Page 1

KKOODDAAKK PPRROOFFEESSSSIIOONNAALL

ENDURA Papers

DDeeffiinniinngg PPrriinntt LLiiffee::

TThhee ccrriittiiccaall bbaallaannccee ooff lliigghhtt

aanndd tthheerrmmaall ssttaabbiilliittyy

© Eastman Kodak Company, 200

.

7

Page 2

KODAK PROFESSIONAL ENDURA Papers

The following pages discuss light and thermal

stability as they apply to Kodak’s newest generation

of professional color negative papers, KODAK

PROFESSIONAL SUPRA, SUPRA VC Digital, and

LTRA ENDURA and ENDURA Metallic papers.

U

Since the earliest days of photography, people have

wanted to increase the stability and extend the

ongevity of captured images. As the medium

l

evolved, ongoing improvements in image stability, as

well as the discovery of new challenges to image

stability, have been the rule.

The introduction of KODACHROME Film for color

movies and slides in the 1930s brought new stability

challenges related to color. In 1942, Kodak

announced KODACOLOR Film for prints,

the world’s first true color negative film. The

advancements of color technology into prints allowed

color photography to expand rapidly

into the professional portrait/social and consumer

environments.

It was at this time that Kodak recognized the need

for dedicated testing facilities to examine the

stability of images. Since then, the company has

invested in and expanded its testing capability

continuously for over 50 years.

As advances in technology have improved image

stability and reduced major concerns, new, more

subtle c

silver halide-based photographic materials of all

manufactur

need for more precise measurements of image

stabilit

have also brought a need for a better understanding

of these factors:

•

• how the different uses of images affect

The following pages discuss these factors as

they apply to Kodak’s newest generation of

prof

PROFESSIONAL SUPRA, SUPRA VC Digital, and

ULTRA ENDURA and ENDURA Metallic Papers, and

will cover the f

oncerns have arisen. In the last 15 years, the

s have improved significantly, creating a

er

er time periods. New technologies

er long

v

y o

omplexities of how images on modern

the c

photographic print materials fade

e

e lif

imag

sional color negative papers, KODAK

es

opics:

wing t

ollo

ow materials are processed and used by finishing

• h

laboratories

• how prints are used and stored by the end-user

• what image stability means today

• the importance of the ways in which image stability is

easured and interpreted

m

Note: In this discussion of image stability, we

ssume that the process conditions in the finishing

a

lab meet specifications set by the manufacturer of

the photographic material. A process that does not

meet specifications can have an impact on image

stability that is as large as or larger than any of the

variables discussed here.

Philosophy of Product Design

Obviously image stability is a decisive factor in the

design of color photographic paper. In fact, it would

be possible to design a paper solely to optimize

image stability. However, designing and optimizing

for a single criterion such as image stability will

often degrade other key factors.

During the last 20 years, the design of Kodak silver

halide color papers has been driven by a three-prong

strategy, coupled with continuous improvement.

While a typical Kodak color paper has more than 60

individual design parameters, we follow three major

design criteria:

• image quality today

• image quality tomorrow (i.e., print longevity)

• ease of use in the finishing lab

In many instances, trade-offs between the major

crit

eria would be possible. For example, excellent

image quality with accurate color and pleasing flesh

eproduction depends on the image dyes formed by

r

the paper, so color and flesh reproduction could be

omised t

ompr

c

dyes optimized for image stability can be more

process-sensitive, which can cause difficulties for the

finishing lab.

