Komatsu PC118MR-8 Operation And Maintenance Manual

FOREWORD

WEAM014802

11

FOREWORD

WARNING

WEAM014802

FOREWORD

FOREWORD 1

q This manual has been compiled by Komatsu S.p.A. in order to supply customers with all the necessary

information on the machine and on safety regulations, as well as the use and maintenance instructions that

enable the operator to ex ploit the capacity of th e machine with opti mal results and to keep the machine

efficient over time.

q The operation ma nual, together with the spare parts catalogue, is an integr al part of the machine a nd must

accompany it, even when it is resold, until its final disposal.

q The illustrations contained in this manual may represent machine configurations available on request.

Komatsu machines are constantly imp roved in order to i ncrease th eir efficiency an d reliabil ity; this man ual

sums up all the information regarding the most recent technology applied at the moment in which the machine

is launched.

For any further and/or updated information, contact your Komatsu distributor.

q Punctual periodic annotations regarding the maintenance operations that have been carried out are important,

since they provide a clear report on the situation and say exactly what has been done and what has to be done

after the next maintenance interval. Therefore, it is advisable to consult both the hour meter and the

maintenance plan frequently.

q Komatsu distributor have g athered a consid erable amount of expe rience over year s of work in clos e contact

with the users.

If more information is needed, do not hesitate to contact your Komatsu distributor: he always knows how to get

the best performance from the machine, he can recommend the equipment that is most suitable for specific

needs and can provide the technical assistance necessary for any change that may be required to conform the

machine to safety standards rules.

Komatsu distributo r also provide assistance for the supply of origi nal Komatsu spare parts, whic h alone

guarantee safety and interchangeability.

q The table included in this manual must be filled in with the machine data, which are also the data that must be

communicated to the distributor when requiring assistance and ordering spare parts.

Before beginning operation or maintenance, operators and maintenance personnel must always observe

the following points.

Read this manual thoroughly and understand its contents fully.

Read the safety messages and safety labels given in thi s manual carefully so that they should be

understood fully.

Keep this manual at the storage location for the Operation and Maintenance Manual given below so that

all personnel involved in working on the machine can consult it periodically.

In case this manual should be lost or damaged, immediately cont act Komatsu or your Komatsu distri butor

to obtain a new copy.

When you sell the machine, make sure that this manual should be provided to the new owner together

with the machine.

In this manual, measuremen ts are expressed in interna tiona l standard units (SI). As a re fe rence, th e units

of weight used in the past are shown in brackets ( ).

1-2

FOREWORD

WEAM014802

Storage location for the Operation and Maintenance Manual:

FOREWORD

1-3

SAFETY INFORMATION

DANGER

WARNING

CAUTION

NOTICE

REMARK

WEAM014802

FOREWORD

SAFETY INFORMATION 1

Many accidents are caused by i nsufficient kn owledge of an d failure to comply w ith the safety regulations

prescribed for the maintenance operations that must be performed on the machine.

In order to avoid accidents, before starting work and before carrying out any maintenance operation, carefully read

and be sure to understand all the information and warnings contained in this manual and given on the plates

applied onto the m achin e. To enable the operator to use thi s machin e safel y, safety precautions ar e explai ned in

this manual and labels and warning plates are affixed to the machine to highlight situations involving potential

hazards and suggest how to avoid them.

Komatsu machines are manu facture d and sold accord ing to the rul es or s tandards of the countries whe re they

have to work. If the machines have to work in other countries, it is necessary to check that every safety devices

and technical specifications are in compliance with the regulations in force; for this reason, ask Komatsu distributor

before using the machine.

Terminology used in the signs

The following words are used in the signs to inform the user that there is a potential hazard that may lead to

personal injury or damage to property.

In this manual, on the labels and on the plates, the following words are used to express the potential level of the

hazard.

Indicates a situation of imminent danger that, if not avoided, may cause serious injury and even death. The use of

this term must be limited to situations of extreme danger.

Indicates a situation of potential danger that, if not avoided, may cause serious injury and even death.

Indicates a situation of potential danger that, if not avoided, may cause m oderate in jury. This term can also be

used as a warning against dangerous interventions.

Other terms used in the signs

In addition to those indicated above, the following warning terms are used to recommend the precautions to be

taken to protect the machine or to supply useful information.

This term is used to indicate precautions that must be taken in order to avoid actions that may shorten the life of

the machine.

This word is used to indi cate a useful piece of information.

1-4

FOREWORD

DANGER

DANGER

DANGER

DANGER

DANGER

DANGER

WEAM014802

Before starting any maintenance operation, position the machine on a firm and level surface, lower the

equipment to the ground, engage the safety locks of the equipment and the controls, and stop the engine.

To make the information clearer, some illustrations in this manual represent the machine without safety

guards. Do not use the machine without guards and do not start the engine when t he hood is ope n, unless

this is expressly prescribed for certain maintenance operations.

It is strictly forbidden to modify the setting of the hy draulic system safety valves ; Komat su cannot be held

liable for any damage to persons, property or the machine, if this has been tampered with by modifying

the standard settings of the hydraulic system.

SAFETY INFORMATION

Before carrying out any electric welding, disconnect the battery and the alternator. (See "PRECAUTIONS

CONCERNING THE BATTERY AND THE ALTERNATOR (2-58)").

Install only optional tools or tools especially recommended and approved by Komatsu and that meet the

requirements included in section "EQUIPMENT CONFIGURATION (6-5)"

It is absolutely forbidden to operate the machine while standing on the ground.

Every single manoeuvre must be carried out by the operator, correctly seated in driving position.

1-5

SAFETY INFORMATION

WEAM014802

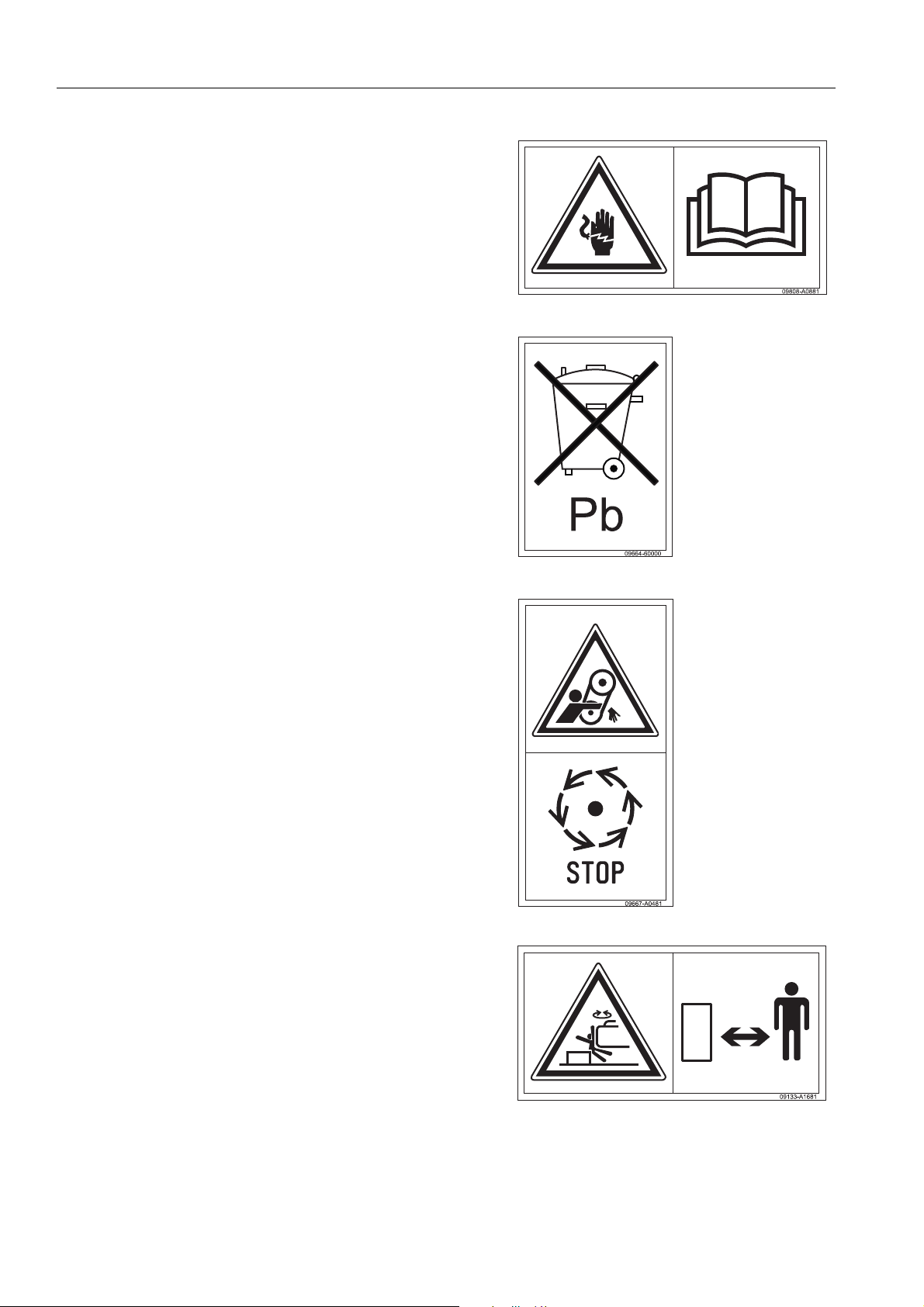

q Safety labels

Safety labels are affixed to the ma chine to infor m t he o pera tor or m aint ena nce w ork er on th e spo t when carr ying

out operation or maintenance of the machine that may involve hazard.

