Kohler SV590-0004, SV590-0002 Owner’s Manual

OWNER'S MANUAL

COURAGE_ SERIES

SV470, SV480, SV530, SV540, SV590, SV600

VERTICAL CRANKSHAFT

Safety Precautions

To ensure safe operation please read the following statements and understand their meaning.

Also refer to your equipment owner's manual for other important safety information. This manual

contains safety precautions which are explained below. Please read carefully.

WARNING

Warning is used to indicate the presence of a hazard that can cause severe oersonal injury,

death, or substantial property damage if the warning is ignored.

CAUTION

Caution is used to indicate the presence of a hazard that will or can cause minor personal injury

or property damage if the caution is ignored.

NOTE

Note is used to notify people of installation, operation, or maintenance information that is

important but not hazard-related.

For Your Safety!

These precautions should be followed at all times. Failure to follow these precautions could result

in injury to yourself and others.

WARNING

Explosive Fuel can cause fires and

severe burns.

Stop engine before filling fuel tank.

Explosive FueH

Gasoline is extremely flammable

and its vapors can explode ff

ignited. Store gasoline only in

approved containers, in well

ventilated, unoccupied buildings,

away from sparks or flames. Do not

fill the fuel tank while the engine is

hot or running, since spilled fuel

could ignite if it comes in contact

with hot parts or sparks from

ignition. Do not start the engine near

spilled fuel. Never use gasoline as a

cleaning agent.

WARNING

Rotating Parts can cause severe

injury.

Stay away while engine is in

operation.

Rotating Parts!

Keep hands, feet, hair, and clothing

away from aft moving parts to

prevent injury. Never operate the

engine with covers, shrouds, or

guards removed.

CAUTION

Electrical Shock can cause injury.

Do not touch wires while engine is

running.

Electrical Shock!

Never touch electrical wires or

components while the engine is

running. They can be sources of

electrical shock.

WARNING

Hot Parts can cause severe burns.

Do not touch engine while operating

or just after stopping.

Hot Parts!

Engine components can get

extremely hot from operation. To

prevent severe burns, do not touch

these areas while the engine is

running, or immediately after it is

turned off. Never operate the engine

with heat shields or guards

removed.

California

Proposition 65 Warning

Engine exhaust from this product

contains chemicals known to the

State of Cafifornia to cause cancer,

birth defects, or other reproductive

harm.

Safety Precautions (Cont.)

WARNING

Accidental Starts can cause severe

mjury or death.

Disconnect and ground spark plug

lead before servicing.

Accidental Starts!

Disabfing engine. Accidental

starting can cause severe injury

or death. Before working on the

engine or equipment, disable the

engine as follows: 1) Disconnect the

spark plug lead(s). 2) Disconnect

negative (-) battery cable from

battery.

WARNING

_ t-r:;_21.... 5:;fP ,:"

Carbon Monoxide can cause

severe nausea, fainting or death,

Do not operate engine in closed or

confined area.

Lethal Exhaust Gases!

Engine exhaust gases contain

poisonous carbon monoxide.

Carbon monoxide is odorless,

colorless, and can cause death if

inhaled. Avoid inhafing exhaust

fumes, and never run the engine in

a closed building or confined area.

WARNING

Explosive Gas can cause fires and

severe acid burns.

Charge battery only in a well

ventilated area. Keep sources of

ignition away.

Explosive Gas!

Batteries produce explosive

hydrogen gas while being charged.

Toprevent a fire or explosion,

charge batteries only in weft

ventilated areas. Keep sparks, open

flames, and other sources of ignition

away from the battery at aft times.

Keep batteries out of the reach of

children. Remove all jewelry when

servicing batteries.

Before disconnecting the negative

(-) ground cable, make sure aft

switches are OFF. If ON, a spark will

occur at the ground cable terminal

which could cause an explosion if

hydrogen gas or gasofine vapors

are presenL

Congratulations - You have selected a fine four-cycle, single cylinder, air-cooled engine. Kohler designs long

life strength and on-the-job durability into each engine...making a Kohler engine dependable...dependability you

can count on. Here are some reasons why:

• Efficient dual cam, overhead valve design with full pressure lubrication, provides maximum power, torque,

and reliability under all operating conditions.

• Dependable, maintenance free electronic ignition ensures fast, easy starts time after time.

• A reciprocating balance system ensures smooth running and low vibration.

• Kohler engines are easy to service. All routine service areas (like the dipstick and oil fill, air cleaner, and

carburetor) are easily and quickly accessible.

• Parts subject to the most wear and tear (like the cylinder liner) are made from precision formulated cast iron

for longer life.

• Every Kohler engine is backed by a worldwide network of over 10,000 distributors and dealers. Service

support is just a phone call away. Call 1-800-544-2444 (U.S. & Canada) for Sales & Service assistance.

