UEAM000602

Operation &

Maintenance Manual

PC130

PC150LGP

HYDRAULIC EXCAVATOR

SERIAL NUMBER

PC130-6K - K30001

PC150LGP-6K - K35001

and up

-6K

-6K

and up

WARNING

Unsafe use of this machine may cause serious injury or

death. Operators and maintenance personnel must read

this manual before operating or maintaining this

machine. This manual should be kept inside the cab for

reference and periodically reviewed by all personel who

will come into contact with the machine.

1. FOREWORD

This manual provides rules and guidelines which will help you use this machine safely and effectively. Keep

this manual handy and have all personnel read it periodically . If this manual has been lost or has become dirty and

cannot be read, request a replacement manual from Komatsu or your Komatsu distributor.

If you sell the machine, be sure to give this manual to the new owners.

Continuing improvements in the design of this machine can lead to changes in detail which may not be

reflected in this manual. Consult Komatsu or your Komatsu distributor for the latest available information for your

machine of for questions regarding information in this manual.

WARNING

• This operation & maintenance manual may contain attachments and optional equipment that are not

available in your area. Please consult your local Komatsu distributor for those items you require.

• This machine complies with EC directive (89/392/EEC).

Machines complying with this directive display the CE mark.

• Improper operation and maintenance of this machine can be hazardous and could result in serious

injury or death.

• Operators and maintenance personnel should read this manual thoroughly before beginning operation or maintenance.

• Some actions involved in operation and maintenance of the machine can cause a serious accident,

if they are not done in a manner described in this manual.

• The procedures and precautions given in this manual apply only to intended uses of the machine. If

you use your machine for any unintended uses that are not specifically prohibited, you must be sure

that it is safe for you and others. In no event should you or others engage in prohibited uses or

actions as described in this manual.

• Komatsu delivers machines that comply with alle applicable regulations and standards of the country to which it has beed shipped. If this machine has been purchased in another country of purchased from someone in another country , it may lack certain safety devices and specifi-cations that

are necessary for use in your country . If there is any question about whether your product complies

with the applicable standards and regulations of your country, consult Komatsu or your Komatsu

distributor before operating the machine.

• The description of safety is given in SAFETY INFORMATION on page 0-2 and in SAFETY from page

1-1.

PC130/150LGP-6K ENG

0-1

2. SAFETY INFORMATION

2.1 SAFETY MESSAGES

Most accidents are caused by the failure to follow fundamental rules for the operation and maintenance of

machines.

To avoid accidents, read, understand and follow all precautions and warmings in this manual and on the

machine before performing operation and maintenance.

To identify hazards on the machine pictorial decals are used (see POSITION FOR ATTACHING SAFETY

LABELS)

RED WARNING TRIANGLE - This is used on safety labels where there is a high probabil-

ity of serious injury or death if the hazard is not avoided.

These safety messages or labels usually describe precautions that must be taken to avoid the hazard. Failure to

avoid this hazard may also result in serious damage to the

machine.

ORANGE WARNING TRIANGLE - This is used on safety labels where there is a potentially

dangerous situation which could result in serious injury or

death if the hazard is not avoided. These safety messages

or labels usually describe precautions that must be taken

to avoid the hazard. Failure to avoid this hazard may also

result in serious damage of the machine

YELLOW SAFETY TRIANGLE - This is used on safety labels for hazards which could result

in minor or moderate injury if the hazard is not avoided.

This word might also be used for a hazard where the only

result could be damage to the machine.

NOTICE - This word is used for precautions that must be taken to

avoid actions which could shorten the life of the machine.

Safety precautions are described in SAFETY from page 1-1.

Komatsu cannot predict every circumstance that might involve a potential hazard in operation and maintenance. Therefore that safety message in this manual and on the machine may not include all possible safety

precautions. If any procedures or actions not specifically recommended or allowed in this manual are used, you

must be sure that you and others can do such procedures and actions safely and without damaging the machine.

If you are unsure about the safety of some procedures, contact Komatsu or your Komatsu distributor.

NOTICE:

The PC150LGP has been designed specifically for low ground pressure applications.

Under no circumstances should this machine be used for heavy duty/demolition purposes. If you are unsure of

the suitability of the machine to your particular application, please contact Komatsu or your Komatsu distributor.

0-2

PC130/150LGP-6K ENG

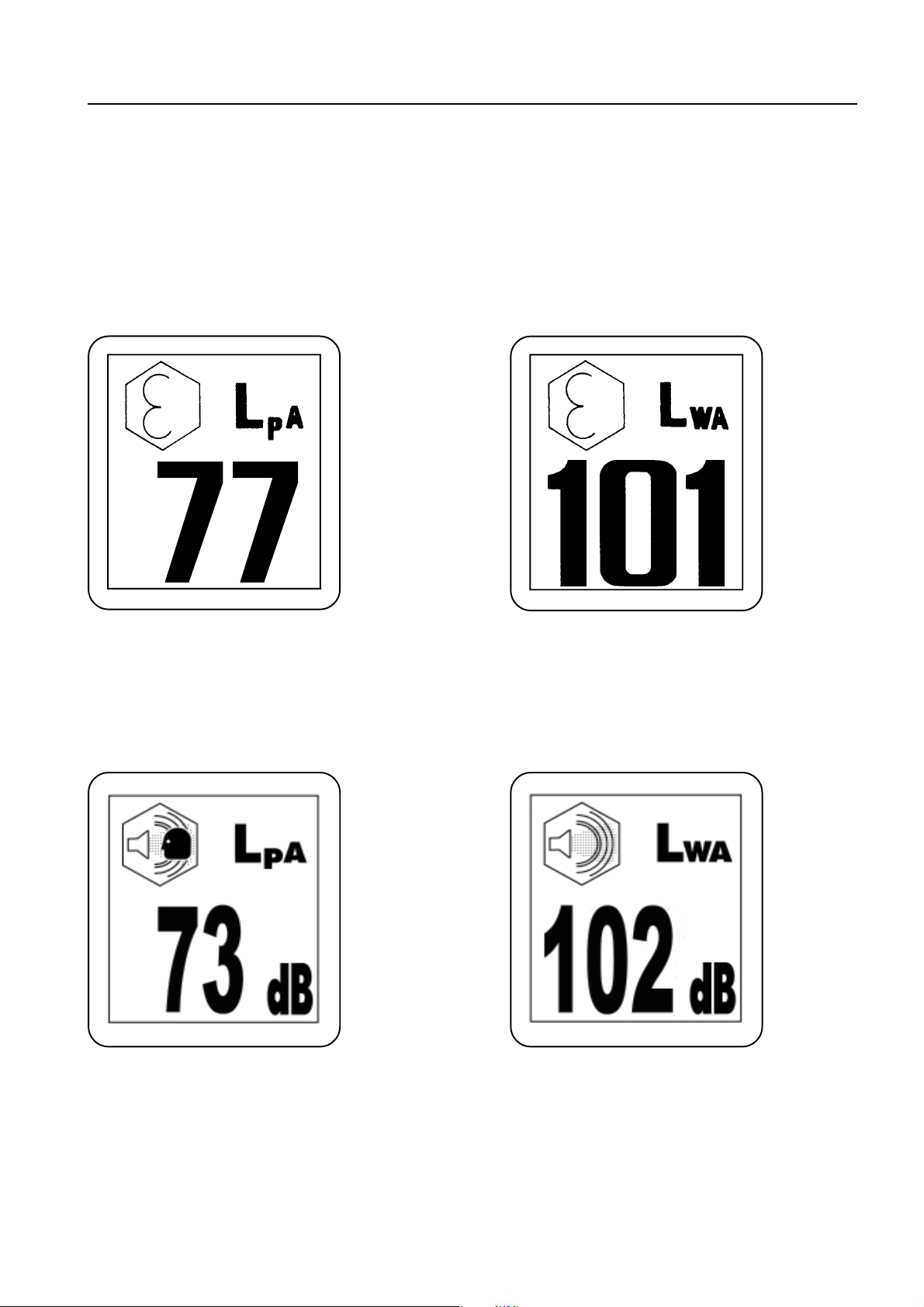

2.2 NOISE

PC130-6K + PC150LGP-6K

Valid until 31 december 2001

Operator ears noise value Ambient noise value

(Sound pressure level) (Sound power level)

2. SAFETY INFORMATION

95/27/EC

Noise level indicated is the guaranteed value as specified in the directive 86/662/EEC, as amended by 95/27/EC.

95/27/EC

Valid as of 1 January 2002

• Sound pressure level at the operator's station,

measured according to ISO6395 (Dynamic

test method, simulated working cycle)

• Sound power level emitted. This is the guaranteed value as specified in European directive

2000/14/EC.

2.3 VIBRATION

The weighted root mean square acceleration value to which the operator's

arms are subjected does not exceed 2.5 m/s

The weighted root mean square acceleration value to which the operator's

body is subjected does not exceed 0.5 m/s

These results were obtained by accelerometers during trench digging.

PC130/150LGP-6K ENG

2

2

0-3

3. INTRODUCTION

3.1 INTENDED USE

This Komatsu HYDRAULIC EXCAVATOR is designed to be used mainly for the following work:

• Digging work

• Smoothing work

• Ditching work

• Loading work

See the section "12.15 WORK POSSIBLE USING HYDRAULIC EXCAVATOR" for further details.

3.2 FEATURES

• This Komatsu HYDRAULIC EXCA V A T OR is equipped with various controls based on an advanced electronics

system.

° The monitor panel greatly facilitates daily maintenance and self-diagnosis.

° Working mode, active mode and travel speed are selectable.

° Digging and lifting force can be increased by light-touch control.

(For details, see operaton section).

• Adjustable wrist control levers make operations smooth and easy.

• Fresh filtered air heater assures comfortable operaton.

• Low noise level and smart urban-style design and coloring.

• Superb operating performance provided by powerful engine and high-performance hydraulic pumps.

• Low fuel consumption controlled by an electronic control system provides an environment-friendly machine.

3.3 BREAKING IN THE MACHINE

Your Komatsu machine has been thoroughly adjusted and tested before shipment.

However, operating the machine under severe conditions at the beginning can adversely affect the perform-

ance and shorten the life of the machine.

Be sure to break in the machine for the initial 100 hours (as indicated by the service meter).

During breaking in:

• Idle the engine for 5 minutes after starting it up.

• Avoid operation with heavy loads or at high speeds.

• Avoid sudden starts, sudded acceleration, sudden steering and sudded stops except in cases of emergency.

The precautions given in this manual for operating, maintenance and safety procedures are only those that

apply when this product is used for the specific purpose. If the machine is used for a purpose that is not listed in this

manual, Komatsu cannot bear any responsibility for safety. Alle consideration of safety in such operations is the

responsibility of the user.

Operations that are prohibited in this manual must never be carried out under any circumstances.

