NovaJet 750 Printer

Trr

T

Ink Installation

Printer Calibrations

Routine Maintenance

Preventive Maintenance

Cartridge Checklist

Advanced Troubleshooting

Print Server Networking

aii

a

nii

n

n

n

g

g

G

G

uii

u

d

d

e

e

NJ750 Training Guide

A. Ink Installation

1. ‘Plug and Play Cartridge’ characteristics

Installed needle assembly

Do not break connection when installing

new cartridge

25 ml inside - preprimed

2. Installing ink into reservoirs

It is suggested to fill reservoirs over a table to prevent spills on printer; fill to a

maximum of 400 ml (50 ml minimum).

3. Attach septum fitting to valve body. Prime line (and cartridge if

necessary).

NOTE: When the valve body is raised to the up

position ink flow is cut off, when the valve body (latch)

is closed then the ink line is open.

2

NJ750 Training Guide

a) Prime line using the short needles

(purple in color); attach short needle

to each of the 4 valves. Connect

septum needle to EasyPrime by

inserting into female receiver.

Depress and hold EasyPrime

activation button to provide a solid

burst, wait 20 seconds, or until ink

line is full.

b) Lift valve actuator (to up postion)

and remove purple septum needle

assembly.

c) Connect cartridge’s septum needle to valve and close valve – wait 60 seconds

then remove the blue tape from cartridge jet plate.

NOTE: If attempting to recharge an

existing cartridge, then disconnect

cartridge from stall position and

prime cartridge (print head) using

multiple sets of one-second bursts

until ink is visible in the ink line.

This may take 1-2 minutes to

accomplish depending on the

prime of entire ink line. Ensure

EasyPrime adapter is flush to

cartridge jet plate – a siphoning

sound (slight sucking) should be

heard when priming the cartridge

properly.