o achie

ve good dye stability. Similarly,

• objectives in the design of photographic materials

1

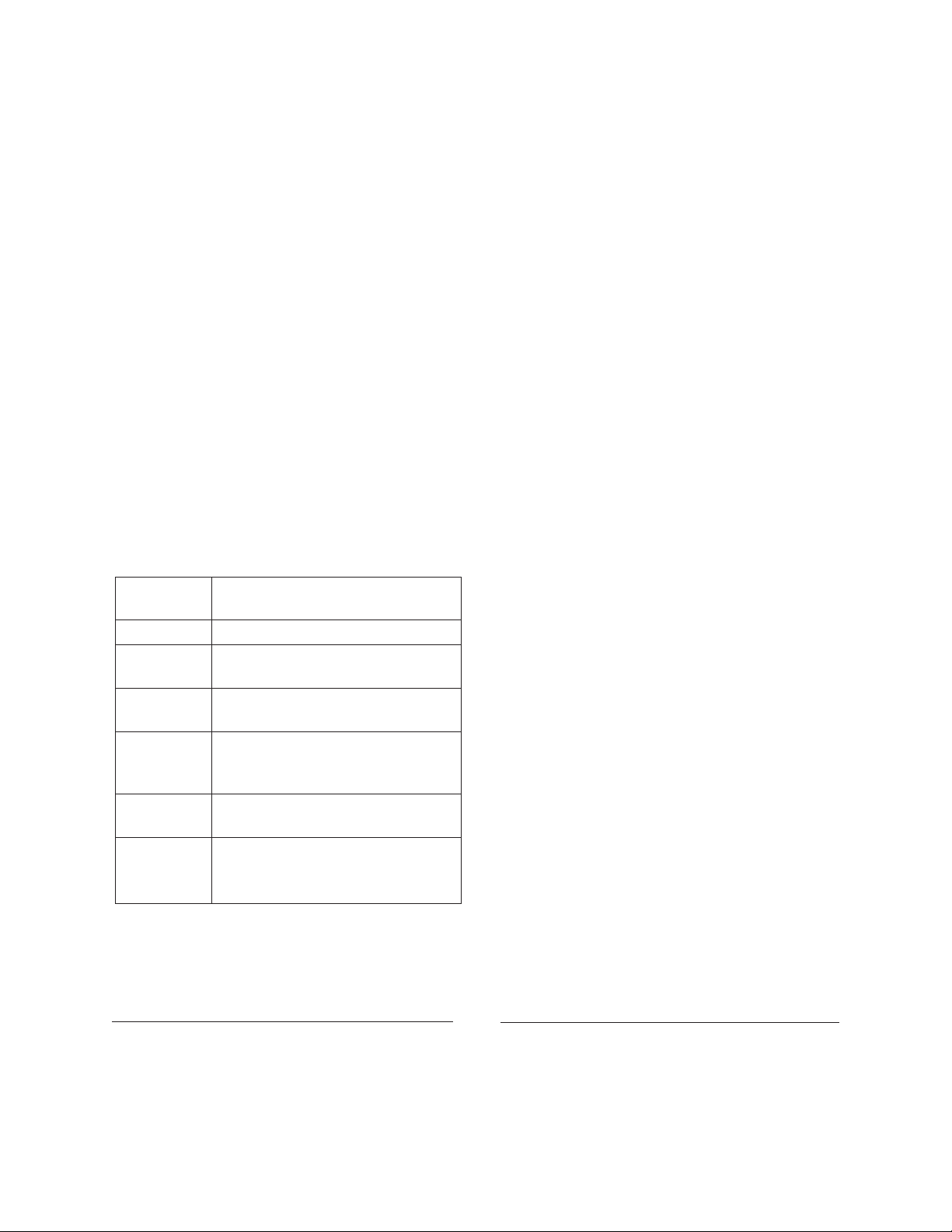

Page 3

KODAK PROFESSIONAL ENDURA Papers involve no

24°C

years

100

log days

Inverse Kelvin

.0034.0033.0032

.0031

.003.0029.0028.0027

5

4

3

2

1

uch trade-offs. Both the dye set used and the

s

emulsions and curve shape drive short-term and

long-term image quality, as well as ease of handling

and processing.

Kodak has supplemented its three-prong design

philosophy with continuous improvement between

major development programs. Ongoing

improvements keep products fresh by adding new

technology as it becomes available. Over the last 20

years, we have made a multitude of improvements

in image quality and lab operations in addition to

image stability.

As the stability of papers improves, the testing

ecomes more complex. Predictions of image

b

stability are based on accelerated testing, and the

accuracy of predictions depends entirely on

generating test data that are low in noise. Figures 1

and 2 show a hypothetical example of two different

apers tested for thermal stability. One paper is

p

more stable than the other, but because of time

imitations, both samples were tested for one year.

l

Figure 1

Four-Point Prediction

—Linear Fit

KODAK PROFESSIONAL ENDURA Papers, however,

are truly revolutionary. Made with advanced dye

technology, they represent a major leap forward in

Linear Fit

Log Days = 13.04666 + 5229.7488 Inverse Kelvin

image stability and print life without sacrificing

image quality, while also enhancing ease of use in

the lab

.

In the professional market, flesh reproduction is the

paramount image-quality criterion. In many color

papers optimized for image stability, image quality

and flesh reproduction suffer. But the three new

dyes in KODAK PROFESSIONAL ENDURA Papers

have been optimized for excellent image stability

without degrading color reproduction or flesh

reproduction. SUPRA ENDURA Paper has additional

patented technologies specifically designed to

optimize flesh reproduction through modifications

es combined with precise curve-

o the imag

t

e dy

shape control in the emulsions.

Testing Methodology and Modern

aper C

P

Stabilit

major degradation pathways, and includes testing

for light fade, thermal fade (degradation due to

heat, often referred to as “dark fade”), and base

omponents

y testing of c

olor paper

s focuses on the

igur

F

enerat

g

e 1

s four data points based on fade

w

sho

ed from four high-temperature conditions.

The points form a straight line with a high linear

correlation coefficient, and the extrapolated

prediction of room-temperature performance is 100

years. Given the correlation and the statistically

calculated error from this extrapolation, the high

w limit around the predicted 100 years is plus

and lo

he actual performance may be

or minus 40 y

ears. T

as high as 140 years or as low as 60.

degradation. Although we will not discuss the

specifics of imag

important to understand the major challenges in

e-stabilit

y testing here, it’s

performing the tests correctly and in interpreting

est data.

