Page 1

User Guide

for the

KODAK EKTASCAN 160 Laser Imager

with the

KODAK X-OMAT 2000 Processor

Health Imaging

EASTMAN KODAK COMP ANY

June 2000

Page 2

Credits and Trademarks

KODAK, Ektascan, and X-Omat are trademarks of the Eastman

Kodak Company.

Other trademarked names may be used throughout this manual.

Instead of listing all the names and companies that own these

trademarks, or inserting a trademark symbol with each occurrence

of the trademarked name, Eastman Kodak Company states that

these names are used for editorial purposes, with no intent to

infringe upon trademarks.

CAUTION: Federal law restricts this device to sale to, by, or

on order of a physician.

The information contained herein is based on the experience and

knowledge relating to the subject matter gained by Eastman

Kodak Company prior to publication.

No patent license is granted by this information.

Eastman Kodak Company reserves the right to change this infor-

mation without notice and makes no warranty , express or implied,

with respect to this information. Kodak shall not be liable for any

loss or damage, including consequential or special damages,

resulting from the use of this information, even if loss or damage

is caused by Kodak’s negligence or other fault.

Pub. No. 5E2234

© Eastman Kodak Company, 2000

Printed in U SA

HEAL TH IMAGING

EASTMAN KODAK COMPANY

Rochester, NY 14650

Page 3

Medical Device Directive (MDD)

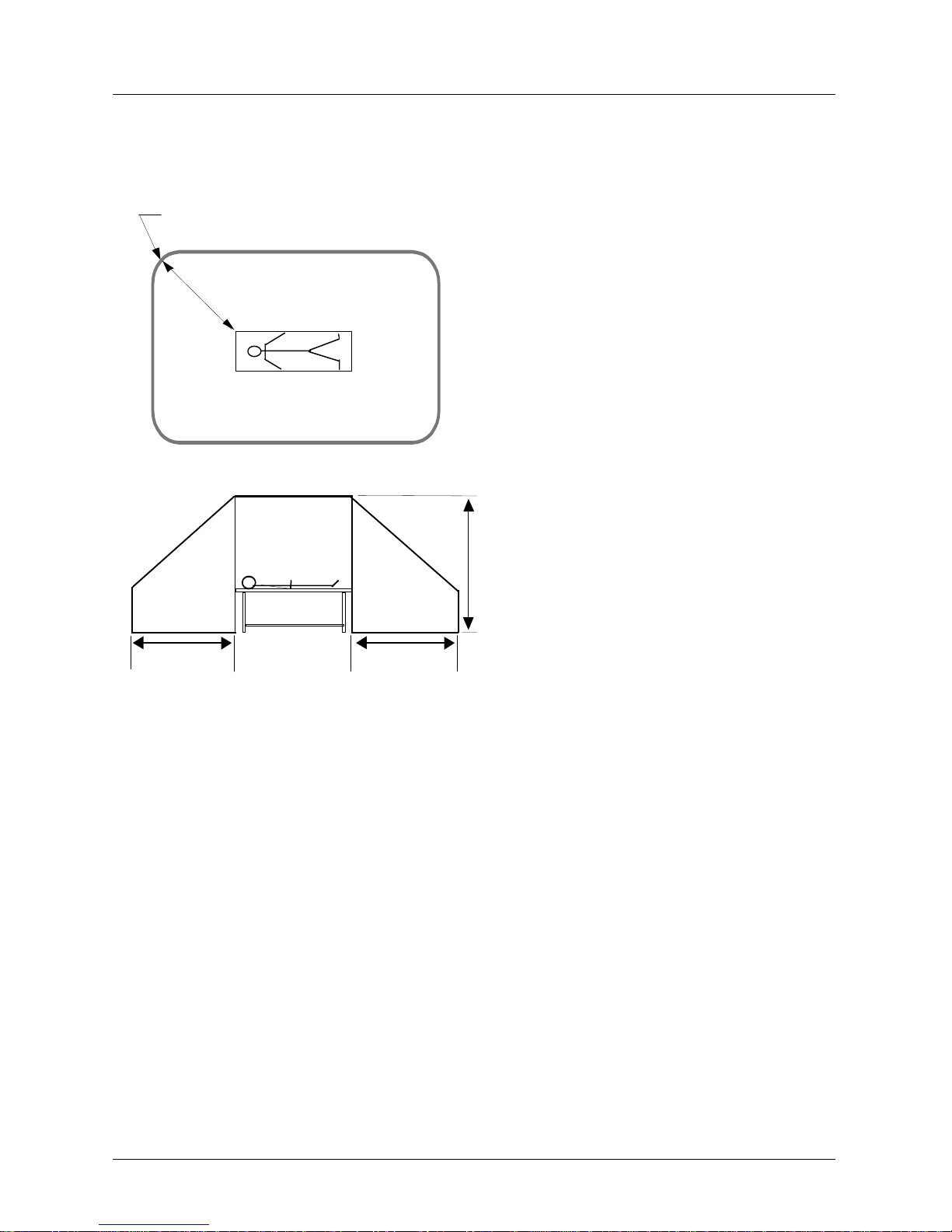

m

m

1,83

2,5m

1,83m

1,83

English

This device is not medica l equipment a ccording to EN 6 0 601-1 and mus t therefore not e nter

the Patient Environment as defined in EN 60 601-1-1. The following requirements have to

be met:

1. Distance from devi ce to Pat ien t Cont act Equi pment (see il lustrat ion). H orizon tal = 1,83

metres; Vertical = 2,5 metres above the floor under the patient.

2. Contact of patient and device simultaneously by caregiver not allowed.

3. NO direct electrical connection between device and Patient Contact Equipment is

allowed.

AUTHORISED AGENT:

Manager, Product Safety; Kodak AG; Hedelfingerstr. 54-56; 70327 Stuttgart, GERMANY.

Page 4

Dansk

Denne enhed klacificeres ikke som medicinsk udstyr jævnfør standarden EN 60 601-1 og

må derfor ikke komme i nærheden af patientomgivelserne, som beskrevet i EN 60 601-1-1.

Følgende krav skal være opfyldt:

1. Afstanden fra enheden til p atientlejet (se tegningen). V and ret = 1,83 meter; Lo dret = 2,5

meter over gulvet under patienten.

2. Personalet må ikke berøre enheden og patienten samtidigt.

3. Der må IKKE forekomme direkte elektrisk forbindelse mellem enheden og patientlejet.

AUTORISERET FORHANDLER:

Manager, Product Safety; Kodak AG; Hedelfingerstr. 54-56; 70327 Stuttgart, TYSKLAND

Deutsch

Dieses Gerät ist kein medizinisches Gerät nach dem Standard EN 60 601-1 und darf sich

daher nicht in der Umgebung des Patienten, die durch den Standard EN 60 601-1-1 festgelegt ist, befinden. Die folgenden Anforderungen müssen erfüllt sein:

1. Abstand vom Gerät zum Patient Contact Equipment, d. h. zu mit dem Patienten in

Berührung stehenden Gerätschaften (siehe Abbildung). Horizontal = 1,83 Meter; Vertikal = 2,5 Meter über dem Boden unter dem Patienten.

2. Gleichzeitige Berührung von Patient und Gerät durch das Pflegepersonal nicht zuläs-

sig.

3. KEINE direkte elektrisc he Verbindung zwischen Gerät und Pati ent Cont act Equi pment

zulässig.

AUTORISIERTE VERTRETUNG:

Manager, Produktsicherheit; Kodak AG; Hedelfingerstr. 54-56; 70327 Stuttgart,

DEUTSCHLAND.

Español

Este dispositi vo no constituye un equipo médi co según el estándar EN 60 601 -1, por lo tanto

no necesita cumplir las normas para el entorno del paciente definidas en

EN 60 601-1-1. Deben cumplirse los siguientes requisitos:

1. Distancia del dispositivo al equipo de contacto con el paciente (véase diagrama). Hor-

izontal = 1,83 metros; Vertical = 2,5 metros por encima del suelo debajo del paciente.

2. No debe permitirse el contacto del asistente con el paciente y el dispositivo al mismo

tiempo.

3. NO debe permitirs e la conex ión eléc trica direc ta entre e l disposi tivo y el e quipo de co n-

tacto con el paciente.

AGENTE AUTORIZADO:

Gerente, Seguridad de producto; Kodak AG; Hedelfingerstr. 54-56; 70327 Stuttgart,

ALEMANIA.

Page 5

Français

Ce dispositif n' est p as assimil é à un équip ement méd ical comm e défini p ar l'EN 60 6 01-1 et

ne doit donc pas se conformer aux exigences d'environnement du patient que définit

l'EN 60 601-1-1. Les exigences suivantes doivent être respectées:

1. Distance ent re le dispositif et l'é qui pem en t en con t ac t av ec le p a tie nt (v oir i llu stration):

horizontalement = 1,83 mètres ; verticalement = 2,5 mètres au-dessus du sol sous le

patient.

2. Interdiction stric te au soigna nt d'être simult anémen t en cont act avec le patient et le di s-

positif.

3. INTERDICTION d' établi r une conn exion éle ctrique di recte entre le dispo sitif et l' équipe-

ment en contact avec le patient.

AUTORISATION:

Directeur, Contrôle sécurité; Kodak AG; Hedelfingerstr. 54-56; 70327 Stuttgart,

ALLEMAGNE.

Italiano

Questo disposi tivo non è un 'appa recchiat ura medica le ai sens i di EN 60 601 -1 e quindi n on

deve essere posta in prossimità del paziente, come definito in EN 60 601-1-1. Devono

essere soddisfati i requisiti elencati nel segui to:

1. Distanza tra il dispositivo e le attrezzature a contatto del paziente (vedere la figura).

Orizzonta le = 1,83 metri; V erticale = 2 ,5 metri sopra i l livello del pavimen to del pazi ente.

2. Non deve essere consentito al personale il contatto diretto contemporaneo con il

paziente ed il dispositivo.

3. NON deve esistere alcun contatto elettrico diretto tra il dispositivo e le attrezzature a

contatto del paziente.

AGENTE AUTORIZZATO:

Manager, Sicurezza Prodotto; Kodak AG; Hedelfingerstr. 54-56; 70327 Stuttgart,

GERMANIA.

Lietuviðkai

Ðis prietaisas nëra medicinos prietaisas pagal EN 60 601-1 ir todël privalo nepatekti á

paciento aplinkà, apibrëþtà EN 60 601-1. Bûtina laikytis ðiø reikalavimø:

1. Atstumas nuo prietaisas iki su pacientu kontaktuojanèios árangos (þr. paveikslà): hori-

zontaliai - 1.83 m; vertikaliai - 2.5 m virð grindø, po pacientu.

2. Pacientà priþiûrinèiam asmeniui vienu metu prie paciento ir prie prietaisas liestis

neleidþiama.

3. NELEIDÞIAMAS tiesioginis elektros kontaktas tarp prietaisas ir su pacientu susil-

ieèianèios árangos.

ÁGALIOTASIS ATSTOVAS:

Produkcijos saugos vadybininkas; Kodak AG; Hedelfingerstr. 54-56; 70327 Stuttgart,

VOKIETIJA.

Page 6

Nederlands

Deze app araat i s geen medisc he app ara tuu r volge ns EN 60 601-1 en ma g d aarom nie t bi nnen de behandelingsomgeving van de patiënt staan zoals bepaald is in EN 60 601-1-1. Er

moet aan de volgende eisen worden voldaan:

1. Afstand vanaf apparaat tot behandelinstallatie patiënt (zie afbeelding). Horizontaal =

1,83 meter; Verticaal = 2,5 meter boven de vloer vanaf de vloer onder de patiënt.

2. Gelijktijdig contact met patiënt en apparaat door verzorger is niet toegestaan.

3. Directe elektrische verbinding tussen apparaa t en behandelinstallatie patiënt is NIET

toegestaan.

GEVOLMACHTIGD VERTEGENWOORDIGER:

Manager, Productveiligheid; Kodak AG; Hedelfingerstr. 54-56; 70327 Stuttgart, Duitsland.

Norsk

Denne enheten betegnes i kke som medi sinsk ut styr i henhold ti l EN 60 601-1, og m å derfor

ikke settes inn i pasientmiljø som definert i EN 60 601-1-1. Følgende krav må overholdes:

1. Avstand fra enheten til utstyr i kontakt med pasient (se illustrasjon). Horisontalt = 1,83

meter, vertikalt = 2,5 meter over gulvet under pasienten.

2. Personalet må ikke ha samtidig kontakt med pasient og enheten.

3. INGEN direkte e lek tris k forbindelse mellom enheten og ut sty r i k ontakt med pasient er

tillatt.

AUTORISERT FORHANDLER:

Leder, produktsikkerhet; Kodak AG; Hedelfingerstr. 54-56; 70327 Stuttgart, TYSKLAND.

Português

De dispositiv o aco rdo com o dete rmina do em EN 6 0 601-1 , este proce ssad or não é con siderado equipamento médico e como tal não tem que obedecer às normas definidas em EN

60 601-1-1. Têm que ser cumpridos os seguintes requisitos:

1. Distância do dispositivo ao equipamento de contacto com o paciente (ver ilustração).

Horizontal = 1,83 metros; Vertical = 2,5 metros acima do chão debaixo do paciente.

2. Não é permitido o contacto simultâneo entre o assistente, o paciente e o dispositivo.

3. NÃO é permitida a ligação eléctrica directa entre o dispositivo e a equipa de contacto

com o paciente.

AGENTE AUTORIZADO:

Gerente, Segurança do Produto; Kodak AG; Hedelfingerstr. 54-56; 70327 Stuttgart,

ALEMANHA.

