Page 1

®

NOVAJET®

500/630/700 SERIES

COLOR INKJET

PRINTER

SER VICE MANUAL

Part Number 213526-01

Page 2

NovaJet 500/630/700 Series Service Manual

Copyright © 1999-2002 Eastman Kodak Company. All

rights reserved.

KODAK, ENCAD and NovaJet are trademarks of

Eastman Kodak Company.

Other trademarks and registered trademarks are the

property of their respective owners.

Except as provided below, no p art of this manual may be

copied or distributed, transmitted, transcribed, stored in

a retrieval system, or translated in any human or computing language, in any form or by any means, electronic,

mechanical, magnetic or otherwise, or disclosed to a

third party without the express written permission of

Encad, Inc., 6059 Cornerstone Court West, San Diego,

CA 92121, U.S.A.

Certain manuals developed by Encad are in an electronic

format to be distributed on CDs or over the internet. The

registered user of an Encad product whose manual is

distributed in this fashion may print one copy for their

personal use only .

Printing history

1st Edition Rev A May 1999

2st Edition Rev B October 2001

ii

Page 3

FCC Statement (U.S.A.)

The United States Federal Communications Commision has specified

that the following notice be brought to the attention of the users of the

NOVAJET 500, 630 or 700 series printers.

FEDERAL COMMUNICATIONS COMMISION RADIO AND TELEVISION INTERFERENCE FOR CLASS B DEVICE

This equipment has been tested and found to comply with the limits for a

class B digital device, pursuant to part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful interference to radio communications.

User Instructions:

If the equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on,

the user is encouraged to try to correct the interference by one of the

following measures:

NovaJet 500/630/700 Series Service Manual

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from

that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for

help.

Changes or modifications not expressly approved by ENCAD, Inc. could

void the user’s authority to operate the equipment.

v

Page 4

NovaJet 500/630/700 Series Service Manual

for NovaJet 736 and 750

FCC Statement (U.S.A.)

The United States Federal Communications Commision has specified that

the following notice be brought to the attention of the users of the

NOVAJET 736 or 750 printers.

FEDERAL COMMUNICATIONS COMMISION RADIO AND TELEVISION

INTERFERENCE FOR CLASS A DEVICE

This equipment has been tested and found to comply with the limits for a

class A digital device, pursuant to part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

in a residential installation. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance

with the instructions, may cause harmful interference to radio communications.

User Instructions:

If the equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on,

the user is encouraged to try to correct the interference by one of the

following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from

that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for

help.

Changes or modifications not expressly approved by ENCAD, Inc. could

void the user’s authority to operate the equipment.

vi

Page 5

VDE Statement

Hiermit wird bescheinigt, daß der NOVAJET 500/630/700 in

Übereinstimmung mit den Bestimmungen der BMPT-AmstbIVfg 234/1991

funkentstört ist. Der vorschriftsmäßige Betrieb mancher Geräte (z.B.

Meßsender) kann allerdings gewissen Einschränkungen unterliegen.

Beachten Sie deshalb die Hinweise in der Bedienungsanleitung.

Dem Zentralamt für Zulassungen im Fernmeldewesen würde dan

Inverkehrbringen dieses Gerätes angezeigt und die Berechtigung zur

Überprüfung der Serie auf die Einhaltung der Bestimmungen

eingeräumt.

ENCAD, Inc. U.S.A

NovaJet 500/630/700 Series Service Manual

vii

Page 6

NovaJet 500/630/700 Series Service Manual

Material Safety Data Sheet

ENCAD QIS (Quality Imaging Supplies) ink is nonhazardous, requiring no

special disposal handling. It can be harmful if swallowed and should be

kept away from children.

To obtain a Material Safety Data Sheet, contact ENCAD, Inc. at:

6059 Cornerstone Court West

San Diego, CA 92121-3734

(619) 452-4350

International users should contact their local dealer or distributor.

viii

Page 7

NovaJet 500/630/700 Series Service Manual

WARRANTY OR DAMAGE CLAIMS

United States

ENCAD®, Inc., warrants its printers ("PRODUCT") to be free from defects in workmanship

and materials for a period of one year from the date of purchase. In order to submit a

Warranty claim, please contact the ENCAD Help Desk at (619) 452-4350.

ENCAD reserves the right to make changes or improvements to Products, without incurring

any obligation to similarly alter Products previously purchased.

Buyer's sole and exclusive rights pursuant to this Warranty shall be for the repair or

replacement of defective Product. ENCAD specifically disclaims any and all other warranties, expressed or implied, including but not limited to, implied warranties of merchantability

and fitness for a particular purpose. In no event shall ENCAD be liable for any loss of

profit or other commercial damages, special, incidental or consequential damages, or any

other damages or claims, whatsoever.

This Warranty gives Buyer specific legal rights, and Buyer may also have other rights that

vary from state to state.

This Warranty applies only to printers purchased from ENCAD, or authorized ENCAD

distributors or dealers. The intent of this Warranty is to repair or replace defective Products subjected to normal wear and tear, when operated according to ENCAD instructions.

This Warranty does not cover damage to the Product resulting from the following:

• Accident or negligence.

• Unauthorized modification of the Product.

• Adverse environmental conditions.

• Service of the Product by other than an ENCAD authorized service provider.

• Unauthorized or improper use, including but not limited to:

– Use in applications for which the Product was not designed.

– Using cartridges or ink other than those supplied by ENCAD or authorized

ENCAD resellers.

– Using media other than that supplied by ENCAD or authorized ENCAD

resellers.

– Lubricating any part of the printer.

Internationally: Contact your dealer or distributor for warranty information.

ix

Page 8

NovaJet 500/630/700 Series Service Manual

Table of Contents

Chapter 1 General Description ............................................................ 1-1

Introduction ...............................................................................................................1-1

Overview ................................................................................................................... 1-3

Related Publications .......................................................................................... 1-3

Electrostatic Discharge (ESD) Sensitivity ................................................................. 1-3

Warnings, Cautions and Notes ................................................................................. 1-4

Printer Specifications ................................................................................................ 1-5

Contents of this Service Manual ................................................................................1-6

Technical Support ..................................................................................................... 1-8

Chapter 2 Theory of Operation ............................................................ 2-1

Introduction ............................................................................................................... 2-1

NovaJet 500/630/700 Printers General Block Diagram .............................................. 2-1

Paper (Media) Axis Drive .......................................................................................... 2-3

The Carriage Axis Drive............................................................................................. 2-4

Media Feed and Take-Up System ............................................................................. 2-5

Main Printed Wiring Assembly (MPWA) ................................................................... 2-6

Microprocessor .................................................................................................. 2-7

Gate Array ......................................................................................................... 2-7

Memory Circuits ................................................................................................. 2-8

Flash EEPROM ........................................................................................... 2-8

DRAM .......................................................................................................... 2-9

Serial EEPROM ......................................................................................... 2-10

Stepper Motor Controller................................................................................... 2-10

Servo Motor Controller ...................................................................................... 2-12

Interface Circuits: Serial & Parallel ................................................................... 2-14

Carriage Assembly Circuits .................................................................................... 2-15

Control Panel .......................................................................................................... 2-16

Power Supply ......................................................................................................... 2-17

Beeper and Fans .................................................................................................... 2-17

Chapter 3 Maintenance ........................................................................ 3-1

Introduction ............................................................................................................... 3-1

Scheduled Maintenance ........................................................................................... 3-1

Cleaning Procedures .......................................................................................... 3-2

External Cleaning .........................................................................................3-2

x

Page 9

NovaJet 500/630/700 Series Service Manual

Table of Contents (cont)

Chapter 3 Maintenance (cont)

Service Station Cleaning .............................................................................. 3-2

Slide Shaft Cleaning..................................................................................... 3-3

Linear Encoder Strip Cleaning ...................................................................... 3-4

Cartridge Jet Area & Dimples Cleaning ........................................................ 3-5

Flex Cable Contact Cleaning ........................................................................3-6

Clean and Inspect Stepper Motor Gears....................................................... 3-7

Clean and Inspect MPWA ............................................................................ 3-7

Clean and Inspect Carriage Assembly ......................................................... 3-8

Reseat Connectors on MPWA and Carriage Board .............................................3-8

Replace Carriage Bushings .............................................................................. 3-11

Servo Motor Winding Resistance Check ................................................................. 3-12

Stepper Motor Winding Resistance Check .............................................................. 3-13

Power Feed and Take-Up Motor Winding Resistance Check ................................... 3-14

Banding: Hardware vs Software ............................................................................... 3-15

Common Banding Causes ......................................................................... 3-16

Alignments/Adjustments ......................................................................................... 3-18

Slide Shaft Profile Adjustment .......................................................................... 3-18

Head Height Alignment Procedure .................................................................... 3-22

Color Calibration ............................................................................................... 3-26

Deadband Alignments ...................................................................................... 3-29

Deadband Alignment (for 500 Series) ......................................................... 3-32

Color Deadband Alignment (for 630/700) .................................................... 3-33

Paper Axis Calibration ...................................................................................... 3-35

Diagnostics Menu ................................................................................................... 3-37

Limited Access Menu ............................................................................................. 3-40

Firmware Download/Upgrading for the PC ............................................................... 3-41

Firmware Download/Upgrading for the MAC ............................................................ 3-42

Internal Cabling and Signal Flow Diagrams ............................................................. 3-44

Chapter 4 Troubleshooting .................................................................. 4-1

Introduction ............................................................................................................... 4-1

No Power ........................................................................................................... 4-1

Initialization Failure............................................................................................. 4-2

Media Does Not Move ........................................................................................ 4-2

Internal ERROR “Carriage Axis Failure” .............................................................. 4-3

xi

Page 10

NovaJet 500/630/700 Series Service Manual

Table of Contents (cont)

Chapter 4 Troubleshooting (cont)

Internal ERROR “Encoder Sensor Failure” .......................................................... 4-5

Internal ERROR “Paper Sensor Failure” .............................................................. 4-5

Internal ERROR “Auto-Sensor Failure” ................................................................4-6

Internal ERROR “MPCB Failure” ......................................................................... 4-6

Unrecognized Cartridges Error ............................................................................ 4-6

Image Skews or Moves ...................................................................................... 4-7

Does Not Print.................................................................................................... 4-7

Ink Cartridge Misfiring ......................................................................................... 4-7

Paper Skewing ................................................................................................... 4-9

Printer Output is Banding (Horizontal) ................................................................ 4-9

Printer Output is Banding (Vertical) .................................................................. 4-11

Printer Output is Banding (Horizontally and Vertically)...................................... 4-11

Keypad Locked-Up or Not Functioning Properly ............................................... 4-11

