Kohler K-50205T-XT-NA, K-5525T-XT-NA, K-5526T-XT-NA, K-5531T-XT-NA, K-5529T-XT-NA Installation And Homeowners Manual

Installation and Homeowners Guide

Steam Generator

I

Cloud Version/

50205T-XT-NAS2 KS3 K-5525T / S5 K-5526T

S7 K-5529T / S9 K-5531T

-XT-NA

-XT-NA

-XT-NA

-XT-NA

1313992-T01-A

KOHLER CHINA INVESTMENT CO., LTD NO.158, JIANG CHANG SAN ROAD,

JING'AN DISTRICT, SHANGHAI, PRC POST CODE: 200436

科勒(中国)投资有限公司 上海市静安区江场三路158号 邮编:200436

TOOLS AND MATERIALS

Plug:

·1/2" copper tubing

·Assorted copper fittings; G3/8", G1/2" and G3/4" copper

unions

·Wire Cutters or Wire Strippers

·Conventional woodworking tools and materials

·45 and 90 degree elbows

·Support Blocks (heat resistant)

Hacksaw or

Tube Cutter

Drill w/ 1-1/4" &

2-1/2" Hole Bit

Sealant Tape

Solder

Propane Torch

IMPORTANT SAFETY INSTRUCTIONS

This product complies with IEC EN 60335-2-53:2011 and EN 60335-1:2012/A11:2014.

Water Pressure: 0.14MPa~0.55MPa

IMPORTANT! When using this unit, basic precautions should always be followed.

DANGER: Risk of electrocution. Disconnect the electricity to the working area at the main breaker panel

before performing these installation steps.

WARNING: Risk of personal injury. If you become uncomfortable while taking a steam bath, you should

power off the unit. Cool off with the shower, open the door, or exit the unit.

WARNING: Risk of allergic reaction. Before adding any oils, aromatic therapies, or skin care products to

the aromatherapy well, make sure they will not cause an allergic reaction to the user.

WARNING: Risk of personal injury. This steam bath may not be suitable for use if you are pregnant, have

a heart condition, have high blood pressure, have circulatory problems, are under the influence of alcohol,

are taking drugs or are under the care of a physician. A steam bath can put undue stress on the body, as

does any hot bath, shower, or sauna.

WARNING: Risk of personal injury. The wet surfaces of steam enclosures may be slippery. Use care

when entering or leaving.

WARNING: Risk of personal injury. Prolonged use of the steam system can raise excessively the internal

human body temperature and impair the body’s ability to regulate its internal temperature (hyperthermia).

The appliance is to be continuously attended. Limit your use of steam to 10-20 minutes until you are certain

of your body’s reaction.

WARNING: Risk of personal injury. DO NOT consume alcoholic beverages or take medications/drugs

prior to or when using the steam bath. Alcohol and drugs affect mental judgement and inhibit bodily

functions such as heartbeat and respiration, resulting in potentially dangerous effects.

WARNING: Risk of injury to children. This appliance can be used by children aged from 8 years and

above and persons with reduced physical, sensory or mental capabilities or lack of experience and

knowledge if they have been given supervision or instruction concerning use of the appliance in a safe way

and understand the hazards involved. Children shall not play with the appliance. Cleaning and user

maintenance shall not be made by children without supervision.

WARNING: Risk of personal injury. Do not plumb a trap in the steam line or plumb the pressure relief

valve into the steam line. Plumbing the pressure relief valve into the steam line can be hazardous if the

steam outlet is capped.

WARNING: Risk of scalding. Do not touch the steam head during operation. The steam head is hot during

operation.

WARNING: Risk of personal injury. HYPERTHERMIA occurs when the internal temperature of the body

reaches a level several degrees above the normal body temperature of 37°C. The symptoms of

hyperthermia include an increase in the internal temperature of the body, dizziness, lethargy, drowsiness,

and fainting. The use of alcohol, drugs, or medication can greatly increase the risk of hyperthermia.

WARNING: Risk of personal injury or property damage. Avoid coming in contact with the water tank

and/or steam discharge line while the generator is operating or shortly after shutdown. Wear eye protection

and protective clothing when servicing the steam generator. The steam generator operates at high

temperatures.

WARNING: Risk of personal injury or property damage. DO NOT install the heating apparatus in the

steam enclosures.

NOTICE: If any heating apparatus(electric stove, bath heater etc.) is installed in the shower enclosure and both

the heater and steam generator is activated at the same time, the steam generator may malfunction due to heat of

the heating apparatus. Also, the heating apparatus could malfunction or be out of the order by steam of steam

generator.

1313992-T01-A

2

NOTICE: The warranty could not apply to damaged unit by reason of hard water condition. KOHLER Co.

recommend that water hardness should be less than 85mg/L.

NOTICE: Use this unit only for its intended use as specified in this manual. DO NOT use attachments not

recommended by Kohler Co.

NOTICE: Do not apply excessive heat to the generator connections when you solder connections. Do not apply

flux or acids directly to the generator, as damage to the seals, plastic components, and trim finish may result. Do

not apply petroleum-based lubricants to the generator components, as damage may result.

Inspect the product for any damage. Contact the KOHLER Customer Service Centre using the information on

the Compliance Certification.

Follow all local plumbing and electrical codes. All electrical work should be done by a qualified electrician.

Disconnect all power before making any electrical connections.

Kohler Co. reserves the right to make revisions in the design of products without notice, as specified in the

Price book.

SAVE THESE INSTRUCTIONS.

