Page 1

KODAK PROFESSIONAL LED II Pr inter 20R

Operator’s Guide Part No. 6B6192

Page 2

© Eastman Kodak Company, 2000

All rights reserved. Contents of this publication may not be reproduced in any form

without permission from Eastman Kodak Company.

Page 3

Regulatory Information

Radio Frequency Interference

The United States (47 CFR Part 15 Subpart B, FCC Class A, EMC)

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at

his own expense.

IMPORTANT: Changes or modifications to the product that are not authorized by

Eastman Kodak Company could void the FCC Certification and

negate your authority to operate this product.

Canada (ICES-003 Issue 2 Rev1 Canada, Class A, EMC)

This Class A digital apparatus meets all requirements of the Canadian

Interference-Causing Equipment Regulations.

Cet appareil numerique de la classe A respecte toutes les exigences du

Reglement sur le materiel brouilleur du Canada.

European Union (EU, CE Marking, EMC)

This equipment has been type tested and found to comply with the requirements

for electromagnetic compatibility as established by European Communities

Council Directive 89/336/EEC and Low Voltage Directive (Product Safety)

73/23/EEC.

Japan (VCCI, Class 1 EMC)

The following is a translation of the above statement:

“This equipment is in the Class 1 category (information to be used in commercial

and/or industrial areas. Consequently, when used in a residential area or in an

adjacent area thereto, radio interference may be caused to radios and TV

receivers, etc. Read the instructions for correct handling”.

Page 4

Safety Regulations

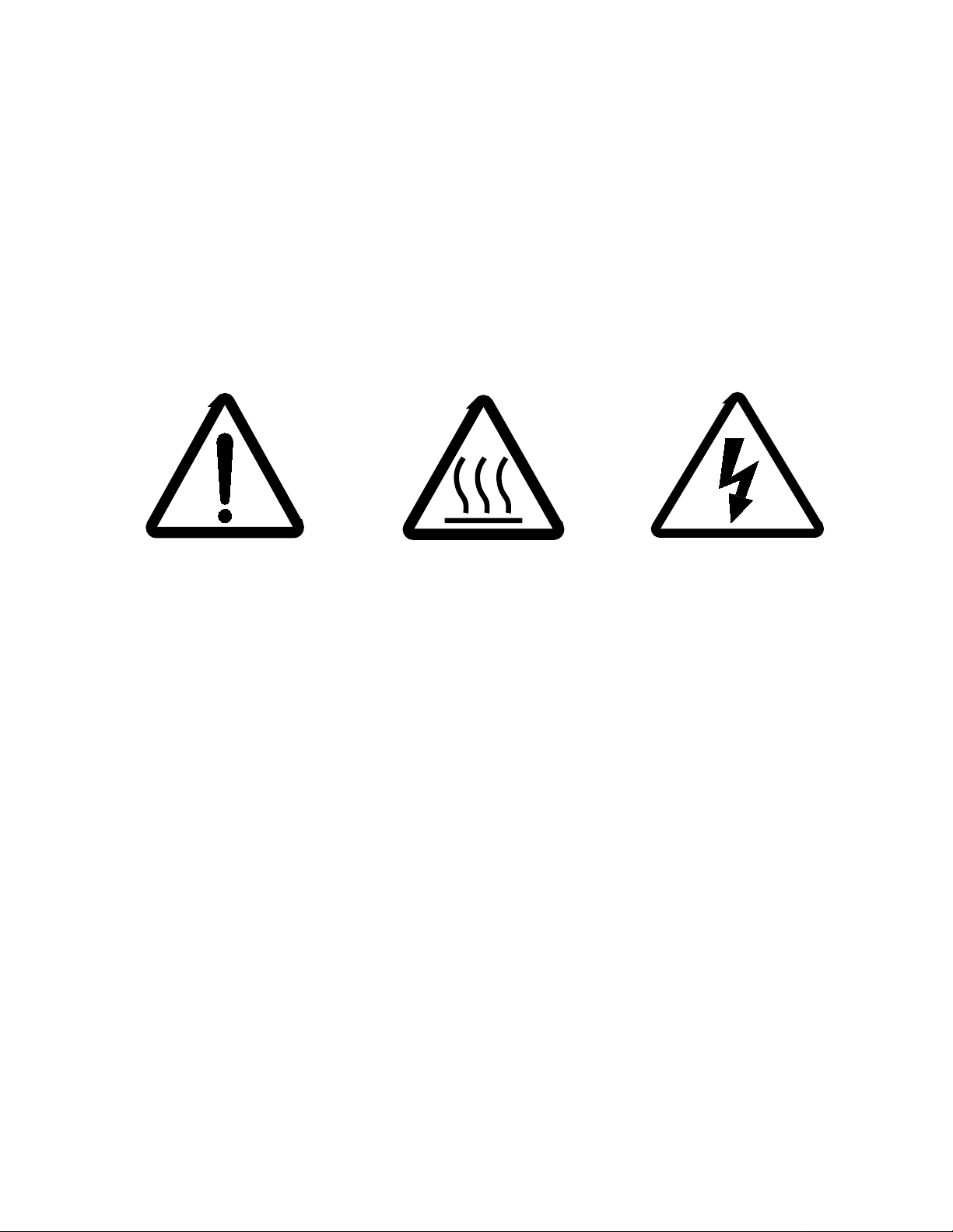

IMPORT ANT: This equipment incorporates high-voltage components. Adequate safeguards and interlocks

have been designed into this equipment to reduce the risk of injury during normal operation.

As with any electrical equipment of this kind, adequate ventilation must be provided to

minimize exposure to heat, dust , ozone, and othe r emis sions. The following labels will be

found on the product. The exclamation point symbol (A) indicates that the user should refer

to this guide for safety information. The hot symbol (B) indicates a hot surface area on the

printer that should not be touched. The electrical hazard/shock warning symbol (C)

identifies the possibilit y of electrica l shock inside an area that should only be accessed by

Kodak CES personnel.

A B C

CAUTION: Before connecting or disconnecting the SCSI cable or terminator, tur n off the power

for the printer and the host computer. Also, if you replace the SCSI cable, remove the

Ferrite bead from the existing SCSI cable and install it on the new SCSI cable.

Environmental Regulations

IMPORTANT: Always adhere to your local ordinances and regulations for disposal of paper, chemicals,

filters, cleaning supplies, etc.

Page 5

Warranty Information

The following warranty information pertains to equipment that is installed in the United States

only. For equipm ent installed in countr i es ot he r t han the Uni ted S tates, the terms and conditions

of the new equipment warranty will be provided by the Kodak company in the country in which

the sale is finalized, or by a Kodak-appointed distributor in those countries where Kodak does

not have direct sales representation.

Warranty Period

Kodak warrants new equipment to function properly for 90 days from the date of initial

installation. This warranty covers the purchaser of this equipment as well as anyone else who

owns i t during the warranty period.

Warranty Repair Coverage

If this equipment does not function properly during the warranty period, a Kodak Customer

Equipment Services Field Engineer will repair the equipment without charge during Kodak’s

normal working hours (usually 8:00 a.m. to 5:00 p.m., Monday through Friday). Such repair

service will include any adjustments and/or replacement of parts required to maintain your

equipment in good working order. Supply items are billed as required.

Off-hours services are available at overtime rates.

How to Obtain Service

For techn i cal support, service, repai r and fuse repl ace men t i nfo r mat ion, contact E ast m an Kodak

Company’s Technical Assistance Center at 1-800-822-1414.

Limitations

Warranty Service is limited to areas within Kodak’s established marketing centers in the

contiguous United States, the island of Oahu in Hawaii, and certain areas of Alaska.

This warranty does not cover circumstances beyond Kodak’s control; service or parts for any

attachments, accessories, or alterations not marketed by Kodak, nor to correct problems

resulting from their use.

Damaged caused by failure to meet electrical specifications in this manual will not be covered

under the warranty or service agreement claim.

Damage to the imaging shoe as a result of customer misuse or abuse will not be covered under

the warranty or service agreement claim. Do not use sharp objects to clear paper in this area.

Kodak makes no other warranties, express, implied or of merchantability, for this

equipment.

Repair or repl a cem ent without charge is Kodak’s only obligation under this warranty. Kodak will

not be responsible for any consequential or incidental damages resulting from the sale, use or

improper functioning of this equipment, even if loss or damage is caused by the negligence or

other fault of Kodak.

Such damages, for which Kodak will not be responsible, include, but are not limited to, loss of

revenue of profit, downtime costs, loss of use of the equipment, cost of any substitute

equipment, facilities or services or claims of your customers for such damages.

This limitation of liability will not apply to claims for injury to persons or damage to property

caused by the sole negligence or fault of Kodak or by persons under its direction or control.

Kodak Service Agreements

For information on Kodak Service Agreements, call Kodak Service Marketing Operations

at 1-800-645-6325.

Page 6

Page 7

Table Of Contents

About This Guide................................................................................................................. ................... . xiii

Using This Guide.................................................................................................................... xiii

About Other Publications .............................................................................. ....... ............ ..... xiv

Software Included With the Printer........................................................................................ xiv

Getting Help from Kodak........................................................................................................ xv

1 Introducti on......................... .......... ......... ................... .......... ................... ......... ........... ........................... 1-1

Product Description............................................................................................................... 1 - 1

SCSI Interface ................................................................................................................ 1-1

KODAK PROFESSIONAL LED II Prin te r 2 0R.............. .......... ......... ................... .......... .. 1-1

Installation and Service ...................... .......... ......... ................... .......... ................... ......... 1-1

Equipment Overview............ ......... .......... ................... ......... ................... .......... ......... ............ 1-2

2 Using the System ............. ................... ......... ................... .......... ................... ......... .......... ..................... 2-1

Starting up the Printer........................................................................................................... 2- 1

Calibrat i ng th e Prin ter .................................. ......... ................... .......... .................. .......... ....... 2 -2

Obtaining Densities ........................................................................................................ 2-5

Obtaining Densi ties from a File .......... ................... .......... ................... ......... .......... ...2-5

Using the Densitometer to Read Densities ..............................................................2-5

Completing the Calibration ............................................................................................. 2-6

Making Prints ........................................................................................................................ 2-8

Shuttin g Down the Printer.................. ................... .......... ................... ......... ................... ....... 2-8

Soft Shutdo w n........ ......... ................... .......... ................... ......... .......... ................... ......... 2-8

Hard Shutdown............................................................................................................... 2-9

3 Operating Procedures .......................................................................................................................... 3-1

Operator Control Panel (OCP).............................................................................................. 3-2

OCP Key/Light Descriptions........................................................................................... 3-3

Menu ........................................................................................................................3-4

Taking the Printer Offline .........................................................................................3-4

Cancelling Jobs ........................................................................................................3-4

Printing Deferred or Buffered Jobs ...........................................................................3-4