Noisy Operation ............................................................................................... 4-12

Line Quality Degraded ...................................................................................... 4-13

Fan Does Not Power Up ................................................................................... 4-14

Media Take-Up Motor Not Operating, Sensor Works ........................................ 4-14

Media Feed Motor Not Operating, Sensor Works ............................................. 4-15

Media Feed and Take-Up Motors Not Operating, Both Sensors Working .......... 4-15

Media Feed or Take-Up Sensor(s) Not Operating .............................................. 4-15

Initialization Troubleshooting (500 Series) ............................................................... 4-18

Initialization Troubleshooting (630/700 Series) .........................................................4-20

Chapter 5 Assembly\Disassembly ...................................................... 5-1

Introduction ............................................................................................................... 5-1

Remove the Left, Top, and Right Covers .................................................................... 5-2

Install the Left, Top, and Right Covers ....................................................................... 5-6

Remove the Keypad and Display .............................................................................. 5-7

Install the Keypad and Display.................................................................................. 5-9

Remove Extra Memory (SIMM) ............................................................................... 5-10

Install Extra Memory (SIMM) .................................................................................. 5-11

Remove the MPCB (Main Printed Circuit Board) ..................................................... 5-11

Install the MPCB .................................................................................................... 5-14

Remove Power Supply, Cooling Fan, and AC Entry Module .................................... 5-15

Install the Power Supply, Cooling Fan, and AC Entry Module ................................. 5-17

xii

Page 11

NovaJet 500/630/700 Series Service Manual

Table of Contents (cont)

Chapter 5 Assembly/Disassembly (cont)

Remove Servo Motor ............................................................................................... 5-18

Install Servo Motor .................................................................................................. 5-20

Remove the Ink Delivery System .............................................................................5-21

Install the Ink Delivery System................................................................................ 5-23

Remove the Carriage Assembly, Carriage Belt, and the Frame Tensioner................ 5-24

Install the Carriage Assembly, Carriage Belt, and the Frame Tensioner .................. 5-27

Remove the Carriage PCB ...................................................................................... 5-29

Install the Carriage PCB ......................................................................................... 5-31

Remove the Paper Sensor or the Encoder Sensor .................................................. 5-31

Install the Paper Sensor or the Encoder Sensor...................................................... 5-33

Replacing the Carriage Bushings ............................................................................ 5-34

Remove the Service Station .................................................................................... 5-36

Install the Service Station ....................................................................................... 5-36

Remove the Trailing Cable Assembly ...................................................................... 5-37

Install the Trailing Cable Assembly ......................................................................... 5-37

Remove the Stabilizer Bracket and Encoder Strip ...................................................5-38

Install the Stabilizer Bracket and Encoder Strip ...................................................... 5-40

Remove the Y-Arm Assembly, Pinch Rollers, Slide Shaft, and Auto-Load Sensor ... 5-40

Install the Y-Arm Assembly, Pinch Rollers, Slide Shaft, and Auto-Load Sensor ...... 5-43

Remove the Lower Roller Assembly, Stepper Motor and Vacuum Fan ..................... 5-44

Install the Lower Roller Assembly, Stepper Motor and Vacuum Fan ........................ 5-47

Remove the Media Take-Up and Feed Sensor Brackets and Sensors ..................... 5-50

Install the Media Take-Up and Feed Sensor Brackets and Sensors ........................ 5-52

Remove the Media Take-Up and Feed Motors ......................................................... 5-52

Install the Media Take-Up and Feed Motors ............................................................ 5-54

Remove the Media Drying Fans .............................................................................. 5-54

Install the Media Drying Fans ................................................................................. 5-55

Remove the Thermal Dryer Assembly (NovaJet 750) ............................................... 5-56

Install the Thermal Dryer Assembly (NovaJet 750) .................................................. 5-57

Chapter 6 Parts List .............................................................................. 6-1

xiii

Page 12

NovaJet 500/630/700 Series Service Manual

List of Illustrations

Figure Page

Chapter 1 General Description

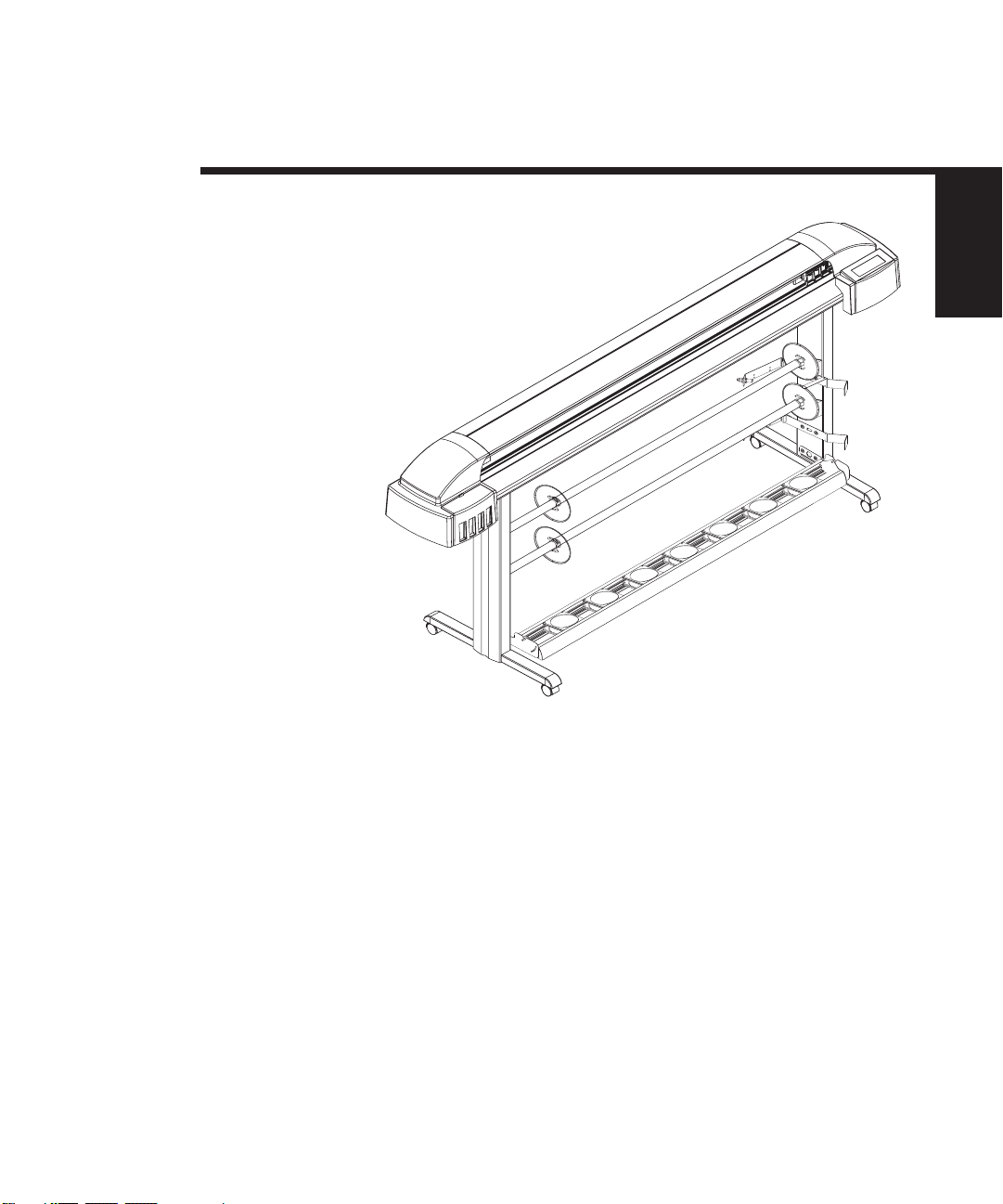

1-1. NovaJet 500/630/700 Series Inkjet Printers ..................................................... 1-1

Chapter 2 Theory of Operation

2-1. General Block Diagram ................................................................................... 2-2

2-2. Paper (Media) Axis Drive ................................................................................. 2-3

2-3. Carriage Axis Drive ..........................................................................................2-4

2-4. Power Feed and Take-Up System ................................................................... 2-5

2-5. Main Printed Wiring Assembly ........................................................................2-6

2-6. Gate Array ...................................................................................................... 2-7

2-7. Stepper Motor Controller ............................................................................... 2-10

2-8. Servo Motor Controller ................................................................................... 2-12

2-9. Quadrature Signal Generation ....................................................................... 2-13

2-10. Interface Circuits ........................................................................................... 2-14

2-11. Carriage Assembly Circuits........................................................................... 2-15

2-12. Main Menu .................................................................................................... 2-16

Chapter 3 Maintenance

3-1. Encoder Strip Cleaning ................................................................................... 3-5

3-2. Cartridge Dimple Region ..................................................................................3-5

3-3. Flex Cable Contacts ....................................................................................... 3-6

3-4. MPWA Connection Locations ......................................................................... 3-9

3-5. Carriage PWA Connection Locations ............................................................ 3-10

3-6. Ribbon Connector Locking Mechanism ......................................................... 3-11

3-7. Servo Motor ................................................................................................... 3-12

3-8. Stepper Motor ............................................................................................... 3-13

3-9. Power Feed and Take-Up Motor .................................................................... 3-14

3-10. Examples of Banding .................................................................................... 3-15

3-11. Dial Gauge Micrometer Assembly ................................................................. 3-19

3-12. Measurement Positions for Slide Shaft .......................................................... 3-20

3-13. Slide Shaft Profile Adjustment ....................................................................... 3-21

3-14. Carrier Head Height Tolerance ....................................................................... 3-22

3-15. Setting Up Tools from Height Gauge Kit ........................................................ 3-22

3-16. Zeroing the Micrometer Gauge ...................................................................... 3-23

xiv

Page 13

NovaJet 500/630/700 Series Service Manual

List of Illustrations (cont)

Figure Page

Chapter 3 Maintenance (cont)

3-17. Test Cartridge Installed .................................................................................. 3-23

3-18. Support Bracket Placement .......................................................................... 3-24

3-19. Color Calibration ............................................................................................ 3-26

3-20. Utility Menu................................................................................................... 3-27

3-21. Color Calib Menu........................................................................................... 3-28

3-22. Cyan Vertical Options Menu.......................................................................... 3-28

3-23. Slow Deadband ............................................................................................. 3-29

3-24. Service Menu ................................................................................................ 3-30

3-25. Calibration (Deadband) Menu (500 Series)..................................................... 3-31

3-26. Calibration (Deadband) Menu (630/700 Series) .............................................. 3-31

3-27. Calibration Menu ........................................................................................... 3-33

3-28. Color Db Menu .............................................................................................. 3-34