Page 7

Suomeksi

Tämä laite e i ole sairaan hoi tol aitt eis too n kuuluva laite siten kuin st andardissa EN 60 601-1

asia määritellään ja siksi sitä ei tule viedä standardin EN 60 601-1-1 mukaiseen potilasympäristöön. Seuraavat vaatimukset on täytettävä:

1. Etäisyys laitteesta potilaan kanssa kosketuksessa olevaan laitteistoon (ks. piirros).

Vaakatasossa = 1,83 metriä; pystytasossa = 2,5 metriä potilaan alla olevan lattian

yläpuolella.

2. Hoitohenkilö ei saa koskettaa potilasta samanaikaisesti kun hän koskettaa laitetta.

3. Laite EI saa olla s uorassa s ähköises sä kosk etukses sa potilaa n kanssa kosketuk sessa

olevaan laitteistoon.

VALTUUTETTU EDUSTAJA:

Johtaja, Product Safety; Kodak AG; Hedelfingerstr. 54-56; 70327 Stuttgart, SAKSA.

Svenska

Denna enheten utgör ej medicinsk utrustning enligt EN 60 601-1 och får därför ej införas i

patientnära miljö såsom denna definieras i EN 60 601-1-1. Följande krav måste vara uppfyllda:

1. Avstånd från enhete n till u trustni ng med pat ientko nta kt (se fi guren). Ho risont ellt = 1,8 3

m; vertikalt = 2,5 m ovanför golvet under patienten.

2. Vårdgivande person får ej samtidigt vidröra patienten och enheten.

3. INGEN direkt elektrisk förbindelse mellan framkallare och utrustning med patientkon-

takt får enheten.

AUKTORISERAT OMBUD:

Manager , Product Safety ; Kodak AG; Hedelfingerstr . 54-56; D-70327 S tuttgart , TYSKLAND.

Pub. No. 5E2234 Health Imaging

© Eastman Kodak Company, 2 000 EASTMAN KODAK COMPANY

Printed in USA, June 2000 Rochester, New York 14653

Page 8

Page 9

1

Safety

••••••••

In this chapter

Responsibility of the Manufacturer ....................... 1-2

General Information.............................................. 1-3

1-1

Page 10

Safety

Responsibility of the Manufacturer

IMPORTANT: To meet Electromagnetic Compatibility

requirements at a frequency of 50 Hz, the 160 Laser

Imager and the Medical Image Manager 200 were connected to the Power Kit/for KODAK PACS Link Medical

Image Managers, Catalog No. 198 4160. Please refer to

“Safety Standards and Regulatory Approvals” in the Site

Specifications for the KODAK EKTASCAN 160 Laser

Imager, Publication No. 5E2235.

The manuf actur er is re sponsi ble for the effects on safety,

reliability, and performance of the 160 Laser Imager when

the following conditions are followed:

Assembly operations, extensions, readjustments,

modifications or repairs are carried out by persons

authorized by the manufacturer.

The electrical installation of the site complies with the

site specifica tio n requ ir em ents.

Operation of the 160 Laser Imager complies with the

instructions for use in the User Guide.

NOTE: Please refer to the Site Specifications for

the KODAK EKTASCAN 160 Laser Imager,

Publication No. 5E2235, for site preparation

information.

1-2 5E2234 June 2000

Page 11

General Information

DANGER: Read and understand all instructions before using the KODAK EKTASCAN

160 Laser Imager.

Do not use the Laser Imager for direct patient contact.

Do not use the Laser Imager within a 6 ft. radius of an

immobilized patient.

Do not use the Laser Imager in an explosive environ-

ment.

Safety

Use of controls or adjustments or performance of pro-

cedures other than those specified herein may result

in hazardous radiation exposure.

CAUTION: This device is intended for use

only by professional, trained personnel.

5E2234 June 2000 1-3

Page 12

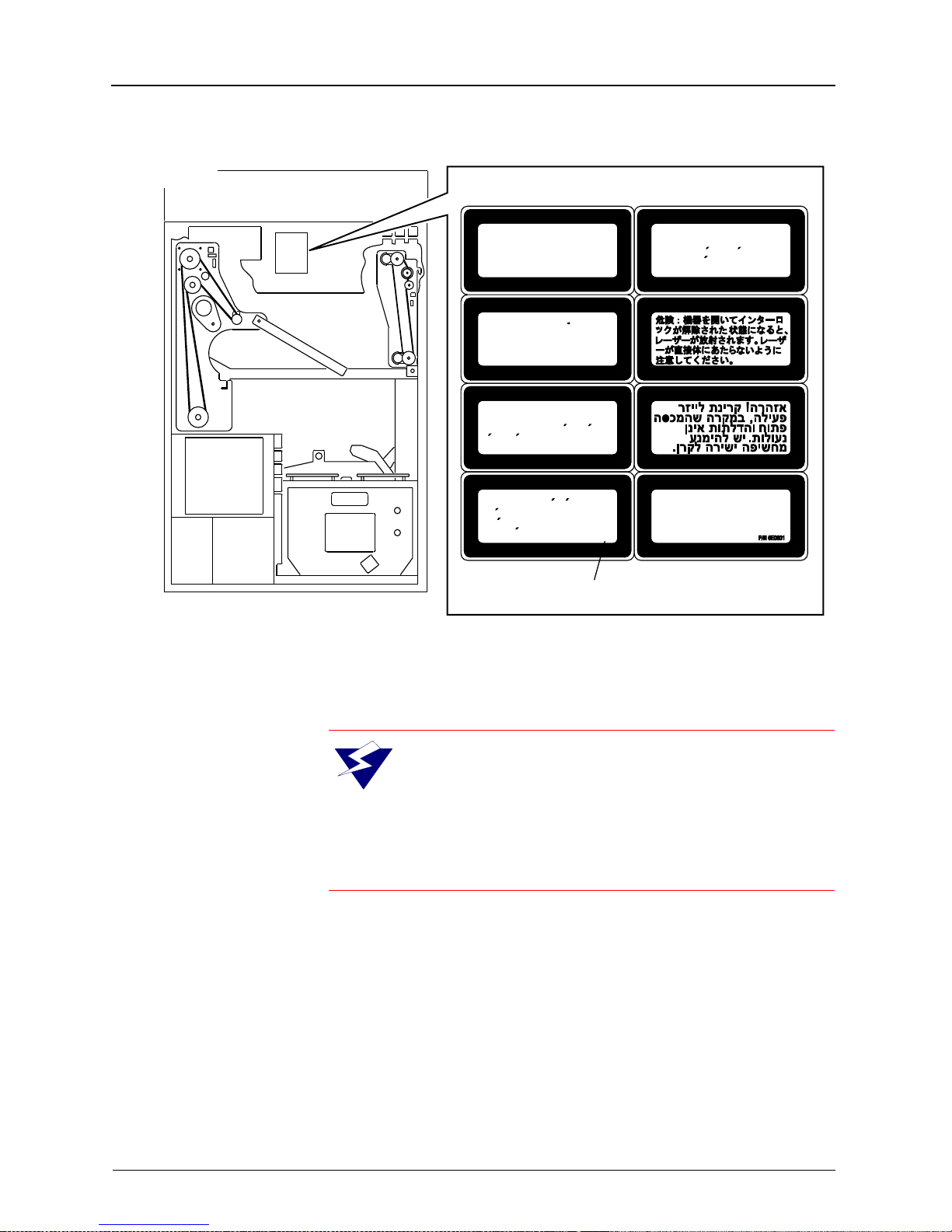

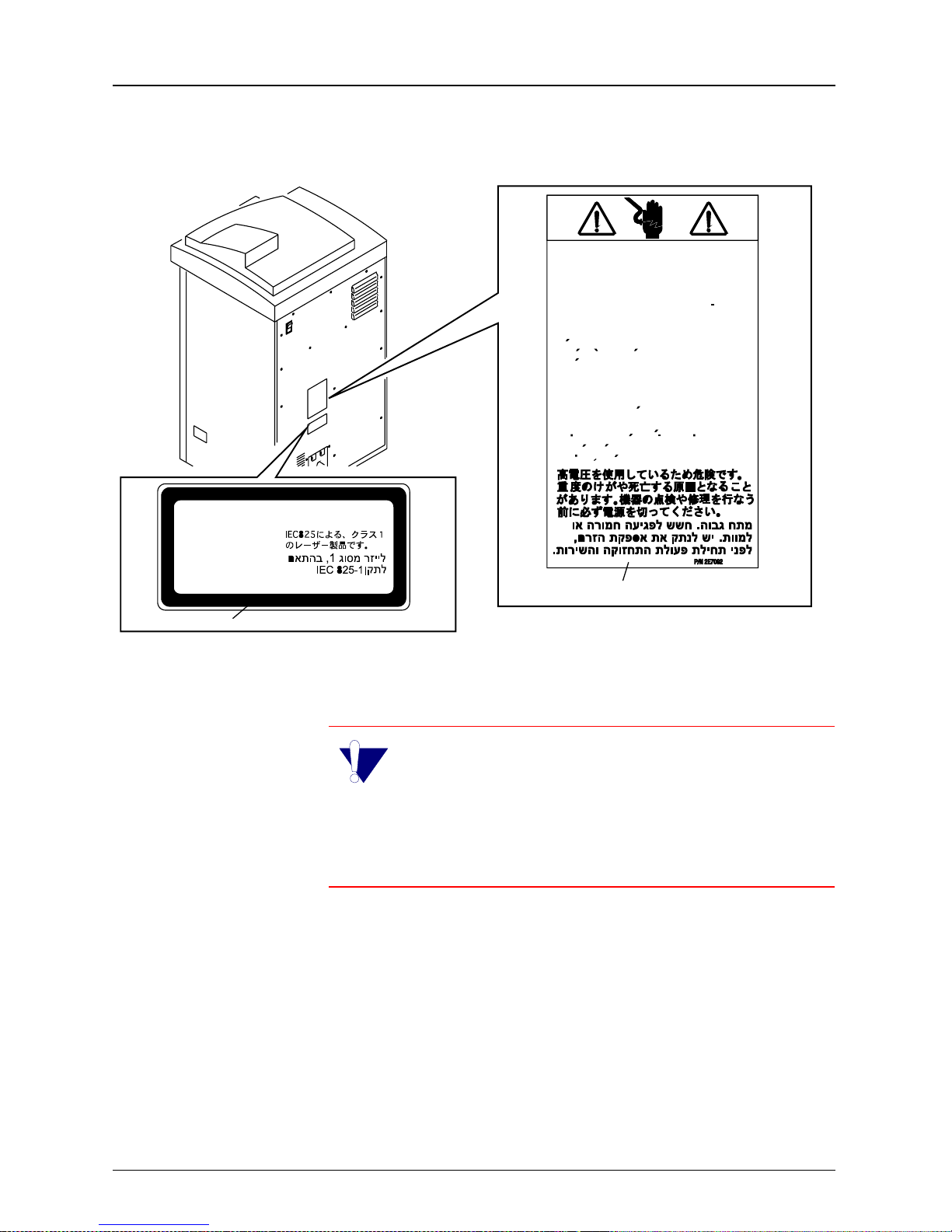

Safety

BACK VIEW

H178_0141HCA

H178_0141HC

Laser radiation when open

Danger:

and interlocks defeated. Avoid

direct exposure to beam.

Laserstrahlung bei

Achtung:

geoffnetem Gerat und

a b g e s h a l t e t e n

Sicherheitsvorrichtungen. Setzen

Sie sich nicht direkt dem

Laserstrahl aus.

Attention:

lorsque l’appereil est ouvert et les

verrouillages de securite sont

desactives. Eviter toute exposition

directe au faisceau.

Peligro:

esta abierto y los enclavamientos

estan desactivados. Evite la

exposicion directa al haz.

Rayonnement laser

Radiacion laser cuando

Uwaga: Niewidzialne promieniowanie

laserowe po otwarciu i pokonaniu

zabezpieczen. Unikac wystawiania

sie na bezposrednie dzialanie

promienia lasera.

INVISIBLE LASER DANGER LABEL

1-4 5E2234 June 2000

W ARNING: Danger, avoid laser beam. This

equipment uses an invisible infrared laser.

Laser Radiation can be present when the

machine is operated with the panels off and the interlocks defeated. Avoid direct exposure to the laser

beam.