Status Messages ..................................... ............ ....... ......... ............ ....... ....... ............ ..... 3-5

Loading Paper Into the Supply Cassette............................................................................... 3-6

Removing the Supply Ca sse tte ...... ......... ................... ......... ................... ................... ..... 3-6

Loading the Paper .......................................................................................................... 3-7

Attaching a Digital Paper Saver.................................................................................... 3-10

Installing the Loaded Paper Supply Into the Printer ..................................................... 3-12

Installing the Takeup Cassette............................................................................................ 3-14

Preparing the Takeup Cassette.................................................................................... 3-14

Installing the Takeup Cassette ..................................................................................... 3-15

Cinching the Media to the Cardboard Core.................................................................. 3-17

Unloading the Paper from the Printer.................................................................................. 3-19

Reaching the End of Roll of Paper...................................................................................... 3-19

Removing the Takeup Cassette.......................................................................................... 3-20

Removing Exposed Paper from the Takeup Cassette.................................................. 3-21

Adjusting the Pape r Hol e Punchers.......................... ......... ................... .......... ................... 3-22

September 2000 vii

Page 8

Using the Printe r Fea tu re s........................... ......... ................... .......... .................. .......... ..... 3-23

Accessing the Menu..................................................................................................... 3-23

Unloading Paper........................................................................................................... 3-23

Unloading the Supply and Takeup .........................................................................3-23

Unloading the Takeup and Rethread .....................................................................3-23

Shutdown and Restart.................................................................................................. 3-24

Shutdown ...............................................................................................................3-24

Restart ....................................................................................................................3-24

Selecting a Loading Option .......................................................................................... 3-24

Paper Loading Options ................................................................... ....... .......... ......3-25

Selecting the Paper Load Option . . .........................................................................3-25

Changing the Paper Loading Option ......................................................................3-26

Additional Paper Loss ............................................................................ ............ ....3-26

Changing the Length of Paper Remaining on the Supply Roll ..................................... 3-26

Setting the Length of the Paper Trailer......................................................................... 3-27

Setting the Punches ..................................................................................................... 3-27

Determinin g the Loc at ion of the Cut and Order Punches ...... ................... .............3-28

Using the Automatic Roll ID.......................................................................................... 3-29

Using Page Starts......................................................................................................... 3-29

Setting the Page Sta r ts Value ............................. ......... ................... .......... ......... ....3-30

Producing Borderless Prints ...................................................................................3-30

Resetting the Defaults.................................................................................................. 3-31

Resetting the Parameters ................ .......... .................. .......... ................... ......... ....3-31

Resetting the Pr inting LUTs ........................... .......... ................... ......... ..................3-31

Resetting the Copyright Detection LUTs ................................................................3-32

Selecting the SCSI Ports.............................................................................................. 3-32

Setting the Target Pad Reads...................................................................................... 3-32

Selecting A Modem .... .................................................................................................. 3-33

Resetting the Modem Por t ........................... ................... ......... ................... .......... .3-33

Checking the Modem Presence .............................................................................3-33

Setting the Time and Date............................................................................................ 3-33

Setting the Current Time ........................................................................................3-33

Setting the Current Date ........................................................................................3-33

Setting the Current Day .......................................................................................... 3-34

Setting the Amount of Space Between Images ............................................................ 3-34

Changing the Units of Measurement for Paper Sizes................................................... 3-35

Changing the Gutter Width........................................................................................... 3-35

Accessing the Software Version Number..................................................................... 3-35

Setting the Copyright Detection Feature ...................................................................... 3-36

Handling and Storing the Paper.......................................................................................... 3-37

Storing Paper by Using the Soft Shutdown Feature..................................................... 3-37

About Printing...................................................................................................................... 3-37

Image Size....... ......... .......... ................... ......... ................... .......... ......... ................... ..... 3-37

Buffered and Unbuffered Jobs (or Deferred and Immediate) ....................................... 3-37

Host Software Functions Supported By the Printer...................................................... 3-38

Bar Coding ............... ................... .......... ................... ......... ................... .......... ........3-38

Pixel Doubling ........................................................................................................3-38

viii September 2000

Page 9

4 Maintaining the Equipment................................................................................................................... 4-1

Maintaining the Printer........... .......... ................... ......... .......... ................... ......... ................... 4-1

Daily Maintenance.......................................................................................................... 4-1

Calibrat i ng th e Prin ter .................................... .......... ................... ......... ................... .4-1

Removing the Punch Chad ......................................................................................4-2

Periodic Maintenance..................................................................................................... 4-3

Replacing the Air Filter .............................................................................................4-3

5 Diagnostics and Troubleshooting ......................................................................................................... 5-1

Printer Error Messages......................................................................................................... 5-1

Manual or Automatic Reinitialization............................................................................... 5-1

Printer Paper Path.......................................................................................................... 5-2

Printer Error Messages................................................................................................... 5-3

Miscellaneous Printer Error Messages............................................ ..... .. ....... ..... ....... ..... 5-8

Clearing Pap er Jams.......... ......... .......... ................... ......... ................... ......... ................. 5-9

Troubleshooting Observable Errors.............................................................................. 5-11

Additional Troubleshooting Tips for the Printer............................................................. 5-13

Calibration Troubleshooting ....................................... .. ....... ....... ..... ....... ....... ....... ..... ....... ... 5-14

Calibrat i on Grap h ................... .......... ................... ......... ................... .......... ................... 5-14

Numbered Error Messages .......................................................................................... 5-14

Non-Numeric Error Messages...................................................................................... 5-21

Getting Additional Help ....................................................................................................... 5-22

Appendix A: Ordering Supplies .............................................................................................................. A-1

Accessories.......................................................................................................................... A-1

Supplies ............................................................................................................................... A-1

Standard (U.S.) Paper............... ......... ................... .......... ................... ......... ......... ................ A-2

Metric Paper ......................................................................................................................... A-2

Leaders and Splice Tape . . ................................................................................................... A-3

Publications.......................................................................................................................... A - 3

Appendix B: Specifications..................................................................................................................... B-1

Printer Specifications ........................................................................................................... B-1

Dimensions and Weight................................................................................................. B-1

Acoustic Specifications.................................................................................................. B-1

Site Requireme n ts......... ................... ......... ................... .......... ................... ......... .......... ........ B-2

Operator and Service Access........................................................................................ B-2

Floor Require men ts........................ ......... ................... ......... ................... .......... ............. B-2

Electrical........................................................................................................................ B-3

Power Cords.... ................... ......... ................... .......... ................... ......... ................... ...... B-3

Power Outlet s......................... ................... .......... ................... ......... ................... .......... . B-4

Line Frequency.............................................................................................................. B-4

Line Voltage................................................................................................................... B-5

Power Receptacles (U.S. and Canada) ......................................................................... B-6

Printer Power Receptacles (Europe)............................................................................. B-7

Telephone line ............................................................................................................... B-8

Densitometer ................................................................................................................. B-8

SCSI Cable.................................................................................................................... B-8

Operatin g Envi r o n men t.............. ......... .......... ................... ......... ................... .......... ........ B-8

September 2000 ix

Page 10

Appendix C: Additional Calibration Information...................................................................................... C-1

Installing the Calibration Software........................................................................................ C-1

System Requireme n ts............................... .......... ................... ................... ......... ........... C-1

Installation Procedure........... .......... ................... ......... ................... ......... ................... .... C-2

Kodak Device Calibration Software...................................................................................... C-4

Application Window Definitions ..................................................................................... C-4

Starting the Kodak Device Calibration Software............................................................ C-6

Adding a Device ............................................................................................................ C-6

Editing th e Log Settings........................... ................... ......... ................... .......... ............. C-8

Updating a Device ......................................................................................................... C-9

Deleting a Device ........................................................................................................ C-10

Advanced Features of the LED II Calibration Software...................................................... C-11

Viewing Graphs.............................. ......... ................... ......... ................... .......... ........... C-11

Sending LUTs...................................................................... ..... ....... ..... ....... .. .......... .. .. C-16

Sending Targets .............................................................................. ..... ....... ....... ....... .. C-17

Editing the Calibration Configuration........................................................................... C-20

Editing Information on the Procedure Tab ............................................................C-22

Editing Information on the Density Source Tab .....................................................C-24

Editing Information on the Aim Tab .......................................................................C-25

Editing Information on the History Tab ..................................................................C-26

Editing Information on the Paper Tab ....................................................................C-27

Editing Information on the DP2 (Windows NT) or KPIS (Macintosh) Tab .............C-27

Completing the Edit Configuration ........................................................................C-31

Creating a Density File for Use with Calibration.......................................................... C-32

File Format s................. ......... ................... .......... .................. .......... ................... ......... .. C-32

Installing the Densitometer................................................................................................. C-33

Appendix D: Using the Image Print Server Software.............................................................................. D-1

Installing the IPS Software................................................................................................... D-1

Hardware Requirements. ............................................................................................... D-1

Software Requirements................................................................................................. D-1

Installing the Software ................................................................................................... D-2

Using the Image Print Server............................................................................................... D-2

Inserting Images into the Print Queue........................................................................... D-2

Source Direc to ry In se r ti o n .............. ................... ......... ................... ................... .......D-2

Menu Bar Insertion ..................................................................................................D-2

Suspending and Resuming .......................................... ..... ....... ..... .. ..... ....... .. ..... ....... .... D-3

Failed Jobs .................................................................................................................... D-3

Attended Operation .... ................................................................................................... D-3

Enqueue Example ......................................................................................................... D-4

Dialog Boxes and Print Options........................................................................................... D-6

Option Descriptions....................................................................................................... D-7

Enqueue Dialog Box...................................................................................................... D-8

Option Descriptions .................................................................................................D-8

Source Directo r y Pr e fe re n ce s Dia l o g Box......... ......... ......... ................... ................... .... D-9

Option Descriptions .................................................................................................D-9

Initialize Default Parameters Dialog Box..................................................................... D-10

Description ............................................................................................................ D-10

File Format Details ...................................................................................................... D-10

Supported Tags........................................................................................................... D-10

LZW Compression........... .......... ................... ................... ......... ................... .......... ...... D-10

x September 2000

Page 11

Appendix E: Using the PHOTOSHOP Expo rt Mod ule............................................................................ E-1

Installing the Export Module................................................ ....... ............ ............ ............ ...... E-1

Hardware Requirements. ............................................................................................... E-1

Software Requirements................................................................................................. E-1

Installing the Software ................................................................................................... E-2

Printing Images .................................................................................................................... E-3

Dialog Boxes and Print Options........................................................................................... E-6

KODAK LED Main Dialog Box....................................................................................... E-6

Option Descriptions .................................................................................................E-6

Other options ...........................................................................................................E-7

Punch Attributes ..................... ................... .......... ................... ......... .......... ................... . E-7

Option Descriptions .................................................................................................E-7

Page Layout Attri b u te s............................. .......... ................... ......... .......... ................... . E-8

Option Descriptions .................................................................................................E-8

Select an LED Printer Dialog Box.................................................................................. E-8

Option Descriptions....................................................................................................... E-9

Printer Status Dialog Box .............................................................................................. E-9

Option Descriptions..................................................................................................... E-10

Troubleshooting ................................................................................................................. E-10

Error messages ........................................................................................................... E-10

General err or messages ......... ................... ......... ......... ................... .......... ............E-10

Other Problems .....................................................................................................E-11

Index.................................................................................................................................................. Index-1

September 2000 xi

Page 12

Page 13

This is a User’s Guide for the KODAK PROFESSIONAL LED II Printer 20R. It

provides step-by-step instructions for the operations you perform while using the

Printer. It also includes procedures and information for operating, maintaining,

troubleshooting, and calibrating the printer.