3-29. Paper Axis Test ............................................................................................ 3-36

3-30. Diagnostics Menu ......................................................................................... 3-37

3-31. Accessory Menu ........................................................................................... 3-37

3-32. NVRAM Clear and Clock Reset Menu ........................................................... 3-40

3-33. MPWA Connections Diagram........................................................................ 3-45

3-34. Carriage PWA Connections Diagram............................................................. 3-46

3-35. Leg Harness Connections Diagram ............................................................... 3-47

3-36. Leg Harness Connections Diagram (750) ...................................................... 3-48

Chapter 4 Troubleshooting

4-1. Carriage Board LED D2 Location for NJ 500 Series ....................................... 4-19

4-2. Carriage Board LED D2 and D5 Location for NJ 630/700 Series .................... 4-21

Chapter 5 Assembly/Disassembly

5-1. Right Cover Assembly Removal/Installation ..................................................... 5-3

5-2. Left Cover Assembly Removal/Installation ....................................................... 5-4

5-3. Left Cover Assembly Removal/Installation (NovaJet 750) ................................. 5-5

5-4. Keypad and Display Removal/Installation ........................................................ 5-8

5-5. Keypad and Display Grounding Connection .....................................................5-9

5-6. Extra Memory (SIMM) Removal/Installation ................................................... 5-10

5-7. MPCB Removal ............................................................................................. 5-13

5-8. Power Supply Removal ................................................................................. 5-16

xv

Page 14

NovaJet 500/630/700 Series Service Manual

List of Illustrations (cont)

Figure Page

Chapter 5 Assembly/Disassembly (cont)

5-9. Cooling Fan/AC Entry Module Removal ......................................................... 5-17

5-10. Slacken Carriage Belt ................................................................................... 5-19

5-11. Chain Support Bracket Removal .................................................................... 5-22

5-12. Cariage Cover Removal ................................................................................. 5-22

5-13. Chain Support Bracket Adjustment ............................................................... 5-24

5-14. Strain Relief Removal/Installation .................................................................. 5-25

5-15. Frame Tensioner ........................................................................................... 5-26

5-16. Carriage Belt Clamp ...................................................................................... 5-26

5-17. Carriage PCB Removal/Installation ................................................................ 5-30

5-18. Paper and Encoder Sensor Removal ............................................................. 5-32

5-19. Paper and Encoder Sensor Installation .......................................................... 5-33

5-20. Carriage Bushing Removal ............................................................................ 5-35

5-21. Carriage Bushing Installation ......................................................................... 5-35

5-22. Service Station Removal ................................................................................ 5-36

5-23. Stabilizer Bracket Installation/Removal .......................................................... 5-39

5-24. Y-Arm Installation/Removal ........................................................................... 5-41

5-25. Pinch Roller .................................................................................................. 5-42

5-26. Stepper Motor Removal/Installation ............................................................... 5-47

5-27. Inside Platen, Right Side ............................................................................... 5-49

5-28. Media Take-Up and Feed Sensor Removal .................................................... 5-51

5-29. Media Take-Up and Feed Motor Removal ...................................................... 5-53

5-30. Inner Platen Assembly/Disassembly ............................................................. 5-57

Chapter 6 Parts List

6-1. Left Side Parts Breakdown .............................................................................. 6-3

6-2. Left Side Parts Breakdown (NovaJet 750) ........................................................ 6-5

6-3. Platen and Above Parts Breakdown ................................................................ 6-7

6-4. Right Side Parts Breakdown ........................................................................... 6-9

6-5. Right Side Parts Breakdown (NovaJet 750) ................................................... 6-11

6-6. Inner Platen Parts Breakdown ....................................................................... 6-13

6-7. Carriage Assembly Parts Breakdown ............................................................ 6-15

6-8. Carriage Cover Parts Breakdown ................................................................... 6-17

6-9. Service Station Parts Breakdown .................................................................. 6-19

6-10. Power Feed and Take-Up Parts Breakdown ................................................... 6-21

xvi

Page 15

NovaJet 500/630/700 Series Service Manual

List of Tables

Table Page

Chapter 1 General Description

Chapter 2 Theory of Operation

Chapter 3 Maintenance

3-1. MPWA Connections Table .............................................................................. 3-9

3-2. Carriage PWA Connections Table ................................................................. 3-10

Chapter 4 Troubleshooting

4-1. Troubleshooting Table ......................................................................................4-1

Chapter 5 Assembly/Disassembly

Chapter 6 Parts List

xvii

Page 16

NovaJet 500/630/700 Series Service Manual

This Page Intentionally Left Blank

xviii

Page 17

General Description

1

DESCRIPTION

GENERAL

Introduction

This manual provides service information for the ENCAD®, Inc.

NovaJet® 500, NovaJet 630 and the NovaJet 700 Series of Color

Inkjet Printers. The NovaJet 500 series includes the NovaJet 500 and

NovaJet 505 printers. The NovaJet 700 series includes the NovaJet

700, NovaJet 736 and NovaJet 750 printers. All three NovaJet 500/

630/700 printer series comes in two sizes: a 42 inch model and a 60 inch

model. The NovaJet 736 printer comes only as a 36 inch model.

The service manual is written for service personnel who possess analog

and digital circuitry experience. Chapter 2, Theory of Operation, should

Figure 1-1. NovaJet 500/630/700 Series Inkjet Printers.

1-1

Page 18

NovaJet 500/630/700 Series Service Manual

be read and thoroughly understood before troubleshooting/calibrating

the printers.

The printers support pre-cut and roll media. Media size is automatically determined and hardclip limits are set accordingly. Pre-cut media

uses different maximum plotting areas than roll media. See the Printer

Specifications in the User Guide for more details on the media size

printable area.

Both RS-422 serial and Centronics parallel connections are provided to

interface with the host computer. For proper operations, the NovaJet

750 must be connected to a 100BaseT network print server. Commands

sent from the host computer can be in several forms including HP-GL/

2, HP-RTL and EN RTL formats.

Drivers are supplied to support Windows-based PC’s (3.XX, 95/98, and

NT) as well as Macintosh and Power PC computers.

These printers expand upon ENCAD’s tradition of delivering fast, highquality color or monochrome graphics for a variety of applications.

ENCAD has made significant advances in designing these printers to

respond to and anticipate our customers’ needs. Principal features are

summarized below.

Locally or Remotely Configured via Host Computer

Powered Media Take-Up and Feed System (700 series only)

Powered Feed Roll and Take-Up Basket (500 & 630 series)

Optional Powered Take-Up Roll System (500 & 630 series)

Media Drying System (optional on the 500 & 630 series)

Thermal Media Drying System (NovaJet 750)

Quick Ink Changeover

Self-Aligning Pinch Rollers

PowerPC 33 MHz Microprocessor

8 User Configurable Settings

104 Jet Ink Cartridges (500 series)

208 Jet Ink Cartridges (630 & 700 series)

Ink Priming System

4 500ml Ink Reservoirs (8 for the NovaJet 750)

Smart Cartridges

Odometer Function

Improved Septum Connector Design

1-2 General Description

Page 19

Overview

Related Publications

NovaJet 500/630/700 Series Service Manual

Printers draw according to instructions issued from a “host” computer. Every printer is engineered to understand a specific set of

instructions and to execute each instruction in a precise manner. In

addition, most printers are designed to execute predetermined

characters automatically without a specific line-by-line instruction

from the program. These characters are part of the printer’s permanent memory.

The following publication contains additional information which may

be useful in servicing the ENCAD, Inc. NovaJet 500/630/700

Series Color Inkjet Printers:

• ENCAD NovaJet 500/630/700 Quick Start Guide,

P/N 212528-04

• ENCAD NovaJet System CD-ROM,

P/N 212532-02

DESCRIPTION

GENERAL

Copies of these and other ENCAD, Inc. publications may be obtained by contacting your nearest authorized ENCAD, Inc. dealer or

by contacting ENCAD’s Technical Support and Service Department.

Electrostatic Discharge (ESD) Sensitivity

All PWAs (Printed Wiring Assemblies) associated with the NovaJet

500/630/700 series printers have components sensitive to ESD

(electrostatic discharge). Care must be taken to avoid damage to any

of the components by following current ESD handling procedures and

practices.

Always use an approved ESD grounding strap when handling or

working with PWAs.

