and Vgrooves.

a If a belt is lengthened to the adjustmen t li mit,

cut, or cracked, replace it with new one.

4. After finishing adjustment, return the covers.

a If a V -belt is replaced, adjust its tension again

after 1 operating hour.

20-118 PC130-7

(1)

TESTING AND ADJUSTING

MEASURING CLEARANCE OF SWING CIRCLE BEARING

MEASURING CLEARANCE OF

SWING CIRCLE BEARING

a Measuring instrument for cl earance of swin g cir-

cle bearing

Symbol Part No. Part name

G

a When measuring the clearance of the swing cir-

cle bearing on th e actual mach ine, obse rve the

following procedure.

Commercially

available

Dial gauge

k While measuring, do not pu t your h ands o r foot

under the undercarriage.

1. Fix dial gauge G to outer race (1) or inner race

(2) of the swing cir cle and app ly the probe t o the

end face of inner race (2) or outer race (1) on the

opposite side.

a Set dial gauge G on the front o r at rear side

of the machine

2. Set the work equ ipment in the maximum reach

posture and set the bucket tip to the height of the

revolving frame bottom.

a At this time, the front end of the upper s truc-

ture lowers and the rear end rises.

4. Set the arm at almos t a r ight an gle to the ground

and lower the boom until the track shoe at the

front side of the machine is floated.

a At this time, the front end of the upper struc-

ture rises and the rear end lowers.

5. Under this condition, read dial gauge G.

a Dial gauge G indicates the clearance of the

bearing.

6. Return the ma chine to the postu re of s tep 2 and

check that dial gauge G indicates 0 again.

a If dial gauge G does not indicate 0, repeat

steps 3 – 5.

3. Set the dial gauge G to the 0 point.

PC130-7 20-119

7. After finishing measurement, remove the measuring instruments and return the removed parts.

(1)

