Page 1

LSDT

Internal SCSI Option

Operators’ Supplement

Manual

May 13, 1997

P/N 0070-275 Rev. 01

David W. Funk

Page 2

Table of Co ntents

1. INTRODUCTION..................................................................................3

2. SYSTEM DESCRIPTION..................................................................... 3

3. INSTALLATION...................................................................................3

3.1 SCSI CABLING...........................................................................................................3

3.2 SCSI ID AND SCSI TERMINATION........................................................................4

3.3 HARDWARE CONFIGURATION.....................................................................................4

3.4 SCANNER CONFIGURATION (LSDTCONF.DAT).........................................................5

3.4.1 Protocol..............................................................................................................5

3.4.2 Inquiry Type.......................................................................................................5

3.4.3 Target SCSI ID...................................................................................................6

3.4.4 Wait for Digitize.................................................................................................6

3.4.5 Mode..................................................................................................................6

3.4 .6 Film Present........................................................................................................6

3.4.7 Request Sense Length.........................................................................................6

4. DIAGNOSTICS......................................................................................7

4.1 SERIAL PORT SETUP ...................................................................................................7

4.2 SCANNER CONTROL PROGRAM...................................................................................7

4.3 COMMAND LINE MAINTENANCE AND DIAGNOSTICS UTILITIES ....................................8

4.3.1 CHKCLUT - Check CLUT.................................................................................8

4.3.2 MKCLUT - Make CLUT ....................................................................................9

4.3.3 CHKMTF - Check MTF.....................................................................................9

4.3.4 CHKXYLIN - Check X/Y Linearity....................................................................9

4.3.5 LNADJDT - Adjust X Linearity........................................................................10

4.4 COMMAND LINE TOOLS............................................................................................10

4.4.1 EDDEN - Edit the Density file..........................................................................10

4.4.2 ED - Simple Line Editor....................................................................................14

4.4.2.1 ED Syntax..........................................................................................................................14

4.4.2.2 ED Commands...................................................................................................................14

P/N 0070-275, Rev 01, LSDT INTL SCSI OPTION, OPERATORS’ SUPPLEMENT MANUAL EC2051

Form No. 0069-978, Rev 01 2 OF 16

Page 3

1. Introduction

This document is intended to descr ibe the unique features of the Inter nal SCSI

Option on LSDT scanners. This is not a replacement for the “Operators’ Reference

Guide”.

2. System Description

The Internal SCSI Option is composed of a standard LSDT scanner with an

embedded microprocessor based co nt r oller. The unit’s external interfaces consists of a

SCSI 2 connecto r , RJ-11 serial connecto r , and a rotar y switch for selecting the SCSI

ID. The scanner control program running on the internal microprocessor board

provides the interface between the host commands coming from the SCSI bus and the

scanner hardware.

During a scan operation, image data from the scanner is buffered in a circular buffer

on the contr oller. The circular buffer is 4MB or optionally 16MB. If the host co mputer

fails to read th e image data in a timely fashion a data lost er ror will occur. T h is data

lost error is unique to the internal SCSI option. The older external SCSI option was

always configured with enough internal memory to buffer a complete image.

3. Installation

Please refer to the “Operato r s’ Reference Guide” section 2 for general unpacking

and setup. However ignore the sections 2.2.4 “Installation of Data Control Board

(DCB)” and 2.2.4 “Installation of Control Interconnect Cable”

Installation of the LSDT scanner with internal SCSI option should be easy. Plug in

the scanner power, at tach the SCSI cable and select t he SCSI I D and t he system is

ready to scan. Depending on the host system software the scanner configuration file

may need to be modified using the serial interface.

3.1 SCSI Cabling

The scanner has a 50 pin SCSI-2 connecto r. Connect directly from the host interface

card or another SCSI device.

P/N 0070-275, Rev 01, LSDT INTL SCSI OPTION, OPERATORS’ SUPPLEMENT MANUAL EC2051

Form No. 0069-978, Rev 01 3 OF 16

Page 4

3.2 SCSI ID and SCSI TERMINATION

There is a small rotary switch on the back of the scanner next to where the SCSI

cable is connected. This switch selects bot h t he SCSI I D and enables SCSI bus

termination. SCSI ID’s range from 0 through 7. Every device on the SCSI bus must

have a unique ID. The switch rotates from “0” to “F”. Switch values from 0 through

7 select SCSI ID = value, with bus termination DISABLED. Switch values from 8

through F select SCSI ID = (value - 8), with bus termination ENABLED. For example

if t he rot ary sw itch is set to “C” then the scan n er will res pond to SCSI ID 4 with the

SCSI bus termination ena bled.