General Description 1-3

Page 20

NovaJet 500/630/700 Series Service Manual

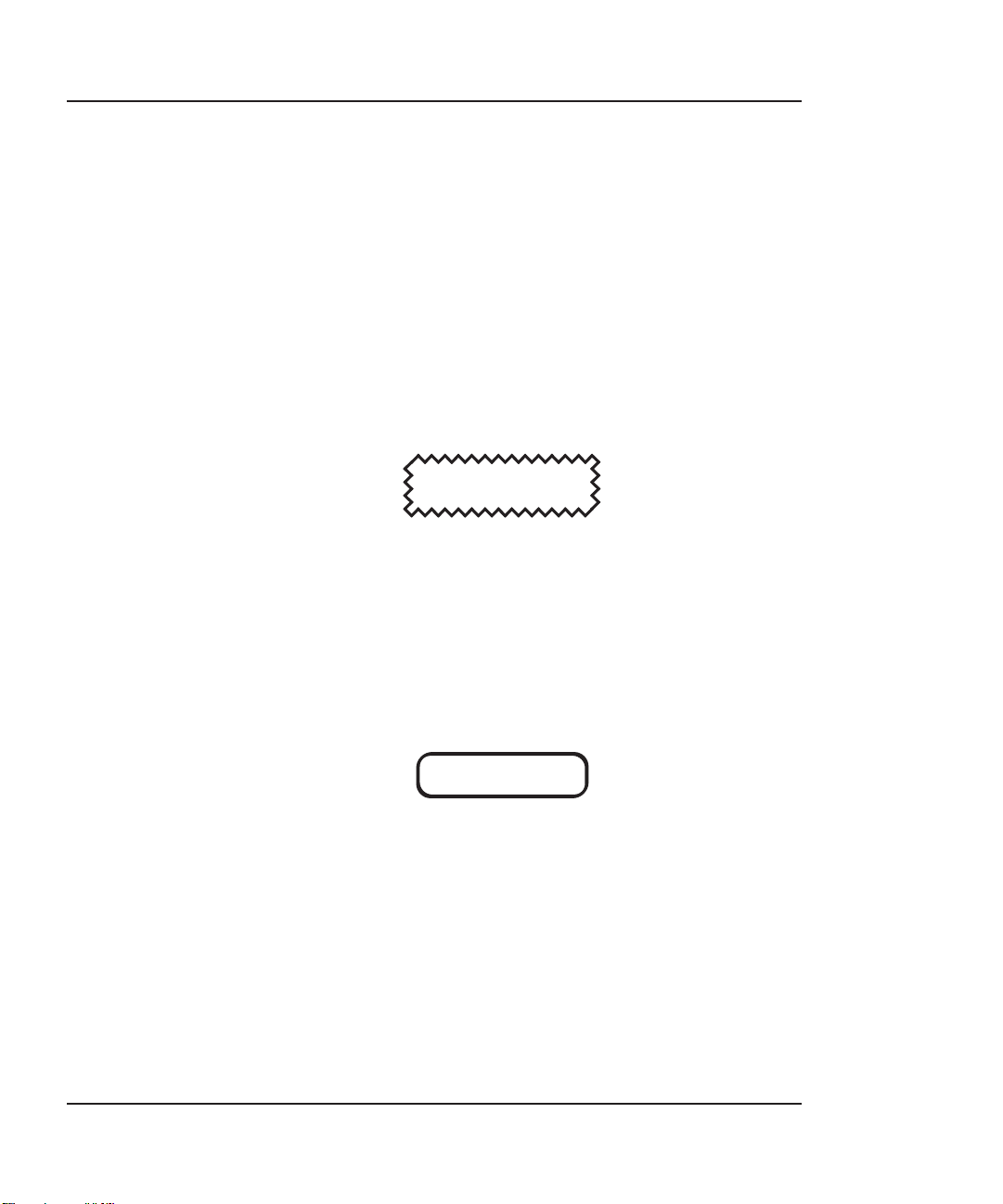

Warnings, Cautions and Notes

Warnings, cautions and notes are used when additional information,

instructions or care should be observed. In this manual warnings,

cautions and notes precede the text to which each applies. The definition of each is provided below.

WARNINGS - Warnings are used to stress that the following steps or

procedures has the potential to cause serious harm or death to service

personnel. Extreme care should be observed when following the procedures and to exercise standard safety procedures. They are indicated

by:

WARNING

Followed by a paragraph describing the concern.

CAUTIONS - Cautions depict that the following steps or procedures can

cause damage to the equipment if not properly followed. Extreme care

should be observed when following the procedures and to exercise

standard safety procedures. They are indicated by:

CAUTION

Followed by a paragraph describing the concern.

NOTES - Notes are placed before a procedure to inform the service

personnel of specific details to improve quality, to give reminders of

interrelated parts and to provide other helpful information. They are

indicated by:

NOTE

Followed by a paragraph describing the concern.

1-4 General Description

Page 21

Printer Specifications

The specifications and performance characteristics of the NovaJet

500/630/700 Series Color Inkjet Printers are as follows:

NovaJet 500/630/700 Series Service Manual

DESCRIPTION

GENERAL

Max Printing Area:

42 inch 60 inch

Norm 40.8” 58.8”

1.04m 1.49m

Extend 41.61” 59.61”

1.06m 1.51m

Language Emulation:

HP-RTL

EN RTL

HP GL/2

Buffer:

32 MB installed (630/700)

8 MB installed (500 series)

upgradeable to 128 MB

Power Requirements:

Input Voltage:

90-264 VAC

48-63 Hz

Output Power:

20 W idle

140 W typical

215 W maximum

Resolution:

630/700 series

600x600 dpi or

300x300 dpi, addressable

500 series

300x300 dpi

Baud Rates:

9600, 19200, 38400

Accuracy:

+/- 0.2% line length using

ROLL feed and 4 mil

drafting matte film

Interface:

Centronics parallel

(IEEE 1284)

RS-422 serial

Network Option: via

10/100BaseT, 10Base2

Print Server

Certifications:

Safety

CSA, CSE/NRTL

(equivalent to UL1950)

TUV GS

EN 50 082-1

EN 60 950

UL1950

NOM-019-SCFI-1993

IEC 950

AS/NZS 3260

EMI

FCC Class A, B

CSA C108.8

EN 55 022 Class A, B

CE Mark

CISPR 22- Class A, B

AS/NZS 3548

General Description 1-5

Page 22

NovaJet 500/630/700 Series Service Manual

Environment:

Operating:

59° to 95° F

(15° to 35° C)

10% to 70% RH

non-condensing

Storage:

-5° to 140° F

(-21° to 60° C)

5% to 80% RH

non-condensing

Contents of this Service Manual

Figures are used in this manual to clarify procedures. They are for

illustrative purposes only and may not necessarily be drawn to scale.

Material in this manual may be repeated in various chapters so that

each chapter can “stand alone”. This allows information to be located

without having to refer back and forth between chapters.

Weight:

60” 88 lbs 135 lbs (boxed)

42” 72 lbs 117 lbs (boxed)

Dimensions:

Height 44” (1.12m)

Width 77” (1.96m)

42 inch

95” (2.41m)

60 inch

Depth 28” (0.71m)

Figures and tables are easily located and cross-referenced, and are listed

in the front of the manual under List of Illustrations and List of Tables.

This manual is divided into six chapters as:

Chapter 1 GENERAL DESCRIPTION - Contains a general

description of the ENCAD NovaJet 500/630/700 printers.

This includes printer specifications, and related materials.

Also included is a description of the use of Warnings,

Cautions and Notes as used in this manual and chapter

contents.

1-6 General Description

Page 23

NovaJet 500/630/700 Series Service Manual

Chapter 2 THEORY OF OPERATION - Functional

descriptions of the overall printer and major assemblies

are contained in this chapter.

Chapter 3 MAINTENANCE - This chapter covers the

scheduled maintenance, cleaning procedures and

alignment/adjustments recommended to perform on the

printers. Diagnostics and a signal flow diagram are also

listed.

Chapter 4 TROUBLESHOOTING - A table containing

problems that could occur and possible causes and repairs

is found in this chapter. This table is not intended to be a

complete listing of troubleshooting procedures. It will

isolate the problem down to the lowest replacable

assembly. If the problem happens to be the wiring

between assemblies, standard troubleshooting techniques

will have to be implemented to correct the problem.

Chapter 5 ASSEMBLY/DISASSEMBLY - Contains detailed

procedures to remove and replace printer parts and

assemblies.

DESCRIPTION

GENERAL

Chapter 6 PARTS LIST - Contains a complete listing of all

field replacable parts and assemblies for the NovaJet 500/

630/700 Color Inkjet Printers. Illustrated parts

breakdown drawings are included to help clarify and

identify parts for ordering. Special kits and adjustment

jigs may also be required.

ORIENTATION - Instructions in this manual are based on the

assumption that the service person is facing the front of the printer.

References to top view, back view, and so forth are consistent with

this engineering standard. References to the X Axis and Y Axis

(Paper Axis and Carriage Axis, respectively) follow the standard of

AutoCAD™ absolute coordinates: up and down for X, left to right for

Y.

General Description 1-7

Page 24

NovaJet 500/630/700 Series Service Manual

Technical Support

ENCAD offers full technical support and service for its various products. If you are unable to find the answer to your question in either the

User’s Guide, Service Manual, or other related publications, check out

ENCAD’s Knowledge Base located on ENCAD’s website support:

ENCAD Website: http://www.encad.com

Additional information is available though our Technical Support and

Service Department’s Help Desk.

ENCAD, Inc.

Technical Support & Service Dept.

6059 Cornerstone Court West

San Diego, CA 92121

Help Desk Telephone: (858) 452-4350 or

Help Desk FAX: (858) 558-4672

(877) ENCAD-TS (362-2387)

International users contact your local ENCAD service provider. See

details on your ENCAD registration card.

1-8 General Description

Page 25

Theory of Operation

Introduction

This chapter explains the mechanical and electrical theory of operation

of the ENCAD NovaJet 500/630/700 Series Color Inkjet printers.

The NovaJet 500/630/700 Series is a PowerPC 33MHz microprocessorbased digital printer that receives plotting instructions from a host

computer through either the RS-422 serial interface or the Centronics

parallel interface.