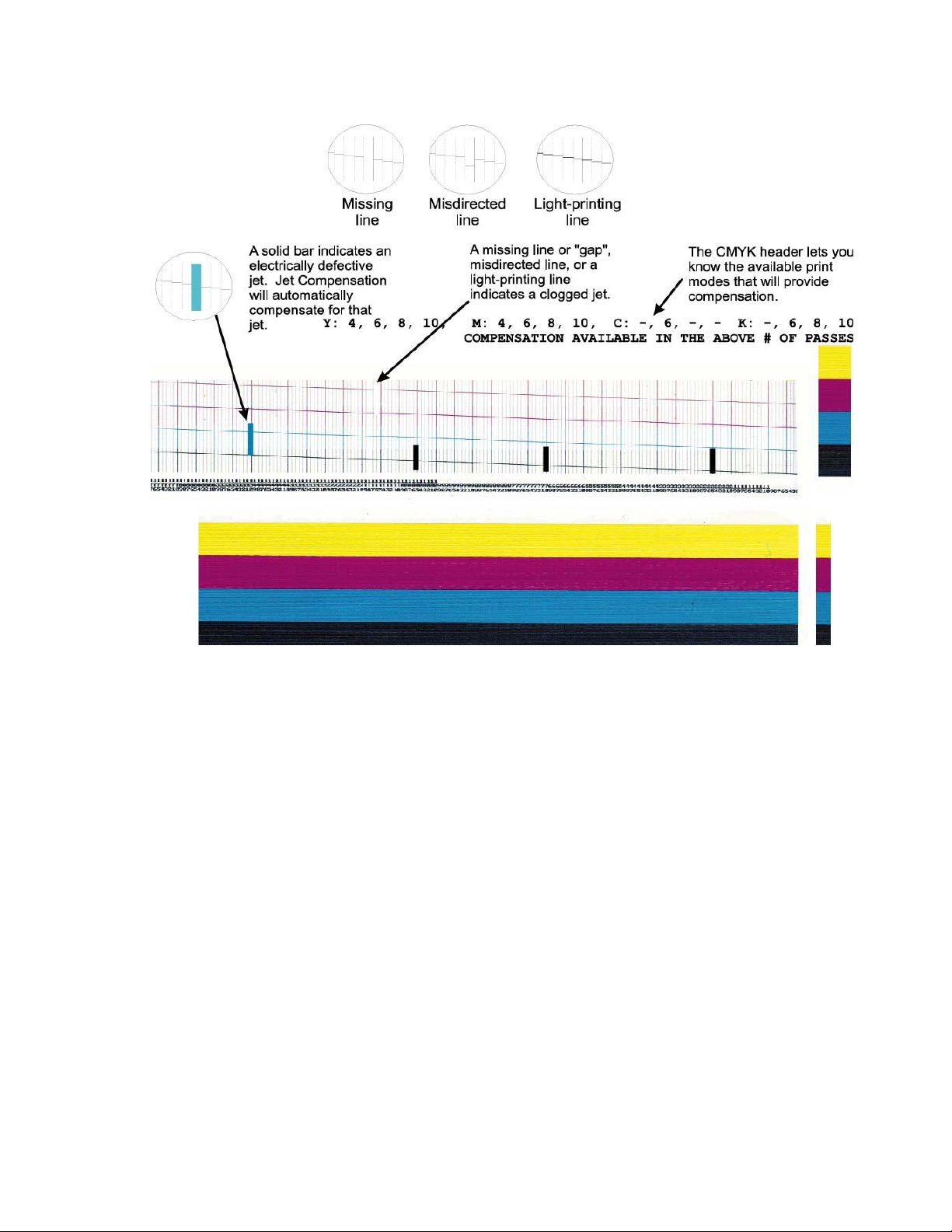

4. Activate the color test pattern for ink starvation problems.

Select: SETUP MENU – PRINT MODE MENU – PRINT PASSES – SELECT 3, OK.

Select: UTILITY MENU – SERVICE MENU – DIAGNOSTICS – COLOR TEST MENU –

STALL SELECT (or ALL COLORS)– choose color. Select DENSITY SELECT to 100%.

Select COLOR TEST PRINT. Verify color bar is printed without ink starvation.

Ink Test/Recovery Procedure

(Color Test Print)

This is a pressure test of the

system, so please disregard the

two-pass quality. Each pass of

the carriage assembly should lay

3

down a solid band of color with 33% ink load.