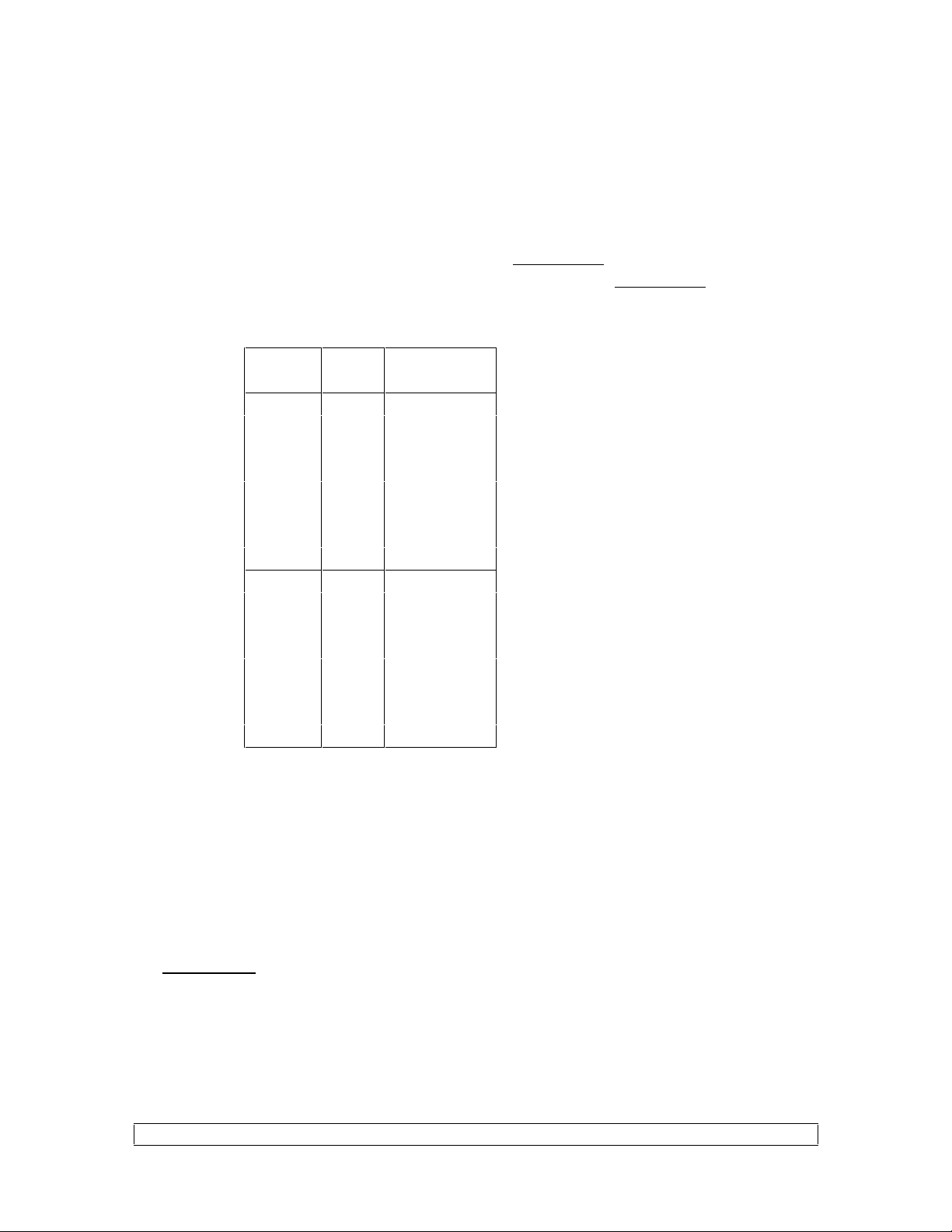

Switch

position

SCSIIDTer mination

enabled

00 NO

11 NO

22 NO

33 NO

44 NO

55 NO

66 NO

77 NO

80 YES

91 YES

A2 YES

B3 YES

C4 YES

D5 YES

E6 YES

F7 YES

3.3 Hardware Configuration

Normally no hardware co nfiguration is required. The microcontr oller interface board

has 4 jumpers (JP1 , JP 2 , JP3, JP4) . Jumper JP1 is really a connector for a r e set butt on,

if jumped the syste m will not run (c on stan t re set). Jumpe rs JP 2 and JP3 are used to

configure the memory size. Jumper JP4 enables the SCSI bus state indicator LEDs.

When JP4 is enabled the LEDs show t he curr ent S CSI bus state. S ince the LEDs are

located inside the scanner they are only used for tro uble shoot ing.