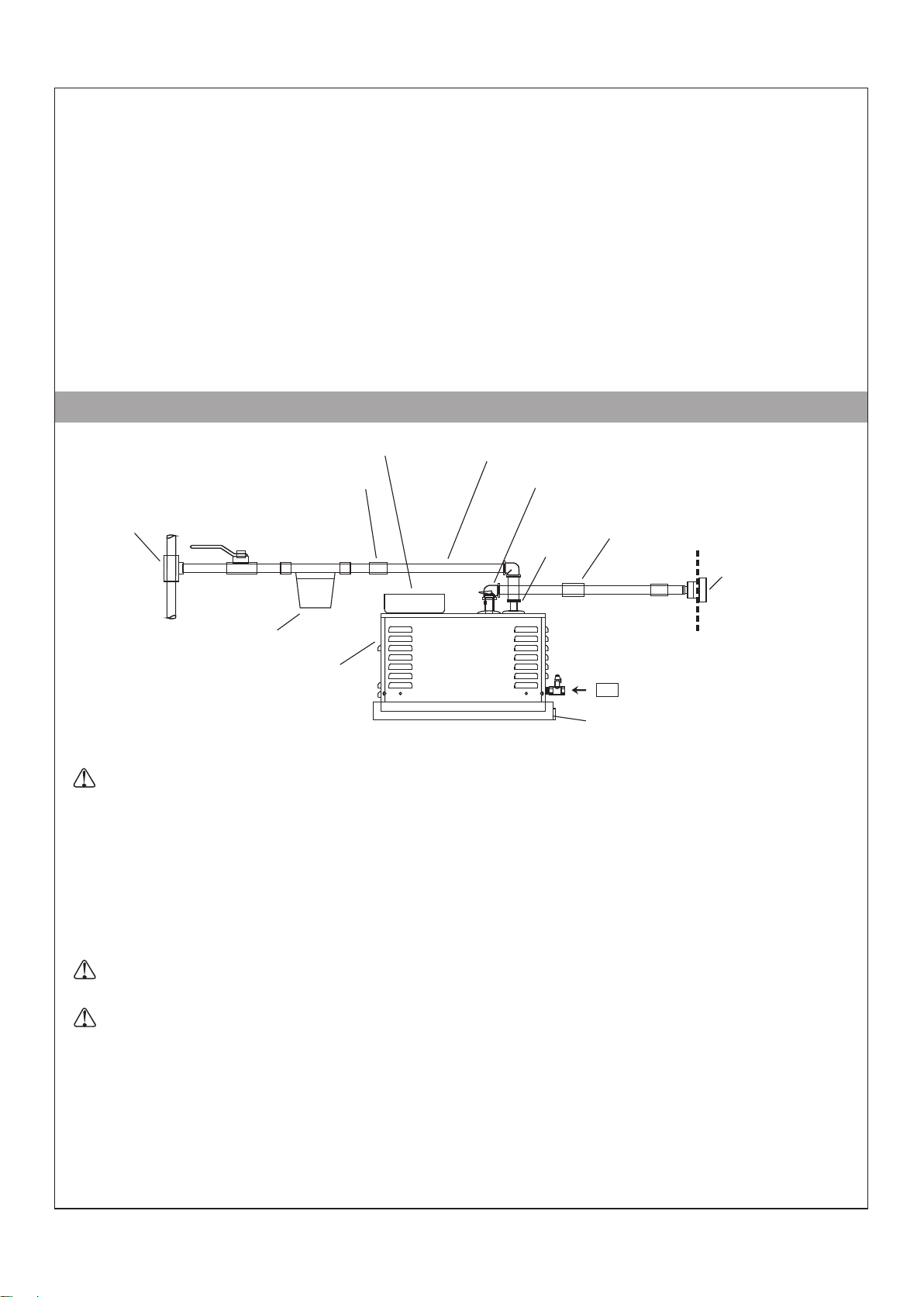

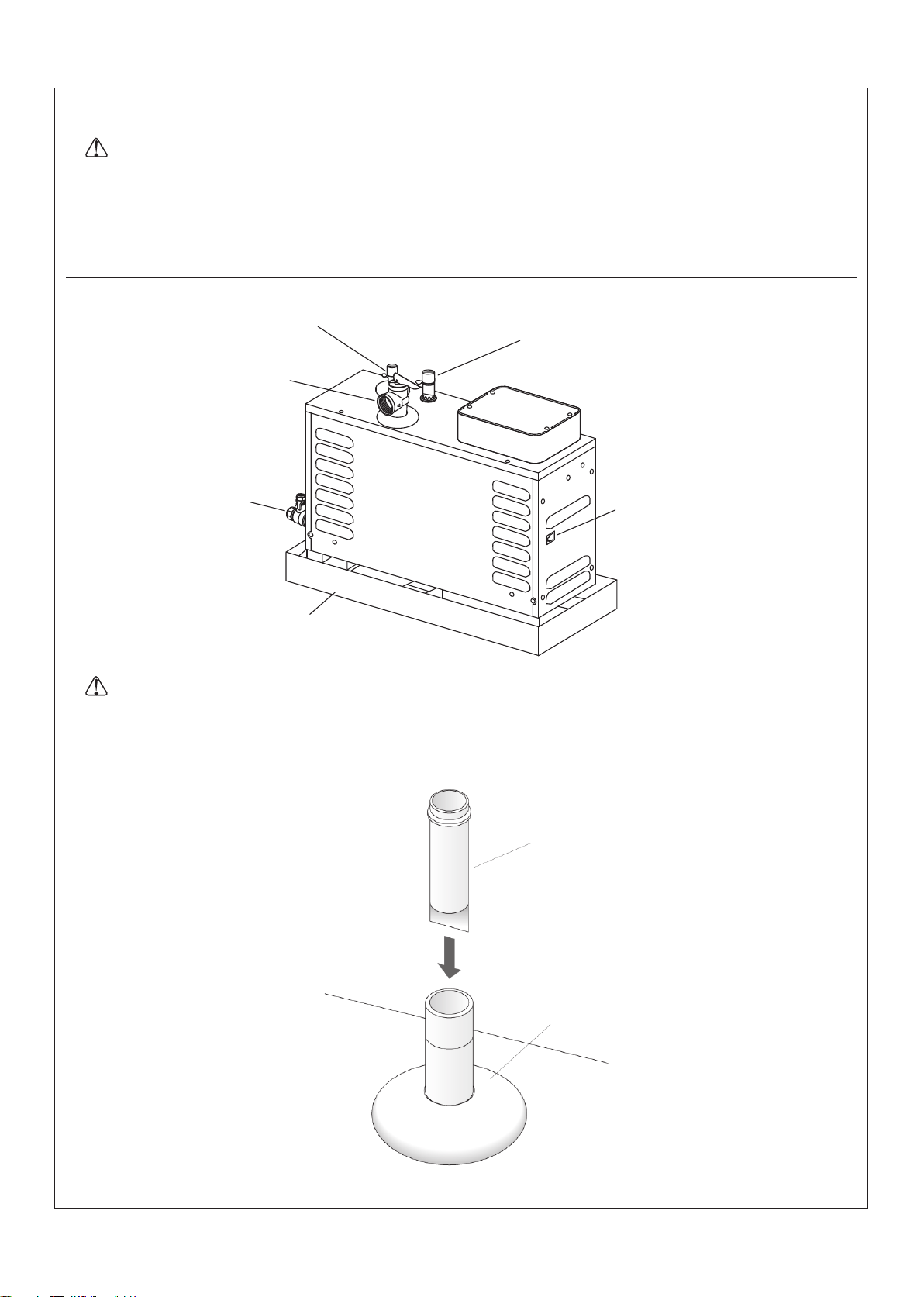

A. STEAM GENERATOR INSTALLATION

Tee

Field service box

Install copper union

in water feed line.

Shut-Off

C×F 3/8

Valve

Water Feed to Steam Generator

Pressure Relief Valve

Install copper union as close

Water

Inlet

as possible to steam generator.

C×F 1/2

Steam Head

Recommended In-Line

Water Filter

Control Cable Input

C×M 3/8

Drain Pan

1. Determine the Layout

WARNING: Risk of property damage. Allow a minimum of 30cm of air space around the steam generator

at all times. This provides an area for the heat generated by the unit to dissipate.

NOTICE: The steam generator will perform best when installed as close as possible to the steam head. The unit

should be installed within 7.6m of the steam head.

NOTICE: For optimum performance install the steam generator below the level of the steam head.

NOTE: When possible, use 45 degree elbows. Performance will be increased when 45 degree elbows are used.

Determine the location of the steam generator. Allow for a 30cm air gap on all sides of the generator. Allow for

a drain pan.

The steam generator have an integral drain pan.

2. Determine the Location of the Steam Hardware

WARNING: Risk of personal injury. Do not install the Steam Control User Interface outside the steam

enclosure. The User Interface must be installed within the enclosure to allow the sensors to regulate the

temperature and control the flow of steam. Refer to the Installation Guide for the Steam Control Kit.

WARNING: Risk of scalding. Do not block the steam head or locate it near a seat or bench, as the steam

head is hot during operation and may scald the user if touched.

Modules; Steam Head and Control Location

NOTE: All dimensions should be taken from the inside of the shower.

IMPORTANT! Do not install the steam control directly above or in-line with the steam head.

It is recommended to locate the steam head and the steam control on the same wall as the plumbing controls.

Locate the steam head 15.2cm above the shower floor and 12cm from the threshold.

Locate the steam control 150cm above the floor of the shower. Refer to the Steam Control Kit Installation

Instructions for more dimensional and installation information.

Make sure there is adequate clearance between the steam line and any surrounding surfaces.