0-4

PC130/150LGP-6K ENG

4. LOCATION OF PLATES, TABLES TO ENTER SERIAL NO. AND DISTRIBUTOR

4. LOCATION OF PLATES, TABLES TO ENTER SERIAL NO.

AND DISTRIBUTOR

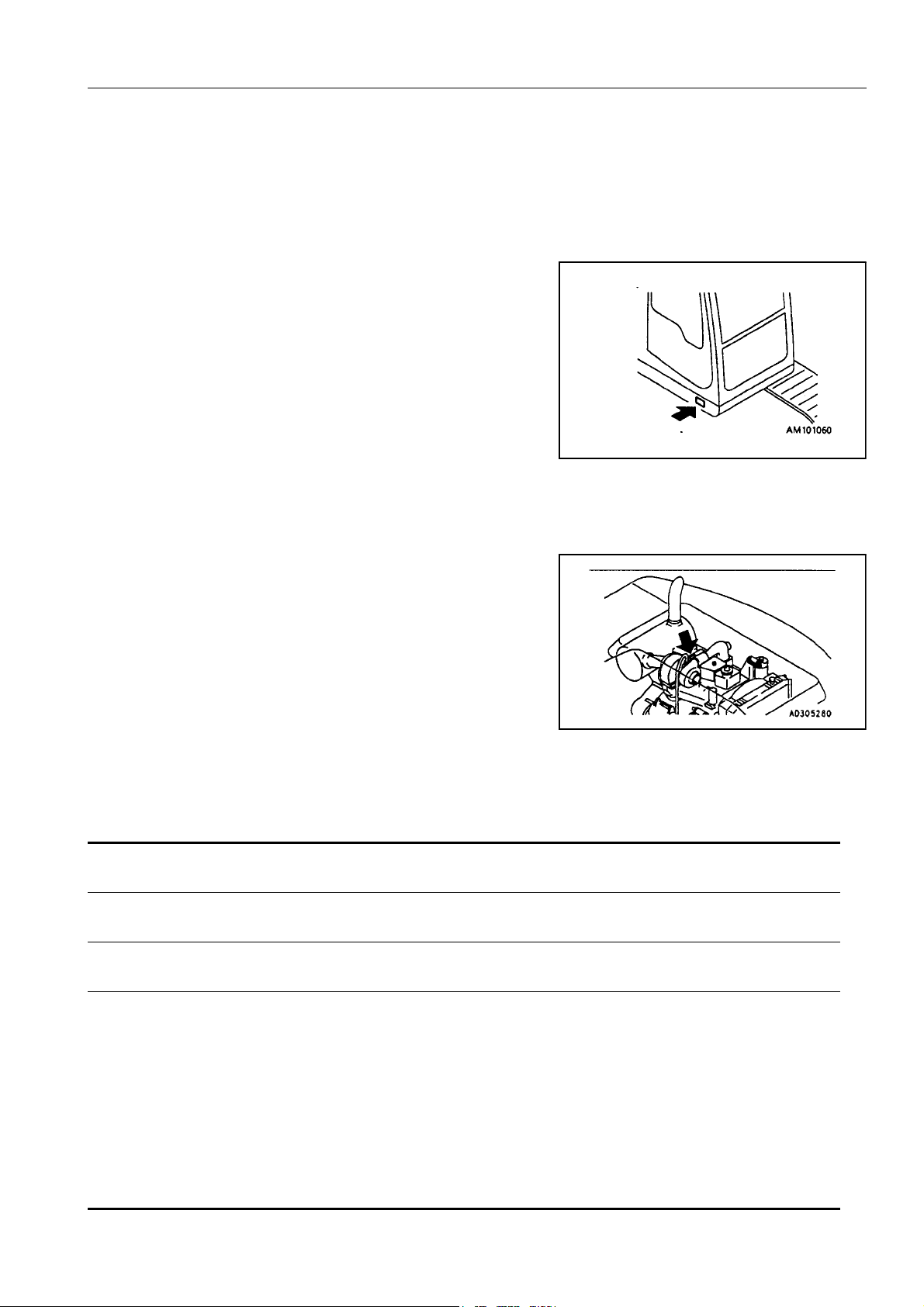

MACHINE SERIAL NO. PLATE POSITION

On the front bottom right of the operator’s cab

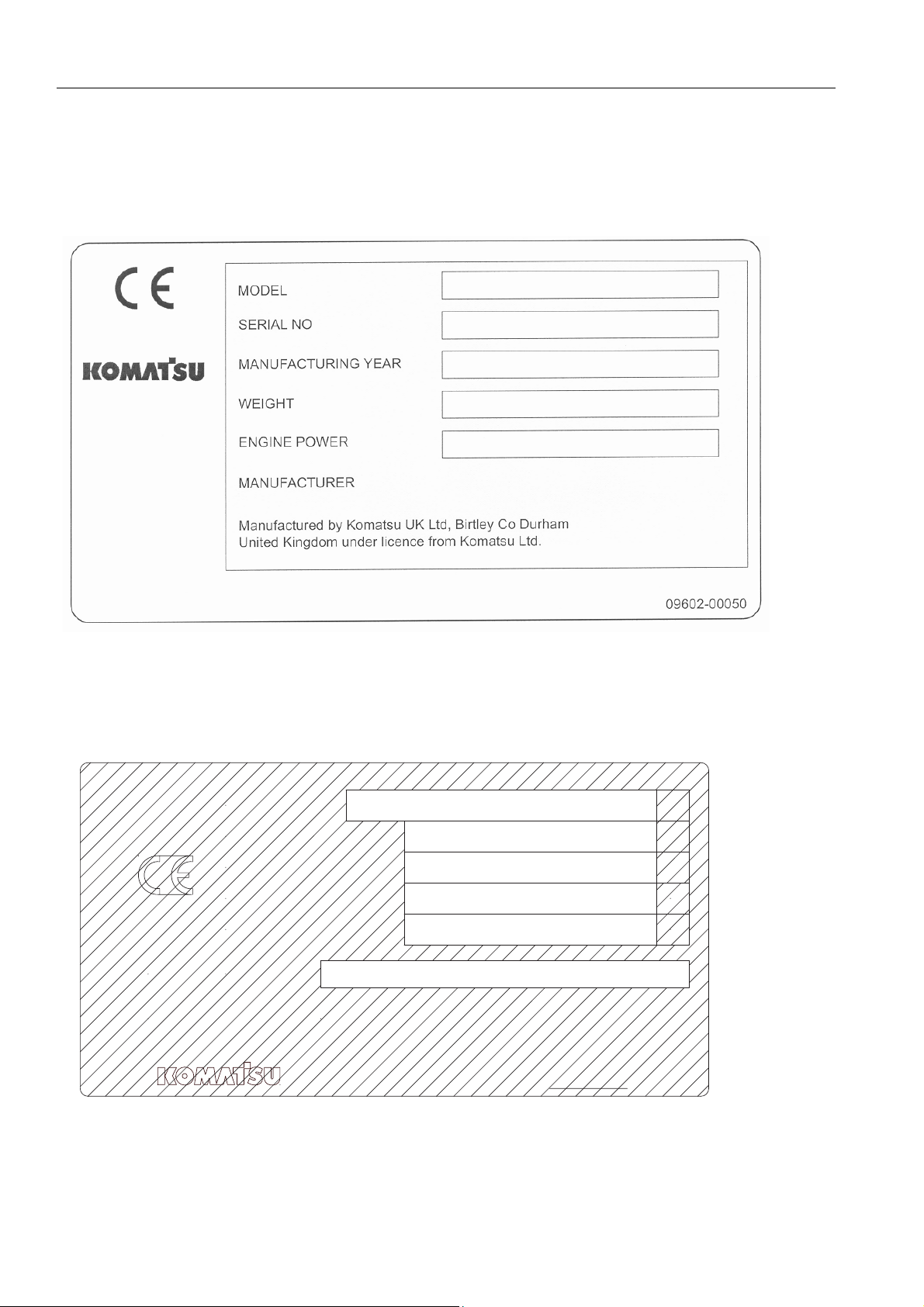

ENGINE SERIAL NO. PLATE POSITION

On the upper side of the engine cylinder head cover.

TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

Machine serial No.

Engine serial No.

Product Identification Number :

Manufacturers name: KOMATSU UK Ltd.

Address: Durham Road

Birtley

Chester-Le street

County Durham DH32QX

United Kingdom

Distributor

Address

Phone

0-5

4. LOCATION OF PLATES, TABLES TO ENTER SERIAL NO. AND DISTRIBUTOR

MACHINE SERIAL PLATE.

Valid until 31 December 2003

Valid as of 1 January 2004

MODEL

SERIALNo.

MANUFACT.YEAR

MASS

ENGINEPOWER

ProductIdentificationNumber

MANUFACTURER

kg

kW

ManufacturedbyKomatsuUKLtd.

forKomatsuLtd.,Tokyo,Japan

205-00-K1291

0-6

5. CONTENTS

1. Foreword.......................................................................................................................................... 0-1

2. Safety information .......................................................................................................................... 0-2

3. Introduction ..................................................................................................................................... 0-4

4. Location of plates, tabel to enter serial No. and distributor ....................................................... 0-5

SAFETY

6. General precautions ....................................................................................................................... 1-2

7. Precautions during operation........................................................................................................ 1-9

7.1 Before starting engine............................................................................................................ 1-9

7.2 After starting engine............................................................................................................... 1-11

7.3 Transportation........................................................................................................................ 1-18

7.4 Battery ................................................................................................................................... 1-19

7.5 Towing.................................................................................................................................... 1-21

7.6 Bucket with hook.................................................................................................................... 1-22

8. Precautions for maintenance......................................................................................................... 1-23

8.1 Before carrying out maintenance........................................................................................... 1-23

8.2 During maintenance............................................................................................................... 1-27

9. Position for attaching safety labels ................................................................................................... 1-32

9.1 Lifting capacity....................................................................................................................... 1-36

OPERATION

10. General view.................................................................................................................................... 2-2

10.1 General view of machine ....................................................................................................... 2-2

10.2 General view of controls and gauges .................................................................................... 2-3

11. Explanation of components........................................................................................................... 2-4

11.1 Machine monitor .................................................................................................................... 2-4

11.2 Switches ................................................................................................................................ 2-15

11.3 Control levers, pedals ............................................................................................................ 2-19

11.4 Ceiling window....................................................................................................................... 2-24

11.5 Front window ......................................................................................................................... 2-25

11.6 Door lock................................................................................................................................ 2-27

11.7 Cap, cover with lock............................................................................................................... 2-28

11.8 Luggage tray.......................................................................................................................... 2-29

11.9 Ashtray................................................................................................................................... 2-29

11.10 Car heater.............................................................................................................................. 2-30

11.11 Car radio................................................................................................................................ 2-32

11.12 Fuse....................................................................................................................................... 2-34

11.13 Fusible link............................................................................................................................. 2-34

11.14 Controllers ............................................................................................................................. 2-34

11.15 Tool box ................................................................................................................................. 2-34

11.16 Grease pump holder .............................................................................................................. 2-34

11.17 Refueling pump...................................................................................................................... 2-35

PC130/150LGP-6K ENG

0-7

5. CONTENTS

12. Operation ......................................................................................................................................... 2-36

12.1 Check before starting............................................................................................................. 2-38

12.2 Starting engine....................................................................................................................... 2-48

12.3 Operations and checks after starting engine ......................................................................... 2-51

12.4 Moving machine off................................................................................................................ 2-57

12.5 Steering machine................................................................................................................... 2-60

12.6 Stopping machine .................................................................................................................. 2-62

12.7 Swinging ................................................................................................................................ 2-63

12.8 Operation of work equipment................................................................................................. 2-64

12.9 Working mode selection ........................................................................................................ 2-65

12.10 Handling active mode ............................................................................................................ 2-67

12.11 Prohibitions for operation....................................................................................................... 2-69

12.12 Precautions for operation....................................................................................................... 2-71

12.13 Precautions when traveling up or down hills.......................................................................... 2-72

12.14 How to escape from mud....................................................................................................... 2-74

12.15 Work possible using hydraulic excavator............................................................................... 2-75

12.16 Replacement and inversion of bucket.................................................................................... 2-76

12.17 Parking machine .................................................................................................................... 2-78

12.18 Check after finishing work...................................................................................................... 2-79

12.19 Stopping engine..................................................................................................................... 2-80

12.20 Check after stopping engine .................................................................................................. 2-81

12.21 Locking .................................................................................................................................. 2-81

12.22 Overload warning device ....................................................................................................... 2-82

12.23 Offset boom ........................................................................................................................... 2-83

13. Transportation................................................................................................................................. 2-85

13.1 Loading, unloading work........................................................................................................ 2-85

13.2 Precautions for loading .......................................................................................................... 2-86

13.3 Precautions for transportation................................................................................................ 2-87

13.4 Lifting the machine................................................................................................................. 2-87

14. Cold weather operation .................................................................................................................. 2-92

14.1 Precautions for low temperature............................................................................................ 2-92

14.2 Precautions after completion of work..................................................................................... 2-94

14.3 After cold weather.................................................................................................................. 2-94

15. Long-term storage .......................................................................................................................... 2-95

15.1 Before storage ....................................................................................................................... 2-96

15.2 During storage ....................................................................................................................... 2-96

15.3 After storage .......................................................................................................................... 2-96

15.4 Starting machine after long-term storage .............................................................................. 2-96

16. Troubleshooting.............................................................................................................................. 2-97

16.1 When machine runs out of fuel .............................................................................................. 2-97

16.2 Phenomena that are not failures............................................................................................ 2-97

16.3 Method of towing machine..................................................................................................... 2-97

16.4 Using method for light-weight towing hook ............................................................................ 2-98

16.5 Precautions on particular jobsites.......................................................................................... 2-98

16.6 If battery is discharged........................................................................................................... 2-99

16.7 Other trouble.......................................................................................................................... 2-103

0-8

PC130/150LGP-6K ENG

5. CONTENTS

MAINTENANCE

17. Guides to maintenance .................................................................................................................. 3-2

18. Outlines of service.......................................................................................................................... 3-4

18.1 Outline of oil, fuel, coolant ..................................................................................................... 3-4

18.2 Outline of electric system....................................................................................................... 3-8

18.3 Outline of hydraulic system.................................................................................................... 3-9

19. Wear parts list ................................................................................................................................. 3-10

20. Use of fuel, coolant and lubricants according to ambient temperature .................................... 3-11

21. Standard tightening torques for bolts and nuts .......................................................................... 3-15

21.1 Introduction of necessary tools .............................................................................................. 3-15

21.2 Torque list .............................................................................................................................. 3-16

22. Periodic replacement of safety critical parts ............................................................................... 3-17

23. Maintenance schedule chart.......................................................................................................... 3-21

23.1 Maintenance schedule chart.................................................................................................. 3-21

23.2 Maintenance interval when using hydraulic breaker.............................................................. 3-23

24. Service procedure........................................................................................................................... 3-24

24.1 Initial 250 hours service ......................................................................................................... 3-24

24.2 When required ....................................................................................................................... 3-25

24.3 Check before starting............................................................................................................. 3-41

24.4 Every 50 hours service .......................................................................................................... 3-46

24.5 Every 100 hours service ........................................................................................................ 3-47

24.6 Every 250 hours service ........................................................................................................ 3-50

24.7 Every 500 hours service ........................................................................................................ 3-54

24.8 Every 1000 hours service ...................................................................................................... 3-60

24.9 Every 2000 hours service ...................................................................................................... 3-63

24.10 Every 4000 hours service ...................................................................................................... 3-65

24.11 Every 5000 hours service ...................................................................................................... 3-66

SPECIFICATIONS

25. Specifications.................................................................................................................................. 4-2

PC130/150LGP-6K ENG

0-9

5. CONTENTS

OPTIONS AND ATTACHMENTS

26. General Precautions .............................................................................................................................. 5-2

26.1 General precautions related to safety......................................................................................... 5-2

26.2 Precautions when installing attachments.................................................................................... 5-3

27. Handling bucket with hook ..................................................................................................................... 5-4

27.1 Checking for damage to bucket with hook.................................................................................. 5-4

27.2 Prohibited operations.................................................................................................................. 5-4

27.3 Precautions during operation...................................................................................................... 5-4

28. Machine ready for attachments.............................................................................................................. 5-5

28.1 Explanation of components ........................................................................................................ 5-5

28.2 Operation .................................................................................................................................... 5-7

28.3 Long-term storage ...................................................................................................................... 5-9

28.4 Specifications.............................................................................................................................. 5-9

29. Introduction of optianal parts and attachments .................................................................................... 5-10

29.1 Introduction of optianal parts and attachments......................................................................... 5-10

29.2 Attachment installation combination table .................................................................................5-11

29.3 Selection of track shoes............................................................................................................ 5-12

30. Extending machine service life ............................................................................................................ 5-14

30.1 Hydraulic breaker...................................................................................................................... 5-14

30.2 Power ripper ............................................................................................................................. 5-17

30.3 Fork grab .................................................................................................................................. 5-18

30.4 Grapple bucket ......................................................................................................................... 5-19

30.5 Scrap grapple ........................................................................................................................... 5-20

30.6 Crusher & cutter........................................................................................................................ 5-21

30.7 Hydraulic pile driver .................................................................................................................. 5-22

30.8 Hydraulic excavator with multi-purpose crane .......................................................................... 5-23

0-10

PC130/150LGP-6K ENG

SAFETY

PC130/150LGP-6K ENG

WARNING

Read and follow all safety precautions. Failure to do so may result in serious injury or death.

This safety section also contains precautions for optional equipment

and attachments.

1-1

WARNING: for reasons of

safety, always follow these

6 GENERAL PRECAUTIONS

safety precautions.

SAFETY RULES

• Only trained and authorised personnel can operate and maintain the machine.

• Follow all safety rules, precautions and instructions when operating or performing maintenance on the machine.

• Do not operate the machine of you are not feeling well, or if you are taking medicine which will make you

sleepy, or if you have been drinking. Operating in such condition will adversely affect your judgement and

may lead to an accident.

• When working with another operator of with a person on worksite traffic duty, be sure that all personnel

understand all hand signals that are to be used.

• Always follow all rules related to safety .