To keep your engine in top operating condition, follow the maintenance procedures in this manual.

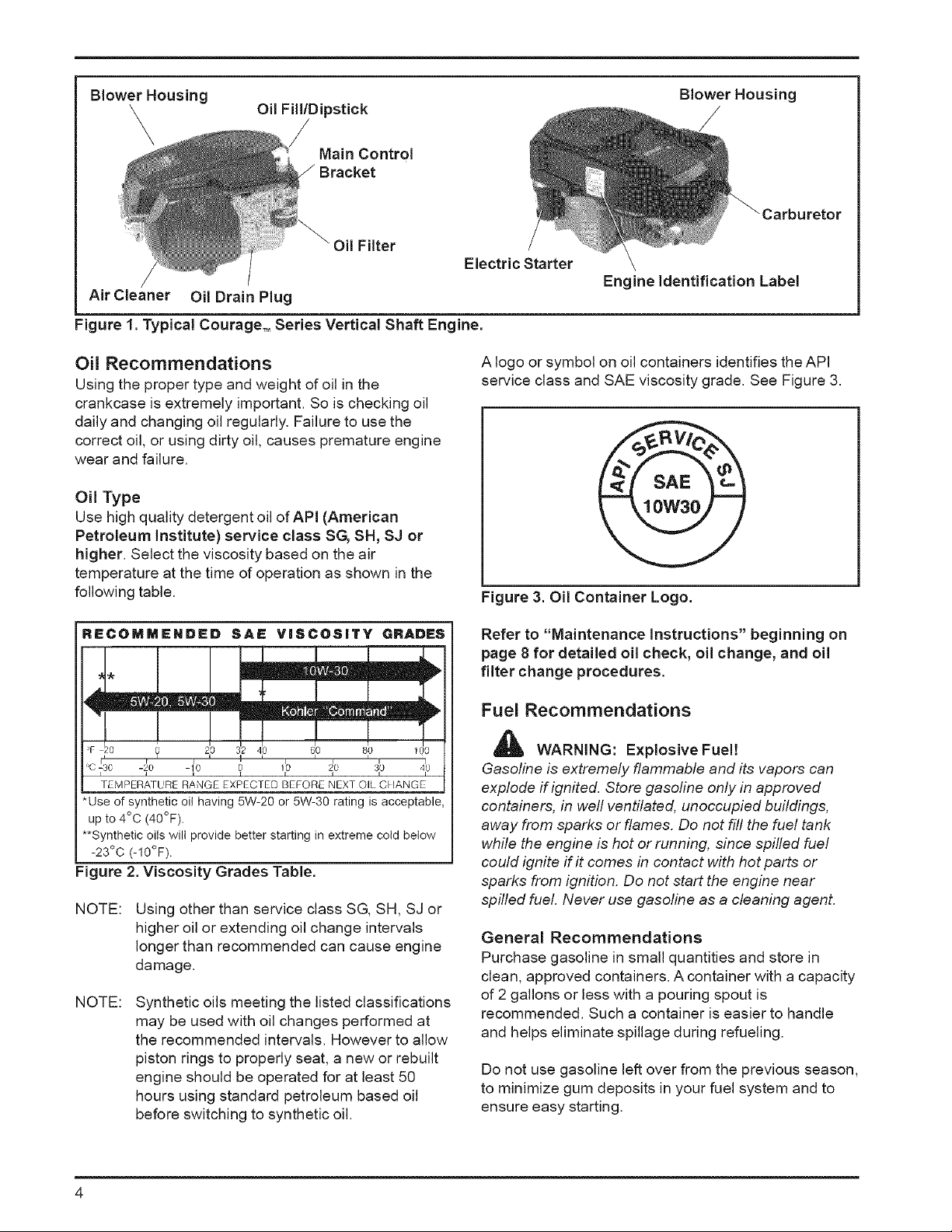

BlowerHousing

OilFill/Dipstick

Main Control

Bracket

Oil Filter

Electric Starter

Air Cleaner Oil Drain Plug

Figure 1. Typical Courage,M Series Vertical Shaft Engine.

Blower Housing

/

Engine identification Label

Oil Recommendations

Using the proper type and weight of oil in the

crankcase is extremely important. So is checking oil

daily and changing oil regularly. Failure to use the

correct oil, or using dirty oil, causes premature engine

wear and failure.

Oil Type

Use high quality detergent oil of APl (American

Petroleum Institute) service class SG, SH, SJ or

higher. Select the viscosity based on the air

temperature at the time of operation as shown in the

following table.

RECOMMENDED SAE VISCOSITY GRADES

TEMPER_,TURE RANGE EXPECTED BEFORE NEXT OIL CI IANGE

*Use of synthetic oil having 5W-20 or 5W-30 rating is acceptable,

up to 4°C (40°F).