3

1313992-70T-A

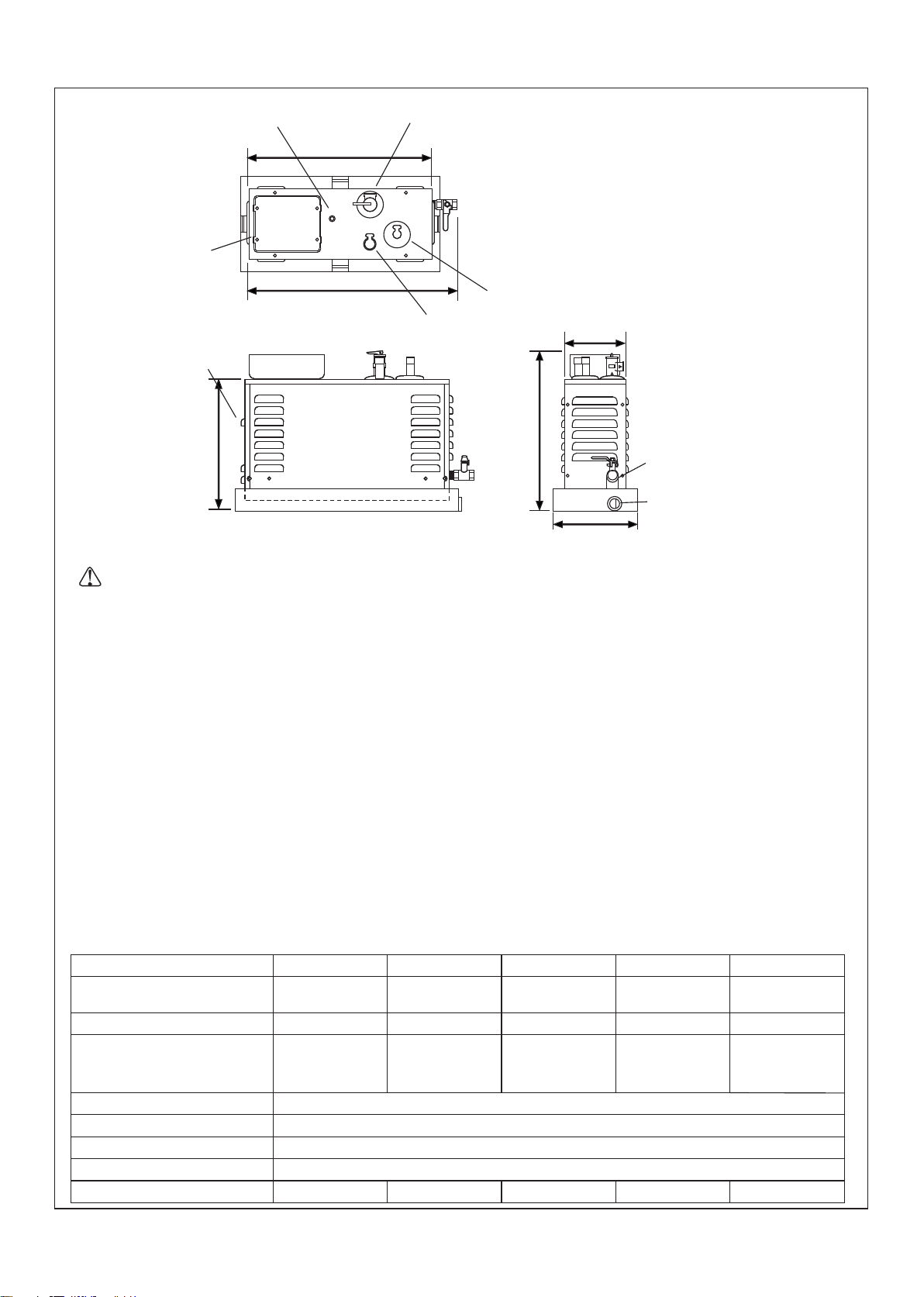

Green LED

Diagnostic Light

3/4" NPT

Pressure Relief

44.8cm

Minimum required access panel is

61cm L ×38cm H.

Allow for a minimum of 30cm of Space around

all sides of the steam generator.

The space between the generator and the drain

Field Wiring

pan was manufactured 1.9cm space.

Service Box

3/8" NPT Water inlet

15.6cm

Control

50cm

1/2" NPT Steam

Outlet

Cable Input

30.8cm

37.3cm

3/8" NPT Drain

3/4" NPT

21.3cm

3. Determine the Location of the Steam Generator

IMPORTANT! The minimum required access panel is 61cm L × 38cm H. Allow for a minimum 30cm

space around all sides of the steam generator. between the generator and the drain pan was The space

manufactured 1.9cm space.

A pilot lamp showing that the heater is switched on is to be installed in the attendant's room

Ensure clearance between the steam line and any surrounding surfaces.

Allow for access to the steam generator after installation.

Allow for a 30cm air gap on all sides of the generator.

For optimum performance, install the steam generator below the level of the steam head and as close as

possible to the steam head. The steam generator should be installed within 7.6m of the steam head in a dry,

well-ventilated area.

The minimum volume of the sauna room or cabin should be 2m

The minimum height of the sauna room or cabin should be 1.8m

The materials to be used for the walls and the ceiling of the sauna room or cabin should be waterproof

The installation of adjacent sauna heaters or a statement that the sauna heater or infrared emitter must be

2

used alone;

The connection and position of controls in the sauna room or cabin;

That thermostat sensors shall be installed so that they are not influenced by incoming air.

4. Install the Electrical Supply

Model

Generator - Dedicated

Circuit Required

Weight

Electrical Rating

Water Supply

Steam Line

Pressure Relief Valve (supplied)

Drain Line Valve

Sizing The Steam Room

1313992-70T-A

K-50205T-XT-NA

3.28 kW, 220-240V~,

20 A, 50-60Hz

220-240V~,

3.28kW

14.3A, 50-60Hz

1/2" copper line (3/8" NPT(F) to G1/2" Nipple Inlet(M))

1/2" copper line, (3/8" NPT(M) to G1/2"(M) Nipple Drain)

3

2.4m

K-5525T-XT-NA

5.95 kW, 220-240V~

40 A, 50-60Hz

5526T-XT-NA

K-

7.93 kW, 220-240V~

50 A, 50-60 Hz

K-5529T-XT-NA

9.92 kW, 220-240V~

60 A, 50-60 Hz

11.9kg 11.9kg 11.9kg 11.9kg11.9kg

220-240V~,

5.95kW

25.9A, 50-60Hz

220-240V~,

7.93kW

34.5A, 50-60Hz

220-240V~,

9.92kW

43.2A, 50-60Hz

1/2" copper line (1/2" NPT(M) to G1/2"(F))

3/4" NPT female thread(3/4" NPT(M) to G 3/4"(M))

2.4m

3

4.0m

3

6.8m

3

4

K-5531T-XT-NA

10.13 kW, 220-240V~

60 A, 50-60Hz

220-

240V~,

10.13kW

44.1A, 50-60Hz

3

9m

NOTICE: Each steam generator requires a dedicated circuit.

DANGER: Risk of electrocution. Disconnect the electricity to the working area at the main breaker panel

before performing these installation steps.

Follow all local electrical codes. All electrical work should be done by a qualified electrician.

Review the illustration showing specific Steam Generator Installation Requirements for your Steam Generator.

Install the appropriate electrical supply.

Maintain a 30cm space around the unit

Inlet

Steam Outlet

Pressure Relief Valve

Drain (install per

Applicable codes.)