Also included in this guide are instructions for installing and using the various

software packages needed.

This guide is intended for personnel who operate this system. It assumes that you

can perform basic computer operations.WINDOWS NT and MACINTOSH

Platforms are supported in this guide.

Using This Guide

This guide is organized as follows:

Chapter 1 Introduction—describes and illustrates th e KODAK

Chapter 2 Using the System—explains how to use the printer. It

About This Guide

PROFESSIONAL L ED II P rinter 2 0R. This chapter i ncludes

general and introductory information for all of the equipment.

includes the step-by-step instructions for daily operation,

from startup to shutdown.

Chapter 3 System Operating Procedures—provides an overview of

the OCP and all of the procedures for operating the Printer.

Chapter 4 Maintaining the Equipment—includes the information that

you need to properly maintain the printer. All maintenance

procedures are categorized by frequency.

Chapter 5 Diagnostics and Troubleshooting—provides an error

code listing, solutions to common operational problems for

the printer and calibration. It also provides information for

obtaining additional help.

Appendix A Ordering Equipment, Accessories, and Supplies—

provides ordering information for many associated items. It

includes information such as size, quantities, and catalog

numbers.

Appendix B Specifications—provides specifications, site

requirements, and environmental information for the syst em.

Appendix C Calibrating the Printer—describes the calibration

functions for the KODAK Calibration Software as well as

Printer Calibration Software.

Appendices D-F Software—explains how to install and use the software that

is included with the printer.

September 2000 xiii

Page 14

About This Guide

About Other Publications

The following publication is included with the printer:

Quick Reference Guide for the KODAK PROFESSIONAL LED II Printer 20R

and the KODAK PROFESSIONAL LED II Processor 20R–provides quick and

easily accessible information for operating and maintaining the printer as well as

answers to common printer problems and hints for operating the processor. Keep

the Quick Reference Guide close to your printer.

Software Included With the Printer

The compact disc (CD) included with the KODAK PROFESSIONAL LED II Printer

20R contains the KODAK Calibration Software and the Printer Calibration

Software for WINDOWS NT and MACINTOSH Host Computers. It also includes

additional applications the printer can interface with.

This software is usually installed by a Kodak representative. However, install ation

instructions are included in this Operator’s Guide.

A PDF file of this Operator’s Guide is also included on the CD.

You can find the latest software and documentation for the KODAK

PROFESSIONAL LED II Printers on the Kodak Web site: www.kodak.com.

xiv September 2000

Page 15

Getting Help from Kodak

Your Kodak sales representative is the best source for information about setting

up and operating your printer and for obtaining accessories and supplies. Please

contact your Kodak sales representative if you have any questions.

Kodak Sales Representative:___________________________

Representative’s Telephone Number:_____________________

K-Number:_________________________________________

In addition, for technical support in the U.S., call 1-800-3Kodak3 between

8:00 a.m. and 11:00 p.m. Eastern Standard Time on regular business days.

Telephone numbers for help outside the United States are in the Chapter 5,

Diagnostics and Troubleshooting.

You can also use the technical support number for information on:

• operating the printer

• how or where to obtain supplies

• how to obtain service

• the warranty

• other Kodak products

About This Guide

If you are calling for technical support, please know your printer’s K-Number. The

K-Number label is attached to the front of the printer, next to the operator

control panel.

Product Li te rat ure

The faxback number for product literature is 1-800-508-1531. You may call this

number 7 days a week, 24 hours a day.

September 2000 xv

Page 16

Page 17

This chapter includes the following information about the KODAK

PROFESSIONAL LED II Printer 20R:

Product Description ...........................................................................................1-1

SCSI Interface .............................................................................................1-1

KODAK PROFESSIONAL LED II Prin te r 2 0R ........ ......... ................... ........1-1

Installation and Service .......................... ................... ......... .......... ...............1-2

Equipment Overview ......................... .......... ................... ......... ................... ........1-2

Product Description

The KODAK PROFESSIONAL LED II 20R printing system offers a combination of

printing options that produces photographic quality output of digital images. The

images are printed at a resolution of 250 dpi and at sizes varying from 8 x 10 in. to

20 x 33 in.

Images printed with this system are comparable to images produced on an optical

printer. By using KODAK PROFESSIONAL Digital Paper with proper color

management, the 20R printer provides the “look” of VPS fil m on KO DAK PORT RA

or SUPRA Paper, or GOLD Film on KODAK EKTACOLOR Edge Paper.

1 Introduction

The system consists of a MACINTOSH or PC host computer to manage and

manipulate the digital source image, a SCSI interface to transfer the digital image

to the printing system, and the KODAK PROFESSIONAL LED II Printer 20R to

expose the digital image.

You can use a variety of software applications (such as KODAK Image Print

Server Software) to manage and manipulate the digital images.

SCSI Interface

A SCSI cable connects the host computer to the KODAK PROFESSIONAL LED II

Printer 20R. This interface transfers the digital i mage data f rom the host computer

to the printer.

KODAK PROFESSIONAL LED II Printer 20R

The KODAK PROFESSIONAL LED II Printer 20R exposes digital images on

photographic quality paper using a sophisticated technology involving Light

Emitting Dio des ( LEDs). Th e pr inte r use s KO DAK P ROFESSI ONAL Digit al Paper,

in 10, 11, 12, 20 inch and A4 widths to create prints of 6.5 x 10 in. to 20 x 33 in.

The images are wound onto a takeup roll which is then taken to an RA-4

processor for developing.

Installation and Service

The KODAK PROFESSIONAL LED II Printer 20R printer must be installed and

serviced by a qualified Kodak service representative.

