Page 1

Page 2

Safety

User Precautions

• Place the scanner on a sturdy, level work surface capable of supporting 50.8 kg (112 lbs) and leave adequate clearance on

all sides of the scanner.

• When relocating the scanner, it is recommended that two people lift the scanner and use safe lifting techniques.

• Do not install the scanner in a location subject to dust, humidity or steam. This may cause electrical shock or a fire. Only use

the scanner indoors in a dry location.

• Make sure the electrical power outlet is located within 1.52 meters (5 feet) of the scanner and is easily accessible.

• When disconnecting equipment from the electric socket, be sure to grasp the plug, not the cord.

• Be sure the power cord is securely plugged into the wall outlet. Failure to do so may cause electrical shock or fire.

• Do not damage, knot, cut or modify the power cord or use a damaged power cord. This may cause electrical shock or fire.

• The scanner requires a dedicated and properly grounded power outlet. Do not use an extension cord or power strip with the

scanner.

• Do not leave the power cord plugged into the AC outlet if the scanner is not used for an extended period of time.

• Leave sufficient space around the power outlet so it can be easily unplugged in case of an emergency.

• Do not use the scanner if it becomes inordinately hot, has a strange odor, emits smoke, or makes unfamiliar noises.

Immediately stop the scanner and disconnect the power cord from the power outlet. Contact Kodak Service.

• Do not disassemble, service or modify the scanner except as explained in the User’s Guide.

• Do not move the scanner with the power cord and interface cable attached. This may cause damage to the cord/cable.

Remove the power cord from the wall outlet before moving or relocating the sca nner.

• Follow the Kodak recommended cleaning procedures. Do not use air, liquid or gas spray cleaners. These cleaners displace

dust, dirt and debris to other locations within the scanner, which may cause the scanner to malfunction.

• Material Safety Data Sheets (MSDS) for chemical products are available on the Kodak website at: www .kodak.com/go/msds.

When accessing the MSDSs from the website, you will be required to provide the catalog number of the consumable you

want the Material Safety Data Sheet for. See the section entitled, “Supplies and consumables” later in this guide for supplies

and catalog numbers.

Users and their employers need to observe the common sense precautions applicable to the operation of any machinery. These

include, but are not limited to, the following:

• Do not wear loose clothing, unbuttoned sleeves, neckties, etc.

• Do not wear loose jewelry, bracelets, bulky rings, long necklaces, etc.

• Hair length should be kept short, using a hair net if needed, or tying long hair up in a bundle.

• Remove all other loose objects from the area that could be drawn into the machine.

• Take sufficient breaks to maintain mental alertness.

• Use only the recommended cleaning supplies.

• Do not use canned/compressed air.

Supervisors should review their employee practices and make compliance with these precautions a part of the job description

for operation of the scanner or any mechanical device.

Page 3

Environmental information

•The Kodak Ngenutiy Scanners are designed to meet world wide environmental requirements.

• Guidelines are available for the disposal of consumable items that are replaced during maintenance or service; follow local

regulations or contact Kodak locally for more information.

• The product packaging is recyclable.

• Kodak Ngenutiy Scanners are Energy Star compliant and shipped from the factory with the default time set to 15 minutes.

European Union

This symbol indicates that when the last user wishes to discard this product, it must be sent to appropriate

facilities for recovery and recycling. Please contact your local Kodak representative or refer to www.kodak.com/

go/recycle for additional information on the collection and recovery programs available for this product.

Please consult www.kodak.com/go/REACH for information about the presence of substances included on the candidate list

according to article 59(1) of Regulation (EC) No. 1907/2006 (REACH).

Acoustic emission

Maschinenlärminformationsverordnung – 3, GSGV

Der arbeitsplatzbezogene Emissionswert beträgt <70 dB(A).

[Machine Noise Information Ordinance — 3, GSGV

The operator-position noise emission value is <70 dB(A).]

EMC statements

United States

This equipment has been tested and found to comply with the limits for a Class A digital device pursuant to Part 15 of the FCC

rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated

in a commercial environment. This equipment generates, uses, and can radiate radio frequently energy and, if not installed and

used in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be required to correct the

interference at their own expense.

Japan

This is a Class A product based on the standard of the Voluntary Control Council for interference by information Technology

Equipment (VCCI). If this equipment is used in a domestic environment, radio disturbance may arise. When such trouble

occurs, the user may be required to take corrective action.

Taiwan

WARNING: This is a Class A product. In a domestic environment this product may cause radio interference in which case the

user may be required to take adequate measures.

Page 4

Peoples Republic of China

WARNING: This is a Class A product. In a domestic environment this product may cause radio interference in which case the

user may be required to take adequate measures.

Korea

Please note that this equipment has obtained EMC registration for commercial use. In the event that it has been mistakenly sold

or purchased, please exchange it for equipment certified for home use.

European Union

WARNING: This is a Class A product. In a domestic environment this product may cause radio interference in which case the

user may be required to take adequate measures.

Page 5

OVERVIEW 1-1

INSTALLATION 2-1

CONTROL PANEL AND NGENUITY OPERATOR UTILITY 3-1

ADVANCED FEATURES 4-1

MAINTENANCE 5-1

TROUBLESHOOTING 6-1

APPENDICES A-C

Page 6

1 Overview

Contents Supporting documentation..............................................................1-1

Optional accessories.......................................................................1-2

What’s in the box ...........................................................................1-2

Scanner components......................................................................1-3

Front view...................................................................................1-3

Rear view....................................................................................1-7

Kodak Ngenuity 9000 Series

Scanners offer optimal image quality

and scans a wider range of

documents than any other scanner in

its class. With an easy-to-use

operator interface and smart front

panel functionality, Ngenuity

Scanners are user-friendly and ideal

for companies in industries such as

health care, financial services,

insurance, government, transportation and service bureaus.

Supporting

documentation

These models are available:

• Kodak Ngenuity 9090DC Scanner — duplex scanner that scans 90

pages per minute in color, grayscale or black and white in landscape

mode.

• Kodak Ngenuity 9090DB Scanner — duplex scanner that scans 90

pages per minute in black and white in landscape mode.

• Kodak Ngenuity 9125 Scanner — duplex scanner that scans 125

pages per minute in color, grayscale or black and white in landscape

mode.

• Kodak Ngenuity 9150 Scanner — duplex scanner that scans 150

pages per minute in color, grayscale or black and white in landscape

mode.

This User’s Guide provides information and procedures for using and

maintaining the Kodak Ngenuity 9000 Series Scanner. The information

in this guide is for use with all models unless otherwise noted.

The following documentation is available in support of the Kodak

Ngenuity Series Scanners:

• User’s Guide

• Installation Guide

• Quick Maintenance Reference Guide

A-61662 April 2010 1-1

Page 7

Optional accessories Front/Rear Printer Kit — front (pre-scan) and rear (post-scan)

imprinting prints the user-specified alphanumeric string on the front/

back side of documents when they are scanned, with the printed results

also reflected on the scanned images. CAT No. 863 4230

What’s in the box • Kodak Ngenuity 9090DC, 9090DB, 9125 or 9150 Scanner

• 10-foot power cord and USB cable

• Camera calibration kit

• Starter cleaning kit

• Kodak Ngenuity Series Scanners brochure

• Installation CD which includes:

-VRS Software

- VRS User Manual and Release notes

- Ngenuity Operator Utility (NOU)