WARNING: If JP4 is enabled th e LED s will cause stra y light that will adv erse ly effe ct

t he image qua lity.

P/N 0070-275, Rev 01, LSDT INTL SCSI OPTION, OPERATORS’ SUPPLEMENT MANUAL EC2051

Form No. 0069-978, Rev 01 4 OF 16

Page 5

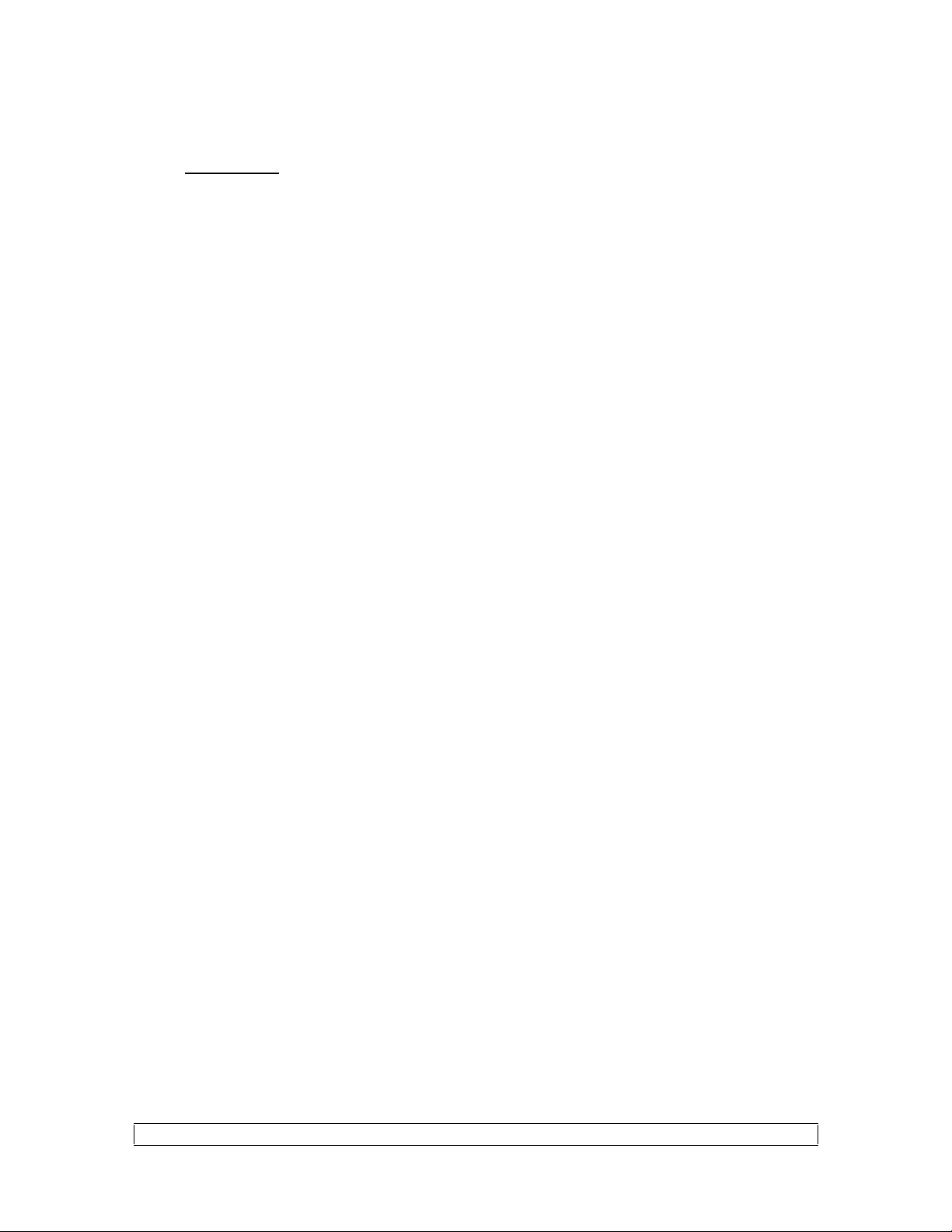

Syst em Memor y Configuration Jumpers

JP2 JP3 Memory size

1-2 1-2 1MB (1MB is NOT enough to run the scanner)

2-3 1-2 4MB

2-3 2-3 16MB

3.4 Scanner Configuration (LSDTCONF.DAT)

The s c anner ha s sever al minor configura tion options. The file D: \LSD TCON F .DAT

on the internal controller defines all user configuration options. There ar e 7 option

parameters: protocol, inquiry type, target SCSI ID, wait for digitize, mode, film

present, and request sense length. The meaning and syntax of each parameter is

described in the following sections. The factory default sett ings are corr ect for the

majorit y of user s.