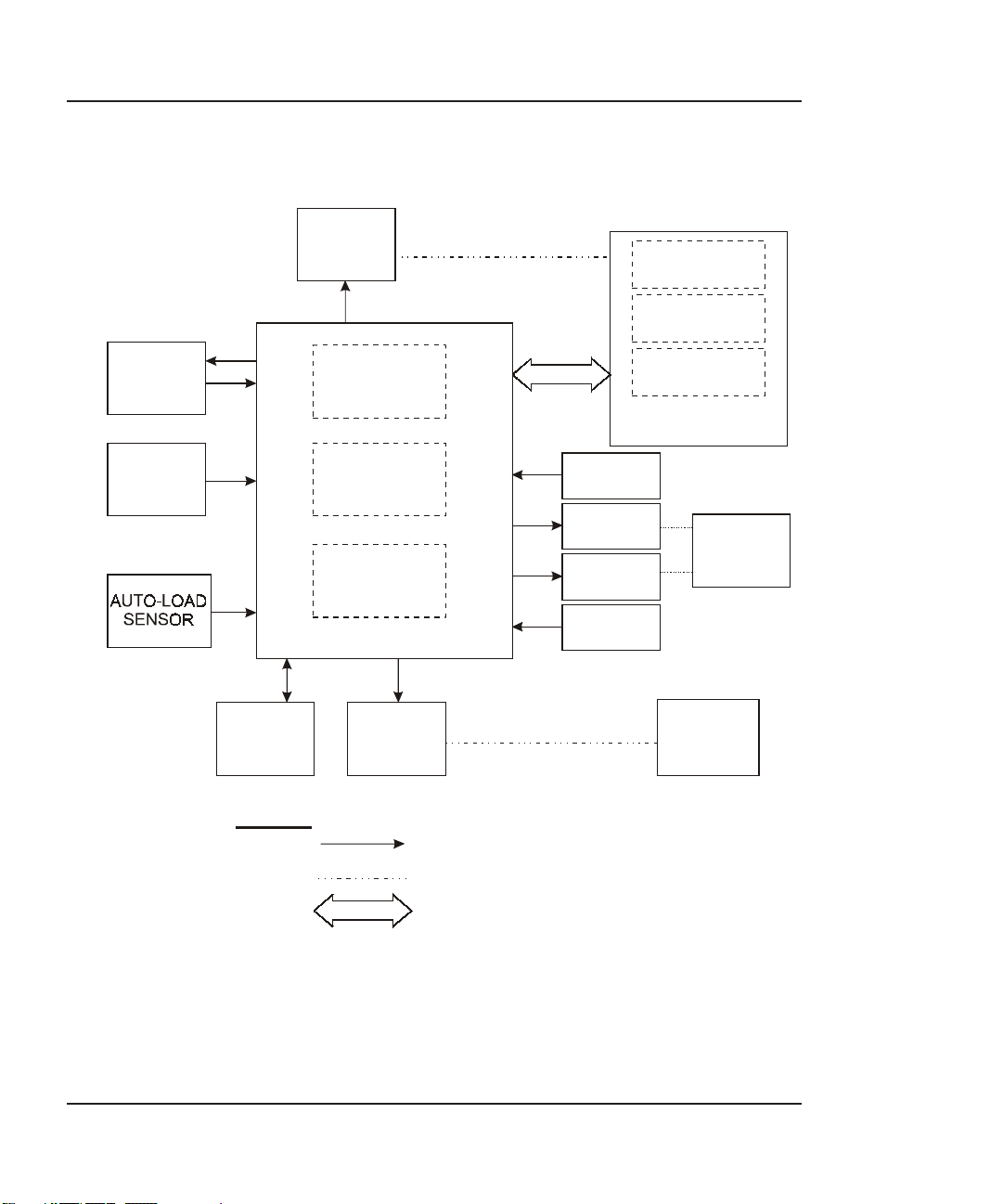

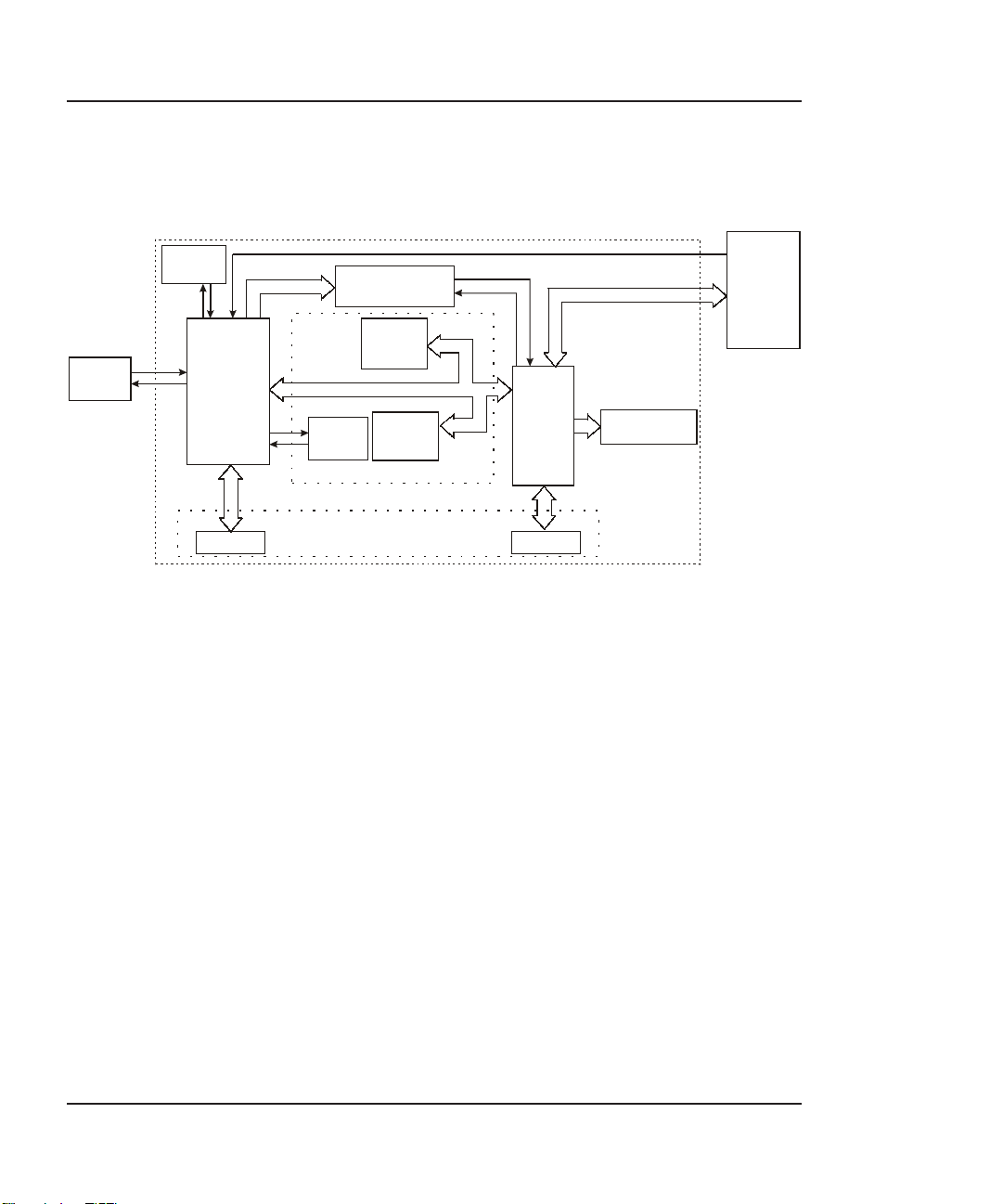

NovaJet 500/630/700 Printers General Block Diagram

Figure 2-1 illustrates the major functional areas of the printers.

The NovaJet 500/630/700 Series printers consist of three mechanical

assemblies:

1. Paper (Media) Axis Drive

2

OPERATION

THEORY OF

2. Carriage Axis Drive

3. Media Feed and Take-Up System

(Mechanical Take-Up system is optional on the 500 & 630

printers.)

and four main electrical assemblies:

1. MPCB (Main Printed Circuit Board)

2. Carriage Assembly

3. Control Panel

4. Power Supply

2-1

Page 26

NovaJet 500/630/700 Series Service Manual

CONTROL

PAN EL

POWER

SUPPLY

PRINT

SERVER

SERVO

MOTOR

MICRO-

PROCESSOR

GATE

ARRAY

MEMORY

CIRCUITS

MPWA

STEPPER

MOTOR

CARRIAGE AXIS DRIVE

PAPER AXIS DRIVE

FEED

SENSOR

FEED

MOTOR

TAK E-U P

MOTOR

TAK E-U P

SENSOR

PAPER

SENSOR

ENCODER

SENSOR

CARRIAGE

PCB

CARRIAGE

ASSEMBLY

MEDIA

LOWER

DRIVE

ASSEMBLY

LEGEND

ELECTRICAL CONNECTION

MECHANICAL CONNECTION

MAIN DATA BUS

Figure 2-1. General Block Diagram.

2-2 Theory of Operation

Page 27

NovaJet 500/630/700 Series Service Manual

Paper (Media) Axis Drive

PINCH ROLLERS

STEPPER MOTOR

LOWER ROLLER SHAFT ASSY

REDUCTION GEAR

Figure 2-2. Paper (Media) Axis Drive.

The Paper (Media) Axis Drive moves the plotting media in a direction

perpendicular to the length of the printer. This friction drive utilizes a

micro-step drive technology and consists of a stepper motor, reduction

gears, lower drive shaft assembly, and pinch rollers. This can be seen

in Figure 2-2.

The micro-step technology associated with the stepper motor gives the

capability of a resolution up to 9600 dpi.

The reduction gear meshes the stepper motor to the lower drive shaft

assembly which allows the media to advance or retract. The purpose of

the pinch rollers is to apply pressure to the media onto the drive shaft

assembly to reduce the chance of slipping.

OPERATION

THEORY OF

Misaligned pinch wheels is a main cause of skewing of the media. For

that reason the NovaJet 500/630/700 Series was designed with self

aligning pinch rollers. As the media is fed forward, the rollers are

aligned correctly. However, these pinch rollers will not stay aligned

while the media is being fed backwards.

Theory of Operation 2-3

Page 28

NovaJet 500/630/700 Series Service Manual

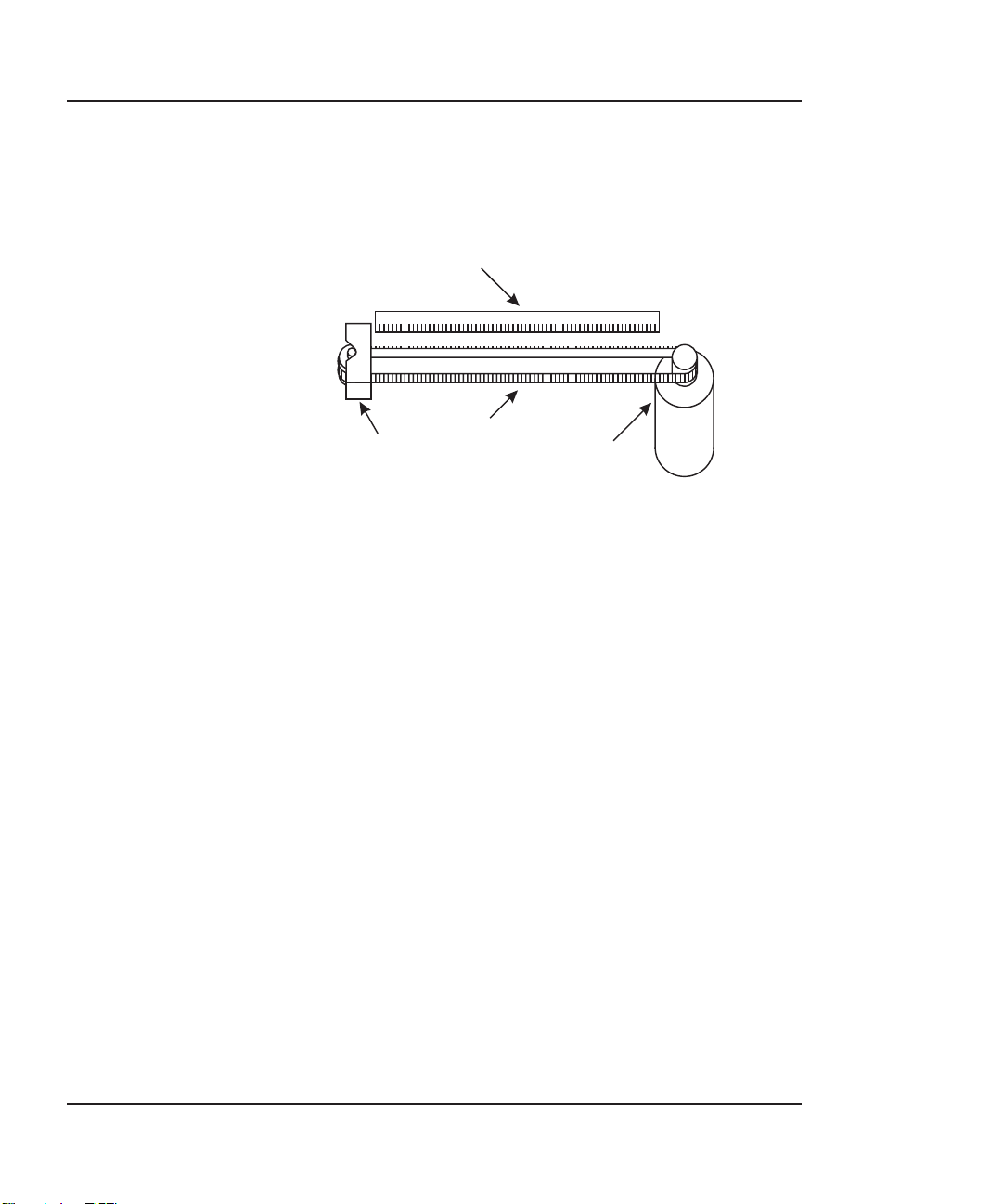

The Carriage Axis Drive

ENCODER STRIP

TENSIONING

ASSY

Figure 2-3. Carriage Axis Drive.