- ISIS/TWAIN Drivers

- USB drivers

- Kodak Ngenuity User’s Guide

- Kodak Ngenuity Installation Guide

- Kodak Ngenuity Quick Maintenance Reference Guide

1-2 A-61662 April 2010

Page 8

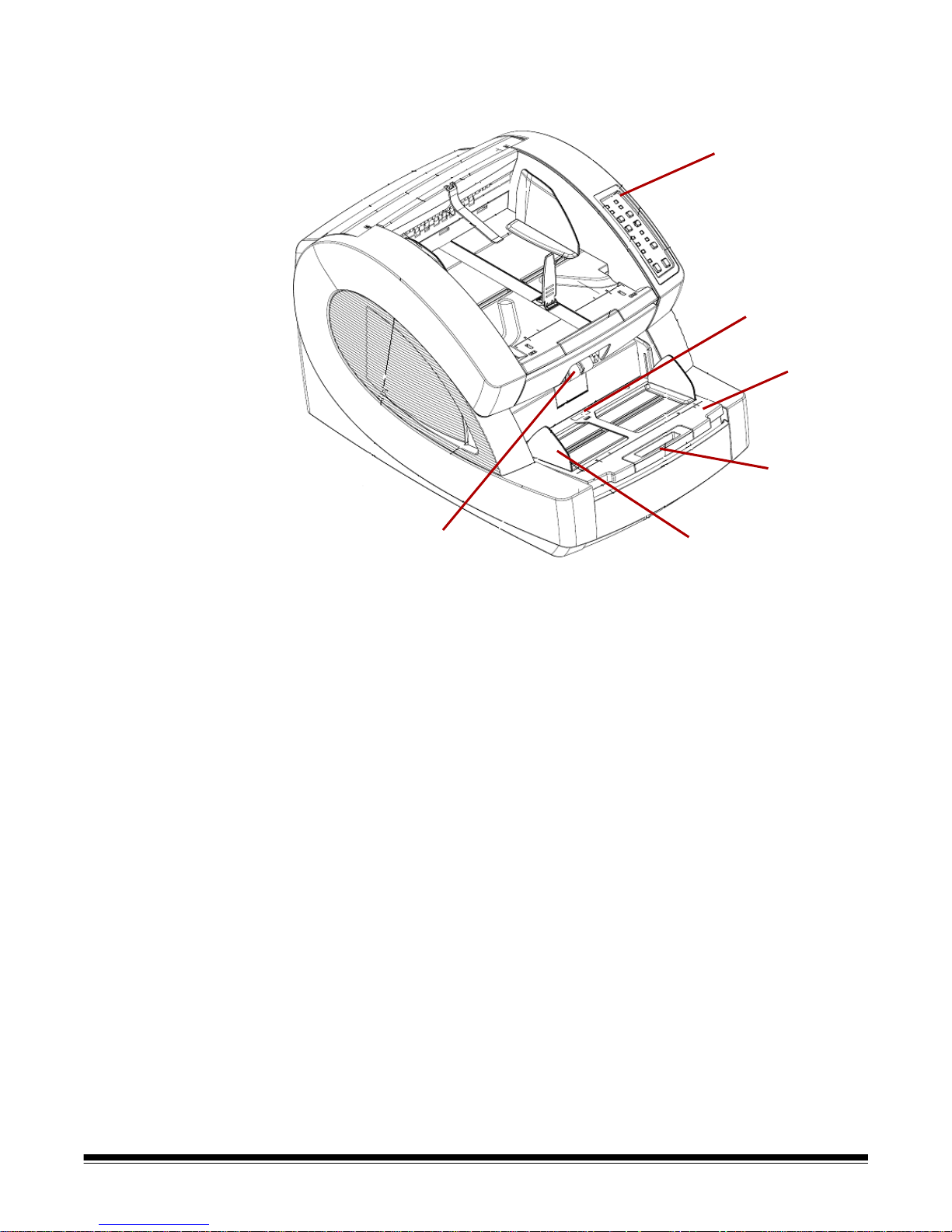

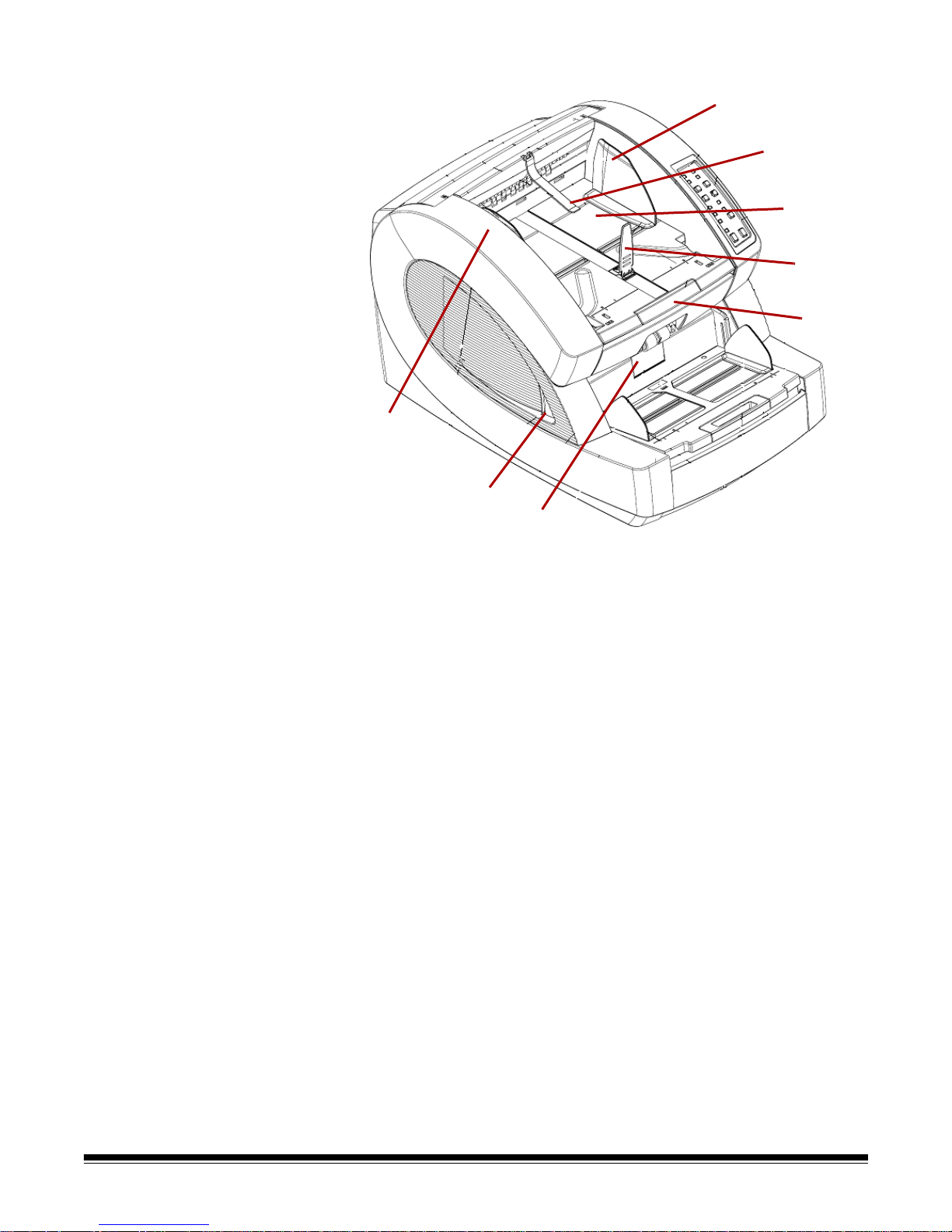

Scanner components

1

2

3

4

5

6

Front view

1 Control Panel — allows you to initiate scanner functions directly

from the scanner.

2 Cork pad — assists in preventing multifeeds by making it easier

for the skimmer rollers to grab one document at a time.

3 Feeder table — place the document s to be scanned on the feeder

table. It can be raised and lowered using the feeder table buttons

on the control panel.

4 Feeder table extender — provides a support for longer

documents that extend beyond the standard length. The extender

can be pulled out to add approximately 7 inches (18 cm) to the

feeder table.

5 Document feed guides — used to guide document(s) into the

scanner’s transport. They can be width-adjusted independently,

which allows for left-, right-, or center-feeding of documents.

6 Skimmer module — contains two rollers that assist in grabbing

and feeding documents into the scanner transport. The skimmer

assembly can be placed in an up position for manual feeding or a

down position for automatic document feeding.

A-61662 April 2010 1-3

Page 9

7 Separator roller door — allows access to the separator roller . The

7

8

9

10

11

12

13

14

separator roller assists in separating documents as they feed into

the transport.

8 Transport cover release lever — there is a transport cover

release lever on each side of the scanner. Pull one or both levers

towards you while standing in the front of the scanner to release

and open the transport cover.

9 Transport co ver — opens in an upward position and will stay open

in a full-up position with the support of two gas springs that are

located inside the scanner.

10 Document output guides — used to guide the scanned

document(s) into a neat stack on the exit tray. They can be widthadjusted independently for left-, right- or center-document

alignment.

11 Exit deflector — assists in the placement of document s in the exit

tray.

1-4 A-61662 April 2010

Page 10

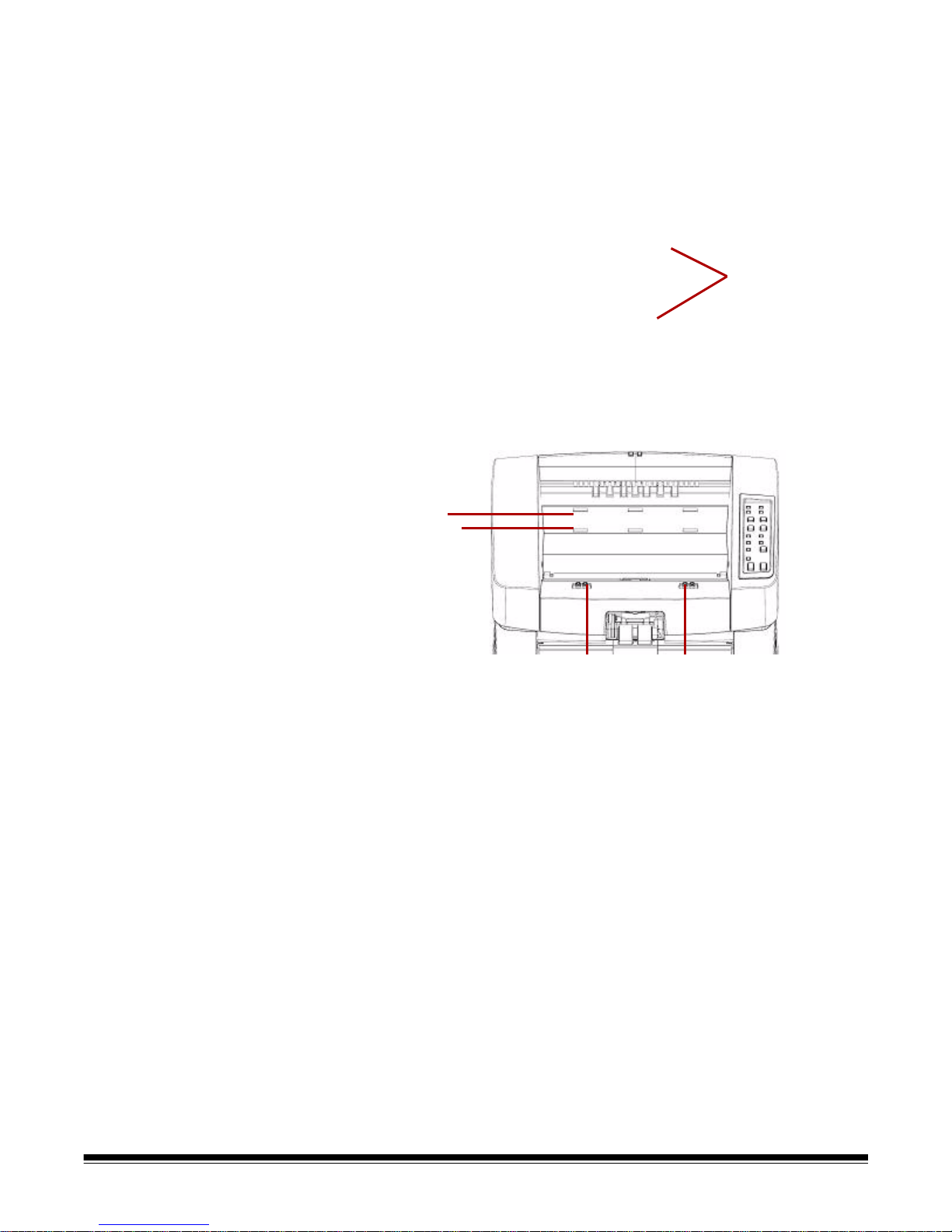

12 Exit tray — where document(s) are deposited after they have

Tabs

Back of exit tray

Top/Front view of scanner - exit tray removed

Top row

Bottom row

Slots-

(slide into

slots)

Stops for bracing

kickstand wire

passed through the transport. There are two sets of slots that are

used for exit tray positioning depending on the types of document s

being scanned.

These positions are available:

- Flat: exit tray rests on top of the scanner in a flat, horizontal

position, with the tabs on the back of the tray hinged into the

bottom row of slots.

- Tilted Forward: tabs at the back of the exit tray are in the top

slots causing the exit tray to tilt in a downward position. This

position aids stacking of long documents in the exit tray.

- Tilted Backward: tabs at the back of the tray are in the bottom

row of slots. Pull the kickstand wire on the bottom of the exit tray

down and out. Snap the kickstand wire in the slots of the

scanner cover. This is useful when scanning small documents.

NOTE:If you have an optional imprinter, there is a door underneath

the exit tray that allows access to the front page imprinter.

A-61662 April 2010 1-5

Page 11

13 Document stop guide — adjust this guide to match the length of

13

14

the documents being scanned, which aids in neat document

stacking. Slide the document stop guide toward you to lengthen the

distance or slide it away from you to shorten the distance.

The document stop guide should be folded down when scanning

extra long documents that require the use of the exit tray extender.