This machine uses "Safety labels using pictograms" to indicate safety procedures.

Safety labels using pictogram

Safety pictogra ms use a picture to expres s a level of

hazardous condition equivalent to the signal word. These

safety pictograms use pictures in order to let the operator or

maintenance worker understand the level and type of

hazardous condition at all times.

Safety pictograms show the type of hazardous condition at the

top or left side, and the method of avoidin g the hazardous

condition at the botto m or right side. In addition, t he type of

hazardous condition is displayed inside a triangle and the

method of avoidi ng the haza rdous con dition is shown ins ide a

circle.

FOREWORD

Komatsu cannot predict every circumstance that might involve a potential hazard in operation and maintenance.

Therefore, the saf ety messages in th is manual and on the machine may not include all po ssible safety

precautions.

If any procedures or actions not specifically recommended or allowed in this manual are used, it is your

responsibility to take the necessary steps to ensure safety.

In no event should you engage in prohibited uses or actions described in this manual.

The explanations, valu es, and ill ustrati ons in th is man ual were pr epared ba sed on th e lates t infor mation avail able

at that time. Some illu strati ons may be di fferent from the details of the ma chine in your poss ession: this is du e to

the continuous improvements made to the machines. Consult Komatsu or your Komatsu distributor for the latest

available information of your machine or for questions regarding information in this manual.

The numbers in circles in the illustrations correspond to the numbers in ( ) in the text. (For example: (1))

1-6

FOREWORD

ISO 6396

WEAM014802

SAFETY INFORMATION

NOISE LEVELS 1

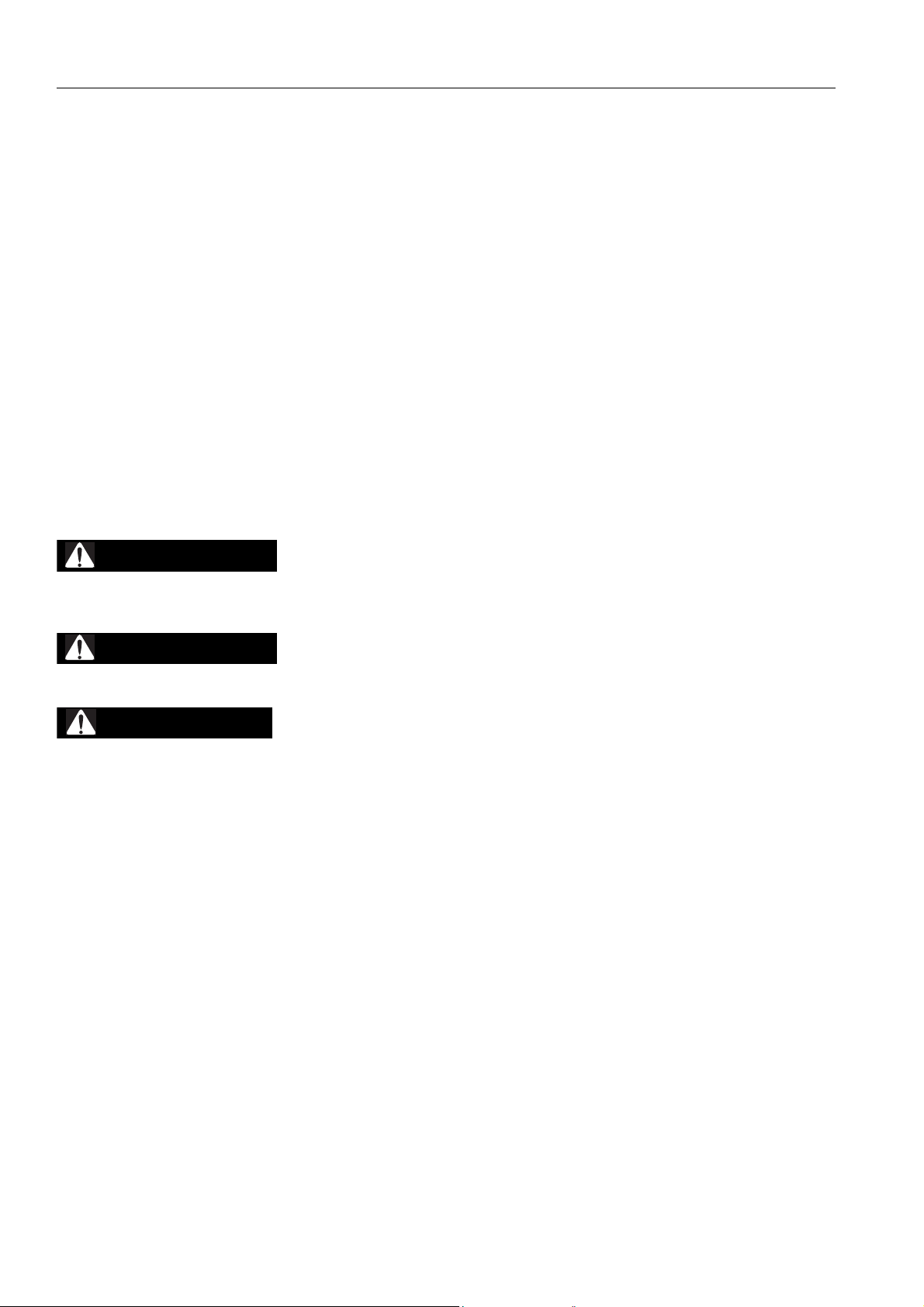

q The noise plates must always be legible and in good

conditions; for this reason, if they are dirty with dust, oil or

grease, it is neces sary to cle an them wit h a soluti on made

of water and detergent. Do not use fuel, petrol or solvents.

q If the plates are damaged, ask for new ones to Komatsu or

to your Komatsu distributor.

q In case of replacement of a component provided with a

noise plate, make sure that such a plate is applied also to

the new part.

q Sound power level emitted by the machine, measured

according to ISO 6395 (Dynamic test method, simulated

working cycle).

This is the guara nteed value as specified in Eur opean

directive 2000/14/EC. This value includes an uncertainty-of

1.6 dB.

q Sound pressure leve l at the operator’s station, measured

according to ISO6396 (Dyn amic test method , simulated

working cycle).

The maximum value of the standard deviation of the

measured time-a veraged A-weighted emission sound

pressure level at the operator’s position is 2.5 dB, in

accordance with ISO 11201.

1-7

SAFETY INFORMATION

WEAM014802

FOREWORD

VIBRATIONS TO WHICH THE OPERATOR IS SUBJECTED 1

When the earth moving machine is used for its intended purpose, the vibration levels transmitted from the

operator's seat are le ss than or equa l to the vi brati on test ed on the r elated class of mac hinery i n acco rdanc e with

ISO7096.

The actual acceleration value for the hands and arms is less than or equal to 2.5 m/s², the factor of uncertainty for

this vibration value is 1.2 m/s² according EN 12096: 1997.

The actual acceler ation value for the body is less than or equal t o 0.5 m/s², the factor of uncertainty for this

vibration value is 0.2 m/s² according EN 12096: 1997.

These values were determined using a representative machine and measured during the typical operating

condition indicated below according to the measurement procedures that are defined in the standards ISO 2631/1

and ISO 5349.

OPERATING CONDITION 1

Excavating (Digging-loading-rotating-unloading-rotating).

GUIDE TO REDUCE VIBRATION LEVELS ON MACHINE 1

The following guides can help an operator of this machine to reduce the whole body vibration levels:

1. Use the correct equipment and attachments.

2. Maintain the machine according to this manual.

Q Tension of crawler (for crawler machines).

Q Brake and steering systems.

Q Controls, hydraulic system and linkages.

3. Keep the terrain where the machine is working and travelling in good condition.

Q Remove any large rocks or obstacles.

Q Fill any ditches and holes.

Q Site manager should provide machine operators with machine and schedule time to maintain terrain

conditions.

4. Use a seat that meets ISO 7096 and keep the seat maintained and adjusted.

Q Adjust the seat and suspension for the weight and size of the operator.

Q Wear seat belt.

Q Inspect and maintain the seat suspension and adjustment mechanisms.

5. Steer, brake, accelerate, and move the attachment levers and pedals slowly so that the machine moves

smoothly.

6. Adjust the machine speed and travel path to minimize the vibration level.

Q When pushing with bucket or blade, avoid sudden loading; load gradually.

Q Drive around obstacles and rough terrain conditions.

Q Slow down when it is necessary to go over rough terrain.

Q Make the curve radius of travelling path as large as possible.

Q Travel at low speed when travelling around sharp curves.

1-8

FOREWORD

WEAM014802

7. Minimize vibrations for long work cycle or long distance travelling.

Q Reduce speed to prevent bounce.

Q Transport machines long distances between worksites.

8. The following guidelines can be effective to minimize risks of low back pain.

Q Operate the machine only when you are in good health.

Q Provide breaks to reduce long periods of sitting in the same posture.

Q Do not jump down from the cab or machine.

Q Do not repeatedly handle and lift loads.

SAFETY INFORMATION

GUIDE WHEN WORKING IN AREAS WHERE AIR POLLUTION 1

When working in area s wh er e air po ll uti on i s c ons id er abl e ( tunn el s, d usty places, small or bad ly ve nti lated rooms,

etc.) use the air conditioning with the internal air rec irculation function selected. (For details, see "AIR

CONDITIONER (3-87)").