**Synthetic oils will provide better starting in extreme cold below

-23°C (-10°F).

Figure 2. Viscosity Grades Table.

NOTE:

NOTE:

Using other than service class SG, SH, SJ or

higher oil or extending oil change intervals

longer than recommended can cause engine

damage.

Synthetic oils meeting the listed classifications

may be used with oil changes performed at

the recommended intervals. However to allow

piston rings to properly seat, a new or rebuilt

engine should be operated for at least 50

hours using standard petroleum based oil

before switching to synthetic oil.

A logo or symbol on oil containers identifies the API

service class and SAE viscosity grade. See Figure 3.

Figure 3. Oil Container Logo.

Refer to "Maintenance Instructions" beginning on

page 8 for detailed oil check, oil change, and oil

filter change procedures.

Fuel Recommendations

WARNING: Explosive Fuel!

Gasoline is extremely flammable and its vapors can

explode if ignited. Store gasofine only in approved

containers, in well ventilated, unoccupied buildings,

away from sparks or flames. Do not fill the fuel tank

while the engine is hot or running, since spilled fuel

could ignite if it comes in contact with hot parts or

sparks from ignition. Do not start the engine near

spilled fuel. Never use gasoline as a cleaning agent.

General Recommendations

Purchase gasoline in small quantities and store in

clean, approved containers. A container with a capacity

of 2 gallons or less with a pouring spout is

recommended. Such a container is easier to handle

and helps eliminate spillage during refueling.

Do not use gasoline left over from the previous season,

to minimize gum deposits in your fuel system and to

ensure easy starting.

4

Donotaddoiltothegasoline.

Donotoverfillthefueltank.Leaveroomforthefuelto

expand.

FuelType

Forbestresultsuseonlyclean,fresh,unleaded

gasolinewithapumpstickeroctaneratingof87or

higher.IncountriesusingtheResearchmethod,it

shouldbe90octaneminimum.

Unleadedgasolineisrecommendedasitleavesless

combustionchamberdeposits.Leadedgasolinemay

beusedinareaswhereunleadedisnotavailableand

exhaustemissionsarenotregulated.Beaware

however,thatthecylinderheadsmayrequiremore

frequentservice.

Gasoline/Alcoholblends

Gasohol(upto10%ethylalcohol,90%unleaded

gasolinebyvolume)isapprovedasafuelforKohler

engines.Othergasoline/alcoholblendsarenot

approved.