Example LSDTCONF.DAT file:

Protocol LUMISYS ; LUMISYS or ANSI

Inquiry_Type ANSI ; LUMISYS or ANSI

TARGET_SCSI_ID 4 ; from 0 through 6 are valid

WAIT_FOR_DIGITIZE FALSE ; either TRUE, or FALSE

; TRUE -> more like LS150/200

MODE NORMAL ; INTERRUPTABLE/NORMAL

; INTERRUPTABLE returns busy

; on image data reads when no

; data is available. Host must

; retry.

; NORMAL holds the SCSI bus

; until data is available.

FILM_PRESENT NO ; TRUE or YES if sensor present

REQ_SENSE_LENGTH 0 ; Non-Zero overrides response length

3.4.1 Protocol

This parameter sele cts the scanne r c ommand proto col, cu rren tly on ly “ LUMI SY S”

is supported.

Default = LUMISYS

3.4.2 Inquiry Type

This parameter selects t he format o f the Inquiry response data. Legal values are

“LUMISYS” or “ANSI”. It is highly recommended that “ANSI” be used. The correct

value is determined by th e host so ftware. So me host so ftware will ex cept eith er format.

Default = ANSI

P/N 0070-275, Rev 01, LSDT INTL SCSI OPTION, OPERATORS’ SUPPLEMENT MANUAL EC2051

Form No. 0069-978, Rev 01 5 OF 16

Page 6

3.4.3 Target SCSI ID NOT USED T his parameters is provided only for compatibility w ith previous

version of the scanner. The SCSI I D is set ONLY using the rotar y switch at the back of

the scanner.

3.4.4 Wait for Digitize

This parameter det er mines the behavior of the scanner when a Digitize command is

received. Legal values are “TRUE” or “FALSE”. Most host systems prefer FALSE,

but a value of TRUE cause a more LUMISCAN 150/200 like behavior.

Default = FALSE

3.4.5 Mode

This parameter determines the behavior o f the scanner when a Receive Data

command is processed and the is no dat a cur r ent ly available. Legal values are

“NORMAL” or “INTE RRUP TABLE”. A setting of NORMAL causes the SCSI bus to

be held bu sy wh ile w aiting for the image data. While th e S CS I bus is he ld no othe r

SCSI device can be accessed during the 8+ seconds that it takes to load the film fo r

scanning. A sett ing of IN TER R UPT AB L E re turns a BUSY c ondition and the host

must poll until data is availab le. Most syste ms will scan co rrectly with either value, but

general host system performance could be affected. The corr ect value is determined by

the host system.

Default = NORMAL

3.4.6 Film Present

Th e setting of the p ar ameter s ind icates to the scanner the pres ence of a film presen t

sensor in the hardware. The factory value for this parameters should not be changed

except by a field service person insta lling a hardware upgrade.

Default = (depends are act ual hardware, TRUE if detecto r is present in hardware)

3.4.7 Request Sense Length

This parameter allows the length of the response to a “Request S ense” command to

be overridden. The correct value is determined by the host software. Don’t change this

parameters unless your host software requires it.

Default = 0

P/N 0070-275, Rev 01, LSDT INTL SCSI OPTION, OPERATORS’ SUPPLEMENT MANUAL EC2051

Form No. 0069-978, Rev 01 6 OF 16

Page 7

4. Diagnostics

There are several diagnostic and maintenance programs that may be executed to

keep the scanner pe rformance optimal. At this time all diagn ostics must be run by u sing

internal “c ommand line utilities ”. To access the microprocessor a terminal, or a

computer running a terminal emulation progr am, should be connected to the serial port.

4.1 Serial Port Setup

At the back of the scanner, next to t he SCSI connector is a phone jack (RJ-11)

connector for an RS-232 serial line. This serial line uses a “3 wire” connection. Only

the transmit, r eceive, and ground wires are used. This port is set for 9600 baud, 8 bits,

No Par ity, 1 st op bit. (Note: some systems may be set t o 56K baud). T he serial port is

used to access the internal microcontro ller for system configuration, maintenance, and

diagnostics.

4.2 Scanner Control Program

Normally when the scanner is powered o n t he main contr ol program is executed.

Th e ma in pro gram is named “ LS DT ISO.EXE” . For hist oric al r easons it is some times

called LSDTS CS I. The L SD TISO p rog ra m takes command input from the SC SI bu s

and translates it into control oper ations for the scanner hardware. Image data is taken

from the scanner ha rdware, buffere d in onboard memory, a nd the n sent to the host.