September 2000 1-1

Page 18

Introduction

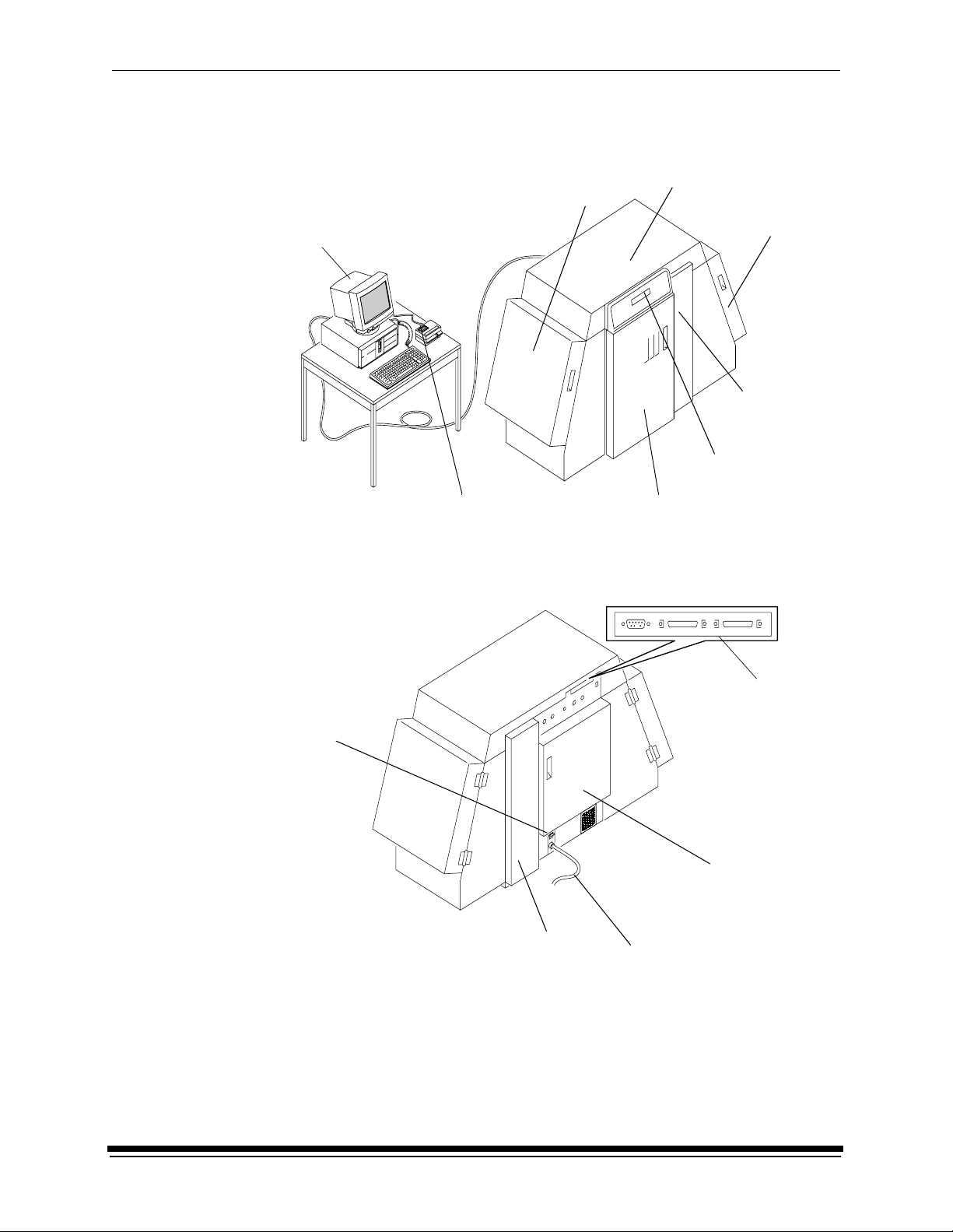

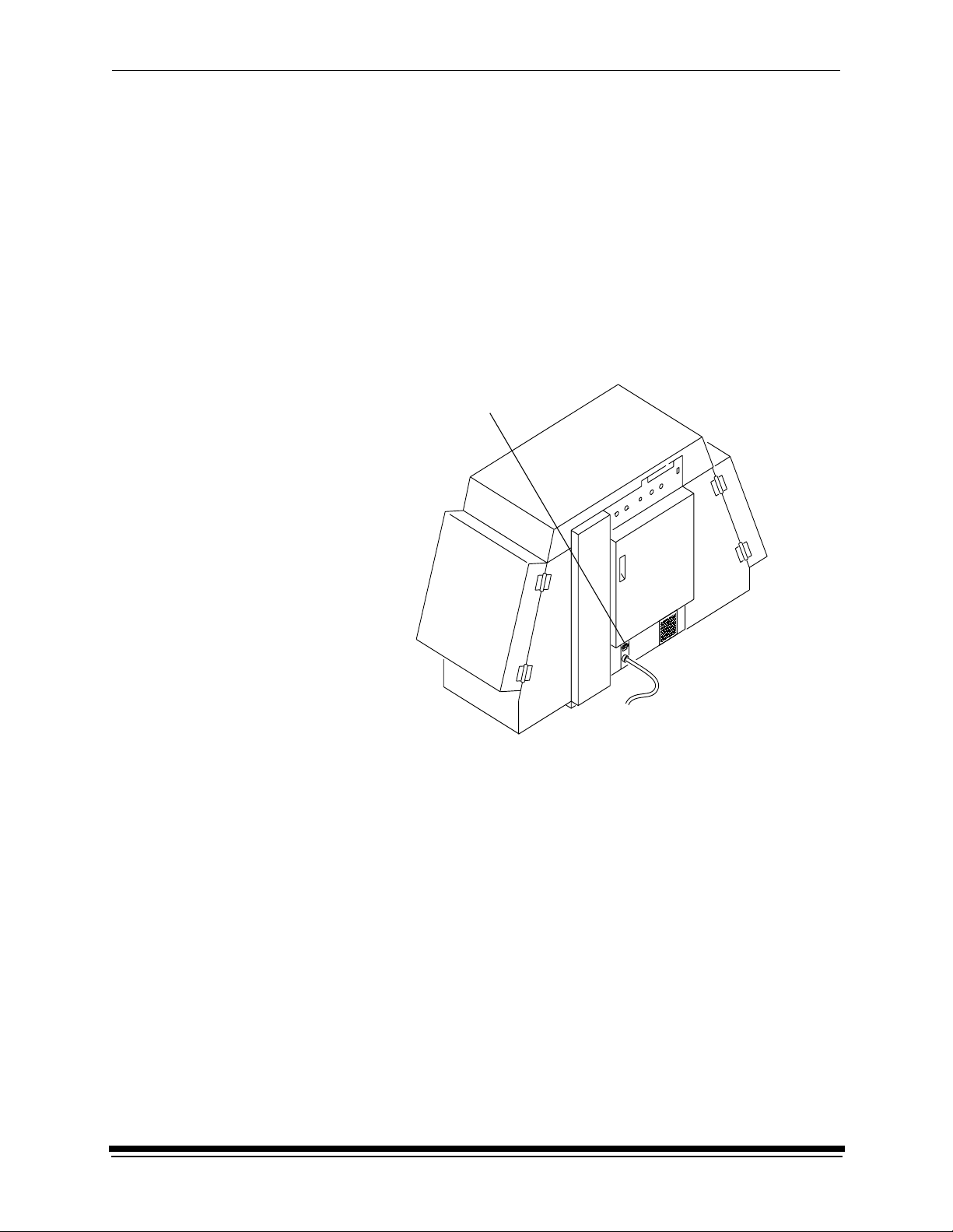

Equipment Overview

Front View

host computer and SCSI cable

(not included)

densitometer (not included)

Rear View

paper supply

door

prin t e r

paper takeup

door

front door

front

slack loop

door

operator

control panel

circuit

breaker

connector

ports

back door

back slack loop door

power cord

1-2 September 2000

Page 19

This chapter explains how to use the KODAK PROFESSIONAL LED II Printer

20R. It takes you from startup to shutdown. T opics include:

Starting up the Printer ........................................................................................2-1

Calibrat i ng th e Prin ter ........... .......... ................... ......... ................... .......... ..........2-2

Obtaining Densities .....................................................................................2-4

Completing the Calibration ..........................................................................2-6

Making Prints .....................................................................................................2-7

Shuttin g Down the Printer ............................... .......... ................... ................... ...2-8

Soft Shutdo w n.......... ................... .......... ......... ................... ......... .......... ........2-8

Hard Shutdown ...........................................................................................2-9

Starting up the Printer

1. If needed, turn the circuit breaker on the back of the printer on.

2. Press the Start key on the OCP to begin the printer initialization process.

If paper is loaded, when initialization is complete (3 to 4 minutes) the

message “Status: ON LINE - Ready” appears on the OCP . S tartup is complete

and the printer is ready to print. Turn the host computer on; then go to the next

page and calibrate the printer.

2 Using the System

If paper is not loaded, the message “Out of paper, open supply door

to load” appears on the OCP. Do the procedures below.

• “Loading Paper Into the Supply Cassette” on page 3-6

• “Installing the Takeup Cassette” on page 3-14

When “On-line and Ready” is displayed, turn the host computer on. Go to

the next page and calibrate the printer.

September 2000 2-1

Page 20

Using the System

Calibrating the Printer

You need to calibrate the printer when you start the system up each day. You also

need to calibrate the printer when:

• you change paper

• print quality is questionable

• the temperature at the site changes more than 5° F (2.8° C)

• if running more than one shift, at the beginning of each shift

If you are calibrating at any time other than during the daily startup procedure:

Before you begin, make sure the printer is not receiving printing commands from

the host.

NOTE: Most windows displayed in this section are from the Windows NT version

of the software. The windows for the Macintosh version of the software are

similar.

For information about editing the calibration settings (for example, you may want

to display a calibration graph only if calibration is out of tolerance), see “Editing

the Calibration Configuration” on page C-20.

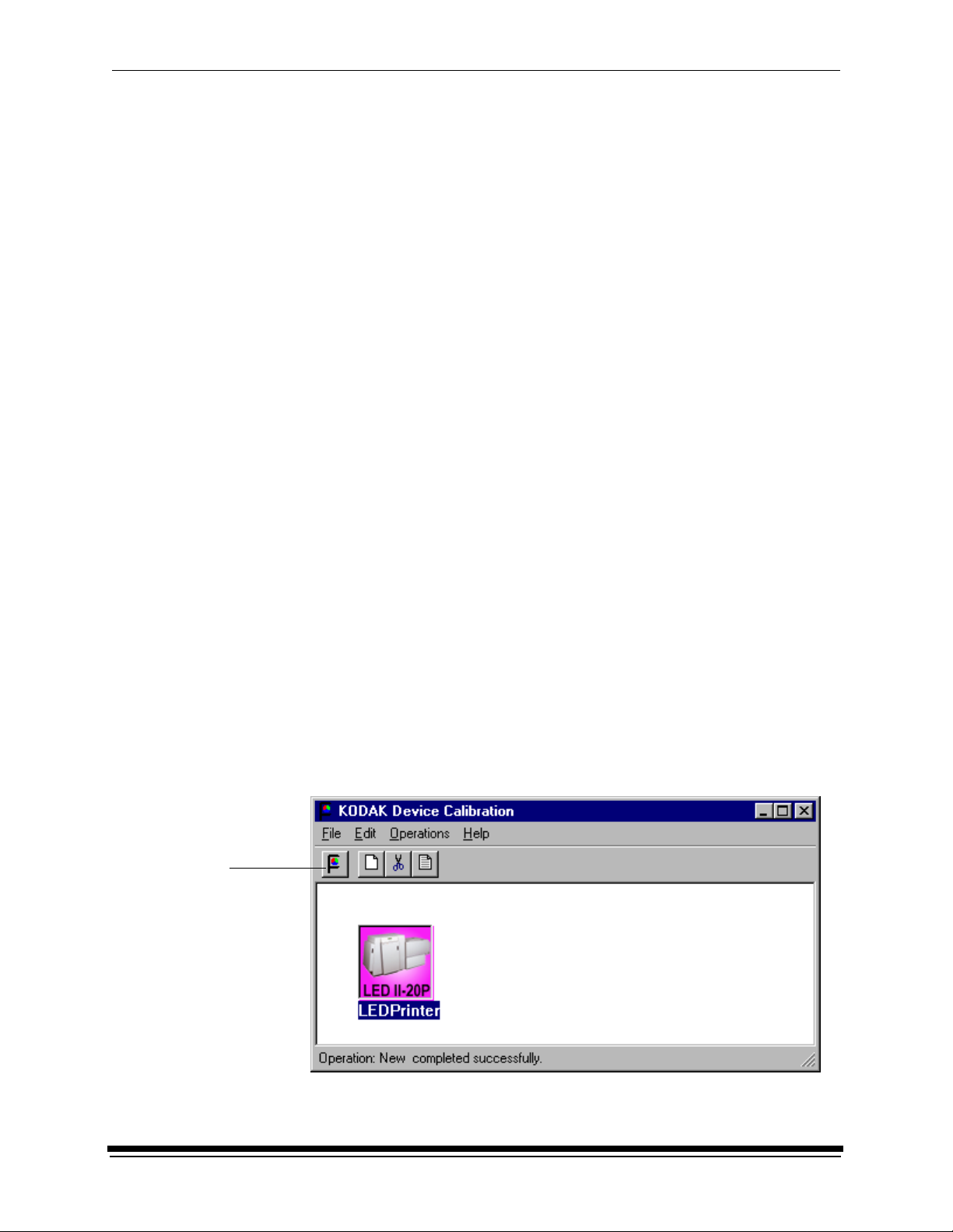

Calibrate

icon

To calibrate the printer:

1. Check that:

• the densitometer is connected and calibrated

• the printer status is “Online and Ready”

• the processor is in control

• the calibration application is running

2. Select the icon for the LED Printer on the KODAK Device Calibration screen

and click the Calibrate icon. The calibration software needs complete control

of the printer to successfully calibrate the printer.

IMPORT ANT:If no icon appears on the KODAK Device Calibration screen, you

need to add a calibration device. See “Adding a Device” on

page C-6.