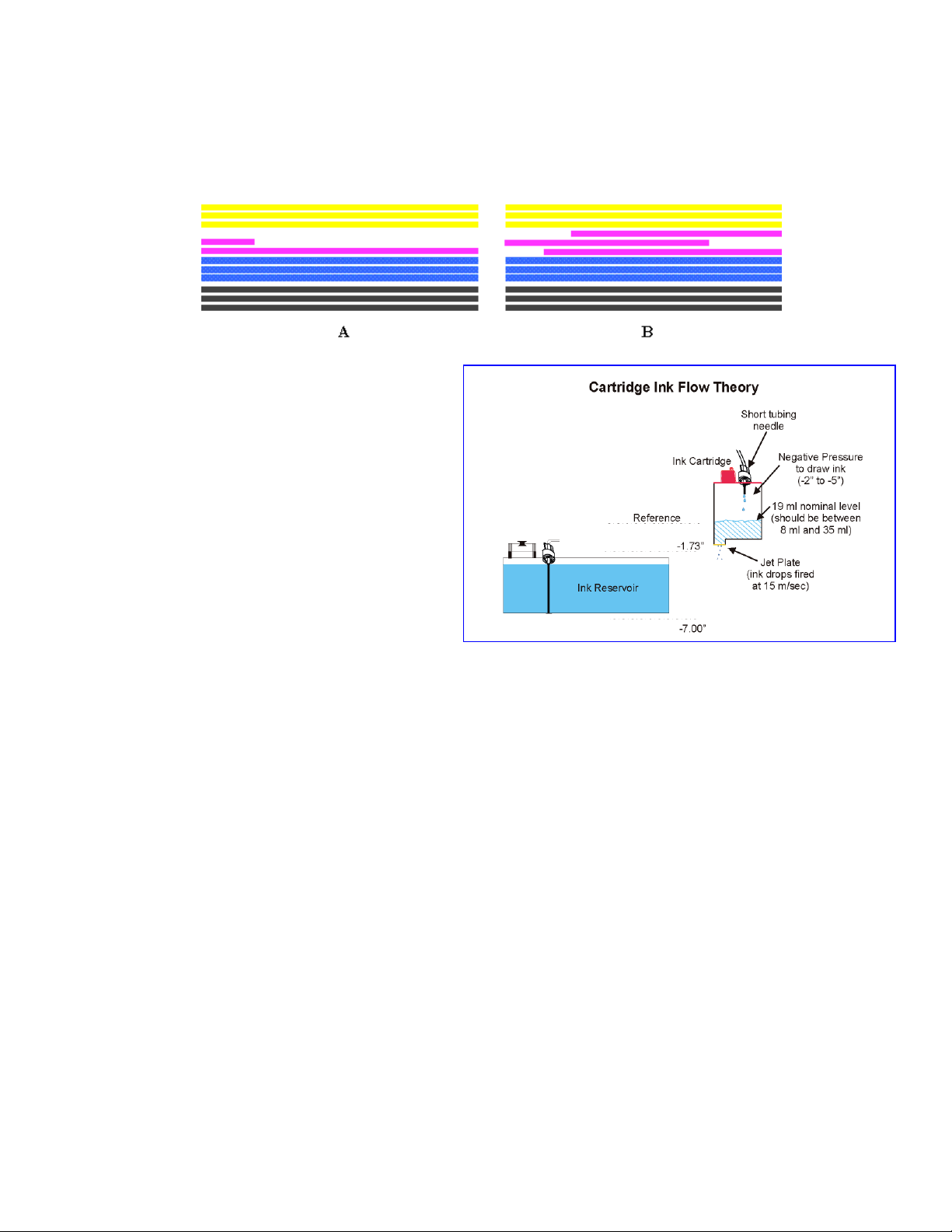

Color Test Failures:

- Example A above depicts

complete ink starvation in magenta.

This problem may be corrected by

using the EasyPrime and

establishing the required pressure

inside the cartridge. Replace

septum connector/needle if repeated

attempts continue to fail.

- Example B above depicts partial

ink starvation in magenta (ink fires

at 100% at the beginning of each

pass but then starves). This

problem can be corrected by

ensuring 19 ml of ink is present

inside the cartridge (level must be between 8 ml and 35 ml for proper operation – refer to

NOTE below).

NOTE: To install ink into a cartridge or to verify proper cartridge ink level obtain syringe

with tube extension from accessory kit. Pull 20 ml of ink into syringe. Lift cartridge stall

position valve to up position to cut off ink flow. Temporarily remove septum connector

from cartridge. Install ink into cartridge by depressing syringe plunger; pull back on

plunger to remove excess ink (if any). Reconnect septum needle to cartridge and close

valve actuator (lower) to restore ink flow to cartridge. The cartridge will need to be primed

to restore negative pressure inside cartridge – refer to step 3 above.

5. Activate the Prime pattern.

Select UTILITY MENU – PRIME. Verify all colors are printed. Verify no clogs are

present in the prime pattern. Manual or automatic jet compensation is provided up

to 20 jets in each cartridge. Ensure the integrity of the diagonal lines are

consistent and smooth. Clean or replace cartridge if unsatisfactory.