the t

2

Page 4

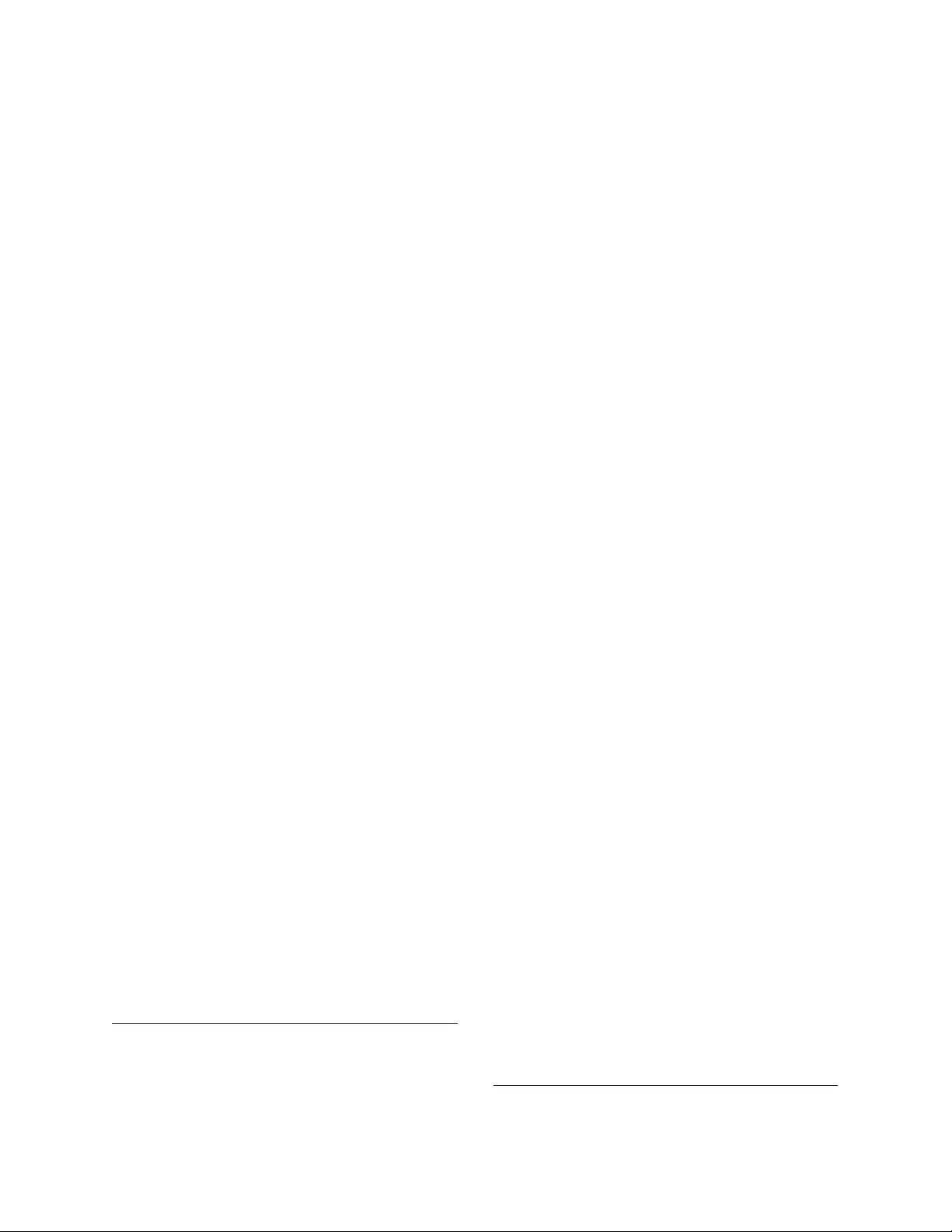

log days

Inverse Temp

.

0034.0033.0032

.0031

.

003.0029.0028.0027

5

4

3

2

1

24°C

y

ears

200

Figure 2

Bivariate Fit of Log Days by Inverse Temp

testing, which predicts a material’s stability over

00 years, is used. Because the test is so highly

1

accelerated and run in such a short time, it cannot

detect the impact of ambient ozone. Only after

images were displayed in the real environment,

which included low levels of ambient ozone, was the

rue stability determined. Then it turned out that

t

product stability was measured in weeks, not years.

As Kodak added new resin stabilizers to increase

the stability of the paper base, Kodak scientists

encountered another example of a test becoming

difficult to use because of noise in the data. The

then-current accelerated test to measure cracking

and crazing of the resin was no longer generating

—Linear Fit

Linear Fit

Figure 2 shows a straight-line extrapolation to 200

years. However, because the paper is more stable

than that in Figure 1, only three data points are

available. Because of noise, the three points are

scattered around the predicted straight line. With

only three points and the higher noise, the

correlation is lower and the error band is higher. So

while the straight-line extrapolation predicts a

performance of 200 years, the statistically

calculated error is very wide and quite nonlinear.

According to the plot, the paper could last as long

as 600 y

running the test for a longer period of time would

v

e

more precise prediction with less error around the

pr

In light-fade testing, using only highly accelerated

tests can lead to significant errors because of

ecipr

r

we now know that some inkjet materials are highly

susceptible to image fading due to very low levels of

ambient ozone in the atmosphere.

outcome when only high-intensity light-fade

ears or as few as 50. In this example,

entually g

enerate a fourth data point to give a

ediction.

ocity and other external factors. For example,

1

Consider the

the normal response of cracks that would predict

long-term resin stability. Instead of trying to

accelerate the test further and risk the creation of

even more noisy, possibly erroneous data, Kodak

scientists looked to the molecular level for a

predictive mechanism. They made measurements of

the actual decay of the resin molecules and found

that those measurements provided a good

correlation to the prediction of long-term resin

stability.

In these times when companies, including Kodak,

introduce new products at a faster pace, it is

tempting to run image-stability tests for shorter

times with greater acceleration and noisier data. It

would be even worse to use the high end of the

statistical noise to promote a product as more

stable than it really may be.

t Kodak we do neither. We continue to run highly

A

accelerated light- and thermal-fade screening tests,

using high light levels and high temperatures.

, we verify the results with less accelerated

er

v

e

How

tests by using lower light levels and lower

temperatures. Although these tests take

significantly longer, often more than a year, the data

is much more reliable. We use only this data to

support product claims for image stability. We take

xtra time to generate reliable data because

the e

1

D.E. Bugner, D. K

Reciprocity Failure Resulting from the Accelerated Fade of Inkjet Photographic

Prints,”

Technology,

opperl, and P

Proceedings of IS&T’s 12th International Symposium on Photofinishing

2002, pp. 54–57.

. Artz, “Further Studies on the Apparent

3

Page 5

of our commitment to report image-stability data

ccurately and to maintain integrity and credibility

a

with our customers.

These same four degradation mechanisms also

pply to inkjet materials. However, we must also

a

consider other mechanisms:

Kodak is very confident in the revolutionary image

tability of KODAK PROFESSIONAL ENDURA

s

Papers. To further demonstrate this confidence we

commissioned a major study with the Image

Permanence Institute at the Rochester Institute of

Technology. Through this study, we not only

achieved independent substantiation of Kodak’s own

internal testing, but learned that in fact our intrnal

claims were conservative.

Defining Print Life—

Degradation Mechanisms

Defining print life requires information on the

mechanisms that degrade prints and which

mechanism first becomes limiting. This often

requires knowledge of the environment in which the

image is stored or displayed, because different

degradation mechanisms may outweigh others in

different environments.