2-2 September 2000

Page 21

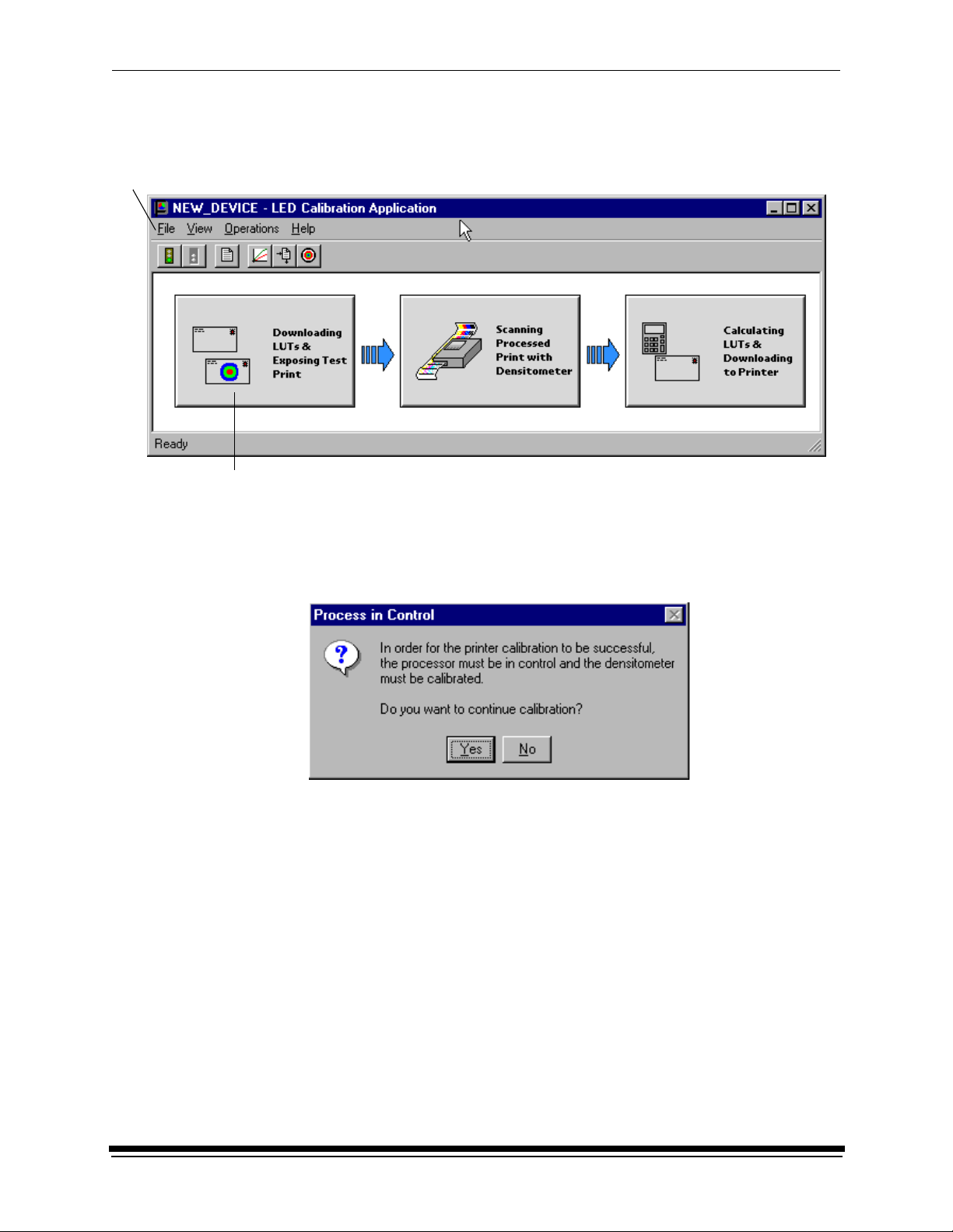

Go icon

This icon highlights after

you select Go

Using the System

The LED Calibration screen appears.

3. Click Go to start the calibration cycle .

Downloading LUTs and Sending Test Print highlights.

If the configuration file specifies to Ask if processor is in control, the

Process In Control dialog box appears.

The processor is critical to printer calibration. You can calibrate the printer

only if the processor is in control. Densitometers require calibration at regular

intervals. Refer to your densitometer’s manual for instructions on how to

calibrate your densitometer.

4. Click Yes.

September 2000 2-3

Page 22

Using the System

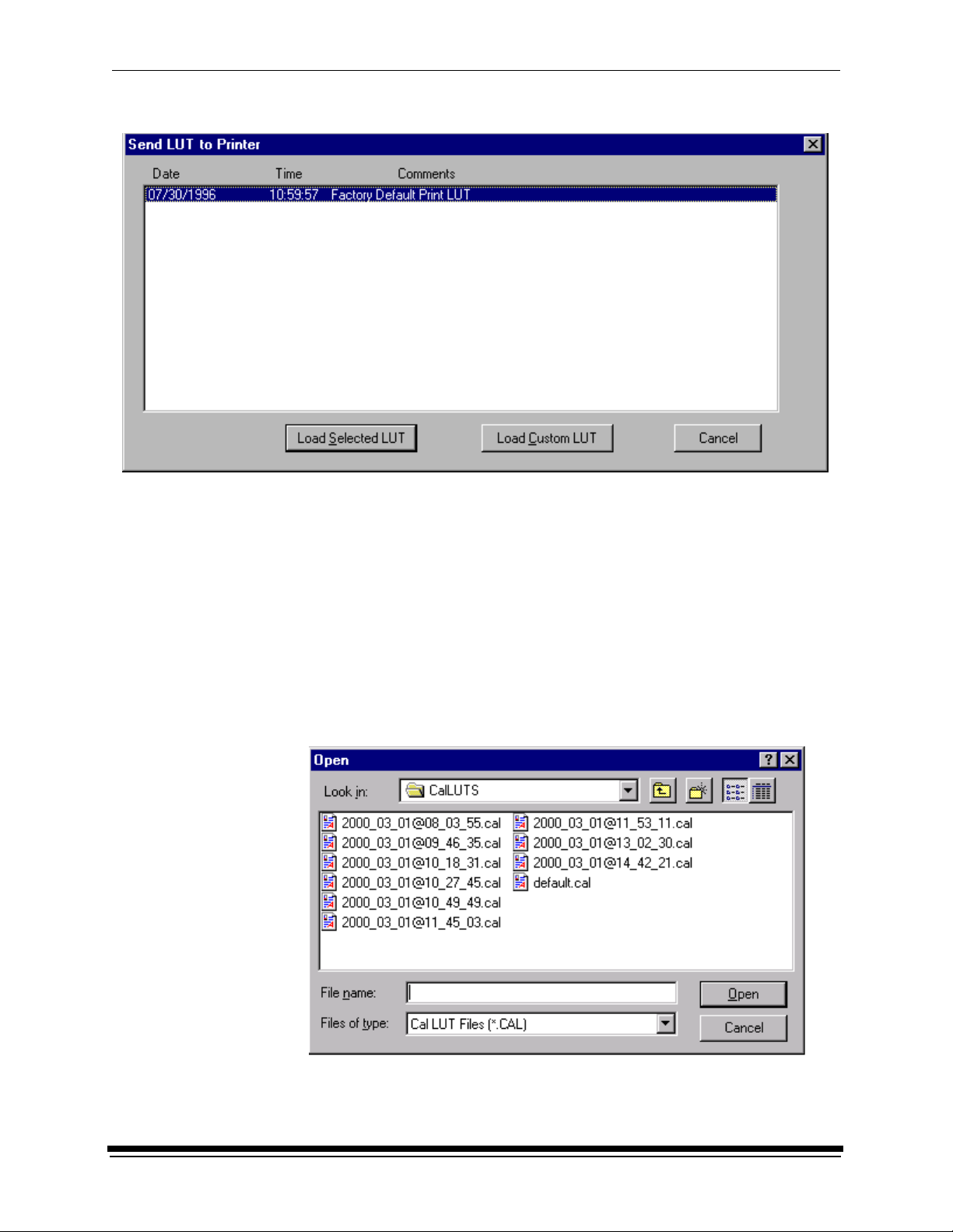

The Send LUT to Printer screen appears.

NOTE: The highlighted LUT in the dialog box above is the most recent

calibration LUT.

5. Click either Load Selected LUT or Load Custom LUT (or Cancel to cancel

the calibration process).

If you click Load Selected LUT, the system automatically downloads the

highlighted LUT to the printer to create a test print.

When the test print has been sent, the Scanning Processed Print with

Densitometer status icon on the LED Printer Calibration screen is

highlighted.

Go to “Obtaining Densities” on page 2-5.

6. If you selected Load Custom LUT in step 5, the Open dialog box appears.

Select or type the name of the LUT file you want and click Open.

2-4 September 2000

Page 23

Using the System

The system automatically downloads the LUT file to the printer to create a test

print. When the test print has been sent to the printer, the Scanning

Processed Print with Densitometer status icon on the KODAK LED Printer

Calibration screen is highlighted.

Obtaining Densities

Obtaining Densities from a File

If the configuration settings include obtaining the density data from a file, the

Waiting for Density File dialog box appears. Otherwise, go to “Using the

Densitometer to Read Densities.”

NOTE: T o create a density file, see “Creating a Density File fo r Use with Calibration”

on page C-32.