NOTE:Positioning the document stop guide too close to the back of

the exit tray (towards the back of the scanner) can cause

documents to jam as they exit the scanner.

14 Exit tray extender — pull the extender out when scanning longer

documents.

A second document stop guide is located on the end of the exit tray

extender when scanning extra long documents. When not in use,

fold the extender down.

1-6 A-61662 April 2010

Page 12

Rear view

1

2

3

4

5

6

7

8

9

1 Imprinter door — provides access to the optional imprinter for

installation and maintenance. It requires an additional 3.5 inches

(9 cm) of clearance to open fully.

2 Straight pass-through door — allows you to use the straight

pass-through feature. When the door is open, documents are fed

through this exit. This is useful for scanning thick or stiff

documents. It requires an additional 3.5 inches (9 cm) of clearance

to open fully. Only open this door when you are using the straight

pass-through feature, if the door is opened while scanning in rotary

mode, a document jam will occur.

3 SCSI connector — connects an optional SCSI cable (cable and

SCSI card are not provided).

4 USB connector — connects the USB cable to the scanner and

host PC.

5 Fan — for cooling the scanner. The fan is part of the scanner’s

power supply. Make sure to properly vent the scanner for optimal

performance.

6 Power connector — connects the power supply to the scanner.

7 Power switch — turns the scanner on (I) and off (O).

8 Foot — four rubber feet allow for clearance below the scanner.

9 Intake vent (on side) — used for drawing air in for cooling. Be sure

to position the scanner in such a way that the intake vent is not

blocked.

A-61662 April 2010 1-7

NOTE: Be sure to maintain an addition 4-5 inches (10-13 cm) of

additional clearance at the front, back and sides of the scanner

for proper ventilation.

Page 13

2 Installation

Contents Installation: with a USB connection ................................................2-1

Installation: with an optional SCSI connection................................2-2

This chapter provides installation instructions for the Kodak Ngenuity

9000 Series Scanners. Instructions for a USB connection and an

optional SCSI connection follow.

Installation: with a

USB connection

1. Verify that your host PC meets the system requirements as

specified in Appendix A, Specifications.

2. Unpack the scanner.

NOTE: The scanner weighs approximately 112 pounds (50.8 kg).

Be sure to incorporate the appropriate manpower before

moving or lifting the scanner.

3. Without the scanner attached, turn on the host PC.

4. Load the Installation CD into the CD-ROM drive and install the

software in the following order: Ngenuity VRS software first, then

the Ngenuity Operator Utility (NOU). Do not reboot the host PC

after installing each software application.

NOTE: For the latest drivers, go to www.Kodak.com/go/scanners.

5. Power down the host PC.

6. Attach the host PC to the scanner using the supplied USB cable.

NOTE: If you are using the optional SCSI connection, refer to the

next section for installation instructions before proceeding.

7. Turn on the scanner. After the initialization sequence has finished,

turn on the host PC.

A-61662 April 2010 2-1

NOTE: If you are prompted to check for VRS updates, select No.

8. Complete the “Found New Hardware” wizard (twice) to install the

USB drivers.

9. Launch the Ngenuity Operator Utility (NOU) by double-clicking the

NOU icon found on the desktop of the host PC.

10.Confirm the Ngenuity Operator Utility is communicating with the

scanner and all the self tests have passed.

The installation is complete. You are now ready to scan. Refer to the

instructions for your scanning application or document management

software.

Page 14

Installation: with an

optional SCSI

connection

The Kodak Ngenuity Scanner is equipped to accommodate a SCSI

connection for communication between the scanner and host PC. The

optional SCSI connection can be used in lieu of the standard USB

connection.

To use a SCSI connection, a SCSI card and cable is required. Kodak

does not provide a SCSI card or cable with the Ngenuity Scanner;

therefore, these items must be purchased separately. A SCSI

connection kit is not available through Kodak; however, Kodak has

certified that Adaptec’s 29160 LP or regular profile card is compatible

with Ngenuity Scanners. The SCSI cable must be a D68-pin SCSI-3

cable.

1. Verify that your host PC meets the system requirements as

specified in Appendix A, Specifications.

2. Unpack the scanner.

NOTE: The scanner weighs approximately 112 pounds (50.8 kg).

Be sure to incorporate the appropriate manpower before

moving or lifting the scanner.

3. Without the scanner attached, turn on the host PC.

4. Load the Installation CD into the CD-ROM drive and install the

software in the following order: Ngenuity VRS software first, then

the Ngenuity Operator Utility (NOU). Do not reboot the host PC

after installing each software application.

NOTE: For the latest drivers, go to www.Kodak.com/go/scanners.

5. Power down the host PC and remove the power cord.

6. Install the SCSI card (Adaptec 29160) in the host PC. See the

instructions that are included with the SCSI card.

7. Connect the host PC to the scanner.

8. Connect power to the scanner and reconnect power to the host PC.

9. Turn the scanner on and wait for the initialization sequence to

complete.

10. Turn on the host PC.

11. Follow the prompts within the New Hardware Found wizard.

12.Launch the Ngenuity Operator Utility (NOU) by double-clicking the

NOU icon found on the desktop of the host PC.

2-2 A-61662 April 2010

Page 15

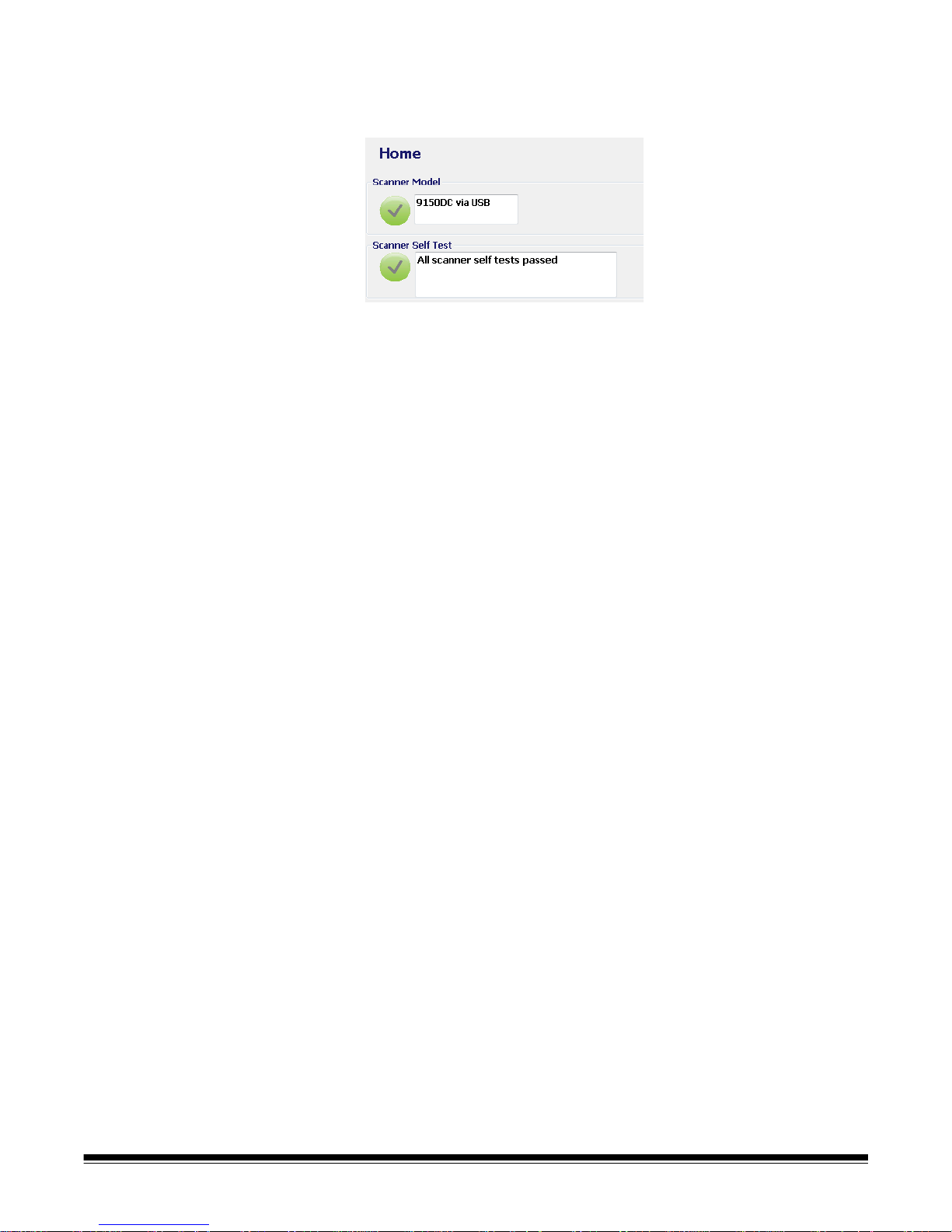

The Ngenuity Operator Utility Home Screen (default) will update

when the scanner self tests have passed and communication with

the scanner has been established.

NOTE: If the Ngenuity Operator Utility failed to connect with the

scanner, refer to Chapter 6, Troubleshooting for more

information.

A-61662 April 2010 2-3

Page 16

3 Control Panel and Ngenuity Operator Utility

Contents Control panel...................................................................................3-1

Status........................................................................................3-2

Feeder table..............................................................................3-5

Custom functions......................................................................3-5

Scan monitor.............................................................................3-5

Batch control.............................................................................3-7

Ngenuity Operator Utility.................................................................3-8

Ngenuity Operator Utility main screen............................................3-8

Menu bar...................................................................................3-9

Home screen ..........................................................................3-10

Settings button........................................................................3-12

Maintenance button................................................................3-14

Control panel The control panel is located on the front of the scanner. The LEDs and

audible tones notify you of the current state of the scanner (e.g., power

state, maintenance needed, active features, errors, etc.).

The control panel has five sections:

•Status

• Feeder table

• Custom functions

• Scan monitor

• Batch control

This chapter provides detailed information for control panel

functionality.

A-61662 April 2010 3-1

Page 17

Status The status area of the control panel consists of: Power Mode, Back

Door, Maintenance and Manual Feed.

Power Mode — this green LED indicates the power status or transition

between power modes.