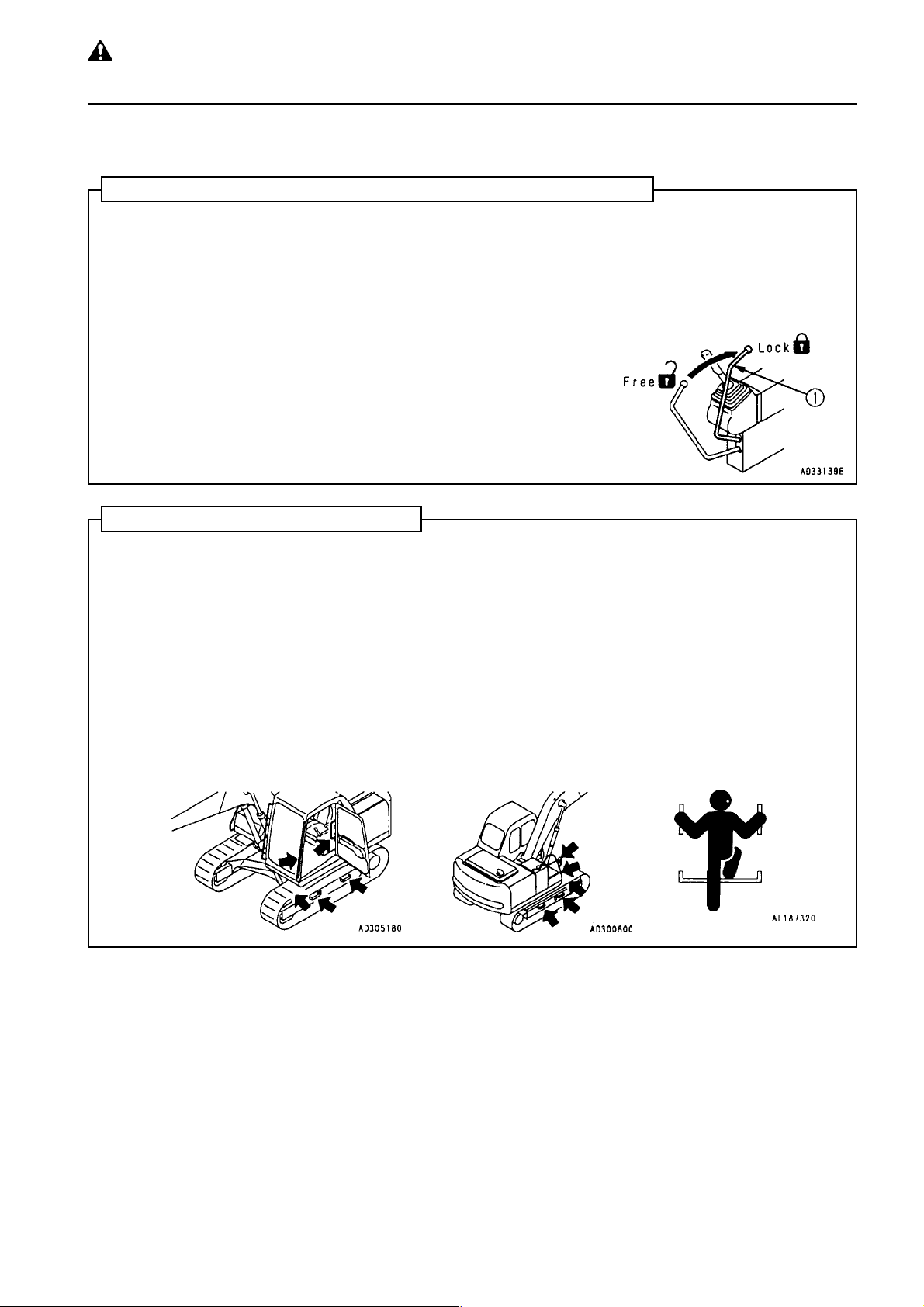

SAFETY FEATURES

• Be sure that all guards and covers are in their proper position. Have guards and covers repaired if damaged.

• Use safety features such as safety lock levers 햲 properly .

• Never remove any safety features. Always keep them in good operating condition.

Safety lock lever see "12.17 PARKING MACHINE".

• Improper use of safety features could result in serious bodily injury or death.

CLOTHING AND PERSONAL PROTECTIVE ITEMS

• Avoid loose clothing, jewelery , and loose long hair . They can catch on controls or in moving parts and cause

injury or death.

• Also, do not wear oily clothes, because they are flammable.

• Wear a hard hat, safety glasses, safety shoes, mask or gloves wehn operating or maintaining the machine.

Always wear safety goggles, hard hat and heavy gloves if your job involves scattering metal chips or minute

materials particularly when driving pins with a hammer and when cleaning the air cleaner element with

compressed air. Check also that there is no one near the machine.

• Check that all protective equipment functions properly before using.

UNAUTHORIZED MODIFICA TION

Any modification made without authorization from Komatsu can create hazards. Before making a modification,

consult your Komatsu distributor. Komatsu will not be responsible for any injury or damage caused by any

unauthorized modification.

1-2

PC130/150LGP-6K ENG

WARNING: Failure to follow

these safety precautions may

lead to a serious accident.

6 GENERAL PRECAUTIONS

ALWA YS APPLY LOCK WHEN LEAVING OPERATOR'S SEAT

• When standing up from the operator's seat, always place the safety lock levers 햲 securely in the LOCK

position. If you accidentally touch the levers when they are not locked, the work equipment may suddenly

move and cause serious injury or damage.

• When leaving the machine, lower the blade and ripper completely to the ground, set the safety lock levers 햲

to the LOCK position, then stop the engine. Use the key to lock alle the equipment.

Always remove the key and take it with you.

Work equipment posture see "12.17 PARKING MACHINE".

Locking see "12.21 LOCKING"

MOUNTING AND DISMOUNTING

• Never jump on or off the machine. Never get on or off a moving machine.

• When getting on or off the machine, always face the machine and use the handrails and steps.

• Never hold any control levers or lock levers when getting on or off the machine.

• To ensure safety, always maintain three-point contact (both feet and one hand, or both hands and one foot)

with the handrails and steps to ensure that you support yourself.

• If there is anyu oil, grase, or mud on the handrails or steps, wipe it off immediately . Always keep these parts

clean. Repair any damage and tighten any loose bolts.

• When getting on or off the machine, or when moving along the top of the track, if you hold the handrail inside

the door when moving on top of the track shoe, and the door lock is not locked securely , the door may move

and cause you to fall.

Always lock the door securely .

Method of locking door see "11.6 DOOR LOCK"

PC130/150LGP-6K ENG

1-3

WARNING: for reasons of

safety, always follow these

6 GENERAL PRECAUTIONS

safety precautions.

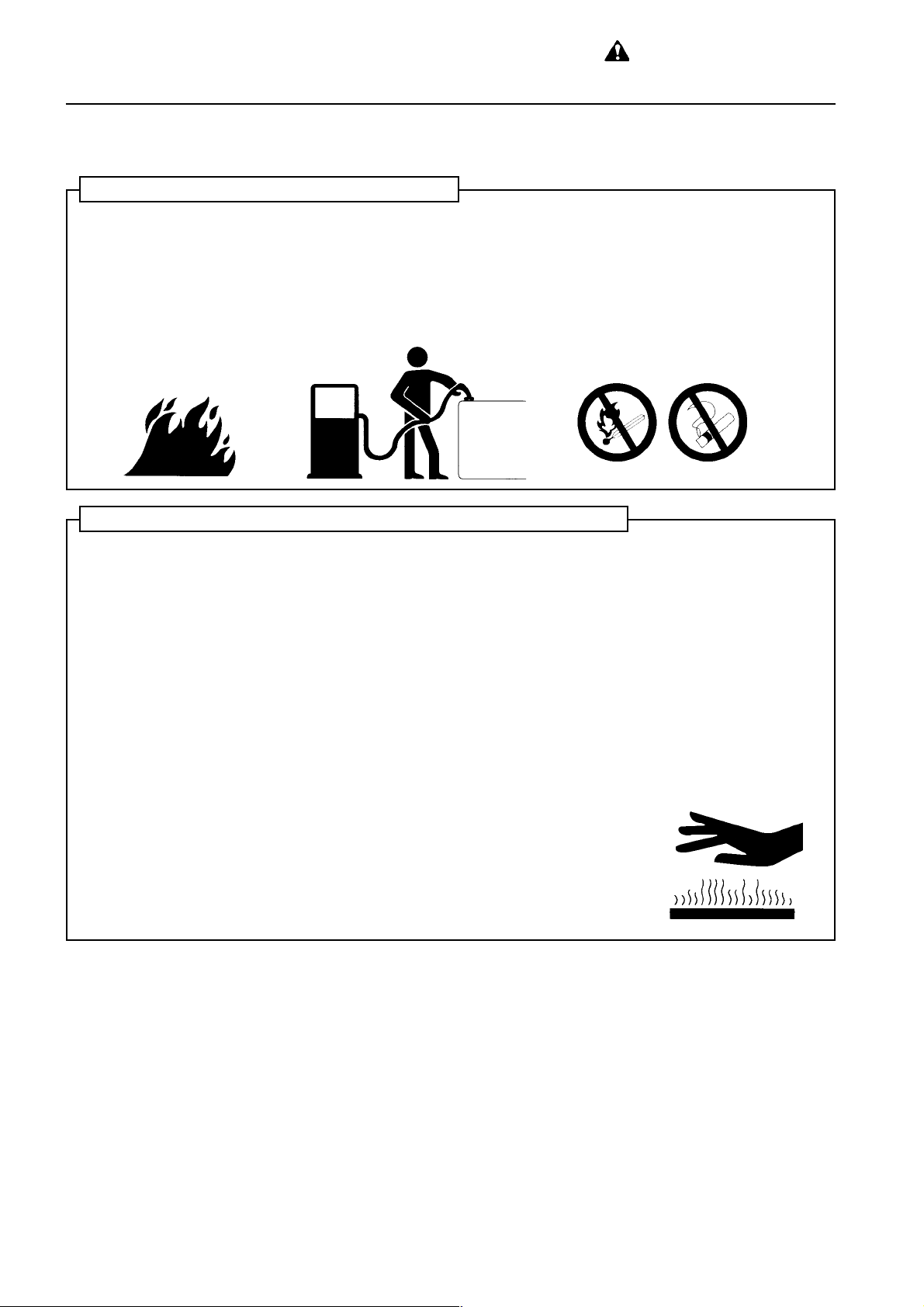

FIRE PREVENTION FOR FUEL AND OIL

Fuel, oil, and antifreeze can be ignited by a flame. Fuel is particularly flammable and can be hazardous.

Always observe the following:

• Keep any flame or lighted cigarette away form flammable fluids.

• Stop the engine and do not smoke when refueling

• Tighten all fuel and oil caps securely

• Use well-ventilated areas for adding or storing oil and fuel.

• Keep oil and fuel in the determined place and do not allow unauthorized persons to enter.

PRECAUTIONS WHEN HANDLING AT HIGH TEMPERATURE

• Immediately after operations are stopped, the engine oil and hydraulic oil are at high temperature and are

still under pressure. Attempting to remove the cap, drain the oil or water, or replace the filters may lead to

serious burns. Always wait for the temperature to go down, and follow the specified procedures when carrying out these operations.

• T o prevent hot water from spurting out, stop the engine, wait for the water to cool, then loosen the cap slowly

to relieve the pressure before removing the cap.

(When checking if the water temperature has gone down, put your hand near the front face of the radiator

and check the air temperature. Be careful not to touch the radiator).

• To prevent hot oil from spurting out, stop the engine, wait for the oil to cool, then loosen the cap slowly to

relieve the pressure before removing the cap.

(When checking if the oil temperature has gone down, put your hand near the front face of the hydraulic tank

and check the air temperature. Be careful not to touch the hydraulic tank).

1-4

PC130/150LGP-6K ENG

WARNING: Failure to follow

these safety precautions may

lead to a serious accident.

6 GENERAL PRECAUTIONS

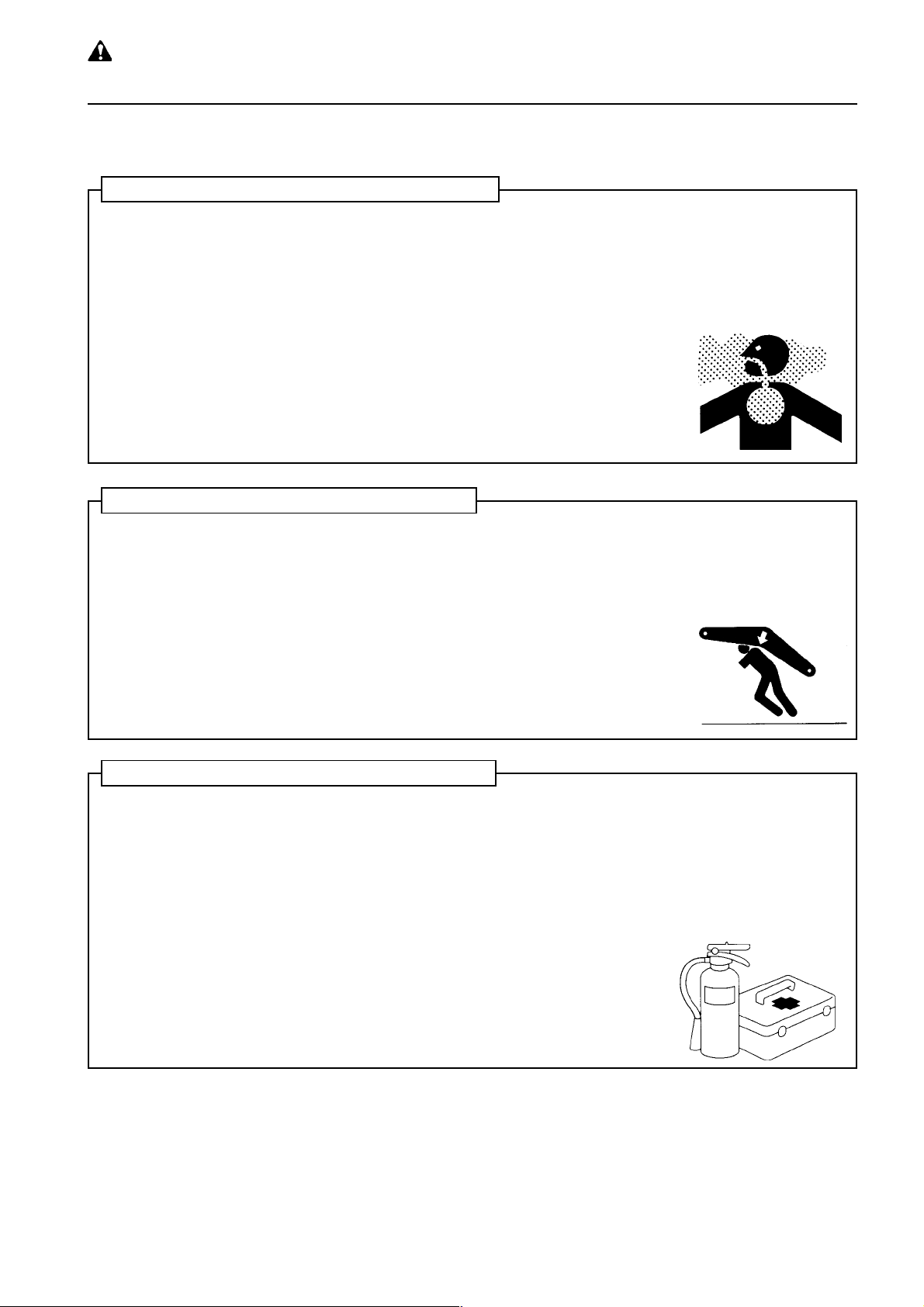

ASBESTOS DUST HAZARD PREVENTION

Asbestos dust can be hazardous to your health if it is inhaled.