Page 13

Safety

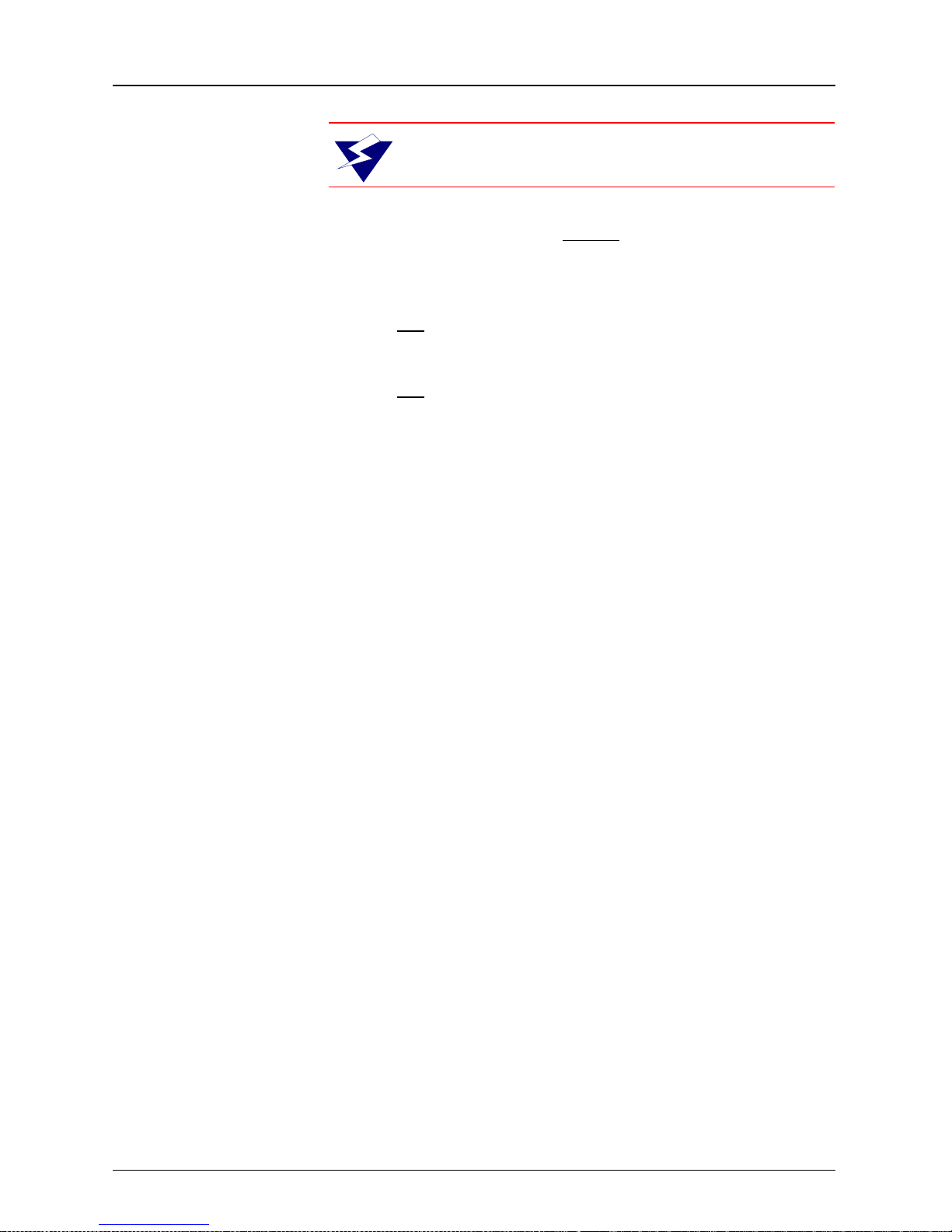

CAUTION

Remove the wall plug before servicing equipment.

This equipment is operated with hazardous voltage

that can shock, burn, or cause death.

Do not pull the cord from the outlet. Grasp the plug

and pull to disconnect.

Do not operate equipment with a damaged power

cord. Position the power cord so that it will not be

tripped over or accidentally pulled.

Do not use extension cords to power the Laser

Imager. Connect the equipment to grounded outlets.

Refer to the Site Specifications for the KODAK

EKTASCAN 160 Laser Imager, Publication No.

5E2235 for additional details.

This equipment generates, uses, and can radiate

radio frequency energy. If not installed and used in

accordance with the instruction manual, it may cause

interference with radio communications.

This equipment has been tested and found to be

exempt from the limits for a Class A computing device

pursuant to Part 15, Subpart J of FCC Rules. This is

designed to provide reasonable protection against

such interference when operated in a commercial

environment.

Operation of this equipment in a residential

environment is likely to cause interference, in which

case the user, at the user’s own expense, will be

required to take whatever measures may be required

to correct the interference.

5E2234 June 2000 1-5

Page 14

Safety

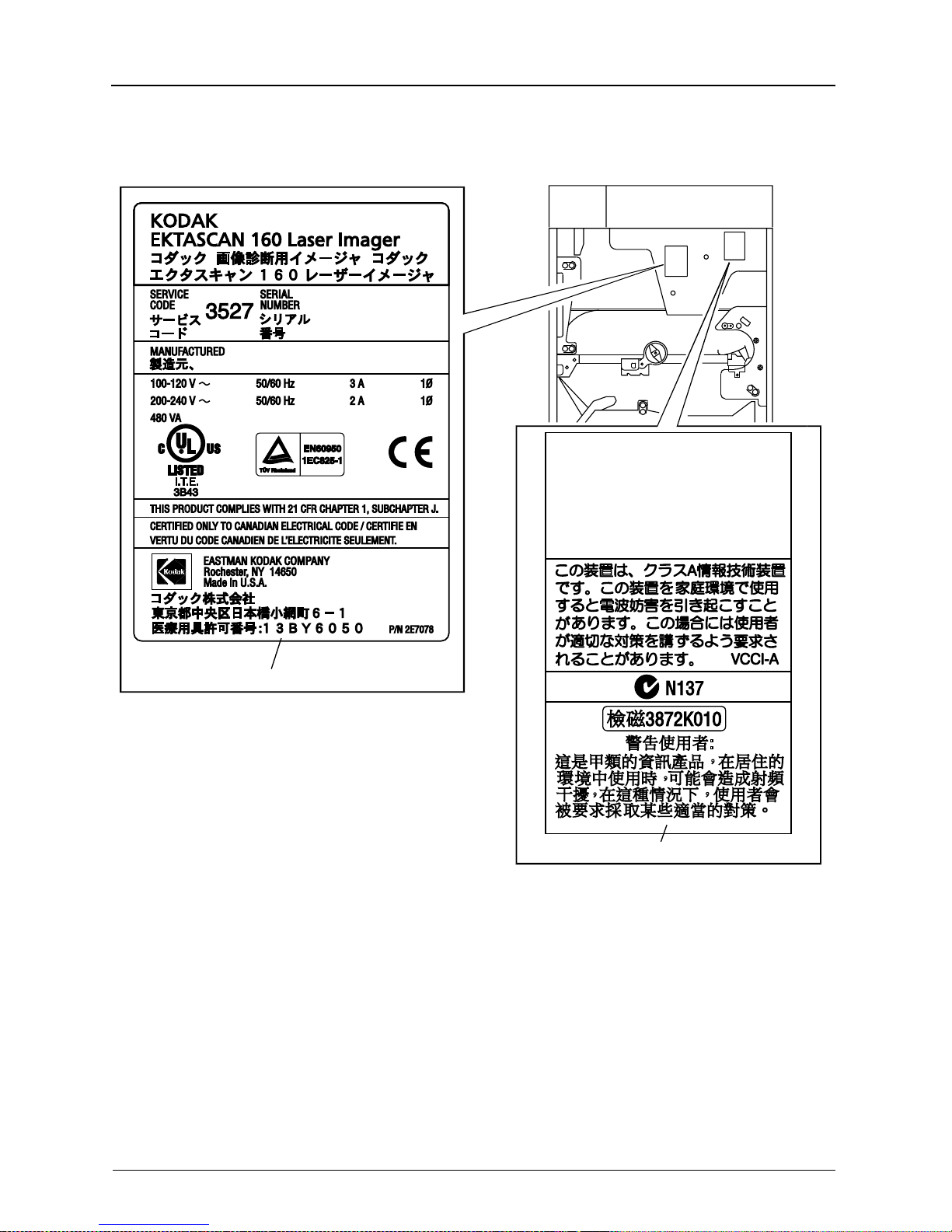

This device complies with the RFI requirements of

EN55011, Class A.

This device complies with Part 15 of the FCC rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference,

and (2) this device must accept any interference

received, including interference that may cause

undesired operation.

This Class A digital apparatus complies with Canadian

ICES-003.

Cet appareil numérique de la classe A est conforme

à la norme NMB-003 du Canada.

H178_0063DCA

H178_0063DC

DATA PLATE LABEL

EMC LABEL

1-6 5E2234 June 2000

Page 15

Hazardous Voltage.

Can cause severe injury or death. Disconnect

power supply before servicing machine.

Hochspannung.

Verletzungsund Lebensgefahr. Schalten Sie die

Stromversorgung ab, bevor Sie das Gerat warten.

Tension dangereuse.

Peut provoquer des blessures graves ou la mort.

Debrancher le cordon d’alimentation avant de

proceder a toute operation de maintenance ou

de reparation sur la machine.

Voltaje peligroso.

Puede producir lesiones graves o la muerte.

Desconecte el suministro de corriente antes de

hacer funcionar la maquina.

Niebezpieczne napiecie.

Moze spowodowac powazne obrazenia albo

nawet smierc. Przed wykonywaniem napraw

nalezy odlaczyc zasilanie.

Safety

CLASS 1 LASER PRODUCT

ACCORDING TO IEC 825-1

KLASSE 1 LASER PRODUKT

ENTSPRECHEND IEC 825-1

APPAREIL A RAYONNEMENT

LASER DE CLASSE-1

‘‘PRODCUTO LASER TIPO UNO’’

SEGUN NORMATIVA 825 DE LA C.E.I.-1

CLASS 1 LABEL

PRODUCKT LASEROWY KLASY 1

ZGODNIE IEC 825-1

HAZARDOUS VOLTAGE LABEL

IMPORTANT: The KODAK EKTASCAN 160

Laser Imager is a Class 1 device. To protect the

user against electrical shock, this device complies with the ground requirements as specified in the

KODAK EKSTASCAN Site Specifications for the 160

Laser Imager, Publication No. 5E2235.

H178_0064HCA

H178_0064HC

5E2234 June 2000 1-7

Page 16

Safety

1-8 5E2234 June 2000

Page 17

2

Overview

••••••••

In this chapter

Product Description .............................................. 2-2

System Configuration ........................................... 2-3

Single Input .................................................... 2-3

Multiple Input and Network.............................2-4

Using the Control Panel........................................ 2-5

Features......................................................... 2-8

Screen Types............................................... 2-10

Main Display Screen............................................2-11

Using the “Setup Menu” and “Configure Display”2-14

2-1

Page 18

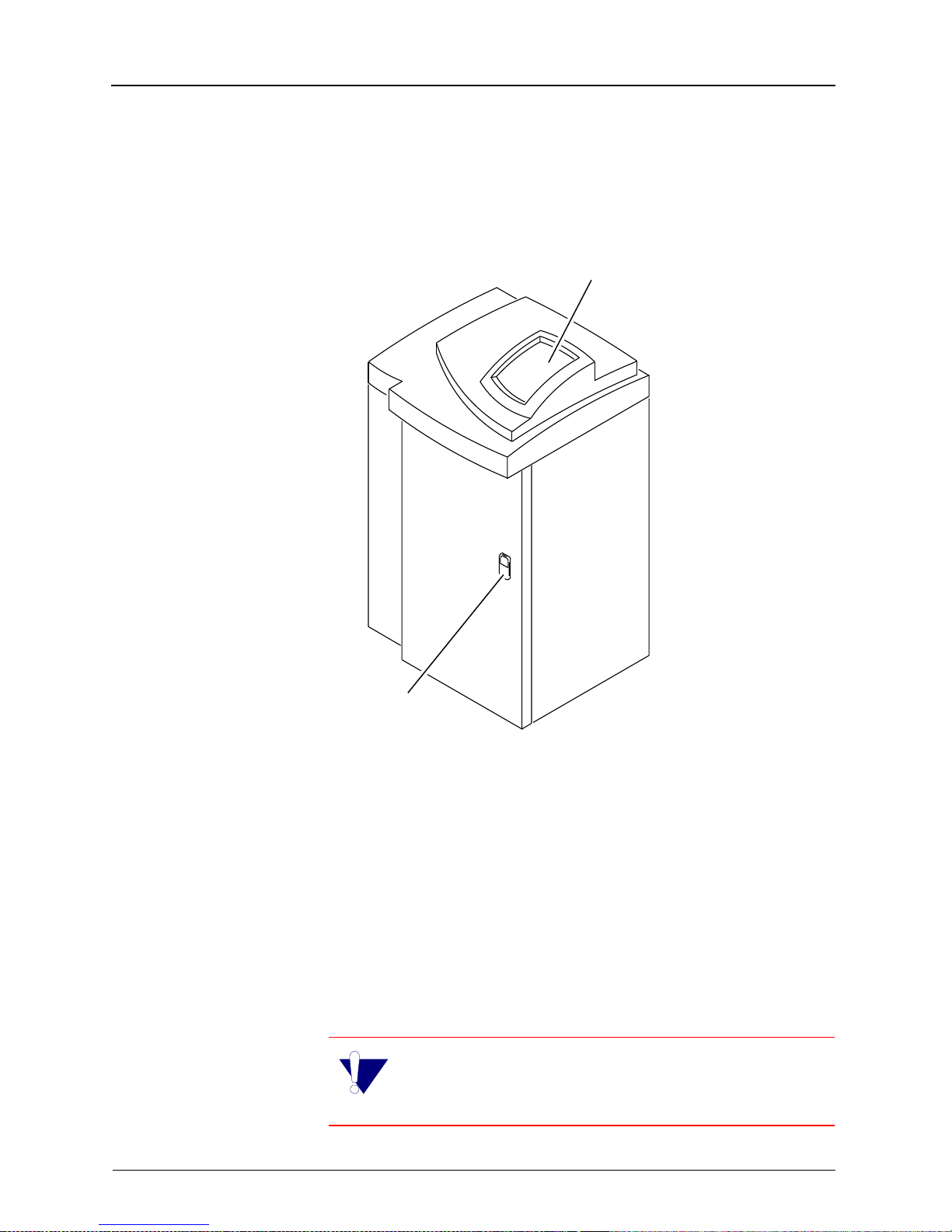

Overview

Product Description

160 Laser Imager

Control Panel

ront Door Latch

H178_0008GCA

H178_0008GC

The KODAK EKTASCAN 160 Laser Imager (Laser Imager) is a

high quality di gital laser image r intended for diagnost ic hardcopy

applications. The Laser Imager can be used as a stand-alone

unit (as illustrated above) or with direct docking to a KODAK XOMAT 2000 Processor. The Laser Ima ger use s EIR- 23 (blu ebase) IR film in roomlight loadable 35 x 43 cm (14 x 17 in.) cartridges. The dig ital image d ata for the Las er Imager are prov ided

by a dedicated network connection to the KODAK PACS Link

Medical Image Manager (MIM).