1. Click OK to continue with the calibration process.

2. Go to “Completing the Calibration” on page 2-6.

Using the Densitometer to Read Densities

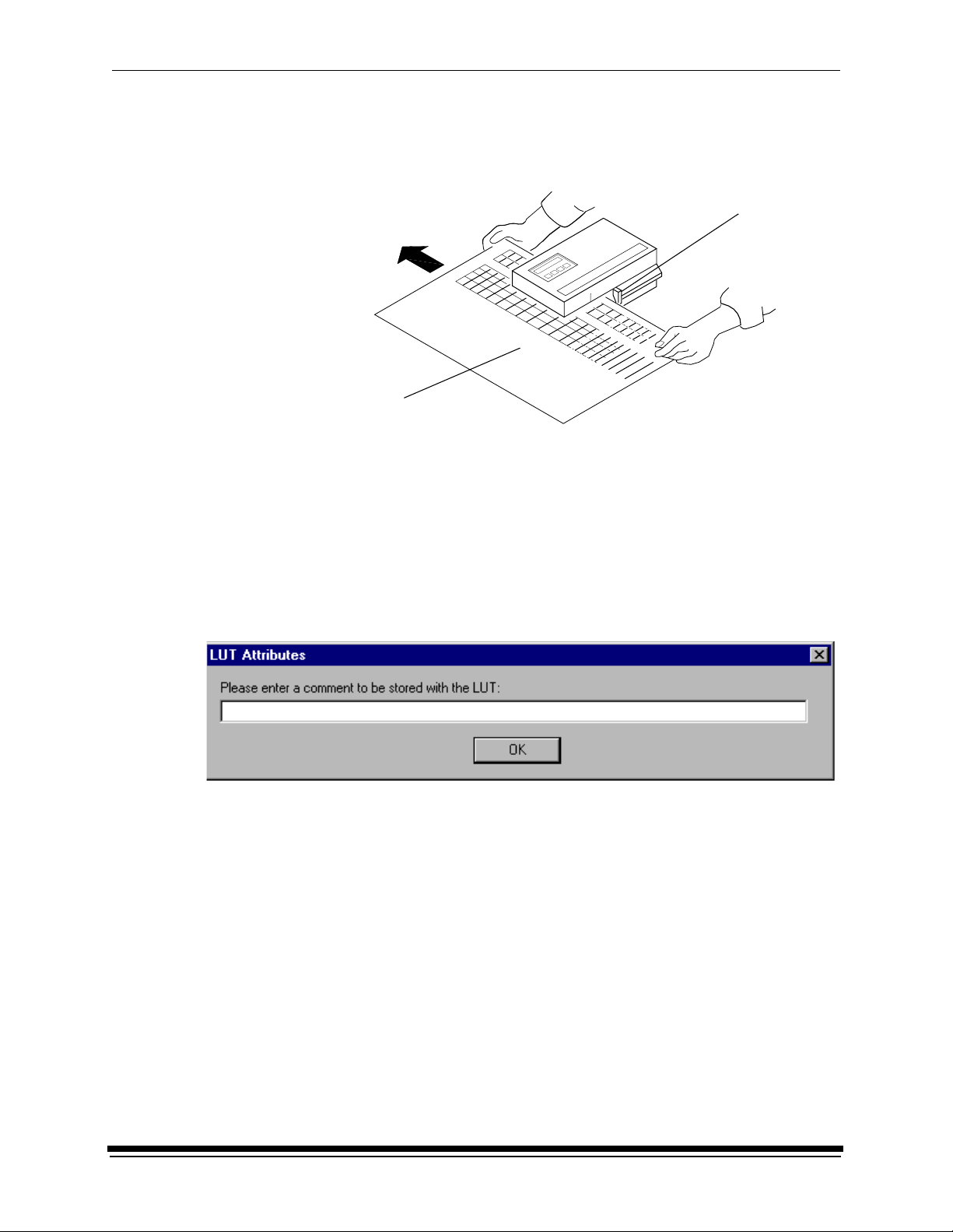

Do the following to scan the neutral (gray) patches on the processed test print into

the densitometer (refer to your densitometer manual for detailed instructions on

using the densitometer):

1. Slide the lever on the densitometer to position 15. Align the edge of the test

print with the lever on the densitometer. Gently feed the test print through the

densitometer to scan the patches labeled “even”.

2. Slide the lever on the densitometer to position 20. Align the edge of the test

print with the lever on the densitometer. Gently feed the test print through the

densitometer to scan the patches labeled “odd”.

September 2000 2-5

Page 24

Using the System

3. Slide the lever on the densitometer to position 30. Align the edge of the test

print with the lever on the densitometer. Gently feed the test print through the

densitometer to scan the patches labeled “both”.

Test print

If the test print is read successfully, several messages will appear in the status

bar; the final message indicates that the densitometer values have been

successfull y recei ve d . Go to “Completing the Calibration.”

Lever

If the test print is not read successfully, refer to “Calibration Troubleshooting”

on page 5-14.

Completin g th e Calib r ati on

1. If calibration is in tolerance, the LUT Attributes dialog box appears.

a. E n ter a n ame or comment in the dialog b ox . The commen t you en t er w ill

appear on the Send LUT to Printer screen to identify the LUT file with a

name that is meaningful to you (up to 75 characters).

b. Click OK.

The new printing LUT is calculated and downloaded. “Calibration

Complete” appears in the status bar. The calibration is complete.

2-6 September 2000

Page 25

Using the System

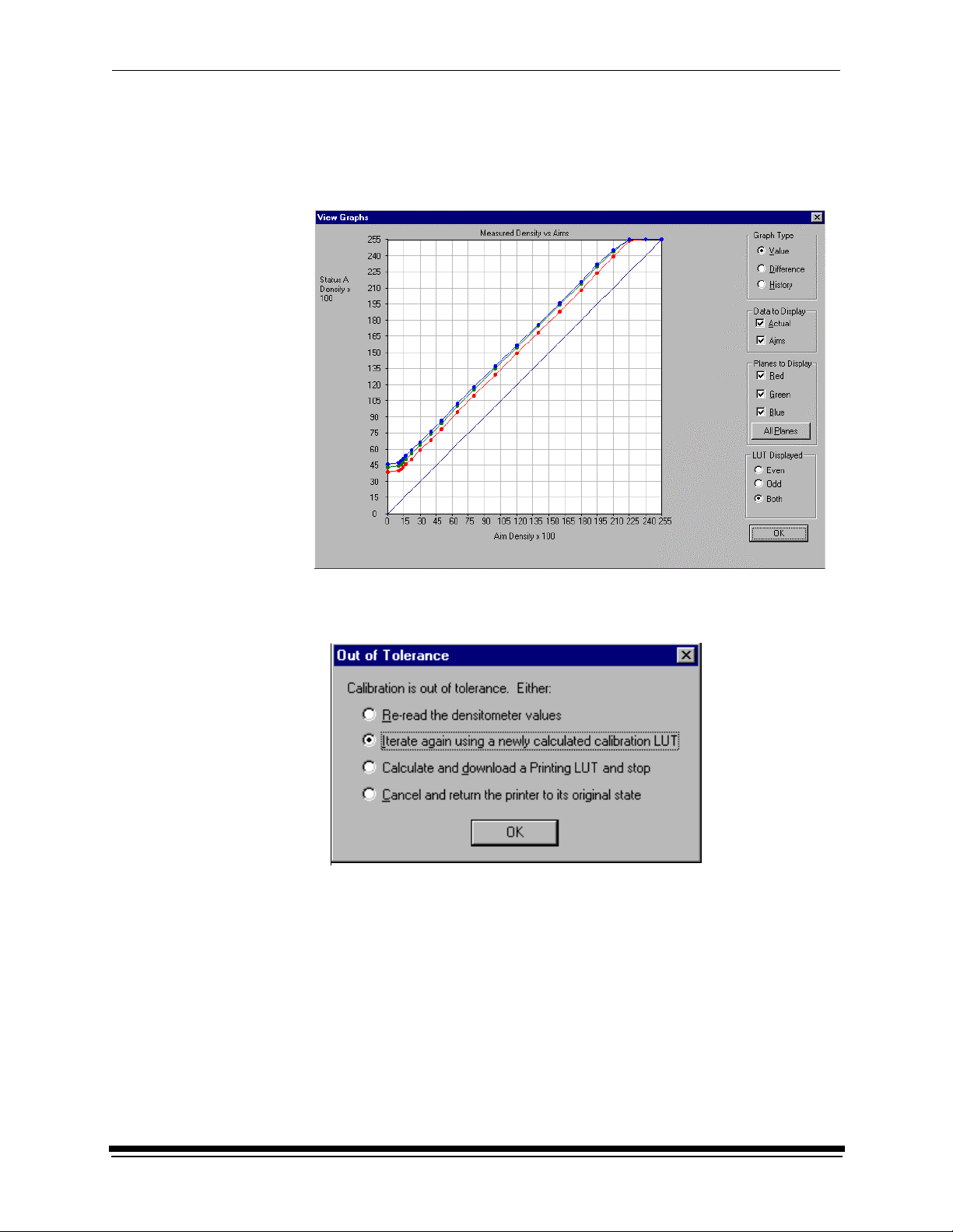

2. If cal ibrati o n is out of toleran ce, it ma y be necessar y to r un four or more

iterations o f the cal ibra tion cycle to achieve a successful cali br at i on.

If the print densities are out of tolerance, a graph appears, allowing you to

select the type of data and planes that you want to see displayed.

a. Click OK.

The following list of options appears.

Re-read the densitometer values is the most useful when the graphs

show an unusual plot. Rereading the test print lets you validate the graph,

then returns you to the Out of Tolerance dialog box.

Iterate again using a newly calculated calibration LUT allows you to

keep printing test prints with the newly created LUT without having to save

the LUT table.

Calculate and download a printing LUT and stop: When you select this

option, the file is saved and given the same creation date and time as the

name.

Cancel and return the printer to its original state saves nothing. Any

corrupted data created after you saved the last time is thrown away.

September 2000 2-7

Page 26

Using the System

Making Prints

You can make prints using the LED Printer 20R with a wide variety of applications

that run on WINDOWS NT Computers and MACINTOSH Computers. One

application that is widely used for printing is the KODAK PROFESSIONAL

Imaging System.

Two applications that you may wish to print from are included with the system.

You can use the KODAK PROFESSIONAL Image Print Server for WINDOWS NT

to print TIFF images. You can use the Export Module for ADOBE PHOTOSHOP

that runs on MACINTOSH Computers to print images from the PHOTOSHOP

application.

b. Select one of the four options to try to complete the calibration

successfully.

• If th e Out of Toleranc e dialog box appears again, repeat this step until

you get a successful calibration; go to step 1.

• If you cannot get a successful calibration, request help from a system

administrator or service person.

For more information about these applications, see the appropriate Appendix in

this guide.

Shutting Down the Printer

There are two methods for shutting down the printer. The soft shutdown method is

the recommended way to shut down the printer overnight or for a period of several

hours. The hard shutdown method should be used for shutting down the printer

for an extended period of time (several days or longer).

Soft Shutdown

IMPORTANT: The soft shutdown method ensures that all printer information is

saved and that the print head is safely turned off if paper is loaded

in the printer.

1. Check that all jobs in the print queue are printed.

2. Press the O n /Off Line k e y on the OCP to tak e th e printe r o ffline.

3. Press the Menu button on the OCP to access the menu.

4. Select “Shutdown” in the message displ ay.

5. Press the Start key.

6. Select “Shutdown now” in the message display.

7. Press the Select key to begin the shutdown.

NOTE: If any jobs are not complete, you will be asked if you want to delete the

remaining jobs before you can select Shutdown.

2-8 September 2000

Page 27

Using the System

Hard Shutdown

Use this method for shutting down the printer for an extended period of time

(several days or longer).

1. Do a soft shutdown. See “Soft Shutdown” on page 2-8.

CAUTION: T urn off the cir cuit breaker only after doing the soft shutdown.

Otherwise, you could lose printer status information and will

cause dark lines to appear in the middle of the prints if paper

is loaded.

