Page 1

Publication No. XP3210-006

Repairing the

LASER PRINTER KEYPAD

a component of the

3230 Kodak Ektascan 2180 LASER PRINTER,

3226 Kodak Ektascan 1120 LASER PRINTER,

3210 Kodak Ektascan LASER PRINTER

Model 100 XLP,

3222 Kodak Ektascan LASER PRINTER

Model 100 XLP Upgrade,

18JUL97

3140 Kodak Ektascan IMAGE MANAGER

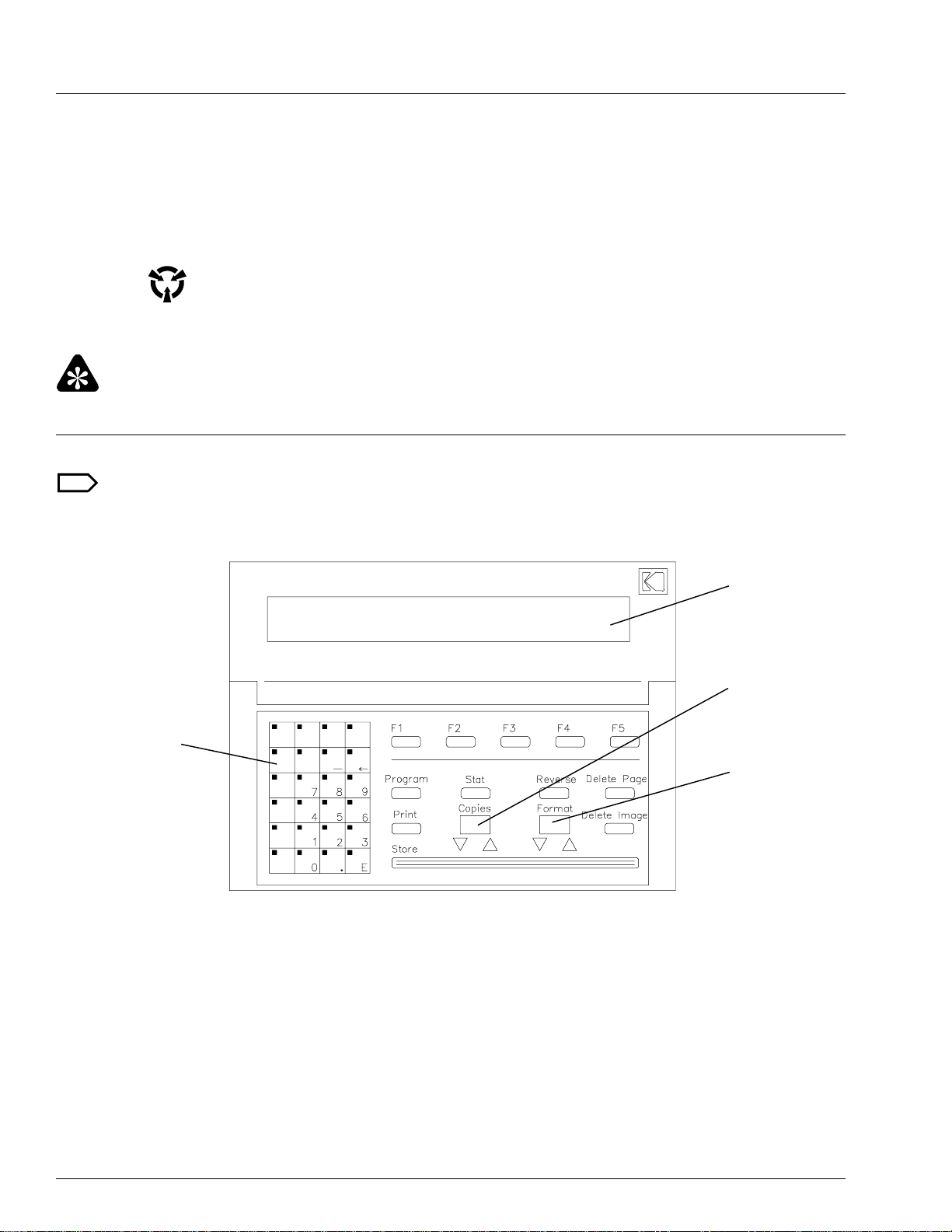

Purpose: Use this procedure to repair only the KEYPAD with the tilting MESSAGE DISPLAY, identified by

the figure below.