When a terminal is attached to the serial port , input is received and process by the

control program. The LSDTISO prog r am accepts several single key commands: X, O,

D, F, L, and Q. These commands are case sensitive.

‘X’ - dump internal SCSI interface chip registers

‘O’ - display status of internal FIFO error flag (good or overflow)

‘D’ - enable/disable screen debugs (toggle), internal program status info

‘F’ - enable/disable SCSI commands (toggle), data, and status display

‘L’ - dump internal DMA controller registers [CAN CAUSE ERRORS]

‘Q ’ - qu it pro gr am, ex it to c ommand line pro mpt.

Note: the ‘L’ command can cause data loss and other erro r s if used while the

scanner is transferring data, DMA active.

Normally only the ‘Q’ quit command is used to get access to the command line

diagnostics.

Sometimes the ‘F’ Formatted SCSI data dump command may be used to try and

diagn ose syste m setup of h ost progra mming pr ob lems.

Sample ‘F’ Debug Output

P/N 0070-275, Rev 01, LSDT INTL SCSI OPTION, OPERATORS’ SUPPLEMENT MANUAL EC2051

Form No. 0069-978, Rev 01 7 OF 16

Page 8

[SCSI command bytes] : [data] ; [status code]

0A 00 00 00 02 00 : 10 00 ; 00

0A 00 00 00 0B 00 : 06 00 00 00 00 36 B0 42 68 09 B7 ; 00

0A 00 00 00 09 00 : 02 01 49 05 C4 01 00 04 91 ; 00

0A 00 00 00 02 00 : 10 01 ; 00

0A 00 00 00 0B 00 : 06 00 00 00 00 18 6A 1E A9 04 7D ; 00

0A 00 00 00 09 00 : 02 01 49 05 C5 01 00 04 92 ; 00

4.3 Command Line Maintenance and Diagnostics Utilities

Th e c ommand line utilit ies ar e access through the serial interface. After connecting

to the serial port , type ‘Q’ to cause the cont r ol program “LSDTISO” to exit. When the

“D:\>“ pro mpt a pp ears th e u tilities are r ea dy to run. A sub set of standa rd DOS

comma nds are available. When you ar e finished w ith the utilit ies eithe r reb oot the

system by power cycling, or run the LSDTISO program.

NOTE: Do NOT use the “DEL” de lete command to remove files for

the system flash memory file system. All the files on the system

are re qu ire d, miss in g file s will cause erro rs .

4.3.1 CHKCLUT - Check CLUT

The CHKCLUT program is used to verify that the CLUT file being used by the

scanner is corr ect. The CLUT file is used to adjust the pixel values to the cor r ect

optical density values. If CHKCLUT reports that perfor mance is out of specification

t he MKCLUT ut ility shou ld be run.

Th e CHKCLU T program scans a special film, called t he “step wedge ” film. The step

wedge is a film with band s of constan t den sity acr oss the film. A t ext file, called th e

“density file”, containing a list of the actual density vales for each wedge is read. The

program then compares the pixel values in the image with the “true” density values.

CHKCLUT serial_number density_tag

se ria l_numbe r - syst em ser ial numbe r, provide for compatibility, not used

density_tag - the unique specifier for the density filename. See the MKCLUT

description.

P/N 0070-275, Rev 01, LSDT INTL SCSI OPTION, OPERATORS’ SUPPLEMENT MANUAL EC2051

Form No. 0069-978, Rev 01 8 OF 16

Page 9

4.3.2 MKCLUT - Make CLUT

The MKCLUT program is used to create a CLUT file from scratch. The CLUT is a

lookup table that corr ects the raw pixel values to there true o p tical density values.

Th e MK CLUT pro gr am scans a special film, called t he “step wedge ” film. The step

wedge is a film with band s of constan t den sity acr oss the film. A t ext file, called th e

“density file”, containing a list of the actual density values for each wedge is read. The

program then compares the pixel values in the image with the “true” density values. By

using the differences between scanned pixel values and the true values, a co r r ection

LUT is generated. T his correction LUT is the “D:\CLUT0000.DAT” written to the

flash file system.

MKCLUT serial_number density_tag

se ria l_numbe r - syst em ser ial numbe r, provide for compatibility, not used

density_tag - th e unique specifier for the density filena me. The den sity file co nt ains

t he actual op tical densitie s of the step wedge film.

density filename = “DEN[density_ tag].DAT”

Example:

MKCLUT 0000 L15

uses density file “DENL15.DAT”

4.3.3 CHKMTF - Check MTF

Th e CHKMTF progra m is used to ve rify that t he s ca n ner is performing within

sp ecification s. This prog ra m re qu ire s the special “M TF” test film, an 8” by 10 ” film

with a group of vertical lines, a center black square, and a group of horizontal lines.