TESTING AND ADJUSTING

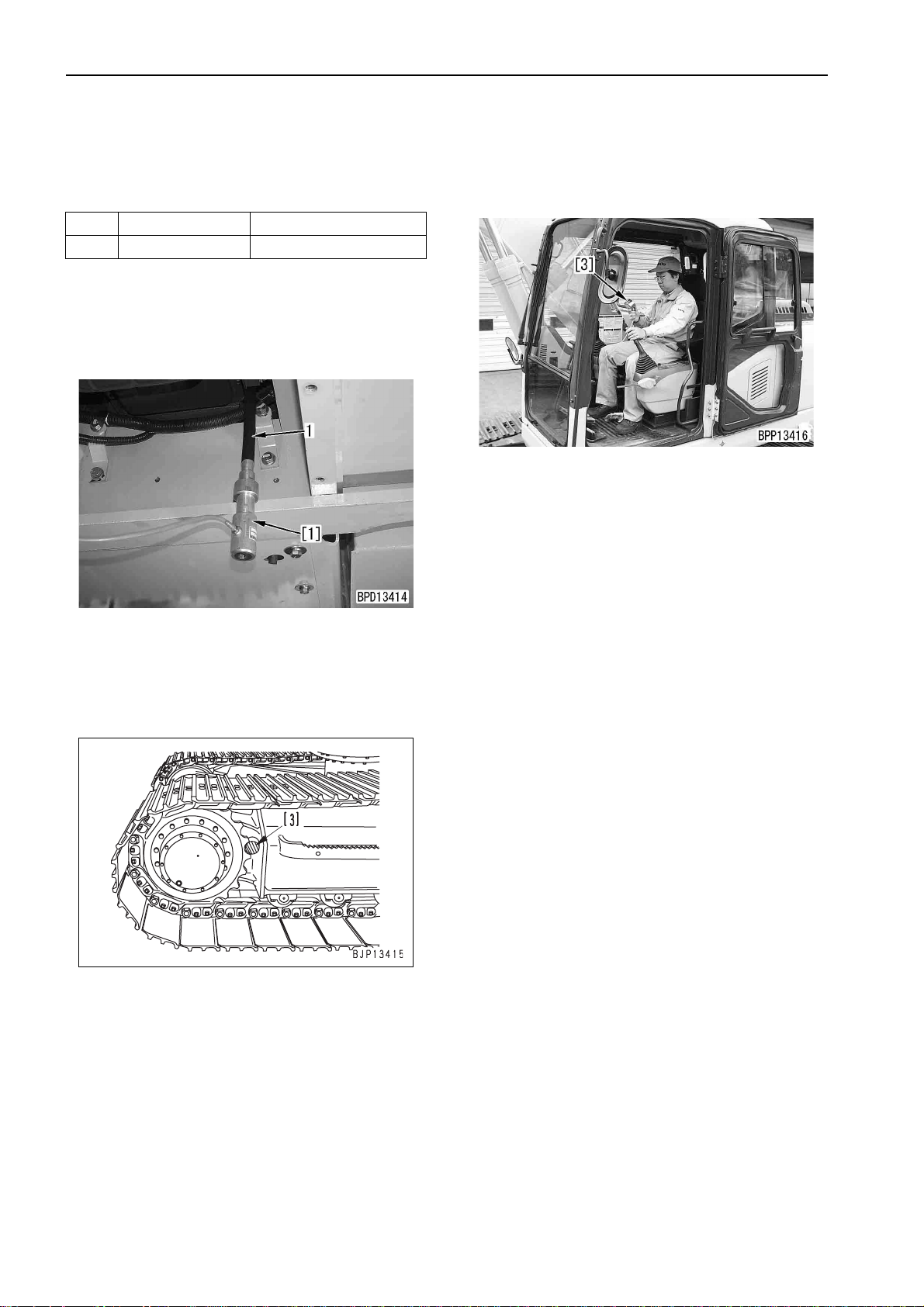

TESTING AND ADJUSTING TRACK SHOE TENSION

TESTING AND ADJUSTING

TRACK SHOE TENSION

TESTING

1. Running the engine at low idling, move the

machine forward by the length of track on ground

and stop slowly.

2. Place straight bar [1] on the track shoe between

the idler and the 1st carrier roller.

a As straight bar [1], use an L-shape steel, etc.

which will be deflected less.

3. Measure maximum clearance (a) between

straight bar [1] and track shoe.

• Standard maximum clearance (a):

10 – 30 mm

ADJUSTING

a If the track shoe tension is out of the standard

range, adjust it according to the following procedure.

1. When tension is too high

1) Loosen va lve (1) gradually to discharge the

grease.

k Since the valve may jum p out because

of the high-press ure grease in it , do no t

loosen it more than 1 turn.

a If the grease is not discharged well, drive

the machine forward and in reverse

slowly.

2) Tighten valve (1).

3 Valve: 58.8 – 88.2 Nm {6 – 9 kgm}

3) After finishing adjustment, check again that

the track shoe tension is normal according to

the above described procedure.

2. When tension is low

1) Add grease through valve (2).

a If the track shoe is not tensed well, drive

the machine forward and in reverse

slowly.

2) After finishing adjustment, check again that

the track shoe tension is normal according to

the above described procedure.

20-120 PC130-7

(1)

TESTING AND ADJUSTING

a You may supply grease until distance (b)

between the idler guide and track frame end

is 0 mm. If the tension is still low, the pin and

bushing are worn excessively. In this case,

turn over or replace the pin and bushing.

TESTING AND ADJUSTING TRACK SHOE TENSION

PC130-7 20-121

(1)