Komatsu does not use asbestos in its products, but if you handle materials containing asbestos fibers, follow

the guidelines given below:

• Never use compressed air for cleaning.

• Use water to keep down the dust when cleaning

• If there is danger that there may be asbestos dust in the air, operate the machine from an upwind position

whenever possible.

• Use an approved respirator if necessary .

CRUSHING OR CUTTING PREVENTION

Do not enter, or put your hand or arm or any other part of your body between movable parts such as the work

equipment and cylinders, or between the machine and work equipment.

If the work equipment is operated, the clearance will change and this may lead to serious damage or personel

injury.

If it is necessary to go between movable parts, always lock the levers and be sure that the work equipment

cannot move. For details, see "8. PRECAUTIONS FOR MAINTENANCE".

FIRE EXTINGUISHER AND FIRST AID KIT

Always follow the precautions below to prepare for acton if any injury or fire should occur.

• Be sure that fire extinguishers have been provided and read the labels to ensure that you know how to use

them.

• Provide a first aid kit at the storage point. Carry out periodic checks and add to the contents if necessary.

• Know what to do in the event of a fire or injury.

• Decide which phone numbers of persons (doctor, ambulance, fire station etc.) to contact in case of an

emergency. Post these contact numbers in specified places and make sure that all personnel know the

numbers and correct contact procedures.

PC130/150LGP-6K ENG

1-5

WARNING: for reasons of

safety, always follow these

6 GENERAL PRECAUTIONS

safety precautions.

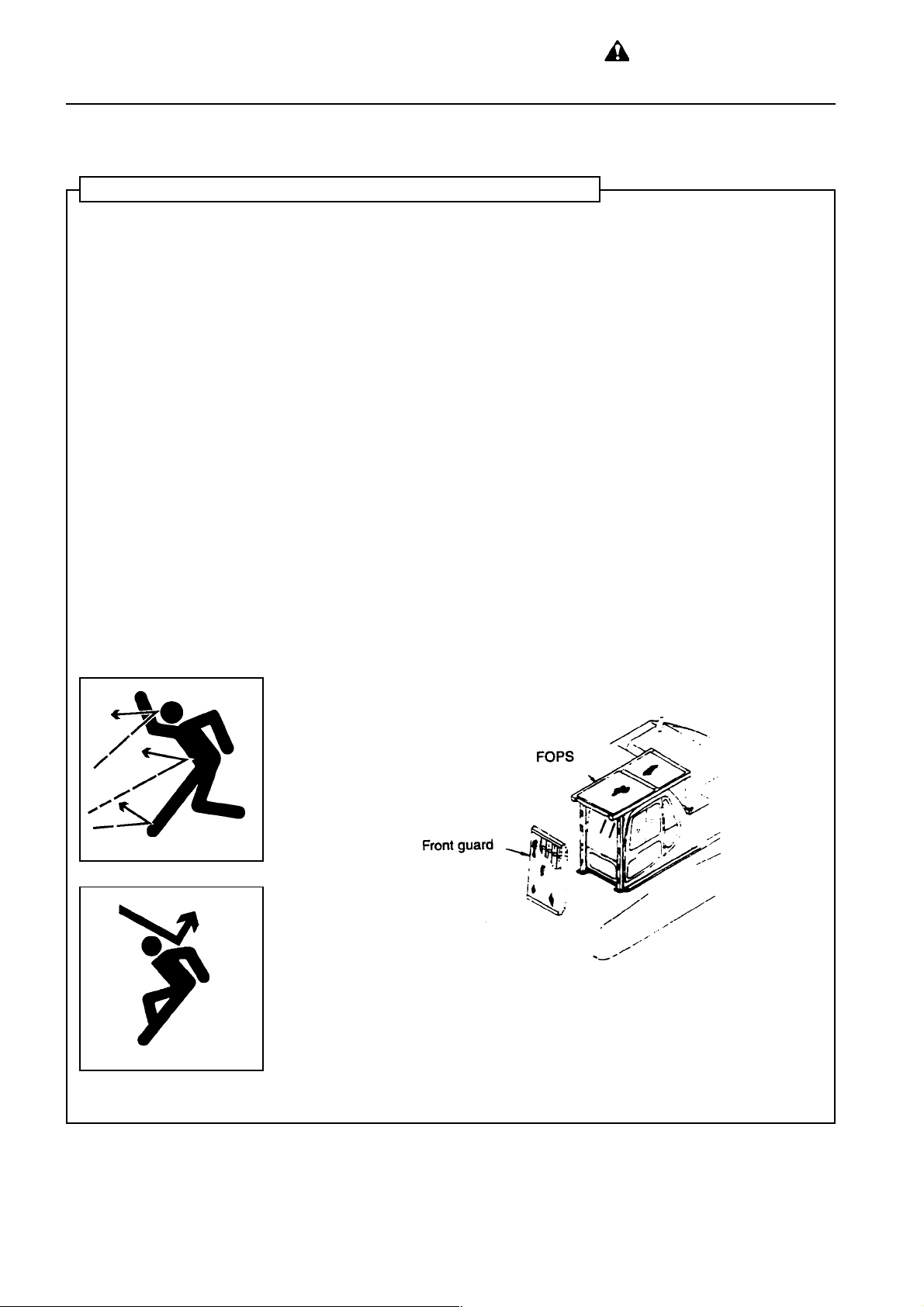

PROTECTION AGAINST FALLING OR FLYING OBJECTS

If there is any danger of falling or flying objects hitting the operator, install protective guards in place to protect

the operator as required for each particular situation.

• For work with breakers, install a front guard on the windshield. Also, place a laminate coating sheet over the

windshield.

• For demolition of shear workk, install a front guard on the windshield and a top guard on the cab. Also, place

a laminate coating sheet over the windshield.

• For work in mines, quarries, demolition, tunnels or other places where there is danger of falling rocks, put

FOPS (falling object protective structure) in place. Also, place a laminate coating sheet over the windshield.

The above comments are made with regards to typical working conditions. By all means you should put on

other guards if required by conditions at your particular site.

For details of safety guards, please contact your Komatsu distributor.

Also, even for other types of work, if there is any danger of being hit by falling or flying objects or of objects

entering the operator's cab, select and install a guard that matches the working conditions.

Be sure to close the front window before commencing work.

When carrying out the above operations, make sure to keep all persons other than the operator outside that

range of falling or flying objects. Be particularly sure to maintain a proper distance when carrying out shear

operations

1-6

PC130/150LGP-6K ENG

WARNING: Failure to follow

these safety precautions may

lead to a serious accident.

6 GENERAL PRECAUTIONS

PRECAUTIONS FOR ATTACHMENTS

• When installing and using an optional attachment, read the instruction manual for the attachment and the

information related to attachments in this manual.

• Do not use attachments that are not authorized by Komatsu or your Komatsu distributor. Use of unauthorized attachments could create a safety problem and adversely affect the proper operation and useful lif of

the machine.

• Any injuries, accidents, product failures resulting from the use of unauthorized attachments will not be the

responsibility of Komatsu.

ERMERGENCY EXIT

• When exit by normal means is prevented in an emergency you can

get out through the emergency exit (rear window).

• Pull the ring at the bottom of the window and remove strip. This will

allow you to push out the glass.

ROT A TING BEACON (OPTION)

• When the machine is operated on or beside a road, a rotating beacon is required to avoid a traffic accident

• Contact your Komatsu distributor to install a beacon lamp.

ELECTROMAGNETIC INTERFERENCE

When this machine is operating close to a source of high electromagnetic interference, such as a radar

station, some abnormal phenomena may be observed.

• The display on the monitor panel may behave erratically

• The warning buzzer may sound

These effects do not signify a malfunction and the machine will return to normal as soon as the source of

interference is removed.

PC130/150LGP-6K ENG

1-7

WARNING: for reasons of

safety, always follow these

6 GENERAL PRECAUTIONS

safety precautions.

VENTILATION FOR ENCLOSED AREAS

Exhaust fumes from the engine can kill.

• If it is necessary to start the engine within an enclosed area, or you handle fuel, flushing oil, or paint, open

the doors and windows to ensure that you provide adequate ventilation to prevent gas poisoning.

• If opening the doors and windows still does not provide adequate ventilation, set up fans.

PRECAUTIONS WITH CAB GLASS

If by mistake the cab glass on the work equipment side should crack, there is danger of direct contact between

the operator's body and the work equipment. This is extremely dangerous.

If the glass is cracked, stop operations immediately and replace the glass.

1-8

PC130/150LGP-6K ENG

7. PRECAUTIONS DURING

OPERATION

WARNING: Failure to follow

these safety precautions may

lead to a serious accident.

7.1 BEFORE STARTING ENGINE

SAFETY A T WORKSITE

• Before starting operations, thoroughly ckeck the area for any unusual conditions that could be dangerous.

• Check the terrain and condition of the ground at the worksite, and determine the best and safest method of

operation.

• Make the ground surface as hard and horizontal as possible before carrying out operations.

If the jobsite is dusty , spray water before starting operations.

• If you need to operate on a road, protect pedestrians and cars by designating a person for worksite traffic

duty or by installing fences and putting up NO ENTRY signs around the worksite.

• If water lines, gas lines, or high-voltage electrical lines may be buried under the worksite, contact each utility

and identify their locations. Be careful not to sever of damage any of these lines.

• Check the ground condition and the depth and flow of water before operating in water or crossing a river.

NEVER be in water which is in excess of the permissible water depth.

Permissible water depth see "12.12 PRECAUTIONS FOR OPERATION"

CHECKS BEFORE STARTING ENGINE

Carry out the following checks before starting the engine at the beginning of the days work.

Failure to carry out these checks may lead to serious injury or damage.

• Completely remove all flammable materials accumulated around the engine and battery, returm all fuel

containers to teir propeer place, remove all parts and tools from the operator's compartment, and remove

any dirt from the mirrors, handrails, and steps.

Walk-around checks see "12.1.1 WALK AROUND CHECK".

• check the coolant level, fuel level, and oil level in the hydraulic tank, check for clogging of the air cleaner, and

check the electric wiring.

Checks before starting see "12.1.2 CHECK BEFORE STARTING"

• Adjust the operator's seat to a positions where it is easy to carry out operations, and check for wear or

damage to the seat belt and seat belt mounting equipment.

Adjusting operator's seat see "12.1.3 ADJUSTING BEFORE STARTING OPERATION".

• Check that the gauges work properly, and check that the control levers are all at the NEUTRAL position.

Method of checking operation of gauges

see "12.1.4 OPERATIONS AND CHECKS BEFORE STARTING ENGINE".

• If any of the mirrors are broken, replace them with new ones.

• When removing and installing the mirrors for replacement or transportation - see "13.3 PRECAUTIONS

FOR TRANSPORT ATION".

• Check that the mirrors and window glass provide a clear view.

If the above inspections show any abnormality, carry out repairs immediately.

PC130/150LGP-6K ENG

1-9

WARNING: for reasons of

safety, always follow these

7. PRECAUTIONS DURING OPERA TION

safety precautions.

WHEN ST ARTING ENGINE

• Walk around your machine again just before mounting it, and check for people and objects that might be in

the way .

• Never start the engine if a warning tag has been attached to the work equipment control lever.

• When starting the engine, sound the horn as an alert.

• Start and operate the machine only while seated.

• An additional worker may ride in the machine only when sitting in the passenger seat, if fitted. Do not allow

anyone to ride on the machine body .

• Do not short circuit the starting motor circuit to start the engine. It is not only dangerous, but will also cause

damage to the equipment.

1-10

PC130/150LGP-6K ENG

WARNING: Failure to follow

these safety precautions may

lead to a serious accident.

7. PRECAUTIONS DURING OPERA TION

7.2 AFTER STARTING ENGINE

CHECKS AFTER STARTING ENGINE

Failure to carry out the checks properly after starting the engine will lead to delays in discovery of abnormalities, and this may lead to serious injury or damage to the machine.

When carrying out the checks, use a wide area where there are no obstructions. Do not allow anyone near the

machine.

• Check the operation of the gauges and equipment, and check the operation of the blade, ripper, brakes,

travel system, and steering system.

• Checks for any abnormality in the sound of the machine, vibration, heat, smell, or gauges; check also that

there is no leakage of air, oil, or fuel.

• If any abnormality is found, carry out repair immediately.

If the machine is used when it is not in proper condition, it may lead to serious injury or damage to the

machine.