1-9

INTRODUCTION

WARNING

WARNING

WEAM014802

FOREWORD

INTRODUCTION 1

This Komatsu machine is designed to be used mainly for the following work:

q Digging work

q Leveling work

q Ditching work

q Loading work

See paragraph "OPERATIONS THAT CAN BE PERFORMED WITH THE HYDR AULIC EXC AVATOR (3-164)" for

further details.

q Occasional lifting and handl ing of the objects. For details see LIFTING OBJECTS WITH LIFTING DE VICE

(OPTIONAL EQU IPMENT) (2-47).

The excavator used in handling operations must conform with current local regulations and be equipped

with safety valves and an overload alarm in compliance with EN 474-5.

DEMOLITION WORK 1

q A demolition machine is a machine based on earth

moving machinery (see EN ISO 6165) and including

equipment and attachment (working tool - e.g.

processor or breaker) specifically designed to

demolish, cut, loosen, separate, pick up, transport and

distribute component parts of buildings or civil

engineering structures.

q This machine is not prepared for use in Demolition.

q Using this machine in demolition work gives an

increased risk of serious injury or death.

q All Komatsu machinery that have been specifically

designed for, and can be used in, demolition work, will

display the Komatsu demolition decal.

q If the machine does not display this decal and it is

necessary to carry out demolition work, contact your

distributor for information on demolition machine ry

compliant with the applicable standards.

1-10

FOREWORD

CAUTION

NOTICE

WEAM014802

INTRODUCTION

IMPROPER OR UNAUTHORIZED USES 1

This paragraph describes some of the improper or unauthorized uses of the machine; since it is

impossible to predict all the possible improper uses, if it is necessary to use the machine for particular

applications, contact your Komatsu distributor before carrying out the work.

q The instructions regarding the authorized optional equipment are given in the relevant operation and

maintenance manuals; if the equipment is supplied by Komatsu, these publications are enclosed to

this manual.

q The instructions regarding the assembly of the authorized equipment, the controls requiring special

arrangements on the machine and the hydraulic couplings neces sary for the operation of such

equipment are grouped in the final section of this manual.

Komatsu machines are constructed exclusively for the handling, excavation and treatment of i nert materials;

therefore, the following uses are absolutely forbidden:

q Use of the machine by minors or inexperienced persons.

q Use of the machine for the lifting of people

q Transport of containers with flammable or dangerous fluids.

q Use of the bucket for driving or extracting piles.

q Use of the machine for towing.

q Use of the machine in tunnels/underground in explosive environments.

MAIN CHARACTERISTICS 1

q Simple and easy operation.

q Hydrostatic transmissi on obtained through two var iable displacemen t motors that operate epi cyclic reduction

gears equipped with negative hydraulic brakes.

q Rotation of the turret achieved by means of an axial piston hydra ulic motor acting on an epicyc lic reduction

gear.

q Ball-bearing ring teeth and pinion lubricated in grease bath.

q Main equipment con trolled through servo levers ensu ring also combin ed movements that can be modulated

proportionally and continually.

q Boom swing and trav el control s with s ervo pedals ensur ing movements th at can be modulated proporti onally

and continuously.

q Travel speed increase function controlled with a button.

q Servo-assisted controls for blade

q Complete series of instruments visible from the operating position.

q Hand accelerator.

q Easy maintenance with simplifie d interv als .

1-11

INTRODUCTION

WEAM014802

FOREWORD

RUNNING-IN 1

All machines have been meticulously adjusted and tested before delivery.

However, a new machine must be used with caution during the first 100 hours, for a correct running in of the

different components.

If the machine is subjected to excessive work load at the beginning of operation, its potential productivity and its

functionality will be shortly and untimely reduced. For more details, see "Running-in (3-136)".

1-12

FOREWORD

WEAM014802

INTRODUCTION

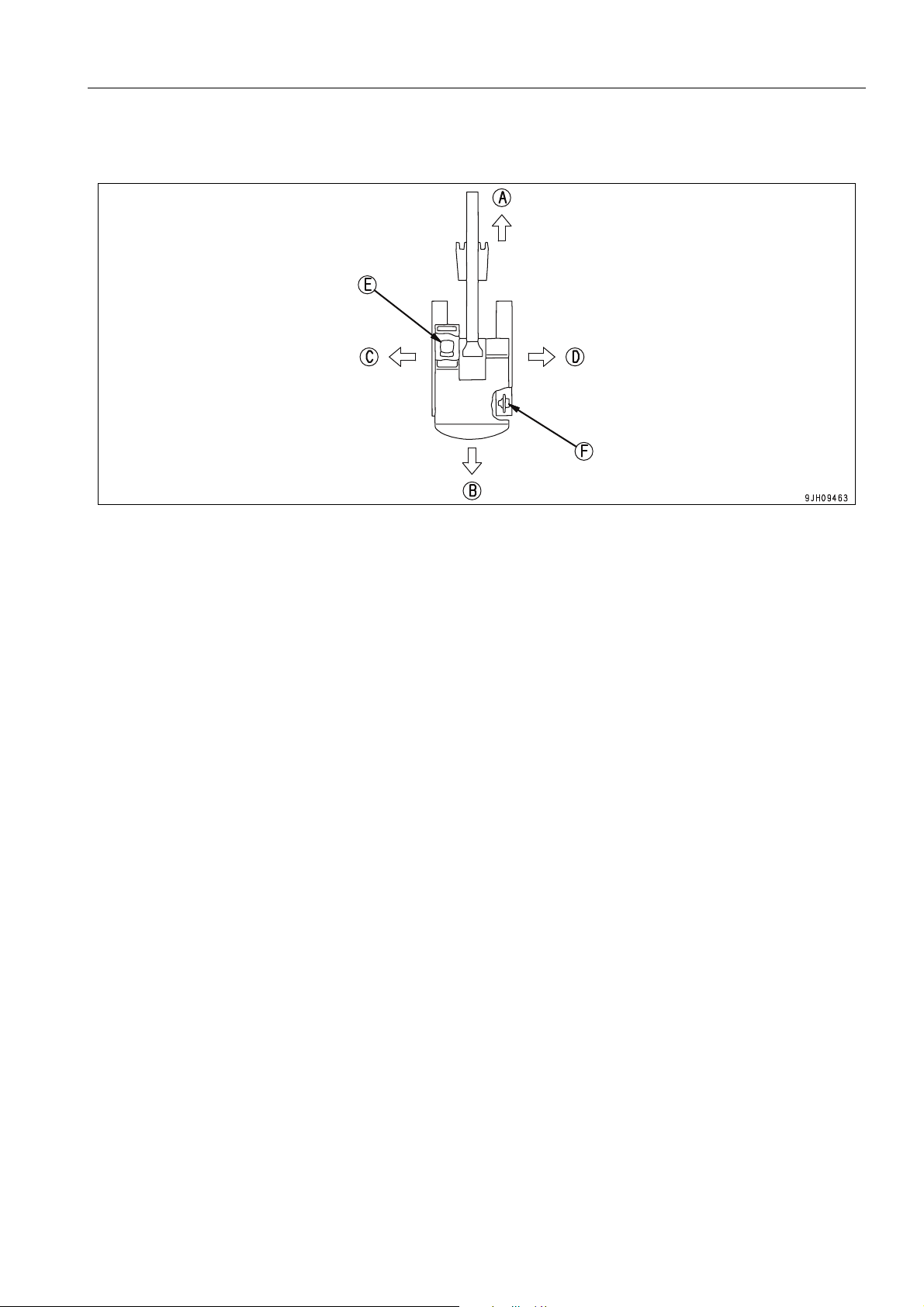

DIRECTIONS OF MACHINE 1

(E)

Forwards

(A)

Backwards

(B)

Left

(C)

Right

(D)

In this manual, the terms front, rear, left, and right refer to the travel directio n as seen from the operator's seat

when the operator's seat is facing the front and the sprocket (F) is at the rear of the machine.

Operator seat

(F)

Sprocket

1-13

PRODUCT IDENTIFICATION

WEAM014802

FOREWORD

PRODUCT IDENTIFICATION

The Komatsu excavator and its main components are identified by serial numbers stamped on the identification

plates. The serial number and the identification numbers of the components are the only numbers that must be

communicated to the distributor when requiring assistance and ordering spare parts.