IMPORTANT: See the User Guide for the

KODAK P ACS Link Medical Image Manager 200

Publication No. 5E9764 for more information.

2-2 5E2234 June 2000

Page 19

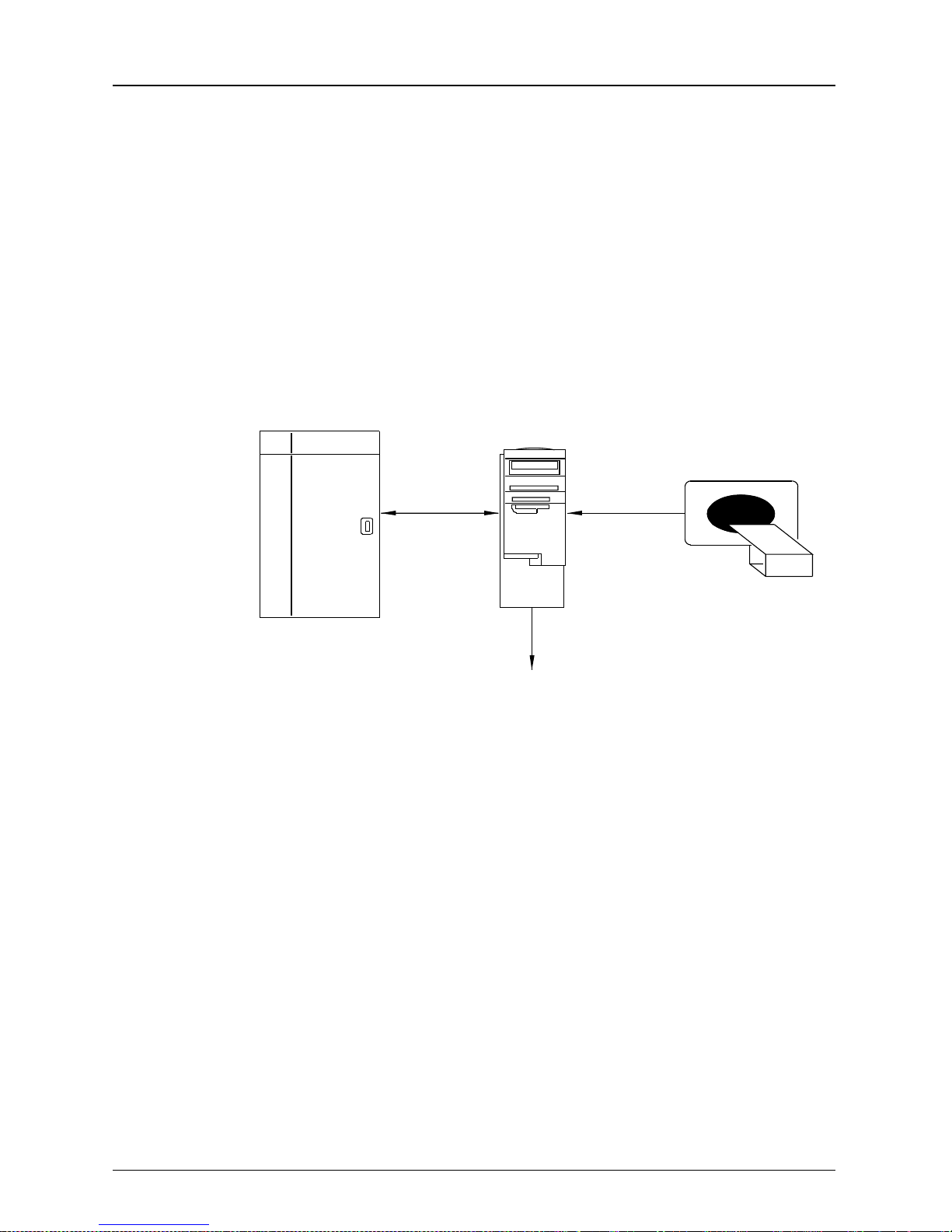

System Configuration

There are many different system configurations for the

160 Laser Imager. Two examples of system configurations are shown.

Single Input

160 Laser

Imager

MIM

Overview

Imaging

Device

121BC

100BaseT

Ethernet

Modem Line (optional)

The diagram above illustrates the stand-alone Laser

Imager in a Single Input configuration. In the Single Input

configuration only one Imaging Device is connected to the

KODAK PACS Link Medical Image Manager (MIM). Using

either an internal digital or video interface the MIM

acquires medical images from the Imaging Device.

The MIM formats the input signal (digitizes the video

input, for example) and transfers the data over a

100BaseT Ethernet Network. The operator sends printing

commands to the Laser Imager from the MIM keypad, or

if autofilming is supported, from the Imaging Device.

5E2234 June 2000 2-3

Page 20

Overview

Multiple Input and Network

Imaging

Device

Imaging

Device

MIM

TCP/IP

Imaging

Device

DICOM

Network

H178_0016HC

2000

Processor

160 Laser

Imager

MIM

100baseT

Ethernet

Modem Line (optional)

Imaging

Device

Imaging

Device

The diagram above illustrates the Laser Imager docked to

the KODAK X-OMAT 2000 Processor in a Multiple Input

configuration and in a DICOM (Digital Imaging and Communications in Medicine) Network. The MIM can acquire

DICOM medical images directly from the Imaging Device

over the network or directly connected through a medical

Imaging Device.

2-4 5E2234 June 2000

In the Multiple Input configuration, up to 2 Imaging

Devices and a DICOM Network can be connected to a single MIM. Using an internal video or digital interface, the

MIM formats the input signal (digitizes the video input signal, for example) and transfers the data over a dedicated

100BaseT Ethernet network.

Remote service access may be provided through a

modem in any MIM on the network.

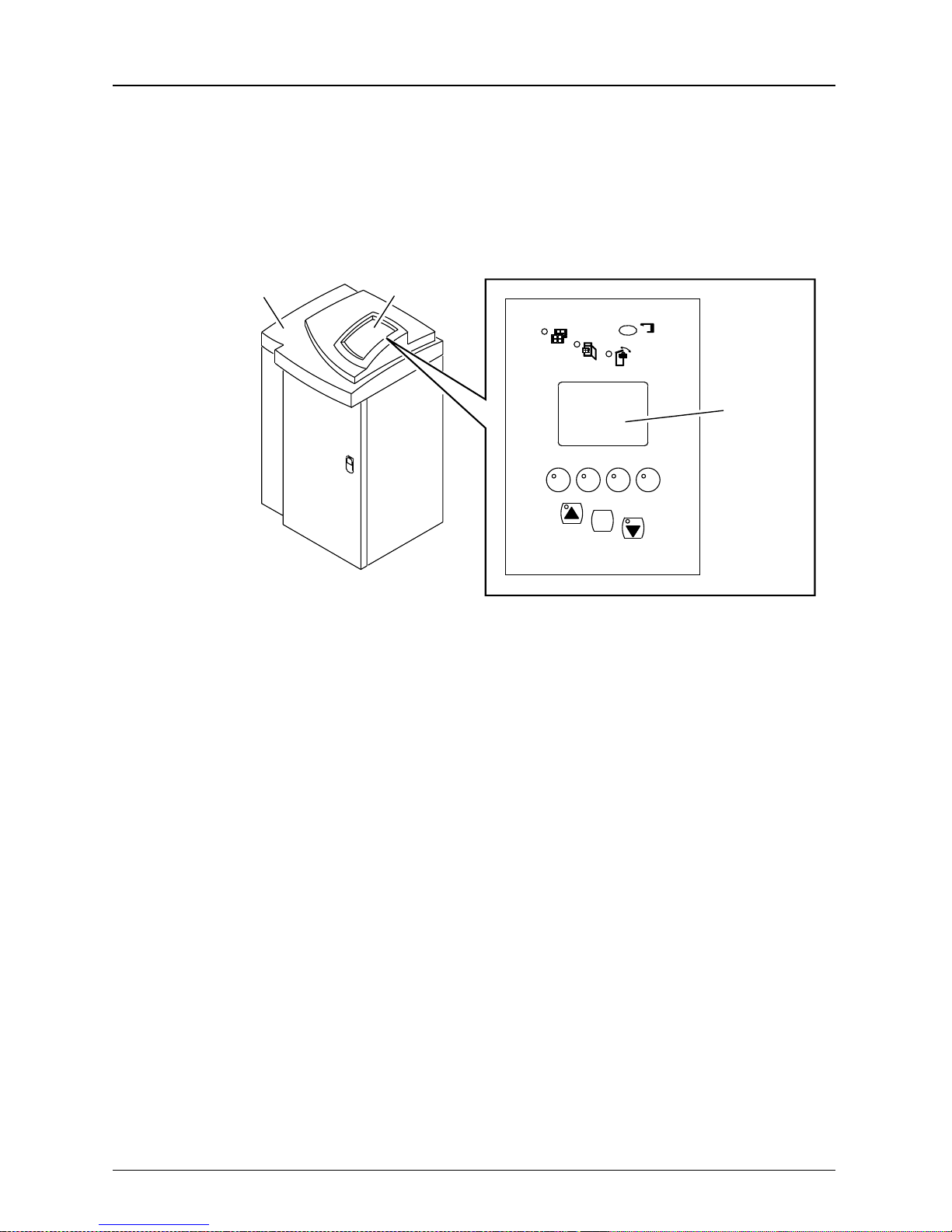

Page 21

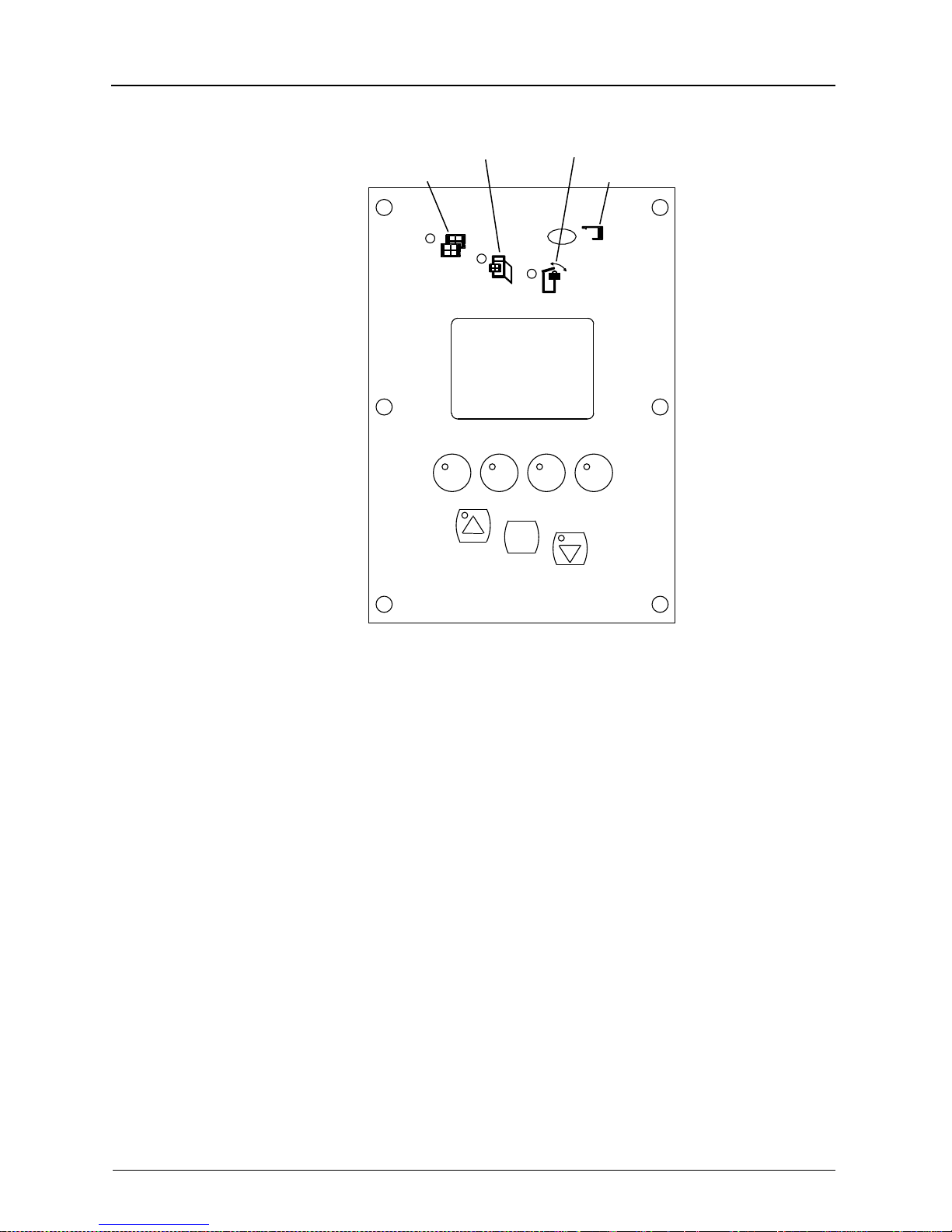

Using the Contro l Panel

The Control Panel allows the user to enter commands and

view the status of the Laser Imager.

Overview

160 Laser Imager

H178_0127BCA

H178_0127BC

Control Panel

x

Main Display

Screen

F2F1 F3 F4

MENU

5E2234 June 2000 2-5

Page 22

Overview

Indicator Functions

ACCESS FILM SUPPLY

FILM

F2F1 F3 F4

ACCESS RECEIVE

ERROR

x

H178_0017GCA

H178_0017GC

MENU

2-6 5E2234 June 2000

Page 23

Overview

Access

Receive

Access

Film Supply

The LED is on steady when the Receive

Magazine is safe to access. The illumination of the Access Receive Indicator does

not ensure safe access of the Film Supply Cartridge. See the Access Supply

Indicator. WARNING: DO NOT OPEN

THE TOP COVER UNTIL THE ACCESS

RECEIVE INDICAT OR IS ILLUMINATED.