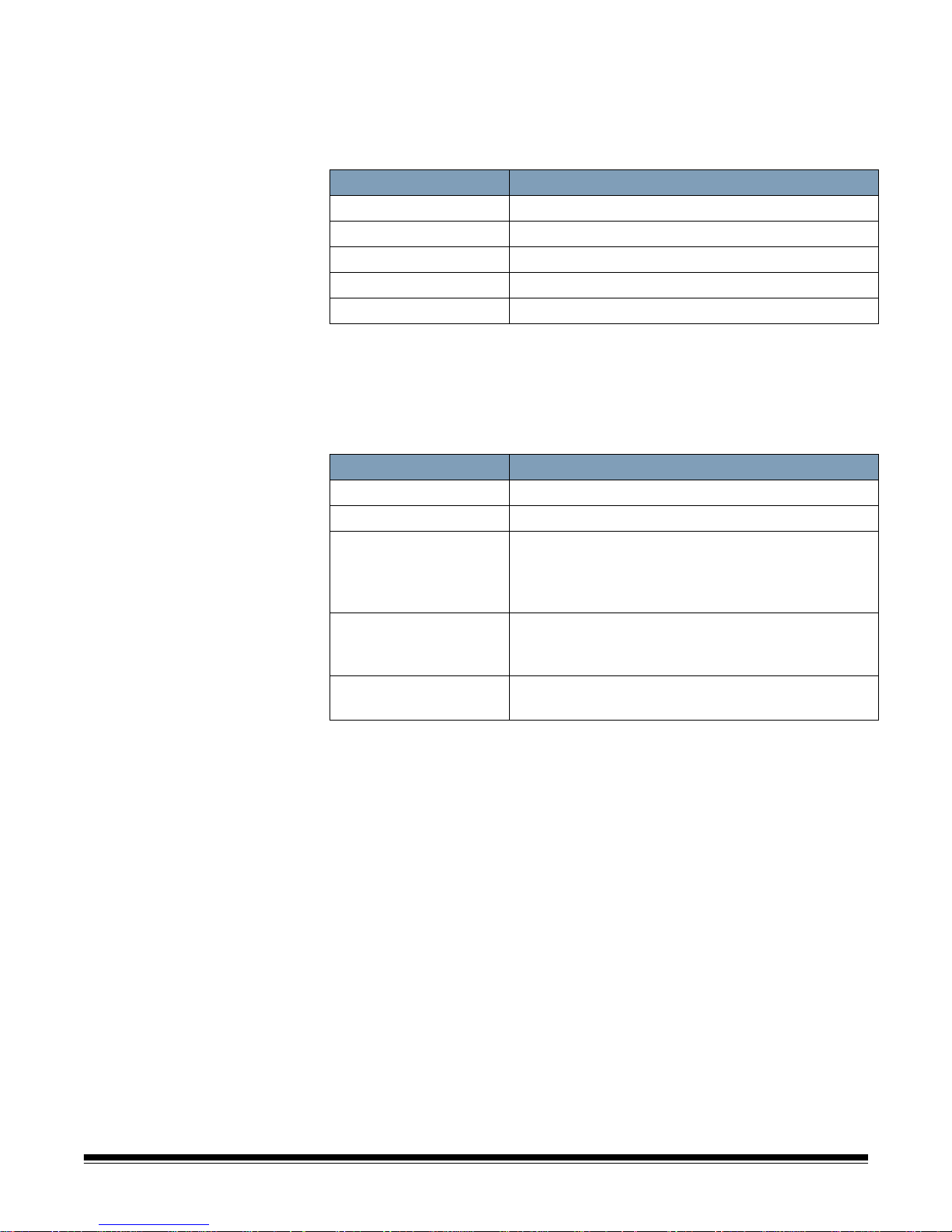

Power State/Transition Power Mode LED

Off Off

Sleep>Powered up Blinking, fast

Ready>Active Steady green

Ready>Sleep Blinking, fast

Sleep Blinking, slow

When the scanner is in sleep mode, the Power Mode LED is the only

indicator that is active; all others are off.

Depending on the current Power Mode, the buttons on the control panel

perform different actions. The following table identifies the function of

the buttons during various Power Modes and transitions.

Power State/Transition Power Mode LED

Off Control panel and scanner are not on.

Sleep>Ready Buttons are not active during this transition.

Ready>Active All buttons perform their normal functions. Press and

hold the Stop button for 5 seconds to start the

transition process to put the scanner into sleep

mode.

Ready>Sleep The scanner is almost ready to go into sleep mode. A

momentary press of any button resets the sleep

count-down timer.

Sleep A momentary press of any button starts the Sleep >

Awake transition to awaken the scanner.

Back Door — this green LED indicates if the straight pass-through

door (located at the back of the scanner) is open or closed.

• LED not lit: when the straight pass-through door is closed, the rotary

path to exit tray is in use.

• LED On: when the straight pass-through door is open, documents

being scanned will be exited through the straight pass-through door.

3-2 A-61662 April 2010

Page 18

Maintenance — this yellow LED indicates that maintenance or service

conditions exist in the scanner.

Maintenance LED Scanner state

Off (not lit) No maintenance is required at this time.

Slow blinking Maintenance is needed. See the section

entitled, “Ngenuity Operator Utility”

(Maintenance monitor) later in this chapter for

more information.

Fast blinking Scanner is busy or offline. This occurs when the

scanner is in off-line mode and not capabl e of

scanning (i.e., ADF test, camera calibration,

downloading firmware, imprinter cleaning, etc.).

Steady on Scanner self-test fault detected; scanner service

may be required. Use the Ngenuity Operator

Utility for more information on the self test

failure.

Manual Feed — this green LED indicates that the feed mode has been

changed from the default, Normal ADF (Automatic Document Feeder),

to Manual feed mode. When the LED is illuminated, the scanner is in

Manual feed mode.

Feed modes The Ngenuity Scanner has four feed modes for feeding documents into

the scanner’s transport:

ADF mode (default) — used for feeding batches of documents that are

similar in size and weight. After a batch of documents is placed on the

feeder table, the batch is fed automatically into the scanner’s transport.

Manual mode — this mode is used to feed exception documents that

cannot be fed in ADF mode (e.g.,multiple forms). In this mode, you

must feed documents manually into the scanner one at a time. When

scanning in Manual mode, the Manual Feed LED on the control panel

will be lit. See the next section, “Manually feeding documents” for more

information.

Assisted Manual mode — once the scanner has entered Manual

Feed mode, the skimmer can be lowered onto the feeder table to

enable Assisted Manual mode. In this mode, the paper sensor on the

feeder table will trigger the skimmer to pull the documents into the

scanner transport. This mode can also be used to automatically feed

small batches while the scanner is in Manual Feed mode.

Test Feed mode — used to test and verify the scanner’s feeding

capabilities, as well as to feed transport cleaning sheets. This mode

allows you to feed documents without generating a scan command

from the host PC.

A-61662 April 2010 3-3

Unlike ADF and Manual (Assisted) modes, the Test Feed mode button

is set from within Custom Functions in the Ngenuity Operator Utility.

NOTE: With the exception of the Test Feed mode, all feed modes are

set through the Advanced Properties window within the

scanning software application.

Page 19

Manually feeding

documents

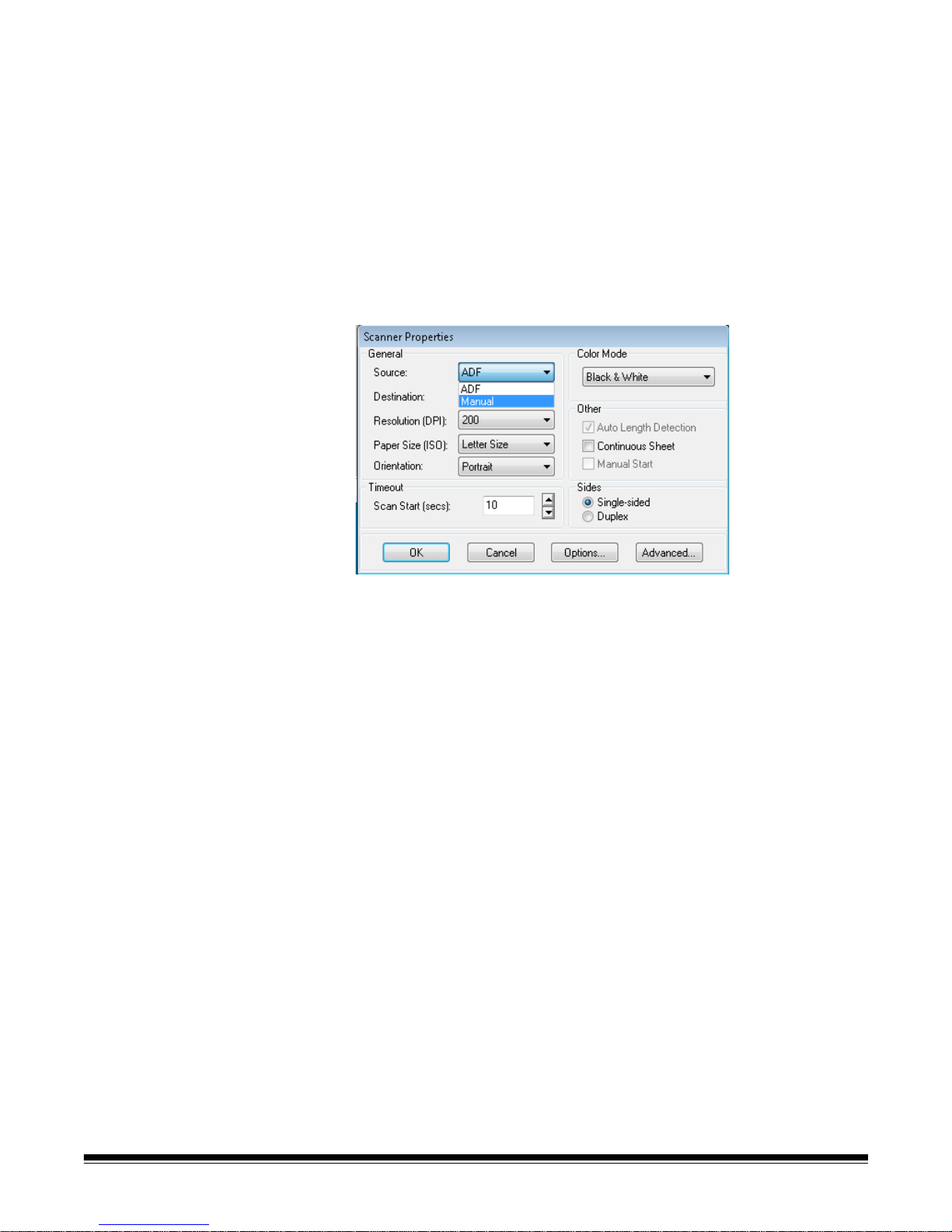

For demonstration purposes, VRS Test Application is used in the

following procedure.

1. Turn on the scanner and wait until the scanner is ready.

2. Lift the skimmer to the up position.

3. Turn on the host PC.

4. Launch the scanning application (in this example, VRS Test

Application) and from the Menu bar, select Source>Scanner

(Source = 9000 with VRS with AIPE).

5. When the scanner is connected, select Source>Properties to open

the scanning application’s Scanner Properties window.

6. Select Manual from the Source drop-down box.

7. Lift the skimmer.

8. Remove any paper from the feeder.

9. Start a scan, either single or batch. The table will move up, and the

Manual Feed LED will light. The scanner motor will start and beep

indicating it is ready for scanning.