NJ750 Training Guide

4

NJ750 Training Guide

5

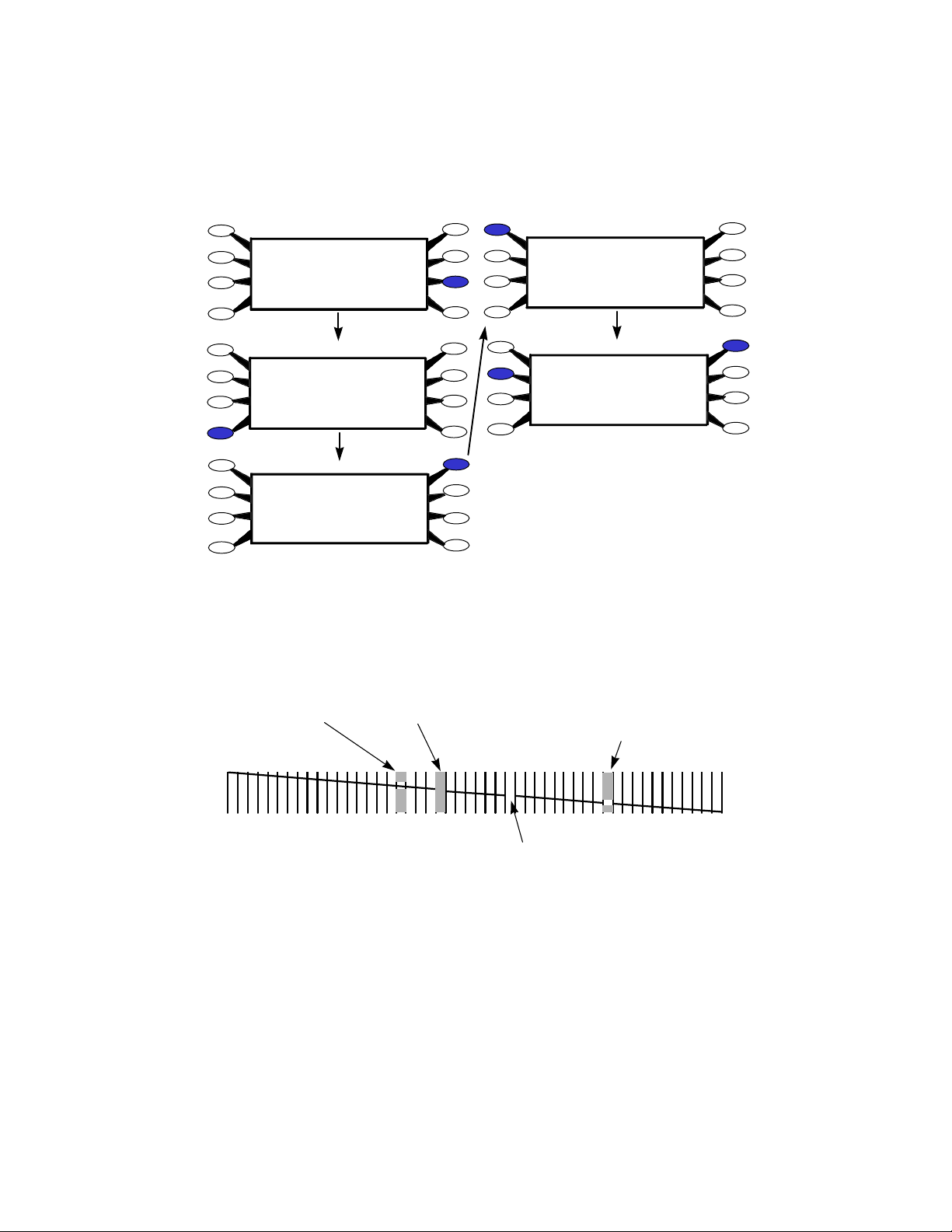

6. Cartridge Jet - Manual Bypass Feature

Example: to manually bypass a clogged black (K) jet, perform the following steps:

NJ750 Training Guide

Load Media

Cut

Pause

Reset

Main Menu

Feed Media Menu

Setup Menu

Utility Menu

Black Edit List

Cyan Edit List

Magenta Edit List

Yellow Edit List

Open Jet Menu

Print Jet List

Clear List Menu

Exit

Prime

Access Cartridge

Color Calib Menu

Calibration Menu

Utility Menu

Display Settings

Print Settings

Service Menu

Exit

Paper Axis

Next Option

# 1: On

Prev Option

Black Edit List

Toggle Jet

Ok

Calibration Menu

Use Calib X/Y

Paper Axis Test

Color Db Menu

Open Jet Menu

Paper Axis

Exit

Press Next Option until

clogged jet number is

displayed, press Toggle Jet

to turn jet OFF, press OK.