FOGGED FILM WILL RESULT.

The LED is on steady to indicate to the

operator when the Laser Imager film

path, including the film supply cartridge

and the receive magazine, may be safely

accessed. WARNING: DO NOT OPEN

THE FILM SUPPLY UNTIL THE

ACCESS FILM SUPPLY INDICATOR IS

ILLUMINATED. FOGGED FILM WILL

RESULT.

Film When illuminated, indicates to the opera-

tor that the Laser Imager is out of film or

the receive magazine is full.

Error Illuminates whenever a Laser Imager

error occurs. The Error Indicator is turned

off either after the operator has cleared

the error from the Error Recover Screen

or when the Laser Imager software

senses that the Laser Imager has been

accessed.

5E2234 June 2000 2-7

Page 24

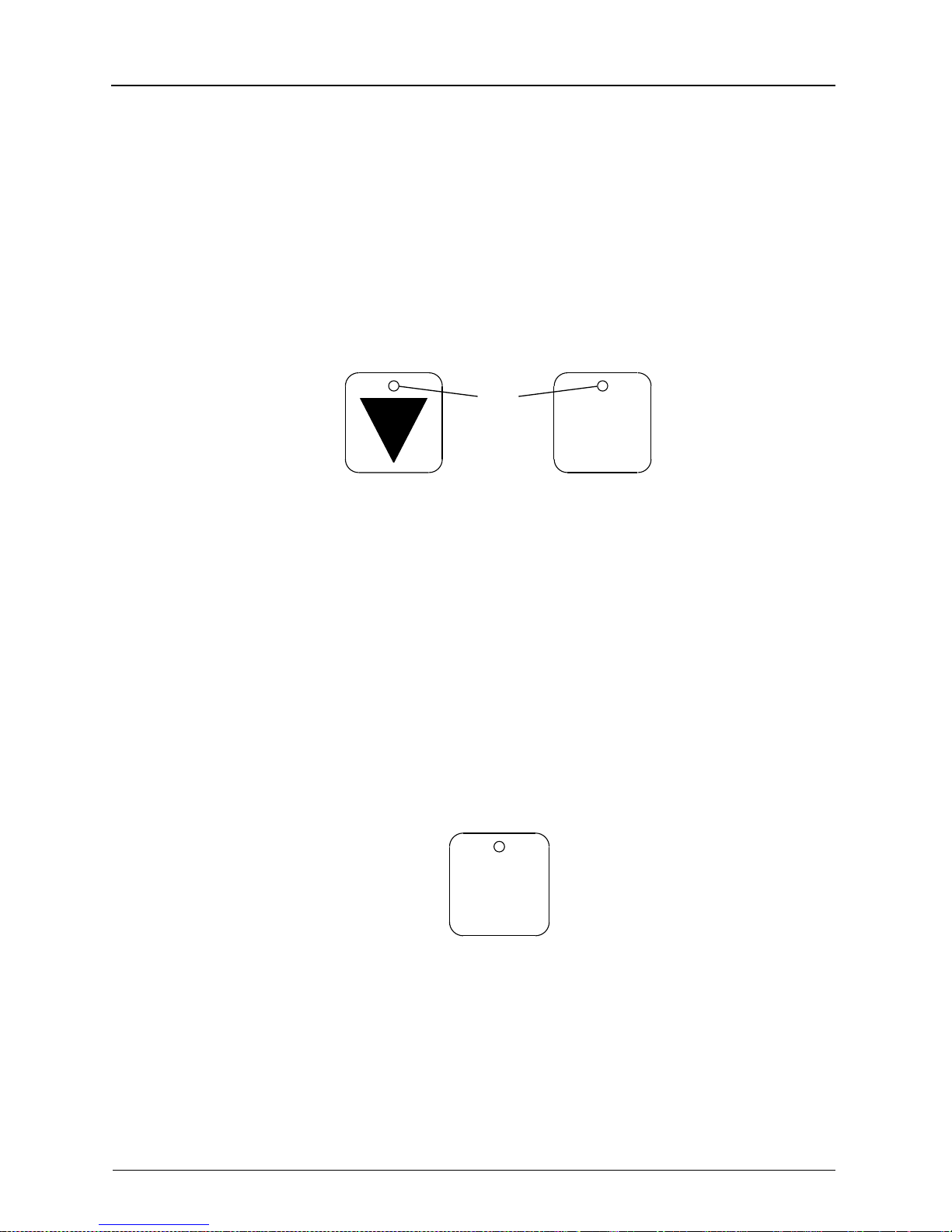

Overview

Features

The Control Panel consists of an LCD display, four F1

through F4 Buttons, Menu Button,

▲ and ▼ Buttons and

four LED functions.

LEDs

Menu

H178_0125ACA

H178_0125AC

The Button LEDs indicate whether the Button is enabled

(illuminated) or disabled (not illuminated).

Menu

2-8 5E2234 June 2000

H178_0126AC

The Menu Button allows you to select a menu option or

complete an operation.

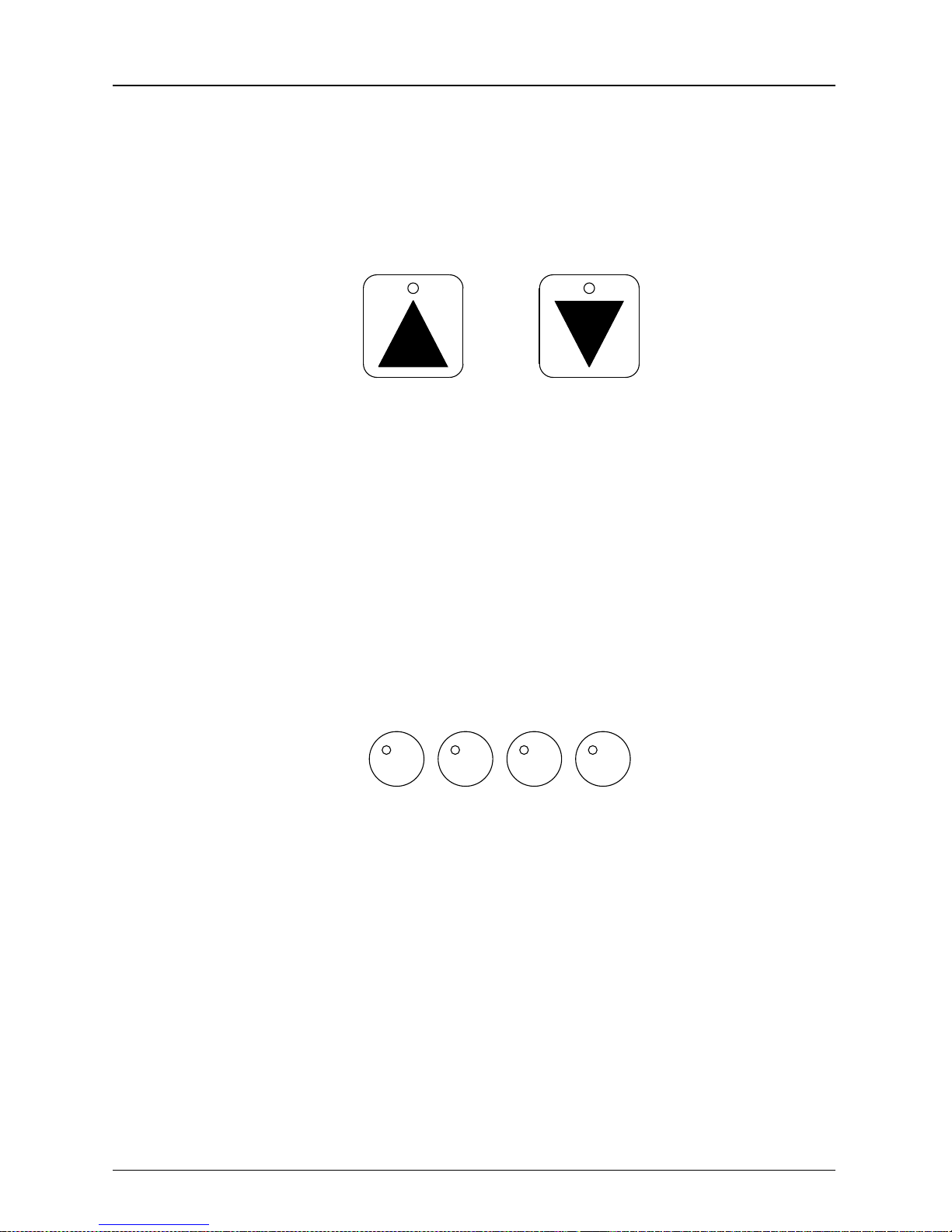

Page 25

Overview

Each time you press the Menu Button, with the cursor on

an Exit Menu row, the previous screen appears.

H178_0124AC

The Up and Down Arrow Buttons allow you to scroll

through items on the screen. Press the up “

scroll up, press the down “

Press the up “

▲” Button to increment, press the down“▼”

Button to decrement

H178_0132AC

.

▼” Button to scroll down.

F4F3F1 F2

▲” Button to

5E2234 June 2000 2-9

The F1 - F4 Buttons allow you to move directly to the

main display screen by pressing any function button that

is not programmed.

Page 26

Overview

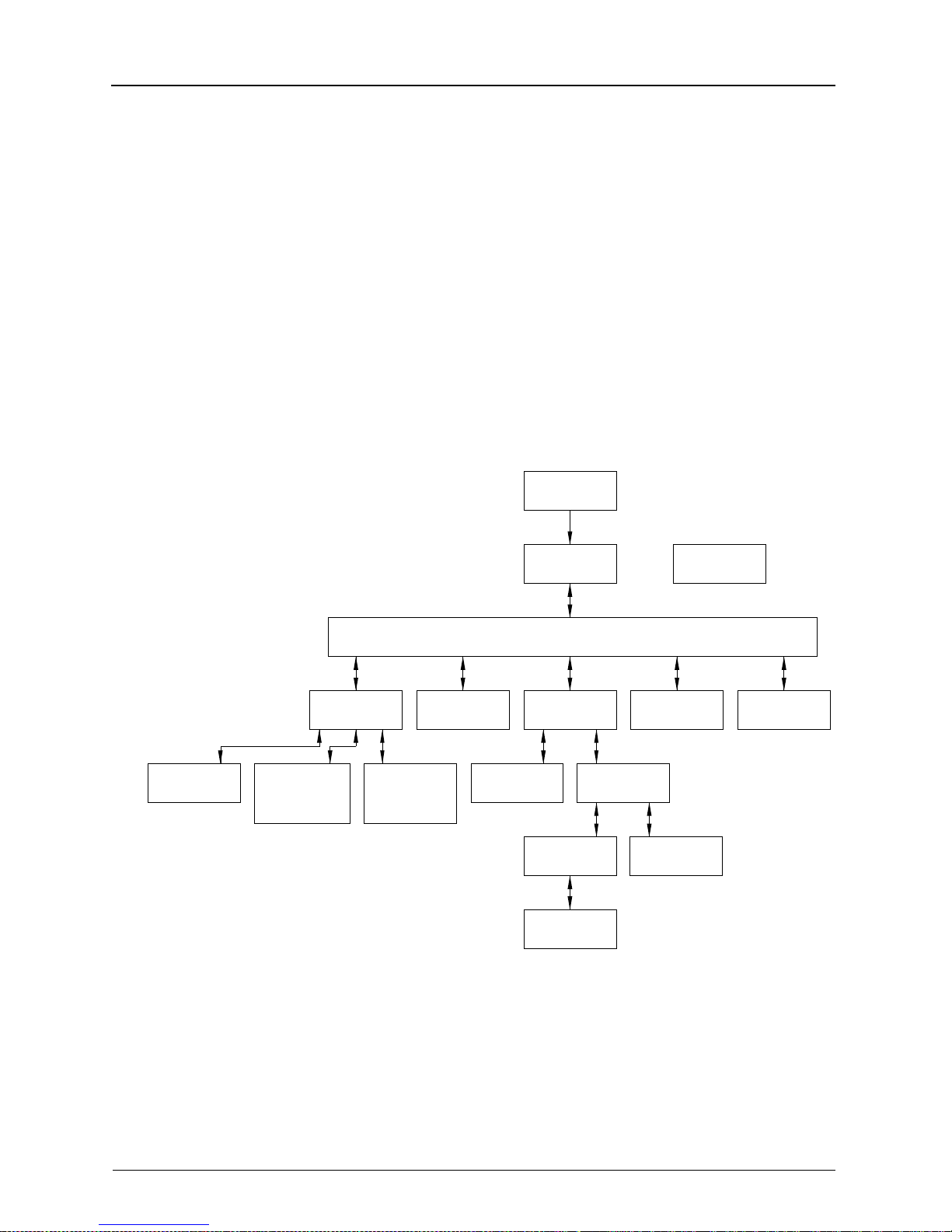

Screen Types

To move directly to a screen of your choice you have to

program a function button to display to that screen:

Navigate to the screen.

Press and hold the function button for two seconds.

When you hear one beep, the button is programmed.

When you press the function key, the screen displays.

Initialization

Actuations

H178_9001HC

View

Setup Menu

Changing

Decimal Point

Convention

* This screen will appear when docked to a 2000 Processor.