Order a replacement KEYPAD only if the KEYPAD cannot be repaired.

HEALTH IMAGING

© Eastman Kodak Company

H027_2527AA

Page 2

MISCELLANEOUS PUBLICATION

Repair Time: Approximately 30 minutes maximum

Special Tools: PUMP, VACUUM DESOLDER TL-3314 or WICK, SOLDER 1C8129

Parts Status: Available from Service Parts Management

Parts Requirements: KEYPAD Repair Kit, Part Number 9B1510

Note: Order the Repair Kit once and order replacement parts. Feedback

information about the parts to SCAN.

KEYPAD Repair kit, Part Number 9B1510

(Parts are available separately)

Item Part Number Description Qty.

1 981821 DC-DC CONVERTER (incl. adhesive pad) 2

2 911355 MESSAGE DISPLAY BOARD 1

3 2B6808 KEYPAD OVERLAY/BOARD ASSEMBLY 1

4 9B1506 STANDOFF, hex, male/female 6

5 9B1507 BUSHING, hex, threaded, female/female 6

6 914278 SHORT STANDOFF 6

7 914279 LONG STANDOFF 6

8 914276 SPACER, plastic 6

9 914287 SHORT SCREW, plastic 6

10 914288 LONG SCREW, plastic 6

11 575822 WASHER, metal 6

12 1C8148 LOCKTITE 414 ADHESIVE, 1 oz. bottle 1

13 6C5726 CASE and PART BOX 1

2 18JUL97 – XP3210-006

Page 3

PLEASE NOTE The information contained herein is based on the experience and knowledge relating to the

subject matter gained by Eastman Kodak Company prior to publication.

No patent license is granted by this information.

Eastman Kodak Company reserves the right to change this information without notice, and

makes no warranty, express or implied, with respect to this information. Kodak shall not be

liable for any loss or damage, including consequential or special damages, resulting from any

use of this information, even if loss or damage is caused by Kodak’s negligence or other fault.

This equipment includes parts and assemblies sensitive to damage from electrostatic

discharge. Use caution to prevent damage during all service procedures.

Important

Use qualified personnel to make the repair.

Diagnosing the KEYPAD Malfunction

Note

The PRINTER and INTERFACE must be ON and in the READY mode before you diagnose the KEYPAD.

You cannot diagnose the KEYPAD correctly if the PRINTER and INTERFACE are in the START-UP or SELFTEST modes.

MESSAGE

DISPLAY

’COPIES’

DISPLAY

NUMERIC

KEYPAD

’FORMAT’

DISPLAY

H027_2508BCB

H027_2508BA

[1] Check that the KEYPAD CABLE is connected correctly.

[2] Press the Format ▲ key several times. As you press the key, observe the illumination of the NUMERIC

KEYPAD and listen for a beep each time the key is pressed.

[3] Study the following and check for incorrect or erratic displays:

• MESSAGE DISPLAY

• NUMERIC KEYPAD

• ‘COPIES’ DISPLAY

• ‘FORMAT’ DISPLAY

3 18JUl97 – XP3210-006

Page 4

MISCELLANEOUS PUBLICATION

6 SCREWS

BACK COVER

H027_2522ACA

H027_2522AC

SCREWS

ESD

Possible damage from electrostatic discharge.

[4] If the KEYPAD does not operate correctly,

remove the six screws and BACK COVER from

the MESSAGE DISPLAY.

[5] Check that the CONNECTOR on the RIBBON

CABLE engages the MESSAGE DISPLAY

BOARD.

ESD

Possible damage from electrostatic discharge.

H027_2516ACA

H027_2516AC

MESSAGE

DISPLAY

RIBBON

CABLE

FOOTSWITCH

BOARD

KEYPAD DISPLAY

RIBBON CABLE

KEYPAD OVERLAY/

BOARD AY

GROUND CABLE

HEX NUT

WASHER

H027_2524ACA

H027_2524AC

[6] Remove the four SCREWS and WASHERS from

the back of the KEYPAD. Turn the KEYPAD

over.

[7] Carefully lift the KEYPAD OVERLAY/

CIRCUIT BOARD ASSEMBLY out of the

KEYPAD.

Caution

Be careful not to damage the wires and ribbon cables

attached to the ASSEMBLY.