CHKMTF serial number

se ria l_numbe r - syst em ser ial numbe r, provide for compatibility, not used

4.3.4 CHKXYLIN - Check X/Y Linearity

The CHKXYLIN program is used to verify that the scanner linearity is within

specifications for both the X (pixels) and Y (lines) axis. This program requires the

special “Line ar ity” test film, a wh ite 14” by 17” film cr isscrossed b y X/Y lines spaced at

half inch intervals. This program detects the lines and measures there spacing.

CHKXYLIN serial number [threshold]

se ria l_numbe r - syst em ser ial numbe r, provide for compatibility, not used

t hresh old - optional th reshold multiplier value (default 1.25). This op tion is only

used in special circumstances where the lines on the XY pattern are not being detect ed.

P/N 0070-275, Rev 01, LSDT INTL SCSI OPTION, OPERATORS’ SUPPLEMENT MANUAL EC2051

Form No. 0069-978, Rev 01 9 OF 16

Page 10

4.3.5 LNADJDT - Adjust X Linearity

The LNADJDT program is used to adjust the scanner X (pixel) linearity. This

program should only be used by a trained Field Service person.

4.4 Command Line Tools

The command line to ols are used to enable system maintenance and diagnostics.

These tools do not directly effect the scanner hardware.

4.4.1 EDDEN - Edit the Density file

The EDDEN prog r am is used to create and modify the density files used by

MKCLUT and CHKCLUT on the Internal SCSI scanner.

Command line:

EDDEN densityFile

where " de nsityFile" is t he actual file na me of the de nsity value

file. If you use MKCLUT/CHKCLUT as follows:

MKCLUT 9999 014

then the "densityFile" should be "DEN014.DAT"

example:

EDDEN den014.dat

Commands:

D num - DELETE wedge entry

nu m = wed ge numb er to delete

E [num] - EDIT / Entry mode

num = optional wedge number to start editing

H - HEL P display list of comman ds

P - P RI NT display the complete list o f de nsity file values

Q - QUIT save file and end program

Note: w riting a file to t he F lash memory can take a long t ime (2+ minu tes)

-----------------------------------------------------------------------

The following is an example of creating a new density file

Note: user inputs are in

-----------------------------------------------------------------------

BOLD

P/N 0070-275, Rev 01, LSDT INTL SCSI OPTION, OPERATORS’ SUPPLEMENT MANUAL EC2051

Form No. 0069-978, Rev 01 10 OF 16

Page 11

D:\>edden den001.dat

EDDEN: Processing density file ’den001.dat’

No DENSITY file found.

EDDEN: Could NOT find density file ’den001.dat’

Do you wish to create a new density file? [Y|N]: y

Serial Number:

% lines to first step = 0.00

% lines of each wedge = 0.00

NO Wedg e densit y info rma tion in file

D num - DELETE wedge entry

num = wedge number to delete

E [num] - EDIT / Entry mode

num = optional wedge number to start editing

H - disp lay this message

P - p rint the d ens ity file va lue s

Q - quit

Enter cmd [H,Q,P,D,E]: e

Enter Serial Number []: 0123

Enter % lines to first step [0.00]:

Enter % lines of each wedge [0.00]: 6.5

Enter Wedge # 1 [0.00]: .04

Enter Wedge # 2 [0.00]: .14

Enter Wedge # 3 [0.00]: .44

Enter Wedge # 4 [0.00]: .35

Enter Wedge # 5 [0.00]: .9

Enter Wedge # 6 [0.00]: 1.2

Enter Wedge # 7 [0.00]: 1.5

Enter Wedge # 8 [0.00]: 1.99

Enter Wedge # 9 [0.00]: 2.12

Enter Wedge #10 [0.00]: 2.50

Enter Wedge #11 [0.00]: 2.8

Enter Wedge #12 [0.00]: 3.01

Enter Wedge #13 [0.00]: 3.3

Enter Wedge #14 [0.00]: 3.9

Enter Wedge #15 [0.00]: 4.5

Enter Wedge #16 [0.00]: (note: a blank line ends input)