Jet manually

bypassed,

jet good

Jet is bad; jet readdressed

automatically

Jet manually bypassed,

jet clogged

Jet is clogged (Jet

electronics are

good though)

6

B. Printer Calibrations

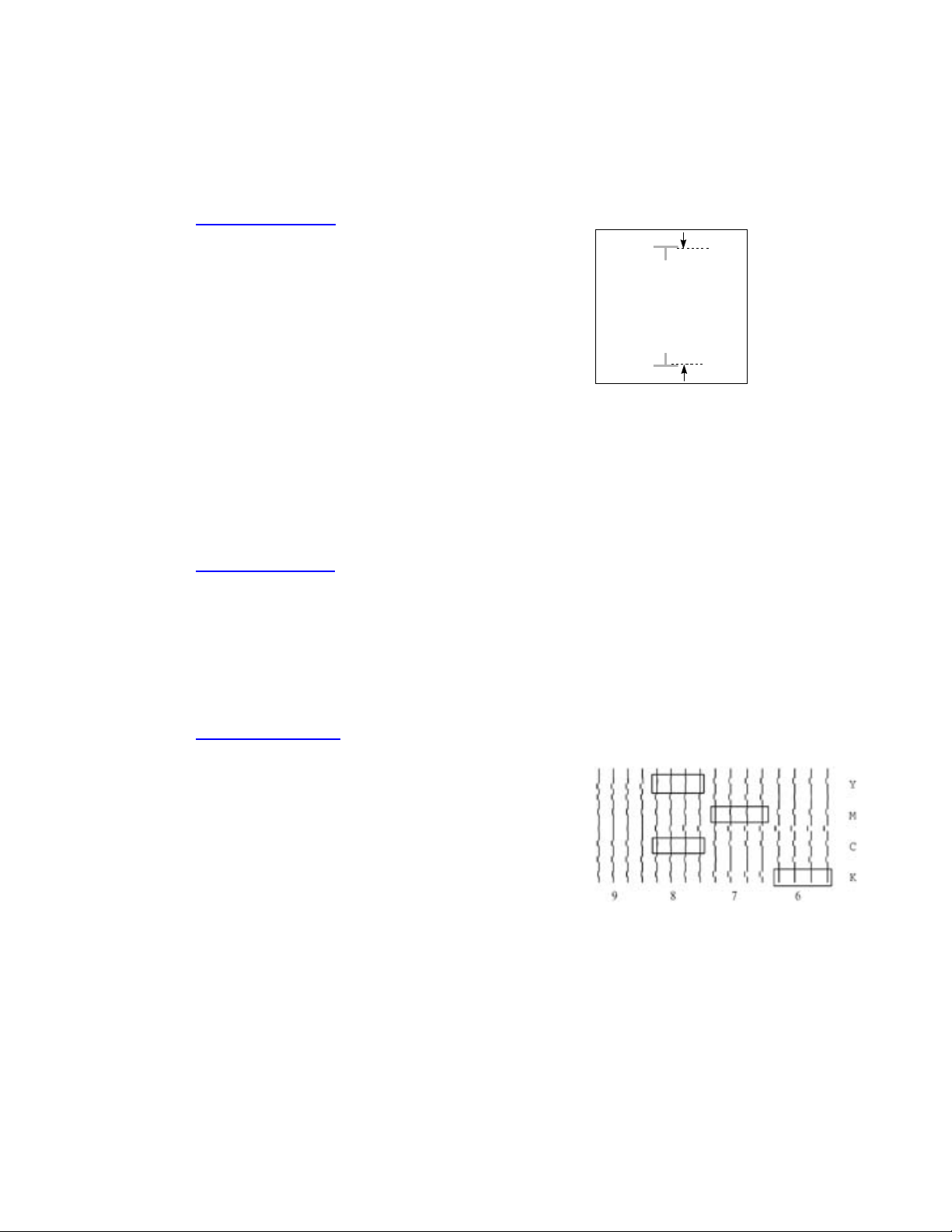

A. Paper Axis Test

Prior to running a Paper Axis Test ensure a

minimum of 36 inch media is loaded. To

activate the Paper Axis Test select Utility

Menu - Calibration Menu - Paper Axis Test.

An upside-down "T" will be printed in the

center of the media, the media will advance

approximately 33 inches or 838 mm and

another "T" will be printed. This calibration

is extremely important for paneling and

framing operations to ensure proper line

length accuracy; printer accuracy is

guaranteed to +/- 0.2%. Cut off and measure

the distance between the two T's using a

draftsman ruler, enter the true value under

under 'Paper Axis'. Select Utility Menu, Calibration Menu, Paper Axis, enter the

true value once only. Note: the display will always indicate 33" or 832.2 mm as the

zero reference position but the printer is now adjusted for this media type.