[8] Check that the CONNECTORS on the following

CABLES and BOARDS are engaged:

• MESSAGE DISPLAY RIBBON CABLE

• KEYPAD DISPLAY RIBBON CABLE

• RIBBON CABLE between the KEYPAD

OVERLAY and CIRCUIT BOARD

• FOOTSWITCH BOARD

4 18JUL97 – XP3210-006

Page 5

[9] Use Steps 2 and 3 to check the KEYPAD operation again.

[10] Use the following table to help you select the correct repair procedure.

Probable Cause/

Malfunction Description

The NUMERIC KEYPAD is not illuminated.

The COPIES and FORMAT DISPLAYS are not illuminated.

The MESSAGE DISPLAY is not illuminated.

Corrective Action Procedure Reference

The DC-DC

CONVERTER might

have failed. Check and

replace.

The MESSAGE DISPLAY is not illuminated or the

illumination is not uniform.

The NUMERIC KEYPAD is illuminated.

The COPIES and FORMAT DISPLAYS are illuminated.

The KEYPAD operation or response is erratic.

The KEYPAD illumination is incorrect or erratic.

The MESSAGE

DISPLAY BOARD

might have failed. Check

and replace.

The KEYPAD

OVERLAY/BOARD

AY might have failed.

Check and replace.

Replacing the DC-DC

CONVERTER, page 6.

Replacing the

MESSAGE DISPLAY

BOARD, page 11.

Replacing the

KEYPAD/OVERLAY

BOARD AY, page 13.

XP3210-006 – 18JUL97 5

Page 6

MISCELLANEOUS PUBLICATION

Replacing the DC-DC CONVERTER

SCREWS

H027_2516ACA

H027_2516AC

KEYPAD OVERLAY

CIRCUIT BOARD

ESD

Possible damage from electrostatic discharge.

[1] Remove the four SCREWS and WASHERS from

the back of the KEYPAD. Keep the SCREWS and

WASHERS.

[2] Carefully lift the KEYPAD OVERLAY/

CIRCUIT BOARD ASSEMBLY out of the

KEYPAD.

PLASTIC

STANDOFFS

H027_2517ACA

H027_2517AC

Caution

Be careful not to damage the wires and ribbon cables

attached to the ASSEMBLY.

[3] Check the KEYPAD OVERLAY/BOARD

ASSEMBLY for damage.

Note

There are plastic STANDOFFS between the KEYPAD

OVERLAY and CIRCUIT BOARD. If only one or two

STANDOFFS are broken, continue with the next step.

If more than two of the plastic STANDOFFS are

broken, you should replace the KEYPAD OVERLAY/

CIRCUIT BOARD ASSEMBLY. Advance to the

procedure Replacing the KEYPAD OVERLAY/

CIRCUIT BOARD ASSEMBLY on page 13.

6 18JUL97 – XP3210-006

Page 7

H027_2528ACA

H027_2528AC

KEYPAD

OVERLAY/

BOARD AY

DC-DC CONVERTER

[4] Locate the DC-DC CONVERTER.

Important

There are 2 styles of DC-DC CONVERTER. You can

replace the DC-DC CONVERTER

style as the DC-DC CONVERTER replacement, Part

Number 981821, in the KEYPAD Repair Kit.

[5] Compare the DC-DC CONVERTER on the

CIRCUIT BOARD to the replacement DC-DC

CONVERTER in the Repair Kit.

[6] If the DC-DC CONVERTER on the CIRCUIT

BOARD is the same style as the replacement part,

advance to Step 7.

If the DC-DC CONVERTER is

as the replacement part, you

KEYPAD OVERLAY/CIRCUIT BOARD

ASSEMBLY. Advance to the procedure

Replacing the KEYPAD OVERLAY/

CIRCUIT BOARD ASSEMBLY on page 13.

only if it is the same

not the same style

must replace the

C36 CAPACITOR

PIN 2

PIN 1

VOLT-OHM

METER

GROUND LEAD

PIN 3

DC-DC

CONVERTER

H027_2518ACA

H027_2518AC

[7] Use the following table to help you measure the

input and output voltages of the DC-DC

CONVERTER. The KEYPAD must be energized

to check the voltage.

Caution

Be careful not to cause a short circuit between any of

the pins on the DC-DC CONVERTER.