In silver halide-based color papers, four

mechanisms contribute to determining print life:

• degradation of the dyes caused by heat

• degradation of the dyes caused by light

• yellowing of the minimum densities (D-min) due

to light or heat

• ambient moisture (relative humidity)

• atmospheric pollutants

• direct water contact

• fingerprinting

A multitude of tests, reports, and conclusions from

many sources have described the significant

advancements made in inkjet light stability.

However, while the thermal stability of most inkjet

systems is quite good and very significant

improvements in colorant stability due to light

exposure have occurred, promotion of products

based on light-stability testing is extremely

misleading when it ignores the other important

degradation mechanisms. To describe print life

accurately requires taking all degradation

mechanisms int

o account. A material could have

excellent light- and thermal-fade performance but

poor print life if the colorant stability is poor when

exposed to moisture or atmospheric pollutants.

For a more detailed discussion of the degradation

mechanisms and image-stability performance of

2,3

Kodak inkjet materials, see the references

below

as well as the technical papers found at:

http://www.kodak.com/eknec/PageQuerier.jhtml?p

.

q-locale=en_US&pq-path=98#technical_papers

.

adation of the resin base

degr

•

ample, a resin-based color paper may have

x

or e

F

very high light stability but only mediocre resin

y in the base. It will perf

stabilit

orm very w

ell in

tests for light stability. However, if it is stored in an

environment where the base degrades faster than

omes

the dy

ellent light stabilit

c

es, ex

y bec

meaningless. In this example, degradation of the

resin base is the limiting mechanism.

4

It is extr

emely important to recognize that

the life of the image may not necessarily be limited

by the stability of the image dyes. A manufacturer

who talks about “dye stability” or “light stability”

alone, or who uses only light-fade data to describe

the performance of a product, is very likely not

esenting an accurate prediction of print life.

pr

2

D.E. Bugner and C.E. Romano, “Printing Memories to Last a Lifetime:

standing Imag

Under

ger Magazine, 13(1), 2001, pp. 134–140.

echar

R

3

D.E. Bugner and P. Artz, “A Comparison of the Image Stability of Digital

Photographic Prints Produced by Various Desktop Output Technologies,”

Proceedings of the International Conference on Imaging Science 2002,

2002, pp. 308–310.

e Stabilit

or Ink Jet P

y f

rints,”

Page 6

Criteria for Defining Print Life

t is very important to know which degradation

I

mechanism is the limiting mechanism in any given

torage environment. It is also important to know

s

the print-life criteria being used in reporting print

life. The print-life criteria determine “how bad is

bad”—for example, when a consumer would take a

print down and throw it away.

Kodak uses the illustrative criteria stated in the

ANSI/ISO standard, which places dye-fade limits at

,5

60%

4

Internal studies done by Kodak

6

Correlated Visual Impact

Very slight—noticeable to an expert

only in a paired comparison

Slight—noticeable in a paired

comparison

Moderate—noticeable in single

original scene quality

ade with a single

eable f

Notic

stimulus, but not objectionable

ery noticeable fade with

V

a single stimulus; possibly

objectionable based on use

30 percent.

indicate that 30-percent fade is a conservative limit.

able 1compares dye-fade limits, consumer

T

descriptors, and consumers’ perceptions or

reactions.

Table 1

Approximate Correlation of Color Descriptors to

Dye Loss from 1.0 Density

Approximate

Dye Loss

0 to 10% Minimal

10 to 15%

15 to 20%

20 to 30% stimulus to a person familiar with

30 to 60%

Greater than

Depending on the scene content, fade levels below

bout 15 to 20 percent are usually not noticeable

a

without direct comparison to an unfaded reference

image. A fade level between 20 and 30 percent

could be considered noticeable without a non-faded

comparison, but typically would not be considered

bjectionable. Fade levels between 30 and 60

o

percent would not be objectionable; consumers

ould continue to value the image based on scene

w

content and emotional involvement.

Additional research continues to confirm that the

use of the 30 percent endpoint criteria is quite

conservative, and that levels of 60 percent or higher

can still be considered to fall within the acceptable

category. Generally, at fade levels above 70 percent,

the psychophysical studies behind this research

found that most prints would fall into the marginally

unacceptable category or worse.

Although it w

ould be possible to use a fade limit

7

greater than 30 percent and report longer print life,

Kodak takes a conservative approach with the 30percent upper limit. It is also important to note that

using a fade limit lower than 30 percent would

result in under-predictions of print life. For example,

a fade limit of 15 percent may be appropriate for

images in a museum, but is far too conservative for

typical consumer environments because a print at

this endpoint would only be slightly changed from

the original. Using a 15% endpoint would predict

print life that is only half of that predicted using a

30% criteria and would be very misleading. Many

onsumer

c

s would see little or no chang

e in a single

stimulus situation and calling this an endpoint could

cause needless concern and worry.

4

St

ANSI IT9.9-1996, and ISO 10977.

5

Stability of Colour Photographic Images—Methods for Measuring, ISO

Publication 18909-

6

D. Oldfield and G. Pino, R. Segur, J. Twist, “Assessment of the Current LightFade End-Point Metrics Used in the Determination of Print Life: Part I”,

Journal of Imaging Scienc

abilit

y of C

olor Phot

aphic Images—Methods for Measuring,

ogr

.

2006

, 48 (6), 2004, pp

echnology

e and T

. 495-501.

7

. Oldfield and J

D

Metrics Used in the Determination of Print Life: Part II”, Proceedings of

IS&T’s 2004 Conference on Archiving, pp. 36-42

. T

sessment of the Current Light-Fade Endpoint

As

wist, “

.

5

Page 7

Standards for Measuring Stability

nternational standards for measuring the stability

I

of color materials are contained in the ANSI/ISO

tandard Stability of Color Photographic Images—

S

Methods for Measuring

and ISO Publication 10977. An updated version of

this standard, ISO Publication 18909-2006, was

issued in 2006. Work currently under way in the

standards committee includes a new set of

publications to address the additional complexities

and degradation mechanisms found in non-silver

halide color materials.