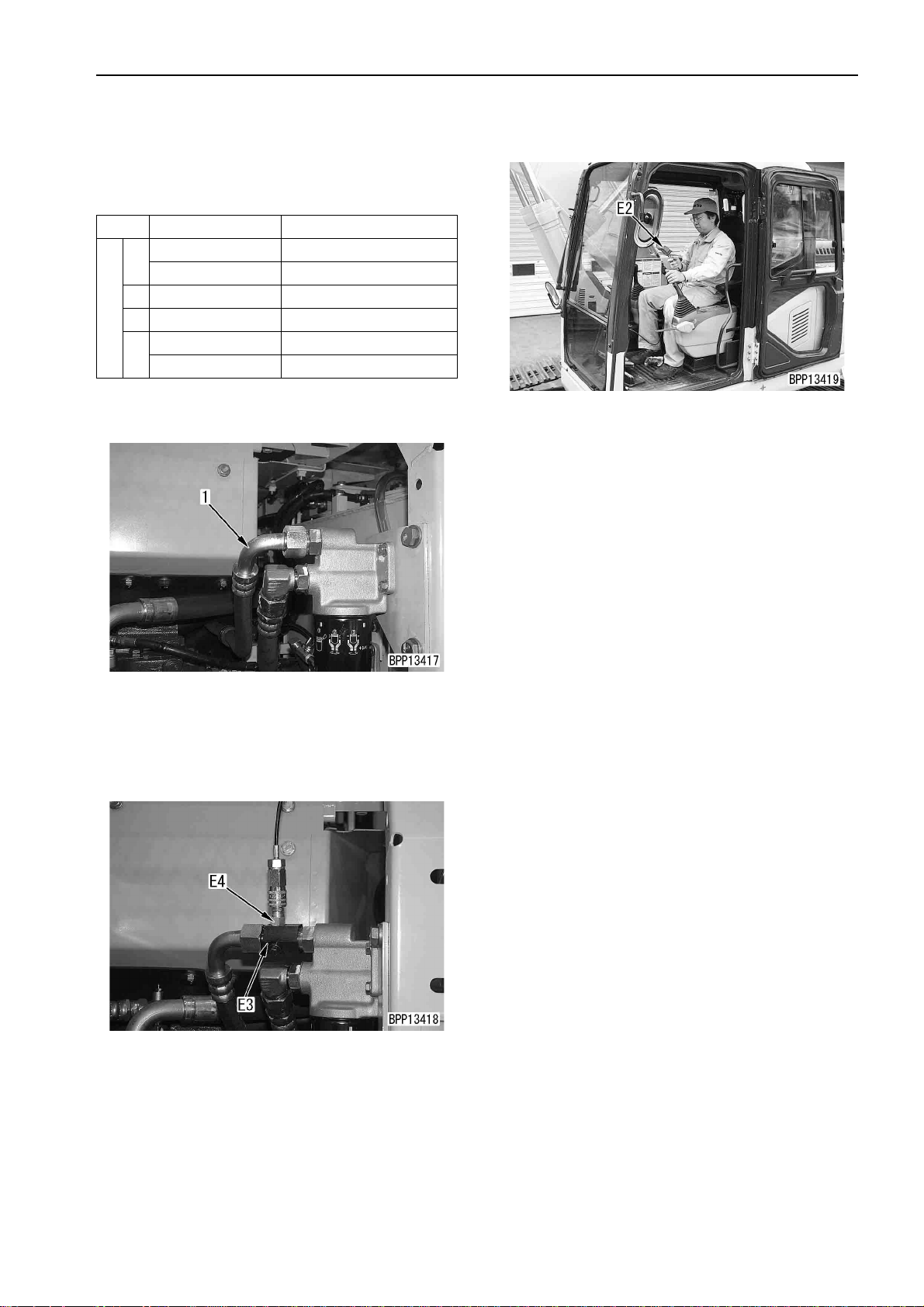

TESTING AND ADJUSTING OIL PRESSURE IN WORK EQUIPMENT,

TESTING AND ADJUSTING

TESTING AND ADJUSTING

OIL PRESSURE IN WORK

EQUIPMENT, SWING, AND

TRAVEL CIRCUITS

a Testing and adjusting instruments for oil pressure

in work equipment, swing, and travel circuits

Symbol Part No. Part name

799-101-5002 Hydraulic tester

1

H

a The oil pressure in work equipme nt, swing, and

travel circuits (pump discharge pressure) can be

checked with moni toring function [02] of th e

monitor panel.

• Monitoring code: 011, 012 (Pump discharge

pressure)

a The pump discharge pressure is disp layed in 1

kg/cm

790-261-1203 Digital hydraulic tester

799-101-5220 Nipple (10 x 1.25 mm)

2

07002-11023 O-ring

2

.

SWING, AND TRAVEL CIRCUITS

2) Install nipple H2 and connect it to oil pressure gauge [1] of hydraulic tester H1.

a Use the oil pressure gauges of 58.8 MPa

{600 kg/cm

2

}.

MEASURING

1. Preparation work

k Lower the work equipment to the ground

and stop the engine. Operate the control

levers seve ral times to r elease the re sidual

pressure in the pipin g, and then loosen the

oil filler cap of th e hydraulic tank slowly to

release the internal press ure of the hydraulic tank.

1) Remove the top cover of the control valve,

and then remove pump pr es sur e pi ckup plug

(1) from the top of the control valve.

3) Run the engine and heighten the hydraulic

oil temperature to 45 – 55°C.

2. Measuring unload pressure

1) Start the engine.

2) Run t he engine at high id ling and set all the

control levers in ne utral and measure the oil

pressure.

a The pressure measured when the unload

valve is unloaded is indicated.

20-122 PC130-7

(1)

TESTING AND ADJUSTING

TESTING AND ADJUSTING OIL PRESSURE IN WORK EQUIPMENT,

SWING, AND TRAVEL CIRCUITS

3. Measuring work equipment circuit relief pressure

1) Start the engine and move th e cylinder to be

measured to the stroke end.