Voltmeter Connections

Black

Red

Pin 1 C36 > +7.0 Volts (Input)

Pin 3 C36 5.0 +/- 0.1 Volts (Output)

[8] If the input and output voltages are correct,

advance to the procedure Replacing the

KEYPAD OVERLAY/BOARD ASSEMBLY

on page 13.

[9] If either voltage is

next step.

(ground) Requirement (VDC)

not correct, continue with the

XP3210-006 – 18JUL97 7

Page 8

MISCELLANEOUS PUBLICATION

RIBBON

CABLE

H027_2519ACA

H027_2519AC

DC-DC

CONVERTER

CIRCUIT BOARD

KEYPAD

OVERLAY

DC-DC CONVERTER

BUSHINGS

PINS

[10] De-energize the LASER PRINTER or IMAGE

MANAGER.

[11] Loosen and remove the plastic BUSHINGS from

the back of the CIRCUIT BOARD. Keep the

BUSHINGS.

[12] Separate the KEYPAD OVERLAY from the

CIRCUIT BOARD. Be careful not to damage the

RIBBON CABLE between them.

[13] Remove the solder from the pins connecting the

DC-DC CONVERTER to the CIRCUIT BOARD.

Important

Two of the pins on the DC-DC CONVERTER are

wider at one end and the third pin is uniformly narrow.

Insert the narrow pin into the hole at the edge of the

BOARD.

[14] Insert the pins of the new DC-DC CONVERTER

through the correct holes in the CIRCUIT

BOARD.

[15] Solder the pins of the DC-DC CONVERTER to

the CIRCUIT BOARD.

CIRCUIT

BOARD

H027_2520GCA

H027_2520GC

[16] Remove the paper from the adhesive pad on the

back of the DC-DC CONVERTER.

[17] Bend the pins and press the DC-DC

CONVERTER so that the adhesive pad adheres to

the CIRCUIT BOARD.

Caution

Be careful not to cause a short circuit between the pins.

[18] Energize the LASER PRINTER or IMAGE

MANAGER.

8 18JUL97 – XP3210-006

Page 9

[19] Measure the input and output voltages of the new

DC-DC CONVERTER and compare these

voltages to the table. If the voltages are

not

correct, advance to the procedure Replacing the

KEYPAD OVERLAY/BOARD ASSEMBLY

on page 13.

[20] If the input and output voltages of the new DC-DC

CONVERTER are correct and none of the

STANDOFFS are broken, assemble the

KEYPAD OVERLAY and the CIRCUIT

BOARD using the 4 BUSHINGS. Advance to

Step 26.

CIRCUIT

BOARD

EXISTING

STANDOFFS

KEYPAD

OVERLAY

H027_2521ACA

H027_2521AC

NEW STANDOFF

BUSHING

PREPARED

SURFACE

[21] If 1 or 2 STANDOFFS are broken, remove any

pieces of the old STANDOFFS from the back of

the KEYPAD OVERLAY. The area where you

attach the new STANDOFFS must be flat.

Sandpaper or a file can be used to make the area

flat.

A broken STANDOFF could be repaired with

adhesive if the pieces can be aligned.

[22] Install each new STANDOFF and BUSHING.

Warning

Do not allow adhesive to contact skin.

[23] Place

[24] Assemble the KEYPAD OVERLAY and

[25] Apply pressure to the KEYPAD OVERLAY/

one drop of Loktite 414 ADHESIVE to the

end of each new STANDOFF.

CIRCUIT BOARD. Attach and tighten

BUSHINGS to the existing STANDOFFS.

CIRCUIT BOARD ASSEMBLY for 60 seconds

until the ADHESIVE is dry enough to handle.

Important

Handle the ASSEMBLY carefully. The ADHESIVE

does not reach full strength for 24 hours.

[26] Place the KEYPAD OVERLAY/BOARD

ASSEMBLY into the KEYPAD. Be careful not to

damage the RIBBON CABLES and other wires.

[27] Inset the four screws and washers into the back of

the KEYPAD and tighten them. If any SCREWS

are broken, replace them.

XP3210-006 – 18JUL97 9

Page 10

MISCELLANEOUS PUBLICATION

[28] Use the procedure Diagnosing the KEYPAD

Malfunction on page 3 to check for the correct

operation of the KEYPAD.