PRECAUTIONS WHEN ST ARTING OFF

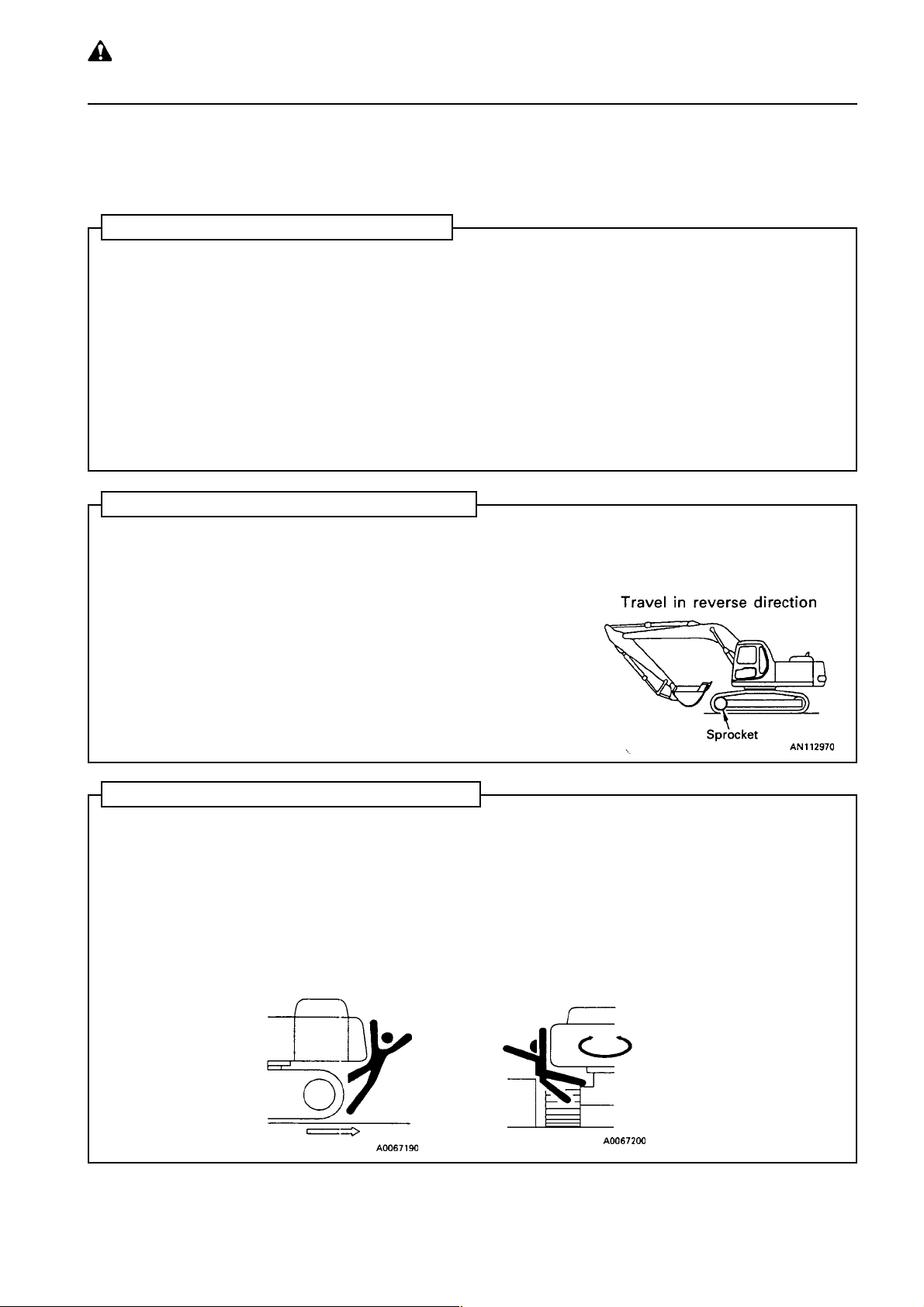

Check the direction of the track frame before operating the travel lever.

• When the sprocket is at the front, the operaton of the travel lever is

reversed, so operate the machine carefully .

Method of steering machine see "12.4 MOVING MACHINE

OFF".

Before moving the machine off, check again that there are no persons or obstacles in the surrounding area.

• When moving the machine off, sound the horn to warn people in the

surrounding area.

• Always sit in the operator's seat when driving the machine.

• Always close the door of the operator' cab and check that the door is

locked in position securely .

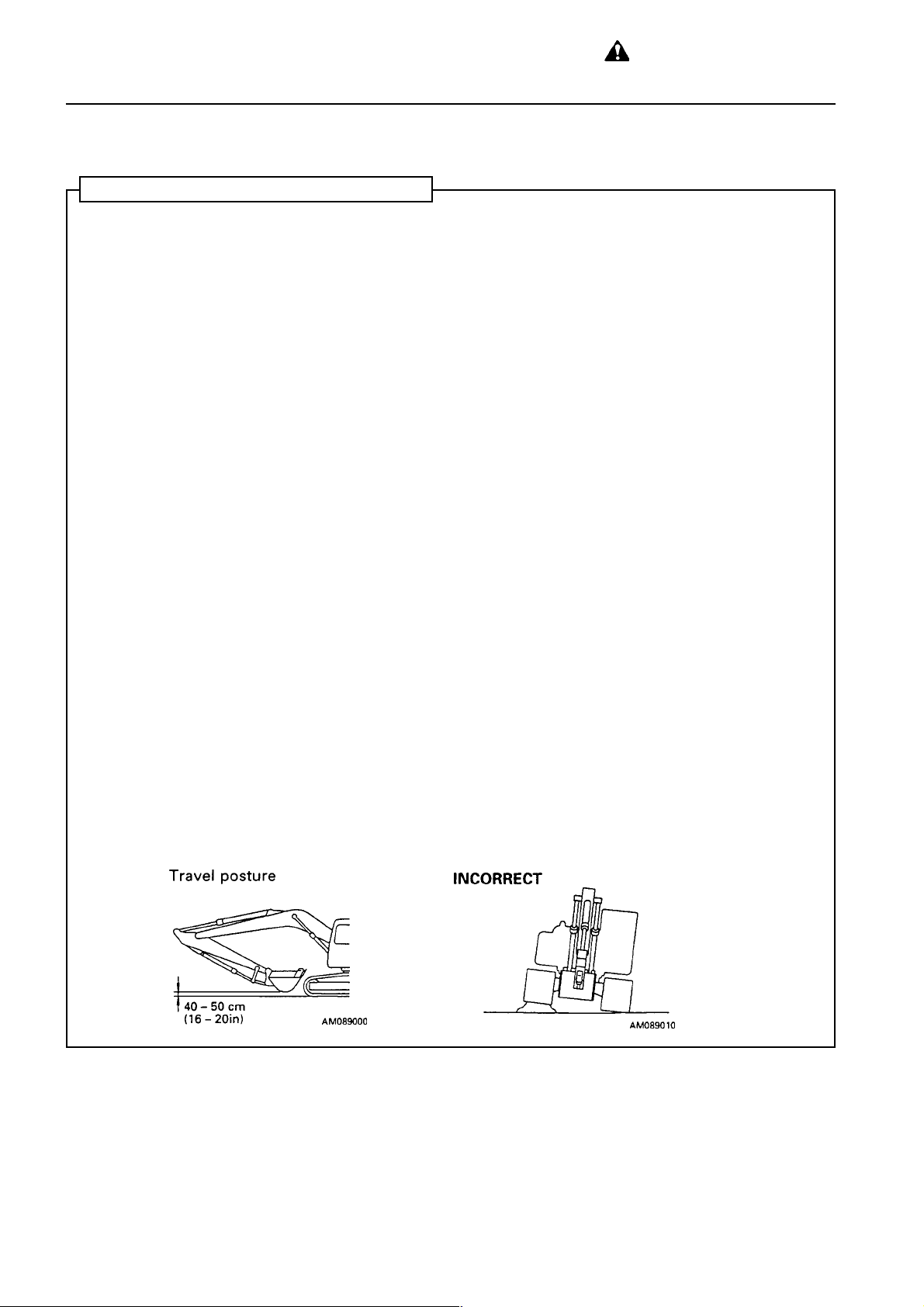

CHECK WHEN CHANGING DIRECTION

To prevent serious injury or death, always do the following before moving the machine or doing the levelling

work.

• Before changing between forward and reverse, reduce speed and stop the machine.

• Before operating the machine, sound the horn to warn people in the area.

• Check that there is no one near the machine. Be particularly careful to check behind the machine.

• When operating in areas that may be hazardous or have poor visibility , designate a person to direct worksite

traffic.

• Ensure that no unauthorized person can come within the direction of turning or direction of travel.

Always be sure to carry out the above precautions even when the machine is equipped with a backup alarm

and mirrors.

PC130/150LGP-6K ENG

1-11

WARNING: for reasons of

safety, always follow these

7. PRECAUTIONS DURING OPERA TION

safety precautions.

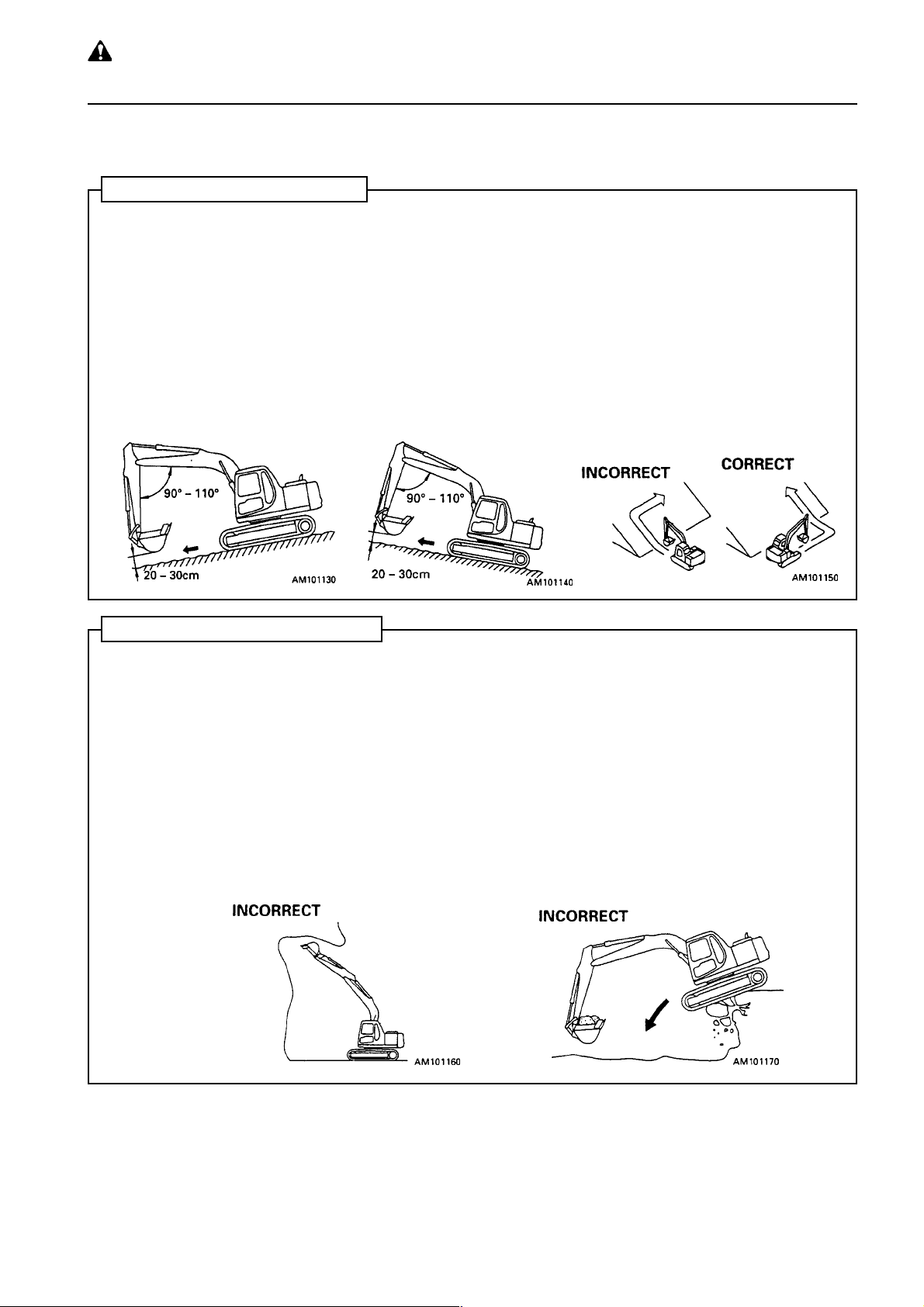

PRECAUTIONS WHEN TRA VELLING

• Never turn the key in the starting switch to the OFF position when travelling.

It is dangerous if the engine stops when the machine is travelling, because it becomes impossible to operate

the steering.

• It is dangerous to look around you when operating. Always concentrate on your work.

• It is dangerous to drive too fast, or to start suddenly, stop suddenly, turn sharply or zigzag.

• If you find any abnormality in the machine during operation (noise, vibration, smell, incorrect gauges, air

leakage, oil leakage, etc.) move the machine immediately to a safe place and look for the cause.

• Set the work equipment to a height of 40 - 50 cm from the ground level and travel on level ground.

• When travelling do not operate the work equipment control levers. If the work equipment control levers have

to be operated, never operate them suddenly .

• Do not operate the steering suddenly. The work equipment may hit the ground surface and cause the machine to lose its balance, or may damage the machine or structures in the area.

• When travelling on rough ground, travel at low speed, and avoid sudden changes in direction.

• Avoid travelling over obstacles as far as possible. If the machine has to travel over an obstacle, keep the

work equipment as close to the ground as possible and travel at low speed. Never travel over obstacles

which make the machine tilt strongly (10° or more).

• When travelling or carrying out operations, always keep your distance from other machines or structures to

avoid coming into contact with them.

• NEVER be in water which is in excess of the permissible water depth.

Permissible water depth see "12.12 PRECAUTIONS FOR OPERATON".

• When passing over bridges or structures on private land, check first that the structure is strong enough to

support the mass of the machine. When travelling on public roads, check first with the relevant authorities

and follow their instructions.

1-12

PC130/150LGP-6K ENG

WARNING: Failure to follow

these safety precautions may

lead to a serious accident.

7. PRECAUTIONS DURING OPERA TION

TRAVELLING ON SLOPES

• Travelling on slopes could result in the machine tipping over or slipping to the side.

• When travelling on slopes, keep the blade approximately 20 - 30 cm above the ground. In case of emergency, quickly lower the bucket to the ground to help the machine to stop.

• Do not turn on slopes or travel across slopes. Always go down to a flat place to perform these operations.

Method of travelling on slopes See "12.13 PRECAUTIONS WHEN TRA VELLING UP OR

DOWN HILLS".

• Do not travel on grass, fallen leaves or wet steel plates. Even slight slopes may cause the machine to slip to

the side, so travel at low speed and make sure that the machine is always travelling directly up or down the

slope.

• If the engine stops on a slope, place the travel lever at the neutral position and lower the bucket to the

ground. Do not operate the steering. There is danger that the machine will turn under its own weight.