2) Run the en gine at high idling an d relieve the

cylinder and measure the oil pressure.

a The pressure measured when the main relief

valve is relieved is indicated.

a If the one-touch power maximizing switc h is

released, the main reli ef valve is relieved at

low pressure. If the former is p ressed, the

latter is relieved at high pressure.

a If the swing lock switch is set in the LOCK

position, the 2-stage relief solenoid valve is

turned ON and the main relief valve is

relieved at high pressu re. Accord ingly, keep

the swing lock switch turned OFF.

4. Measuring swing circuit relief pressure

1) Start the engine and set the swing lock

switch in the LOCK position.

2) Run the en gine at high idling an d relieve the

swing circuit and measure the oil pressure.

a The pressure measured when the swing

motor safety valve is relieved is indicated.

a The swing motor relief pressure is lower than

the main relief pressure.

ADJUSTING

a The unload valve cannot be adjusted.

1. Adjusting main relief pressure (High pressure setting side)

a If the high relief pressure of the work equip-

ment circuit and travel circuit is abnormal,

adjust the high pressure setting side of main

relief valve (2) according to the following procedure.

a The high relief pressure is the pressure

applied when the 2-stage relief solenoid

valve is turned ON and the pilot pres sure is

applied to the selector port.

5. Measuring travel circuit relief pressure

1) Start the engine and lock the travel mechanism.

k Set pin [2] between the sprocket and

track frame to lock the travel mechanism securely.

2) Run the en gine at high idling an d relieve the

travel circuit and measure the oil pressure.

a The pressure measured when the main relief

valve is relieved is indicated. The travel circuit is always relieved at high pressure.

1) Disconnect pilot hose (3).

2) Fixing holder (4), loosen locknut (5).

3) Turn holder (4) to adjust the pressure.

a If the holder is

• turned to the right, the pressure

rises.

• turned to the left, the pressure lowers.

a Quantity of adjustment per turn of holder:

Approx. 12.6 MPa {Approx. 128 kg/cm

4) Fixing holder (4), tighten locknut (5).

3 Locknut: 39.2 – 49 Nm {4 – 5 kgm}

2

}

5) Connect pilot hose (3).

PC130-7 20-123

(1)

TESTING AND ADJUSTING

TESTING AND ADJUSTING OIL PRESSURE IN WORK EQUIPMENT,

SWING, AND TRAVEL CIRCUITS

6) After finishing adjustment, check a gain that the

pressure is normal according to the above

described measurement procedure.

a If the high pressure setting s ide is adjusted,

the low pressure settin g side changes.

Accordingly, adjust the low pre ssure settin g

side, too.

2. Adjusting main relief pr essur e (L ow pr ess ure

setting side)

a If the low relief pressure of the work equip-

ment circuit is a bnormal or the high pr e ssur e

setting was adjusted, adjust the low pressure

setting side of main re li ef v alv e (2) ac c or di ng

to the following procedure.

a The low relief pressure is the pressure

applied when the 2-stage relief solenoid

valve is turned OFF and the pi lot p ressu re i s

not applied to the selector port.

1) Disconnect pilot hose (3).

2) Fixing holder (6), loosen locknut (7).

3) Turn holder (6) to adjust the pressure.

a If the holder is

• turned to the right, the pressure

rises.

• turned to the left, the pressure lowers.

a Quantity of adjustment per turn of holder:

Approx. 12.6 MPa {Approx. 128 kg/cm

2

4) Fixing holder (6), tighten locknut (7).

3 Locknut:

53.9 – 63.7 Nm {5.5 – 6.5 kgm}

3. Adjusting swing relief pressure

a If the relief pressure of the swing circuit is

abnormal, adjust swing motor safety valve

(8) according to the following procedure.

1) Fixing adjustment screw (9), loosen locknut

(10).

2) Turn adjustment screw (9) to adjust the pressure.

a If the adjustment screw is

• turned to the right, the pressure

rises.

• turned to the left, the pressure lowers.

a Quantity of adjustment per turn of adjust-

}

ment screw: Approx. 14 MPa {Approx.

143 kg/cm

2

}

3) Fixi ng adjustment screw (9), tighten locknut

(10).

3 Locknut:

53.9 – 73.5 Nm {5.5 – 7.5 kgm}

5) Connect pilot hose (3).

6) After finishing adjustment, check again that

the pressure is normal according to the

above described measurement procedure.

4) After finishing adjustment, check again that

the pressure is normal according to the

above described measurement procedure.