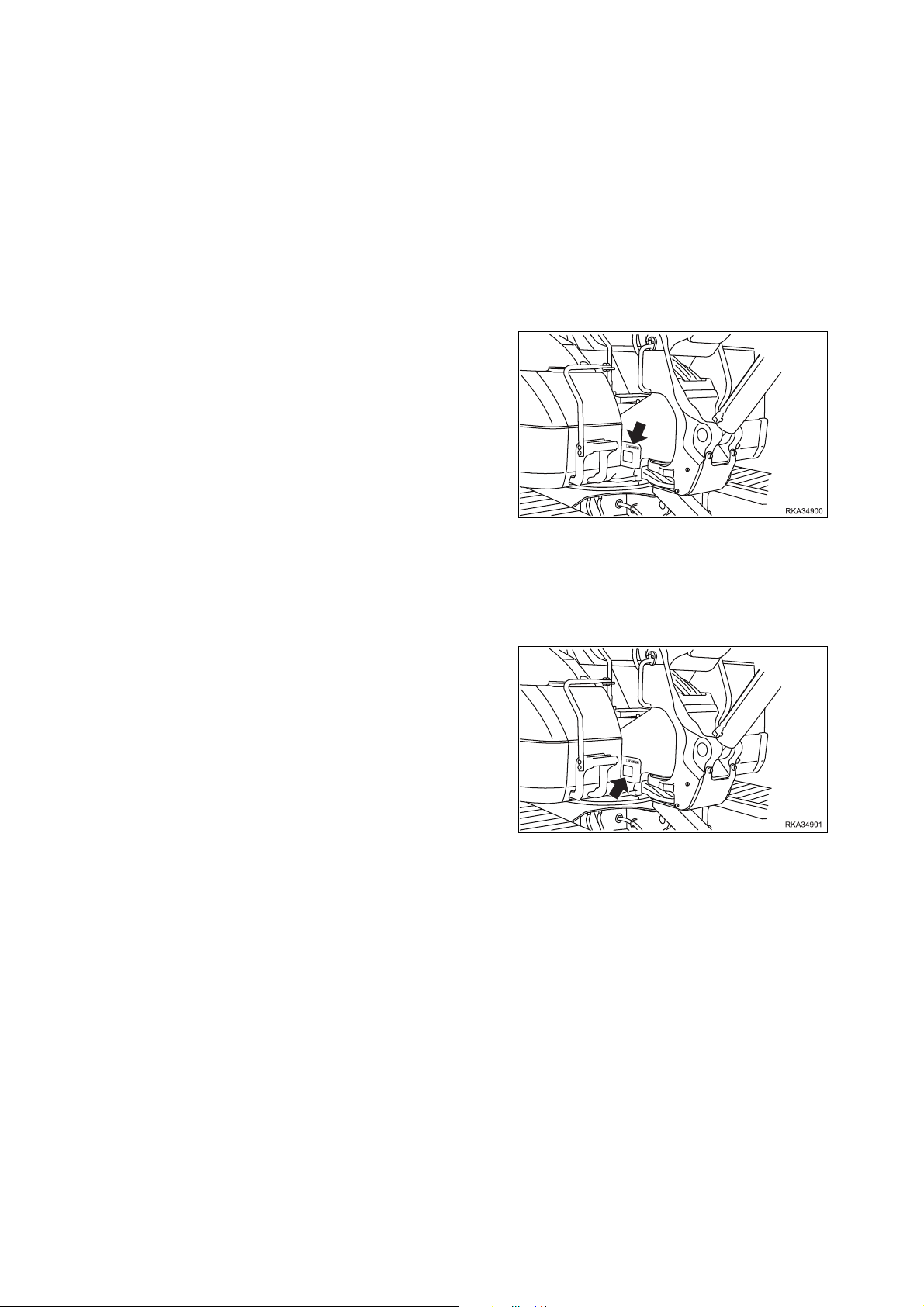

MACHINE SERIAL NUMBER 1

The machine serial number is stamped on the front upper part

of the main frame, on the left side.

MACHINE IDENTIFICATION PLATE AND PRODUCT IDENTIFICATION NUMBER (P IN) 1

The Komatsu excavators described in this manual are CE

marked, in fact they are in com pli an ce with the EU har m oni se d

standards.

The plate with the CE marking is applie d to the fr ont wall of the

main frame, on the left side.