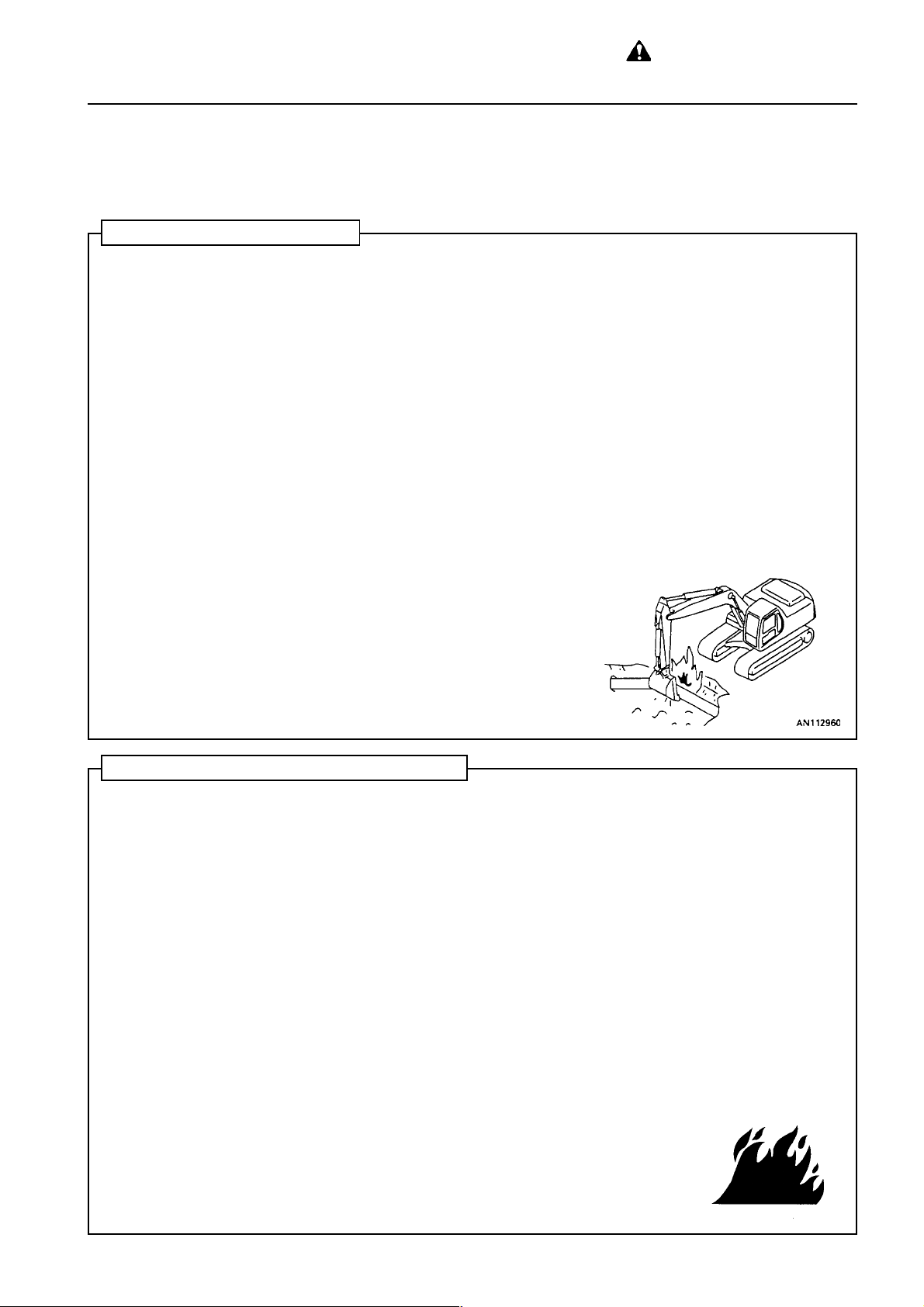

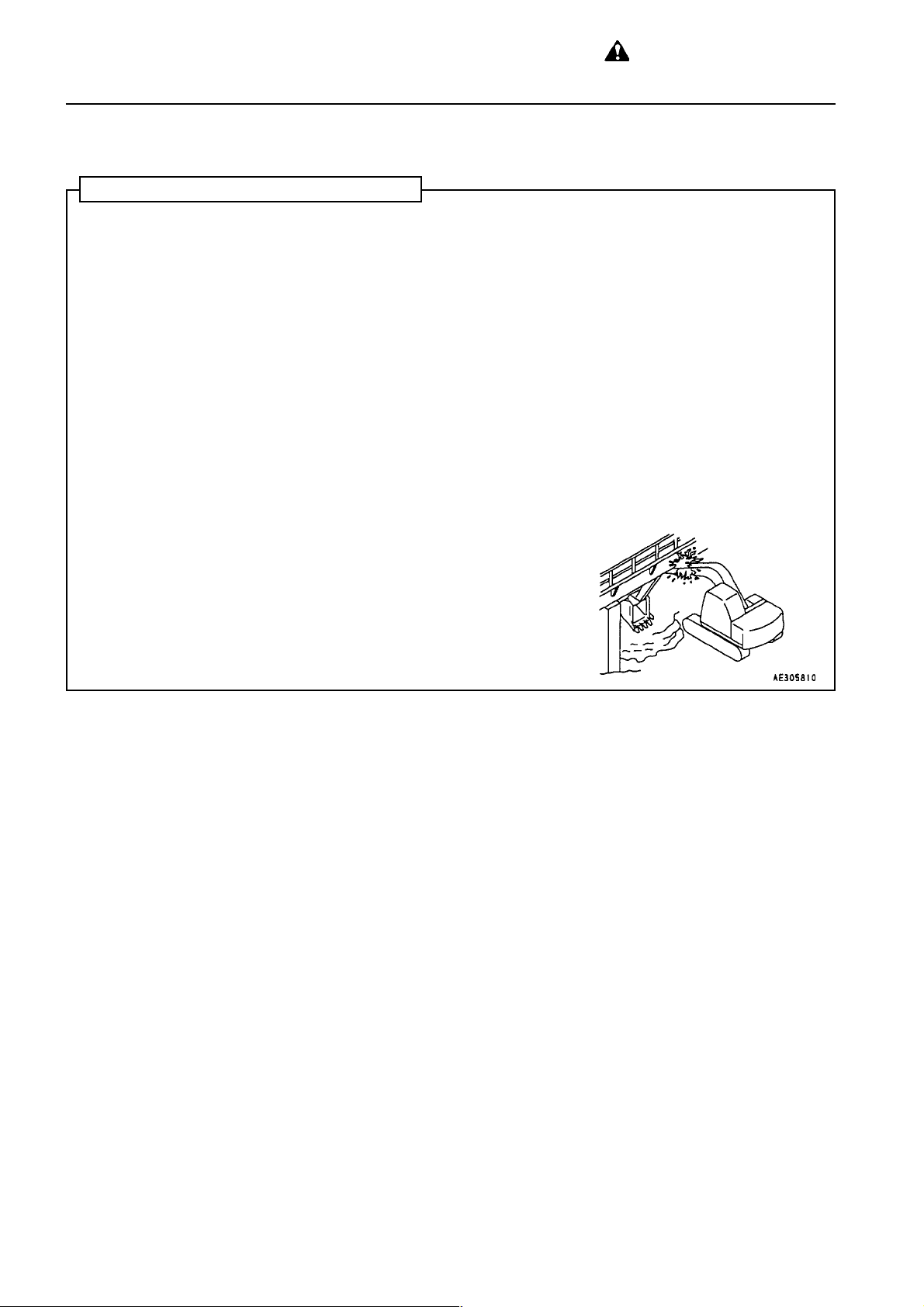

PROHIBITED OPERA TIONS

• Do not dig the work face under an overhang. This may cause the overhang to collapse and fall on top of the

machine.

• Do not carry out deep digging under the front of the machine. The ground under the machine may collapse

and cause the machine to fall. Take emergencies into consideration and set with the travel motor at the rear

and the track (undercarriage) at right angles to the road shoulder before digging to enable the machine to

move back quickly . If the ground under the machine collapses and there is no time to drive in reverse, do not

suddenly raise the arm and boom. In some cases, it may in fact be safer to lower the arm and boom.

• Do not swing the work equipment to the side when it is carrying a heavy load. The stability to the side is less

than the stability to the front, so there is danger that the machine may turn over.

• Limits on use.

To prevent accidents caused by breakage of the work equipment or tipping over of the machine under

excessive load, do not use the machine in excess of its capacity . Always be sure to keep within the maximum

specified load and safe angle determined for the structure.

PC130/150LGP-6K ENG

1-13

WARNING: for reasons of

safety, always follow these

7. PRECAUTIONS DURING OPERA TION

safety precautions.

PRECAUTIONS WHEN OPERA TING

• Be careful not to approach too close to the edge of cliffs.

• Carry out only work that is specified as the purpose of the machine.

Carrying out other operations will cause breakdowns.

Specified operations See "WORK POSSIBLE USING HYDRAULIC EXCAVATOR".

• Do the following to ensure good visibility.

• When operating in dark places, turn on the working lamps and front lamps, and install lighting at the job

site if necessary.

• Do not carry out operations in fog, mist, snow or heavy rain or other conditions where the visibility is

poor. Wait for the weather to clear so that visibility is sufficient to carry out work.

• Always do as follows to prevent the work equipment from hitting other objects.

• When operating in tunnels, under bridges, under electric wires, or other places where the height is

limited, be extremely careful not to let the bucket, boom, or arm hit anything.

• To prevent accidents caused by hitting other objects, always operate the machine at a speed which is

safe for operation, particularly in confined spaces, indoors, and in places where there are other machines.

• Never pass the bucket over the head of any worker or over the operator's cab on a dump truck.

1-14

PC130/150LGP-6K ENG

WARNING: Failure to follow

these safety precautions may

lead to a serious accident.

7. PRECAUTIONS DURING OPERA TION

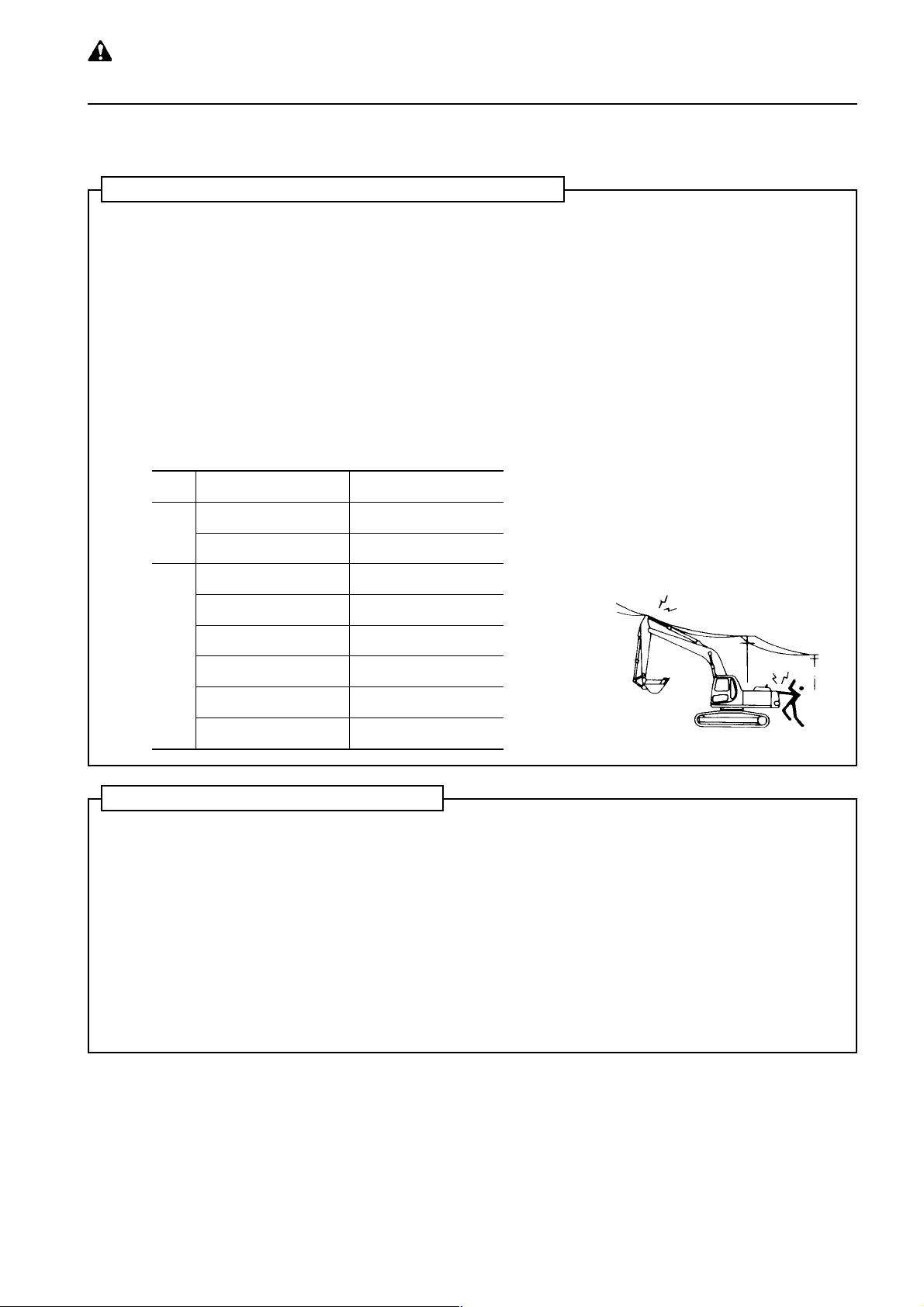

DO NOT GO CLOSE TO HIGH-VOL TAGE CABLES

• Do not let the machine touch overhead electric cables. Even going close to high-voltage cables can cause

electric shock. Always maintain the safe distance given below between the machine and the elctric cable.

• To prevent accidents, always do as follows.

• On job sites where there is danger that the machine may touck the electric cables, consult the electricity

company before starting operations to check that the actions determined by the relevant laws and

regulations have been taken.

• Wear rubber shoes and gloves. Lay a rubber sheet on top of the operator's seat, and be careful not to

touch the chassis with any exposed part of your body.

• Use a signalman to give worning if the machine approaches too close to the electric cables.

• If the work equipment should touch the electric cable,the operator should not leave the operator's com-

partment.

• when carrying out operations near high voltage cables, do not let anyone come close to the machine.

• Check with the electricity company about the voltage of the cables before starting operations.

egatloVecnatsidytefas.niM

V002•001m2

Low

voltage

V006.6m2

V000.22m3

V000.66m4

V000.451m5

V000.781m6

Very high voltage

V000.572m7

V000.005m11

OPERA TE CAREFULLY ON SNOW

• When working ons now or icy roads, even a slight slope may cause the machine to slip to the side, so always

travel at low speed and avoid sudden starting, stopping, or turning. There is danger of slipping particularly on

uphill or downhill slopes.