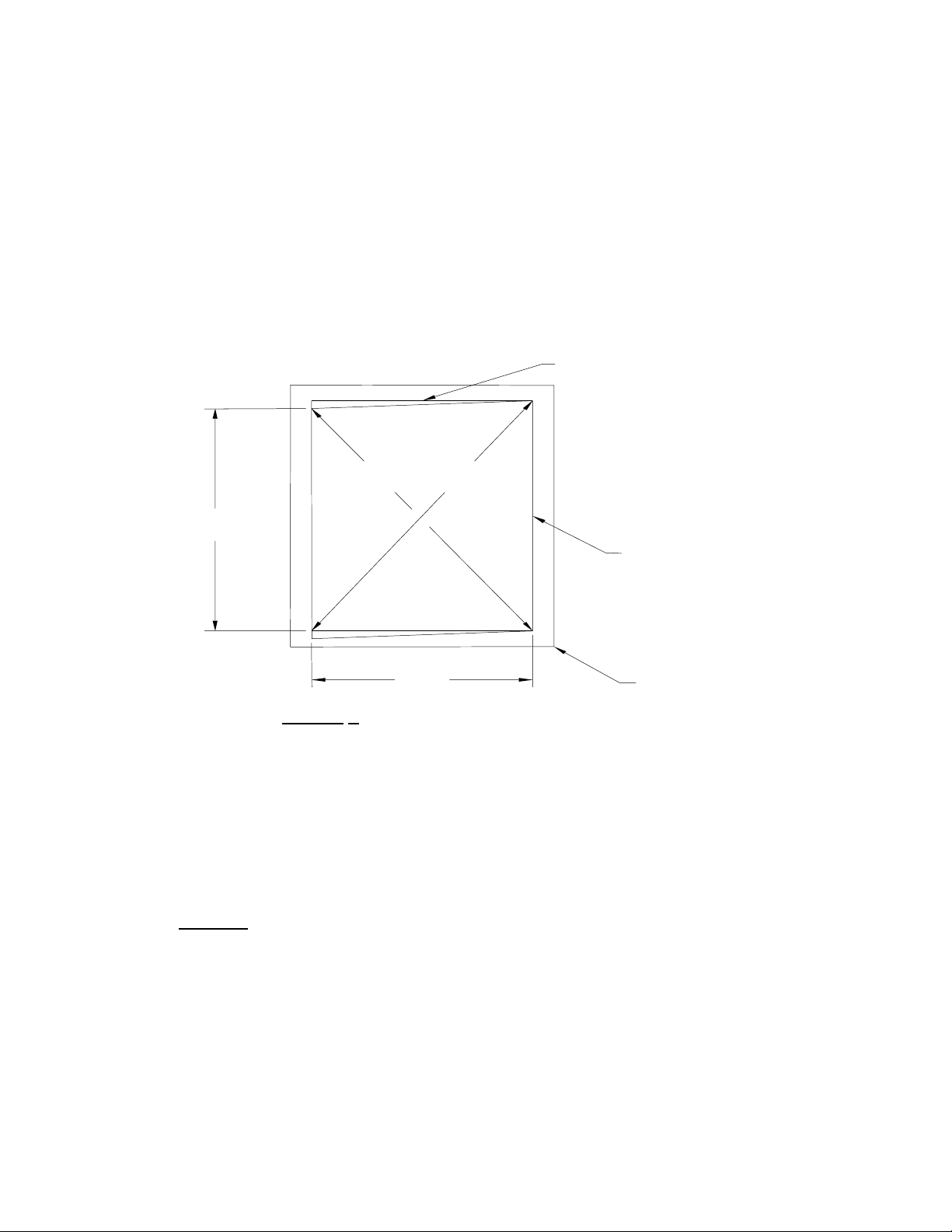

B. Slow Deadband

To activate the Slow Deadband calibration select Utility Menu - Service Menu -

Calibration Menu - Slow Db Test. The Slow dB Test pattern will print very slowly.

This is a mechanical adjustment of the printer servo system and should be

performed monthly. Ensure the vertical lines are straight, if out of alignment, as in

this example, then an adjustment is necessary. Select Utility Menu, Service Menu,

Calibration Menu, Slow Deadband - change the value and rerun the pattern until

correct. NOTE: this calibration is normally not required; for CAD operations mainly.