Control Cable Input

Drain Pan

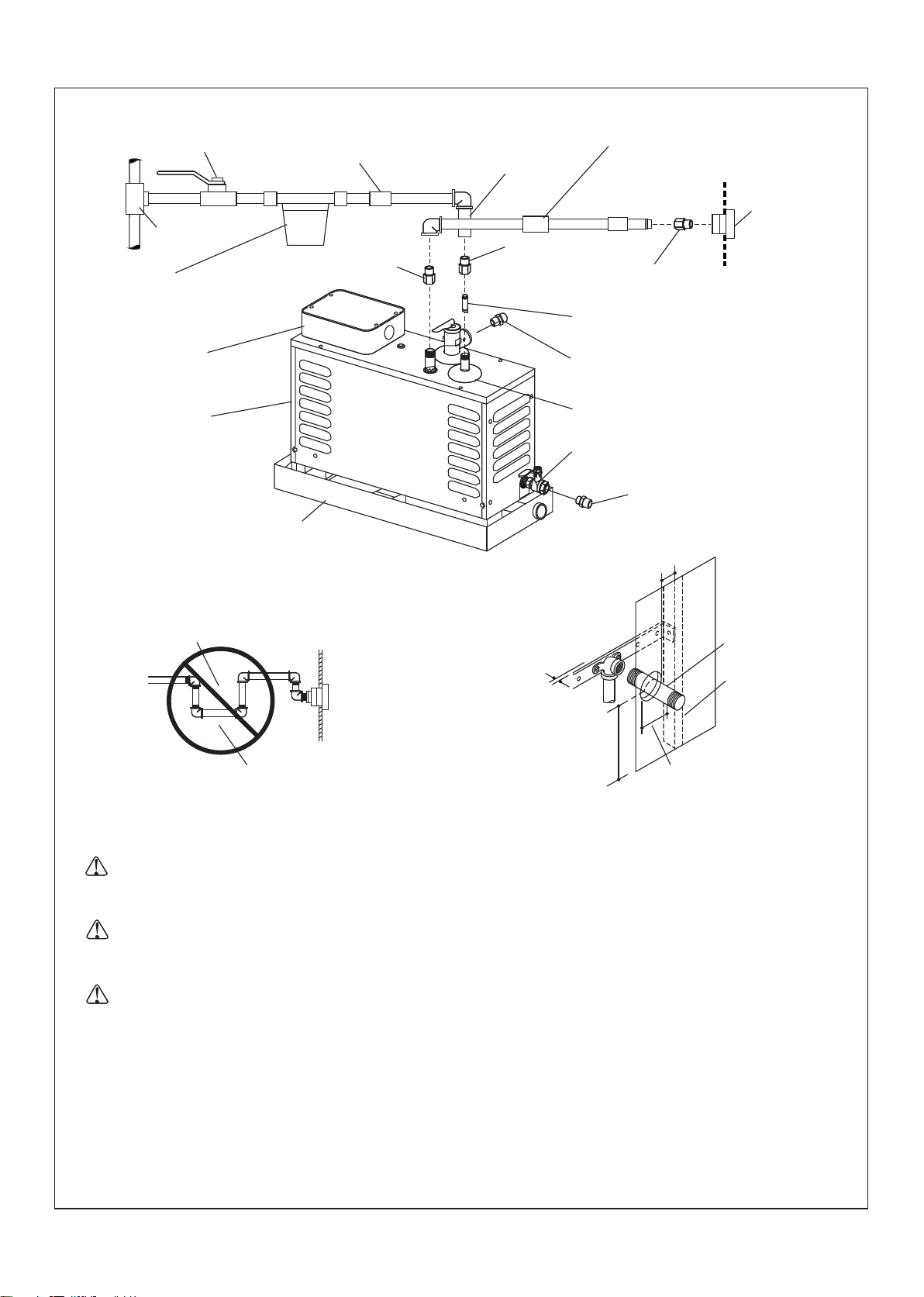

5. Install the Steam Generator

WARNING: Risk of property damage. Allow a minimum of 30cm of air space around the steam generator

at all times. This provides an area for the heat generated by the unit to dissipate.

NOTICE: For optimum performance, install the steam generator as close as possible to the steam head. The

steam generator must be installed within 7.6m of the steam head.

Water Inlet Screen

Inlet pipe

Insert the water inlet screen into the inlet pipe.(The water inlet screen is in the trouble shooting bag.)

5

1313992-70T-A

Shut-Off

Valve

Install copper union

in water feed line

Tee

Recommended In-Line

Water Filter

Water Feed to Steam

Generator (Pipe of Hose)

Nipple Outlet

(1/2" NPT(F)

to G 1/2"(M))

Nipple Pipe

(3/8" NPT(F) to

G 1/2"(M))

Inlet Water Screen

Install copper union as close

as possible to steam generator.

Steam

Head

Nipple Steam

(1/2" NPT(M) to G 1/2"(F))

Field Service

Box

Control Cable

Input

Steam Trap

Drain Pan

Provide clearance

from wall.

Do not run steam line down and then up.

This will create a steam trap.

Nipple Relief

(3/4" NPT(M) to G 3/4"(M))

Water Inlet

Drain Valve

(3/8" NPT(F))

Nipple Drain

(3/8" NPT(M) to G 1/2"(M))