1-14

FOREWORD

WEAM014802

PRODUCT IDENTIFICATION

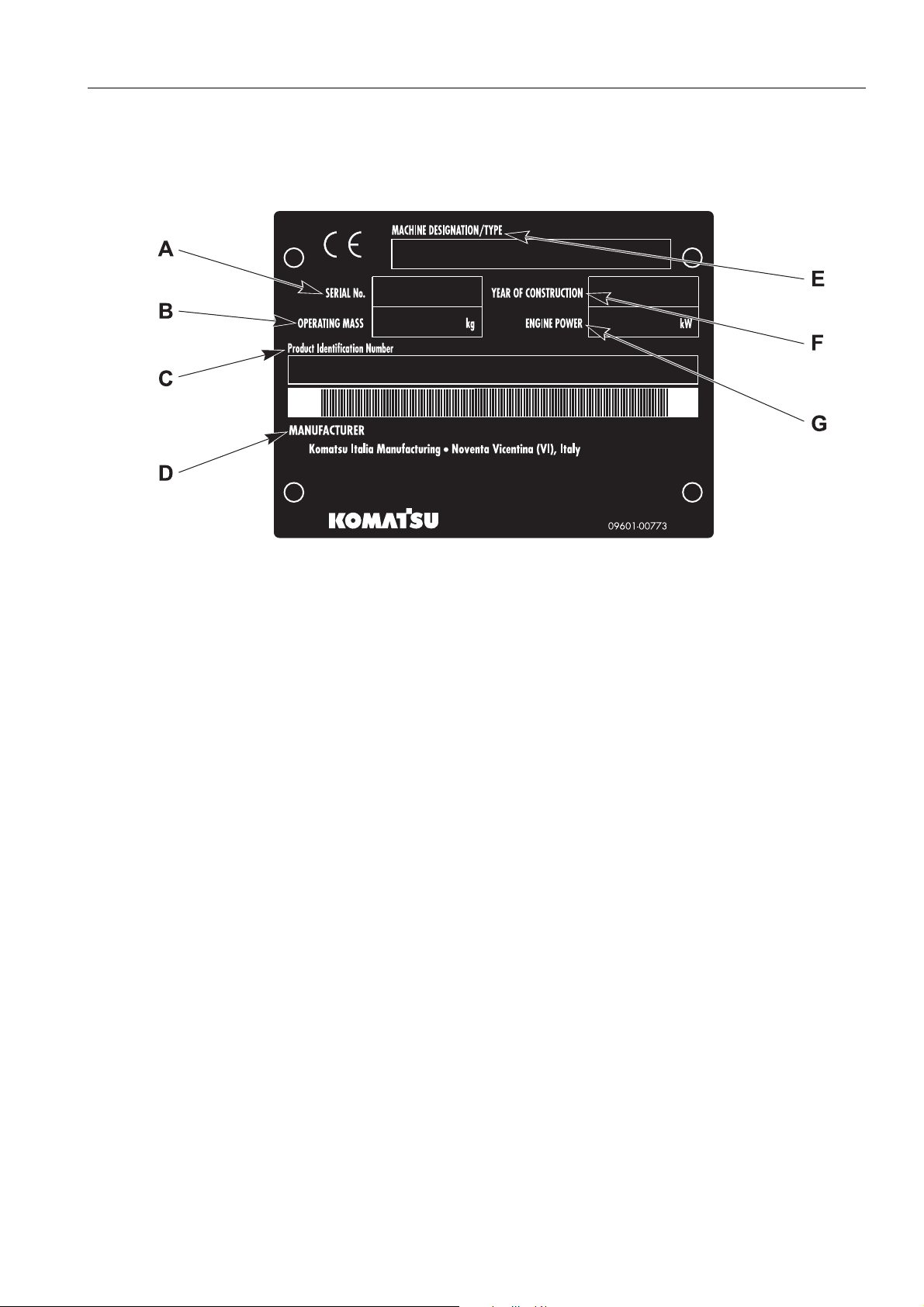

MACHINE SERIAL NUMBER PLATE

(according directive 2006/42/EC) 1

(A) Serial number (E) Machine designation type

(B) Operating mass (F) Year of manufacture

(C) Product identification number (G) Engine power

(D) Manufacturer

1-15

PRODUCT IDENTIFICATION

WEAM014802

FOREWORD

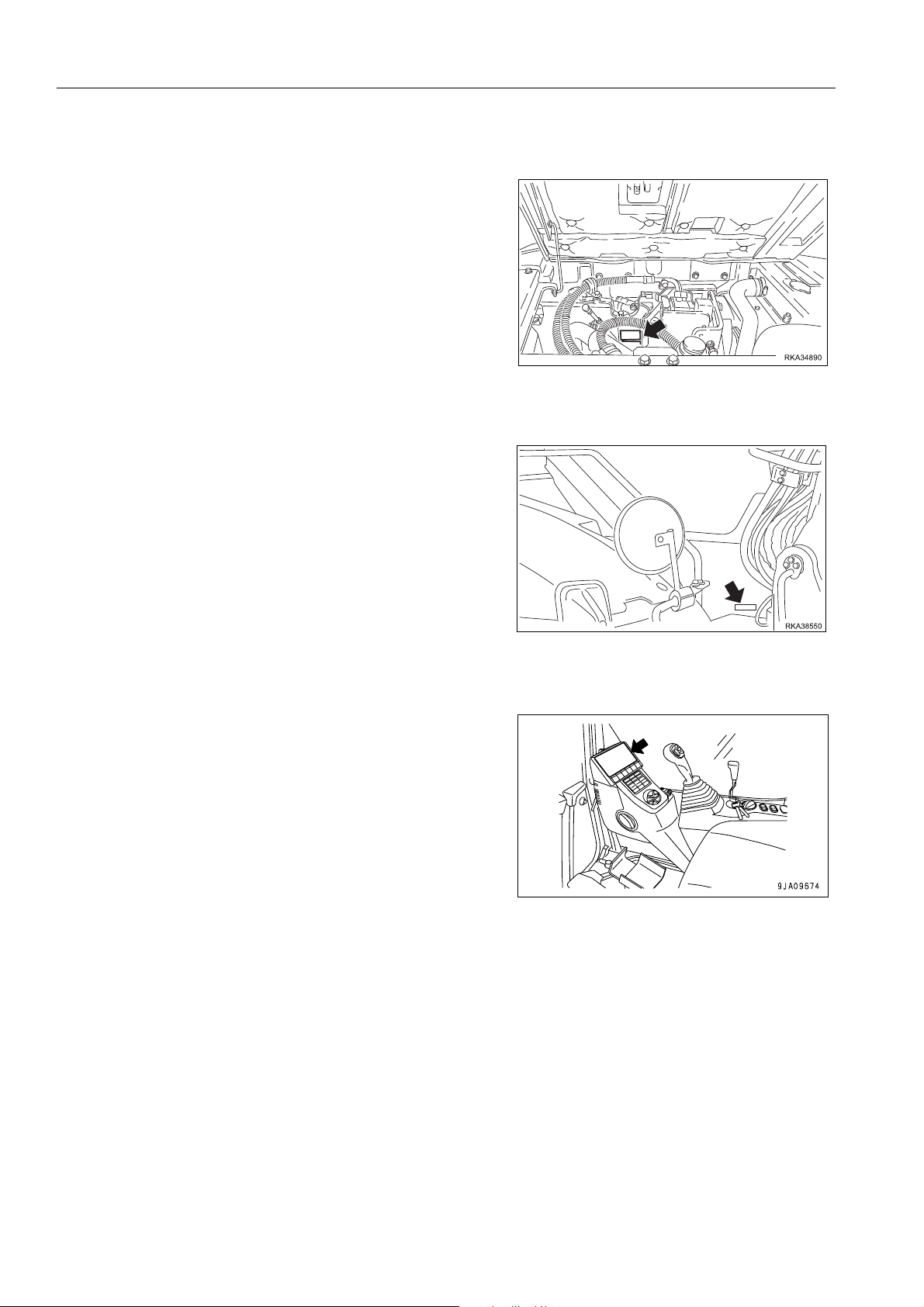

ENGINE SERIAL NUMBER AND EXHAUST GAS EMISSION PLATE 1

The serial number and the exhaust gas emis sion plate are

located on the fuel filter support.

CAB SERIAL NUMBER 1

The serial number is stamped on the plate positioned on the

external right hand side of the cab.

HOUR COUNTER POSITION 1

The hour counter is positioned on the machine panel.

1-16

FOREWORD

WEAM014802

PRODUCT IDENTIFICATION

TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR 1

Machine serial No.

Engine serial No.

Product identification number

(PIN)

Manufacturers name:

Address:

Authorised Representative:

Address:

Distributor name:

Address:

Service Personnel

Phone/Fax

Komatsu Italia Manufacturing S.p.A.

Via Atheste, 4

35042 Este (PD) Italy

DECLARATION OF CONFORMITY (for machines placed on the market as from 29 December 2009) 1

The Manufac turer:

Komatsu I talia Manufacturin g S.p.A.

Via Atheste, 4

35042 Este (PD) Italy

Declares that this machine:

PC118MR-8

Fulfils all the relevant provisions of following EC Directive:

Machinery Directive 2006/42/EC

Electro Magnetic Compatibility Directive

Outdoor Noise Directive 2000/14/EC amended 2005/88/EC

Radio Equipment and Telecommunications Terminal

Equipment Directive

Radio Equipment Directive 2014/53/EU after 13 June 2016

2004/108/EC until 19 April 2016

2014/30/EU after 20 April 2016

1999/5/EC until 12 June 2016

1-17

CONTENTS

WEAM014802

CONTENTS

FOREWORD.........................................................................................................................................................1-2

SAFETY INFORMATION...................................................................................................................................... 1-4

NOISE LEVELS .......................................................................................................................................... 1-7

VIBRATIONS TO WHICH THE OPERATOR IS SUBJECTED...................................................................1-8

GUIDE WHEN WORKING IN AREAS WHERE AIR POLLUTION.............................................................. 1-9

INTRODUCTION.................................................................................................................................................1-10

DEMOLITION WORK ..................................... ...... ....... ...... ............................................. ..........................1-10

IMPROPER OR UNAUTHORIZED USES................................ ...... ...... ....... ...... ....................................... 1-11

MAIN CHARACTERISTICS......................................................................................................................1-11

RUNNING-IN ............................................................................................................................................1-12

DIRECTIONS OF MACHINE ....................................................................................................................1-13

PRODUCT IDENTIFICATION............................................................................................................................. 1-14

MACHINE SERIAL NUMBER...................................................................................................................1-14

MACHINE IDENTIFICATION PLATE AND PRODUCT IDENTIFICATION NUMBER (PIN)..................... 1-14

MACHINE SERIAL NUMBER PLATE

(according directive 2006/42/EC)..............................................................................................................1-15

ENGINE SERIAL NUMBER AND EXHAUST GAS EMISSION PLATE.................................................... 1-16

CAB SERIAL NUMBER ............................................................................................................................ 1-16

HOUR COUNTER POSITION ..................................................................................................................1-16

TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR ............................................................................1-17

DECLARATION OF CONFORMITY

(for machines placed on the market as from 29 December 2009)............................................................1-17

SAFETY LAB EL S.................................................................................................................................................2-2

LOCATION OF SAFETY LABELS..............................................................................................................2-3

SAFETY LABELS .......................................................................................................................................2-4

SAFETY RULES.......................................................................................................................................2-17

IF PROBLEMS ARE FOUND.................................................................................................................... 2-17

WORKING WEAR AND PERSONAL PROTECTIVE ITEMS ................................................................... 2-17

FIRE EXTINGUISHER AND FIRST AID KIT ............................................................................................2-18

SAFETY EQUIPMENT..............................................................................................................................2-18

KEEP MACHINE CLEAN.......................................................................................................................... 2-18

KEEP OPERATOR'S COMPARTMENT CLEAN......................................................................................2-19

LEAVING THE OPERATOR’S SEAT .......................................................................................................2-19

HANDRAILS AND STEPS........................................................................................................................2-20

MOUNTING AND DISMOUNTING ...........................................................................................................2-20

IT IS FORBIDDEN TO CLIMB ON THE EQUIPMENT ............................................................................. 2-20

DO NOT GET CAUGHT IN ARTICULATED PORTION ...........................................................................2-21

BURN PREVENTION ...............................................................................................................................2-21

FIRE PREVENTION AND EXPLOSION PREVENTION....................... ....... ...... ....... ................................ 2-22

ACTION IF FIRE OCCURS ...................................................................................................................... 2-23

WINDSHIELD WASHER FLUID ............................................................................................................... 2-23

FALLING OBJECTS, FLYING OBJECTS AND INTRUDING OBJECTS PREVENTION .........................2-24

1-18

CONTENTS

WEAM014802

CAUTIONS RELATED TO ROPS............................................................................................................. 2-24

ATTACHMENT INSTALLATION............................................................................................................... 2-25

ATTACHMENT COMBINATIONS............................................................................................................. 2-25

PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT ......................................................... 2-25

CAB WINDOW GLASSES........................................................................................................................ 2-25

UNAUTHORIZED MODIFICATIONS........................................................................................................ 2-25

SAFETY AT JOBSITE ... ...... ....... .............................................................................................................. 2-26

WORKING ON LOOSE GROUND............................................................................................................2-26

DISTANCE TO HIGH VOLTAGE CABLES............................................................................................... 2-27

ENSURE GOOD VISIBILITY.................................................................................................................... 2-28

VENTILATION FOR ENCLOSED AREA .................................................................................................. 2-28

SIGNALMAN'S SIGNAL AND SIGNS....................................................................................................... 2-29

EMERGENCY EXIT FROM OPERATOR'S CAB ..................................................................................... 2-34

ASBESTOS DUST HAZARD PREVENTION............................................................................................ 2-34

SAFETY MACHINE OPERATION...................................................................................................................... 2-35

STARTING ENGINE................................................................................................................................. 2-35

FUNCTIONING......................................................................................................................................... 2-37

TRANSPORTING THE MACHINE............................................................................................................ 2-43

BATTERY ................................................................................................................................................. 2-44

TOWING................................................................................................................................................... 2-46

LIFTING OBJECTS WITH LIFTING DEVICE (OPTIONAL EQUIPMENT)............................................... 2-47

SAFETY MAINTENANCE INFORMATION........................................................................................................ 2-50

MACHINE ILLUSTRATIONS................................................................................................................................3-2

GENERAL VIEW OF THE MACHINE WITH MONOBOOM ....................................................................... 3-2

GENERAL VIEW OF THE MACHINE WITH TWO-PIECE BOOM............................................................. 3-3

CONTROLS AND GAUGES....................................................................................................................... 3-4

INSTRUMENTS AND CONTROLS ...................................................................................................................... 3-6

MONITOR MESSAGE................................................................................................................................ 3-6

MONITORING SYSTEM............................................................................................................................. 3-8

SWITCHES AND PUSH BUTTONS ......................................................................................................... 3-62

CONTROL LEVERS AND PEDALS ........................................ ................................................................. 3-69

CAB .................................................................................................................................................................... 3-75

OPENING ROOF...................................................................................................................................... 3-75

WINDSHIELD ........................................................................................................................................... 3-76

SLIDING DOOR........................................................................................................................................ 3-81

EMERGENCY EXIT HAMMER................................................................................................................. 3-82

HOODS AND DOORS FITTED WITH A LOCK ................................................................................................. 3-83

ENGINE COVER ...................................................................................................................................... 3-84

SIDE COVER............................................................................................................................................ 3-85

PUMP COMPARTMENT AND BATTERY COMPARTMENT DOORS..................................................... 3-86

AIR CONDITIONER............................................................................................................................................ 3-87