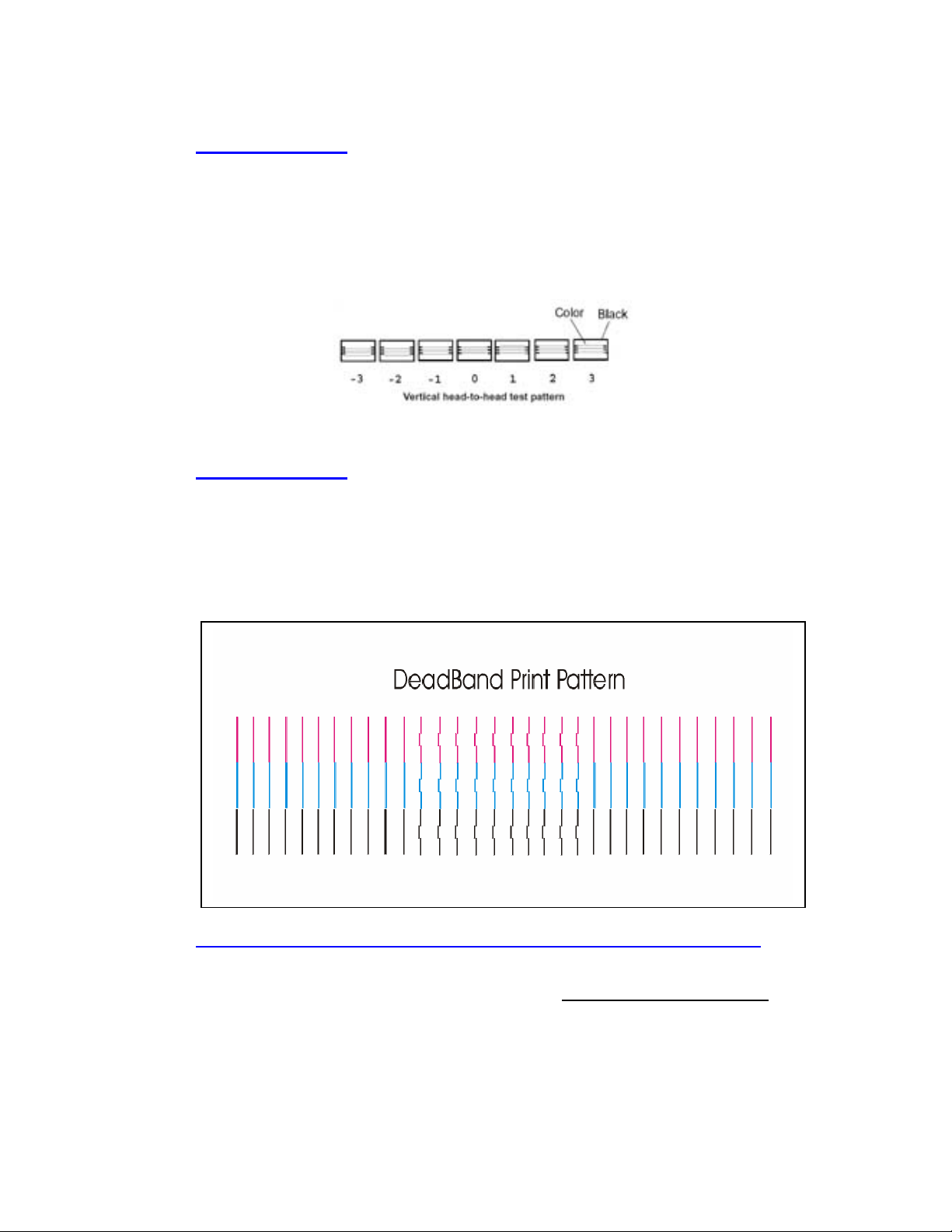

C. Color Deadband

To activate the Color Deadband calibration

select

Utility Menu - Calibration Menu - Color dB Menu -

Color dB Test. The Color dB pattern will print.