The Carriage Axis Drive moves the printer’s carriage assembly along

the length of the printer. The drive consists of a servo motor, linear

encoder strip, drive belt, and tensioning assembly. These items are

illustrated in Figure 2-3.

The servo motor, drive belt, and tensioning assembly are the components that actually drive the carriage assembly. The servo motor drives

the belt back and forth allowing the attached carriage assembly to be

repositioned as required. The tensioning assembly is spring controlled

and allows the proper amount of tension on the belt.

The linear optical encoder strip is used to obtain the printers accuracy

along the axis of the printer. It is made with 150 parallel lines per inch

etched into it. By utilizing two optical encoder sensors that are slightly

offset from each other, and reading the leading and trailing edges of the

lines, a resolution of 600 dpi can be obtained.

The stepper and servo motors are controlled from the main printed

wiring assembly (MPWA) by the microprocessor.

SERVO

MOTOR

BELT

2-4 Theory of Operation

Page 29

NovaJet 500/630/700 Series Service Manual

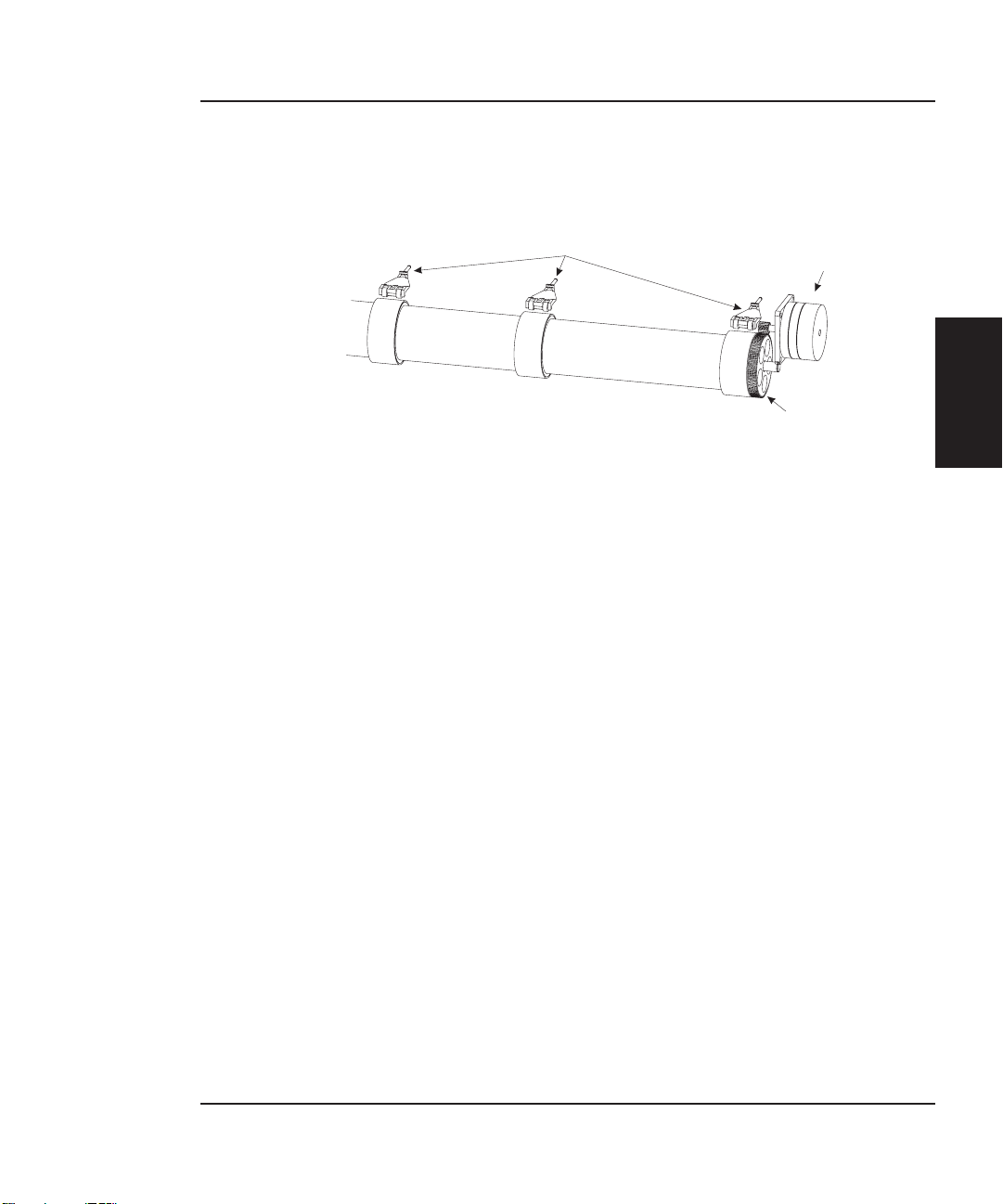

Media Feed and Take-Up System

SENSORS

REFLECTOR

REFLECTOR

Figure 2-4. Power Feed and Take-Up System.

The media feed and take-up system comprises of two optical sensors,

two dc motors and a dryer assembly. See Figure 2-4. The NovaJet

750 uses a thermal drying system while all other models use a blower

drying system as shown above.

Motors are used to advance the media feed roll and the media take-up

roll dependant upon the signals they receive from the MPWA. The

MPWA generates the control signals for the motors from the information it receives from the media feed and take-up sensors. The MPWA

also controls the dryer assembly. It activates only the fans required to

cover the width of the loaded media. The fan assembly also contains an

interlock circuit.

OPERATION

THEORY OF

The optical sensors are designed to inform the MPWA when there is not

a proper amount of slack in the media by sensing the ‘curl’ of the media

at the bottom of its loop. This method is used so that all approved forms

of media (including transparent backlit media) is able to take advantage

of the power feed and take-up system.

Theory of Operation 2-5

Page 30

NovaJet 500/630/700 Series Service Manual

Main Printed Wiring Assembly (MPWA)

CRYSTAL

CONTROL

PANEL

X1

MICRO-

PROCESSOR

(CPU)

STEPPER MOTOR

CONTROLLER

FLASH

EEPROM

DATA BUS

SERIAL

EEPROM

DYNAMIC

RAM

(SIMM)

MEMORY CIRCUITS

GATE

ARRAY

SERVO MOTOR

CONTROLLER

CARRIAGE

PWA

SERIAL

INTERFACE CIRCUITS

PARAL LEL

Figure 2-5. Main Printed Wiring Assembly.

The Main Printed Wiring Assembly (MPWA) consists of six functional

areas:

1. Microprocessor (CPU)

2. Gate Array

3. Memory Circuits

4. Stepper Motor Controller

5. Servo Motor Controller

6. Interface Circuits: Serial & Parallel

2-6 Theory of Operation

Page 31

Microprocessor

The microprocessor (an IBM PowerPC) is the central processor unit

which supervises system functions, executes the printer firmware,

manipulates data, and controls input/output data busses. It has two

built-in serial ports, a two channel DMA (Direct Memory Access)

controller, a timer module, clock generator, and an on-board chip

select generator. One serial port connects to the Mini-DIN connector

which can be used to communicate with the host computer; the other

serial port interfaces to the Control Panel. One DMA channel supplies data to the gate array for jet firing; the other DMA channel is

used to receive data through the parallel port via the gate array, or

the serial port when using a high speed serial mode. One timer

generates a servo interrupt every millisecond; the other is used for

timing the Stepper Motor.

A divide-by-two circuit generates the 33MHz system clock from a

66MHz crystal reference (X1).

The chip select generator is programmed to generate chip selects at

the appropriate addresses, with the appropriate data size (byte, word)

and with the appropriate number of wait states.

NovaJet 500/630/700 Series Service Manual

OPERATION

THEORY OF

Gate Array

PAR A LLEL

PORT

GATE

ARRAY

STATIC

RAM

Figure 2-6. Gate Array.

SERVO

CONTROLLER

TO

CARRIAGE

PWA

Theory of Operation 2-7

Page 32

NovaJet 500/630/700 Series Service Manual

The gate array contains the hardware logic for jet firing, monitoring

changes in the Carriage Assembly position, controlling DMA through

the parallel port, and generating the PWM (Pulse Width Modulation)

waveforms for the servo controller.

The gate array is a Xilinx device. It is a static RAM-based field programmable gate array. This means that the logic that it implements is

determined by configuration information in an internal RAM storage

area. Each time power is turned on, this information must be downloaded from the system EEROM. This type of gate array allows for the

flexibility of upgrading the logic by simply downloading the new system

software.

Memory Circuits

Memory is used to retain large amounts of information. This information is stored in the device memory in the form of binary bits.

Printer memory consists of Flash EEPROM, DRAM, and EEPROM.

Maximum installable memory is as follows:

DRAM = 128 MB

Flash EEPROM = 1 MB

Serial EEPROM = 1KB

Flash EEPROM

Flash EEPROM is Electrically Erasable, Programmable, Read Only

Memory used to store instructions and data constants which the

microprocessor can access and interpret, with no loss of information

when power is off.

2-8 Theory of Operation

Page 33

NovaJet 500/630/700 Series Service Manual

The system firmware is stored in Flash EEPROM. The Flash

EEPROM allows the firmware to be upgraded by downloading the files

containing the new firmware. It can be erased and reprogrammed

more than 10,000 times. The term “Flash” means that bytes cannot be

individually erased. A block or the whole device is erased at the same

time and the block or whole device is then reprogrammed.

The normal method of downloading new firmware is to send the unit

the files containing the code using either the GO.EXE utility or printing the file to the unit. This requires using an appropriate host utility

and can be done through the serial port (for Macintosh users) or the

parallel port (for PC users). See Firmware Downloading in Chapter 3

for the procedures.