AIR CONDITIONER CONTROL PANEL .................................................................................................. 3-88

OPERATING MODES............................................................................................................................... 3-92

1-19

CONTENTS

WEAM014802

USE THE AIR CONDITIONER WITH CAUTION......................................................................................3-99

INSPECTING AND SERVICING A MACHINE WITH AIR CONDITIONER . ...... ....... ...... ....... ...... .............3-99

FUSES .............................................................................................................................................................. 3-100

MAIN FUSE ............................................................................................................................................3-101

SUPPLEMENTARY POWER SUPPLY............................................................................................................ 3-102

CONTROLLER ................................................................................................................................................. 3-104

STORAGE COMPARTMENTS.........................................................................................................................3-105

TECHNICAL DOCUMENTATION COMPARTMENT.............................................................................. 3-105

CUP HOLDER ........................................................................................................................................3-105

TOOL BOX.............................................................................................................................................. 3-105

PUMP SUPPORT FOR GREASING .......................................................................................................3-106

ASHTRAY...............................................................................................................................................3-106

FIRE EXTINGUISHERS ......................................................................................................................... 3-106

KOMTRAX SYSTEM ........................................................................................................................................3-107

GENERAL PRECAUTIONS.................................................................................................................... 3-107

USE OF THE MACHINE AND RELATED CONTROLS...................................................................................3-109

BEFORE STARTING THE ENGINE.......................................................................................................3-109

AFTER STARTING THE ENGINE.......................................................................................................... 3-135

STOPPING THE ENGINE ......................................................................................................................3-146

HOW TO MOVE THE MACHINE............................................................................................................3-147

STEERING THE MACHINE.................................................................................................................... 3-150

TURRET ROTATION..............................................................................................................................3-152

WORK EQUIPMENT CONTROLS AND FUNCTIONS...........................................................................3-153

WORK MODE.........................................................................................................................................3-155

UNAUTHORIZED OPERATIONS...........................................................................................................3-156

PRECAUTIONS FOR USE..................................................................................................................... 3-159

PRECAUTIONS TO BE TAKEN WHEN TRAVELLING ON SLOPES....................................................3-161

GETTING THE MACHINE OUT OF MUD .............................................................................................. 3-163

OPERATIONS THAT CAN BE PERFORMED WITH THE HYDRAULIC EXCAVATOR ........................3-164

LIFTING OBJECTS WITH LIFTING DEVICE .........................................................................................3-166

BUCKET REPLACEMENT AND INVERSION........................................................................................ 3-169

PARKING THE MACHINE......................................................................................................................3-170

CHECKS TO BE CARRIED OUT BEFORE STOPPING THE ENGINE................................................. 3-171

CHECKS TO BE CARRIED OUT AFTER WORK .................................................................................. 3-172

LOCKING THE MACHINE......................................................................................................................3-172

ROAD LINERS........................................................................................................................................3-173

TRANSPORTATION.........................................................................................................................................3-176

TRANSPORT PROCEDURE..................................................................................................................3-176

LOADING AND UNLOADING THE MACHINE.......................................................................................3-177

LIFTING THE MACHINE ...................................... ....... ............................................. .............................. 3-182

USING THE MACHINE IN THE COLD SEASON.............................................................................................3-184

PRECAUTIONS TO BE TAKEN WHEN USING THE MACHINE IN THE COLD SEASON ...................3-184

1-20

CONTENTS

WEAM014802

PRECAUTIONS TO BE TAKEN EVERY DAY AT THE END OF WORK............................................... 3-186

HOW TO PROCEED AT THE END OF THE COLD SEASON............................................................... 3-186

LONG PERIODS OF INACTIVITY.................................................................................................................... 3-187

BEFORE A PERIOD OF INACTIVITY .................................................................................................... 3-187

DURING A PERIOD OF INACTIVITY..................................................................................................... 3-187

RECOMMENDATIONS FOR MACHINES EQUIPPED WITH KOMTRAX SYSTEM DURING LONG

PERIODS OF INACTIVITY..................................................................................................................... 3-188

AFTER A PERIOD OF INACTIVITY .......................................................................................................3-188

ENGINE START-UP AFTER PROLONGED INACTIVITY...................................................................... 3-189

ALLOWED AMBIENT TEMPERATURE RANGE DURING THE OPERATION AND STORAGE OF THE

MACHINE FOR A LONG TIME............................. ............................................. ..................................... 3-189

TROUBLESHOOTING...................................................................................................................................... 3-190

IF FUEL RUNS OUT COMPLETELY...................................................................................................... 3-190

OCCURRENCES THAT ARE NOT FAILURES......................................................................................3-190

REMOVING THE MACHINE................................................................................................................... 3-191

PRECAUTIONS TO BE TAKEN WHEN WORKING IN PARTICULAR CONDITIONS................ ...... ..... 3-191

IF THE BATTERY IS DOWN .................................................................................................................. 3-192

OTHER TROUBLES............................................................................................................................... 3-197

GUIDE TO MAINTENANCE ................................................................................................................................. 4-2

MAINTENANCE NOTES ............................................................................................................................ 4-5

OIL, FUEL, COOLANT AND GREASE.......................................................................................................4-5

KOWA (KOMATSU OIL WEAR ANALYSIS)............................................................................................... 4-8

STORING OIL AND FUEL.......................................................................................................................... 4-9

FILTERS..................................................................................................................................................... 4-9

NOTES ON THE MAINTENANCE OF THE ELECTRICAL SYSTEM......................................................... 4-9

NOTES ON THE MAINTENANCE OF THE HYDRAULIC SYSTEM........................................................ 4-10

MAINTENANCE NOTES REGARDING LUBRICATION .......................................................................... 4-10

PARTS SUBJECT TO WEAR............................................................................................................................ 4-11

LIST OF THE PARTS SUBJECT TO WEAR............................................................................................ 4-11

FUEL, COOLANT AND LUBRICANTS.............................................................................................................. 4-12

RECOMMENDED BRANDS, QUALITY RECOMMENDED FOR PRODUCTS DIFFERENT THAN ORIGINAL

KOMATSU OIL ......................................................................................................................................... 4-13

APPROVED SYNTHETIC BIODEGRADABLE LUBRICANTS TYPE HEES............................................ 4-14

TIGHTENING TORQUES................................................................................................................................... 4-15

STANDARD TIGHTENING TORQUES FOR SCREWS AND NUTS .......................................... ...... ....... 4-15

STANDARD TIGHTENING TORQUES FOR FLEXIBLE HOSES (ORFS).............. ................................. 4-16

LUBRICATION ................................................................................................................................................... 4-17

LUBRICATION DIAGRAM....................................................... ...... ....... ...... .............................................. 4-17

BOOM....................................................................................................................................................... 4-17

2-PIECE BOOM............. ...... ....... ............................................. ................................................................. 4-18

PERIODICAL CHANGE OF SAFETY-RELATED COMPONENTS................................................................... 4-19

SAFETY-RELATED PARTS..................................................................................................................... 4-20

1-21

CONTENTS

WEAM014802

MAINTENANCE PLAN.......................................................................................................................................4-21

MAINTENANCE PLAN .............................................................................................................................4-21

MAINTENANCE INTERVALS IN CASE OF USE OF THE HYDRAULIC BREAKER............................... 4-23

MAINTENANCE PROCEDURES ....................................................................................................................... 4-24

WHEN REQUIRED...................................................................................................................................4-24

CHECKS TO BE CARRIED OUT BEFORE STARTING THE ENGINE....................................................4-44

MAINTENANCE AFTER THE FIRST 50 HOURS OF OPERATION ........................................................4-44

MAINTENANCE EVERY 100 HOURS OF OPERATION ......................................................................... 4-45

MAINTENANCE EVERY 250 HOURS OF OPERATION ......................................................................... 4-47

MAINTENANCE AFTER THE FIRST 500 HOURS OF OPERATION ......................................................4-54

MAINTENANCE EVERY 500 HOURS OF OPERATION ......................................................................... 4-54

MAINTENANCE EVERY 1000 HOURS OF OPERATION ....................................................................... 4-69

MAINTENANCE EVERY 2000 HOURS OF OPERATION ....................................................................... 4-74

MAINTENANCE EVERY 4000 HOURS OF OPERATION ....................................................................... 4-87

MAINTENANCE EVERY 5000 HOURS OF OPERATION ....................................................................... 4-89

FINAL DISPOSAL OF THE MACHINE ..............................................................................................................4-92

SPECIFICATIONS................................................................................................................................................5-2

OPERATING CHARACTERISTICS ..................................................................................................................... 5-3

LIFTING CAPACITIES TABLES..........................................................................................................................5-5

LEGENDE...................................................................................................................................................5-5

LIFTING CAPACITIES WITH BOOM.......................................................................................................... 5-6

LIFTING CAPACITIES WITH TWO-PIECE BOOM ....................................................................................5-9

GENERAL PRECAUTIONS FOR SAFETY.......................................................................................................... 6-2

PRECAUTIONS WHEN SELECTING......................................................................................................... 6-2

READ THE INSTRUCTION MANUAL THOROUGHLY..... ....... ...... ...... .............................................. ........6-2

PRECAUTIONS WHEN REMOVING OR INSTALLING ............................................................................. 6-2

PRECAUTIONS WHEN USING..................................................................................................................6-2

SPECIFICATIONS................................................................................................................................................6-4

ARM-PIN INFORMATION...........................................................................................................................6-4

EQUIPMENT USE GUIDE....................................................................................................................................6-5

COMBINATIONS OF WORK EQUIPMENT................................................................................................ 6-5

EQUIPMENT CONFIGURATION ...............................................................................................................6-5

LONG ARM.................................................................................................................................................6-7

MACHINE CONFIGURATION FOR THE INSTALLATION OF ATTACHMENTS....................................... 6-8

HYDRAULIC QUICK COUPLER........................................................................................................................ 6-17

POSITION OF THE DEVICES..................................................................................................................6-17

FUNCTIONING......................................................................................................................................... 6-18

RECOMMENDED ATTACHMENT OPERATIONS............................................................................................. 6-20

HYDRAULIC BREAKER........................................................................................................................... 6-20

INSTALLING AND REMOVING THE ADDITIONAL COUNTERWEIGHT.........................................................6-25

1-22

SAFETY

WARNING

WEAM014802

12

Read and make sure that the precautions outlined in this manual and the safety labels on the machine

have been fully understood. Always closely observed these safety measures when starting or performing

assistance on the machine.