10.Carefully insert the page, keeping your hands and fingers away from

the rotating rollers on the skimmer. The scanner will feed the page,

run it through the scanner and generate an image.

NOTE: If you selected batch scan, you can continue to insert

pages, one at a time.

11. When you are finished, press Stop.

3-4 A-61662 April 2010

Page 20

Feeder table The Feeder Table adjustment buttons allow you to manually set the

lowest position of the feeder table and lower the feeder. The feeder

table must be empty when you are selecting the Down/Set or Up

position.

Down/Set — positions the feeder table in the lowest position for ADF

mode.

Up — this button is used in conjunction with the Down button when the

feeder is empty, to set to the lowest point the feeder will drop to when

you are scanning and the feeder becomes empty.

If the feeder table has documents in it, the Up button performs no

function.

Custom functions Two custom functions (F1 and F2) can be assigned via the Ngenuity

Operator Utility. Available functions are: Feed Test Batch, Page Eject

and Clean Print Head.

By default, F1 is assigned to Feed Test Batch and F2 is assigned to

Page Eject. See the section entitled, “Ngenuity Operator Utility” later in

the chapter for more information.

Scan monitor The Scan Monitor indicates that an error has occurred during scanning.

The Scan Monitor indicators are lit in yellow.

Error — indicates that an error exists that is not covered by one of the

indicators (i.e., page sensor, error, scanner internal errors, etc.). When

an error is indicated, refer to the scanning application for more

information.

Cover — when illuminated, indicates that the scanner transpo rt cover is

open. Carefully close the scanner cover.

If this error occurs during scanning, press Clear/Restart after you have

securely closed the cover.

Paper Jam — when illuminated, indicates a document jam within the

scanner. Open the scanner transport cover, remove any jammed

documents and close the cover. Press Clear/Restart to continue

scanning.

Misfeed — when illuminated, indicates that a skimmer timeout or

feeder jam has occurred.

• Skimmer timeout: the skimmer is active, but the document to be

scanned does not move out of the feeder tray (commonly due to

roller slippage).

• Feeder jam: the document to be scanned is fed but does not reach

the scanner transport within the expected transit time.

A-61662 April 2010 3-5

Page 21

Multifeed and MF Ignore — when illuminated, indicates a multifed

document or warning. This indicator will momentarily light and remain lit

or blink depending on the multifeed condition. For example:

• If the multifeed mode is set to Stop, the indicator remains lit and the

scanner stops when a multifeed is detected.

• If the multifeed mode is set to Notify, the indicator will light

momentarily along with a sound or prompt for each multifeed that is

detected while scanning.

For more information, see Chapter 4, Advanced Features.

The MF Ignore button toggles the multifeed ignore feature on and off.

When it is on, the scanner will ignore the multifeed sensor during the

next page fed (one page only), and the Multifeed LED will blink.

By pressing the MF Ignore button during batch scanning, you can

preempt the impending multifeed alarm without forcing a batch stop.

This turns off the MF alarm detection for a single page starting with the

next leading edge seen by the page entry sensor. To turn off MF

detection for a series of documents, press and hold the MF Ignore

button.

3-6 A-61662 April 2010

Page 22

Batch Control The Batch Control buttons allow you to start and stop scanning.

Ready — this indicator is illuminated green when the scanner is ready

to scan.

• ADF mode: the Ready indicator will light when:

- there are no errors active

- documents are in the feeder

- the skimmer is lowered

- the feeder table has risen (or is rising) to where the skimmer is

resting on the documents in the feeder.

• Manual Feed mode: the scanner is ready to scan. The LED will

remain a steady green while the scanner is scanning.

Clear/Restart — allows you to clear an error when the error is reso lved

and resume scanning (e.g., paper is removed from the transport which

caused a paper jam).

When using VRS, use Clear/Restart to clear a multifeed (which tells

VRS to discard the multifeed image and rescan the document).

You can also use Clear/Restart to resume scanning after a batch

pause.

Pause/Stop — used to stop feeding or stop the scanner’s transport.

• If there is no scan command queued, no documents in the transport,

and no feeding in progress, pressing Pause/Stop stops the transport

before the automatic transport timeout (20 seconds).

• If the scanner is feeding documents, pressing Pause/Stop once will

stop feeding and a host “scanner paused” error will occur . The Ready

LED will blink to indicate when the batch is paused.

• If Pause/Stop is pressed twice or pushed and held for more than one

second, a hard stop will occur (scanning stops with documents

remaining in the transport) along with a host “scanner stopped” error

(this host error will not happen if the scanner is running in Test

mode). Press Clear/Restart to resume scanning (there is a slight

delay before scanning resumes).

NOTE:If Clear/Restart is pressed before all documents are cleared

from the transport, an audible alarm on the scanner will

sound and the Paper Jam LED will light. Clear the transport

of all documents by pressing and holding the Custom

Function button that is programmed for Page Eject and then

press Clear/Restart to resume scanning (there is a slight

delay before scanning resumes).

•Use Pause/Stop to place the scanner in Sleep mode by pressing and

holding the Pause/Stop for 5 seconds or longer. This can only be

done when the scanner is idle (no scan commands queued) and the

transport is not running.

A-61662 April 2010 3-7

Page 23

Ngenuity Operator

Utility

The Ngenuity Operator Utility (NOU) is the application that

communicates with the scanner to provide scanner status, configure

scanner settings, and to monitor and assist with performing routine

scanner maintenance.

Be sure your scanner is properly connected and the scanner and

host PC are on before accessing the Ngenuity Operator Utility.

• From the host PC’s desktop, double-click the Ngenuity Operator

Utility icon. The NOU will run through an initialization sequence.

When communication with the scanner is established, the scanner

and connection type will be displayed on the Home screen of the

NOU.

NOTE: The Ngenuity Operator Utility remains accessible, but not

functional after connectivity with the scanner has been

established and then the scanner is powered off or if the USB

cable is disconnected. Any changes made to existing settings

with the scanner powered off will not be present when the

scanner is turned on.

If the scanner is powered off and the NOU is closed, the

scanner must be turned on to reestablish connectivity to the

NOU.

Ngenuity Operator

Utility main screen

The Ngenuity Operator Utility main screen provides a menu bar and

options for configuring basic scanner parameters and tasks. The

sections that follow provide descriptions of the components on the

Home screen including the Menu bar, Home button, Settings button

and Maintenance button.

3-8 A-61662 April 2010

Page 24

Menu bar

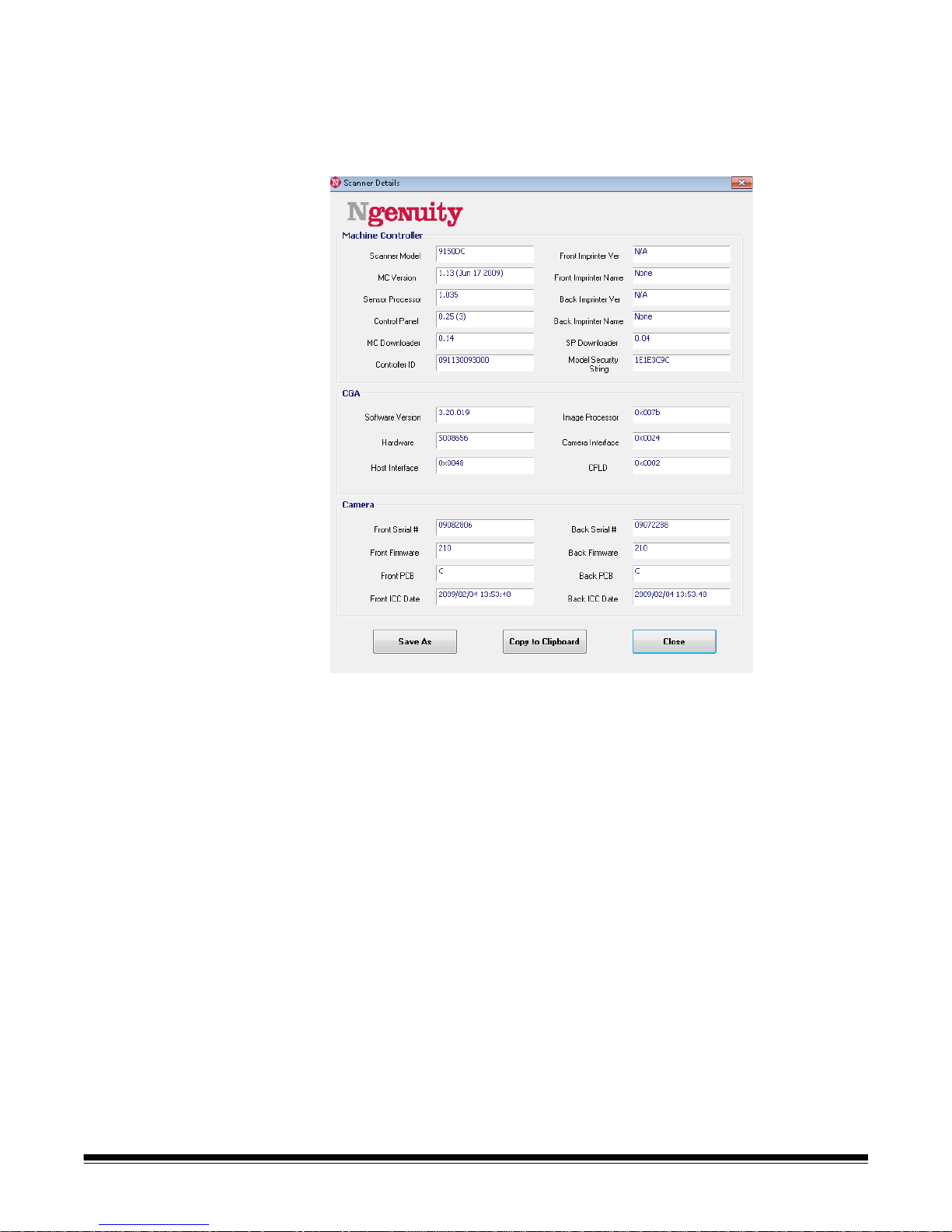

Scanner menu Details — displays a Scanner Details dialog box which contains version

information for scanner firmware components and camera information,

as well as scanner model identification.

• If you click Save As, the Save As dialog box will be displayed

allowing you to save this information on the host PC or a network (if

connected) as a text file (.txt).

• Copy to Clipboard allows you to copy the displayed information to

the Windows clipboard where you can paste it into another

application. This will allow you to save the file in another file format, if

desired. Copy to Clipboard is useful for sending the information via

E-mail for troubleshooting purposes.

• Click Close to close the Scanner Details dialog box.

Update Configuration — for Kodak use only.