DRAM

DRAM is Dynamic Random Access Memory which provides temporary

storage of the microprocessor calculation and input/output data. It is

also a faster type of memory then the Flash EEPROM. That’s why the

printer control program is also copied from the Flash EEPROM to

RAM, where it can be executed faster.

OPERATION

THEORY OF

The printer also has two 72-pin 32-bit SIMM sockets for DRAM. The

printer is supplied with a SIMM installed on the MPWA. The SIMM

size for the 500 series is 8 Megabyte and for the 630/700 series is 32

Megabyte. The following SIMM sizes are supported: 4MB (1Mx32),

8MB (2Mx32), 16MB (4Mx32), 32MB (8Mx32) and 64MB (16Mx32.)

The SIMMs must have a minimum operating speed of 70ns, and

conform to JEDEC Standard 21-D release 4 or later. Remove the Right

Cover to install additional memory (see Chapter 5 for installation

procedures.) Care must be taken when choosing a SIMM module for

the printer. Not all SIMM’s on the market today will work on the

printer. It has to do with the “presence detect” signals on pins 67 and

68 of the SIMM’s. Not all SIMM manufacturers use these signals, so

they disable them.

Theory of Operation 2-9

Page 34

NovaJet 500/630/700 Series Service Manual

Serial EEPROM

Serial EEPROM is an Electrically Erasable, Programmable, Read Only

Memory which provides storage for calibration constants and user

configuration data entered from the host computer.

An 8K bit serial nonvolatile EEPROM stores calibration and configuration information. It retains data while the unit is off.

Stepper Motor Controller

DATA BUS

WAVEFORM

GENERATOR

COMPARATOR

DRIVER

CURRENT

SENSE

STEPPER

MOTOR

Figure 2-7. Stepper Motor Controller.

The media is driven by a Stepper Motor, which drives the media in a

direction perpendicular to the width of the printer. The media in the

printer can advance forward and backward, depending upon the commands which the Stepper Motor receives from the microprocessor.

The Stepper Motor Controller contains two identical circuits, one for

each winding of the stepper motor. The circuit is a combination of two

simpler types of circuits and can be thought of as a variation of either

one.

A waveform generator receives digital data from the CPU and generates

a sine wave output. This signal is fed into a comparator circuit that is

measuring the current through the winding of the stepper motor. If the

current is too low, a pulse of 24V is generated. When the current goes

above the output of the waveform generator, the pulse turns off. Every

time the output of the waveform generator is changed by the microprocessor, the motor moves 1 “micro-step”.

2-10 Theory of Operation

Page 35

NovaJet 500/630/700 Series Service Manual

Each circuit contains four main functions (see Figure 2-7):

1. Reference waveform generator

The microprocessor uses a D/A (digital to analog) converter to set

the desired level for the current in the stepper motor winding. The

output of the D/A converter varies in time to create a reference

waveform. This reference waveform is centered around 10V.

2. Motor current sense

The voltage across a series current sense resistor is measured and

level shifted so that it is centered around 5V.

3. Comparator

This portion divides the output of the reference waveform generator

by two and compares it to the output of the motor current sensor.

Logic inside the gate array generates the control signals for the

power driver that applies voltage across the motor winding in order

to make the actual current match the reference waveform.

OPERATION

THEORY OF

4. Power driver

An H-bridge allows the supply voltage to be applied across the

winding in either polarity used to drive the current level to the

desired value.

Theory of Operation 2-11

Page 36

NovaJet 500/630/700 Series Service Manual

Servo Motor Controller

GATE

ARRAY

MOTOR

DRIVER

MAIN PWA

SERVO

CONNECTOR

CARRIAGE

CONNECTOR

SERVO

MOTOR

ENCODER

CARRIAGE

Figure 2-8. Servo Motor Controller.

The Carriage Assembly is driven by the Servo Motor. The speed of the

Carriage Assembly is controlled by varying the duty cycle of the signal

applied to the controller. The microprocessor checks the position of the

Carriage Assembly approximately 1,000 times per second (during the

servo interrupt). It then updates the PWM (pulse width modulator)

register in the gate array which sets the duty cycle to make adjustments to the Carriage Assembly speed. A linear optical encoder is used

to monitor the Carriage Assembly position.

The optical encoder strip runs the length of the Stabilizer Bracket and

contains 150 lines and spaces per inch. Thus there are 300 edges per

inch. The detector circuit actually consists of two optical edge detectors.

They are separated from each other by one half the width of one of the

optical lines on the encoder strip. This allows 4 evenly spaced pulses to

be developed for each line on the encoder strip. This is known as quadrature signals. It gives an effective resolution of 600 lines per inch. See

figure 2-9 for a graphical representation of quadrature signals. For 300

dpi resolution, one of the detectors is not used.

2-12 Theory of Operation

Page 37

NovaJet 500/630/700 Series Service Manual

DETECTOR 2

DETECTOR 1

ENCODER STRIP

OUTPUT OF DETECTOR 1

OUTPUT OF DETECTOR 2

COMPOSITE TRANSITION-TRIGGERED OUTPUT OF BOTH DETECTORS

OPERATION

THEORY OF

4 OUTPUT PULSES

PER OPTICAL LINE

Figure 2-9. Quadrature Signal Generation.

The direction that the Carriage Assembly is moving is known based

upon the state of one detector’s output and the direction of the transition

of the other detector’s output.

A hardware counter in the gate array increments as the Carriage

Assembly moves left and decrements as the Carriage Assembly moves

right. The hardware counter is only eight bits wide, so it cannot store a

value large enough to represent an absolute Carriage Assembly position.

Instead, it is read during the servo interrupt and its value compared

with that from the previous interrupt. This difference is used to update

the absolute position value in the software.

Theory of Operation 2-13

Page 38

NovaJet 500/630/700 Series Service Manual

Interface Circuits: Serial & Parallel

SERIAL

CONNECTOR

TRANSCEIVER

MICRO-

PROCESSOR

GATE

ARRAY

PARALLEL

CONNECTOR

Figure 2-10. Interface Circuits.

Data from the host computer is received either through the Centronics

parallel port or the serial port. The gate array provides the control

signals for DMA transfers from the parallel port to DRAM.

The serial port is designed primarily to interface to a Macintosh®

computer. It has an eight pin Mini-DIN connector. The data (TXD,

RXD) signals meet RS-422 electrical specifications, and the control

signal (DTRCLK) meets the RS-423 electrical specifications.

Due to the data flow speed limitations of using the serial interface with

a Macintosh computer system ENCAD does not recommend using this

port for production usage with the new printers. Hesitation may result

if using this port and that can degrade the quality of the output print.

Possible solutions for the Macintosh computer user include using a

print server device with an established network or installing a parallel

port add-on card in the computer to interface with the printer.

The serial port is still required to download new firmware to the printer

with a Macintosh computer.

The serial port is compatible with RS-422 devices when an appropriate

adapter cable is used. This cable is available from ENCAD.

The NovaJet 750 printer ships with a high speed print server that

attaches to the parallal port for network compatibility.

2-14 Theory of Operation

Page 39

NovaJet 500/630/700 Series Service Manual

Carriage Assembly Circuits

OPTICAL ENCODER

TRAILING

CABLE

CONNECTION

FROM

MPWA

TRAILING

CABLE

CARRIAGE

PWA

INKJET

DRIVERS

CARRIAGE ASSEMBLY

Figure 2-11. Carriage Assembly Circuits.

The Carriage Assembly contains:

1) Carriage PWA

2) Optical Sensors

3) Paper Sensor

4) Inkjet Cartridges

OPTICAL SENSOR

PAPER SENSOR

CARTRIDGE 1

CARTRIDGE 2

CARTRIDGE 3

CARTRIDGE 4

OPERATION

THEORY OF

The Carriage PWA contains the logic and drive circuitry for the firing of

the inkjet cartridges. It also establishes an interface path for the optical

sensor and paper sensor to communicate with the MPWA.

The optical sensors receive their inputs from the optical encoder strip

and sends this data to the MPWA. The MPWA uses this information to

determine the horizontal position of the carriage assembly so that

accurate printing can be established.

Theory of Operation 2-15

Page 40

NovaJet 500/630/700 Series Service Manual

The paper sensor circuitry senses for the presence of loaded media. It

does this automatically during the start-up and load sequences. It also

constantly monitors the media during printing to determine if the

media has run out.

If no paper is sensed, the paper sensor sends this information to the

MPWA, which immediately begins an ‘out of paper’ subroutine. This

subroutine stops the printer from printing until more media is loaded.

The sensor also checks for the size of the media loaded so it can determine the proper printing parameters.

Control Panel

The Control Panel is located on the right side of the printer and consists

of 8 variable-action control buttons and an LCD graphics display. The

control buttons are assigned to different functions and are dependant

upon the selections that were previously selected. There are four buttons

on the left of the display and four buttons on the right, with the display

showing up to eight possible selections.

Load Media

Cut

Pause

Reset

Figure 2-12 shows the control panel after the printer has been turned on

and completed the start up process. As seen in the figure, the control

buttons are assigned to the corresponding command that is displayed

closest to the physical location of the button.

2-16 Theory of Operation

Feed Media Menu

*

Setup Menu

Figure 2-12. Main Menu.

Utility Menu

Page 41

Power Supply

An internal UL recognized switching power module supplies power for

the NovaJet 500/630/700 Series printers. It provides a constant

24VDC output from input voltage in the 90-132 VAC and 180-246 VAC

ranges. A power switch turns the power on and off. The 24VDC is

applied to the MPWA where it is further regulated and separated into

24VDC, 13VDC, and 5VDC. The 24V supply is used for: the stepper

controller (which advances the paper); the servo controller (which

moves the Carriage); and power to fire the inkjets. The 5V supply

powers the logic circuits.

The power supply is fused using a 6.3A 250V fast blow type fuse.

The outputs share a common ground which is isolated from earth

ground with in the supply itself. Earth ground and DC ground are

connected external of the power supply.

The power supply will shut down under overload/short circuit conditions on any output over the full range of input voltage. Overvoltage

protection is 20%-30% above nominal for the 24V output.

NovaJet 500/630/700 Series Service Manual

OPERATION

THEORY OF

Beeper and Fans

The beeper contains built-in driver circuitry so that it beeps under

firmware control. The beeper alerts the user to error conditions.

There exists three types of fans that can be on the NovaJet 500/630/

700 series printers.

A single fan, located behind (below for the NovaJet 750) the power

supply, is used for cooling the power supply. Air blows over the power

supply and the heated air is forced out of the printer.

A fan is located inside the platen with its fan vent seen from under

the platen on the right side of the printer. This fan provides suction

on the platen bed and holds the paper (media) flat during the printing

process. The 60 inch model has an additional suction fan located near

the center of the printer inside the platen.