A look thr

silver halide materials quickly reveals that the

testing and measurement of image stability is a very

complex science. The standard also provides

recommendations and guidance on interpreting and

using test data generated by the testing methods.

Why doesn’t the standard provide specific rules and

definitions on how to interpret the data? The

standard provides only general recommendations

and guidance because images in general have a wide

range of stability requirements based on intended

application, and are stored or displayed under a vast

range of conditions.

The standard strongly suggests that interpretation

of test data be based on the specific conditions

likely to be encountered as the product is used in

the real world. For example, the typical environment

for prints on SUPRA or SUPRA VC Digital ENDURA

Paper is a wall display or a wedding album kept in a

home. This is very different from the typical

vironment for prints on ENDURA Metallic Paper,

en

which is lik

purchase commercial display in a mall. It is logical

that the int

for these two very different products reflect the

different environments.

ough the current 60-page standard on

ely to be a high-int

erpr

, ANSI Publication IT9.9-1996

ensity point-of-

etation of the imag

e-stability data

Design for Real-World Conditions

odak has long recognized the importance of

K

product design based on customer use. KODAK

ROFESSIONAL SUPRA and SUPRA VC Digital

P

ENDURA Papers are designed to be used by endconsumers in the home. These papers are designed

for “portrait and social” applications, i.e., formal

portraits and wedding pictures displayed in a home

or stored in albums.

Remember the three major design criteria: image

quality, print life, and performance in the finishing

lab. In the case of papers for portrait and social

applications, pr

without regard to real-world conditions and the

other two major design criteria, could result in many

trade-offs, even in print life itself. For example,

excellent high intensity light stability with mediocre

thermal stability would be a poor combination in

prints stored and displayed where light intensity is

low but thermal performance is significant.

Similarly, a trade-off in finishing lab operations—

such as permitting high sensitivity to chemical

activity levels to achieve good print life—would be a

poor choice.

KODAK PROFESSIONAL SUPRA and SUPRA VC

Digital ENDURA Papers are optimized for all three

major design criteria in the context of real-world

portrait/social applications. The design criteria for

KODAK PROFESSIONAL ULTRA and ENDURA

Metallic Papers are tailored to the needs of the

commercial display market.

Just as the design of KODAK PROFESSIONAL

ENDURA Papers reflects real-world conditions, any

testing and interpreting of stability data must also

reflect the environment in which the product will be

used and st

ait and social papers, like SUPRA and SUPRA

tr

por

VC Digital ENDURA Papers, without regard to real-

onditions can mislead labs in their choic

orld c

w

a color paper as well as photographers and

consumers in their choice of a finishing lab.

oduct design for print longevity,

ored. Reporting of stability results for

e of

6

Page 8

Some critics have discussed the use of independent,

ingle-condition, highly accelerated light- and dark-

s

8

fade tests as very misleading.

These tests are

useful for rapid screening of experimental dyes, but

are prone to possible errors (e.g., reciprocity in light

fade or reaction-mechanism shift in dark fade),

hich limits their reliability in predicting print

w

longevity. They don’t reflect real-world conditions

nd require very careful interpretation. This is true

a

not only because they are accelerated well beyond

the normal light and heat levels found in a home,

but because the data are often reported in isolation.

Running stability tests in a window gives even more

misleading results.

Because thermal stability is so important in the

portrait and social environment, testing and

reporting on light fade only, without considering the

impact of thermal stability, would be relevant only

to consumers who store their prints in a lighted

freezer.

9

Predominance of Thermal Stability in the

Portrait/Social Environment

Thermal stability, often called “dark stability,” is

driven by ambient temperature. This is especially

important in the portrait and social environment

where light levels are low. Thermal degradation,

even when prints are on display, predominates.

Note: Temperature can play a role in the commercial

or example,

f

vironment as w

en

in transmission display materials used on warm light

w

es. Ho

x

bo

display is relatively short (often three to 12

months). The thermal effects do not become

apparent because the light-fade

effects predominate.

ell—

ever, the time frame for a commercial

When you see the term “dark stability,” remember that it is

ot darkness that causes dyes to fade or D-min to turn

n

yellow; it is heat. Therefore, even when a print is on display

(unless it’s in that lighted freezer), thermal degradation is

taking place. Dark stability is actually the combined effects

of thermal fade and everything else that is not related to

10

owever, from the early history of color

ight fade.

l

H

photography through the early 1980s, thermal fade was

he principal mechanism.

t

Improvements to thermal stability have been

infrequent; but when they do come, they have been

very large:

• Kodak’s introduction of 5-ethyl-4,6-dichloro-2amidophenolic couplers resulted in a three- to

fourfold improvement in print stability. KODAK

EKTACOLOR Plus and Professional Papers first

used this new technology.

• The use of non-yellowing pyrazolotriazole (PT)

class magenta couplers virtually eliminated

yellowing of print D-min caused by both

temperature (thermal yellowing) and light (“printout” due to unreacted magenta coupler). Kodak

first used this technology in KODAK

PROFESSIONAL PORTRA III Paper.

• It was not until the invention of 2,5diacylaminophenol couplers that excellent thermal

stability combined with desirable color hue was

ed. Kodak invented these couplers and

v

achie

11

patented them in 1997.

KODAK EKTACOLOR Edge

8 Paper first used them in 1999.

8

R.E. McComb, “Separating Facts from Fiction: Examining Photo Prints,”

PhotoTrade News, February 1998.

9

Op. cit., R.E. McComb.

10

M. Oakland, D.E. Bugner, R. Levesque, and R. Vanhanehem, Proceedings Paper

from NIP 17,

11

U.S. Patent 5686235 (Nov. 11, 1997) and U.S. Patent 5962198

(Oct. 5, 1999).

2001, p. 175.