2.5cm Min

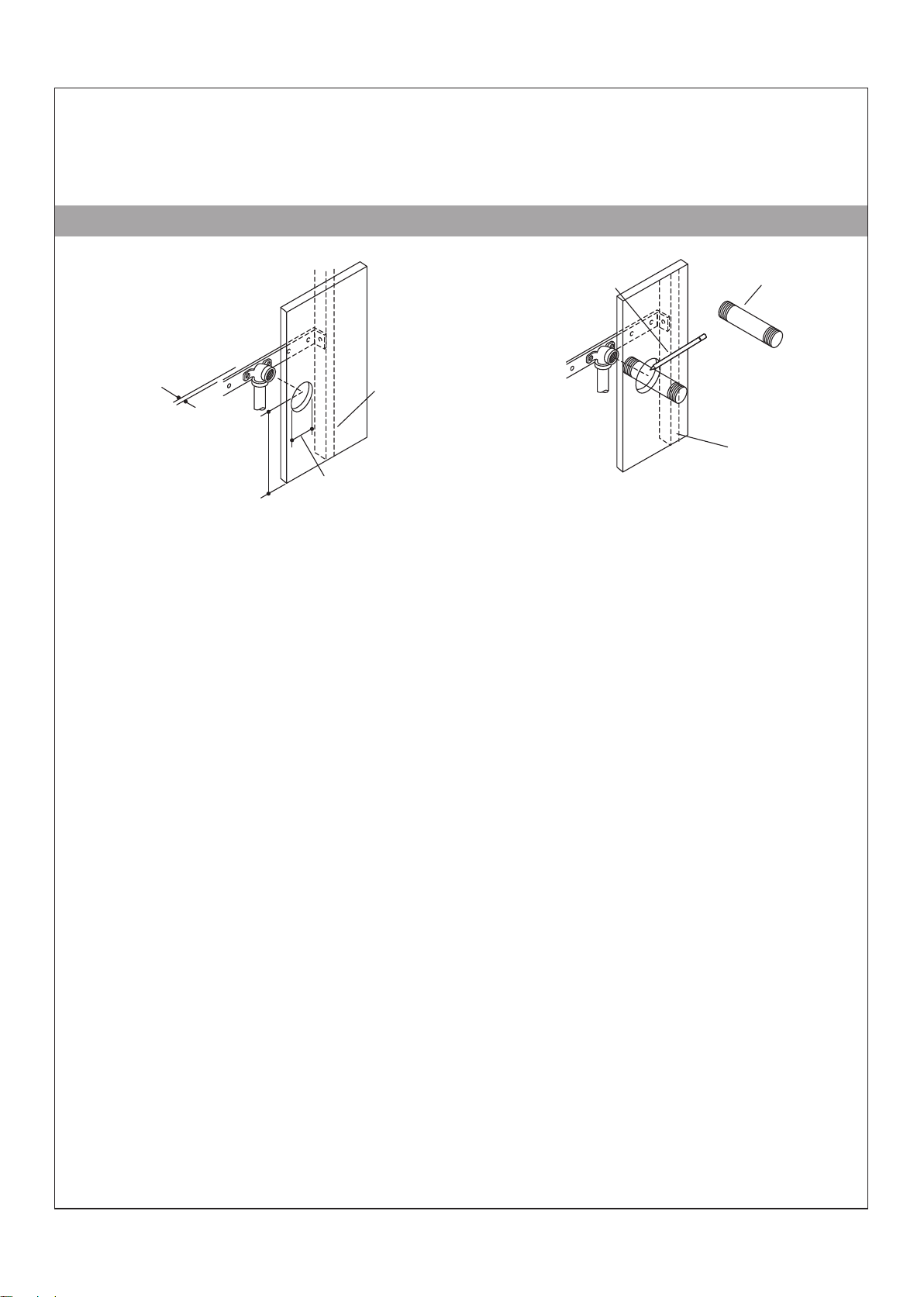

Temporary

Nipple

Wall Stud

15.2cm

from floor

6.4cm

6. Install the Water Supply Line and Steam Line

WARNING: Risk of personal injury or property damage. Do not plumb the pressure relief valve into

the steam line. Plumbing the pressure relief valve into the steam line can create a hazard if the stteam

line is blocked or obstructed.

WARNING: Risk of scalding. Do not plumb a trap, shut-off valve, or pressure relief valve into the steam

line. Plumbing the pressure relief valve into the steam line can be hazardous, if the steam outlet is

capped.

WARNING: Risk of personal injury or property damage. Do not direct the pressure relief valve to the

enclosure. In the event the pressure relief valve activates, the hot water may spray causing burns to the

user and/or damage the enclosure. Therefore, the pressure relief valve should be directed to an area

where damage will not occur from contact with hot water and should conform to national and local

plumbing codes.

1313992-T01-A

6

Install the Water Supply Line to the Generator

NOTE: For all NPT threaded connections, use pipe tape or pipe sealant. Do not overtighten the fittings.

Connect to an existing cold water line, and run a 1/2" cold water line to a shut-off valve before the in-line

water filter.

Before final connection to the steam generator, flush out the water supply line into a large pail. This removes

any debris, silt, sand, or other material that may be in the line.

Install 1/2" copper tubing with a union fitting between the in-line water filter and the water inlet to the steam

generator.

Connect the water supply line to the steam generator.

Make sure that the water drain valve on the generator is closed.

Fill the steam generator with water and check for leaks.

NOTICE: Steam generators are equipped with an automatic shut-off. The water will stop after the unit is full. If

the water flows out of the steam outlet shut off the water and consult the "Troubleshooting Guide" or contact the

Customer Service Center using the number located on the Compliance Certification.

If the water supply line exceeds 3m or is exposed to cold areas, insulate the piping with appropriate

insulation.

Install the Steam Line

WARNING: Risk of scalding. Do not locate the steam head near a seat or bench or scalding may occur

upon contact with the steam head.

NOTICE: Never run the steam line down, then up. Running the steam line down and then up will create a steam

trap, blocking the flow of steam. The steam line should run up to the steam head from the steam generator, at a

pitch of 1cm to 1.3cm per 30.5cm of pipe.

NOTICE: Provide clearance between the back wall and the elbow leading into the steam housing. The elbow

must not contact any wall material.

NOTICE: Provide clearance between the steam line and surrounding surfaces.

NOTICE: Do not apply excessive heat to the generator connections when you solder connections. Do not apply

flux or acids directly to the steam generator, as damage to the seals, plastic components, and trim finish may

result. Do not apply petroleum-based lubricants to the steam generator components, as damage may result.

NOTE: For all the threaded connections, use thread sealant tape or pipe sealant. Do not overtighten the fittings.

NOTE: Use 1/2" copper tube for the steam line.

NOTE: Always install a unions/nipples fitting as close to the steam generator as possible.

Add blocking behind the desired steam head location.

Install and secure a G 1/2" elbow to the blocking directly behind the desired steam head location.

Cut a hole through the wall material to accept a temporary 1/2" copper tube nipple.

Add a temporary 1/2" copper tube nipple.