This is an electronic calibration for

compensating

the differences in cartridge resistances. Always

perform this calibration whenever a cartridge is

replaced. To adjust left NJ850 print head (i.e.

values 1-4), select Left at control panel. Choose

the best value under each aligning set of colors. To adjust the right print head

(values Y, M, C, and K) select Right at the control panel. Select the value under the

best group of vertical lines in each color. Please do not choose one value to

characterize all colors unless illustrated by the pattern.

NJ750 Training Guide

33.00 inches

Distance between the two

“T’s” should be 33.00” +/-

0.05” (inches)

7

NJ750 Training Guide

D. Color Calibration

To activate the Color calibration select Utility Menu - Color Calib. Menu – Calib Test

(NJ850: Both Vert Calib Test and Horiz. Calib. Test.) Seven horizontal patterns

followed by seven vertical patterns will print. The color calibration pattern should

be performed whenever a cartridge is removed from the carriage for cleaning or

replacement. Choose the best value under each aligning set of colors, i.e. yellow

to magenta, then magenta to cyan, then cyan to black. Enter the most correct

value for each of the 14 fields. Note: stalls 1 through 4 correspond to the Left 4

cartridges.

E. Deadband Check

To activate the Deadband calibration select Utility Menu - Service Menu -

Calibration Menu - Deadband. The deadband pattern will print very quickly in all

color ranges. This is a final check of printer calibrations to ensure alignment has

been achieved. Ensure the vertical lines are straight with respect to each color, if

severely out of alignment, as in this example, then a re-calibration of the printer is

necessary or cleaning of the encoder strip is necessary. Note: The pattern does

not have to be perfect, just close to maintaining vertical alignments.

F. Controlling Image Skew (not media skew as this is mechanical).

The NovaJet 750/800 series of printers are designed with self-aligning pinch rollers. The

alignment process takes place when media is advancing forward, but not backwards.

Loading media is critical to the media alignment and reducing skew. Many times the

media is loaded at a slight skew and will take several feet of advancing media to get it

aligned properly. This can be improved by following the steps below.

1. Load the media and align the rear media guides.

8

NJ750 Training Guide

R

2. Advance the media though the printer about 1 foot, using the Feed Media Menu/Forward

button.

3. Put the printer media feed in “Sheet” mode (Set-up Menu/Paper Option Menu/Supply

Type/Sheet). Using the media “Forward” button, drive the media forward until it is pulled tight.

4. Change the media feed back to “Roll” or “Take-up” (Set-up Menu/Paper Option Menu/Supply

Type/

5. Roll or Take-up).

6. Advance the media forward three feet to check alignment with the white media guideline.

7. Start printing the image.

G. ACCEPTABLE IMAGE SKEW:

PERFECT REFERENCE

RECTANGLE

L

L

L

12

ACTUAL

OU TP UT

L

W

MED I A PERIMETE

EXHIBIT

A

Assuming the media loading instructions as defined in the user manual

have been followed, Exhibit A describes the maximum permissible

image skew.

The maximum skew is:

0.30% of ∆L = (L1 - L2) – except for NJ880 (no skew specification has been

designated)

Example:

Then: L

The actual permissible skew (L

(5.82 mm.)

NOTE: This is the only method used to determine skew.

If LW = 59.61 inches (1.51 m.), L = 48.00 inches (1.22 m.)

should equal L2 = 76.53 inches (1.94 m.)

1

- L2) = (.003) (76.53) = .229”

1

9

NJ750 Training Guide

C. Routine Maintenance

1. Perform routine maintenance at

recommended plot time hours and in

accordance with prescribed

documentation.

NOTE: The NovaJet printer must be cleaned and

serviced routinely or print output anomalies or

printer failures may occur during normal

operations. It is strongly suggested to take 15

minutes once a week (i.e. every Monday morning) and

perform printer cleaning rather than attempt to remember each cleaning cycle as listed below.

INTERVAL COMPONENT CLEANING AGENT

25-50 Hours Platen/External Surfaces NovaKlean solution on Lint-Free Towel

Can cause paper sensing errors;

resulting in ‘no printing’ symptoms.

INTERVAL COMPONENT CLEANING AGENT

10-20 Hours Service Station NovaKlean or Distilled Water

10

Loading...

Loading...