7

Page 9

Significant modifications of this most recent coupler

llowed its use in the critical professional markets,

a

i.e., in SUPRA and SUPRA VC Digital ENDURA

Papers. The successful commercialization of these

couplers produced a twofold improvement in

thermal stability over all earlier papers that use the

revious class of couplers.

p

Kodak papers that incorporate this patented coupler

technology have thermal stability that is twice as

good as that of any other silver halide-based color

photographic paper. For portrait and social

applications, which have a totally thermal-driven

environment (e.g., dark album storage), this means

that prints will last over 200 years before noticeable

fade occurs. In a typical home display environment,

it means that prints will last over 100 years before

noticeable fading occurs.

Light Levels

Because the large majority of prints in portrait and

social applications are stored in the dark, strong

thermal performance is a must. However, images are

displayed as well, and simultaneously undergo both

thermal fade and light fade. The longevity of the

paper will depend on the light levels that will be

encountered and the paper‘s stability to thermal

fade and light fade. Therefore, the design process

includes the balancing of thermal- and light-fade

mechanisms.

A study to measure actual light levels in homes has

documented 120 lux as the representative light

intensity for the home display category. This study

12

was first published in 1987

and repeated in 1991.

The conclusions were confirmed through a 10-year

study in which prints w

ere placed in people’s homes

around the United States, kept in places where

people typically display prints, and measured at

regular intervals. After 10 years, the level of fade

erified the pr

v

edict

vel based on 120 lux,

ed le

confirming that the 120 lux level is typical.

12

S. Anderson and G. Larson, “A Study of Environmental Conditions

omer Keeping of Photographic Prints,”

Associated with C

Journal of Imaging T

13

S. Anderson and R. Anderson, “A Study of Lighting Conditions Associated

with Print Displa

127–131.

ust

echnology

y in Homes,

,

, pp. 49–54.

7

13, 198

Journal of Imaging T

”

echnology

,

17 (3), 1991, pp

13

How bright is 120 lux? Consider a typical suburban

iddle-class home in the United States, with images

m

displayed in a living room with two west-facing

windows and one south-facing window. Taking into

account the seasonal cycle of short (winter) and

long (summer) days, with daylight periods averaged

ver a 12-hour “daylight period,” the light levels in

o

the room might range from 50 to 100 lux at the low

imes of the day (morning in this example) to 150 to

t

200 lux at the high times of the day

(afternoon/evening in this example). The average

12-hour “daylight period” would include times of

only indirect sun illumination, times with direct sun

illumination, and times with only artificial

illumination. Over the course of these daily and

seasonal periods, the average level would typically

be 120 lux.

14,15

If the living room had two south-facing windows and

one west-facing window, the light levels would

average somewhat higher, perhaps up to 150 lux. If

the living room had only north- and east-facing

windows, the levels would average somewhat lower,

perhaps only 100 lux.

Apartments or condominiums with only one or two

outside-facing walls would have fewer windows and

might have lower average illumination levels. A

house with very large windows and skylights could

have intensity levels of 1000 lux at a peak point

during the day, depending on the room orientation

to the sun and the number of windows and

skylights.

Based on the published studies and the 10verification study, we believe the average intensity

of 120 lux is a good one for the typical suburban

e of the higher and lower

ag

er

home, and a good a

v

light levels in homes and apartments typically found

in the United States. Of course, the actual range can

be quite large. From prints displayed in the

apartment bedroom with no windows to prints

displayed in the sunroom of a lavish home in

southern Calif

w points widens fr

lo

ornia, the range of the daily high and

om near zero to as high as

4000 or 5000 lux.

14

. cit., S. Ander

.

Op

15

. cit., S. Anderson and R. Anderson.

Op

son and G. Lar

son.

y

ear

8

Page 10

Taking into account the income-weighted population

istributions in the U.S., the darker rooms would be

d

much more prevalent than the very bright rooms.

However, to be conservative, the studies defining

120 lux as the typical home display condition

considered neither of these extremes.

A very recent multi-year study covering homes in

cities around the world has again verified the 120

lux light level as typical, if not conservative.

Findings of this study indicated that the 90th

percentile of light levels studied was 137 lux. That

is, fully 90% of the homes would have light levels

below 137 lux. This study was done over a two-year

time period, covering homes in North and South

America, Asia, Europe, and Asutralia, and included

6

well over 100,000 discrete measurements.

In commercial applications, the light intensity of

typical display conditions covers a range much

wider than that of t

Typical home conditions are clustered over a

relatively narrow range of intensities. Commercial

conditions are not clustered at all, and the

difference between the lower and higher light levels

can be a factor of 1000 or more. The range would

cover museum conditions at 50 to 100 lux to

outdoor displays at 50,000 to 100,000 lux. This

wide range makes it impossible to pick one light

intensity level to represent all commercial

conditions. Using a single light intensity for

predicting commercial print life would be extremely

misleading.

eloping the new KODAK PROFESSIONAL

v

In de

ENDURA Papers for commercial applications, Kodak

acknowledged the extremely wide range of

cial c

ommer

c

commercial applications, even in relatively similar

display environments, have the same ambient light,

temperature, and humidity conditions. Nevertheless,

various studies have been done to quantify

commercial conditions and several broad categories

ve been recognized.

ha

able 2

T

y establishing t

. B

ypical home display conditions.

e when any two

onditions. It is r

ar

17

hese are summarized in

T

ypical light levels in the

1

broad categories, it is possible to provide a broad

stimate of print life. A more accurate estimate

e

would require quantifying ambient conditions of

light intensity and temperature at a minimum.

able 2

T

ommercial Display Categories and Approximate

C

Light Levels

Approximate

Display Category Light level

(Lux)

Museum 150

e 450

Offic

Moderate-Intensity

Commercial Reflection Display

High-Intensity

Commercial Reflection Display

As a guide for estimating print life in the

commercial environment,

estimate for ULTRA ENDURA Paper in commercial

reflection display situations.