20-124 PC130-7

(1)

TESTING AND ADJUSTING

MEASURING CONTROL CIRCUIT BASIC PRESSURE

MEASURING CONTROL

CIRCUIT BASIC PRESSURE

a Measuring instruments for control circuit basic

pressure

Symbol Part No. Part name

799-101-5002 Hydraulic tester

1

J

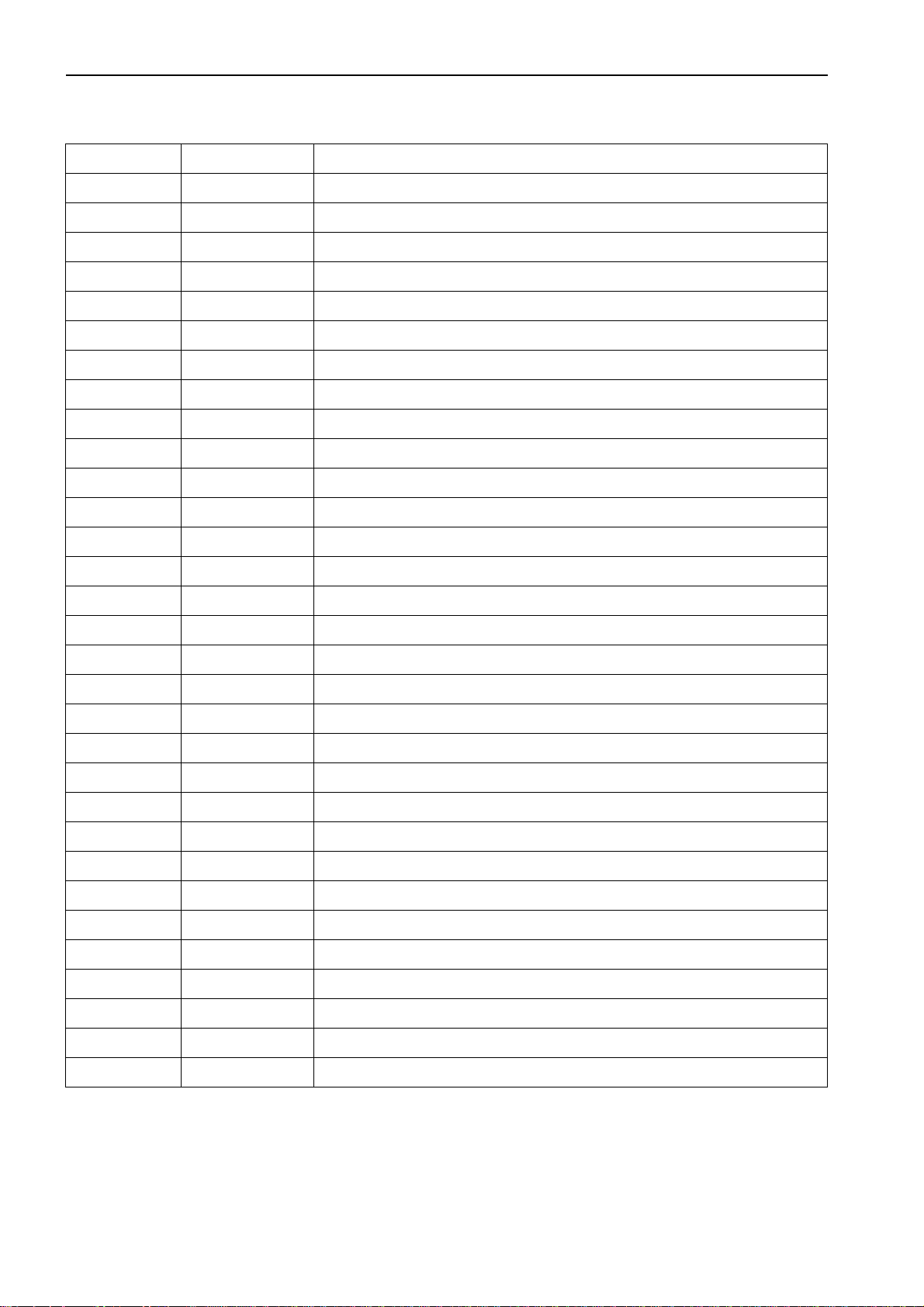

k Lower the work equipment to the ground and

1. Open the pump room cov er and remove control

circuit basic press ure pickup plug (1) under the

hydraulic pump.

790-261-1203 Digital hydraulic tester

799-101-5230 Nipple (10 x 1.25 mm)

2

07002-11423 O-ring

stop the engine. Operate the control levers

several times to release the residual pres sure

in the piping, and then loosen the oil filler cap of

the hydraulic tank slowly to releas e the inte rnal

pressure of the hydraulic tank.

4. Run the engine at hig h idl in g a nd se t a ll the control levers in ne utral and measure the oil pressure.

5. After finishing measurement, remove the measuring instruments and return the removed parts.