[29] Use any available diagnostics or equipment to

check the correct operation of all the KEYPAD

components and functions. For example, on some

equipment you can use the “KEYPAD LED/Tone

Test” and “KEYPAD Recognition Test” under the

Diagnostic Functions of the Interface CES Main

Menu.

[30] If the KEYPAD does not operate correctly,

replace it.

10 18JUL97 – XP3210-006

Page 11

Replacing the MESSAGE DISPLAY BOARD

BACK COVER

H027_2522ACA

H027_2522AC

SPACERS

H027_2523ACA

H027_2523AC

6 SCREWS

MESSAGE

DISPLAY

BOARD

2 LONG

STANDOFFS

2 SHORT

STANDOFFS

[1] De-energize the LASER PRINTER or IMAGE

MANAGER.

[2] Disconnect the KEYPAD CABLE from the back

of the KEYPAD.

[3] If there is a FOOTSWITCH connected to the

KEYPAD, disconnect the FOOTSWITCH

CABLE from the back of the KEYPAD.

ESD

Possible damage from electrostatic discharge.

[4] Remove the six SCREWS from the back of the

MESSAGE DISPLAY. Keep the SCREWS.

[5] Remove the BACK COVER.

[6] Disconnect the RIBBON CABLE from the

MESSAGE DISPLAY BOARD.

Note

Some KEYPADS might have a metal strip between the

RIBBON CABLE and MESSAGE DISPLAY

BOARD.

[7] Loosen and remove the plastic STANDOFFS

from the MESSAGE DISPLAY BOARD. Keep

the STANDOFFS.

[8] Carefully pry the MESSAGE DISPLAY BOARD

from the KEYPAD and keep the SPACERS.

[9] Install the new MESSAGE DISPLAY BOARD

and the SPACERS. Be sure the CONNECTOR

SOCKET of the MESSAGE DISPLAY BOARD

is on the correct side.

[10] Attach and tighten the four plastic STANDOFFS.

Important

There are 2 styles of STANDOFFS. Insert the longer

STANDOFFS in the top holes.

[11] Attach the RIBBON CABLE to the MESSAGE

DISPLAY BOARD.

[12] Install the BACK COVER and secure it with the

six SCREWS.

[13] Connect the KEYPAD CABLE to the KEYPAD.

[14] If there is a FOOTSWITCH, connect the

FOOTSWITCH CABLE to the KEYPAD.

XP3210-006 – 18JUL97 11

Page 12

MISCELLANEOUS PUBLICATION

[15] Energize the LASER PRINTER or IMAGE

MANAGER.

[16] Use the procedure Diagnosing the KEYPAD

Malfunction on page 3 to check for the correct

operation of the KEYPAD.

[17] Use any available diagnostics or equipment to

check the correct operation of all the KEYPAD

components and functions. For example, on some

equipment you can use the “KEYPAD LED/Tone

Test” and “KEYPAD Recognition Test” under the

Diagnostic Functions of the Interface CES Main

Menu.

[18] If the KEYPAD does not operate correctly,

replace it. Remove the new MESSAGE

DISPLAY BOARD from the broken KEYPAD

and keep it.

12 18JUL97 – XP3210-006

Page 13

Replacing KEYPAD OVERLAY/BOARD ASSEMBLY

[1] De-energize the LASER PRINTER or IMAGE

MANAGER.

[2] Disconnect the KEYPAD CABLE from the back

of the KEYPAD.

[3] If there is a FOOTSWITCH connected to the

KEYPAD, disconnect the FOOTSWITCH

CABLE from the back of the KEYPAD.

ESD

Possible damage from electrostatic discharge.

MESSAGE

DISPLAY

RIBBON

CABLE

FOOTSWITCH

BOARD

KEYPAD DISPLAY

RIBBON CABLE

KEYPAD OVERLAY/

BOARD AY

GROUND CABLE

HEX NUT

WASHER

H027_2524ACA

H027_2524AC

[4] Remove the four SCREWS and WASHERS from

the back of the KEYPAD. Keep the SCREWS and

WASHERS.

[5] Remove the KEYPAD OVERLAY/BOARD

ASSEMBLY from the KEYPAD.

[6] Disconnect the MESSAGE DISPLAY RIBBON

CABLE from the CIRCUIT BOARD.