*

Destination

Adjusting

Screen

Contrast

Film

Main Display

Main Menu

Print Cal

Film

Calibrate

Printer

Calibration

Density

Values

Data Entry

Film Supply

Data

Calibration

Recovery

Access

Compute

Error

Access

Receive

2-10 5E2234 June 2000

Page 27

Main Display Screen

The Main Display Screen is displayed most of the time

during normal operation.

Overview

Film Base

Film Destination

H178_0006BCA

H178_0006BC

Ready

Blue Film

Receive

The screen is divided into two sections. The top section of

the screen displays the Laser Imager Status and the bottom section of the screen is the Command and Data Section.

Status Section

34

Command/Data Section

5E2234 June 2000 2-11

Page 28

Overview

Status Section

Initializing

Printing

Not Printing

Ready

Testing

The Laser Imager is in the process of

warming up.

The Laser Imager is in the process of

printing films. The Laser Imager is also

accepting commands and data from the

MIM.

The Laser Imager has stopped printing

films. Any pages that are already in

progress will finish printing. The Laser

Imager accepts commands and data in

this state.

The Laser Imager is ready to print. The

Laser Imager accepts commands and

data in this state.

The Laser Imager is not printing films

from the imaging devices, but is printing

test films or transporting films. The

Laser Imager is accepting commands

and data from the MIM.

Offline

The off li ne co nd i ti o n is sho wn in a r i gh tjustified position on the Status Line.

When offline, the Laser Imager is not

accepting commands or data from the

MIM. The offline condition may exist

during power-up diagnostics and initialization, after certain errors and when

diagnostics are run by a Service Representative.

2-12 5E2234 June 2000

Page 29

Command/Data Section

In the bottom portion of the screen is the data and menu

information.

Data screen: the data displayed on the bottom of the

screen will be preceded by “

ence of more data, the down arrow Button will be

active.

Menu screen: the selection cursor “>” precedes the

active menu item. Undisplayed menu items at the top

and bottom of the screen are indicated by “

“

▼” respectively.

The Main Display Screen displays the following:

Overview

▼” indicating the pres-

▲“ and

Laser Imager Status

The film base and level of the loaded cartridge - if no

cartridge is loaded this line is blank

Possible film destinations with the currently selected

destination highlighted. If the selected destination is

the Receiv e Magazine , the level of film in the R eceive

Magazine is displayed.

IMPORTANT: To disable the Laser Imager during operation select “Access Receive” or

“Access Film Su pply “. W ai t for the stea dy il lumi -

nation of the Indicator then open the Top Cover.

5E2234 June 2000 2-13

Page 30

Overview

Using the “Setup Menu” and

“Configure Display”

Description

Using the screen

The Setup Menu screen allows

viewing actuation count, changing

the number convention for the decimal point and adjusting the display

screen contrast.

Press the “▼” to move the “>” Exit

Menu. The Exit Menu returns to the

Main Menu Screen.

Press the Menu Button to select

your choice. You are automatically

moved to the screen of your

choice.

To exit, use the arrow Button to

move to the Exit Menu.

2-14 5E2234 June 2000

Page 31

3

Operation

••••••••

In this chapter

Start up and Shutdown ......................................... 3-2

System Start up.............................................. 3-2

Laser Imager Startup Screen......................... 3-3

System Shutdown .......................................... 3-4

Loading Film......................................................... 3-5

Film Supply Cartridge..................................... 3-6

Accessing the Receive Magazine......................... 3-8

Store and Print Images....................................... 3-10

Changing the Film Destination............................ 3-10

Viewing the Laser Imager Actuation Count ........3-12

Changing the Decimal Point Convention............3-13

Adjusting the Screen Contrast............................ 3-14

3-1

Page 32

Operation

Start up and Shut do wn

System Start up

2000 Processor

160 Laser Imager

Power Switch

H178_0130BCA

H178_0130BC

Power Switch

IMPORTANT: To avoid poor image quality, do

not send images to the Laser Imager until the

Processor has warmed up. The Processor takes

approximately 30 minutes to warm up.

1. Turn on the Processor. Wait approximately 30 min-

utes for the Processor to warm up.

2. Turn on the Laser Imager.

NOTE: The Laser Imager, as a stand-alone unit,

takes le ss than 10 minu tes to initia lize. When the

Laser Imager is docked to a 2000 Processor, the

Processor must warm up approximately 30 minutes

before initializing the Laser Imager.

3-2 5E2234 June 2000

Page 33

See the Service Manual for the KODAK PACS Link

Medical Image Manager 200, Publication No. 2H7443, for

more start up information.

Laser Imager Startup Screen

Operation

Initializing

Offline

KODAK EKTASCAN

160 Laser Imager

~xxx seconds remain

H178_0122AC

The Laser Imager initially displays this screen with the

prompt “Initializing” at power up. The screen will display

the approximate number of seconds remaining until the

Laser Imager is “Ready”.

5E2234 June 2000 3-3

NOTE: During in it i al iz at i on , no ke ys ar e ac tive.

When initializa tio n is compl ete, the Mai n Menu

Screen will appear.

Page 34

Operation

System Shutdown

1. Wai t for all films to be printed. You ca n look at the MIM

Print Screen to see the source, pages, total films, and

status of the studies in the Print Queue. There are no

films waiting to be printed if the Laser Imager state in

the upper left-hand corner of the Display Screen is

“Ready”.

CAUTION: Do not open the Front Door

when you turn off the Laser Imager. The

Film Supply Cartridge is open. T o prevent

exposure to the film, press “Access Supply” and

wait for the Indicator to light before you turn off

the Laser Imager.

2. Turn off the Laser Imager by moving the Main Power

Switch to the “

0” position.

3-4 5E2234 June 2000

Page 35

Loading Film

Film Types

Operation

IMPORTANT: For film recommendations,

consult your Kodak Sales Representative.

The KODAK EKTASCAN 160 Laser Imager uses KODAK

EKT ASCAN IR Laser Imaging Films. Each box contains

4 cartridges of 125 sheets each.

IMPORTANT: The Film Supply Cartridge for the

Laser Imager is packaged similar to the KODAK

969 Laser Imager. The Laser Imager accepts

only EIR-23 film. Check that you are using the correct film

supply cartridge.

KODAK EKTASCAN IR Laser Imager Film

Film Code Color Description

EIR-23 Bluebase Roomlight Load

5E2234 June 2000 3-5

Page 36

Operation

Film Supply Cartridge

1. Remove the Film Supply Cartridge from the box.

2. From the Main Menu, select “Access Film Supply”

and press the Menu Button. Wait for steady

illumination of the Indicator.

Ready

Exit Menu

Access Receive

>Access Film Supply

Calibrate Printer

Setup Menu

Film Destination

W ARNING: Do not open the Film Supply until

the “Access Film Supply” Indicator is illumi-

nated. Fogged film may result.

3-6 5E2234 June 2000

Page 37

Film Supply

Cartridge

LASER IMAGING FILM

Ektascan

Kodak

Operation

H178_0020HCB

H178_0020HC

Film Supply

3. Lift and rotate the Front Door Latch counterclockwise

to pull open the Front Door.

4. Remove the empty Film Supply Cartridge if present.

5. Slide the cartridge into the Film Supply with the Bar

Code down. See the illustration for the correct orientation of the Film Supply Cartridge.

6. Close the Front Door.

7. Rotate the Front Door Latch clockwise. Push down

the Latch.

5E2234 June 2000 3-7

Page 38

Operation

Accessing the Receive Magazine

Top Cover

Top Cover

Latch

Receive

H178_0011GCB

H178_0011GC

Magazine

WARNING: Do not open the Top Cover until

the “Access Receive Magazine” Indicator is

lit. Fogged film may result.

1. From the Main Menu select “Access Receive” and

press the Menu Button. Wait for steady illumination of

the Indicator.

Ready

Exit Menu

>Access Receive

Access Supply

Calibrate Printer

Film Destination

Setup Menu

3-8 5E2234 June 2000

2. Open the T op Cover and engage the T op Cover Latch.

Page 39

Operation

3. Remove the Receive Magazine by lifting the Handle

and pulling toward you.

4. In a darkroom pull down on the top of each Latch to

open the Receive Magazine and remove the film.

5. Engage each Latch to close the Receive Magazine.

6. Place the Receive Magazine into the Magazine Slot

and verify that the Magazine is securely in place.

7. Disengage the Top Cover Latch and close the Top

Cover.

5E2234 June 2000 3-9

Page 40

Operation

Store and Print Images

See the User Guide for the KODAK PACS Link Medical

Image Manager 200, Publication No. 5E9764, on how to

store and print images.

Changing the Film Destination

Do the following to change the Film Destination from the

Receive Magazine to the Processor, or from the

Processor to the Receive Magazine.

1. From the Main Menu press the ”▼” to move the “>” to

”Film Destination”. Press the Menu Button. The Laser

Imager displays the initial Film Destination Screen.

Ready

Receive Magazine

Last calibrated on

13-Dec-1998 07:24

>Exit Menu

Change Destination

IMPORTANT: For a new film destination,

advance to Step 2. For more information on

calibrating the Laser Imager, see Chapter 4,

“Calibration”.

3-10 5E2234 June 2000

Page 41

Operation

2. Press the “▼” to move the “>” to “Change Destina-

tion”. Pressing the M enu Button toggles the destination. The Calibrate Printer menu item appears on the

screen.

Ready

Processor

Last calibrated on

13-Dec-1998 07:24

Exit Menu

>Change Destination

Calibrate Printer

3. Use the “▲” to move the “>” to Exit Menu. Press the

Menu Button twice to return to the Main Display.

5E2234 June 2000 3-11

Page 42

Operation

Viewing the Laser Imager Actuation Count

1. From the Main Display press the Menu Button. The

Main Menu is displayed.

2. Use the “▼” to move the “>” to “Setup Menu”.

Ready

Exit Menu

Access Receive

Access Supply

Calibrate Printer

>Setup Menu

Film Destination

3. Press the Menu Button. The Setup Menu Screen is

displayed.

Ready

Actuations: 5,567

>Exit Menu

0.00 to 0,00

Screen Contrast (7)

4. Use the “▲” or “▼” to move the “>” to Exit Menu.

Press the Menu Button to return to the Main Display.

3-12 5E2234 June 2000

Page 43

Operation

Changing the Decimal Point Convention

To comply with local conventions, change the convention

for the decimal point from a “.” to a “,”. For example 0.00

to 0,00. To change the convention, do the following:

1. From the Main Display, press the Menu Button. The

Main Menu is displayed.

Ready

>Exit Menu

Access Receive

Access Supply

Calibrate Printer

Setup Menu

Film Destination

2. Use the “▼” to move the “>” to “Setup Menu”. Press

the Menu Button. The Setup Menu Screen is displayed.

Ready

Actuations: 5,567

>Exit Menu

0.00 to 0,00

Screen Contrast (7)

3. Use the “▼” to move the “>” to “0.00 to 0,00”. The

menu selection appears with the currently selected

decimal point in the number to the left of “to”. Pres s

the Menu Button to change to the desired symbol.

4. Use the ”▲” to move the “>” to Exit Menu. Press the

Menu Button 2 times to return to the Main Display.

5E2234 June 2000 3-13

Page 44

Operation

Adjusting the Screen Contrast

1. From the Main Display press the Menu Button. The

Main Menu is displayed.

2. Use the “▼” to move the “>” to “Setup Menu”. Press

the Menu Button. The Setup Menu Screen is displayed.

Ready

Exit Menu

Access Receive

Access Supply

Calibrate Printer

>Setup Menu

Film Destination

3. Use the “▼” to move the “>” to “Screen Contrast”.

Press the Menu Button to select the desired contrast

setting.

Ready

Actuations: 5,567

>Exit Menu

0.00 to 0,00

Screen Contrast (7)

4. Use the ”▲” to move the “>” to Exit Menu. Press the

Menu Button to return to the Main Display.

3-14 5E2234 June 2000

Page 45

4

Calibration

••••••••

In this chapter

Introduction........................................................... 4-2

When to Calibrate............... ...... ....... ...... ...... ....... .. 4-3

Performing the Calibration.................................... 4-4

4-1

Page 46

Calibration

Introduction

Calibration is the method of ensuring consistent image

appearance by compensating for variations in laser

power, differences between film emulsions and other

process variables .

IMPORTANT: When the Laser Imager is docked

to a 2000 Processor, separate calibration is

required for the docked 2000 Processor and the

Receive Magazine.

You will do the following during calibration:

1. If the 2000 Processor is docked to the Laser Imager,

2. Print and process the calibration film.

3. Read the densities of the film and enter the density

4. Compute the Calibration.

Calibration Screens

Calibrate Printer Prints the calibration film and

Calibration Data Allows viewing and modification

select “Film Destination”.

values.

Screen Function

allows access to calibration data

of Laser Imager calibration data

4-2 5E2234 June 2000

Calibration Densities Allows viewing and modification

of Laser Imager calibration densities

Page 47

When to Calibrate

For optimum image quality, the Laser Imager should be

re-calibrated whenever there is any change in the following conditions:

new film emulsion

the processing environment - for example, the

processor chemistry , processor temperature or different processor

Film Box Label - Emulsion Number

Calibration

Kodak

4

Ektascan IR Laser Imaging Film

35 x 43 cm

561992 025 03

LOT

REF

CAT 880-0013

4-125 Sht. Cartridges

EIR

2001-10

H178_0165ACA

H178_0165AC

To determine if the emulsion number has changed, check

the 3-digit emulsion number on the side of the film box.

Emulsion Number

5E2234 June 2000 4-3

Page 48

Calibration

Performing the Calibration

NOTE: This calibration procedure can be per-

formed on a stand-alone Laser Imager or when

docked to a 2000 Processor.

1. From the Main Display, check the selected Film Des-

tination. If it is not the desired destination, change the

selected Film Destination.