P/N 0070-275, Rev 01, LSDT INTL SCSI OPTION, OPERATORS’ SUPPLEMENT MANUAL EC2051

Form No. 0069-978, Rev 01 11 OF 16

Page 12

Enter cmd [H,Q,P,D,E]: p

Serial Number: 0123

% lines to first step = 0.00

% lines of each wedge = 6.50

Wedge # 1 = 0.04 Wedge # 9 = 2.12

Wedge # 2 = 0.14 Wedge #10 = 2.50

Wedge # 3 = 0.44 Wedge #11 = 2.80

Wedge # 4 = 0.35 Wedge #12 = 3.01

Wedge # 5 = 0.90 Wedge #13 = 3.30

Wedge # 6 = 1.20 Wedge #14 = 3.90

Wedge # 7 = 1.50 Wedge #15 = 4.50

Wedge # 8 = 1.99

Enter cmd [H,Q,P,D,E]: q

Serial Number: 0123

% lines to first step = 0.00

% lines of each wedge = 6.50

Wedge # 1 = 0.04 Wedge # 9 = 2.12

Wedge # 2 = 0.14 Wedge #10 = 2.50

Wedge # 3 = 0.44 Wedge #11 = 2.80

Wedge # 4 = 0.35 Wedge #12 = 3.01

Wedge # 5 = 0.90 Wedge #13 = 3.30

Wedge # 6 = 1.20 Wedge #14 = 3.90

Wedge # 7 = 1.50 Wedge #15 = 4.50

Wedge # 8 = 1.99

Wedge # 3 = 0.44 >= # 4 = 0.35

Do you wish to write the density file with ERRORS? [Y/N]: y

Saving values to file ’den001.dat’

Note: w riting a file to t he F lash memory can take a long t ime (2+ minu tes)

-----------------------------------------------------------------------------The following is an example of editing the previous density file

-----------------------------------------------------------------------------D:\>edden den001.dat

EDDEN: Processing density file ’den001.dat’

Serial Number: 0123

% lines to first step = 0.00

% lines of each wedge = 6.50

Wedge # 1 = 0.04 Wedge # 9 = 2.12

Wedge # 2 = 0.14 Wedge #10 = 2.50

Wedge # 3 = 0.44 Wedge #11 = 2.80

P/N 0070-275, Rev 01, LSDT INTL SCSI OPTION, OPERATORS’ SUPPLEMENT MANUAL EC2051

Form No. 0069-978, Rev 01 12 OF 16

Page 13

Wedge # 4 = 0.35 Wedge #12 = 3.01

Wedge # 5 = 0.90 Wedge #13 = 3.30

Wedge # 6 = 1.20 Wedge #14 = 3.90

Wedge # 7 = 1.50 Wedge #15 = 4.50

Wedge # 8 = 1.99

D num - DELETE wedge entry

num = wedge number to delete

E [num] - EDIT / Entry mode

num = optional wedge number to start editing

H - disp lay this message

P - p rint the d ens ity file va lue s

Q - quit

Enter cmd [H,Q,P,D,E]: e 4

Enter Wedge # 4 [0.35]: .75

Enter Wedge # 5 [0.90]: q (note: while editing a blank line will NOT end)

Enter cmd [H,Q,P,D,E]: p

Serial Number: 0123

% lines to first step = 0.00

% lines of each wedge = 6.50

Wedge # 1 = 0.04 Wedge # 9 = 2.2

Wedge # 2 = 0.14 Wedge #10 = 2.50

Wedge # 3 = 0.44 Wedge #11 = 2.80

Wedge # 4 = 0.75 Wedge #12 = 3.01

Wedge # 5 = 0.90 Wedge #13 = 3.30

Wedge # 6 = 1.20 Wedge #14 = 3.90

Wedge # 7 = 1.50 Wedge #15 = 4.50

Wedge # 8 = 1.99

Enter cmd [H,Q,P,D,E]: q

Serial Number: 0123

% lines to first step = 0.00

% lines of each wedge = 6.50

Wedge # 1 = 0.04 Wedge # 9 = 2.12

Wedge # 2 = 0.14 Wedge #10 = 2.50

Wedge # 3 = 0.44 Wedge #11 = 2.80

Wedge # 4 = 0.75 Wedge #12 = 3.01

Wedge # 5 = 0.90 Wedge #13 = 3.30

Wedge # 6 = 1.20 Wedge #14 = 3.90

Wedge # 7 = 1.50 Wedge #15 = 4.50

Wedge # 8 = 1.99

Saving values to file ’den001.dat’

P/N 0070-275, Rev 01, LSDT INTL SCSI OPTION, OPERATORS’ SUPPLEMENT MANUAL EC2051

Form No. 0069-978, Rev 01 13 OF 16

Page 14

Note: w riting a file to t he F lash memory can take a long t ime (2+ minu tes)

D:\>

4.4.2 ED - Simple Line Editor

ed - line-oriented text editor , simila r to UNIX V7 ed

ED is a ve ry s imple lin e editor . It can be used to ed it all the text files used by the

internal controller system, even the density file normally edited by EDDEN. Nor mally

ED is only used to modify the LSDTCNFG.DAT file.