Update Firmware — to maintain optimal scanner performance and

image quality, be sure the scanner is running with the most current

versions of software and firmware. Only software and firmware from

Kodak is certified to work with Ngenuity Scanners. Firmware updates

should only be performed when instructed by Kodak Technical Support.

Exit — closes the Ngenuity Operator Utility.

A-61662 April 2010 3-9

Page 25

Help menu Displays help topics for the following: View Operator Manual, Product

Support, and About Scanner Operator Utility.

View Operators Manual — launches a PDF file for the Kodak Ngenuity

9000 Series Scanners User’s Guide.

NOTE: You must have Adobe Reader installed on your PC to view this

file.

Product Support — displays the Product Support dialog box which

provides technical support information and links.

About Scanner Operator Utility — displays the About dialog box

which provides the Ngenuity Operator Utility application version and

copyright information.

Home screen When you click the Home button on the main Ngenuity Operator Utility

screen, the following information is displayed.

3-10 A-61662 April 2010

Scanner Model — displays the scanner connection status. If the

scanner is properly connected, the icon indicates a successful

connection. The scanner model and connectivity type (USB or SCSI) is

also displayed.

Page 26

Scanner Self Test — displays the results of the internal scanner fault

monitoring. A green checkmark icon indicates that no scanner faults

were detected. A red X icon indicates one or more scanner faults were

detected. The text box will list each self test failure.

If there are one or more faults, the icon changes and each fault is listed.

If the Self Test monitor returns a fault(s), power cycle the scanner and

check the Scanner Self Test monitor again. If the problem persists,

contact Technical Support.

Maintenance monitor — this section of the Home screen displays any

scanner maintenance and the type of maintenance needed (i.e., clean

transport, replace feed rollers, etc.). Monitored maintenance includes:

• Clean feed rollers

• Clean transport

• Clean optics (e.g., imaging guides, camera glass covers, sensors)

• Replace feed rollers

• Calibration of the front/back camera

• Replace imprinter ink cartridge (if optional imprinter is installed)

If maintenance is required, the tool icon which is normally blue (no

maintenance required) changes to yellow.

The Maintenance monitor also displays when or how soon specific

maintenance should occur in the form of a bar graph. See Chapter 5,

Maintenance for detailed maintenance procedures.

When a component’s pre-set interval expires, the scanner’s

Maintenance light will blink slowly, the icon will change from blue to

yellow and the bar graph will be red. In addition, an alert will be

displayed (yellow triangle).

NOTE: The presence of a red bar graph will not disrupt or stop the

scanner.

A-61662 April 2010 3-11

Page 27

Resetting the maintenance reminders

If a component’s maintenance interval expires triggering the

maintenance reminders, a hyperlink for that component will navigate

you to reset and restart the interval count. This process is necessa ry to

ensure required maintenance continues to be monitored appropriately.

NOTE: The alerts for calibrating the front and back cameras cannot be

adjusted. If an alert to calibrate the camera(s) is displayed, click

the corresponding hyperlink to reset the reminder and begin

calibration. For procedures on calibrating the cameras, see

Chapter 5, Maintenance.

Settings button When you click the Settings button on the Ngenuity Operator Utility

main screen, the Configure Scanner Settings screen will be displayed.

3-12 A-61662 April 2010

Y ou can configure basic scanner settings (e.g., Sleep timeout, Multifeed

range, Custom Functions and Audio volume and sound) using this

screen.

Sleep timeout — you can set the delay time in hours and minutes that

the scanner can be idle with full power before going into “sleep” mode.

The default timeout is 15 minutes; the maximum time is 4 hours.

Multifeed — allows you to adjust the sensitivity when scanning Normal

or Very thin documents.

• Normal: for documents that range from thick card stock to thin

carbon copies. This setting should be used for most documents.

• Very thin: used to detect multifeeds when scanning ultra-thin

documents such as rice paper.

Page 28

Custom Functions — allows you to set a function for the F1 and F2

buttons on the control panel. Available options are:

• None: no function will be performed when F1/F2 is pressed.

• Feed Test Batch: activates the Test feed mode which is used to test

and verify the scanner’s feeding capabilities and allows you to feed

transport cleaning sheets. This is the default setting for the F1 key.

• Page Eject: will activate the transport to eject multi-fed documents or

clear the transport after a stop. This is the default setting for the F2

key.

• Clean Print Head: if you have the optional imprinter installed, will

activate the imprinter to clean the print head.

Audio — allows you to set the volume of a selected sound that alerts

you to an error.

• Volume: can be set to Mute, Low, Medium or High.

• Error Sound: one of three sounds can be selected: Sound1,

Sound2, Sound3. Click Play Sound to hear the currently active

error sound.

Advanced — when you click Advanced, the Advanced Settings

screen will be displayed.

A-61662 April 2010 3-13

From this screen, you can adjust the image boundaries or borders of a

scanned image which is determined by autocrop. Each side of a

scanned image can be individually adjusted by cropping or adding extra

black border. This only affects images as part of the scanning process.

This adjustment cannot be made to an existing image.

The range of adjustment is between -0.500 to 0.500 inches; negative

values crop, and positive values add extra border. The default values

are 0.000 for all sides.

When finished, click Save to save your changes and close the

Advanced Settings window.

Page 29

Maintenance button When you click the Maintenance button on the Ngenuity Operator

Utility main screen, the Maintenance screen will be displayed.

This screen provides scanner statistics for total hours, total pages fed

and total pages scanned. The Maintenance screen also allows you to

configure reminders for different maintenance tasks that are required to

ensure optimal performance.

Scanner Stats — this area provides statistics for Total On Time

(awake and sleeping), Total Pages (fed) and total Scanned Pages.

These totals are updated every 2 seconds.

Configuration Maintenance Reminders — allows you to set the

interval values for triggering the reminders that are visible in the

Maintenance section of the Home screen.

Intervals can be set for cleaning the feed rollers (skimmer rollers: pick

and drive and separator roller), the transport rollers, the optics and to

replace the feed rollers (skimmer rollers and separator roller). These

reminders can also be individually enabled and disabled. It is

recommended that you do not disable any of these reminders.

To enable and adjust a maintenance reminder, click the check box next

to the corresponding component and use the up/down arrows in the

Page Interval column to change the value. Click Save to save your

changes or Restore to reset the values to the previously saved

settings.

The available interval settings and their defaults are:

Reminder Range Default

Clean Feed Rollers (skimmer rollers and separator roller) 1K - 50K 10K

Clean Transport Rollers 5K - 100K 50K

Clean Optics (camera covers, imaging guides, sensors) 5K - 150K 50K

Replace Feed Rollers (skimmer rollers and separato r roller) 100K - 900K 600K

3-14 A-61662 April 2010

Page 30

4 Advanced Features

Contents Accessing Advanced features.........................................................4-2

Advanced features..........................................................................4-3

Color screen...............................................................................4-4

Piking Rectangle screen.............................................................4-5

Rotation screen ..........................................................................4-6

Document Setup screen.............................................................4-7

Advanced Color screen..............................................................4-9

Multifeed screen.......................................................................4-10

About screen ............................................................................4-12

This chapter provides information about advanced features that can be

used with Kodak Ngenuity 9000 Series Scanners. The controls for

operating the Advanced Features are accessible within the

®

VirtualReScan

NOTE: When VRS is not installed, similar settings can be found in the

Direct ISIS and TWAIN settings.

(VRS) Interactive Viewer.

The features on the Advanced Properties dialog box can be used to

control scanner-specific features that are not accessible through the

Kofax VRS or scanning application screens. The general rule for VRS

integrations is that if there is a control for a feature in both VRS and in

the Advanced Properties dialog box, then the VRS control’s setting will

override the setting in the Advanced Properties dialog box. For

example, if you have health forms where you need to drop out a form

color or if you have documents with labels that cause false multifeed

alarms, etc., you can change the scanner’s settings on the Advanced

Properties dialog box to enable Multifeed detection or electronic color

dropout scanner features. These settings can be saved as part of a

profile. Any settings made on the Advanced Settings screen will

override the same settings defined in a saved profile. For more

information on scanning with VRS Test Application and Profiles, see the

Kofax VRS 4.5 (or newer) User’s Guide.

NOTE: Any settings made in the Advanced Properties dialog box must

be saved in a profile or they will be lost when the application is

closed.

Some of the settings that can be made using the Advanced Properties

dialog box include: color dropout, multifeed, rotation, document setup

(i.e. allowing for large skew, etc.)

A-61662 April 2010 4-1

Page 31

Accessing Advanced

features

To access the VRS Interactive Viewer, Ngenuity VRS Professional

software must be loaded on the host PC that the scanner is connected

to. VRS Professional will be active when the scanning application being

used is launched and a VRS scan source is selected. There are three

types of scan sources, depending on the VRS driver used.

• VRS ImageControls®-based Applications

• VRS ISIS-based Applications

• VRS TWAIN-based Applications

NOTE: This User’s Guide only documents the VRS-based scanning

setup.

For scanning applications that utilize the VRS-based driver, the VRS

icon will be displayed in the Windows Taskbar on the host PC when the

scan source (scanner) is selected.

To launch the VRS Interactive Viewer, right-click on the VRS Taskbar

icon and select Preview.

The VirtualReScan Interactive Viewer window will be displayed.

1. Within the Interactive Viewer, access the Advanced features by

clicking the Scanner Driver Settings icon ( ) to display the

Advanced Properties window.

4-2 A-61662 April 2010

Page 32

Advanced features NOTE:If you have the optional Imprinter, see Appendix B for

installation procedures, maintenance and instructions for using

the front page (pre-scan) and back page (post-scan) imprinter.

Clicking the Scanner Driver Settings icon displays the Advanced

Properties window.

To display the functions contained within a menu, click the

corresponding hyperlink.

OK — saves any changes and closes the window.

Cancel — reverts the screen settings back to the last saved settings.

Help — displays a brief description of the controls on the Advanced

Properties window.

A-61662 April 2010 4-3

Page 33

Color screen The Color screen allows you to dropout a form's background so that

only the entered data is included in the electronic image (i.e., remove

the form’s lines and boxes).

Front side dropout color — select the desired dropout color you want

to eliminate from the front side. Selections are: None, Red, Green or

Blue.

Back side dropout color — select the desired dropout color you want

to eliminate from the back side. Selections are: None, Red, Green or

Blue.

JPEG Compression — click Enabled to select a JPEG Quality option.

Choices are:

• Good: a fair amount of compression but still produces acceptable

image quality.

• Better: some compression which produces decent image quality.

• Best: minimal compression which produces very good image quality.

• Custom: select this option to customize your JPEG compression

values. When selected, the YUV and Value percent options are

available.

- YUV is a type of color space used in JPEG compression. The 4-2-2

selection (default) uses downsampling (throws away a lot of the

image color data) and generates smaller files comp ared to the 4-4-4

selection, which uses no downsampling (keeps as much image

color data as possible) and generates large files.