2. From the Main Display, press the Menu Button. The

Main Menu is displayed.

Ready

>Exit Menu

Access Receive

Access Film Supply

Calibrate Printer

Setup Menu

Film Destination

3. Use the “▼” to move the ">" to “Calibrate Printer”.

Press the Menu Button. The Calibrate Printer Screen

is displayed.

Ready

Exit Menu

Access Receive

Access Supply

>Calibrate Printer

Setup Menu

Film Destination

The Calibrate Printer Screen displays the calibration

time and date for the currently selected destination.

4-4 5E2234 June 2000

Page 49

Calibration

4. Use the “▼” to select Print Cal Film. Press the

Menu Button.

Ready

Receive Magazine

Last calibrated on

19-Jun-2000 14:24

Exit Menu

>Print Cal Film

Calibration Data

5. The Printing Cal Film Screen is displayed.

Printing Cal Film

Receive Magazine

Last calibrated on

19-Jun-2000 14:02

Exit Menu

Print Cal Film

Calibration Data

6. Retrieve the film from the Receive Magazine or the

Processor Receive Bin. Refer to Chapter 3

“Operation”.

7. Process the film.

5E2234 June 2000 4-5

Page 50

Calibration

Calibration Image

21-step

5

10-step

H178_0038GC

1098761234

IMPORTANT: The 21-step density data on the

Calibration Test Film can be used for process

control.

8. Measure the 10-step density data by using a

Densitometer.

a. Prepare the Densitometer for use.

b. Measure the density at the center of each grey

step on the Calibration Image.

4-6 5E2234 June 2000

c. Record the data.

9. Enter the film densities from the Calibrate Printer

Screen.

Page 51

Calibration

10. Use the “▼” to select “Calibration Data”. Press the

Menu Button. The Calibration Data Screen is dis-

played.

Ready

Receive Magazine

Last calibrated on

13-Dec-1998 07:24

Exit Menu

Print Cal Film

> Calibration Data

11. Use the “▼” to select “Density Values”. Press the

Menu Button. The Calibration Densities Screen is

displayed.

Ready

Receive Magazine

Last Calibrate on

13-Dec-1998 07:24

Exit Menu

>Density Values

Compute Calibration

12. Use the “▼” to select each density to be changed.

Press the Menu Button .

Ready

Calibration Densities

>Exit Menu

1) 0.25

2) 0.32

3) 0.69

4) 1.31

▼ 5) 1.95

5E2234 June 2000 4-7

Page 52

Calibration

13. Press the Menu Button at the density value to be

changed. The cursor will flash, which will allow you to

change the values. Use the “

▼” or “▲“ to change the

value. Press the Menu Button to accept the change.

Ready

Density Step 1

>0.14 _

Exit

Cancel Change

Menu to change

14. Use the “▼” to move the “>” to Exit. Press the Menu

Button.

15. Repeat steps 12 - 14 for all densities to be changed.

16. Use the “▲“ to move the “>” to Exit. Press the Menu

Button to return to the Calibration Densities Screen.

Ready

Receive Magazine

Last Calibrate on

13-Dec-1998 07:24

>Exit

Density Values

Compute Calibration

17. Use the “▼” to select “Compute Calibration”.

18. Press the Menu Button to complete the calibration.

The calibration information is erased from the screen

display, and is replaced by “Computing Film Model”. If

the calibration is not successful, see Chapter 5

“Tro ubleshooting” for more information.

19. Use the “▲“ to move the “>” to Exit. Press the Menu

Button 2 times to return to the Main Menu.

Ready

Receive Magazine

Calibration Complete

13-Dec-1998 07:24

>Exit

Density Values

Compute Calibration

4-8 5E2234 June 2000

Page 53

5

Troubleshooting

••••••••

In this chapter

Overview............................................................... 5-2

Clearing Film Jams............................................... 5-3

Clearing a Film Jam in the Laser Imager ....... 5-3

Clearing a Film Jam in the Processor ............ 5-5

Replacing the Receive Magazine Latches............ 5-6

Error Codes and Messages.................................. 5-7

General Information ....................................... 5-7

Error Recovery............................................. 5-26

Preventive Maintenance..................................... 5-27

Cleaning the 160 Laser Imager.................... 5-27

Replacing the Air Filter................................. 5-28

Streaks on the Film ...................................... 5-29

5-1

Page 54

Troubleshooting

Overview

This chapter will provide suggestions for what to do if

problems arise. After an overview of the path that the film

takes through the Laser Imager, this chapter will give you

guidance for clearing film jams.

In order to clear f ilm jams, you must ope n the Film D oor of

the Laser Imager.

Before opening the Film Door, read the Safety Information

that is provided at the beginning of this User Guide and

note the location of the laser beam in the Laser Imager.

5-2 5E2234 June 2000

Page 55

Clearing Film Jams

Clearing a Film Jam in the Laser Imager

If a film jam occurs during normal operation, the Laser

Imager will stop printing. An Error Message will be displayed on the Control Panel. Follow the instructions on

Page 5-5 to clear the error and return to normal operation.

If the problem persists, record the error message number

and call your Kodak Service Representative.

Troubleshooting

5E2234 June 2000 5-3

Page 56

Troubleshooting

Film Path of the Laser Imager

2000 Processor

Processor Entrance

Upper Film Path

Middle Film Path

Lower Film Path

Exposure Optics Module

Receive Magazine Film Path

Receive Magazine

Picker Assembly

Film Supply

Optics Door Latch

H178_0134HCA

H178_0134HC

Optics Module Door

W ARNING: Do not open the Film Supply until

the “Access Film Supply” Indicator is illuminated. Fogged film will result.

5-4 5E2234 June 2000

Page 57

Troubleshooting

When a Film Jam occurs, do the following:

1. From the Main Menu, press “Access Film Supply”.

Wait for the indicator to illuminate steady before pro-

ceeding.

2. Open the Front Door of the Laser Imager.

3. Open the Top Cover.

4. If necessary, pull the Optics Door Latch out to open

the Optics Door.

5. Check the film path to locate the jam.

6. Carefully remove the film and check that all the films

are removed from the Laser Imager.

7. Empty all the film from the Receive Magazine before

inserting the empty Magazine into the Laser Imager.

This will ensure a correct film count in the Receive

Magazine for the next session.

8. Close the Optics Door.

9. Close the Top Cover and the Front Door.

10. If the film jam persists, call your local Kodak Service

Representative.

Clearing a Film Jam in the Processor

See the User Manual for the KODAK X-OMAT 2000

Processor, Publication Number 7C8770, for more information.

5E2234 June 2000 5-5

Page 58

Troubleshooting

Replacing the Receiv e Magazine Latches

The 2 Receive Magazine Latches can be replaced. Contact your local Kodak Representative to order the

Replacement Latch / for KODAK EKTASCAN 160 Laser

Imager Receive Magazine, Catalog Number 109-3004.

Screwdriver

H178_0133ACA

Latch

1. Insert a screwdriver between the Latch and the

H178_0133AC

Magazine to loosen and remove the Latch.

2. Install the new Latch.

5-6 5E2234 June 2000

Page 59

Error Codes and Messages

General Information

During normal operation, the Laser Imager will provide

feedback to the user . If an error occurs, the LCD displays

an Error Message. See the Error Messages T able for a list

of error messages and suggested action to clear these

error messages.

Wait for the “Access Film Supply” Indicator to illuminate

steadily before opening the Top Cover or the Film Supply.

Troubleshooting

5E2234 June 2000 5-7

Page 60

Troubleshooting

Error Messages

MESSAGE DESCRIPTION ACTION

7001 - 7006

System Software Error

7125

7150

7155 - 7157

7250 - 7251

7260 - 7261

7270

7280 - 7282

7300 - 7302

7343 - 7346

7351

7394 - 7395

7040 - 7043 Mechanical Control Error

1. Press “Access Film

Supply”. Turn off the

Laser Imager.

2. Turn on the Laser

Imager.

3. If the above actions do

not solve the problem,

record the Error Message number displa ye d

and call your Kodak Service Representative.

1. Press "Access Film

Supply".

2. Turn off the Laser

Imager.

3. Turn on the Laser

Imager.

7050 Initialization Error

4. If the above actions do

not solve the problem,

record the Error Message number displa ye d

and call your Kodak Service Representative.

1. Press "Access Film

Supply".

2. Turn off the Laser

Imager.

3. Turn on the Laser

Imager.

4. If the above actions do

not solve the problem,

record the Error Message number displa ye d

and call your Kodak Service Representative.

5-8 5E2234 June 2000

Page 61

Troubleshooting

MESSAGE DESCRIPTION ACTION

7075 CAL Density Error

7076 - 7077

Calibration Error

7320

1. Enter the Density Value

again. See Chapter 4

“Calibration.

2. Calibrate the Laser

Imager, see Chapter 4

“Calibration”.

3. If the above actions do

not solve the problem,

record the Error Message number displa ye d

and call your Kodak Service Representative.

1. Calibrate the Laser

Imager, see Chapter 4,

“Calibration”.

2. If the above action does

not solve the problem,

record the Error Message number displa ye d

and call your Kodak Service Representative.

7078 - 7079 Calibration Software Error

1. Press "Access Film

Supply".

2. Turn off the Laser

Imager.

3. Turn on the Laser

Imager.

4. If the above actions do

not solve the problem,

record the Error Message number displa ye d

and call your Kodak Service Representative.

5E2234 June 2000 5-9

Page 62

Troubleshooting

MESSAGE DESCRIPTION ACTION

7100 - 7102 Image Data Transfer Error

7210 Connection Error

1. Press "Access Film

Supply".

2. Turn off the Laser

Imager.

3. Turn on the Laser

Imager.

4. If the above actions do

not solve the problem,

record the Error Message number displa ye d

and call your Kodak Service Representative.

1. Press "Access Film

Supply".

2. Turn off the Laser

Imager.

3. Turn on the Laser

Imager.

7310

7311

7312

7313

7314

Mechanism Error

4. If the above actions do

not solve the problem,

record the Error Message number displa ye d

and call your Kodak Service Representative.

1. Press "Access Film

Supply".

2. Turn off the Laser

Imager.

3. Turn on the Laser

Imager.

4. If the above actions do

not solve the problem,

record the Error Message number displa ye d

and call your Kodak Service Representative.

5-10 5E2234 June 2000

Page 63

Troubleshooting

MESSAGE DESCRIPTION ACTION

7315 No Cartridge

7316 Cartridge Empty

1. Install the Film Supply

Cartridge. See

Chapter 3, “Film Supply

Cartridge”.

2. If the error is still present,

record the Error Message number displa ye d

and call you Kodak Service Representative.

1. Install the new Film Sup-

ply Cartridge. See Chapter 3, “Film Supply

Cartridge”.

2. If the erro r is still presen t,

record the Error Message number displa ye d

and call your Kodak Service Representative.

7317

7318

7319

7382

7349

Barcode Error

1. Press "Access Film

Supply".

2. Open the Front Door.

3. Install new Film Supply

Cartridge. V erify th at the

correct film is installed,

EIR-23.

4. Close the Front Door.

5. If the above actions do

not solve the problem,

record the Error Message number displa ye d

and call your Kodak Service Representative.

5E2234 June 2000 5-11

Page 64

Troubleshooting

MESSAGE DESCRIPTION ACTION

7321 Clear All Film

7322 Film Jam at Cartridge

1. Press "Access Film

Supply".

2. Open the Front Door.

3. Locate and remove the

film jam. See Chapter 5,

“Clearing a Film Jam”.

4. Close the Front Door.

5. If the above actions do

not solve the problem,

record the Error Message number displa ye d

and call your Kodak Service Representative.

1. Press "Access Film

Supply".

2. Open Front Door.

3. Locate and remove the

film jam in the Film Supply. See Chapter 5,

“Clearing a Film Jam”.

4. Close the Front Door.

5. If the above actions do

not solve the problem,

record the Error Message number displa ye d

and call your Kodak Service Representative.

5-12 5E2234 June 2000

Page 65

Troubleshooting

MESSAGE DESCRIPTION ACTION

7323 Film Jam at Exposure

7324 Film Jam at Transport

1. Press "Access Film

Supply".

2. Open Front Door.

3. Open the Optics Door.

4. Check the Exposure

Optics Module and

remove the film jam. See

Chapter 5, “Clearing a

Film Jam”.

5. Close the Front Door.

6. If the above actions do

not solve the problem,

record the Error Message number displa ye d

and call your Kodak Service Representative.

1. Press "Access Film

Supply".

2. Open Front Door.

3. Check the Lower Film

Path, Middle Film Path

and Upper Film Path to

locate and remove the

film jam. See Chapter 5,

“Clearing a Film Jam”.

4. Close the Front Door.

5. If the above actions do

not solve the problem,

record the Error Message number displa ye d

and call your Kodak Service Representative.

5E2234 June 2000 5-13

Page 66

Troubleshooting

MESSAGE DESCRIPTION ACTION

7325 Film Jam at Unload

1. Press "Access Film

Supply".

2. Open the Front Door.

3. Open the Optics Module

Door.

4. Check the Exposure

Optics Module Film Path

to locate and remove the

film jam. See Chapter 5,

“Clearing a Film Jam”.

5. Close the Optics Module

Door.

6. Close the Front Door.

7. If the above actions do

not solve the problem,

record the Error Message number displa ye d

and call your Kodak Service Representative.

5-14 5E2234 June 2000

Page 67

Troubleshooting

MESSAGE DESCRIPTION ACTION

7326 Cannot Open Cartridge

1. Press "Access Film

Supply".

2. Turn off the Laser

Imager.

3. Open Front Door.

4. Manually rotate the

Rollback Roller to open

the Cartridge.