4.4.2.1 ED Syntax

ed [existing-file]

existing-file Only an existing file can be opened. Otherwise

a nameless edit buffer is opened; a name can be used with

the ‘f’ or ‘w’ commands.

As a line editor, ed operates in one of two modes: COMMAND mode, in which a

colon is displ ayed at the screen’s bottom to prompt for a command; and INPUT

mode, in which all keyboard input is added to the file (edit buffer). From

COMMAND mode, INPUT mode is entered by either the ‘i’ or ‘a’ commands.

From INPUT mode, the COMMAND mode is restored by entering a line

consisting of a singl e period by itself. If such a line is desired in the file, it can

be created by entering (for instance) two periods, then using the ‘s’ command to

change these to only one period.

A command consists of an optional line-range specification, a single character

indicating the command, and for some commands an optional third argument.

The line-range specification is either a single line number or a first-line number

and a last-line number separated by a comma. The character ‘^’ means the first

line of the file; ‘$’ means the last line of the file.

If the input command does not process correctly the “Oops” error message will

be displayed.

4.4.2.2 ED Commands

<newline>

If a line is specified, make that the new current line.

Otherwise advance the current- line-pointer by one line.

= Print the line number of the current line.

. (b y itself) P rint the cur rent line .

P/N 0070-275, Rev 01, LSDT INTL SCSI OPTION, OPERATORS’ SUPPLEMENT MANUAL EC2051

Form No. 0069-978, Rev 01 14 OF 16

Page 15

- (by itself) Move the current - line-pointer back one, and print

the new current line.

+ (by itself) Move the current-line-pointer forward one, and

print the new current line.

! Execute a shell command and return.

a Go into INPUT mod e with a new lin e follo wing the curren t lin e.

(IN PU T mod e is ter minate d by an input line co nt ainin g only a

period in the first column.)

i Go into INP UT mode with a new line preceding the current line.

(IN PU T mod e is ter minate d by an input line co nt ainin g only a

period in the first column.)

c Delete t he specified lines (or t he curr ent line) and then

add new lines in their place. This is equivalent to a ‘d’

comma n d followed b y an ‘ i’ comman d.

d Delete the specified range of lines (or the current line).

Leave the current-line-pointer at the following line.

e Clear the edit buffer and begin editing a new file. This

command fails if the buffer cont ains changes (or new lines)

which have not been writt en o ut. To discard these changes

and edit a new file, use ‘E’ instead of ‘e’.

E Clear the edit buffer and begin editing a new file, regardless

of any changes to t he current edit buffer.

f Print the filename, or set it to a new name if specified.

j Join the addressed lines to gether (or the current line to the

previo us line).

k Mark the addressed line with the specified letter . E xample:

‘17ka’ put s mark "a" on line 17.

l List the addressed lines, showing all non-printing characters

and indicating the end-of-line.

m Move the specified range of lines to follow the line number

given. Example: ‘5,7m3’ moves lines 5 through 7 "up", to

fo llow line 3.

p,P Print the specified lines.

q Quit the editor. This fails if the edit buffer contains any

changes. If so, use ‘Q’ instead.

Q Quit the editor absolutely. Any changes are discarded.

r Read in a file, adding it after the current line.

s Substitute text on the curr ent line. Example: ‘s/alpha/beta/’

finds the string "alpha" and replaces it with "beta".

t Tr ansfer (copy) the specified range of lines to follow the line

number given. Example: ‘5,7t7’ puts a copy of lines 5 through

7 after line 7.

w,W Wr ite t he edit buffer ou t. If a filename is given, it is used

and becomes the current filename. If a range of lines is

specified, only those lines are written.

P/N 0070-275, Rev 01, LSDT INTL SCSI OPTION, OPERATORS’ SUPPLEMENT MANUAL EC2051

Form No. 0069-978, Rev 01 15 OF 16

Page 16

x Write the entire buffer out to its file, and terminate.

z Print 21 lines. ‘-’, ‘.’, or ‘+’ may be given, and mean

"start 21 lines previous, end at curr ent line",

"start 11 lines previous, end 10 lines hence", or

"start at current line, end 21 lines from here", respectively.

P/N 0070-275, Rev 01, LSDT INTL SCSI OPTION, OPERATORS’ SUPPLEMENT MANUAL EC2051

Form No. 0069-978, Rev 01 16 OF 16

Page 17

P/N 0070-275, Rev 01, LSDT INTL SCSI OPTION, OPERATORS’ SUPPLEMENT MANUAL EC2051

Form No. 0069-978, Rev 01 2 OF 16

Loading...

Loading...