- Value: a high percentage value compresses the least (and

generates larger files), while a low percentage value compresses

the most, generating smaller files, which can result in lower quality

images.

4-4 A-61662 April 2010

Page 34

Picking Rectangle screen The Picking Rectangle screen provides the following options:

Front Side/Back Side — allows you to define the area to be imaged by

selecting a value in the Width and Height drop-down boxes and its

offset from the upper left corner of the image (defined by the Top and

Left values). The picking rectangle is relative to the cropped image

such that a value of Top=0.00 and Left=0.00 will always be the very left

corner of the lead edge of the page that was fed into the scanner. The

resulting image is a cut out of the original, larger image. Therefore, if

you scan a letter-size page and have Letter paper size selected, you

will get a rectangular cut out from that image, the location and size of

which is determined by these values.

A-61662 April 2010 4-5

Page 35

Rotation screen The Rotation screen provides the following options.

Front Side/Back Side — allows you to rotate the scanned image 0, 90,

180 or 270 degrees. 0 is the default.

NOTE: Any rotation performed by the scanning application or by Kofax

VRS will be performed after this rotation. For example, if the

Advanced Properties rotation is set to 90 degrees for both the

Front and Rear and VRS auto cropping is enabled, and a

document with text on the front and only a photo on the rear is

fed in portrait mode with the left edge first, the result will be the

front side with text will first be rotated right 90 degrees in the

scanner, then rotated back to portrait by VRS auto crop. The

rear image will be rotated right and will not be rotated by VRS

auto crop.

4-6 A-61662 April 2010

Page 36

Document Setup screen The Document Setup screen provides the following options.

Document Types — allows you to change the transport speed to

accommodate the feeding needs of various document types.

• Normal: highest transport speed for scanning standard document

types. This is the full performance mode.

• Fragile/Difficult: lower transport speed which is useful for delicate

documents that can easily tear.

• Thick or Envelope: for scanning thick paper or envelopes.

• Tri-Fold: for scanning tri-fold documents.

NOTE: Document types other than Normal may reduce scanner speed.

Allow Large Skew — if enabled, this option maximizes image data

capture for documents that are fed into the scanner highly skewed,

helping to eliminate clipped or missing corners.

Very Long Document — when enabled, this option adjusts the

scanner’s transport speed to accommodate a long document (more

than 40 inches/1016 mm) to be scanned into individual images. The

size of the images is determined by the Paper Size setting in the

scanning application.

A-61662 April 2010 4-7

Page 37

The Very Long Document option does not support the simultaneous

use of some other options offered through VRS ImageControls and

Direct Drivers. Following is a table that identifies those other controls as

well as how the scanner and software handle the conflict when you

attempt to use them together.

Conflicting Controls Resolution

Single Page Scan The scan is terminated and an error message is displayed. Very

Long Document is not supported with single-page scanning. Use

the batch scan command.

VRS Administration Utility Warning tab

On Errors QC Mode The document is scanned ignoring the On Errors QC Mode op tions

Every Page QC Mode The scan is terminated and an error message is displayed.

First Page QC Mode The scan is terminated and an error message is displayed.

Deskew and Auto Crop The document is scanned ignoring the Deskew and Auto Crop

Image Rotation of 90, 180, or

270 degrees

Auto Orientation The scan is terminated and an error message is displayed.

Picking Rectangle For best results, do not use Very Long Document and Picking

Automatic Color Detection For best result s, do not use Very Long Document and Automatic

Advanced Clarity For best results, do not use Very Long Docume nt and Advanced

The document is scanned ignoring the warning conditions that are

set. No error message is displayed.

that are set. No error message is displayed.

options that are set. No error message is displayed.

Do not select rotation options if scanning using Very Long

Document.

Rectangle at the same time.

Color Detection at the same time.

Clarity at the same time.

Ignore Holes/Ragged Edges — click Enable to adjust the entry and

exit sensors so they ignore holes on the leading or trailing edge of a

document (e.g. three-hole punched paper), that may cause the scanner

to detect false starting or trailing edges of a document. If you are

receiving Page Sensor or Peripheral Malfunction errors, enable this

feature and adjust the value until the error disappears.

This option can be set using a measurement in inches or millimeters

with a range of 0.0 to 1.7 inches (0 to 43 mm). Set Ignore Holes/

Ragged Edges to a width slightly larger than the holes in the paper (or

whatever may be causing the false detection of the leading or trailing

edges of a document).

NOTE: Enabling Ignore Holes/Ragged Edges may reduce scanning

throughput.

Front/Back Negative Image Enable — allows you to request a black

and white/grayscale image when scanning in black and white or

grayscale only. This control is not supported when scanning in color.

4-8 A-61662 April 2010

Page 38

Advanced Color screen The Advanced Color screen provides the following options.

If the color on your images is not as expected, you can use the

Advanced Color screen to make color adjustments to meet your

scanning needs.

Camera Modes

• sRGB: uses specific camera gamma to achieve the best

approximation of sRGB color response.

NOTE:This setting applies to the camera output only; any post-

capture image processing settings affect the color content of

the final output file.

ICC: select this option to set up scanner cameras to be compatible with

the scanner’s ICC color correction profile and to cause VRS to embed

ICC-compatible profile data into the image file. ICC profile data is used

by some viewing or printing applications to compensate or adjust colors

for optimal quality. ICC data is useful only for applications that are ICCprofile aware. T o properly view the images, the viewing application must

be ICC-profile aware.

NOTE: Do not use other post-processing color adjustments in

combination with this option enabled.

For the ICC profile data to be successfully embedded, the scanning

application must:

• be an ImageControls, Direct ISIS or Direct TWAIN application

• be set up for color scanning

• be set up to store TIFF, JPEG or PDF image file types

• not use VRS Automatic Color Detection (images may be converted to

black and white)

A-61662 April 2010 4-9

Page 39

Gamma (default) — allows you to specify a specific camera gamma

(1.0 - 2.5). The camera gamma value can be entered or selected by

moving the slider to the desired value.

Select a lower gamma value to enhance color saturation for bright

colors and a higher gamma value to enhance color variations for dark

colors. For most documents the camera gamma should be kept at the

default value of 1.3.

NOTE: Selecting one of these Camera Mode options activates that

option for both the front and back camera.

Multifeed screen The Multifeed screen provides the following options.

Multifeed Mode — determines the response of the scanner if a

multifeed occurs.

• Off: no multifeed detection occurs. Scanning continues and all

scanned images are retained.

• Notify: the scanner responds to the multifeed by sounding an audible

alarm and momentarily lighting the Multifeed LED. Scanning

continues, the multifeed is ignored and the image of the multifeed

document is retained.

4-10 A-61662 April 2010

Page 40

• Stop: when a multifeed is detected, the scanner sounds an audible

alarm, the Multifeed LED lights steady and the scanner’s transport

stops. You can delete or keep the multifeed image.

The VirtualRescan Auto Resolve Manager will display the front of

the image of the document that triggered the multifeed alarm.

- T o dele te the image: select the Custom Function button that is set

to Page Eject (F1 or F2) to eject the multifeed document from the

transport. Correct whatever caused the multifeed and place the

multifeed document back in the feeder on top of the batch of

documents to be scanned, and press Clear/Reset button on the

scanner to restart scanning.

- To keep the image: press MF Ignore button on the scanner. The

scanner will automatically eject the multifeed document and

continue scanning, keeping the multifeed image.

NOTE: If the scanner’s audio feature has been set to Mute, you will

not hear the alarm that occurs with the Notify and Stop

options when a multifeed is encountered.

Enable Sensors — allows you to enable or disable the Left, Center

and Right sensors that assist in triggering a multifeed alarm. One or

more of these sensors can be enabled/disabled at any time. If all three

are disabled, the Enable Sensors control grays out and the Multifeed

Mode control automatically is set to Off.

Ignore by Size — allows you to set the maximum size of a multifeed

that will not trigger a multifeed error. This is used to scan documents

with labels or stickers (mailing labels), documents with taped

photographs or receipts while multifeed detection is active.

Ignore by Size can be set in inches or millimeters, with a ran ge of 1.0 to

25.5 inches (25-647 mm). The default setting for this control is

1.0 inch (25 mm).

A-61662 April 2010 4-11

Page 41

About screen The About screen displays the scanner version and copyright

information.

4-12 A-61662 April 2010

Page 42

5 Maintenance

Contents Maintenance schedule ...................................................................5-2

Cleaning supplies............................................................................5-2

Cleaning procedures.......................................................................5-3

Cleaning the feed rollers.............................................................5-4

Cleaning the optics.....................................................................5-8

Cleaning the transport..............................................................5-12

Replacement procedures..............................................................5-13

Replacing skimmer rollers........................................................5-13

Replacing the separator roller ..................................................5-14

Replacing the imaging guides ..................................................5-15

Lamps...........................................................................................5-15

Camera calibration ........................................................................5-15

Supplies and consumables...........................................................5-17

Keeping the scanner’s hardware and software versions current, along

with performing routine maintenance will ensure optimal image quality

and prolong the life of your scanner.

The Maintenance monitor on the Home screen of the Ngenuity

Operator Utility (NOU) provides reminders as to when scanner

maintenance is required.

Based on the intervals set, the Maintenance LED on the control panel

will also blink. To turn the Maintenance LED off and to reset the interval

count for future reminders, perform a quick confirmation in the NOU

after each maintenance procedure is completed.

A-61662 April 2010 5-1

Page 43

Maintenance

schedule

The following table is a recommended schedule for performing basic

maintenance functions. Some procedures may need to be performed

more frequently depending on your operating environment and the

types of documents being scanned.

Maintenance Recommended Range Symptoms

Clean feed rollers: pick, drive,

and separator rollers

Clean transport rollers 50,000 pages 5K - 100K • Multifeeds

Clean Optics: imaging guides,

cameras glass covers, sen sors. Optics does not include

lamps. The lamps (LEDs)

should not be cleaned or

wiped with any type of wipe or

solvents.

Camera calibration Every 1200 hours N/A Poor color image quality (e.g. white tinted

Replace feed rollers 600,000 pages 100K -

10,000 pages 1K - 50K • Skewed documents

• Multifeeds

• Feeder jams

• Transport jams

• Elongated images

50,000 pages 5K - 150K Glass Camera Covers / Imaging Guides

• Streaks in the image

• Reduced OCR/ICR/Barcode recognition

rates

• Blurred images

Page Sensors

• Entry/exit sensor errors

Feeder Sensors

• Feeder table does not lower when out of

paper

green, red or blue)

• Noticeably worn rollers

900K

• Page skewing, multifeeds an d paper

jams continue to occur after cleaning is

performed

Ink cartridge(s) - only relevant

if optional imprinter(s)

installed

Approximately

34,000 pages (can

vary depending on

number of characters per page and

font used, etc.)