Table 3

Approximate Print Lifetimes for KODAK

PROFESSIONAL ULTRA ENDURA Paper in

Commercial Applications

Table 3 adds an average

Approximate

Display Category Light level

(Lux)

Museum 150

1000

5000

Approximate

Print Life

Over 100

years

Office 450 35 years

ensity

e-Int

at

Moder

s

ear

ommercial

C

1000

8.5 y

Reflection Display

High-Intensity

Commercial 5000 20 months

eflection Display

R

Note:All light c

12 hours off. Thermal conditions, used for the low-intensity levels,

assume 24°C and 50% RH.

onditions assume illumination for 12 hours on and

16

D. Bugner, J. LaBarca, et. Al., “A Survey of Environmental Conditions Relative

to the Storage and Display of Photographs in Consumer homes”, Journal of

Imaging Science and Technology, 50 (4), 2006, PP. 309-319.

17

D.F. Kopperl, unpublished results.

9

Page 11

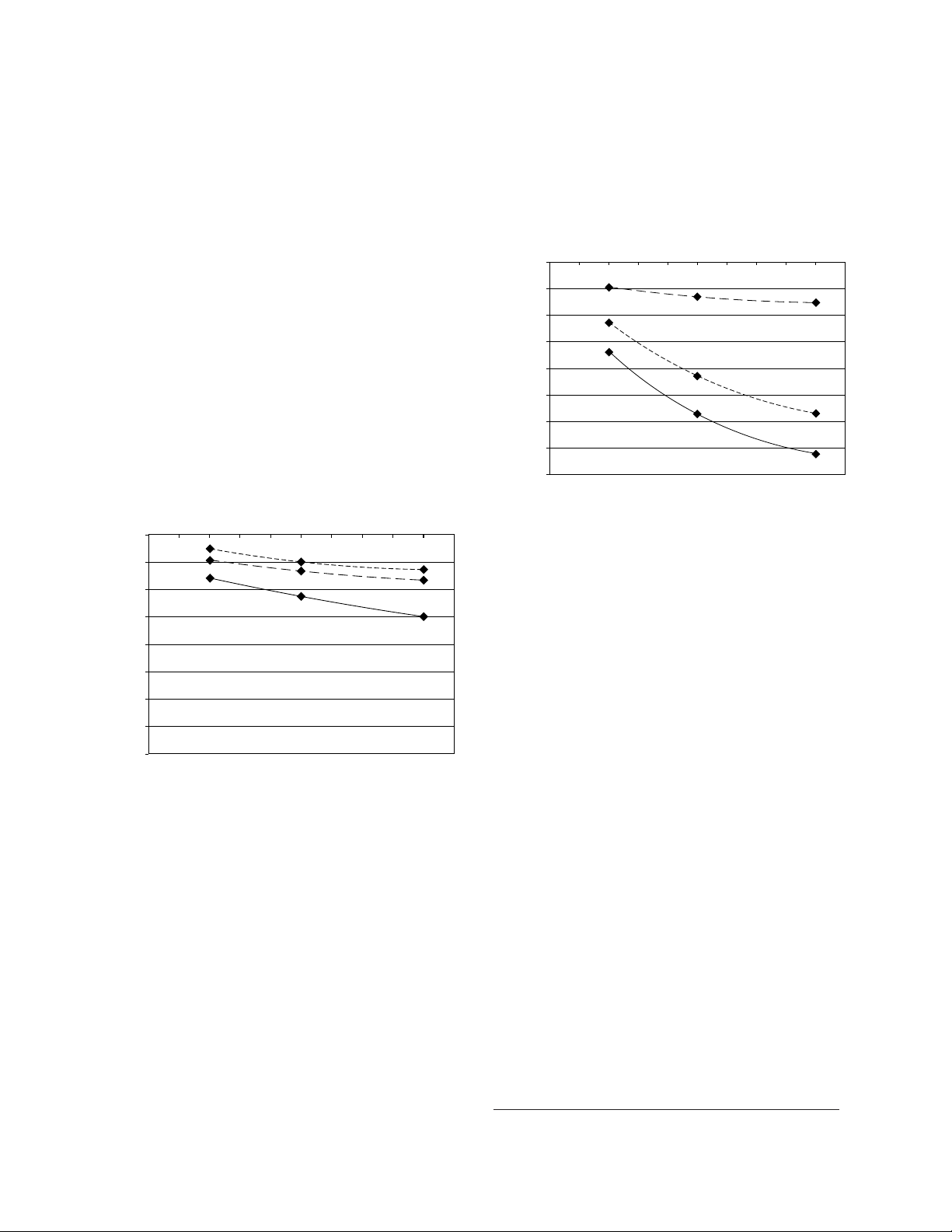

Balance of Light and Thermal Mechanisms

8075706560555045403530

-0.8

-0.7

-0.6

-0.5

-0.4

-0.3

-0.2

-0.1

0

Loss from 1.0 density

Dark

1

20 Lux

Lux

D

ark + 120

Loss from 1.0 density

5

00 Lux

Dark +

5

00 Lux

Dark

0

-

0.1

-0.2

-0.3

-

0.4

-

0.5

-0.6

-

0.7

-0.8

30 35 40 45 50 55 60 65 70 75 80

As mentioned earlier, balancing the rate of dye fade

due to light degradation and dye fade due to thermal

degradation is important in optimizing print life. This

s especially so in the portrait and social

i

environment, where light levels are low.

how examples of the relationship of light and

nd 4

s

a

thermal fade. (For ease of illustration, the data come

rom an earlier generation of Kodak color papers.) In

f

low-light situations, the two degradation mechanisms

contribute nearly equally to overall print life

. Under higher-intensity lighting, such as

3)

commercial displays, the light-fade mechanism

outweighs thermal fade

(Figure 4).