[7] Disconnect the KEYPAD RIBBON CABLE from

the CIRCUIT BOARD.

[8] Loosen and remove the HEX NUT from the

GROUND CABLE stud inside the KEYPAD.

[9] Remove the LOCK WASHER and CIRCUIT

BOARD GROUND CABLE.

[10] Carefully pry the FOOTSWITCH BOARD from

the ADHESIVE PAD.

Note

Some KEYPAD styles do not have the FOOTSWITCH

feature and will

FOOTSWITCH CONNECTOR inside. The

replacement KEYPAD OVERLAY/BOARD AY will

operate correctly in all KEYPADS.

[11] If the KEYPAD does

FOOTSWITCH feature, advance to Step 15.

not have a FOOTSWITCH BOARD or

not have the

XP3210-006 – 18JUL97 13

Page 14

MISCELLANEOUS PUBLICATION

FLANGES

FOOTSWITCH

CONNECTOR

H027_2525ACA

H027_2525AC

FOOTSWITCH

BOARD

Important

Observe the position of the flanges on the

FOOTSWITCH WIRE CONNECTOR. The flanges

might be up or down. You must attach the

CONNECTOR to the new FOOTSWITCH BOARD in

the same position or the FOOTSWITCH will not

operate.

[12] Disconnect the FOOTSWITCH WIRE

CONNECTOR from the FOOTSWITCH

BOARD.

[13] Attach the FOOTSWITCH WIRE CONNECTOR

to the FOOTSWITCH BOARD on the new

KEYPAD OVERLAY/BOARD ASSEMBLY.

Be sure that the flanges on the connector are in the

same position as they were on the old

FOOTSWITCH BOARD.

[14] If the old adhesive pad is attached to the bottom of

the KEYPAD base, remove it.

[15] Remove the paper from the adhesive pad on the

back of the new FOOTSWITCH BOARD.

[16] Place the new FOOTSWITCH BOARD into the

correct position in the KEYPAD and press it

down.

H027_2526ACA

H027_2526AC

STUD

LOCK WASHER

FOOTSWITCH

GROUND

CIRCUIT BOARD

GROUND

STRAP

HEX NUT

[17] Attach the CIRCUIT BOARD GROUND

CABLE to the STUD using the LOCK WASHER

and HEX NUT. See the figure.

[18] Connect the KEYPAD RIBBON CABLE and the

MESSAGE DISPLAY RIBBON CABLE.

[19] Assemble the KEYPAD OVERLAY/BOARD

ASSEMBLY and the KEYPAD.

Caution

Be careful not to damage the RIBBON CABLES and

other wires.

[20] Inset the four SCREWS with WASHERS into the

back of the KEYPAD and tighten them.

[21] Connect the KEYPAD CABLE to the KEYPAD.

[22] If there is a FOOTSWITCH, connect the

FOOTSWITCH CABLE to the KEYPAD.

[23] Energize the LASER PRINTER or IMAGE

MANAGER.

[24] Use the procedure Diagnosing the KEYPAD

Malfunction on page 3 to check for the correct

operation of the KEYPAD.

14 18JUL97 – XP3210-006

Page 15

[25] If there is a FOOTSWITCH, check that it operates

correctly. If it does not, the FOOTSWITCH

CONNECTOR might be incorrectly connected to

the FOOTSWITCH BOARD in the KEYPAD.

[26] Use any available diagnostics or equipment to

check the correct operation of all the KEYPAD

components and functions. For example, on some

equipment you can use the “KEYPAD LED/Tone

Test” and “KEYPAD Recognition Test” under the

Diagnostic Functions of the Interface CES Main

Menu.

[27] If the KEYPAD does not operate correctly,

replace it. Remove the new KEYPAD

OVERLAY/BOARD ASSEMBLY from the

broken KEYPAD and keep it.

XP3210-006 – 18JUL97 15

Page 16

Publication Change Notice Table

Print Date Pub. No. ECO No. Affected Pages File Name Notes

JUL 97 XP3210-6 2632-349 All xp3210_6_18jul97.doc new publication

xp3210_6_18jul97.doc

Printed In USA

Kodak and Ektascan are trademarks

EASTMAN KODAK COMPANY

HEALTH IMAGING

● ROCHESTER, N.Y. 14650

Loading...

Loading...