2. Turn off the circuit breaker on the back of the printer.

circuit breaker

September 2000 2-9

Page 28

Page 29

3 Operating Procedures

This section provides the information you need to operate the KODAK

PROFESSIONAL LED II Printer 20R. Topics include:

Operator Control Panel (OCP) ...........................................................................3-2

OCP Key/Light Descriptions ........................................................................3-3

Status Messages ............................................................................ ....... ......3-5

Loading Paper Into the Supply Cassette ...........................................................3-6

Removing the Supply Ca sse tte........ ................... ................... ................... ...3-6

Loading the Paper .......................................................................................3-7

Attaching a Digital Paper Saver ................................................................ 3-10

Installing the Loaded Paper Supply Into the Printer ..................................3-12

Installing the Takeup Cassette ........................................................................3-14

Preparing the Takeup Cassette ................................................................3-14

Installing the Takeup Cassette .................................................................. 3-15

Cinching the Media to the Cardboard Core ...............................................3-17

Unloading the Paper from the Printer ..............................................................3-19

Reaching the End of Roll of Paper ..................................................................3-19

Removing the Takeup Cassette ......................................................................3-20

Removing Exposed Paper From the Takeup Cassette .............................3-21

Adjusting the Pape r Hole Punchers ............. ................... ......... ................... ....3-22

Using the Printe r Fea tu re s .......................... ......... ................... ......... ................3-23

Accessing the Me nu ............................... ................... ......... ................... ....3-23

Unloading Paper .......................................................................................3-23

Shutdown and Restart ...............................................................................3-24

Selecting a Loading Option .......................................................................3-24

Changing the Length of Paper Remaining on the Supply Roll ..................3-26

Setting the Length of the Paper Trailer .....................................................3-27

Setting the Punches ..................................................................................3-27

Using the Automatic Roll ID ......................................................................3-29

Using Page Starts .....................................................................................3-29

Resetting the Defaults .......................... ................... ......... ................... ......3-31

Selecting the SCSI Ports ...........................................................................3-32

Setting the Targ e t Pa d Reads ..................... ................... ......... ..................3-32

Selecting A Modem ...................................................................................3-33

Setting the Time and Date ........................................................................ 3-33

Setting the Amount of Space Between Images . ........................................ 3-34

Changing the Units of Measurement for Paper Sizes ...............................3-35

Changing the Gutter Width ........................................................................3-35

Accessing the Software Version Number ..................................................3-35

Setting the Copyright Detection Fea tu r e ......... .......... ................... ......... ....3-36

Handling and Storing the Paper .......................................................................3-37

Storing Paper by Using the Soft Shutdown Feature .................................3-37

About Printing ..................................................................................................3-37

Image Size ................. ......... .......... .................. .......... ................... ......... ....3-37

Buffered and Unbuffered Jobs (or Deferred and Immediate) ....................3-37

Host Software Functions Supported By the Printer ...................................3-38

September 2000 3-1

Page 30

Operating Procedures

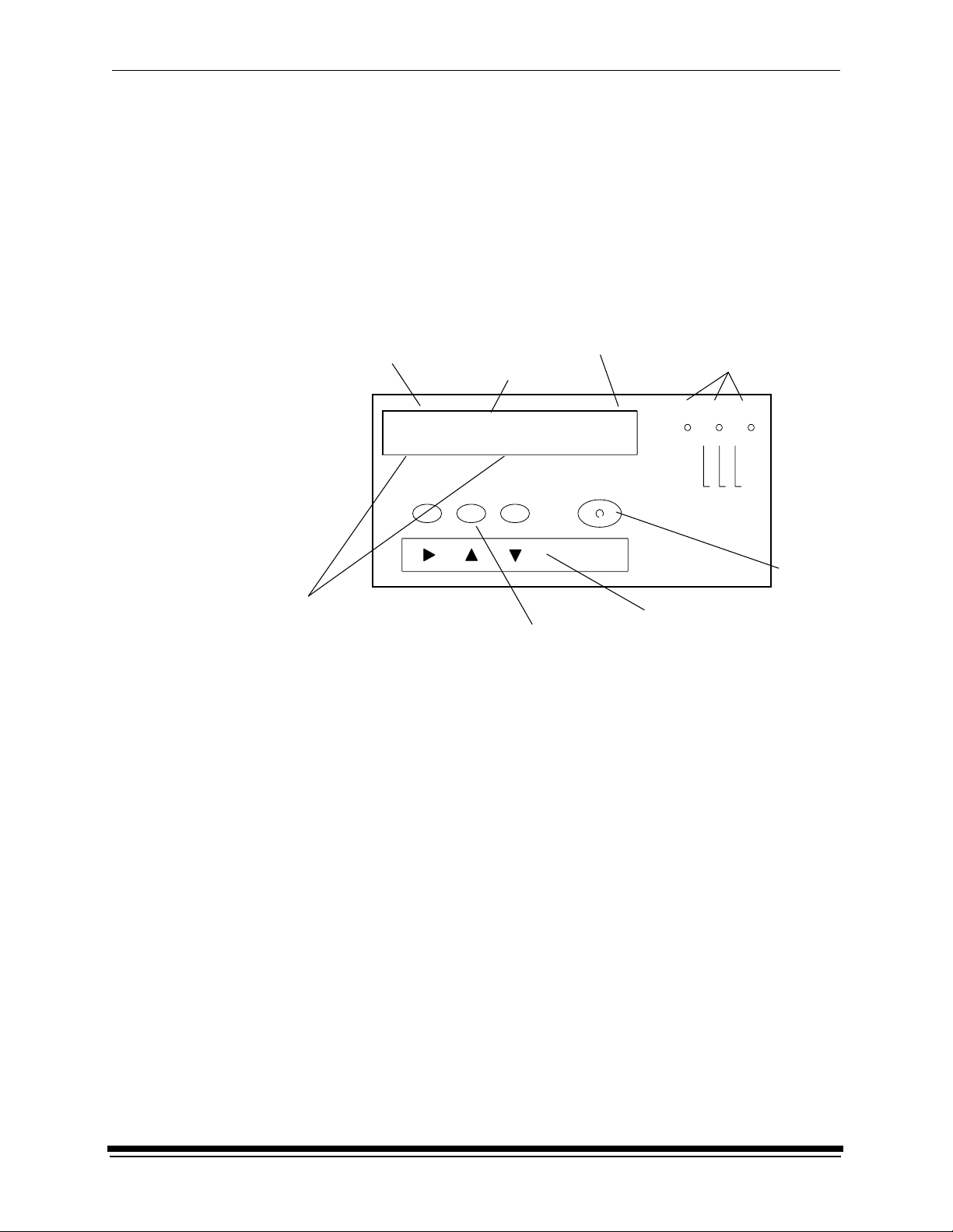

Operator Control Panel (OCP)

The operator control panel (OCP) for the printer allows you to view and control:

• current status of the printer

• current time of day

• paper specifications

• error and power status

• cancel, on/off line and menu functions

• parameters of the printer

• error messages

current status

LCD display

time of day

lights

LED indica tor

Status: Initializing

Status: Initializing

Pages Waiting: Paper Width:

Paper Width:

Paper Supply: Paper Takeup:

Paper Length:Paper Length:

2:43

100Paper Width:

0

Power Error Standby

Cancel On/Off Line Menu

Start

Select

Select

key

printing information

Up, Down, and Right

function keys

select keys

The display on the OCP is a 4 line by 40 character liquid crystal display (LCD). An

audible beeper is installed to the right of the LCD display. Each of the function

keys also operates as the arrow key (selector) directly below it when Menu has

been pressed. LED indicator lights illuminate to indicate power, error, and standby

statuses.

The operator control panel (OCP) displays the current status of the printer,

includin g the following in f or mation:

• Pages Waiting – the number of printing jobs that are waiting in the print

queue/buffer

• Paper Supply – the approximate amount of paper left in the paper cassette.

This information is input by you and is for your convenience only

• Paper Width – the width of the current roll of paper that is installed in the

printer

• Paper Takeup – the amount of paper that has been fed into the takeup

(“**” will appear in this field if the paper is not cinched in the takeup cassette)

3-2 September 2000

Page 31

OCP Key/Light Descriptions

Start

Cancel

On/Off Line

Menu

Select

Power

Error

Standby

Operating Procedures

Key/Light

Key /LED

Indicat or Li gh t

Description/Function

Start Key The Start key turns on the power for the printer when the printer has

been shut down through the OCP. When using the OCP menu, the

Start key functions as a Select key to select the highlighted item

from the OCP menu.

Cancel Key Pressing Cancel causes the job that is currently printing to quit. In

addition, the printer automatically goes into the Offline mode after

the current printing job has quit.

On/Off Line Key This key toggles between the Online and Offline modes. If you press

this key when the printer is in the Online mode, the printer goes into

the Offline mode. If you press this key when the printer is in the

Offline mode, the printer goes into the Online mode.

Menu Key Pressing this key activates the menu for the OCP when the printer

is in the Offline mode.

Arrow Keys When using the OCP menu, the Cancel k ey functions as a Right

Arrow, the On/Off Line key functions as an Up Arrow , and the

Menu key functions as a Down Arrow.

Select Key When using the OCP menu, the Start key functions as a Select key

to select the highlighted item from the OCP menu.

Power Lig ht The pow er ligh t illu m inates to ind ic ate that the main po w er for the

printer is on.

Error Light The error light illuminates to indicate that a printer error occurred.

Standby Light The standby light illuminates to indicate that the printer has been

shut down from the OCP and is now in the Standby mode, waiting

for Start to be pressed.

September 2000 3-3

Page 32

Operating Procedures

Menu

The menu allows you to access other printer features.

NOTE: To access the menu, the print queue must not have any pages waiting to

be printed.

1. Press On/Off Line to take the printer offline.

2. Press Menu.

Taking the Printer Offline

This feature is useful when you need to access the printer OCP menu.

When the printer is offline, it cannot send jobs to the processor or accept jobs

from the host.

To take the printe r o ffl ine, pre ss On/Off Line on the OCP. If a job is printing when

you take the printer offline, the job will complete printing.

Online Mo de

The Online mode is the normal mode and must be activated for the printer to

accept print jobs from the host computer.

Offline Mode

When the printer is in the Offline mode it cannot accept print jobs from the host

computer. When an error occurs, the printer is automatically placed into the

Offline mode.

Cancelling Job s

To cancel the sheet currently being printed, press Cancel on the O CP. After the

sheet has been cancelled, the printer automatically toggles to the Offline mode.

To cancel all jobs wait ing to be printed:

1. Press Cancel on the OCP to cancel the sheet that is currently printing.

2. Press Menu twice.

Printing Deferred or Buffered Jobs

“Pages Deferred” displays on the OCP and a number other than zero displays in

the Pages Waiting field when one or more jobs are waiting to be printed.

1. Press On/Off Line to take the printer offline.

2. Press Menu.

3. Press Start to print the jobs.

3-4 September 2000

Page 33

Operating Procedures

Status Message s

Status messages display on the LCD display of the OCP to indicate the status or

current state of the printer.

Status Message/Printer State Definition

status: ON LINE – Ready The printer is idle and ready to accept jobs.

status: ON LINE – Processing The printer is cu rrent ly downl oad ing or proces sing a

job.

status: ON LINE – Pages Deferr ed Pages are waiting and nothi ng is being

downloaded. If jobs were sent with the “Def er Pr in t”

or “Buffer” option, the printer is waiting for more

data to fill the frame store.

status: ON LINE – Printing The printer is prin ti ng and m ay also be processing

more jobs.

status: OFF LINE – Idle The printer is curr entl y offline. No jobs exist in the

printer. “Idle” is used instead of “Ready” because

the printer is actually idle (not doing anything) and

will not accept jobs.

status: OFF LINE – Processing The printer is off line but a job is being downloaded.