7

1313992-T01-A

AC 220V 50Hz

Typical Two-Pole

GND

L

N

Breaker Box

Circuit Breaker

Equipment Ground

Junction Box

In Breaker Box

Field Wiring

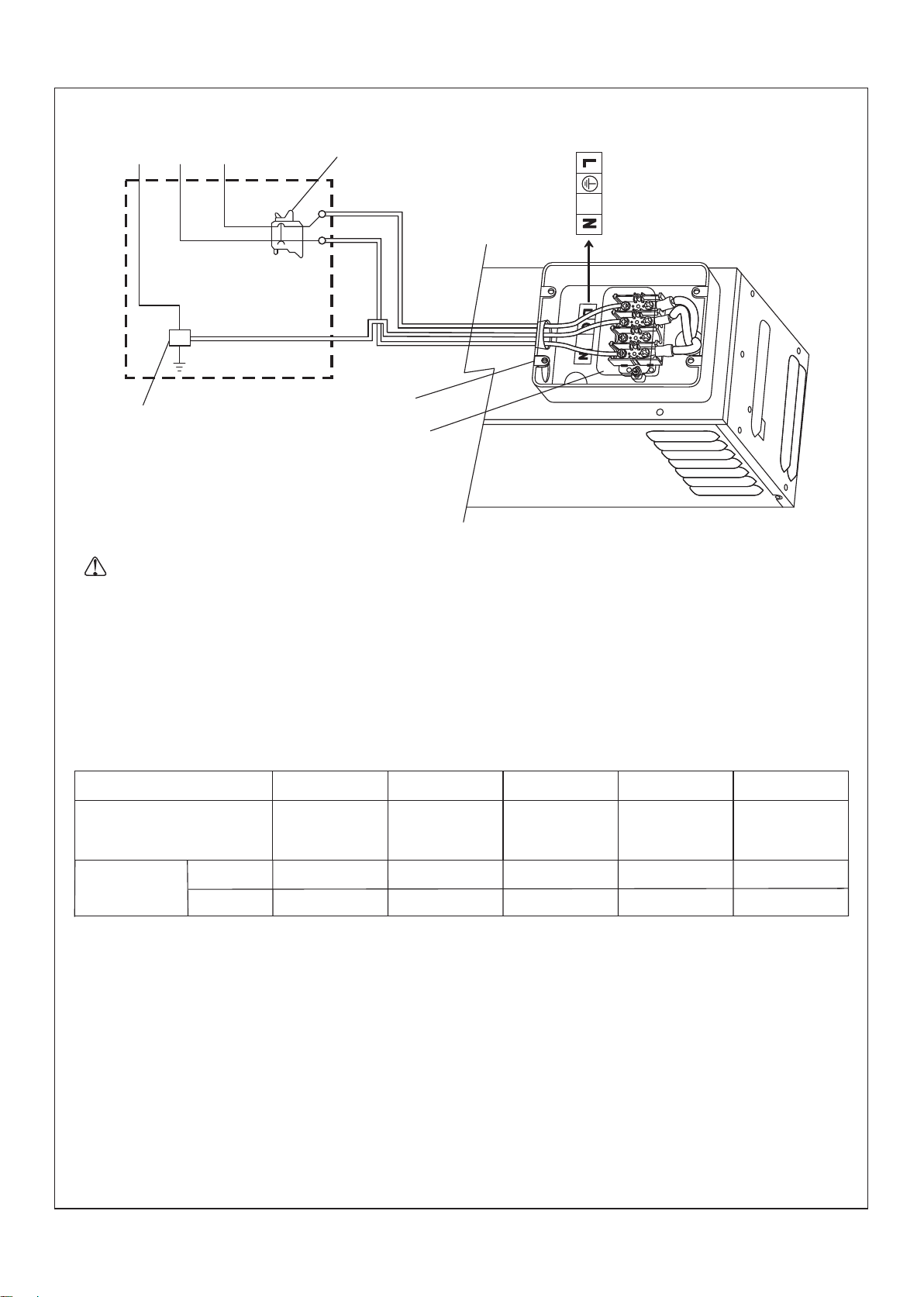

7. Connect the Power

DANGER: Risk of electrocution. Disconnect all power before performing these installation steps.

NOTICE: All electrical work should be done by a qualified electrician.

NOTICE: All electrical wiring must be done in accordance with local codes.

NOTICE: Each steam generator requires a dedicated circuit.

NOTICE: The steam generator is not have a separate power supply. The power circuit breaker that meets the

specifications for each steam generator should be installed.

NOTICE: hardwired must be protected with heat insulating sleeve of an appropriate temperature rating.

Model

Generator - Dedicated

Circuit Required

Wire

Specifications

L, N

GND

K-50205T-XT-NA

3.28 kW,

220-240 V~,

20 A, 50-60 Hz

2.5mm

2.5mm

2

2

K-5525T-XT-NA

5.95 kW,

220-240 V~,

40 A, 50-60 Hz

2

4mm

2

4mm

K-5526T-XT-NA K-5529T-XT-NA

7.93 kW,

220-240 V~,

50 A, 50-60 Hz

2

6mm

2

6mm

9.92 kW,

220-240 V~,

60 A, 50-60 Hz

2

10mm

2

10mm

K-5531T-XT-NA

10.13 kW,

220-240 V~,

60 A, 50-60 Hz

2

10mm

2

10mm

Connect the Power

Turn off all electricity to the working area at the main circuit breaker panel.

Open the steam generator field service box (Junction box) located on top of the steam generator.

Unscrew the screws of the terminals for field wiring on the terminal block located in the junction box.

Connect 220-240V~ electrical lines to their respective terminals, securing them in place by tightening the

screws.

Close the junction box.

Turn on the main power.

The function light should display a green light. If the function light is not green, consult the "Troubleshooting

Guide" or contact the Customer Service Center using the number located on the Compliance Certification.

1313992-T01-A

8

8.

Complete the Installation

1

Install the steam housing and steam head following the Steam Control Kit instructions.

1

Install the steam control following the Steam Control Kit instructions.