GasolinelEtherblends

MethylTertiaryButylEther(MTBE)andunleaded

gasolineblends(uptoamaximumof15%MTBEby

volume)areapprovedasafuelforKohlerengine,

Othergasoline/etherblendsarenotapproved,

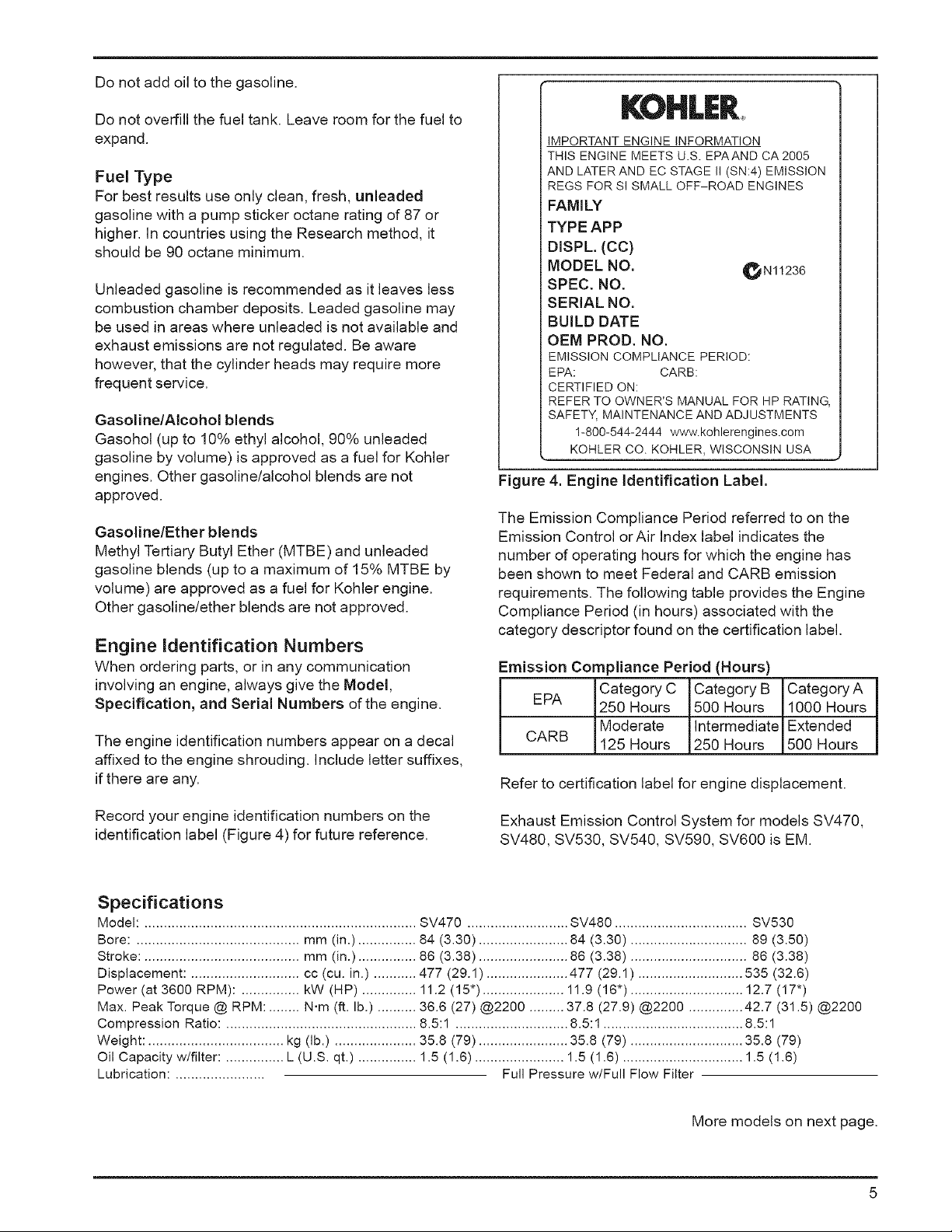

Engine Identification Numbers

When ordering parts, or in any communication

involving an engine, always give the Model,

Specification, and Serial Numbers of the engine.

The engine identification numbers appear on a decal

affixed to the engine shrouding. Include letter suffixes,

if there are any.

KOHLER

IMPORTANT ENGINE INFORMATION

THIS ENGINE MEETS U.S. EPAAND CA 2005

AND LATER AND EC STAGE II (SN:4) EMISSION

REGS FOR SI SMALL OFF-ROAD ENGINES

FAMILY

TYPE APP

DISPL. (CC)

MODEL NO. _,Nl1236

SPEC. NO.

SERIAL NO.

BUILD DATE

OEM PROD. NO.

EMISSION COMPLIANCE PERIOD:

EPA: CARB:

CERTIFIED ON:

REFER TO OWNER'S MANUAL FOR HP RATING,

SAFETY, MAINTENANCE AND ADJUSTMENTS

1-800-544-2444 www.kohlerengines.com

KOHLER CO. KOHLER, WISCONSIN USA

Figure 4. Engine Identification Label.

The Emission Compliance Period referred to on the

Emission Control orAir Index label indicates the

number of operating hours for which the engine has

been shown to meet Federal and CARB emission

requirements. The following table provides the Engine

Compliance Period (in hours) associated with the

category descriptor found on the certification label.

Emission Compliance Period (Hours)

EPA CategoryC Category B CategoryA

CARB

Refer to certification label for engine displacement.

250 Hours 500 Hours 1000 Hours

Moderate Intermediate Extended

125 Hours 250 Hours 500 Hours

Record your engine identification numbers on the

identification label (Figure 4) for future reference.

Exhaust Emission Control System for models SV470,

SV480, SV530, SV540, SV590, SV600 is EM

Specifications

Model: ...................................................................... SV470 ..........................SV480 .................................. SV530

Bore: .......................................... mm (in,) ............... 84 (3.30) ....................... 84 (3,30) .............................. 89 (3,50)

Stroke: ........................................ mm (in,) ............... 86 (3.38) ....................... 86 (3,38) .............................. 86 (3,38)

Displacement: ............................ cc (cu. in.) ........... 477 (29.1) ..................... 477 (29.1) ........................... 535 (32.6)

Power (at 3600 RPM): ............... kW (HP) .............. 11.2(15") ..................... 11.9(16") ............................. 12.7 (17")

Max. PeakTorque @ RPM: ........ N.m (ft. lb.) .......... 36.6 (27) @2200 ......... 37.8 (27.9) @2200 .............. 42.7 (31.5) @2200

Compression Ratio: ................................................. 8.5:1 ............................. 8.5:1 .................................... 8.5:1

Weight: ................................... kg (lb.) .....................35.8 (79) .......................35.8 (79) ............................. 35.8 (79)

Oil Capacity w/filter: ............... L (U.S. qt.) ............... 1.5 (1.6) ....................... 1.5 (1.6) ............................... 1.5 (1.6)

Lubrication: ....................... Full Pressure w/Full Flow Filter

More models on next page.

Loading...

Loading...