A print cycle will not be initiated.

status: OFF LINE – Pages Deferred The printer is offline but there are jobs in the printer

that are waiting to be print ed. A print cycle will not

be initiated.

status: OFF LINE – Printing The printer will com plete the current print cycle and

then pause.

status: OFF LINE – Cancelling Cancel was pressed when the printer was printing.

The sheet that was printi ng was immediately

terminated. This message is also displayed when

you select “Yes” to the prompt to cancel all

remaining jobs when you enter the menu.

status: In it ializing The print er is powering up (after Standby has been

pressed or the printer has been turned on).

status: ON LINE – Resetting The print engine is bei ng reset because of an error

or operator inter vention. The prin ter will return to the

“ON LINE – Ready” state after the machine reset is

complete (even if the printer was offline because of

an error or key that was pressed before the reset).

status: Print er Er ror :

<Error Message>

A printer error (su ch as a paper jam) has occurred.

The error message is di splayed on the second line

of the display. For a complete list of error

messages, see “Printer Error Messages” on

page 5-1.

September 2000 3-5

Page 34

Operating Procedures

Loading Paper Into the Supply Cassette

WARNING: Mo ve the supply cassette from the printer to a table to load or

unload pap e r.

One 10- to 20-inch supply cassette and one 10- to 20-inch takeup cassette are

included with the printer and are designed to hold rolls of paper that are 10-, 11-,

12-, 20-inch, and A4 widths.

The supply cassette and takeup cassette are not interchangeable.

Removing the Supply Cassette

1. Open the paper supply door.

2. Unlock the cassette clamp for the supply cassette.

3. Remove the empty supply cassette.

supply cassette

cassette

clamp

paper supply

door

3-6 September 2000

Page 35

Operating Procedures

Loading the Paper

1. Unlock the supply cassette locks.

2. Open the supply cassette.

3. If necessary, remove paper scraps from the core support assembly.

4. Remove the old core and support assembly from the supply cassette.

NOTE: Keep the felt surfaces clean to prevent scratches on the paper.

felt

5. Remove the screw lock and the old cardboard core from the core support

assembly.

6. Pull the metal spring for the screw adjuster away from the gear and slide the

screw adjuster to the correct posi tion until it locks into place in the detent .

old core and core support assembly

felt

supply cassette locks

screw adjuster

cardboard core

gear

screw lock

core support

assembly

September 2000 3-7

Page 36

Operating Procedures

TIP: Practice the following steps in the light with an empty cardboard core

before you load a new roll of paper in the dark.

CAUTION: Loading paper into the paper cassette must be completed in

a darkroom with the lights off.

7. Position the paper so that the lead edge of the paper is away from you.

8. Insert the core support assembly from the left side into the roll of paper as

shown.

9. Push the cardboard core toward the gear until it engages the detent.

cardboard core

detent

10. Install the screw lock onto the core support assembly and ensure that it is

snug.

11. Place the core support assem bly with the full paper roll into the supply

cassette.

IMPORT ANT :Make sure that the right and left edges of the paper on the paper

roll remain aligned. Do not allow the roll of paper to slide or

“telescope”.

screw lock

3-8 September 2000

Page 37

Operating Procedures

12. Feed the lead edge of the paper through the slotted opening in the paper

cassette.

lead edge of the paper

slotted op eni ng

image or emulsion

side

core support assembly

(side without the gear)

13. Close the supply cassette and latch the supply cassette locks.

NOTE: Be sure that the core support assembly rotates freely in the supply

cassette and that the paper feeds freely.

supply cassette lock

NOTES: – When the paper cassette is locked, you can turn on the room lights.

– See page 3-10 for instructions on how to install a digital printer

paper saver.

IMPORT ANT:When moving the supply cassette, pick up and carry the cassette

by both handles to prevent the paper from sliding or “telescoping”

to one side.

September 2000 3-9

Page 38

Operating Procedures

Attaching a Digita l Paper Saver

To save paper that is lost during the paper loading process when using the

“1-Step Normal” paper loading option, you may install a digital printer paper saver

(leader) to the lead edge of the roll of paper. Using the digital printer paper saver

reduces the amount of paper lost from threading the printer by 5.5 feet as shown

in the table below.

Threading Meth od Amount of Unprintable Paper*

Paper Leader 9 feet

Digital Printer Paper Saver 3.5 feet

*For additional paper saving, see “Selecting a Loading Option” on page 3-24.

To order digital printer paper savers and splice tape, see “Leaders and Splice

Tape” on page A-3.

NOTE: The digital printer paper saver may be used many times.

CAUTION: To prevent spots or scratches on images, keep the digital printer

paper saver away from surfaces that have dust and dirt on them.

1. Load the paper into the supply cassette. See “Loading Paper Into the Supply

Cassette” on page 3-6.

2. If necessary, cut a straight edge on the lead edge of the paper that is coming

through the slotted opening in the supply cassette.

3. Cut a piece of splice tape that is approximately 2 inches longer than the width

of the supply cassette.

4. Set the splice tape on the supply cassette with the adhesive side facing up.

5. Place the lead edge of the paper onto the splice tape.

6. Place the trail edge of the digital printer paper saver (the edge without the

hole) on the splice tape.

NOTE: If the digital printer paper saver is new, wipe it with a damp cloth to

remove dust and static electricity.

IMPORT ANT:The digital printer paper saver must be the same width as the

paper. Also, the curl of the digital printer paper saver and the curl

of the paper must match.

lead edge

of the paper

splice tape

lead edge of th e

digital printer

paper saver

3-10 September 2000

Page 39

Operating Procedures

7. Fold the edges of the splice tape over the digital printer paper saver and the

paper.

8. Cut a second piece of splice tape that is slightly smaller than the width of the

paper.

9. Install the second piece of splice tape over the paper and the digital printer

paper saver.

second piece of

splice tape

10. Turn the core support assembly to rewind the paper and digital printer paper

saver into the supply cassett e .

NOTE: Do not wind the entire digital printer paper saver into the supply

cassette.

September 2000 3-11

Page 40

Operating Procedures

Installing the Lo aded Pap er Supply Into the P rinter

1. Open the paper supply door.

2. Empty the punch chad tray. See “Removing the Punch Chad” on page 4-2.

3. Align the slot on the bottom of the supply cassette with the plate on the bottom

of the shelf and slide the supply cassette into place on the shelf.

Emulsion

shelf

(image) side of

paper (or paper saver)

slot

plate

cassette clamp

4. Check that the gear on the supply cassette aligns and meshes with the gear

on the printer.

5. Lock the clamp to secure the paper cassette into place.

6. If you are not using the digital printer paper saver, check that the cut on the

lead edge of the paper is straight.

NOTE: Use scissors to cut the paper. Knives and razor blades will shred the

paper.

7. Adjust the right punch to the correct paper width (10, 11, 12 or 20 inch

and A4). See “Adjusting the Paper Hole Punchers” on page 3-22.

8. Press Start on the OCP.

9. Enter the number of feet on the roll of paper when prompted and if necessary,

enter the roll ID. See “Using the Automatic Roll ID” on page 3-29.

3-12 September 2000

Page 41

Operating Procedures

10. When the mess age “Feed paper into printer...” appears, pull the lead edge of

the paper (or digital printer paper saver) out of the paper cassette and place

the lead edge of the paper into the punch slots.

paper alig n ment

guide

gear on the

cassette

right hole puncher

lead edge of

the pa per

(or paper saver)

gear on the

printer

1 1. Slide the lead edge of the paper under the feed roller and static brushes using

both hands. Keep the paper flat until you feel it being pulled into the printer.

Keep the left edge of the paper against the paper alignment guide.

NOTE: The sound from the printer will change when the printer is ready to

advance the paper.

CAUTION: If the paper does not load properly or a paper jam occurs,

press Cancel on the OCP. Remove any paper from the shoe

area and repeat steps 7 through 10. If you are not using a digital

printer paper saver, make sure the lead edge is cut square and

does not have any bends or dings. If necessary , install a new

digital printer paper saver.

12. Close the paper supply door. If a 1-step load option is selected, the paper

automatically advances to the takeup cassette. When this is complete, a

message on the OCP prompts you to load the paper into the takeup cassette.

If a 2-step load option is selected, the prompt to cinch paper appears after the

appropriate length of images has been printed. See “Installing the Takeup

Cassette” on page 3-14.

NOTE: For additional paper saving methods, see “Selecting a Loading Option”

on page 3-24.

cassette

clamp

September 2000 3-13

Page 42

Operating Procedures

Installing the Takeup Cassette

Preparing the Takeup Cassette

1. Unlatch the takeup cassette locks and open the takeup cassette.

2. Remove the core support assembly.

3. Move the screw adjuster to the correct position for the paper size that you are

loading. Pull the metal spring for the screw adjuster away from the gear and

slide the screw adjuster to the correct position until it locks into place in the

detent.

4. Slide the correct size cardboard core onto the core support assembly. Push

the cardboard core toward the flange until it engages the detent.

5. Install the flanged nut (when using 10-, 11-, 12-inch and A4 paper) or the

screw lock (for 20-inch paper) onto the core support assembly. The core

support assembly uses left hand threads. The threaded parts are color coded

to prevent confusion.

NOTE: Make sure the screw lock or flanged nut is secure.

6. Place three rubber bands over the cardboard core.

IMPORTANT:The rubber bands must have the same thickness and must not

be twisted or wrinkled when installed.

rubber bands

core support

assembly

screw

lock

flang e d nut

cardboard core

screw adjuster

gear

3-14 September 2000

Page 43

7. Install the core support assembly into the takeup cassette. See the

instructions on the label on the top of the takeup cassette.

NOTE: Make sure that the core support assembly is installed correctly in the

cutouts of the takeup cassette.

core support assembly

cutout

Operating Procedures

takeup

cassette

locks

8. Close the takeup cassette and latch the takeup cassette locks.

NOTE: Be sure the core support assembly rotates freely in the takeup cassette.

Installing the Takeup Cassette

1. Open the takeup door.

If the takeup cassette is in the printer and has paper in it, remove it.

See “Removing the Takeup Cassette” on page 3-20 or “Removing Exposed

Paper from the Takeup Cassette” on page 3-21.

2. If necessary, move the adjustable cassette support arm to accommodate the

size of the cas s et te y ou will b e us in g. To move the adjusta b le a r m:

a. Unscrew the clamping knob.

b. Move the arm to the correct position.

c. Reinstall the clamping knob and tighten.

September 2000 3-15

Page 44

Operating Procedures

adjustable cassette

support arm

3. Install the takeup cassette onto the cassette support arms.

IMPORT ANT:Check that the bearings on the cassette are seated in the support

arms.