SAFETY LABELS

WEAM014802

SAFETY

SAFETY LABELS 2

The following warning signs and safety labels are used on this machine.

q Be sure that you fully understand the correct position and content of labels.

q To ensure that the content of labels can be read properly , be sure that they are in the correct place and always

keep them clean. When clea ning them , do not use organic solvents or gasoline. Th ese may cause the labels

to peel off.

q There are also other labels in addition to the warning signs and safety labels. Handle those labels in the same

way.

q If the labels are damaged, lost, or cannot be read properly, replace them with new ones. For details of the part

numbers for the labels, see this manual or the actual label, and place an order with Komatsu distributor.

2-2

SAFETY

WEAM014802

SAFETY LABELS

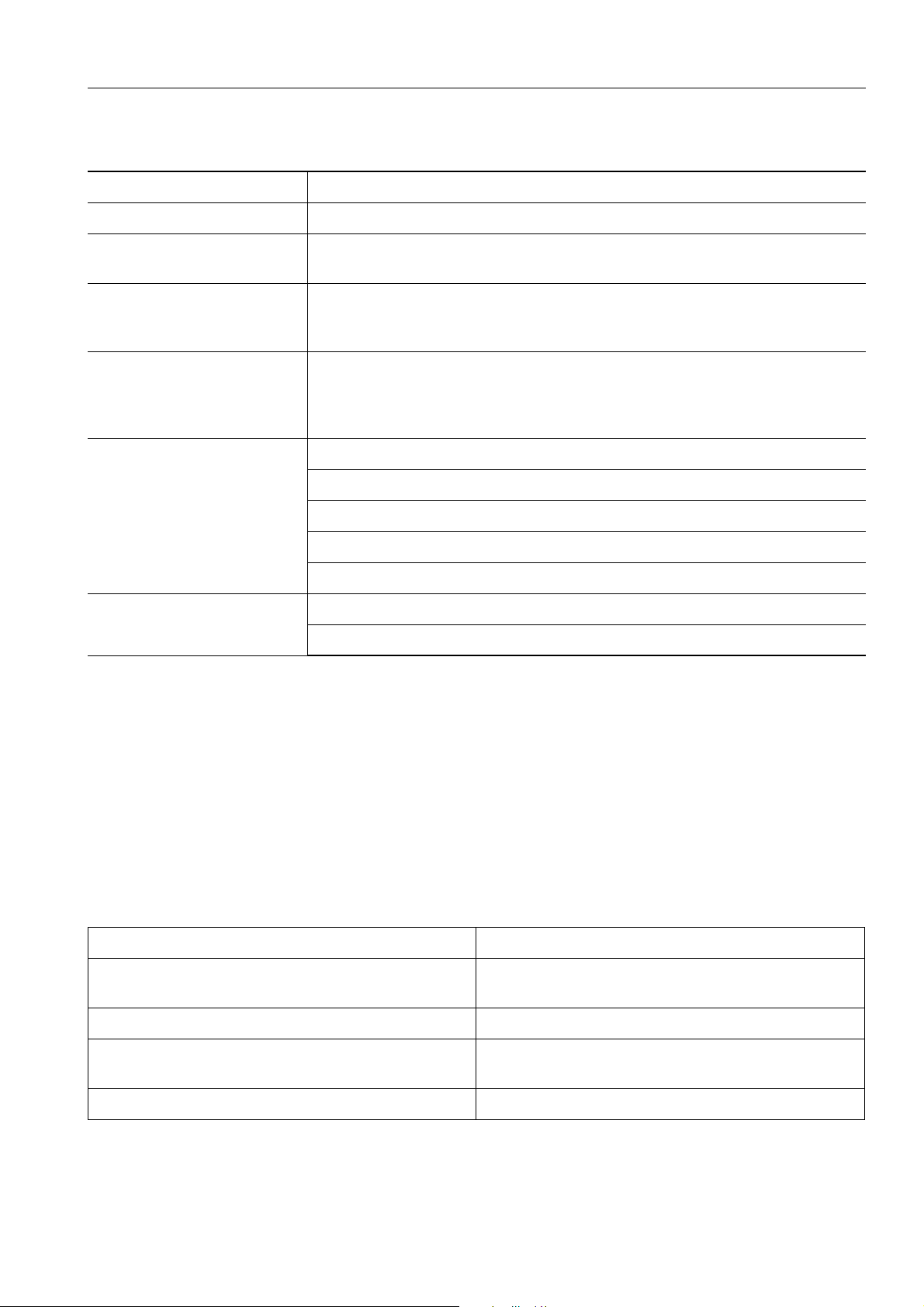

LOCATION OF SAFETY LABELS 2

2-3

SAFETY LABELS

WEAM014802

SAFETY

SAFETY LABELS 2

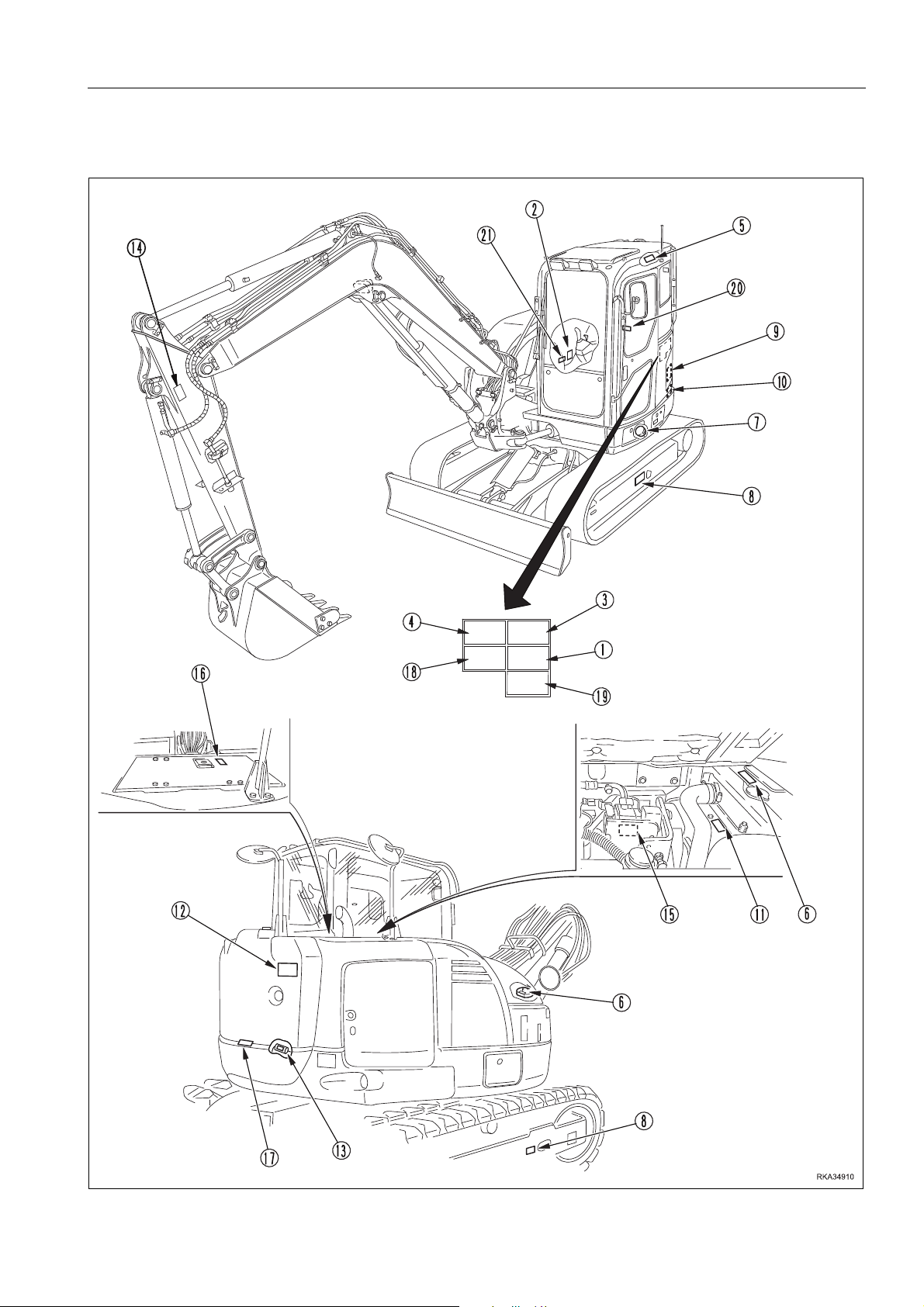

(1) Consult the manual.

q Carefully read the conten ts of the manual before us ing

the machine or performing maintenance operations.