B. STEAM CONTROL KIT INSTALLATION

Mark the nipple even

with finished wall.

Provide clearance

from wall.

15.2 cm

from floor

6.4cm

1. Prepare the Site

NOTE:

to the steam generator installation instructions guide for more information, if required.

NOTE:

steam heads do not need to be located in the same area.

1

1

1

1

This section continues the installation as described in the steam generator installation instructions. Refer

If two steam heads are required, ensure there is at least 32cm between the center of each hole. The

Install the finished wall material.

Mark the temporary pipe nipple at the location of the finished wall surface.

Remove the temporary pipe nipple from the elbow.

Drill or cut a 6.4 cm hole centered around the elbow in the wall.

Wall Stud

Temporary Nipple

Wall Stud

9

1313992-T01-A

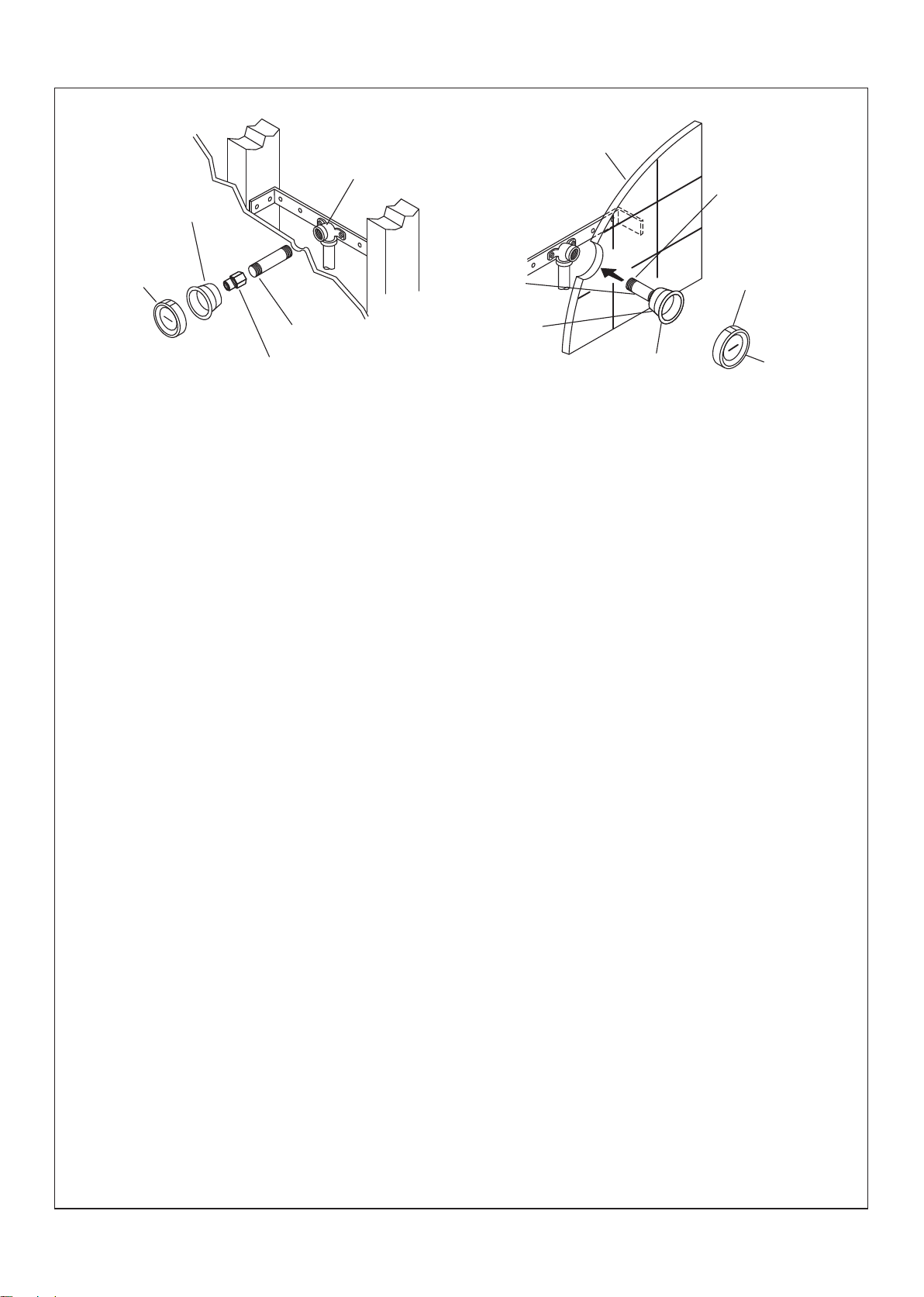

Steaming Housing

G 1/2"

Elbow

Wall

Apply

thread sealant

Steam head

Apply thread sealant

Nipple Steam

(1/2" NPT(M) to G 1/2"(F))

2. Install the Steam Head(s)

NOTICE: Do not obstruct the steam head with shut-off valves, plugs, or caps.

Subtract 3.2cm from the marked length to determine the appropriate nipple size.

1

Choose a nipple length within 3.8cm of the appropriate nipple size.

1

Apply thread sealant to the threads on one side of the nipple and thread that side into the steam head

1

housing until hand-tight.

Apply thread sealant to the threads on the other end of the nipple.

1

Position the gasket around the steam head housing so that it will be between the finished wall and the steam

1

head housing flange.

Use a 1" socket to thread the steam head housing assembly into the elbow in the wall.

1

Make sure the gasket is compressed and a good seal has been achieved around the edges of the steam

1

head housing.

Nipple

Steaming

Housing

Lip

Aromatherapy

Well

Steam

head

Use an appropriate sealant to achieve a watertight seal if needed.

1

Press the steam head assembly into the steam head housing with the aromatherapy well positioned on the

1

top of the steam head.

1313992-T01-A

10

Loading...

Loading...