• With frozen road surfaces, the ground becomes soft when the temperature rises, so the travel conditions

become unstable. In such cases be extremely careful when travelling.

• When there has been heavy snow, the road shoulder and objects placed beside the road are buried in the

snow and cannot be seen, so always carry out operations carefully.

When travelling on snow-covered slopes, never apply the brakes suddenly . Reduce the speed and use the

engine as a brake while applying the foot brake intermittently (depress the brake intermittently several

times). If necessary , lower the bucket to the ground to stop the machine.

• The load varies greatly according to the characteristics of the snow, so adjust the load accordingly and be

careful not to let the machine slip.

PC130/150LGP-6K ENG

1-15

WARNING: for reasons of

safety, always follow these

7. PRECAUTIONS DURING OPERA TION

safety precautions.

WORKING ON LOOSE GROUND

• Do not operate the machine on soft ground. It is difficult to get the machine out again.

• Avoid operating your machine too close to the edge of cliffs, overhangs, and deep ditches. If these areas

collapse under the mass or vibration of your machine it could fall or tip over and this could result in serious

injury or death. Remember that the soil after heavy rain, blasting or earthquakes is weakened in these areas.

• Earth laid on the ground and the soil near ditches is loose. It can collapse under the mass or vibration of your

machine and cause your machine to tip over.

• Install the head guard (FOPS) when working in areas where there is danger of falling stones.

• Install the ROPS and wear the seat belt when working in areas where there is danger of falling rocks or of the

machine turning over.

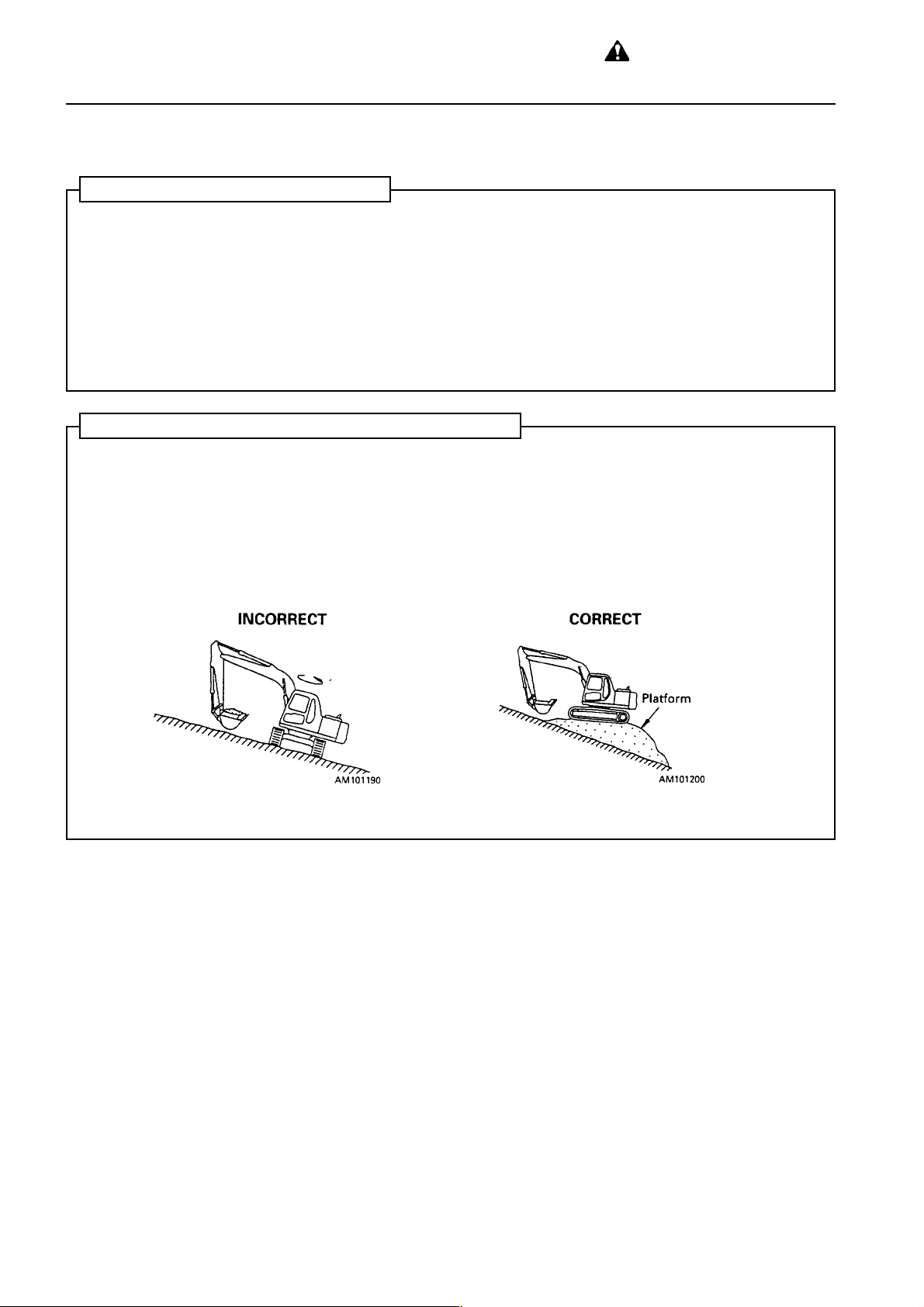

PRECAUTIONS WHEN WORKING ON SLOPES

• When working on slopes, there is danger that the machine may lose its balance and turn over when the

swing or work equipment are operated. Always carry out these operations carefully.

• Do not swing the work equipment from the uphill side to the downhill side when the bucket is loaded. This

operation is dangerous.

• If the machine has te be used on a slope, pile the soil to make a platform that will keep the machine as

horizontal as possible.

Piled soil on slope See "12.13 PRECAUTIONS WHEN TRAVELLING UP OR DOWN HILLS".

1-16

PC130/150LGP-6K ENG

WARNING: Failure to follow

these safety precautions may

lead to a serious accident.

7. PRECAUTIONS DURING OPERA TION

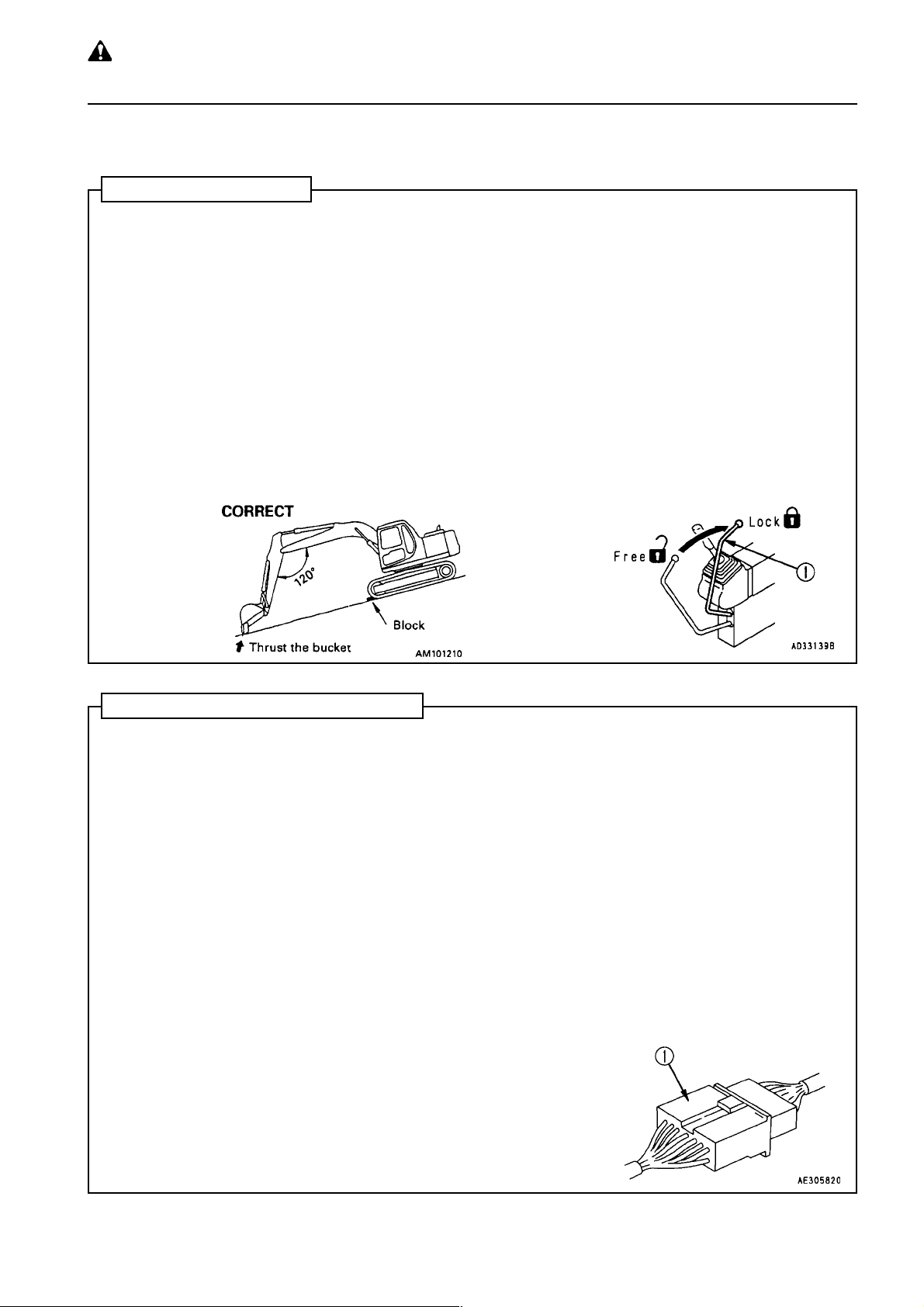

P ARKING MACHINE

• Park the machine on level ground where there is no danger of falling rocks or landslides, or of flooding if the

land is low, and lower the work equipment to the ground.

• If it is necessary to park the machine on a slope, set blocks under the tracks to prevent the machine from

moving, then dig the work equipment into the ground.

• After stopping the engine, operate the right work equipment control lever several times to the RAISE and

LOWER positions te release the remaining pressure in the hydraulic circuit.

• When parking on public roads, provide fences, signs, flags or lights and put up any other necessary signs to

ensure that passing traffic can see the machine clearly , and park the machine so that the machine, flags and

fences do not obstruct traffic.

Parking procedure See "12.17 PARKING MACHINE".

• When leaving the machine, set the safety lock lever 햲 to the LOCK position, stop the engine, and use the

key to lock all the equipment. Always remove the key and take it with you.

Work equipment posture See 12.17 PARKING MACHINE".

Locks See "12.21 LOCKING".

• Always close the door of the operator's compartment.

PRECAUTIONS IN COLD AREAS

• After completing operations, remove all water, snow, or mud stuck to the wiring harness, connector 햲,

switches, or sensors, and cover these parts.

If the water freezes, it will cause malfunctions of the machine when it is next used, which may lead to

unexpected accidents.

• Carry out the warming-up operation thoroughly. If the machine is not thoroughly warmed up before the

control levers are operated, the reaction of the machine will be slow, and this may lead to unexpected

accidents.

• Operate the control levers to relieve the hydraulic pressure (raise to above the set pressure for the hydraulic

circuit and release the oil to the hydraulic tank) to warm up the oil in the hydraulic circuit. This ensures good

response from the machine and prevents malfunctions.

• If the battery electrolyte is frozen, do not charge the battery of start the engine with a different power source.

There is danger that this will ignite the battery.

When charging or starting the engine with a different power source, melt the battery electrolyte and check

for leakage of battery electrolyte before starting.

Battery charge rate See "COLD WEA THER OPERATION".

PC130/150LGP-6K ENG

1-17

WARNING: for reasons of

safety, always follow these

7. PRECAUTIONS DURING OPERA TION

safety precautions.

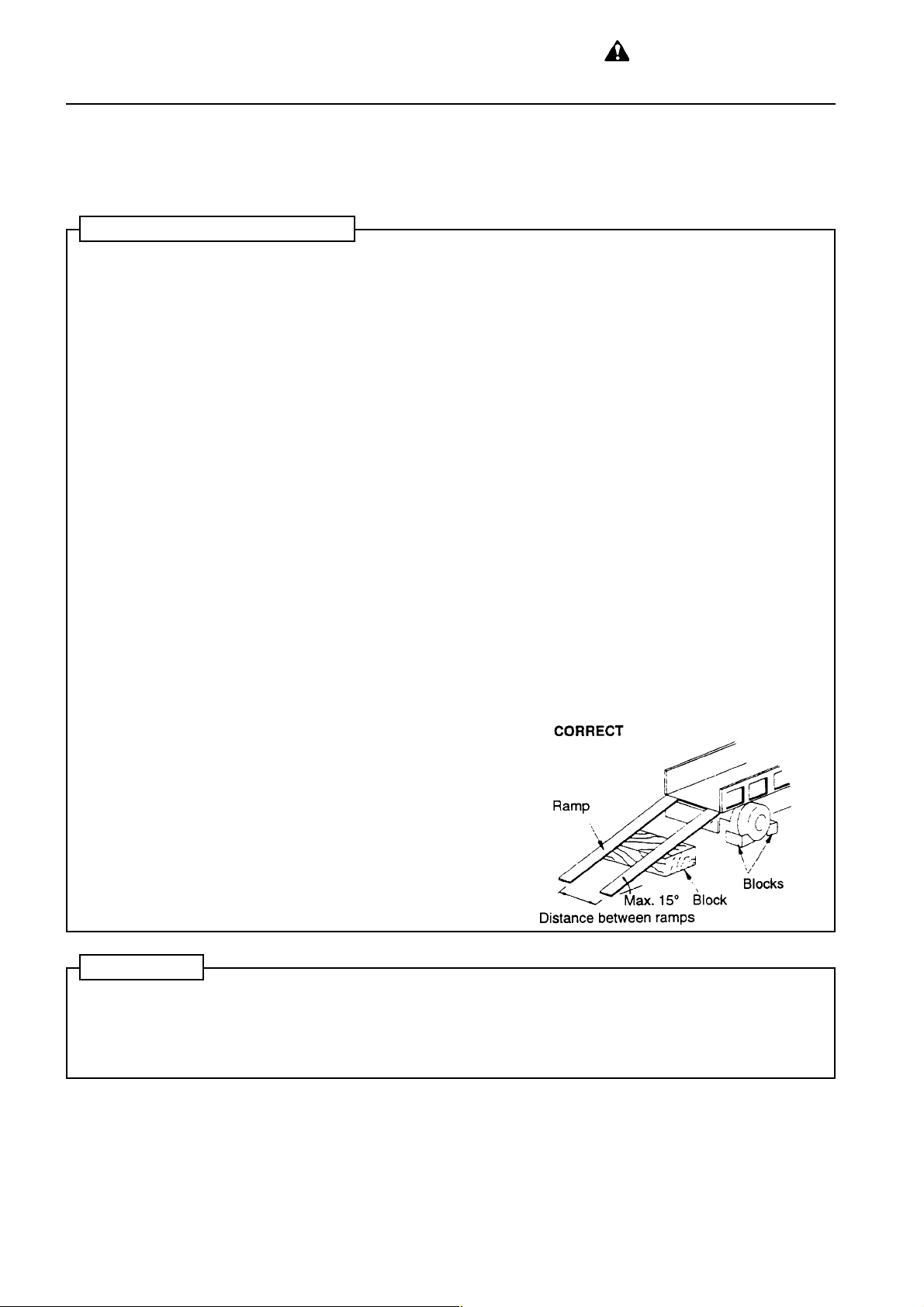

7.3 TRANSPORTATION

LOADING AND UNLOADING

• Loading and unloading the machine always involves potential hazards. EXTREME CAUTION SHOULD BE

USED.