Theory of Operation 2-17

Page 42

NovaJet 500/630/700 Series Service Manual

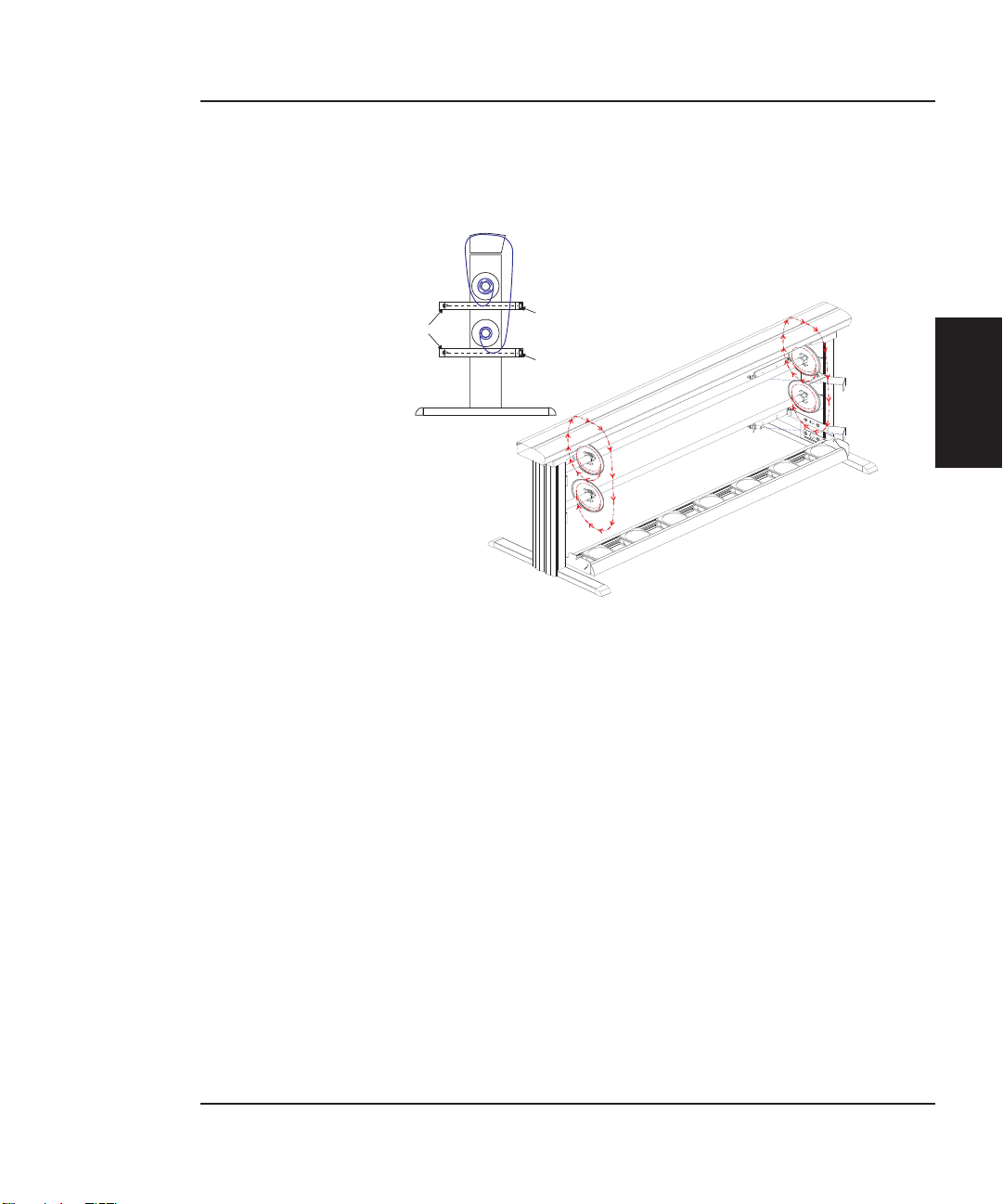

On the NovaJet 500/505/630/700 printers a media drying fan assembly

is attached to the lower part of the printer legs that is used to speed up

the drying time of the ink that is deposited onto the media. This is to

ensure that the ink is completely dry before the media is rolled onto the

take-up reel. The 42 inch model has five drying fans, while the 60 inch

version has seven.

The drying fan assembly has been designed to keep power consumption

down to a minimum by only activating the amount of fans that are

required to dry the size of media that is loaded on the printer.

The fans will not actually engage until a print command is first established. This commmand can be from a sent print job or any onboard

commands that require printing to complete that function. The fans

will automatically shutdown approximately 20 minutes after the print

is complete.

The drying assembly can also be disabled through the printers firmware

via the control panel.

This drying fan assembly is part of the mechanical take-up system that

is optional on the NovaJet 500 and 630 series printers.

On the NovaJet 750 printers a thermal media drying assembly is used

instead of the fan assembly as on the other models. It accepts control

commands from the MPWA that turns the heating elements on and off.

It also has two fans located underneath the plenum to push the heated/

unheated air out of the holes facing the platen to dry the media. The

drying assembly can be operated with or without the heating elements

being turned on.

2-18 Theory of Operation

Page 43

Maintenance

Introduction

This chapter contains general maintenance and cleaning instructions

for the NovaJet 500/630/700 printers.

Scheduled Maintenance

Scheduled maintenance consists of a list of checks that are planned to

be performed on a regular basis or when conditions warrant it.

3

Scheduled maintenance can be thought of as preventive maintenance

since its purpose is to prolong the life of the printer. It is not intended

to repair or isolate an existing problem, though it can sometimes be

helpful in detecting a condition due to a weakened component that has

not yet completely failed.

Below is a list of scheduled maintenance checks and their recommended periodicity.

Clean external areas: as required

Clean service station: 20-30 plot hours

Clean cartridge jet area & dimples: 50-60 plot hours

Clean slide shaft: 75-100 plot hours

Clean encoder strip: 75-100 plot hours

Clean flex cable contacts: 75-100 plot hours

Clean Y-Arm surface: 75-100 plot hours

Clean cutter groove: 75-100 plot hours

Clean pinch/lower roller: 75-100 plot hours

Clean platen vacuum holes: 100-125 plot hours

Clean dryer plenum (body) - NJ 750 only: 100-125 plot hours

Clean paper sensor: as required

Clean and inspect motor gears: annually

Clean and inspect MPWA: annually

Clean and inspect carriage assembly: annually

Reseat connectors on MPWA: annually

Reseat connectors on carriage board: annually

Replace carriage bushings: 3000 plot hours

MAINTENANCE

3-1

Page 44

NovaJet 500/630/700 Series Service Manual

Cleaning Procedures

Always turn the printer OFF, remove the power cord and

the interface cable before cleaning the printer. An electrical shock hazard may be present if these procedures are

not followed.

External Cleaning

Do not use abrasive cleansers of any sort on the surfaces

of the printer. Damage to the surface may result.

WARNING

CAUTION

The exterior surfaces of the printer may be cleaned with a soft cloth

which has been dampened. For more persistent stains, a small amount

of liquid detergent or NovaKlean™ may be used. Cleaning intervals are

determined by the environment in which the printer is used.

Service Station Cleaning

Ink and dust may build up on the service station, resulting in contamination which may smear the prints. The service station is cleaned as

follows:

1. Turn the printer OFF. Disconnect the power cord and interface

2. Raise the printer lid.

3. Carefully move the carriage toward the center of the printer.

3-2 Maintenance

cable.

Page 45

NovaJet 500/630/700 Series Service Manual

4. Using a cotton swab dampened with water, wipe the seals and

the rubber wiper in the service station until no more ink

residue or dust can be removed.

5. With a dry swab, wipe all moisture from the seals and wipers.

6. Close the lid and reconnect the power cord and interface cable.

7. If the service station is filling with ink or very dirty it can be

removed and rinsed under warm water. To remove, pull the

tab on the right side of the service station and lift out. Wash,

dry thoroughly and replace by placing the left side in first then

pushing down on the right side until the tab locks it in place.

Slide Shaft Cleaning

CAUTION

Use only NovaKlean™ or isopropyl alcohol on the slide

shaft of the printer. Damage to the stainless steel slide

shaft may result if cleaned with water and not completely

dried off.

Printer problems can be caused by an accumulation of dirt or other

contamination on the slide shaft. This contamination may lead to drag

on the carriage. Extreme drag results in a “carriage axis failure” fault

and will stop the carriage motion. These problems may be eliminated

by maintaining and cleaning the slide shaft at intervals determined by

the environmental conditions. Do not use any lubrication.

To clean the slide shaft:

1. Turn the printer OFF. Disconnect the power cord and

interface cable.

2. Raise the printer lid.

MAINTENANCE

3. Moisten a clean cloth or paper wipe with NovaKlean™.

Maintenance 3-3

Page 46

NovaJet 500/630/700 Series Service Manual

4. Wipe the length of the slide shaft with the moistened cloth or

wipe.

5. Manually move the carriage assembly from side to side.

6. Wipe the shaft again to remove any deposits left from the

carriage.

7. Close the cover and reconnect the power cord and interface

cable, turn the printer ON and perform the PRIME procedure.

Be sure that the carriage moves freely on the slide shaft.

Linear Encoder Strip Cleaning

Clean the linear encoder strip every 75 - 100 plot hours (every 50 plot

hours if GO ink is being used) or as necessary to remove any buildup of

debris. NovaKlean™ followed by isopropyl alcohol should be used. You

may notice that it tends to fog the encoder strip; however, no detrimental effect has been observed in the field.

To clean the Encoder Strip:

1. Disconnect the power cord and interface cable.

2. Slightly dampen a cotton swab with NovaKlean™ and wipe

3. Slightly dampen a cotton swab with isopropyl alcohol and wipe

4. Reconnect the power cord and interface cable.

3-4 Maintenance

along the length of the encoder strip on both sides.

along the length of the encoder strip on both sides. This is

necessary to remove any possible residue that may have been

left from the NovaKlean™ solution.

Page 47

ENCODER STRIP

NovaJet 500/630/700 Series Service Manual

COTTON SWAB

Figure 3-1. Encoder Strip Cleaning.

Cartridge Jet Area & Dimples Cleaning

CARTRIDGE

DIMPLE

AREA

MAINTENANCE

Figure 3-2. Cartridge Dimple Region.

Maintenance 3-5

Page 48

NovaJet 500/630/700 Series Service Manual

The cartridge dimple area can easily be contaminated by oils and dirt on

fingers and hands or ink spilled onto them. This causes the cartridges

to not receive some of the electrical signals for a proper firing of the jets.

This can be seen as a misfiring of the cartridge.