(2) Safety distance.

q Do not get too near the machine and do not stand

within its operating range.

(3) Before leaving the operator’s seat

q Before leaving the ma chine , lower th e work eq uipmen t

to the ground, shift the safety lever to position “lock”,

stop the engine and remove the ignition key .

(4) Risk of electrocution

q Minimum safety distances from overhead lines. (For

details, see "DISTANCE TO HIGH VOLTAGE CABLES

(2-27)").

2-4

SAFETY

WEAM014802

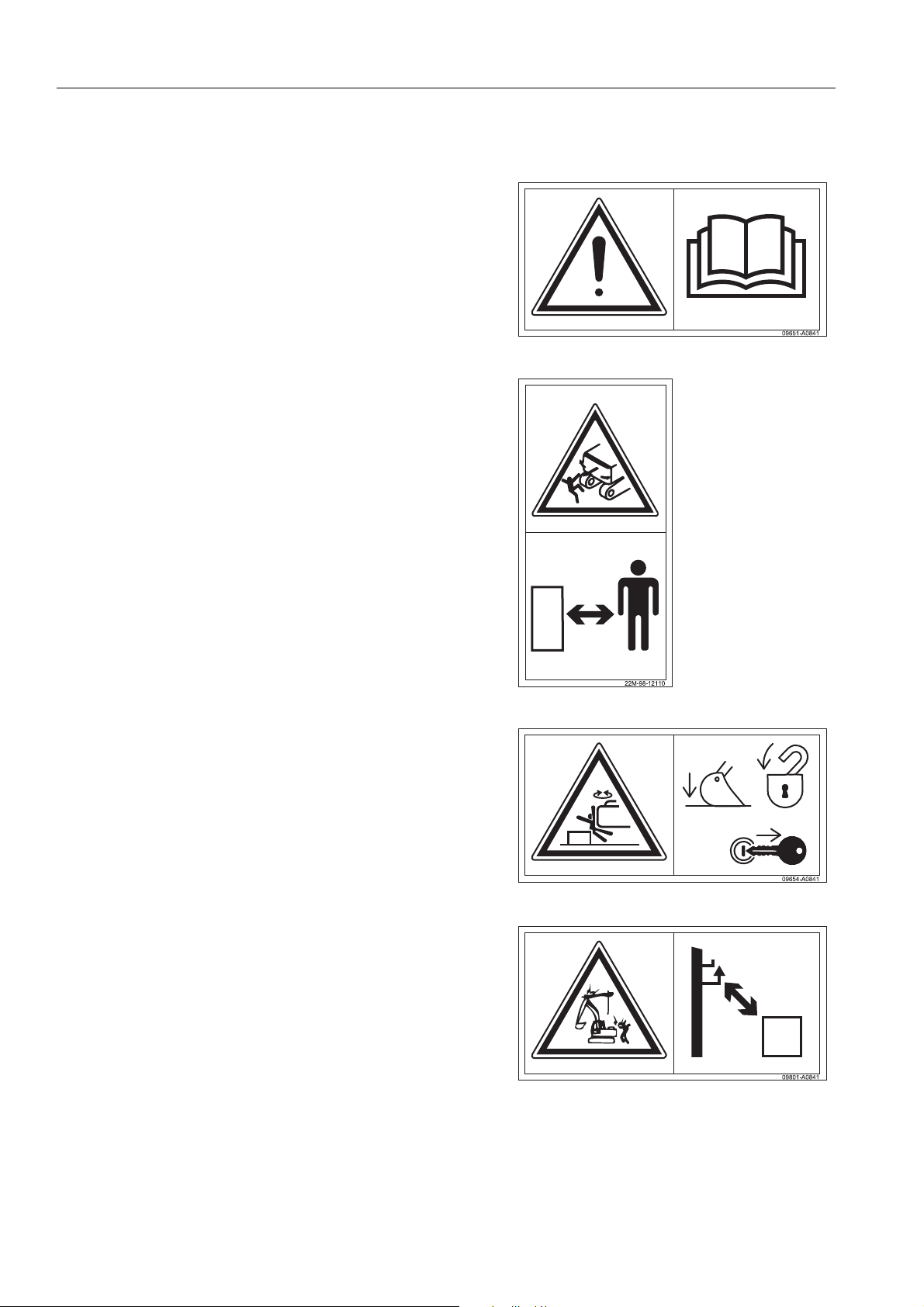

(5) Caution when stowing front window

q Make sure that the front windshield is always locked.

(6) Risk of burns

q Do not open the radiator and the hydraulic oil tank

when the engine is still hot.

SAFETY LABELS

(7) Risk of explosio n on the hydraulic accumulato r and gas

spring

q Working on the accumulator witho ut due caution may

cause explosion, leading to serious personal injury.

Always observe the followi ng prec auti on s:

- Do not dismantle

- Keep away from sparks and flame.

- Do not puncture and do not weld with oxyacetylene

torches

- Do not strike or crush

(8) Adjusting the track tension

q The adjustment of the tracks involves the risk of

injuries.

q To correctly and safely adjust the tracks, read the

instructions in the manual .

2-5

SAFETY LABELS

WEAM014802

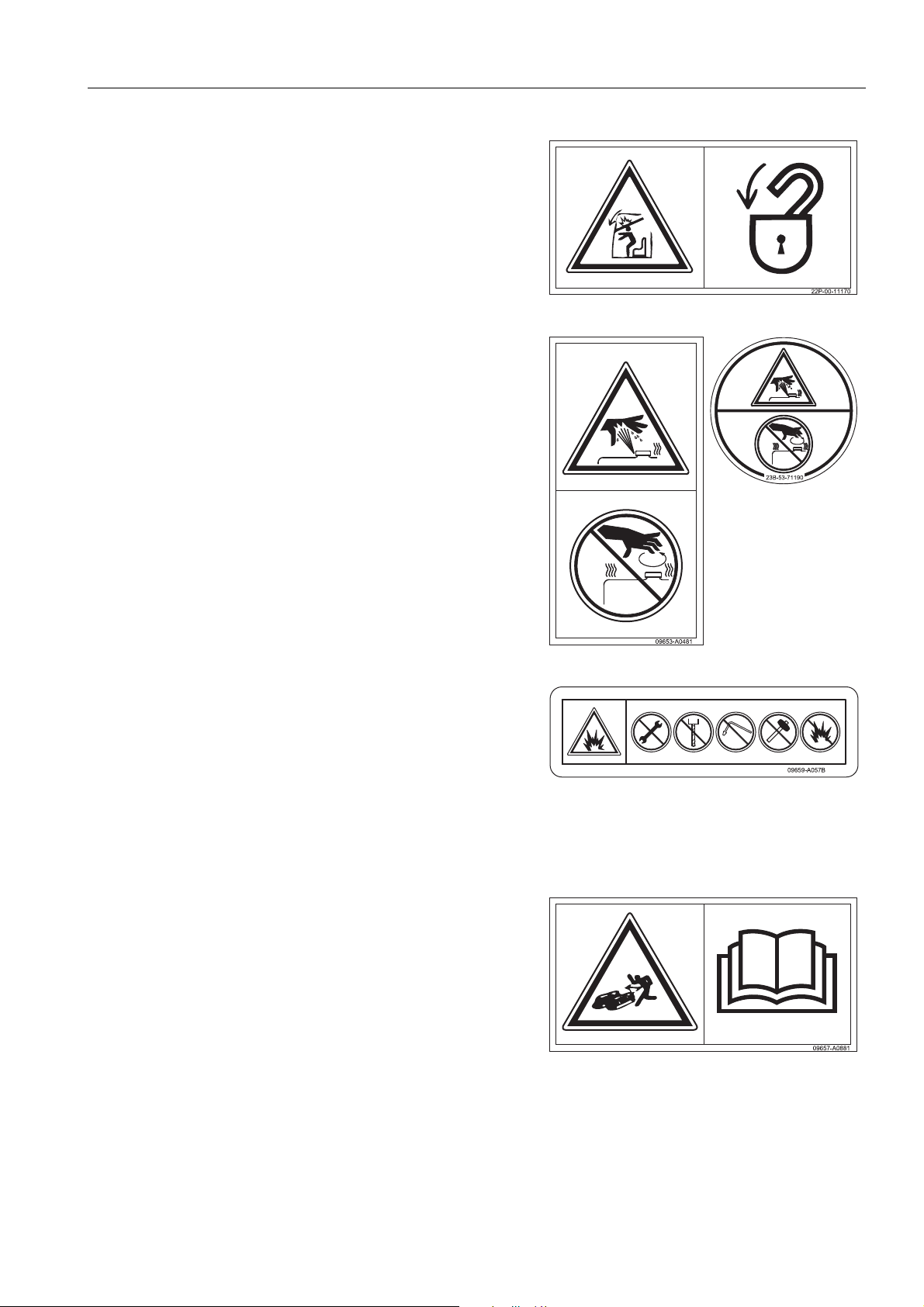

(9) Battery and electric cables

q Risk of electric charges in case of work on the battery

or the electric cables.

(10) Battery

q Precautions for working on the battery.

SAFETY

(11) Do not open the hood.

q Do not open or remove the hood when the engine is

running.

(12) Safety distance.

q Do not get too near the machine and do not stand

within the revolving frame swinging range.

2-6

Loading...

Loading...