When loading or unloading the machine, run the engine at low idling and travel at low speed.

• Perform loading and unloading on firm, level ground only . Maintain a safe distance from the edge of a road.

• ALWAYS block the wheels of the hauling vehicle and place blocks under both ramps before loading and

unloading.

• ALWAYS use ramps of adequate strenght. Be sure the ramps are wide and long enough to provide a safe

loading slope.

• Be sure that the ramps are securely positioned and fastened, and that the two sides are at the same level as

one another.

• Be sure the ramp surface is clean and free of grease, oil, ice and loose materials. Remove dirt from the

machine tracks.

• NEVER correct your steering on the ramps. If necessary drive away from the ramps and climb again.

• Swing the upper structure with extreme care on the trailer to avoid a possible accident caused by body

instability.

. After loading, block the machine tracks and secure the machine with tie-downs.

Loading and unloading See "13 TRANSPORT A TION"

Tie-downs See "13 TRANSPORTATION"

SHIPPING

• When shipping the machine on a hauling vehicle, obey all state and local laws governing the weight, width,

and length of a load. Also obey all applicable traffic regulations.

• Determine the shipping route while taking into account the width, height and weight of the load.

1-18

PC130/150LGP-6K ENG

WARNING: Failure to follow

these safety precautions may

lead to a serious accident.

7. PRECAUTIONS DURING OPERA TION

7.4 BATTERY

BA TTERY HAZARD PREVENTION

Battery electrolyte contains sulphuric acid, and batteries generate hydrogen gas, so mistaken handling can

lead to serious injury or fire. For this reason, always observe the following precautions.

• Never bring any lighted cigarette or flama near the battery.

• When working with batteries, ALWAYS war safety glasses and rubber gloves.

• If you spill acid on your clothes or skin, immediately flush the area with large amounts of water.

• Battery acid could cause blindness if splashed into the eyes. If acid gets into your eyes flush them immediately with large quantities of water and see a doctor at once.

• If you accidentally drink electrolyte, drink a large quantity of water or milk, beaten egg or vegetable oil. Call

a doctor or poison prevention center immediately .

• Before working with batteries, stop the engine and turn the starting switch to the OFF position.

• Avoid short-circuiting the battery terminals (between the positive + terminal and negative - terminal)

through accidental contact with metal objects such as tools.

• When installing the battery , connect the positive + terminal first, and when removing the battery , disconnect

the negative - terminal (ground side) first.

• When removing or installing, check which is the positive + terminal and negative - terminal, and tighten the

nuts securely .

If the battery electrolyte is near the LOWER LEVEL, add distilled water. Do not add distilled water above the

UPPER LEVEL.

• When cleaning the top surface of the battery, wipe it with a damp cloth. Never use gasoline, thinner or any

other organic solvent or cleaning agent.

• Tighten the battery caps securely.

• If the battery electrolyte is frozen, do not charge the battery of start the engine with a different power source.

There is danger that this will ignite the battery.

When charging or starting the engine with a different power source, melt the battery electrolyte and check

for leakage of battery electrolyte before starting.

• Always remove the battery from the chassis before charging it

PC130/150LGP-6K ENG

1-19

WARNING: for reasons of

safety, always follow these

7. PRECAUTIONS DURING OPERA TION

safety precautions.

ST ARTING WITH BOOSTER CABLES

If any mistake is made in the method of connecting the booster cables, it may cause a fire, so always do as

follows.

• Carry out the starting operation with two workers (with one worker sitting in the operator's seat).

• When starting from another machine, do not allow the two machines to touch.

• When connecting the booster cables, turn the starting switch OFF for both the normal machine and problem

machine.

• Be sure to connect the positive + cable first when installing the booster cables. Disconnect the ground or

negative - cable first when removing them.

• The final ground connection is the connection of the ground to the engine block of the problem machine.

However, this will cause sparks, so be sure to connect it as far as possible from the battery.

Starting procedure when using booster cables See "16.5 IF BATTERY IS DISCHARGED".

• When removing the booster cables, be careful not to let the booster cable clips touch each other or to let the

clips touch the machine.

INCORRECT

CHARGING BA TTERY

If the battery is handled incorrectly when it is being charged, there is danger that the battery may explode, so

follow the instructions in HANDLING BATTERY and in the instruction manual for the charger, and always

observe the following precautions.

• Carry out the charging in a well-ventilated place, and remove the battery caps. This disperses the hydrogen

gas and prevents explosion.

• Set the voltage on the cherger to match the voltage on the battery to be charged. If the voltage setting is

wrong, it will cause the charger to overheat and catch fire, and this may lead to an explosion.

Connect the positive + charging clip off the charger to the positive + terminal of the battery, then connect

the negative - charging clip tot the negative - terminal of the battery. Be sure to tighten both terminals

securely.

• If the battery charge is less than 1/10 of the rated charge, and high speed charging is carried out, set to a

value below the rated capacity of the battery .

If there is an excessive flow of charging current, it may cause leakage or evaporation of the electrolyte, which

may catch fire and explode.

INCORRECT

1-20

PC130/150LGP-6K ENG

WARNING: Failure to follow

these safety precautions may

lead to a serious accident.

7. PRECAUTIONS DURING OPERA TION

7.5 TOWING

WHEN TOWING

• Injury or death could result if a disabled machine is towed incorrectly or if there is a mistake in the selection

of the wire rope, so always do as follows.

• Do not tow in a different way from the method given in the section "16.2 METHOD OF TOWING MACHINE".

• Always wear leather gloves when handling wire rope.

• When carrying out the preparation for towing with another worker, agree on signals before starting the

operation.

• If the engine on the problem machine will not start of there is a failure in the brake system, please contact

your Komatsu distributor for repairs.

• It is dangerous to tow a machine on a slope, so choose a place where there is a gradual slope. If there is no

place with a gradual slope, carry out work to make the slope as small as possible.

• If a problem machine is towed by another machine, ALWAYS use a wire rope with a suf ficient towing capacity for the weight of the problem machine.

• Do not uwe a wire rope which has cut strands 훽, kinks 훾, or reduced diameter 훿.

PC130/150LGP-6K ENG

1-21

WARNING: for reasons of

safety, always follow these

7. PRECAUTIONS DURING OPERA TION

safety precautions.

7.6 BUCKET WITH HOOK

PRECAUTIONS WHEN INST ALLING, OPERATING BUCKET WITH HOOK

Using a hydraulic excavator to raise loads is permitted under the following special conditions. These conditions

must be followed strictly .

• The specified hook must be installed to the bucket. For details, please consult your Komatsu distributor.

• When the special hook is installed, additional checks before starting and periodic checks, toghether with

recording and storing of the periodic checks are required.

• When carrying out operations with a lifted load, set the machine on firm flat ground in a safe place and install

the wire securely to the lifting hook.

• Lifting work is prohibited except for the main purpose. Never raise or lower people in this way .

• Do not allow anyonde inside the operating radius.

• When carrying out lifting work, determine the method and order of operations and signals to be used.

Appoint a leader and follow his directions.

• Wear leather gloves when handling the wire rope. Use only wire rope which fulfils the specified standards.

• Run the engine at low speed when carrying out the lifting work.

• Do not leave the operator's seat when the load is raised.

• It is dangerous to use the work equipment to pull loads in or to the side or to carry out work that exceeds the

capacity of the work equipment. Do not carry out such operations.

• Do not travel with a raised load.

• Depending on the operating posture of the work equipment, there is danger that the wire rope or ring may

slip from the hook, so always pay attention to the angle of the hook to prevent the wire or ring from coming

off.

1-22

PC130/150LGP-6K ENG

8. PRECAUTIONS FOR

MAINTENANCE

WARNING: Failure to follow

these safety precautions may

lead to a serious accident.

8.1 BEFORE CARRYING OUT MAINTENANCE

NOTIFICA TION OF F AILURE

Carrying out maintenance not described in the Komatsu operation and maintenance manual may lead to

unexpected failures.

Please contact your Komatsu distributor for repairs.

WARNING T AG

• AL W AYS attach the "DO NOT OPERATE" warning tag to the work equipment control lever in the operator's

cab to alert others that you are working on the machine. Attach additional warning tags around the machine

if necessary.

• If others start the engine, or touch or operate the work equipment controle lever while you are performing

service or maintenance, you could suffer serious injury or death.

• These tags are available from your Komatsu distributor (Part no. 20E-00-K1340)

CLEAN BEFORE INSPECTION AND MAINTENANCE

• Clean the machine before carrying out inspection and maintenance. This will ensure that dirt does not get

into the machine and will also ensure that maintenance can be carried out safely.

• If inspection and maintenance are carried out with the machine still direty , ti will be difficult to find the location

of problems, and there is also the danger that you will get dirty or mud in your eyes, and that you will slip and

injure yourself.

• When washing the machine, always do as follows.

• Wear non-slip shoes to prevent yourself from slipping on the wet surface.

• When using high-pressure steam to wash the machine, always wear protective clothing. This will protect

you from being hit by high-pressure water, and cutting your skin or getting mud or dust into your eyes.

• Do not spray water directly on to the electrical system (sensors, connectors) 햲. If water gets into the

electrical system, there is danger that it will cause defective operation and malfunction.

PC130/150LGP-6K ENG

1-23

WARNING: for reasons of

safety, always follow these

8. PRECAUTIONS FOR MAINTENANCE

safety precautions.

KEEP WORK PLACE CLEAN AND TIDY

Do not leave hammers or other tools lying around inthe work place. Wipe up all grease, oil, or other substances

that will cause you to slip. Always keep the work place clean and tidy to enable you to carry out operations

safely .

If the work place is not kept clean and tidy , there is danger that you will trip, slip or fall over and injure yourself.

APPOINT LEADER WHEN WORKING WITH OTHERS

When repairing the machine or when removing and installing the work equipment, appoint a leader and follow

his instructions during the operation.

When working with others, misunderstanding between workers can lead to serious accidents.

RADIA TOR W A TER LEVEL

• When inspecting the radiator water level, stop the engine and wait for the engine and radiator to cool down.

Check the water level in the sub-tank. Under normal conditions, do not open the radiator cap.

• If there is no sub-tank, or the radiator cap must be removed, always do as follows.

• Wait for the radiator water temperature to go down before checking the water level. (When checking if the

water temperature has gone down, put your hand near the engine or radiator and check the air temperature.

Be careful not to touch the radiator or the engine).

• Release the internal pressure before removing the radiator cap, and remove the radiator cap slowly .

STOP ENGINE BEFORE CARRYING OUT INSPECTION AND MAINTENANCE

• When carrying out inspection and maintenance, park the machine on level ground where there is no danger

of falling rocks or land slides, or of flooding if the land is low, then lower the work equipment to the ground

and stop the engine.

• Operate the right work equipment control lever several times to the RAISE and LOWER positions to release

the remaining pressure in the hydraulic circuit, then set safety lock lever 햲 to the LOCK position.

• Put blocks under the track to prevent the machine from moving.

• The worker carrying out the maintenance should be extremely careful not to touch or get caught in the

moving parts.

1-24

PC130/150LGP-6K ENG

WARNING: Failure to follow

these safety precautions may

lead to a serious accident.

8. PRECAUTIONS FOR MAINTENANCE

SAFETY DEVICES FOR WORK EQUIPMENT

When carrying out inspection and maintenance with the work equipment raised, fit stand (2) securely to the

boom to prevent the work equipment from coming down.

Place the work equipment control levers at HOLD, and set safety lock lever 햲 to the LOCK position.

PROPER TOOLS

Use only tools suited to the task. Using damaged, low quality, faulty or makeshift tools could cause personal

injury.

Broken pieces of chisels or hammers could fly into your eyes and blind you.

Tools See "21.1 INTRODUCTION OF NECESSAR Y T OOLS".

PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

Hoses and other parts of the fuel, hydraulic and brake system are critical parts for ensuring safety, so they must

be replaced periodically .

Replacement of safety critical parts requires skill, so please ask your Komatsu distributor to carry out replacement.

• Replace these components periodically with new ones, regardless of whether or not they appear to be

defective.

These components deteriorate over time, and can cause fire because of oil leakage or failure in the work

equipment system.

• Replace or repair any such components if any defect is found, even though they have not reached the time

specified

Replacement of safety critical parts See 22. PERIODIC REPLACEMENT OF SAFETY CRITICAL

P ARTS".

PC130/150LGP-6K ENG

1-25

WARNING: for reasons of

safety, always follow these

8. PRECAUTIONS FOR MAINTENANCE

safety precautions.

USE OF LIGHTING

• When checking fuel, oil, or battery electrolyte, always use lighting with anti-explosion specifications.

If such lighting equipment is not used, there is danger of explosion.

• If work is carried out in dark places without installing lighting, there is danger of injury, so always install

proper lighting.

• Even if it is dark, do not use a lighter or flame instead of lighting. There is danger of starting a fire and if the

battery gas ignites it may cause an explosion.

• When using the machine as the power supply for the lighting, follow the instructions in this Operation and

Maintenance Manual.

PREVENTION OF FIRE

There is danger of the fuel and battery gas catching fire during maintenance, so always follow the precautions

below when carrying out maintenance.

• Store fuel, oil, grease and other flammable materials away from flame.

• Use non-flammable materials as the flushing oil for cleaning parts. Do not use diesel oil or gasoline. There is

danger that they will catch fire.