5. Check the Film Cartridge

for a film jam and remove

the film jam. See Chapter

5, “Clearing a Film Jam”.

6. Close the Front Door.

The top films in the cartridge will be fogged.

7. Turn on the Laser

Imager.

8. If the above actions do

not solve the problem,

record the Error Message number displa ye d

and call your Kodak Service Representative.

5E2234 June 2000 5-15

Page 68

Troubleshooting

MESSAGE DESCRIPTION ACTION

7327 Cannot Close the Cartridge

1. Press "Access Film

Supply".

2. Open Front Door.

3. Check the Film Cartridge

for a film jam and remove

the film jam. See Chapter

5, “Clearing a Film Jam”.

4. Manually rotate the

Rollback Roller to close

the Film Cartridge.

5. Close the Front Door.

The top films in the cartridge will be fogged.

6. If the above actions do

not solve the problem,

record the Error Message number displa ye d

and call your Kodak Service Representative.

7328 Service Override Switch Failure

1. Press "Access Film

Supply".

2. Turn off the Laser

Imager.

3. Turn on the Laser

Imager.

4. If the above actions do

not solve the problem,

record the Error Message number displa ye d

and call your Kodak Service Representative.

5-16 5E2234 June 2000

Page 69

Troubleshooting

MESSAGE DESCRIPTION ACTION

7329 Film Jam at Transport Sensor

1. Press "Access Film

Supply".

2. Open the Front Door.

3. Check the Middle and

Upper path and remove

the film jam.

4. Close the Front Door.

5. If the above actions do

not solve the problem,

record the Error Message number displa ye d

and call your Kodak Service Representative.

5E2234 June 2000 5-17

Page 70

Troubleshooting

MESSAGE DESCRIPTION ACTION

7330 Film Jam at Receive Magazine

1. Press "Access

Receive".

2. Open the Top Cover.

3. Remove the Receive

Magazine.

4. Remove the film jam

without opening the

Receive Magazine

Cover.

5. Process any films in the

Receive Magazine to

ensure a correct film

count in the Receive

Magazine for the next

session.

6. Install the Receive

Magazine.

7. Close the Top Cover.

8. If the above actions do

not solve the problem,

record the Error Message number displa ye d

and call your Kodak Service Representative.

5-18 5E2234 June 2000

Page 71

Troubleshooting

MESSAGE DESCRIPTION ACTION

7331 Film Jam at Processor

1. Press "Access Film

Supply".

2. Open the Front Door.

3. Check the Upper Film

Transport and remove

the film jam.

4. If necessary, open the

Processor Top Cover and

check for a film jam at the

Entrance Roller.

5. Close the Front Door

6. If the above actions do

not solve the problem,

record the Error Message number displa ye d

and call your Kodak Service Representative.

7332 - 7337

7339 - 7342

7350

Optics Error

1. Press "Access Film

Supply".

2. Turn off the Laser

Imager.

3. Turn on the Laser

Imager.

4. If the above actions do

not solve the problem,

record the Error Message number displa ye d

and call your Kodak Service Representative.

5E2234 June 2000 5-19

Page 72

Troubleshooting

MESSAGE DESCRIPTION ACTION

7338 Waiting for Film Model

7347

7348

Diagnostics Error

Diagnostics Error

1. Press “Menu” to con-

tinue.

2. If necessary, press

“Access Film Supply”.

3. Turn off the Laser

Imager.

4. Turn on the Laser

Imager.

5. If the above actions do

not solve the problem,

record the Error Message number displa ye d

and call your Kodak Service Representative.

1. Press "Access Film

Supply".

2. Turn off the Laser

Imager.

3. Turn on the Laser

Imager.

4. If the above actions do

not solve the problem,

record the Error

Message number displayed and call your

Kodak Ser vice Representative.

5-20 5E2234 June 2000

Page 73

Troubleshooting

MESSAGE DESCRIPTION ACTION

7380 The film cartridge is empty

1. Press "Access Film Supply".

2. Install the new Film Supply

Cartridge. See

Chapter 3, “Film Supply

Cartridge”.

3. If the error is still present,

record the Error

Message number displayed and call you Kodak

Service Representative.

7381 The film cartridge is nearly empty There will be a warning when

there are less than 10 films left

in the cartridge. You can

replace the film cartridge at

that time or wait until the Error

7380 indicates the cartridge is

empty.

7389 The receive magazine is nearly full There will be a warning when

there is room for 10 or fewer

films in the Receive Magazine.

A full magazine can hold 50

films. You can empty the

Receive Magazine at that time

or wait until the Error 7390

indicate the Receive Magazine

is full.

7390 The receive magazine is full

1. Press “Access Receive”

and wait for the indicator to

illuminate steady before

proceeding.

2. Open the Top Cover and

remove the Receive

Magaine.

3. Empty the Receive Magazine and process the film.

4. Install the Receive Magazine.

5E2234 June 2000 5-21

Page 74

Troubleshooting

MESSAGE DESCRIPTION ACTION

7392 Film Fogged

7393 Top Cover Open

1. Check that the Front

Door is completely

closed.

2. Run at least 4 films to

eliminate the fogged

films. Do Step 1-Step 3

on page 5-29 to run the

films.

3. If the above actions do

not solve the problem,

record the Error Message number displa ye d

and call your Kodak Service Representative.

1. Check tha t the T op Cover

is completely closed.

2. If the above actions do

not solve the problem,

record the Error Message number displa ye d

and call your Kodak Service Representative.

7426 - 7428 Operator Interface Error

1. Press "Access Film

Supply".

2. Turn off the Laser

Imager.

3. Turn on the Laser

Imager.

4. If the above actions do

not solve the problem,

record the Error Message number displa ye d

and call your Kodak Service Representative.

5-22 5E2234 June 2000

Page 75

Troubleshooting

MESSAGE DESCRIPTION ACTION

7435 Cartridge Not Closed

1. Press "Access Film

Supply".

2. Open Front Door.

3. Check the Film Cartridge

for a film jam and remove

the film jam. See Chapter

5, “Clearing a Film Jam”.

4. Manually rotate the Roll-

back Roll er to close the

Film Cartridge.

5. Close the Front Door.

The top films in the cartridge will be fogged.

6. If the above actions do

not solve the problem,

record the Error Message number displa ye d

and call your Kodak Service Representative.

5E2234 June 2000 5-23

Page 76

Troubleshooting

MESSAGE DESCRIPTION ACTION

7900 Trouble opening the film cartridge

1. Press "Access Film

Supply".

2. Turn off the Laser

Imager.

3. Open Front Door.

4. Manually rotate the Roll-

back Roller to open the

Cartridge.

5. Check the Film Cartridge

for a film jam and remove

the film jam. See Chapter

5, “Clearing a Film Jam”.

6. Close the Front Door.

The top films in the cartridge will be fogged.

7. Turn on the Laser

Imager.

8. If the above actions do

not solve the problem,

record the Error Message number displa ye d

and call your Kodak Service Representative.

5-24 5E2234 June 2000

Page 77

Troubleshooting

MESSAGE DESCRIPTION ACTION

7901 Trouble closing the film cartridge

1. Press "Access Film

Supply".

2. Open Front Door.

3. Check the Film Cartridge

for a film jam and remove

the film jam. See Chapter

5, “Clearing a Film Jam”.

4. Manually rotate the Roll-

back Roll er to close the

Film Cartridge.

5. Close the Front Door.

The top films in the cartridge will be fogged.

6. If the above actions do

not solve the problem,

record the Error Message number displa ye d

and call your Kodak Service Representative.

5E2234 June 2000 5-25

Page 78

Troubleshooting

Error Recovery

The Error Recovery Screen appears when the Laser

Imager detects an error. The screen that is currently displayed is suspended. You will be able to view the error

message(s).

Error Recovery Screen

Not Printing

***ERROR 7900***

07-APR-2000 08:19:47

Trouble Opening the

Film Cartridge

▼xxxx more

The menu items on the Error Recover Screen are:

Log entry title (Error) and a four-digit identifier

(number)

Date and time the error occurred

Up to three lines of description of the log entry

▼xxxx more - indicates how many more errors may

be viewed by pressing the down arrow button. Only

errors that have occurred since the current display of

the Error Recovery screen are available to be viewed.

Use the down arrow button to view the next error, if one

exists. The up arrow button is not active.

Press the Menu Button to exit the screen and return to

the suspended screen.

5-26 5E2234 June 2000

Page 79

Preventive Maintenance

Cleaning the 160 Laser Imager

WARNING: Use caution around openings

and electrical connections. When soil is

removed, wipe external surfaces dry with

clean soft cloth.

Do the following to clean the Laser Imager:

1. Turn off the Laser Imager and disconnect the Power

Cord.

Troubleshooting

2. Immerse a clean, soft cloth in an appropriate non-

abrasive cleaning solution.

3. Wring cloth to remove excess fluid.

4. Wipe the external surfaces free of soil.

5E2234 June 2000 5-27

Page 80

Troubleshooting

Replacing the Air Filter

Optics

Module

Door

H178_0065ACC

H178_0065AC

Air Filter

NOTE: It is recommended that you replace the

Air Filter once a year.

Every six months it is recommended that you carefully remove the Air Filter and rotate the Air Filter 180°. Do not change the direction of the Air

Filter when you install it back in the Laser Imager. This will prevent dust

from accumulating in the Laser Imager. Do the following to access the

Air Filter.

1. From the Main Menu, press “Access Film Supply”.

Wait for the indicator to illuminate steady before proceeding.

2. Turn off the Laser Imager.

3. Open the Front Door of the 160 Laser Imager.

4. Open the Optics Module Door.

5. Remove the Air Filter and replace if necessary.

Contact Kodak Distribution to order a new Air Filter/

for KODAK EKTASCAN 160 Laser Imager Catalog

Number 116-1272.

5-28 5E2234 June 2000

6. Close the Front Door.

7. Turn on the Laser Imager.

Page 81

Streaks on the Film

Streaks can be caused by debris on the Processor Rollers. This can occur when the system is inactive. To eliminate the streaks, run 3 films to the Processor before

normal operation.

1. From the Main Display, press the Menu Button. The

2. Use the “▼” to move the ">" to “Calibrate Printer”.

Troubleshooting

IMPORTANT: Do not use this film for calibrating

the Laser Imager. This procedure is to be done

only to eliminate streaks on the film.

Main Menu is displayed.

Press the Menu Button. The Calibrate Printer Screen

is displayed.

The Calibrate Printer Screen displays the calibration

time and date for the currently selected destination.

Ready

Exit Menu

Access Receive

Access Supply

>Calibrate Printer

Setup Menu

Film Destination

3. Use the “▼” to select Print Cal Film. Press the

Menu Button.

Ready

Processor

Last calibrated on

13-Dec-1998 07:24

Exit Menu

>Print Cal Film

Calibration Data

5E2234 June 2000 5-29

4. Retrieve the film from the Processor Receive Bin.

5. Return to normal operation.

Page 82

Troubleshooting

5-30 5E2234 June 2000

Page 83

6

Glossary

••••••••

100BaseT

Calibration

Default

Density

DICOM

D-Max

D-Min

Ethernet

100 MHz/baseband/twisted pair. IEEE standard for 24 gauge,

unshielded twisted pair Ethernet.

A process of adapting the Laser Imager to compensate for variations in the laser power, the film and processing conditions in

order to produce consistent image quality.

A preset value that is automatically assigned to a filed/parameter when no value is specified.

A measure of how black the film is.

The Digital Imaging and Communications in Medicine imaging

standard.

The maximum optical density found on a film.

The minimum optical density found on a film in an unexposed

region.

A passive coaxial cable that transmits digital signals for a net-

work in which the interconnections contain active elements.

Image

Imaging Device

IP Address

LAN

Laser

Each picture that you take of a patient through an imaging

device is called an image.

A generic term for the imaging system (imaging device) that

may include the scanner, imaging computer, and operator

workstation.

Internet Protocol. IP part of the TCP/IP protocol, which routes a

message across networks.

Local Area Network. A combination of computer hardware and

software that interconnects numerous computers and peripherals to provide communication and access to shared data.

Light Amplification by Stimulated Emission of Radiation.

6-1

Page 84

Glossary

Menu

MIM

Option

Prompt

RJ-45

Screen

Scroll bar

TCP/IP

A list of related options that you select to perform an action.

KODAK Medical Image Manager

A function that is listed on a menu that performs a certain

action.

Symbol, text or questions which asks/allows a user to enter a

command or response.

Eight wire modular connectors for Ethernet twisted-pair wiring.

The visible area on the display of a data terminal.

Located on a screen that contains a list of items, the scroll bar

shows the position of the items relative to the entire list.

Transmission Control Protocol/Internet Protocol. Set of commu-

nication protocols developed for the Defense Advanced

Research Projects Agency (DARPA) to connect dissimilar systems. The TCP protocol controls the transfer of the data, and

the IP protocol provides the routing mechanism.

Throughput

Twisted Pair

Wiring

The number of sheets of film that can be printed in one hour.

Wiring used in telephone systems and many networks. It con-

sists of a pair of copper wires twisted around each other to

counteract the effects of noise. Commonly used in lieu of coaxial Ethernet in network applicati ons . Usuall y uns hi eld ed; however, the more expensive shielded version supports greater

distance with less risk of electrical interference.

UTP

Unshielded Twisted Pair. See Twisted Pair Wiring.

Publication History

Print

Date

6/27/00 5E2234 2662-011 All om3527book_1 _ jun00 First Printing

9/15/00 5E2234 2662-050 4-7, 4-8

Pub.

No.

ECO No. Affected

Pages

5-21, 5-22

6-1, 6-2

File Name Notes

om3527book_ 1 _ jun00 Internal Page

Replacements

6-2 5E2234 June 2000

Loading...

Loading...