Figure 3

Relationship of Light and Dark Fade

with Typical Home Illumination

Years to a Given Fade

Figures 3

(Figure

Figure 4

elationship of Light and Dark Fade

R

with Typical Commercial Illumination

Years to a Given Fade

Through the mid-1970s, thermal stability had been

the prime fade mechanism. Then product

improvements permitted a catch-up of thermal

stability to light stability. By the mid-1990s, many

manufacturers had achieved a good balance between

light and thermal fade. However, for various reasons,

the industry paid more attention to the light-stability

improvements than to thermal-stability

improvements. This is unfortunate for both the

portrait/social and the commercial markets, because

all images in both environments undergo thermal

degradation, whether displayed in the light or stored

in the dark. Especially in the portrait/social

environment (including both consumer snapshots and

professional portraits), the vast majority of images

are stored in the dark—in albums, shoeboxes, closets,

18

etc.

10

In balancing light and thermal stability, it is

important to evaluate the combination of both

effects, rather than just one or the other individually.

An improvement in light stability without a

esponding improvement in thermal stability, or

orr

c

vice versa, will not necessarily improve print life.

Kodak has long recognized the need to improve both

light and thermal stabilit

, and it was a key factor in

y

creating the new dye technologies that are now used

in KODAK PROFESSIONAL ENDURA Papers. The

echnology

ch, t

esear

s of r

esult of nearly six y

r

18

D.S. Hachey, unpublished report.

ear

Page 12

development, testing, modeling, and

ommercialization, these new papers represent

c

dramatic improvements in print life for all

professional market segments.

or more information on design and balancing

F

of light and thermal degradation mechanisms, see

the Kodak Research and Development

Web site Tech Brief from January 2002 at

http://www.kodak.com/US/en/corp/researchDevel

opment/productFeatures/balance.shtml.

For an in-depth discussion, see “The Importance of

the Balance of Light and Thermal Image Stability

Effects in the Design of Photographic Color Paper.”

Habits in Imag

e Usage—Practical Print-Life

Examples for the End-User

All KODAK PROFESSIONAL ENDURA Papers are

designed to last for more than 200 years before

noticeable changes occur in typical home darkstorage environments, such as albums. In the typical

home display environment, the new papers will last

over 100 years before noticeable changes occur.

Although the vast majority of end-user images in

the portrait and social environment are stored in the

dark, many images are displayed. In the mid-1990s

an informal survey asked U.S. professional portrait

finishing labs about practical print-life expectations

for displayed images. Specifically, it asked how

many of the images made for display would still be

on display after various times. The data from the

survey are shown in

Table 4.

Table 4

Informal Survey of Length of Display of

rofessional Prints

P

Image Age Approximate Images Still

(Years) on Display

5 54 percent

10 42 percent

20 21 percent

40 1.9 percent

60 Virtually none

19

For various reasons, such as home redecorating and

orce, the majority of images placed on display

div

are often taken down after 10 years.

Considering the balanc

the portrait/social environment, the additive effects

of thermal and light degradation, and the fact that

many images displayed initially are eventually

stored in the dark, it is possible to calculate

practical print-life estimates. The estimates are

based on the combined rates of display and darkstorage fade.

Table 5 gives several estimates.

e of thermal and light fade in

19

J. LaBarca and S. O’Dell, “The Importance of the Balance of Light and

Thermal Image Stability Effects in the Design of Photographic Color Paper,”

Proceedings of IS&T’s 12th International Symposium on Photofinishing Technology,

2002, pp. 38–47.

11

Page 13

Table 5

Practical Print-Life Estimates Based on Combined

ome Display (120 Lux) and Eventual Dark Storage

H

(24°C and 50% RH)

Image Estimated

Display Remaining Dark Total Estimated

Time Life After Print Life (Years)

(Years) Display (Years)

0 Over 200 Over 200

10 Over 180 Over 190

20 Over 160 Over 180

40 Over 120 Over 160

60 Over 80 Over 140

80 Over 40 Over 120

After a print is removed from display, the

degradation mechanism reverts to the slower

thermal effect and provides a jump in remaining

print life during dark storage.

Conclusions

learly, the science of measuring, interpreting, and

C

estimating print life is very complex. Print life

epends on many external variables that can cover

d

wide ranges of conditions.

While newer imaging technologies have revealed

dditional degradation mechanisms (and more

a

mechanisms may be discovered in the future), silver

halide-based color photographic paper has been

around for more than five decades. The key

degradation mechanisms of light fade and thermal

fade are very well understood. Product

ovements have made other degradation

impr

mechanisms from earlier days, such as base

stability, inconsequential.

Because color silver halide-based paper has existed

for so long, it is unlikely that any undiscovered

degradation mechanisms will suddenly arise. For all

these reasons, it is possible to predict print life

accurately and with a very high degree of

confidence.

As stated earlier, the accuracy of predictions

depends on the quality of test data, and statistically

good data take a long time and a high degree of

testing precision to generate. Also, designing for

optimum print life and predicting print life

accurately require a thorough understanding of the

degradation mechanisms in the real-world

environment where products will be used.

Finally, it is critically important not to design a

oduct ex

pr

at the expense of other design criteria, i.e., image

qualit

design of KODAK PROFESSIONAL ENDURA Papers

has successfully improved all three major design

criteria. The new papers provide excellent print life,

excellent image quality, and excellent performance

in the lab, all in the context of the real-world

equirements of end-users in the portrait/social and

r

ommer

c

clusively for image stability and print life

y and perf

cial display markets.

ormanc

e in the finishing lab. T

he

12

Page 14

wwwwww..kkooddaakk..ccoomm//ggoo//eenndduurraa

Kodak, Kodak Professional, Kodachrome, Kodacolor, Ektacolor, Endura,, Supra, and Ultra are

trademarks of Eastman Kodak Company. Printed in U.S.A. 12/03 ©Eastman Kodak Company, 2007

PPI-1097 CAT 134 1817

Loading...

Loading...