N/A Poor print quality

Cleaning supplies Scanner consumables and cleaning supplies are available from

resellers, web merchants and from the Kodak on-line store

(http:/scannerstore.kodak.com).

• Ngenuity Roller Kit

• Ngenuity Cleaning Kit including:

- Blower brush

- Transport cleaning sheets

- Roller and glass cleaner

- Lint-free cleaning cloths

- Cleaning wipes

-Swabs

5-2 A-61662 April 2010

Page 44

Cleaning procedures Cleaning your scanner and performing preventative maintenance on a

regular basis is required to ensure the best possible image quality.

Some document types generate more paper dust and debris and may

require more frequent cleaning.

Before cleaning your scanner or replacing consumables, review the

following information:

• Turn the scanner off before performing maintenance procedures.

• Remove any jewelry or any items from hands or wrists that could

become caught on internal scanner components.

• Some debris from the rubber tires on the skimmer module and

separator roller is normal. Tire debris does not always mean that the

tires are worn or damaged. After cleaning, inspect the tires for wear

and replace the separator roller or skimmer module if necessary.

• When cleaning rollers/tires, allow the rollers/tires to dry completely

before scanning.

• Use only the recommended cleaning supplies. Using unapproved

cleaning fluids or solvents may damage the rubber tires.

• Do not use cleaners in confined areas, use with adequate

ventilation.

• Do not use flammable compressed aerosols on or around the

scanner.

NOTE: To access the Material Safety Data Sheet (MSDS), you will

need to provide the catalog number of the supply. See

“Supplies and Consumables” later in this chapter for

catalog numbers.

A-61662 April 2010 5-3

Page 45

Cleaning the feed rollers Feed rollers include the skimmer (pick and drive) roller and separator

Pick

roller

Drive

roller

Release

lever

Skimmer

Spring-loaded

release

roller.

All feed rollers should be cleaned and/or replaced at the same time to

ensure optimal scanner function. Maintenance reminder intervals (both

cleaning and replacing) are based on all feed rollers having the same

life cycle.

Cleaning the skimmer rollers

The skimmer module is comprised of two rollers; the pick roller and the

drive roller. Both rollers contain two, removable rubber tires. One outer

edge of each tire contains at least 3 dots.

These dots are used as a point of reference for correctly installing the

tires on the roller and also the rollers into the skimmer housing. When

installing the tires, the 3 dots should always be facing left. If the

tires or rollers are installed incorrectly in the skimmer housing, the

skimmer module will not function properly.

All four tires and the separator roller should be replaced at the same

time.

When the skimmer rollers become dirty , they may begin to slip on pap er

or cause multifeeds. To prevent feeding problems and avoid rubber tire

replacements, it is recommended that you clean the skimmer rollers

(tires) every 10,000 pages or as needed. Dif ferent document types, the

condition of the documents being scanned, and t he volume of scanning

may require more frequent cleanings.

5-4 A-61662 April 2010

Page 46

Always remove the rollers from the scanner for cleaning to ensure best

results.

1. Turn off the scanner and open the transport cover.

2. Remove the pick roller by rotating the blue pick roller release lever

up, push the pick roller to the right and rotate it out of position.

3. Using the cleaning wipe, scrub the roller tires in a side-to-side

motion, Rotate the roller to clean the entire surface.

4. Re-install the clean pick roller.

• With the pick roller positioned so the dots are facing the left side,

slide the roller onto the right pick roller shaft.

• Holding on to the roller , rot ate the pick rolle r shaft d own and slide

the roller all the way to the left. The right side of the roller should

be clear of the pick roller release lever.

• Bring the pick roller release lever down and snap it into place.

A-61662 April 2010 5-5

Page 47

5. Remove the drive roller by placing your fingers on the left side of the

Driver roller in

Push

roller to

the right

far right position

Hold in place.

Hold shaft in

place to release

driver roller.

drive roller and push the roller as far right as possible. Hold it in

place. The spring-loaded drive roller shaft will move to th e right side

of the scanner’s upper tray. Hold the driver roller shaft in place and

slide the drive roller off to the left and off the shaft. Gently release

the drive roller shaft back into position.

6. Using a cleaning wipe, scrub the drive roller tires in a side-to-side

motion. Rotate the roller to clean the entire surface of the tires.

7. Re-install the drive roller.

• With the drive roller positioned so the dots are facing the lef t side,

slide the roller onto the right drive roller shaft.

• Angle the right side of the drive roller onto the drive roller shaft

Push the roller onto the shaft and push the roller and shaft far

enough to the right so that the left side of the roller can be

positioned onto the left drive roller shaft.

• When the side of the drive roller is properly aligned onto the left

drive roller shaft, gently release the drive roller shaft back into

place.

8. Continue with cleaning the separator roller.

5-6 A-61662 April 2010

Page 48

Cleaning the separator roller

9. Pull the separator roller door forward and hold it in place while you

remove the separator roller by lifting it off the cradle.

10. Using a cleaning wipe, scrub the separator roller tires in a side-toside motion. Rotate the roller to clean the entire surface.

11. Open and hold the separator roller door to reinstall the separator

roller. Align the sep arator roller correctly with the slots. Align the flat

end of the shaft with the slot in the cradle and gently seat the shaft,

which should fall in place. Do not apply pressure to seat the shaft

12. Gently release the separator roller door back in place. Verify that

the separator roller is seated level.

.

13. Close the transport cover and reset the maintenance reminder by

clicking on the Clean Feed Rollers hyperlink on the Maintenance

monitor.

A-61662 April 2010 5-7

14. Click Yes on the dialog box to confirm the feed rollers have been

cleaned. The reminder will be reset for the next required

maintenance session.

Page 49

Cleaning the optics Optics include the imaging guides, camera glass covers and

Fastening clips (2)

sensors. All of the optics components should be cleaned at the same

time.

NOTE: The lamps are not part of the optics. The lamps (LEDs) should

not be cleaned with wipes or solvents.

Cleaning the imaging guides and camera glass covers

To prevent streaks in images, reduced OCR/ICR/Barcode recognition

rates, blurred images, etc., you should clean the imaging guides every

50,000 pages.

The two imaging guides which are inside black, plastic frames are

located in the top and bottom transport trays. When removing a imaging

guide for cleaning or replacement, the entire assembly (imaging guide

and frame) are removed and replaced as one piece.

Clean the camera glass covers at the same time you clean the imaging

guides.

CAUTION: Do not remove the imaging guide from the black frame.

1. Open the transport cover.

2. Gently pull the 2 fastening clips that secure the top imaging guide

towards the front of the scanner to release and remove the imaging

guide from the transport.

5-8 A-61662 April 2010

3. Spray the glass cleaner on a lint free cloth, taking care that any

overspray does not fall inside the scanner.

4. Wipe down both sides of the imaging guide. Be careful not to touch

the cleaned glass.

Page 50

5. With the imaging guide still out of the scanner, locate the glass

Imaging guide removed

Camera cover

LEDs

Lamp

Imaging

Five guides slide underneath the transport tray

Fastening clips

guide

camera cover between and below the LED lamps.

6. Using a clean dry swab, gently wipe across the glass camera cover

to remove any dirt and dust particles. Do not spray any solvent on

the swab unless a dry swab will not remove the residue on the

glass. If you need to use solvent, spray the solvent on the swab.

Use only the supplied glass and roller cleaner. Do not spray sol-

vent in or around the internal components of the scanner.

7. When the camera cover is clean, re-insert the cleaned imaging

guide into the scanner by holding the frame of the imaging guide so

that the fastening clips are on the back side of the imaging guide.

Slide the guides under the transport tray towards the feeder table

and ease the back side of the imaging guide into position.

8. Repeat Steps 2 - 7 to clean the bottom imaging guide and bottom

camera cover.

9. When finished, close the transport cover.

A-61662 April 2010 5-9

Page 51

Cleaning the sensors

Feeder sensor

Top or front page tray assembly

Gap sensor

Page entry

sensors (3)

Pass thru

sensor

There are 7 sensors that require regular cleaning. Use only the

supplied blower brush to clean these sensors. Do not use any type of

cotton swab or cloth as these items may leave lint in the sensors.

NOTE: If problems persist after cleaning the sensors, it may be

necessary to use forced air to clean the sensors. If using forced

air, use the extension tub e on the can to spray the forced air. Do

not turn the can upside down or tip it sideways.

10.Feeder sensor: Place the brush end of the blower brush into the

feeder sensor area and squeeze the blower brush several times to

clean the feeder sensor on the feeder table.

11. Gap sensor, page entry sensors and pass thru sensor: Open

the transport cover to clean these 5 sensors by placing the brush

end of the blower brush into the each sensor area and squeeze the

blower brush several times to clean.

5-10 A-61662 April 2010

Page 52

12. Exit sensor: The exit sensor is located on the transport toward the

Exit sensor

back of the scanner. Clean the exit sensor by placing the brush end

of the blower brush into the exit sensor area and squeeze the

blower brush several times.

13. When all sensors are clean, close the transport cover and reset the

maintenance reminder by clicking on the Clean Optics hyperlink on

the Maintenance monitor.

A-61662 April 2010 5-11

14. Click Reset on the dialog box to confirm the optics have been

cleaned. The reminder will be reset for the next required

maintenance session.

Page 53

Cleaning the transport Over time, the transport will become dirty and may feed documents

erratically or skew the documents as they enter the scanner. T o prevent

erratic feeding, clean the transport every 50,000 pages or as needed.

NOTE: It is recommended that you clean the imaging guides again after

cleaning the transport with a transport cleaning sheet.

1. Establish communication between the scanner and the Ngenuity

Operator Utility.

2. Verify that one of the Custom Functions is set to Feed Test Batch.

3. Press F1 or F2 key depending on which key is assigned to “Feed

Test Batch”. This will start the scanner transport. By default, the F1

key is assigned the Feed Test Batch function.

4. Feed the transport cleaning sheet in landscape orientation into the

scanner transport.

5. Observe the cleaning sheet, and run it through the transport again,

changing its position slightly each time, until the tires leave no dark

streaks.

6. Turn the transport cleaning sheet over and run it through the

scanner transport two times.

7. Press and hold the Pause/Stop button (2-3 seconds) until the

scanner stops running.

8. Press the Clear/Restart button.

9. When finished, discard the transport cleaning sheet. After running

the cleaning sheet, inspect the imaging guides. It may be necessary

to clean off any residue from the cleaning sheet that may be on the

imaging guides.

5-12 A-61662 April 2010

Page 54

Replacement

procedures

Replacing tires With proper cleaning, tire life of each skimmer roller (pick and drive) is

This section provides procedures for replacing the following parts.

When replacing parts, turn the scanner of f by pressing the power switch

located in the back of the scanner.